Effect of Yttrium Treatment on Inclusions and Microstructure of High-Strength Peritectic Steel

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

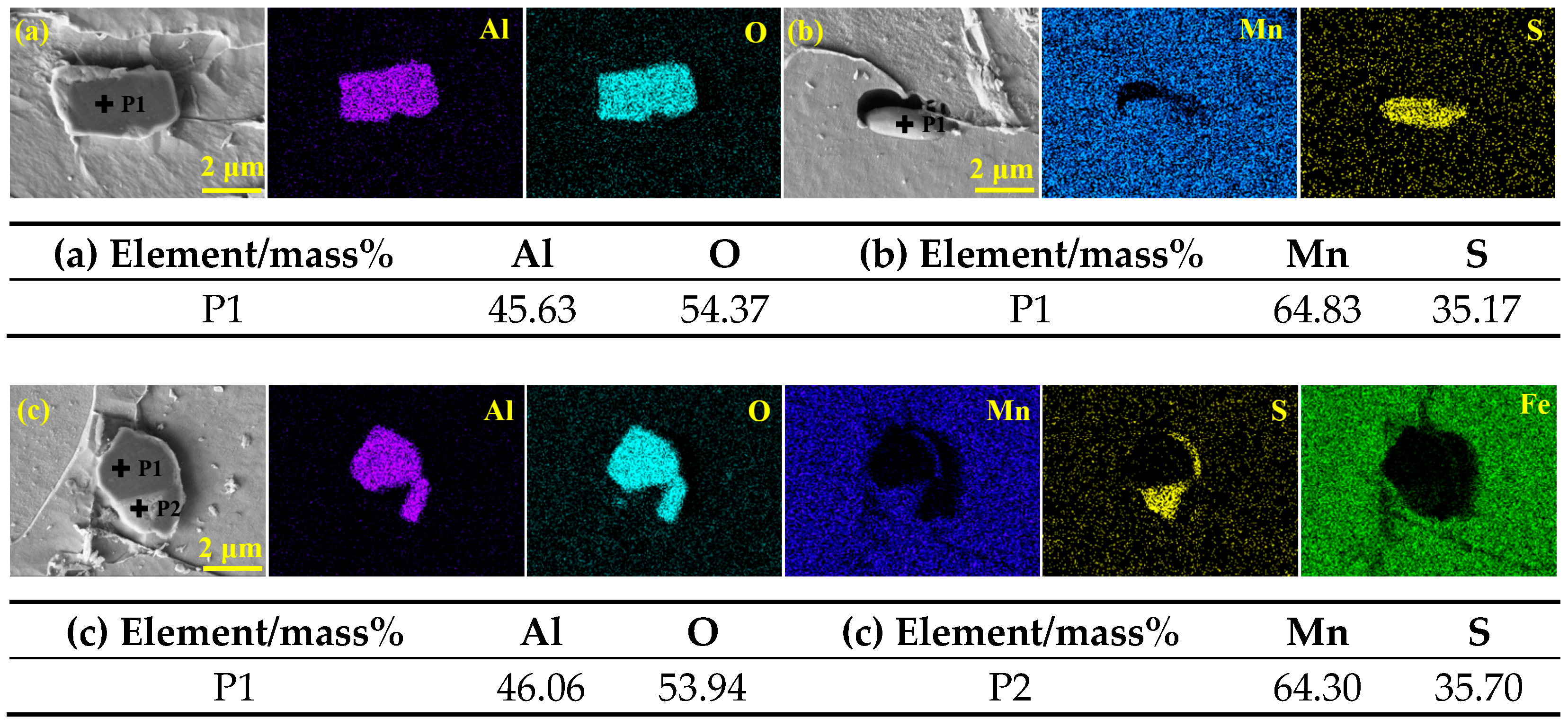

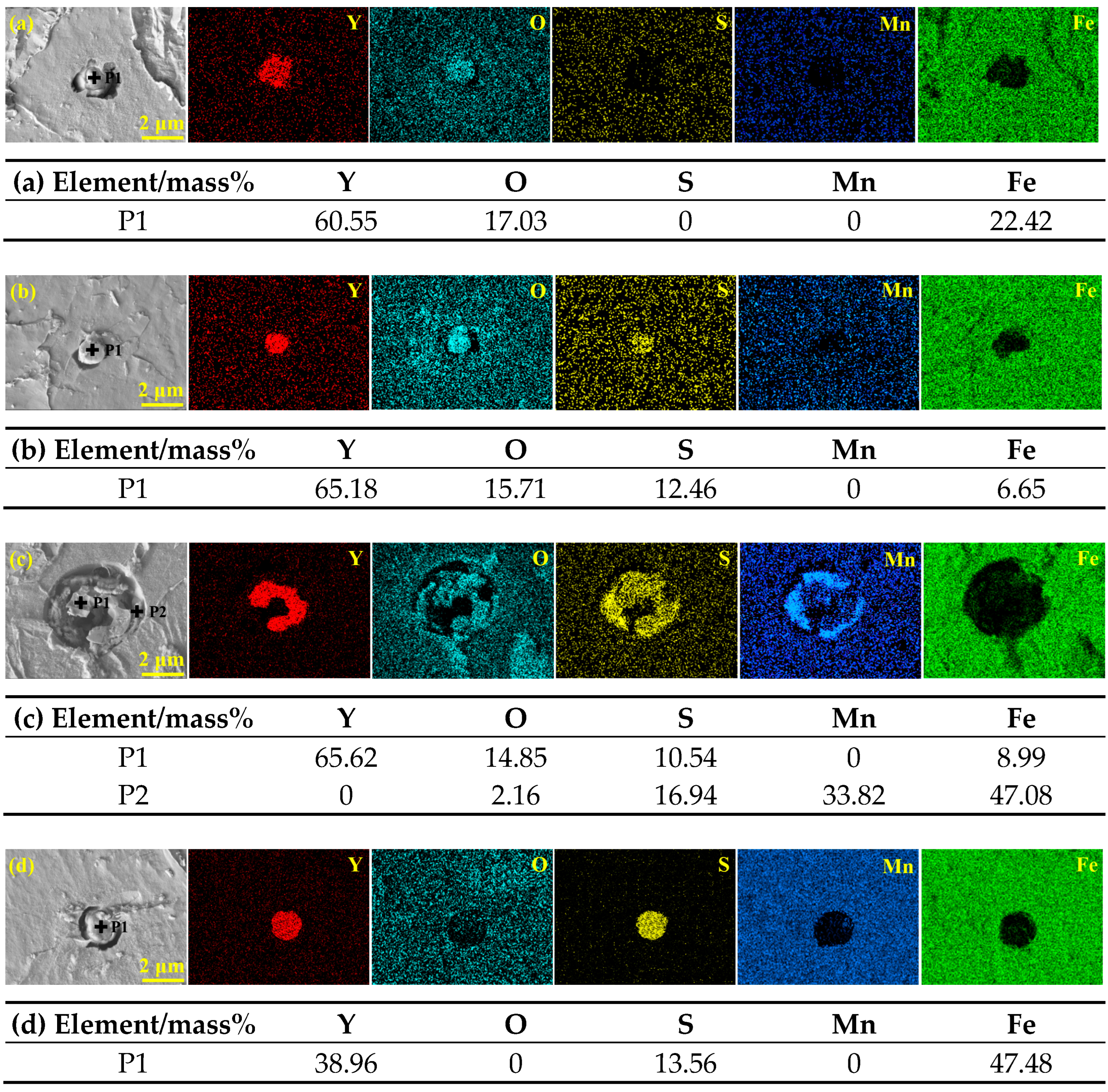

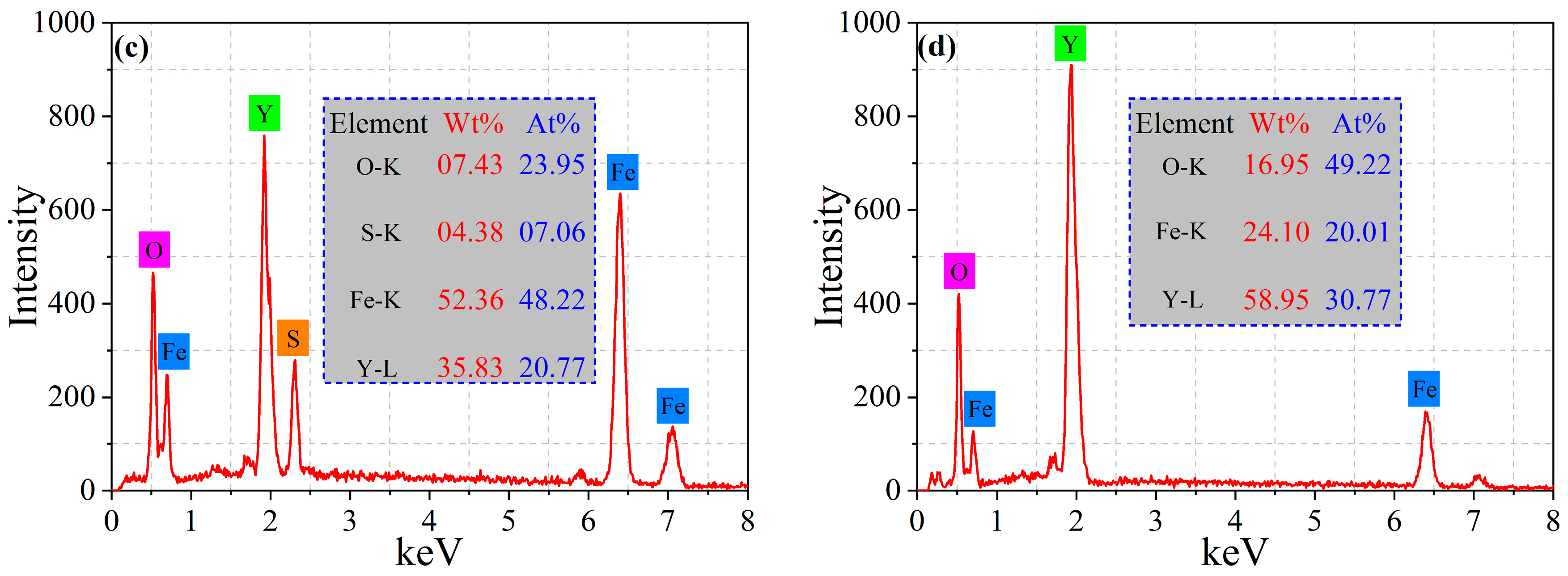

3.1. SEM-EDS Analysis of Chemical Compositions and Morphologies of Inclusions

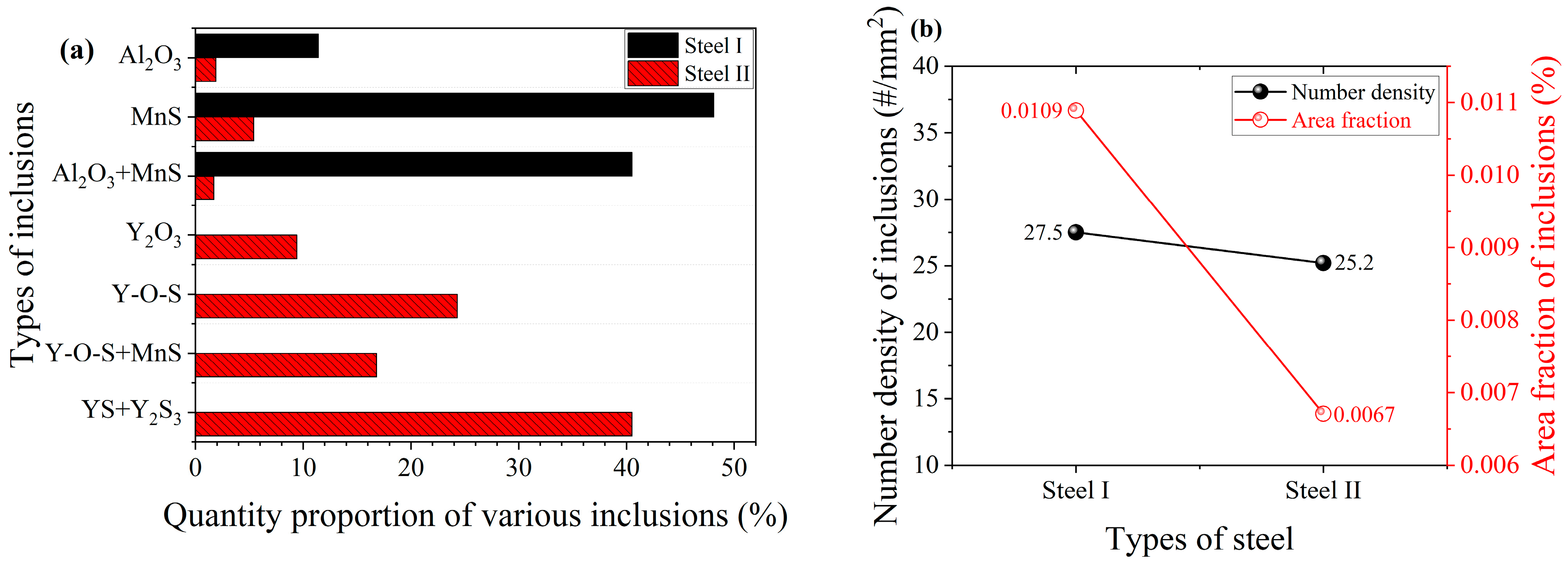

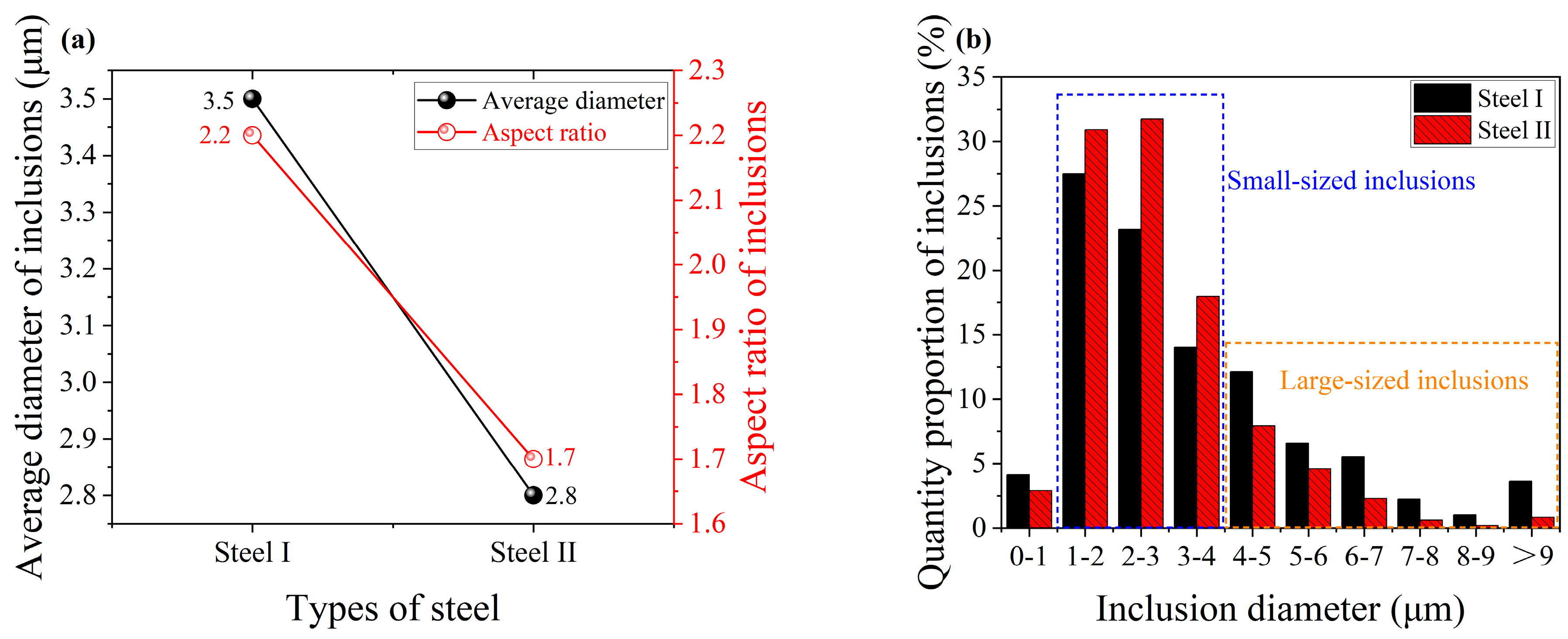

3.2. Statistical Analysis of Quantities and Sizes of Inclusions

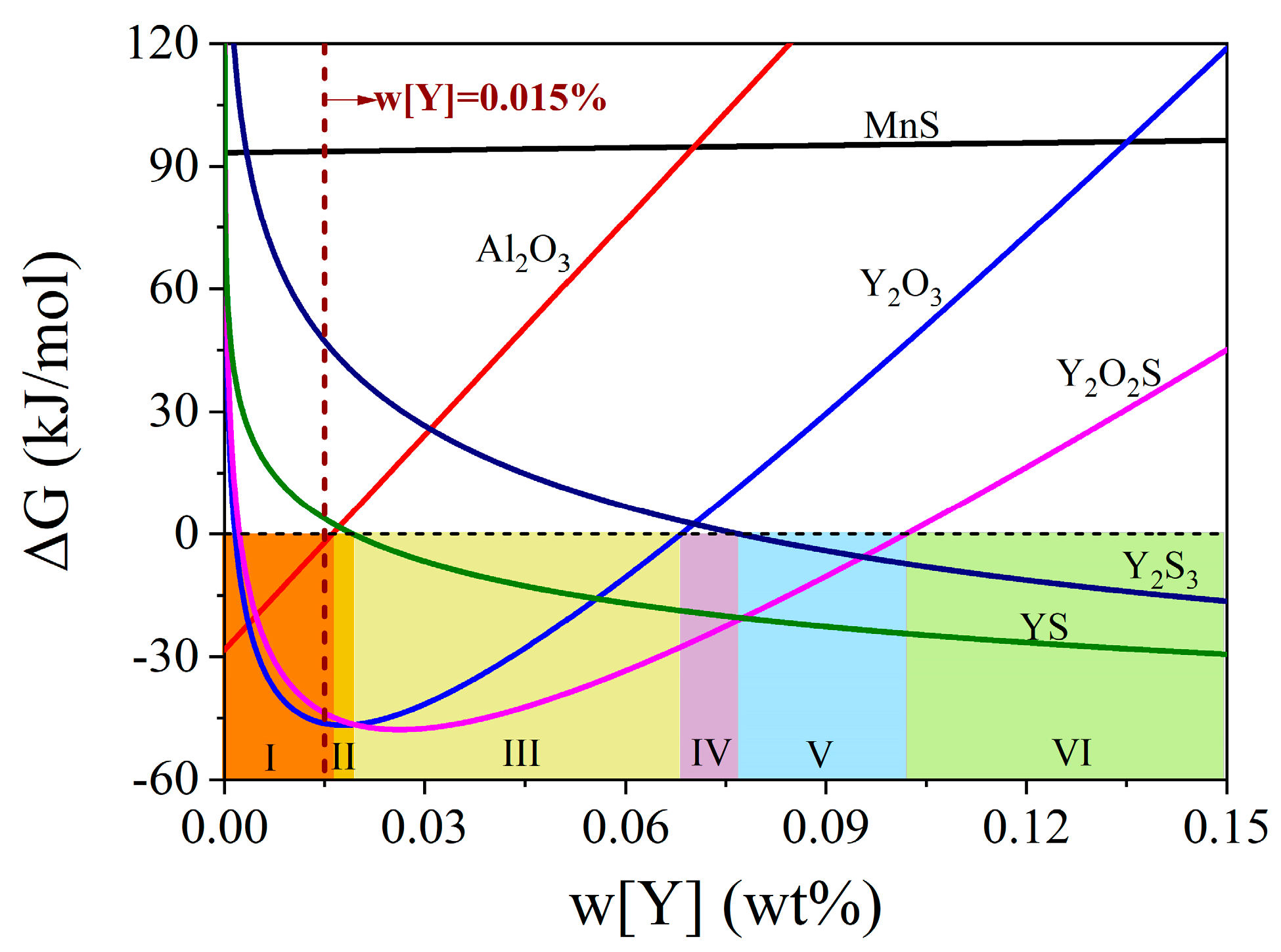

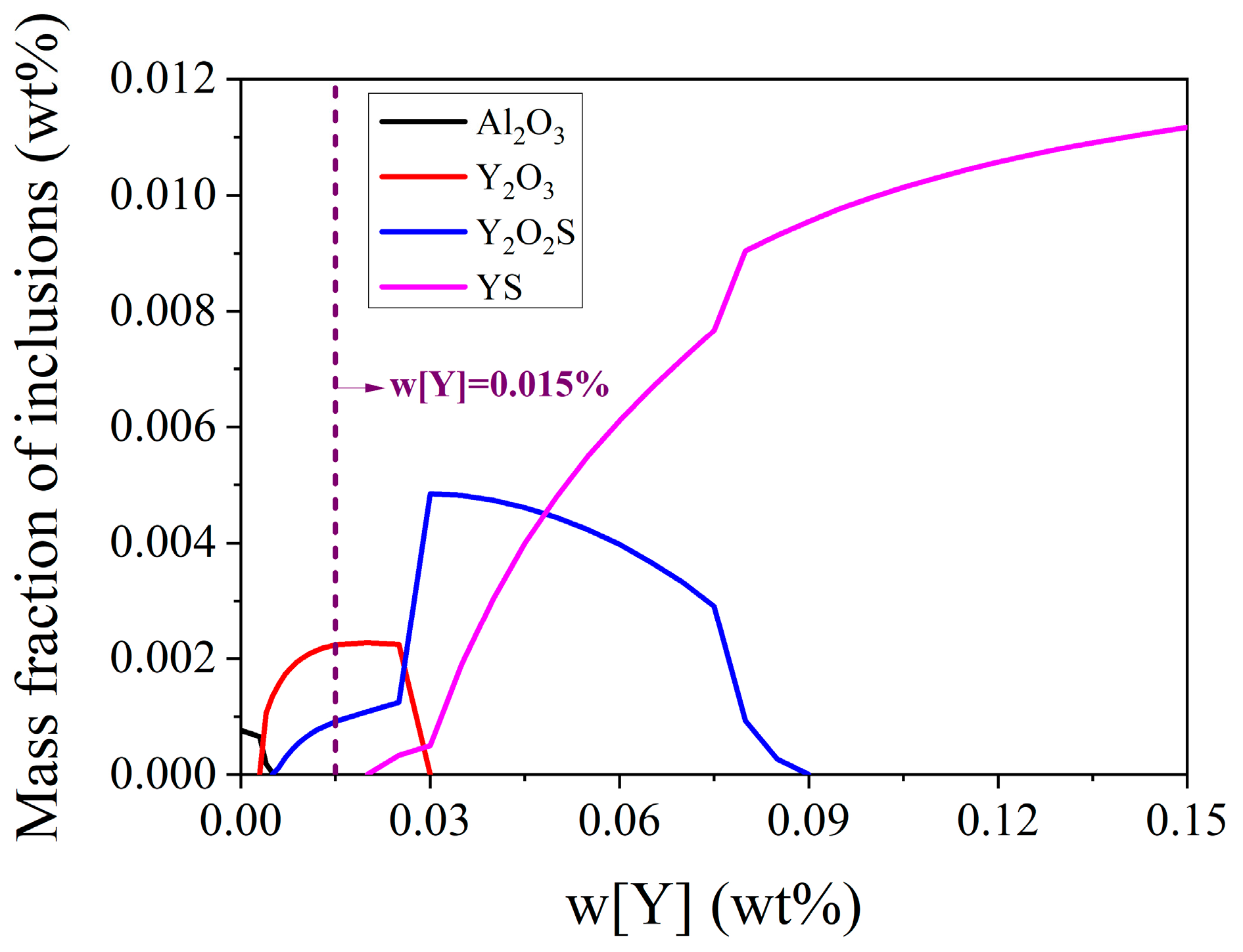

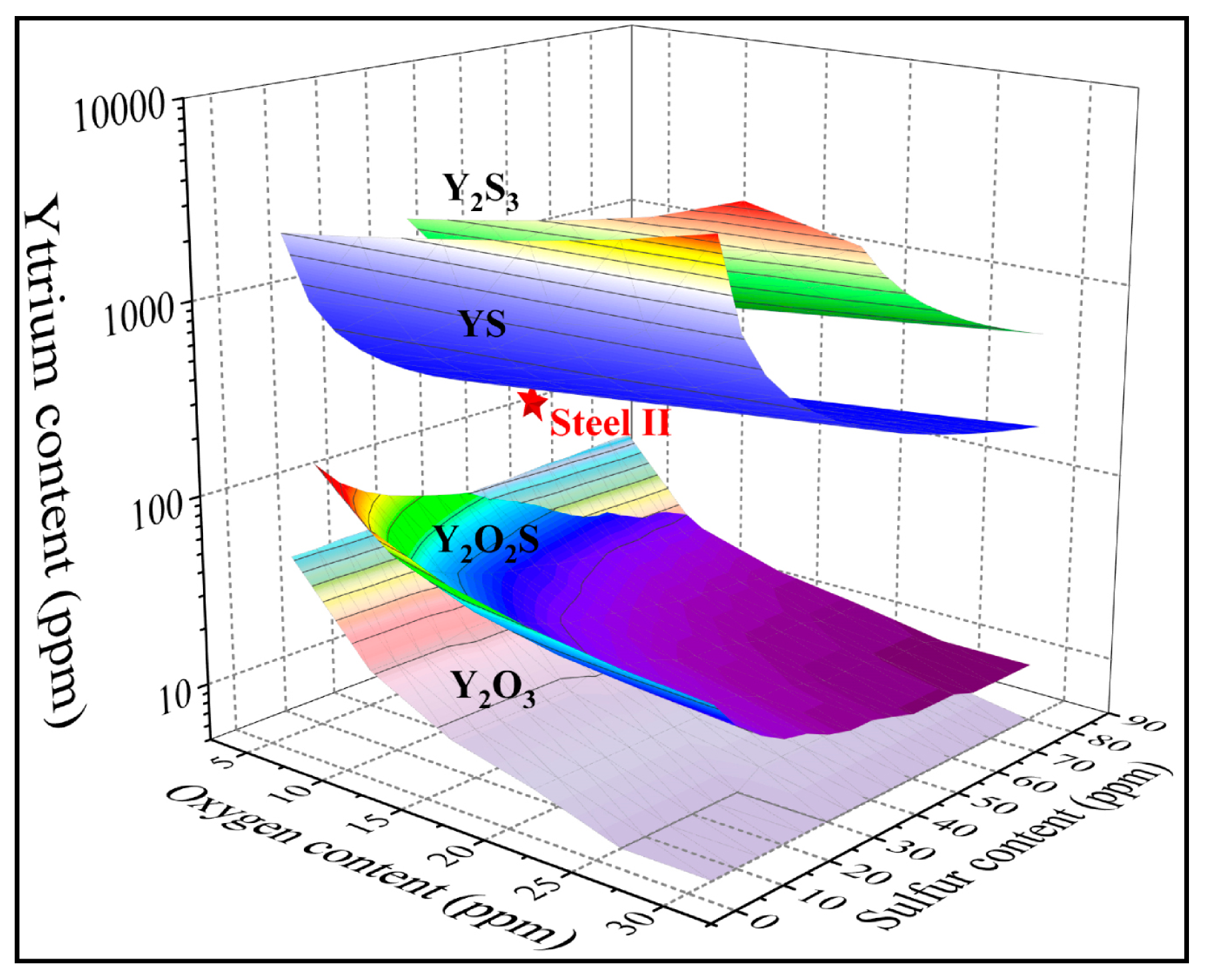

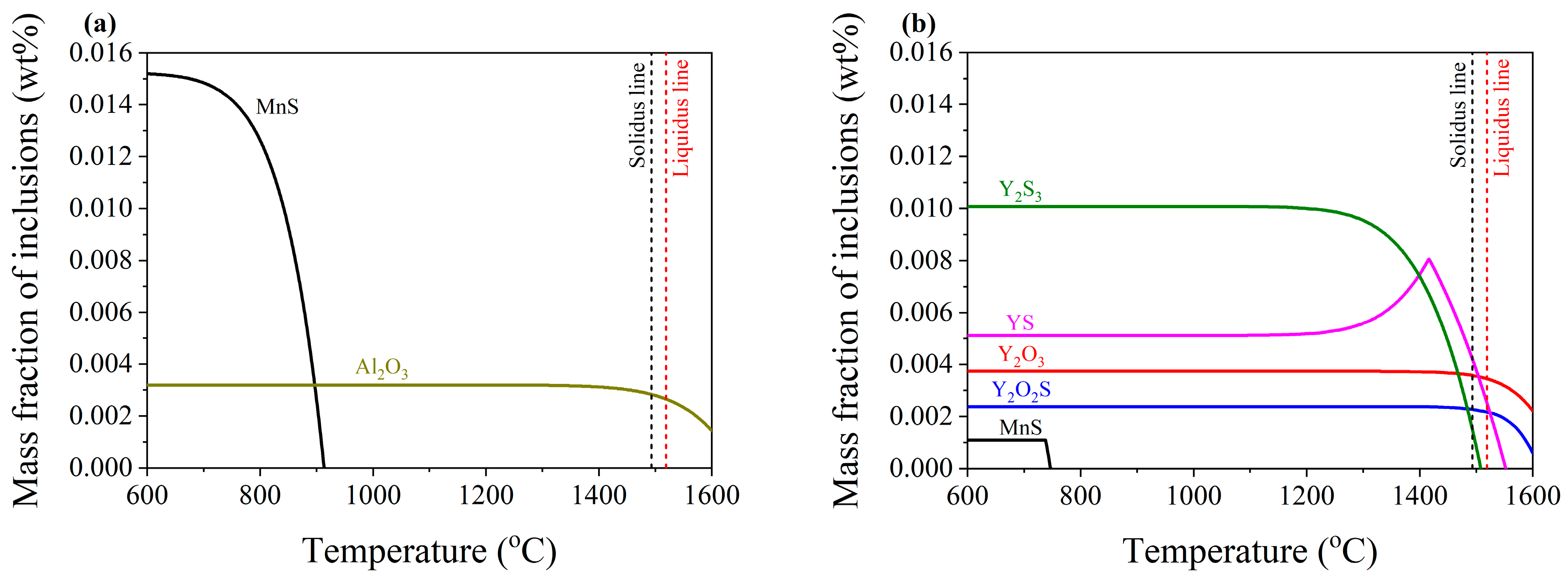

3.3. Thermodynamic Calculation for the Evolution Mechanism of Inclusions

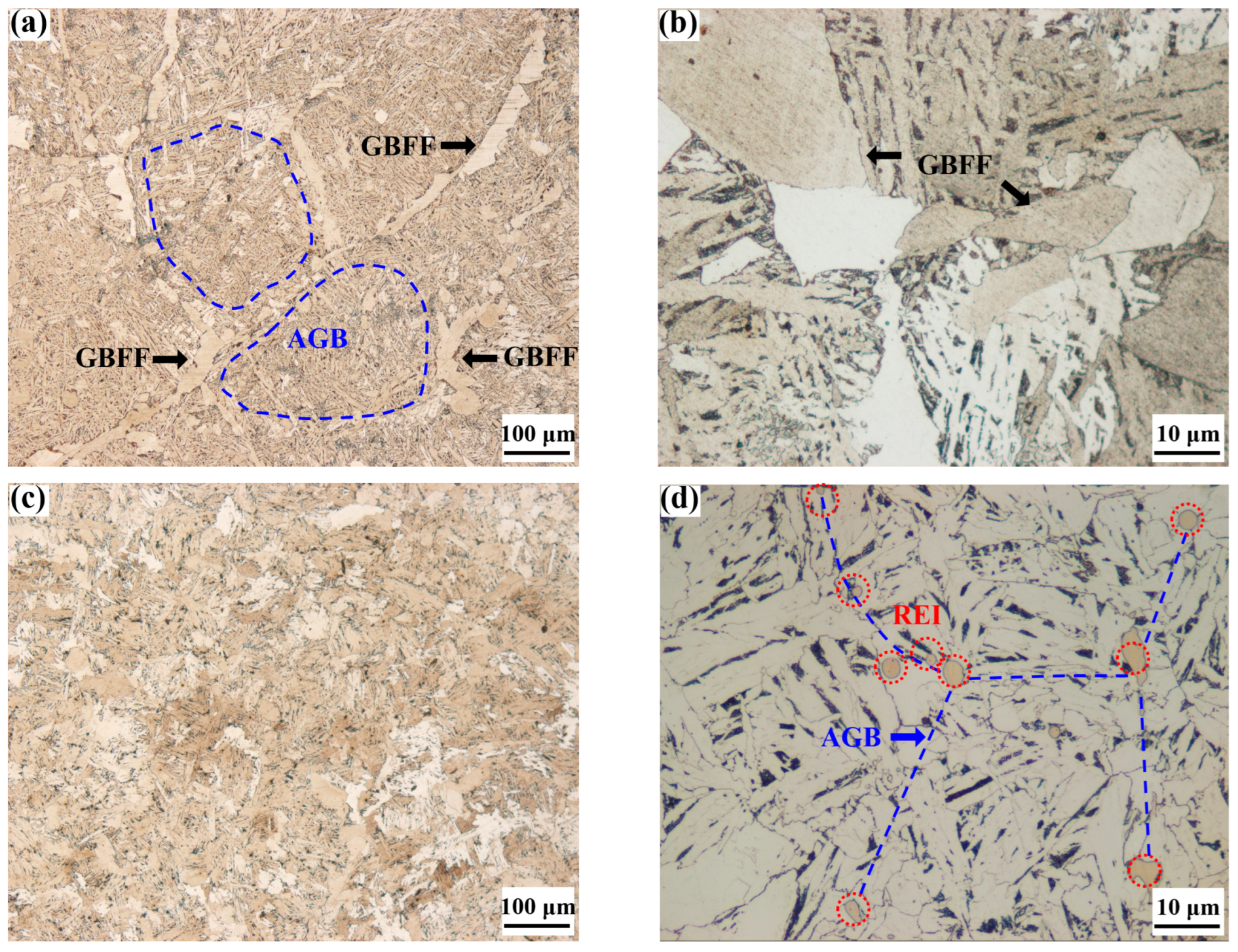

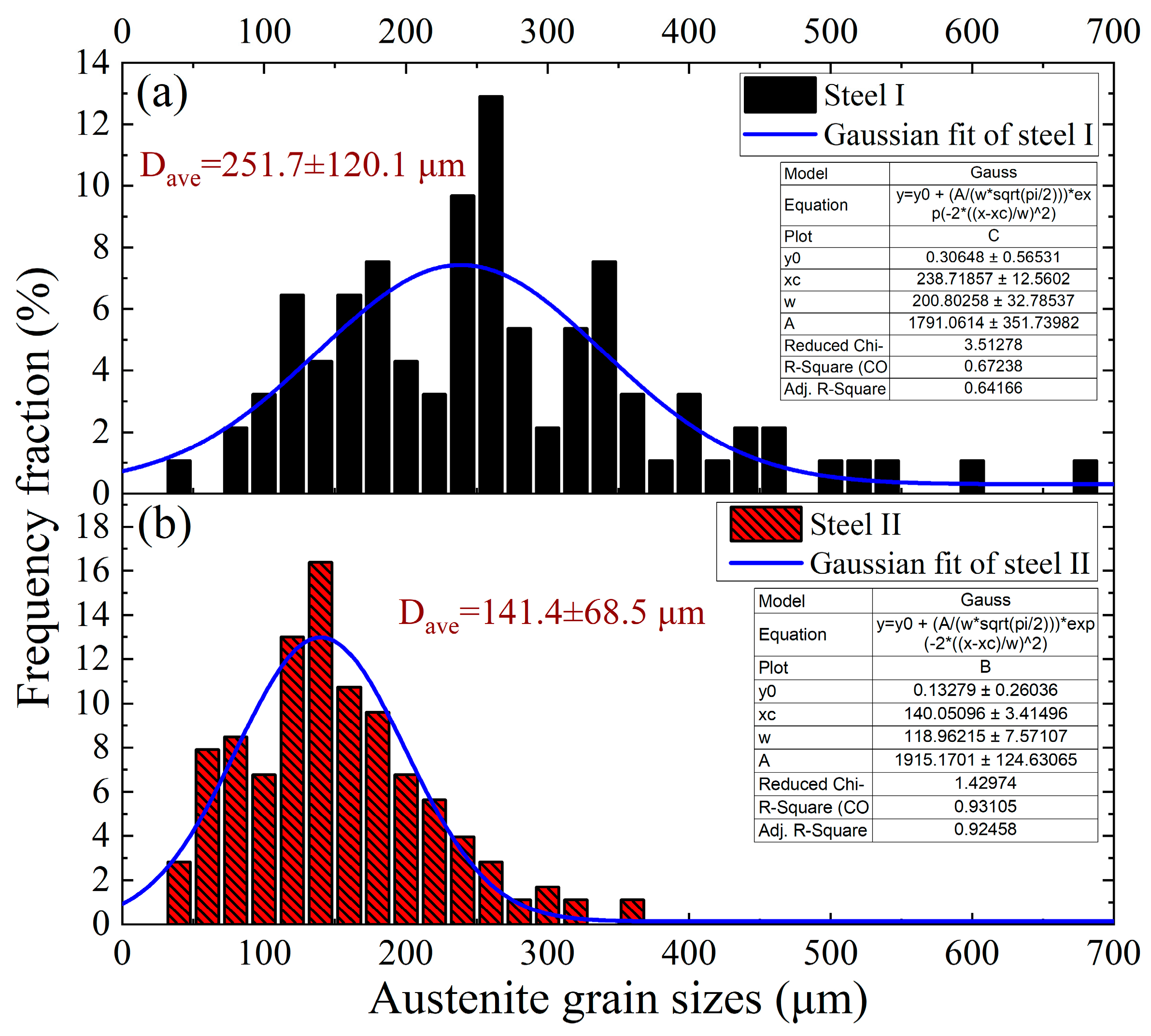

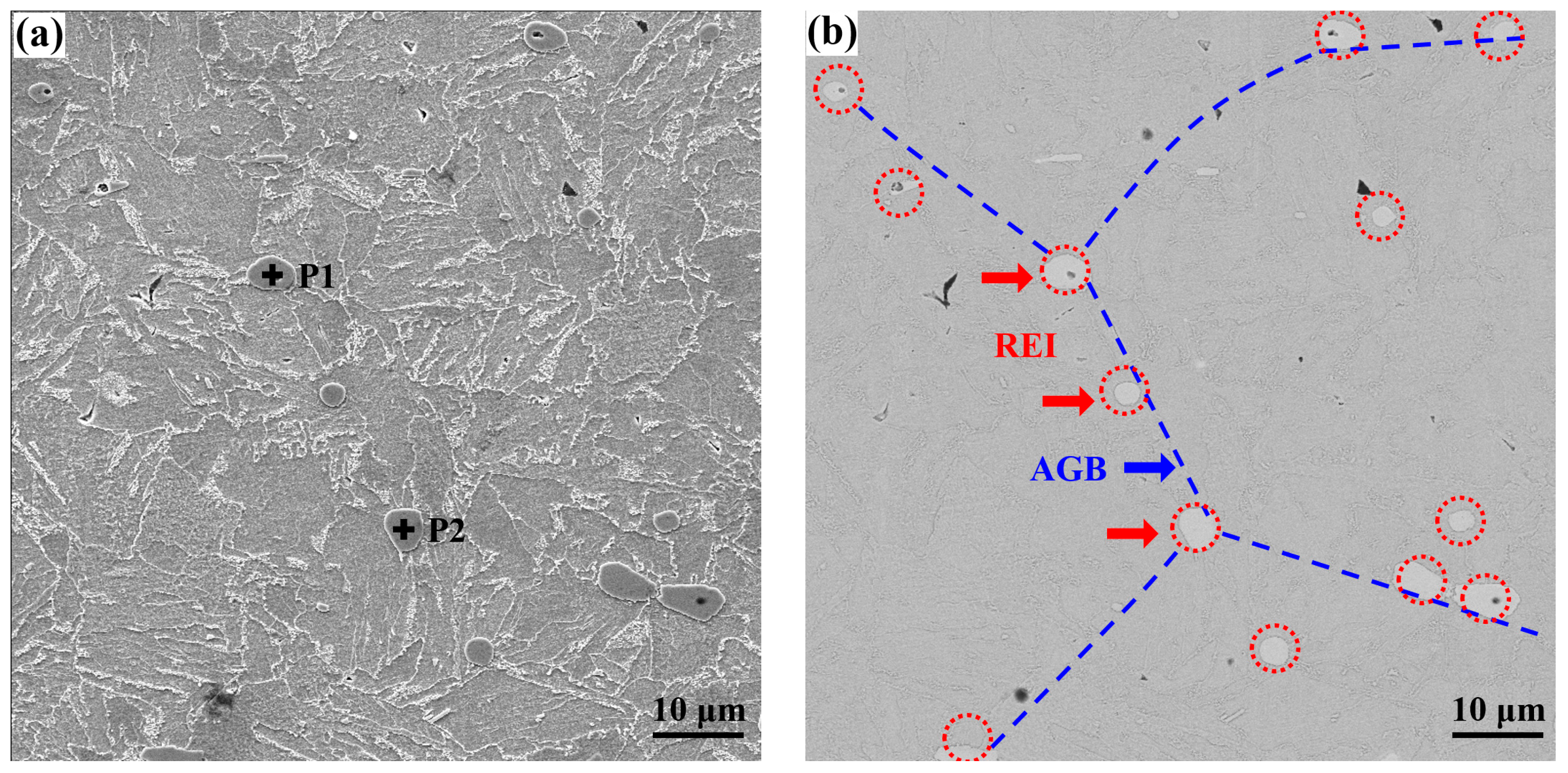

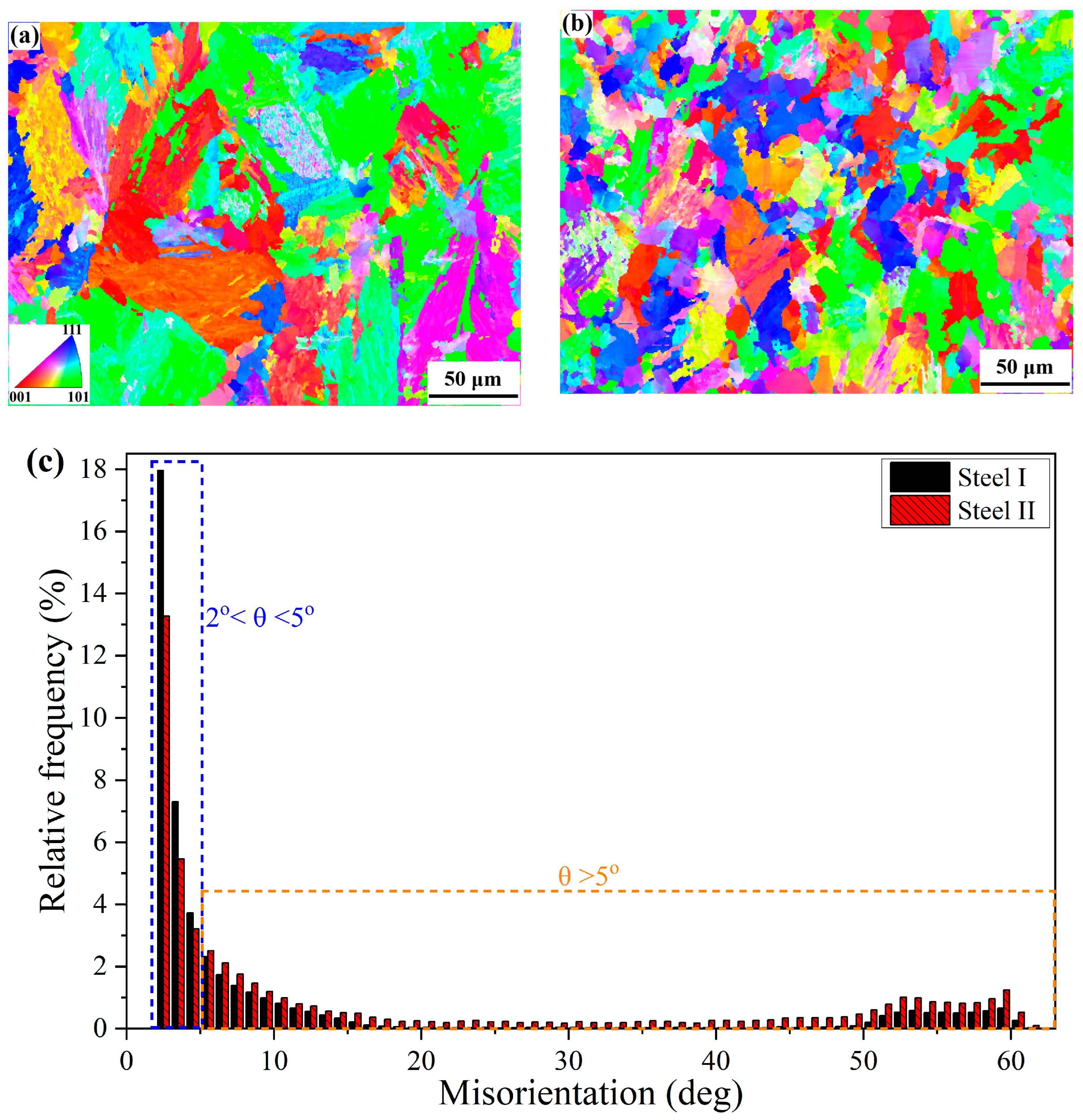

3.4. Microstructure Analysis

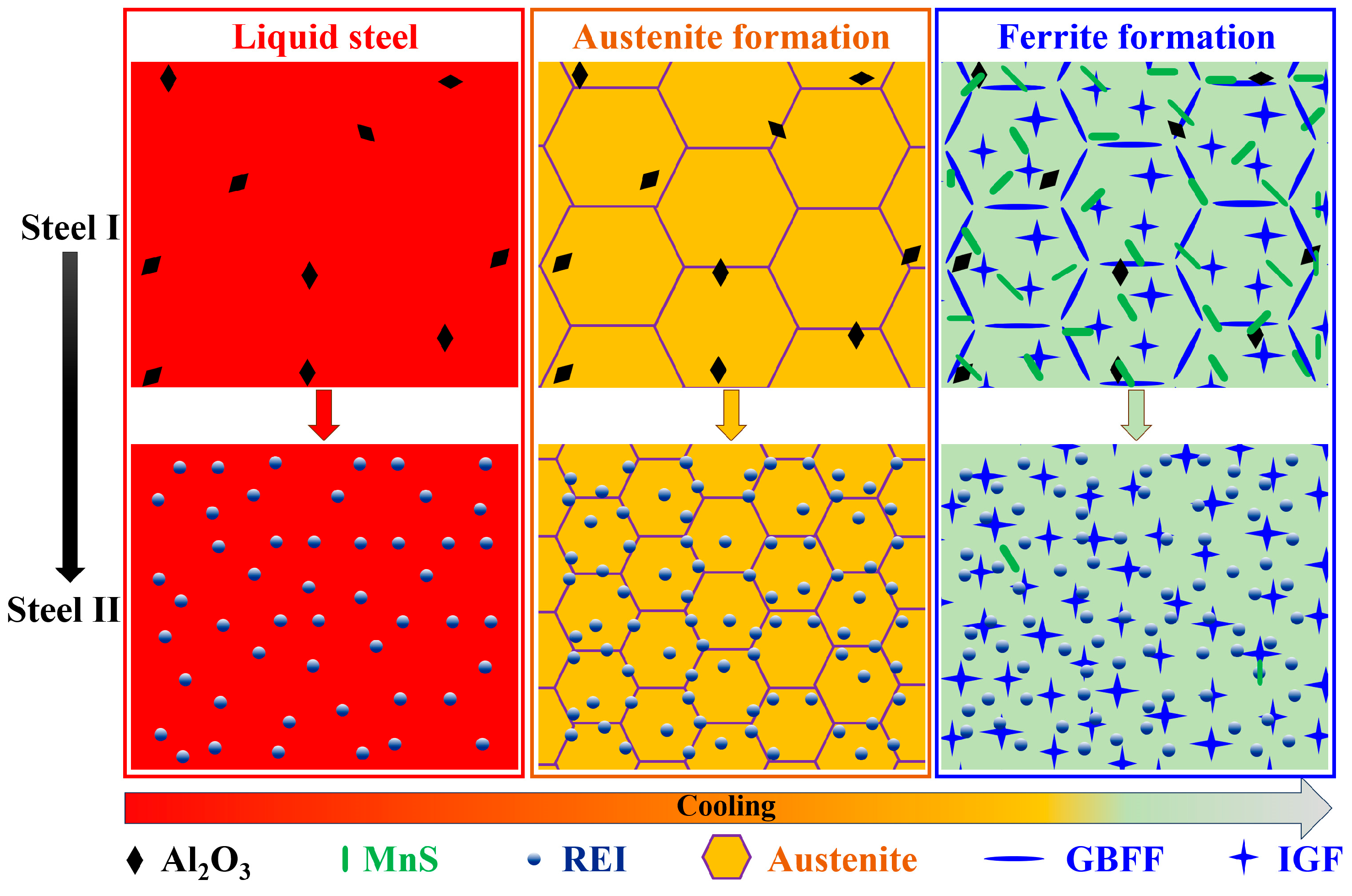

3.5. Evolution of Inclusions and Microstructure After Yttrium Treatment

4. Conclusions

- (1)

- The typical inclusions in Y-free steel are mainly block-shaped Al2O3, rod-like MnS, and their composites. However, in Y-containing steel, spherical or nearly spherical Y2O3, Y2O2S, Y2S3, YS, and Y-O-S + MnS dominate.

- (2)

- With the addition of rare earth yttrium, the average diameter of inclusions decreases from 3.5 μm to 2.8 μm, accompanied by a decrease in aspect ratio from 2.2 to 1.7; the inclusions are refined and spheroidized. In addition, the number density and area fraction of inclusions in the steels are reduced from 27.5 per mm2 and 0.0109% to 25.2 per mm2 and 0.0067%, respectively.

- (3)

- The thermodynamic theoretical calculation results are essentially in agreement with the experimental observations. After adding rare earth yttrium, the evolution route of inclusions in the steel at 1600 °C is Al2O3→Y2O3 + Y2O2S. As the temperature decreases, YS and Y2S3 gradually precipitate instead of MnS, with Y2S3 mainly precipitating after the steel solidifies.

- (4)

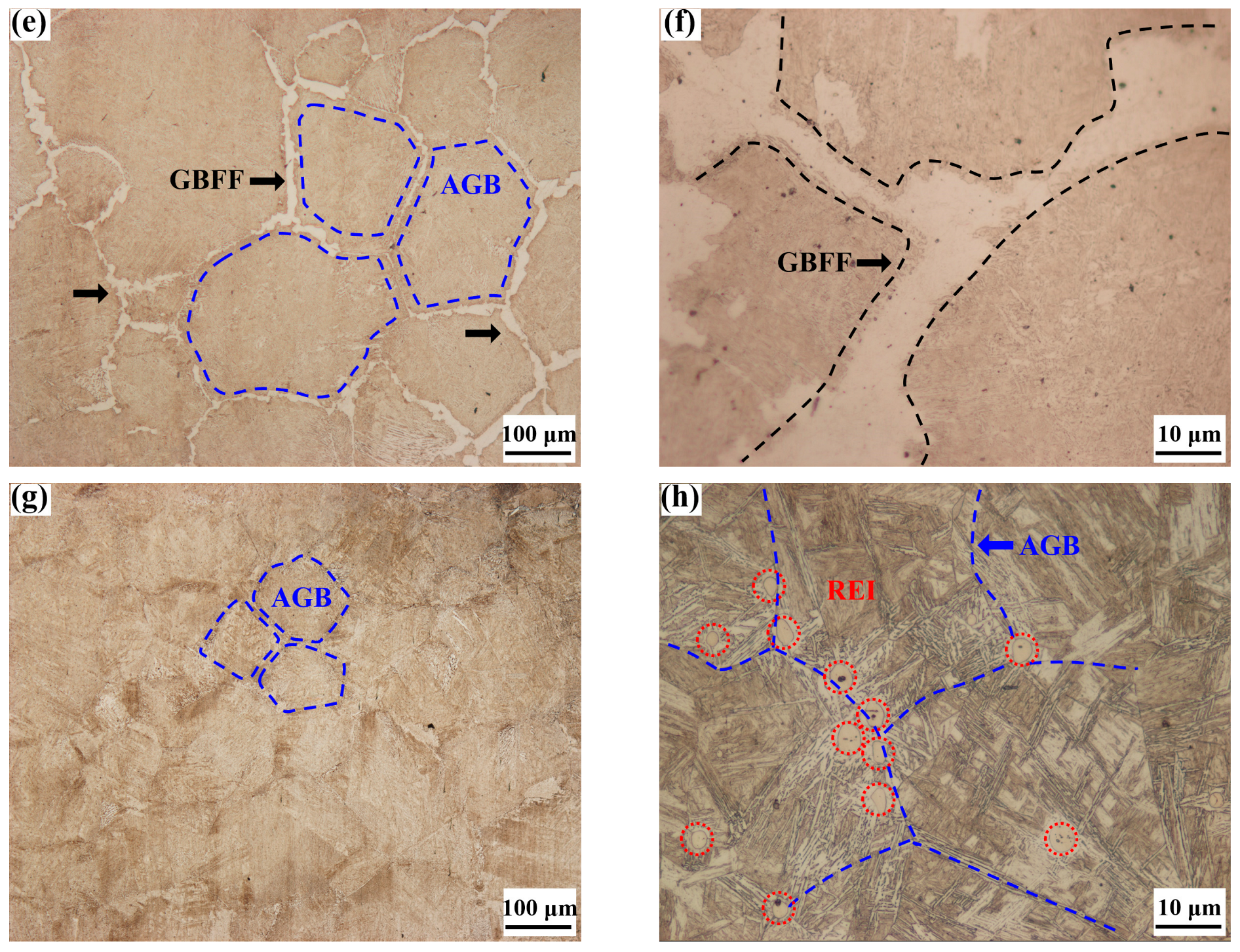

- Rare earth yttrium can significantly affect the microstructure evolution in the studied steel. The average austenite grain size is refined from 251.7 μm to 141.4 μm, with a more uniform size distribution. The rare earth inclusions distributed along grain boundaries have made critical contributions to the grain refinement.

- (5)

- Due to the presence of yttrium element in the steel, the grain boundary ferrite films with thickness ranging from 6.7 μm to 35.8 μm are suppressed. And the fraction of LAGBs decreases from 39.4% to 34.5%, together with the increasing of HAGB fraction from 6.8% to 18.7%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, X.; Zhang, L.; Lai, C.; Li, S.; Li, M.; Deng, Z. A Method to Control the Transverse Corner Cracks on a Continuous Casting Slab by Combining Microstructure Analysis with Numerical Simulation of the Slab Temperature Field. Steel Res. Int. 2018, 89, 1700480. [Google Scholar] [CrossRef]

- Li, S.; Zhang, L.; Yang, X.; Li, M. Control of Transverse Corner Cracks on Hypoperitectic Steel Slabs. Steelmak 2016, 32, 67–72. [Google Scholar]

- Miiko, R.; Fujda, M.; Fedakova, S.A.; Masek, V.; Duka, J.; Matvija, M. Under-solidus austenite grain growth and transverse cracking in hypoperitectic carbon steel. Metall. Res. Tech. 2017, 114, 118. [Google Scholar] [CrossRef]

- Banks, K.M.; Tuling, A.S.; Mintz, B. Influence of chemistry on transverse cracking during continuous casting of medium C high N steel billets. Mater. Sci. Tech. 2012, 28, 1254–1260. [Google Scholar] [CrossRef]

- Mintz, B.; Crowther, D. Hot ductility of steels and its relationship to the problem of transverse cracking in continuous casting. Int. Mater. Rev. 2010, 55, 168–196. [Google Scholar] [CrossRef]

- Wang, P.; Wang, B.; Liu, Y.; Zhang, P.; Luan, Y.; Li, D.; Zhang, Z. Effects of inclusion types on the high-cycle fatigue properties of high-strength steel. Scr. Mater. 2022, 206, 114232. [Google Scholar] [CrossRef]

- Zhao, L.; Zhai, G.; Wu, J.; Chen, X.; Zhai, Q. Evolution mechanism of inclusions and microstructure in low-alloy cast steel with cerium addition. J. Mater. Res. Technol. 2024, 33, 929–939. [Google Scholar] [CrossRef]

- Zarandi, F.; Yue, S. Mechanism for loss of hot ductility due to deformation during solidification in continuous casting of steel. ISIJ Int. 2004, 44, 1705–1713. [Google Scholar] [CrossRef]

- Xing, L.; Zhang, Z.; Bao, Y. Hot ductility behavior of medium carbon sulfur-containing alloy steel. J. Mater. Res. Technol. 2022, 19, 1367–1378. [Google Scholar] [CrossRef]

- Wang, X.; Wu, Z.; Li, B.; Chen, W.; Zhang, J.; Mao, J. Inclusions modification by rare earth in steel and the resulting properties: A review. J. Rare Earths 2024, 42, 431–445. [Google Scholar] [CrossRef]

- Miao, K.; Nabeel, M.; Dogan, N. Evaluation of calcium treatment on oxide and sulfide inclusions through modification indexes. Metall. Mater. Tran. B 2022, 53, 2897–2913. [Google Scholar] [CrossRef]

- Tie, Z.; Jiang, X.; Tang, H.; Li, G.; Wang, Y.; Zhang, J. Effect of Al content on modification behavior of non-metallic inclusions in high-strength steel treated with rare earth. J. Iron. Steel Res. Int. 2024, 31, 1886–1899. [Google Scholar] [CrossRef]

- Liang, Y.; Ni, P.; Liu, Q.; Li, Y. Effect of Rare Earth Metal Alloying on Inclusion Evolution in High-Strength Oil Casing Steel. Metall. Mater. Tran. B 2024, 55, 3158–3173. [Google Scholar] [CrossRef]

- Gong, W.; Wang, C.; Wang, P.; Jiang, Z.; Wang, R.; Li, H. Effect of La on inclusions and fracture toughness of low-alloy ultra-high-strength 40CrNi2Si2MoVA steel. J. Iron. Steel Res. Int. 2021, 28, 1408–1416. [Google Scholar] [CrossRef]

- Hao, C.; Yang, C.; Liu, P.; Luan, Y.; Sang, B. Effects of rare earth elements on inclusions, microstructure and impact toughness of spring steel. J. Iron. Steel Res. Int. 2024, 31, 933–944. [Google Scholar] [CrossRef]

- Gao, J.; Fu, P.; Liu, H.; Li, D. Effects of rare earth on the microstructure and impact toughness of H13 steel. Metals 2015, 5, 383–394. [Google Scholar] [CrossRef]

- Cheng, S.; Hou, T.; Zheng, Y.; Yin, C.; Wu, K. Effect of Rare Earth Elements on Microstructure and Tensile Behavior of Nb-Containing Microalloyed Steels. Materials 2024, 17, 1701. [Google Scholar] [CrossRef]

- Su, C.; Feng, G.; Zhi, J.; Zhao, B.; Wu, W. The effect of rare earth cerium on microstructure and properties of low alloy wear-resistant steel. Metals 2022, 12, 1358. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, J.; Zhou, S.; Wang, X. Effects of rare earth addition on microstructure and mechanical properties of a Fe–15Mn–1.5 Al–0.6 C TWIP steel. Mater. Sci. Eng. A 2014, 608, 106–113. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, Y.; Zhang, S.; Zhang, L. Effect of rare earth element yttrium modified inclusion on corrosion properties of stainless steel. Mater. Today Commun. 2024, 39, 109185. [Google Scholar] [CrossRef]

- Wang, Y.; Li, C.; Wang, L.; Xiong, X.; Chen, L. Effect of yttrium treatment on alumina inclusions in high carbon steel. J. Iron. Steel Res. Int. 2022, 29, 655–664. [Google Scholar] [CrossRef]

- Guo, Z.; Li, X.; Liu, Y.; Zheng, Y.; Zhu, L.; Zhang, Y.; Sun, H.; Feng, J.; Cao, R. Effect of rare earth yttrium on inclusion characteristics of grain-oriented silicon steel. Crystals 2023, 13, 896. [Google Scholar] [CrossRef]

- Liu, J.; Li, G.; Shi, C.; Tang, Z.; Jia, L.; Zhao, Y.; Wang, S.; He, X. Effect of Ce-Y Composite Addition on the Inclusion Evolution in T91 Heat-Resistant Steel. Materials 2025, 18, 1459. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Zhang, F.; Yan, Q.; Zhang, X.; Hong, Z. Microstructure characteristics of 12Cr ferritic/martensitic steels with various yttrium additions. J. Rare Earths 2019, 37, 547–554. [Google Scholar] [CrossRef]

- Zhong, L.; Wang, Z.; Chen, R.; He, J. Effects of Yttrium on the Microstructure and Properties of 20MnSi Steel. Steel Res. Int. 2021, 92, 2100198. [Google Scholar] [CrossRef]

- Hu, J.; Jiang, W.; Huang, C.; Qi, L.; Wang, Z.; Ge, Z. The beneficial effect of yttrium microalloying in the solid solution treatment of AISI 321 stainless steel: Grain refinement and inclusions modification. Mater. Today Commun. 2024, 38, 108077. [Google Scholar] [CrossRef]

- Liu, X.; Liang, J.L. Thermodynamic Analysis and Observation of Inclusions in H13 Die Steel with Rare Earth. Adv. Mater. Res. 2013, 690, 193–196. [Google Scholar] [CrossRef]

- Gan, W.; Huang, Z.; Liu, C.; Wang, Y.; Zhang, H.; Ni, H. Effect of Mg treatment on inclusion behaviors in 430 ferritic stainless steel during solidification. J. Mater. Res. Technol. 2024, 28, 3349–3364. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, L.; Duan, H.; Zhang, Y.; Luo, Y.; Conejo, A.N. Extraction, thermodynamic analysis, and precipitation mechanism of MnS-TiN complex inclusions in low-sulfur steels. Metall. Mater. Trans. A 2016, 47, 3015–3025. [Google Scholar] [CrossRef]

- Yu, Q.; Yang, X.; Lai, C.; Tong, Z. Study on MnS inclusion aggregation along continuous casting slab thickness of medium carbon structural steel. Metals 2021, 12, 56. [Google Scholar] [CrossRef]

- Zhang, Y.; Ye, Q.; Yan, Y. Processing, microstructure, mechanical properties, and hydrogen embrittlement of medium-Mn steels: A review. J. Mater. Res. Technol. 2024, 201, 44–57. [Google Scholar] [CrossRef]

- Seo, E.J.; Cho, L.; Estrin, Y.; De Cooman, B.C. Microstructure-mechanical properties relationships for quenching and partitioning (Q&P) processed steel. Acta Mater. 2016, 113, 124–139. [Google Scholar] [CrossRef]

- Zaefferer, S.; Ohlert, J.; Bleck, W. A study of microstructure, transformation mechanisms and correlation between microstructure and mechanical properties of a low alloyed TRIP steel. Acta Mater. 2004, 52, 2765–2778. [Google Scholar] [CrossRef]

- Yang, X.; Xie, L.; Lai, C.; Luo, D. Study on the mechanism of titanium improving the hot ductility of peritectic microalloyed steels in brittle zone III. Inter. J. Cast Metals Res. 2021, 34, 151–161. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, L.; Li, S.; Li, M. Influence of cooling conditions on the hot ductility of Nb-Ti-bearing steels. Metall. Res. Technol. 2015, 112, 604. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, X.; Li, S.; Li, M.; Ma, W. Control of Transverse Corner Cracks on Low-Carbon Steel Slabs. JOM 2014, 66, 1711–1720. [Google Scholar] [CrossRef]

- Fei, G.; Chengwu, Z.; Pei, W.; Dianzhong, L. Effect of Rare Earth Elements on Austenite-Ferrite Phase Transformation Kinetics of Low Carbon Steels. Chin. J. Mater. Res. 2023, 37, 495–501. [Google Scholar] [CrossRef]

- Li, D.; Wang, P.; Chen, X.-Q.; Fu, P.; Luan, Y.; Hu, X.; Liu, H.; Sun, M.; Chen, Y.; Cao, Y. Low-oxygen rare earth steels. Nature Mater. 2022, 21, 1137–1143. [Google Scholar] [CrossRef]

- Sohn, S.S.; Song, H.; Suh, B.-C.; Kwak, J.-H.; Lee, B.-J.; Kim, N.J.; Lee, S. Novel ultra-high-strength (ferrite+ austenite) duplex lightweight steels achieved by fine dislocation substructures (Taylor lattices), grain refinement, and partial recrystallization. Acta Mater. 2015, 96, 301–310. [Google Scholar] [CrossRef]

- Kaijalainen, A.J.; Suikkanen, P.P.; Limnell, T.J.; Karjalainen, L.P.; Kömi, J.I.; Porter, D.A. Effect of austenite grain structure on the strength and toughness of direct-quenched martensite. J. Alloy. Compd. 2013, 577, S642–S648. [Google Scholar] [CrossRef]

- Ueji, R.; Tsuchida, N.; Terada, D.; Tsuji, N.; Tanaka, Y.; Takemura, A.; Kunishige, K. Tensile properties and twinning behavior of high manganese austenitic steel with fine-grained structure. Scr. Mater. 2008, 59, 963–966. [Google Scholar] [CrossRef]

- Hu, J.; Du, L.; Wang, J.; Gao, C. Effect of welding heat input on microstructures and toughness in simulated CGHAZ of V–N high strength steel. Mater. Sci. Eng. A 2013, 577, 161–168. [Google Scholar] [CrossRef]

- Huang, F.; Li, J.; Zang, R. Effect of Ce on inclusion, microstructure and mechanical properties of Al-killed high-strength steel. Ironmak. Steelmak 2023, 50, 744–756. [Google Scholar] [CrossRef]

- Wang, L.; Qin, J.; Zhu, Y.; Chen, K.; Wang, Y.; Wang, Z. Microstructural optimization by two-step tempering treatment and quantitative analysis of microstructure effect on the toughness at− 40° C in CrNiMoV steel. J. Mater. Res. Technol. 2025, 35, 2781–2790. [Google Scholar] [CrossRef]

- Wu, B.; Wang, Z.; Wang, X.; Zhao, J.; Shang, C.; Misra, R. Relationship between high angle grain boundaries and hardness after γ→ α transformation. Mater. Sci. Technol. 2019, 35, 1803–1814. [Google Scholar] [CrossRef]

| Type | C | Mn | Si | S | P | Al | V | Nb | O | Y | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Steel I | 0.087 | 1.55 | 0.22 | 0.0056 | 0.004 | 0.020 | 0.0043 | 0.0030 | 0.0015 | - | Bal. |

| Steel II | 0.089 | 1.56 | 0.21 | 0.0050 | 0.005 | 0.021 | 0.0040 | 0.0033 | 0.0011 | 0.015 | Bal. |

| Formation Reactions of Non-RE/RE Inclusions | ΔGθ = A + BT (J/mol) |

|---|---|

| 2[Al] + 3[O] = Al2O3(s) | −1,225,000 + 393.8T |

| [Mn] + [S] =MnS(s) | −158,365 + 93.996T |

| 2[Y] + 3[O] = Y2O3(s) | −1,792,600 + 658.0T |

| 2[Y] + 2[O] + [S] = Y2O2S(s) | −1,521,000 + 536.0T |

| [Y] + [S] = YS(s) | −321,080 + 91T |

| 2[Y] + 3[S] = Y2S3(s) | −1,171,000 + 441.0T |

| 2[Y] + Al2O3(s) = Y2O3(s) + 2[Al] | −587,482 + 270.28T |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Lai, C.; Yang, X.; Li, K.; Zhang, Z.; Chen, Y.; Li, W. Effect of Yttrium Treatment on Inclusions and Microstructure of High-Strength Peritectic Steel. Metals 2025, 15, 1284. https://doi.org/10.3390/met15121284

Liu M, Lai C, Yang X, Li K, Zhang Z, Chen Y, Li W. Effect of Yttrium Treatment on Inclusions and Microstructure of High-Strength Peritectic Steel. Metals. 2025; 15(12):1284. https://doi.org/10.3390/met15121284

Chicago/Turabian StyleLiu, Min, Chaobin Lai, Xiaogang Yang, Kexin Li, Zhi Zhang, Yasheng Chen, and Weirong Li. 2025. "Effect of Yttrium Treatment on Inclusions and Microstructure of High-Strength Peritectic Steel" Metals 15, no. 12: 1284. https://doi.org/10.3390/met15121284

APA StyleLiu, M., Lai, C., Yang, X., Li, K., Zhang, Z., Chen, Y., & Li, W. (2025). Effect of Yttrium Treatment on Inclusions and Microstructure of High-Strength Peritectic Steel. Metals, 15(12), 1284. https://doi.org/10.3390/met15121284