Characterizing the Vertical Heterogeneity in Ultra-High Bed Sintering: From Mixture Properties to Stratified Phase Composition and Sinter Strength

Abstract

1. Introduction

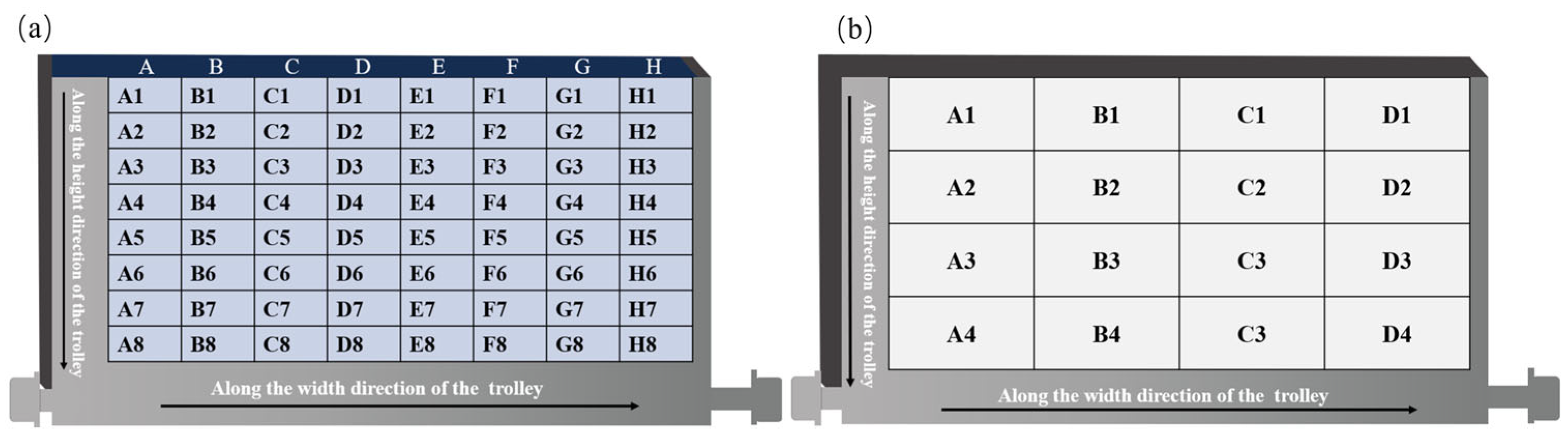

2. Materials and Methods

3. Results and Discussion

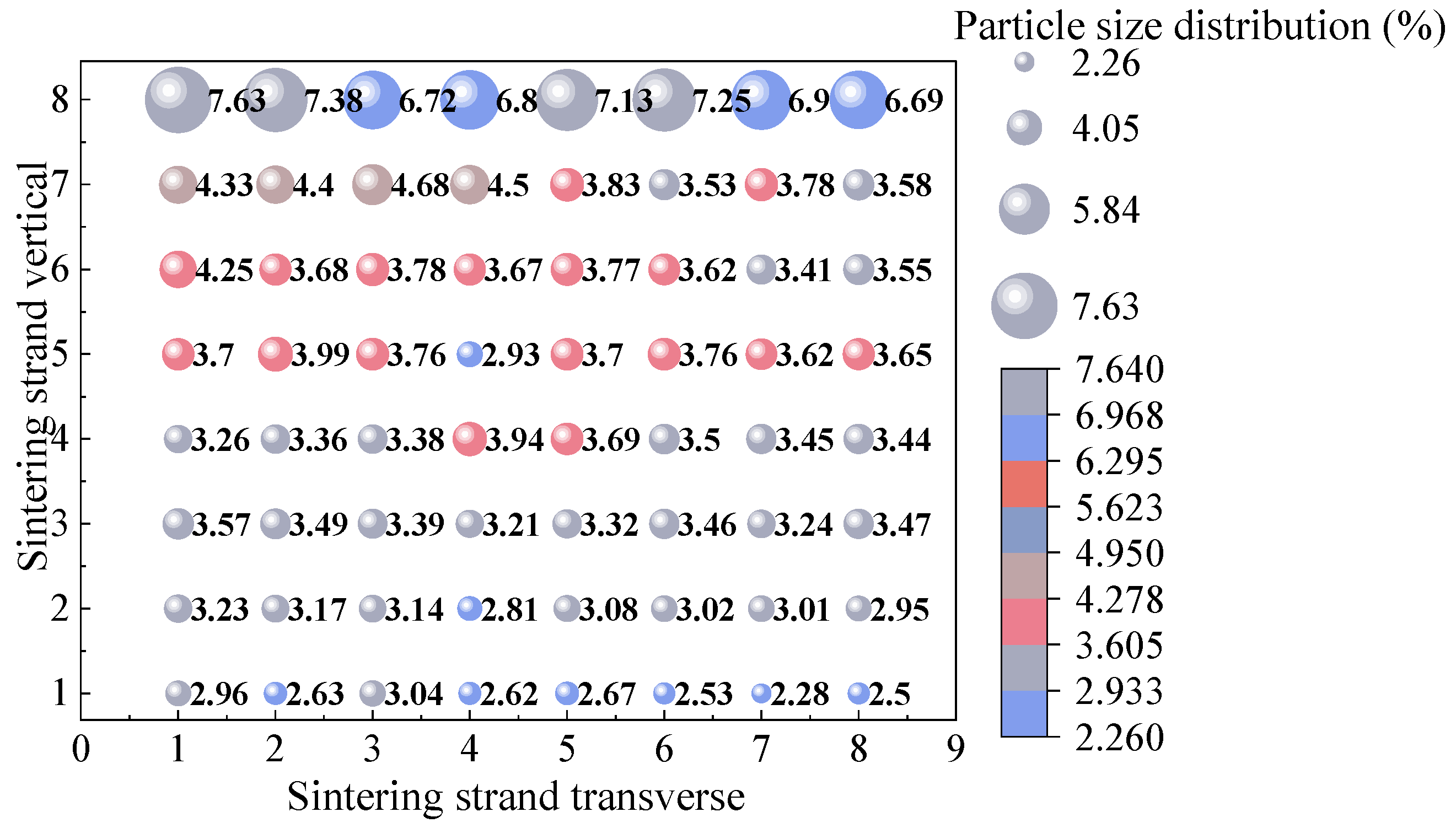

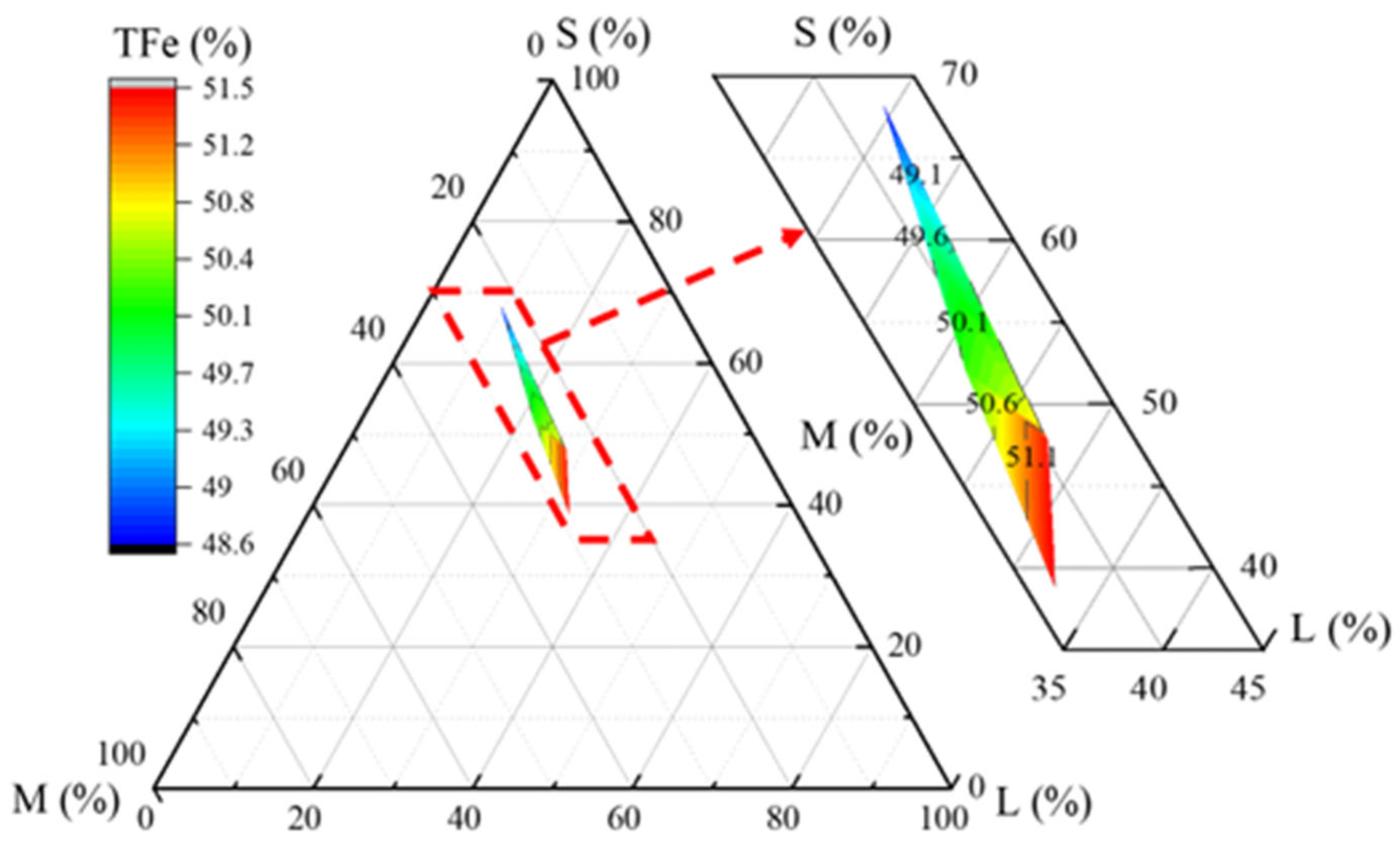

3.1. Mixture Segregation Analysis

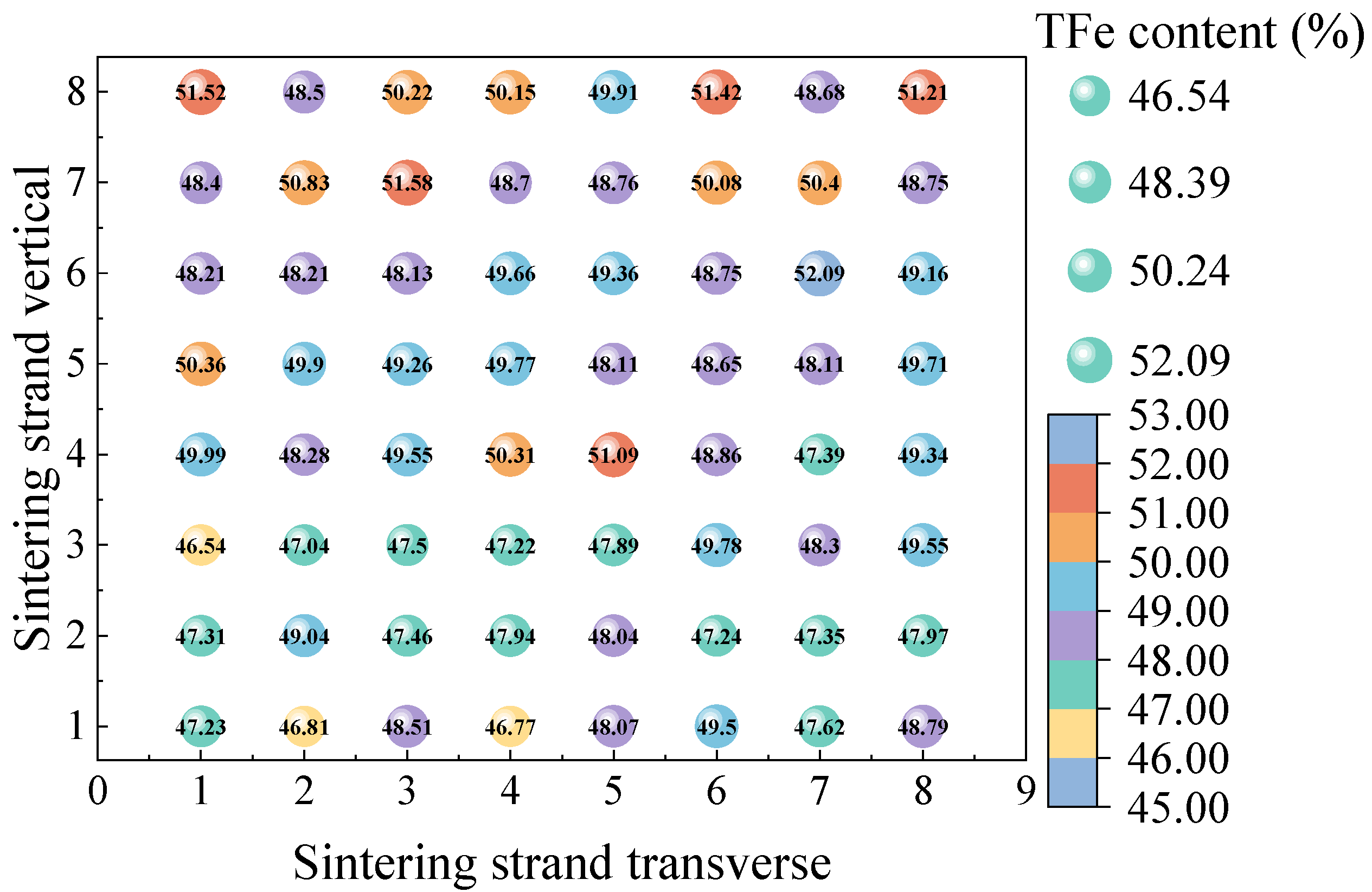

3.2. Segregation Analysis of Sinter

4. Conclusions

- (1)

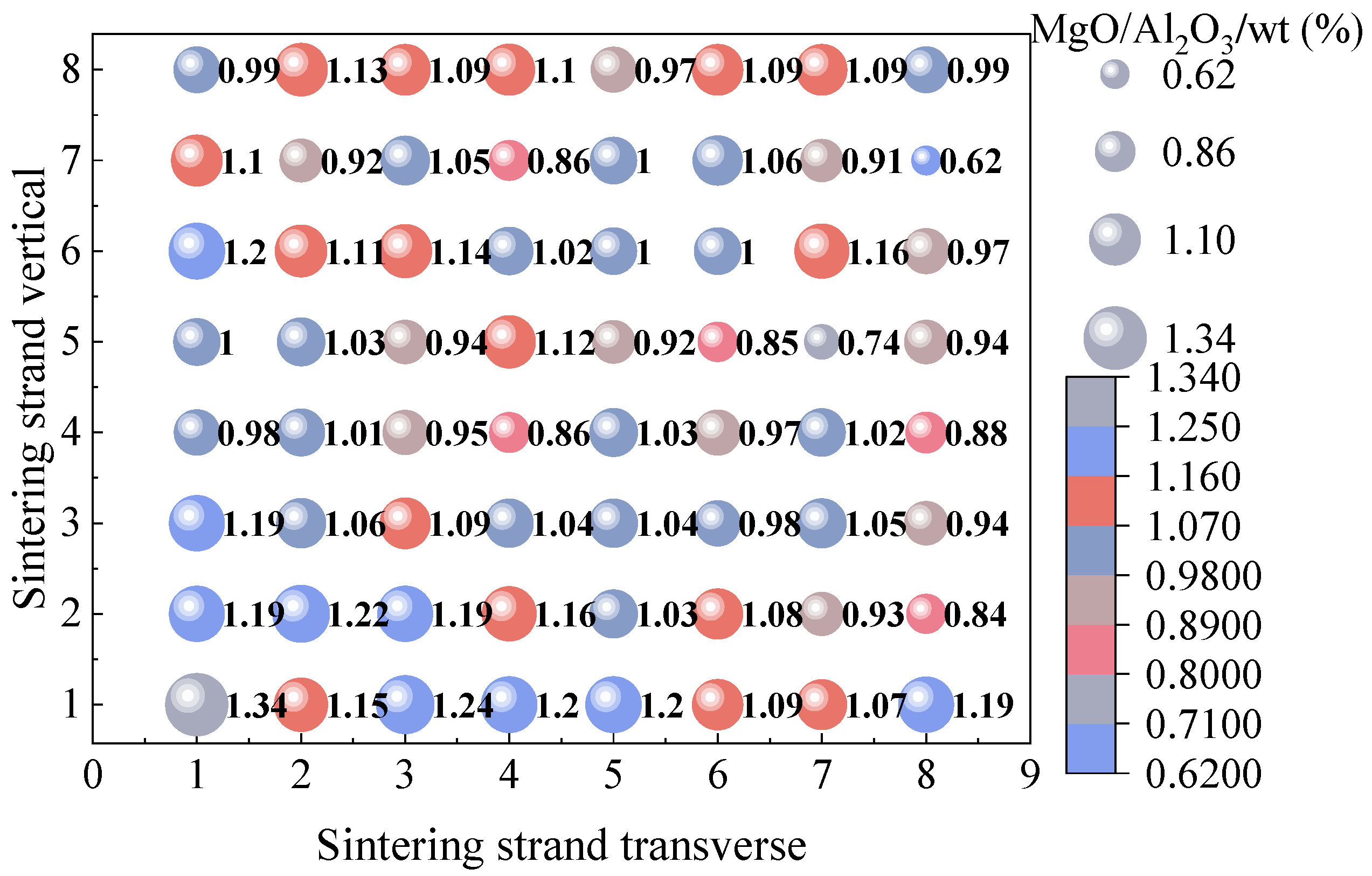

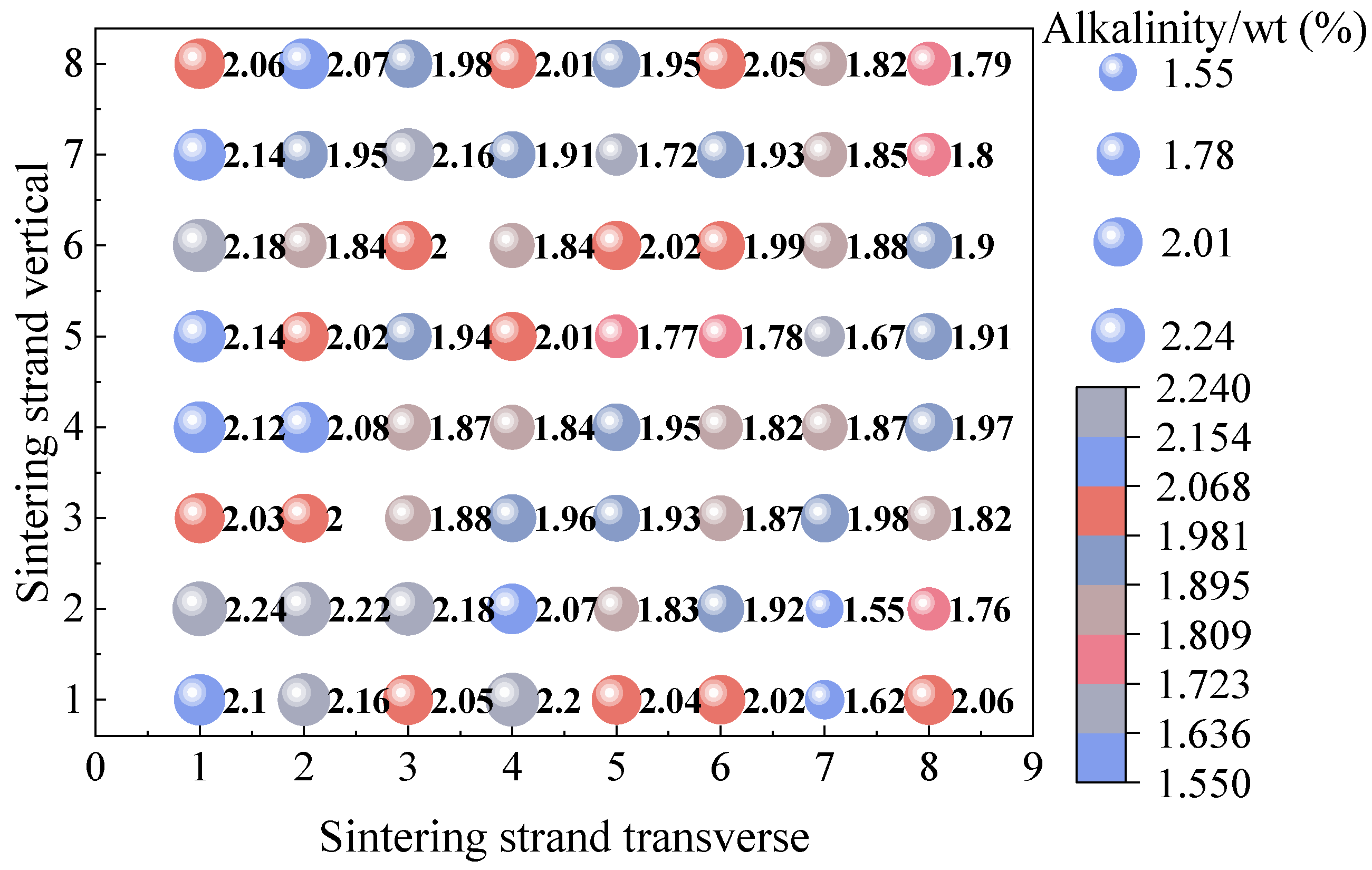

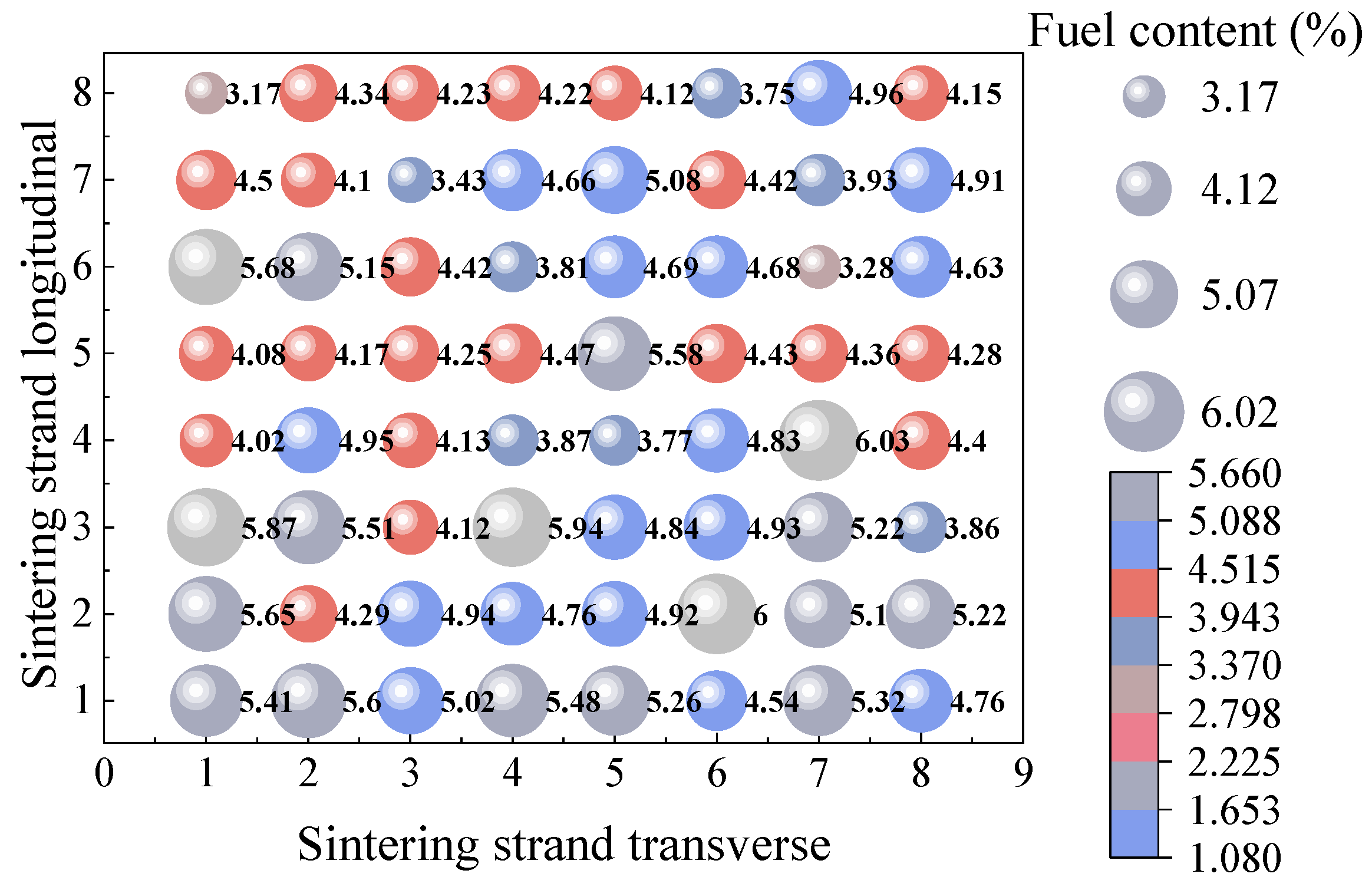

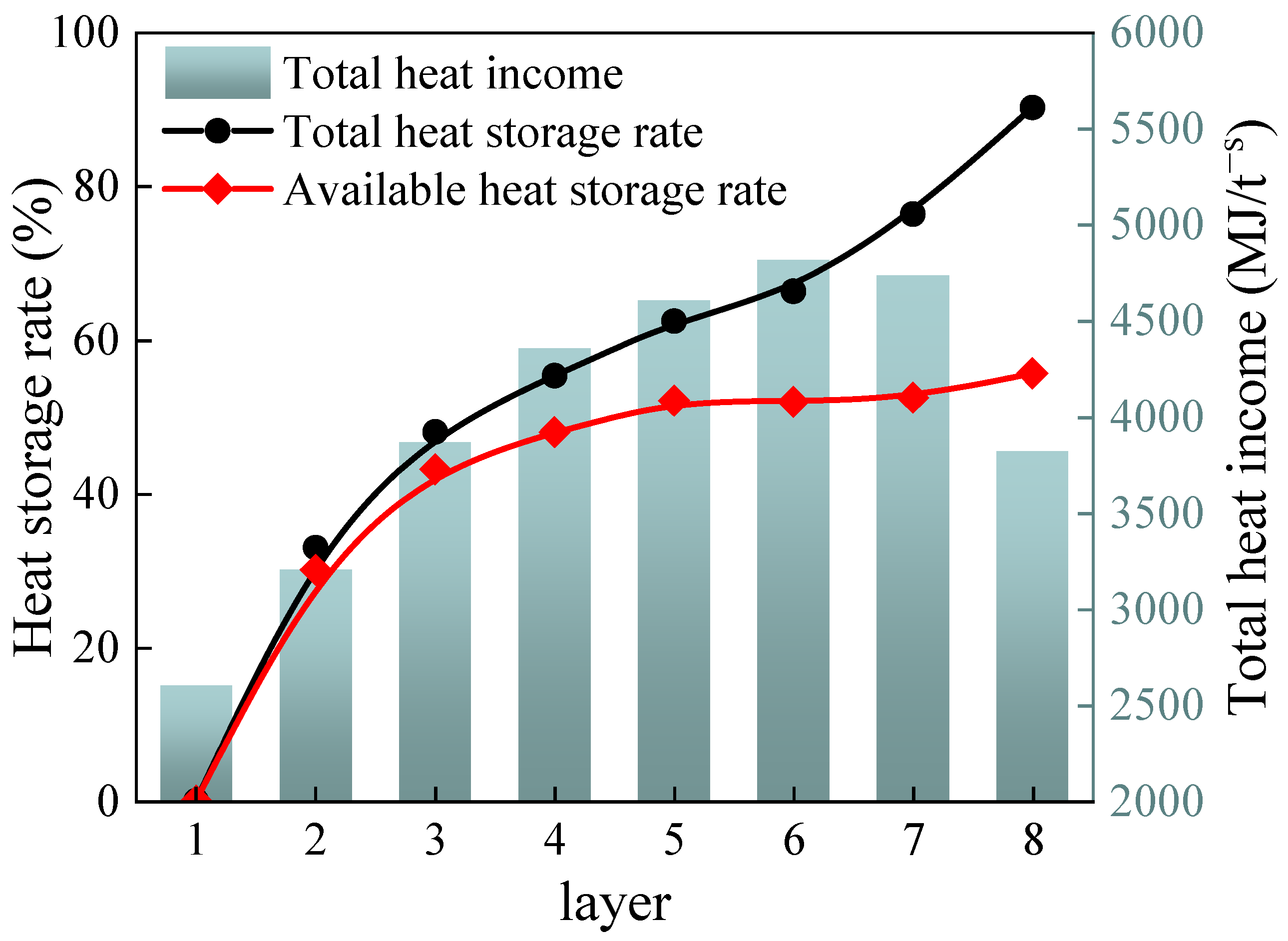

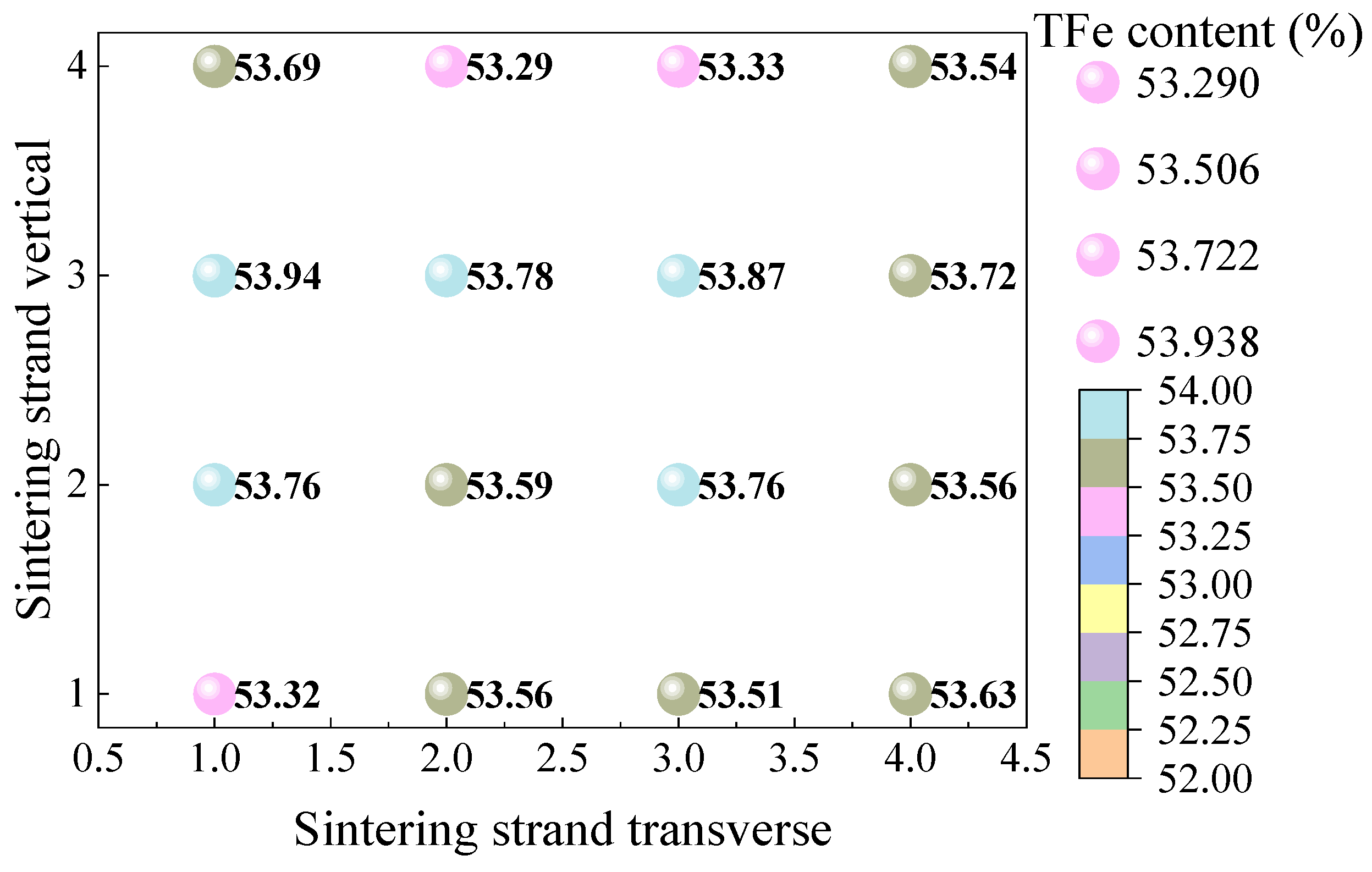

- Under the condition of ultra-high bed sintering, the segregation of particle size in the material layer was mainly caused by the upper mixture, while the segregation of the lower layer exerted less influence on the segregation of the whole material layer than the upper layer. Due to the segregation of particle size, the chemical composition in the mixture also showed serious segregation. The segregation of TFe and fuel in the height direction of the material layer was significant, while the segregation of MgO/Al2O3 and alkalinity appeared in the width direction of the trolley.

- (2)

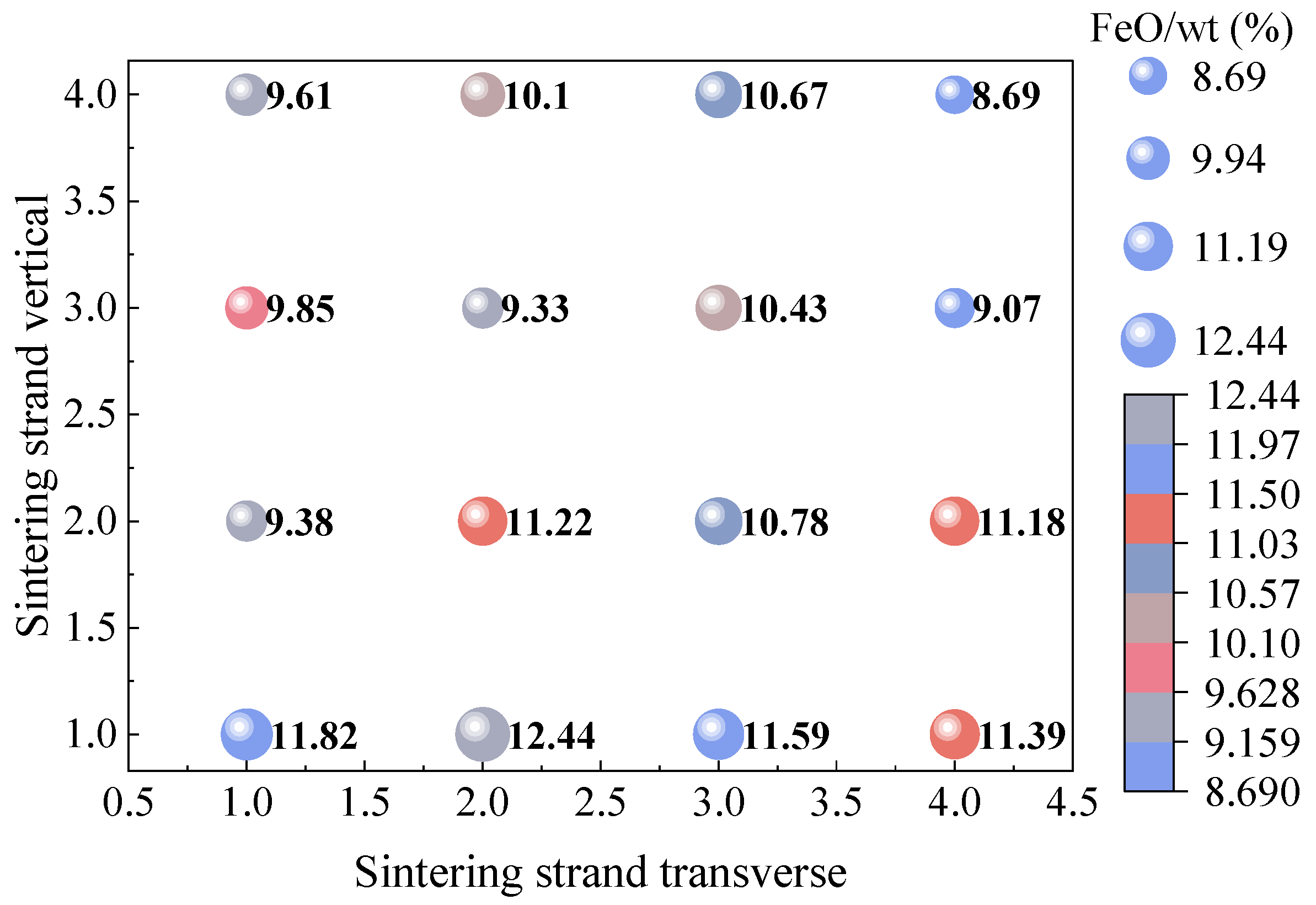

- TFe content in sinter initially increased, and then decreased. The average FeO content in the bottom layer was 9.77%, with a 2.04% difference from the surface layer. FeO content also exhibited segregation in the transverse direction of the trolley, generally displaying lower values at the edges and higher concentrations in the central regions.

- (3)

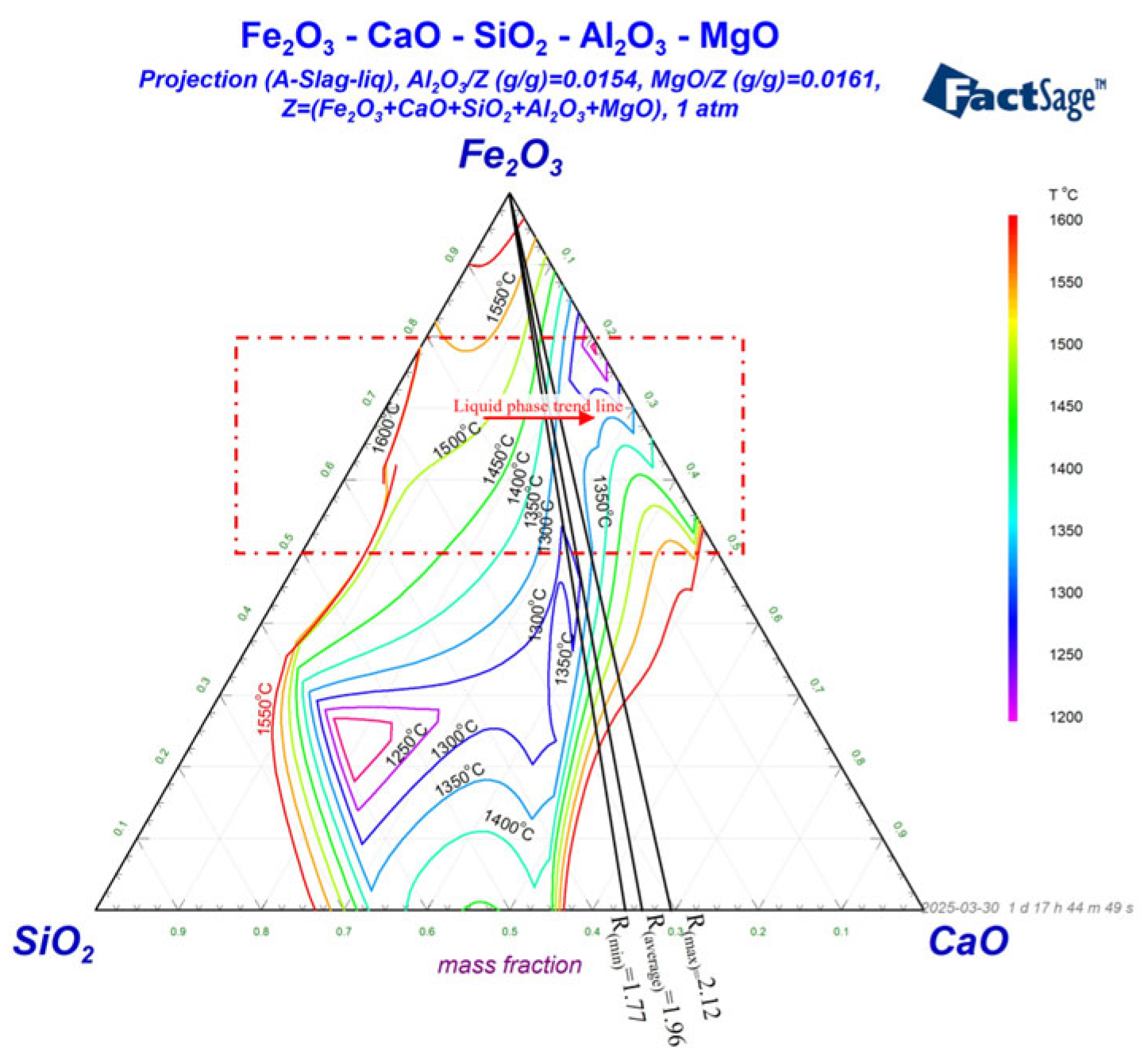

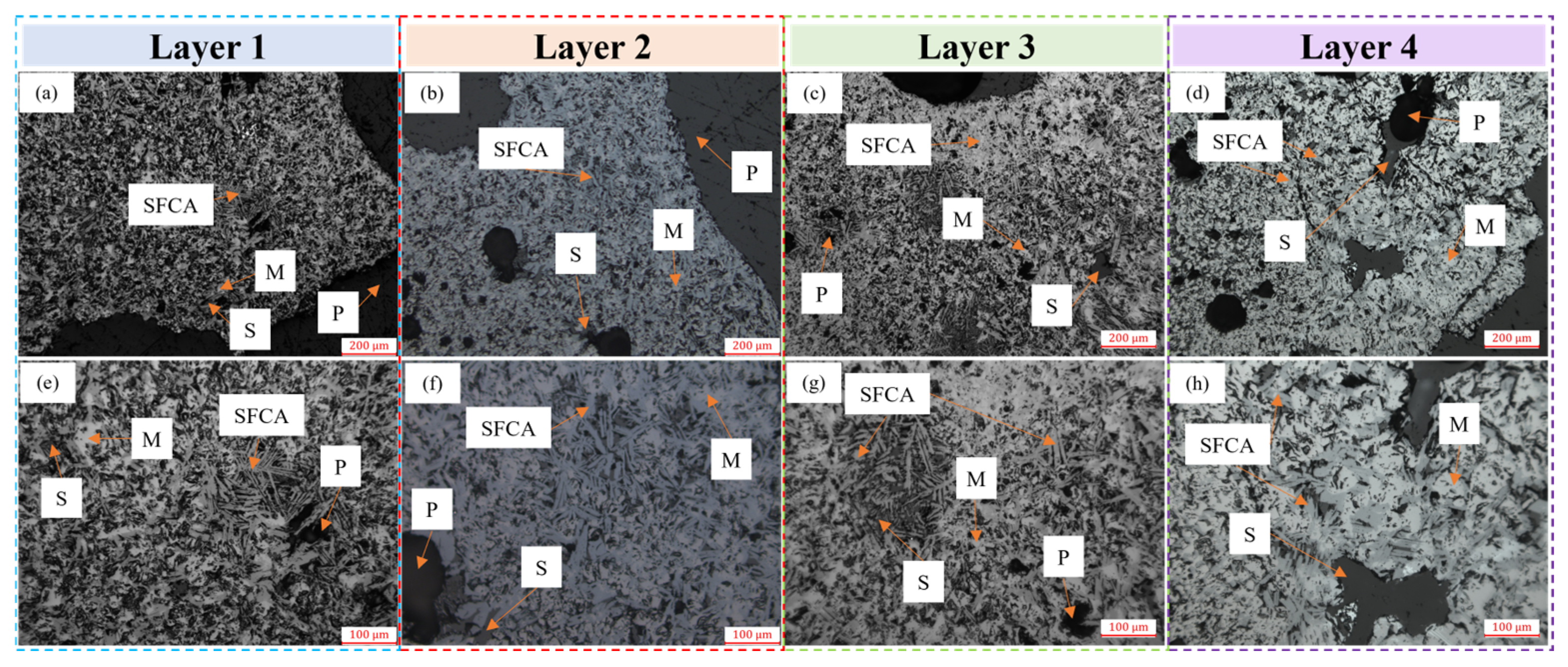

- Sinter strength improved significantly along the bed depth. With increasing FeO content, the drum strength of the sinter decreased. This phenomenon resulted from mixture fuel segregation, which was predominantly concentrated in the surface layer. However, owing to the short high-temperature duration in the surface layer, a limited liquid phase was generated, and residual voids exerted a detrimental effect, consequently causing the surface layer strength to be substantially lower than that of the bottom layer.

- (4)

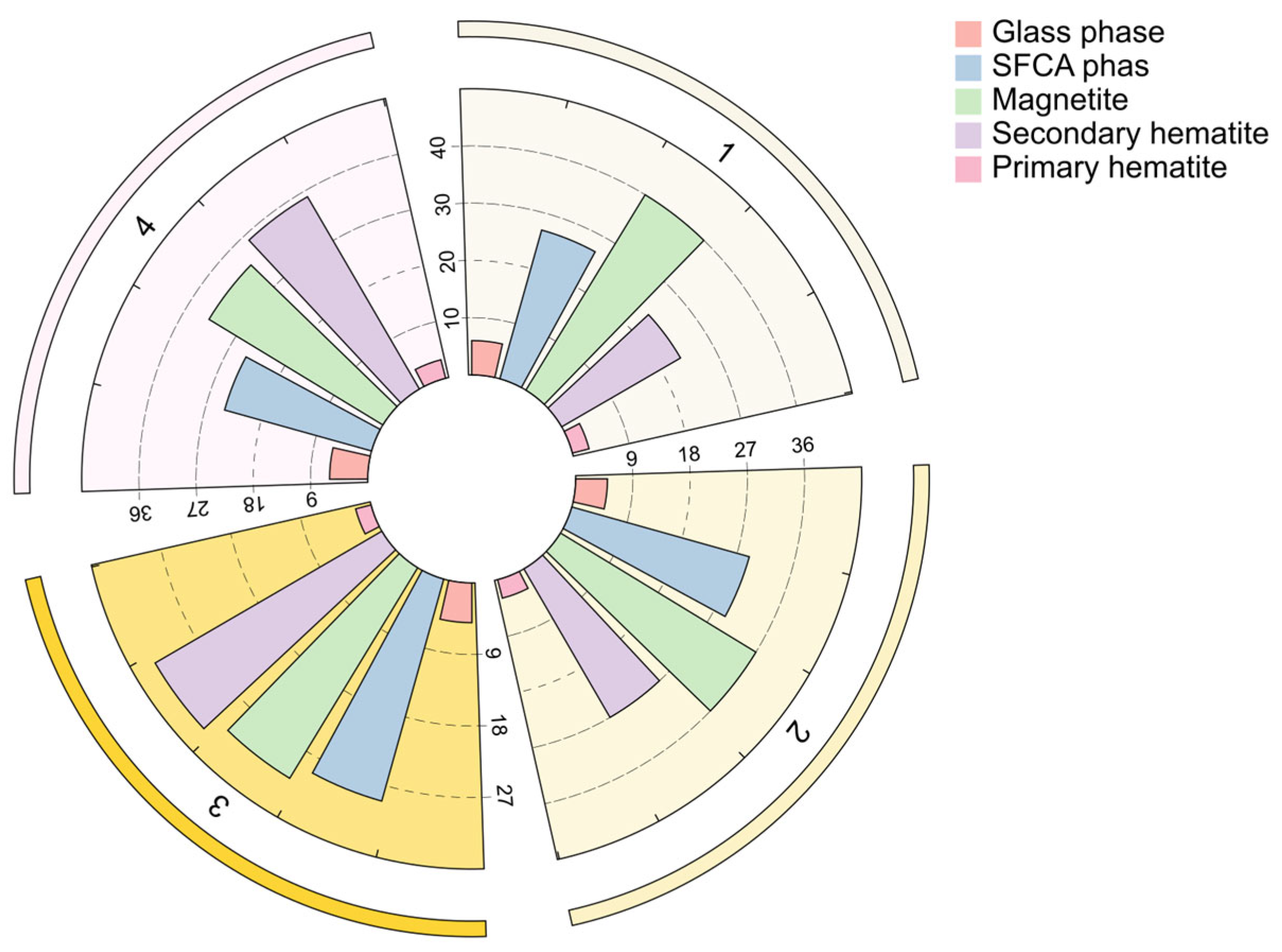

- Phase composition of different sinter layers varied considerably. Hematite content increased gradually from top to bottom, calcium ferrite content initially increased then decreased, and magnetite content decreased progressively along the material layer.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, J.; Wang, S.; Yi, H.H.; Tang, X.L.; Li, Z.L.; Yu, Q.J.; Zhao, S.Z.; Gao, F.Y.; Zhou, Y.S.; Wang, Y.X. Air pollutant emission and reduction potentials from the sintering process of the iron and steel industry in China in 2017. Environ. Pollut. 2022, 307, 119512. [Google Scholar] [CrossRef]

- Wang, Y.Z.; Zhang, J.L.; Liu, Z.J.; Du, C.B. Recent advances and research status in energy conservation of iron ore sintering in China. J. Miner. Met. Mater. Soc. 2017, 69, 2404–2411. [Google Scholar] [CrossRef]

- Liu, Y.; Gao, M. Research on the recent carbon emission reduction path of small and medium-sized iron and steel enterprises under the background of “dual carbon”. In Proceedings of the TMS Annual Meeting & Exhibition, Las Vegas, NV, USA, 25 February 2025; pp. 105–114. [Google Scholar]

- Zhong, T.L.; Li, X.H.; She, X.F.; Wang, Y.J.; Liu, P.; Zuo, H.B.; Xue, Q.G. CO reduction process technology and development of iron ore sintering process. ISIJ Int. 2024, 64, 1737–1757. [Google Scholar] [CrossRef]

- Wang, J.K.; Ma, P.G.; Meng, H.X.; Cheng, F.Z.; Zhou, H. Investigation on the evolution characteristics of bed porous structure during iron ore sintering. Particuology 2023, 74, 35–47. [Google Scholar] [CrossRef]

- Shu, K.Q.; Keiko, S. Occurrence of steel converter slag and its high value-added conversion for environmental restoration in China: A review. J. Clean. Prod. 2022, 373, 133876. [Google Scholar] [CrossRef]

- Xu, W.Q.; Wan, B.; Zhu, T.Y.; Shao, M.P. CO2 emissions from China’s iron and steel industry. J. Clean. Prod. 2016, 139, 1504–1511. [Google Scholar] [CrossRef]

- Li, C.Q.; Qin, S.; Wang, X.; Zhu, T.Y.; Song, J.F.; Zhao, R.Z.; Xu, W.Q. Reduction of carbon emission in iron sintering process based on hot air sintering technology. J. Clean. Prod. 2024, 471, 143403. [Google Scholar] [CrossRef]

- Wang, S.; Liu, J.; Yi, H.H.; Tang, X.L.; Yu, Q.J.; Zhao, S.Z.; Gao, F.Y.; Zhou, Y.S.; Zhong, T.T.; Wang, Y.X. Trends in air pollutant emissions from the sintering process of the iron and steel industry in the Fenwei Plain and surrounding regions in China, 2014–2017. Chemosphere 2022, 291, 132917. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Hu, Q. Research and application of optimization method for iron and steel sintering ingredients. In Proceedings of the 2018 IEEE 3rd Advanced Information Technology, Electronic and Automation Control Conference (IAEAC), Chongqing, China, 12–14 October 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1819–1823. [Google Scholar]

- Liu, Z.J.; Niu, L.L.; Zhang, S.J.; Dong, G.Q.; Wang, Y.Z.; Wang, G.L.; Kang, J.; Chen, L.Z.; Zhang, J.L. Comprehensive technologies for iron ore sintering with a bed height of 1000 mm to improve sinter quality, enhance productivity and reduce fuel consumption. ISIJ Int. 2020, 60, 2400–2407. [Google Scholar] [CrossRef]

- Yu, Y.H.; Feng, G.S.; Su, D.X. Measures of decreasing blast furnace fuel consumption and improving sinter performance in Guofeng. J. Iron Steel Res. Int. 2008, 15, 9–12. [Google Scholar] [CrossRef]

- Bersenev, I.S.; Evstyugin, S.N.; Gorbachev, V.A.; Usoltsev, D.Y.; Vinnichuk, B.G. Comparison of different binders in sintering. Steel Transl. 2015, 45, 575–577. [Google Scholar] [CrossRef]

- Frolov, Y.A.; Filatov, S.V.; Kaplun, L.I.; Semenov, O.A.; Mikhailov, V.G.; Gileva, L.Y. Influence of the composition and height of the bed on the quality of sinter: Fuel consumption, and capacity of the NLMK sinter machines. Metallurgist 2020, 64, 288–300. [Google Scholar] [CrossRef]

- Zhang, Y.P.; Zhang, J.L.; Zhang, C.; Wang, Y.Z.; Liu, Z.J.; Wang, G.W.; Ma, F.T.; Zhao, Z.X. Modelling and visual verification of combustion zone transfer in ultra-thick bed sintering process. Ironmak. Steelmak. 2017, 44, 304–310. [Google Scholar] [CrossRef]

- Vikulov, G.S.; Malygin, A.V.; Melamud, S.G. Further development of sintering conditions in a thick bed and the effectiveness of reducing the mass proportion of ferrous oxide in the sinter. Stal 1988, 5–10. [Google Scholar]

- Zhong, Q.; Liu, H.B.; Xu, L.P.; Zhang, X.; Rao, M.J.; Peng, Z.W.; Li, G.H.; Jiang, T. An efficient method for iron ore sintering with high-bed layer: Double-layer sintering. J. Iron Steel Res. Int. 2021, 28, 1366–1374. [Google Scholar] [CrossRef]

- Zhong, Q.; Jiang, W.Z.; Gao, W.; Li, Q.; Yang, Y.B.; Jiang, T. Pre-reduction sintering process with flue gas recirculation for reduction alkalis harm and flue gas emission. J. Cent. South Univ. 2025, 32, 106–121. [Google Scholar] [CrossRef]

- Wu, Y.F.; Gan, M.; Ji, Z.Y.; Fan, X.H.; Zhao, G.G.; Zhou, H.Y.; Zheng, H.X.; Wang, X.L.; Liu, L.C.; Li, J.H. New approach to improve heat energy utilization efficiency in iron ore sintering: Exploration of surface fuel addition. Process Saf. Environ. Prot. 2024, 190, 125–137. [Google Scholar] [CrossRef]

- Ma, Y.H.; Zhang, Y.; Zhong, Q.; Li, Q.; Yang, Y.B.; Jiang, T. A clean and carbon-reducing pre-granulation process for enhanced muddy iron concentrate and dust sintering: Parameters optimization and deep mechanism analysis. J. Clean. Prod. 2025, 520, 146077. [Google Scholar] [CrossRef]

- Seenivasan, R.; Acharyulu, A.V.B.; Sabariraj, V.; Arvind, J.; Rameshwar, S.; Balachandran, G. Modelling the effect of sinter machine speed on bed temperature and coke combustion characteristics in iron ore sintering process. Ironmak. Steelmak. 2021, 48, 637–648. [Google Scholar] [CrossRef]

- GB/T 24531-2009; Iron Ores for Blast Furnace and Direct Reduction Feedstocks-Determination of the Tumble and Abrasion Indices. Standards Press of China: Beijing, China, 2009.

- Tu, Y.K.; Zhang, Y.B.; Su, Z.J.; Jiang, T. Mineralization mechanism of limonitic laterite sinter under different fuel dosage: Effect of FeO. Powder Technol. 2022, 398, 117064. [Google Scholar] [CrossRef]

- Yu, Z.W. Researches on Bed Structure and Mineralization Theory of Composite Agglomeration Process (CAP) of Iron Ore Fines and Their Application. Ph.D. Thesis, Central South University, Changsha, China, 2016. [Google Scholar]

- Xu, B. Research on Fundamental and Technology of Heat-Homogenizing Sintering of Iron Ores. Ph.D. Thesis, Central South University, Changsha, China, 2011. [Google Scholar]

- Liu, C. Studies on the Basis and Application of Composite Agglomeration Process for Efficiently Recovering Fe–C-Bearing Dusts in Steel Works. Ph.D. Thesis, Central South University, Changsha, China, 2019. [Google Scholar]

- Jiang, T. Principle and Technology of Agglomeration of Iron Ores; Central South University Press: Changsha, China, 2016. [Google Scholar]

- Xu, L.P.; Liu, H.B.; Dong, Z.L.; Zhong, Q.; Zhao, Y.C.; Li, G.H. Super-high bed sintering for iron ores: Behaviors, causes and solutions of horizontal segregation on strand. J. Iron Steel Res. Int. 2024, 31, 1590–1596. [Google Scholar] [CrossRef]

- Gan, M.; Fan, X.H.; Ji, Z.Y.; Chen, X.L.; Yin, L.; Jiang, T.; Li, G.H.; Yu, Z.Y. High temperature mineralization behavior of mixtures during iron ore sintering and optimizing methods. ISIJ Int. 2015, 55, 742–750. [Google Scholar] [CrossRef]

- Sinha, M.; Nistala, S.H.; Chandra, S.; Mankhand, T.R.; Ghose, A.K. Correlating mechanical properties of sinter phases with their chemistry and its effect on sinter quality. Ironmak. Steelmak. 2017, 44, 100–107. [Google Scholar] [CrossRef]

- Fernández, G.; Ruiz, B.; Mochón, J.; Gonzalez, G.; Verdeja, L.F. Iron ore sintering: Quality indices. Miner. Process. Extr. Metall. Rev. 2017, 38, 254–264. [Google Scholar] [CrossRef]

- Niu, L.L.; Liu, Z.J.; Zhang, J.L.; Lan, D.W.; Li, S.D.; Li, Z.; Wang, Y.Z. Mineralogical characteristics, metallurgical properties and phase structure evolution of Ca-rich hematite sintering. Int. J. Miner. Metall. Mater. 2023, 30, 303–313. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Dong, H.; Li, P.; Jiang, W.; Zhong, Q.; Rao, M. Characterizing the Vertical Heterogeneity in Ultra-High Bed Sintering: From Mixture Properties to Stratified Phase Composition and Sinter Strength. Metals 2025, 15, 1282. https://doi.org/10.3390/met15121282

Zhao Y, Dong H, Li P, Jiang W, Zhong Q, Rao M. Characterizing the Vertical Heterogeneity in Ultra-High Bed Sintering: From Mixture Properties to Stratified Phase Composition and Sinter Strength. Metals. 2025; 15(12):1282. https://doi.org/10.3390/met15121282

Chicago/Turabian StyleZhao, Yuchao, Hongzhuang Dong, Peng Li, Wenzheng Jiang, Qiang Zhong, and Mingjun Rao. 2025. "Characterizing the Vertical Heterogeneity in Ultra-High Bed Sintering: From Mixture Properties to Stratified Phase Composition and Sinter Strength" Metals 15, no. 12: 1282. https://doi.org/10.3390/met15121282

APA StyleZhao, Y., Dong, H., Li, P., Jiang, W., Zhong, Q., & Rao, M. (2025). Characterizing the Vertical Heterogeneity in Ultra-High Bed Sintering: From Mixture Properties to Stratified Phase Composition and Sinter Strength. Metals, 15(12), 1282. https://doi.org/10.3390/met15121282