Effect of PVD Nitride Coating Deposition on the High-Temperature Pin–Disc Friction Properties Between WC/Co Carbide and Ti2AlNb Alloy

Abstract

1. Introduction

2. Experimental Procedure

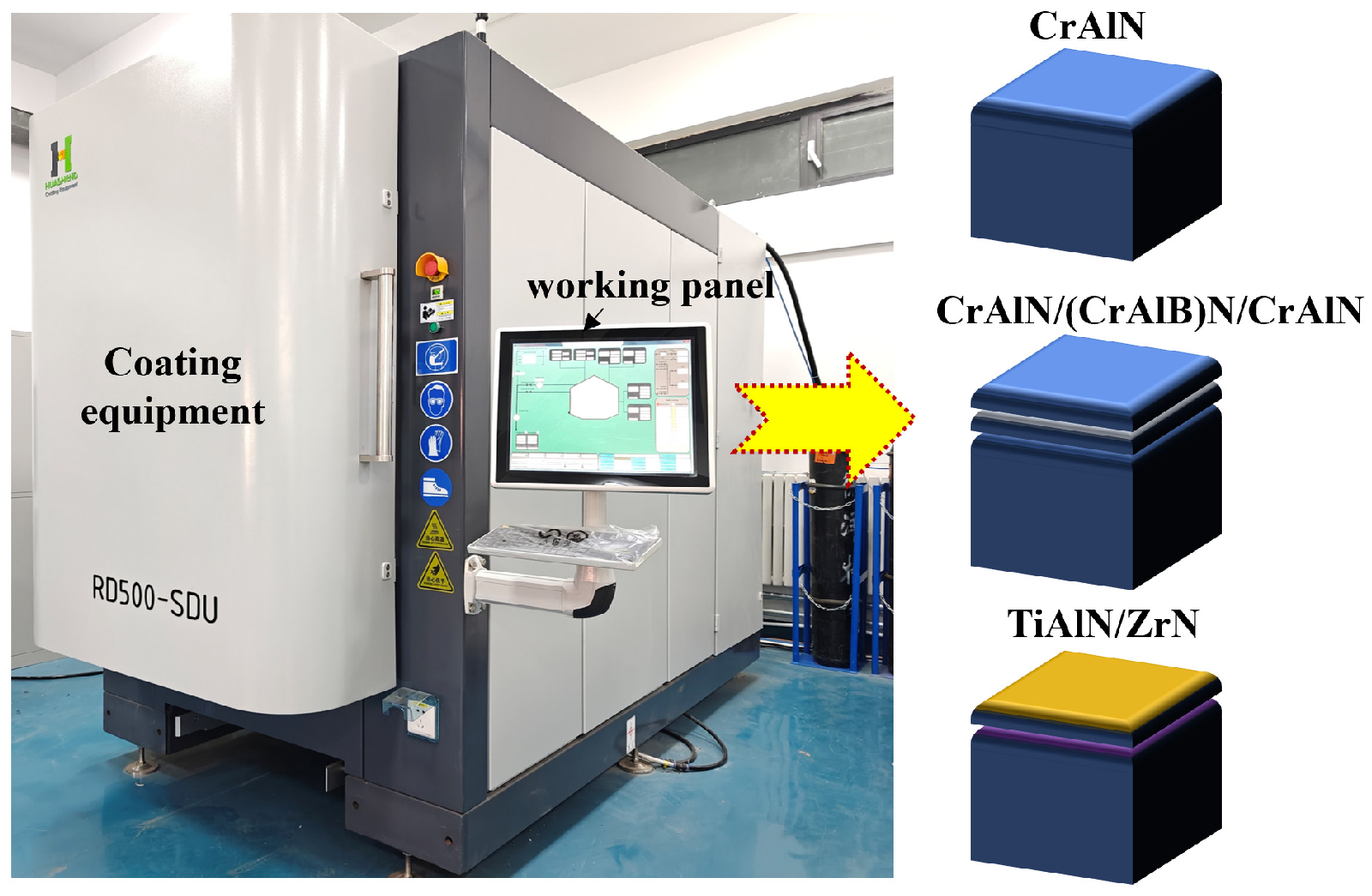

2.1. Coating Deposition and Charactrization

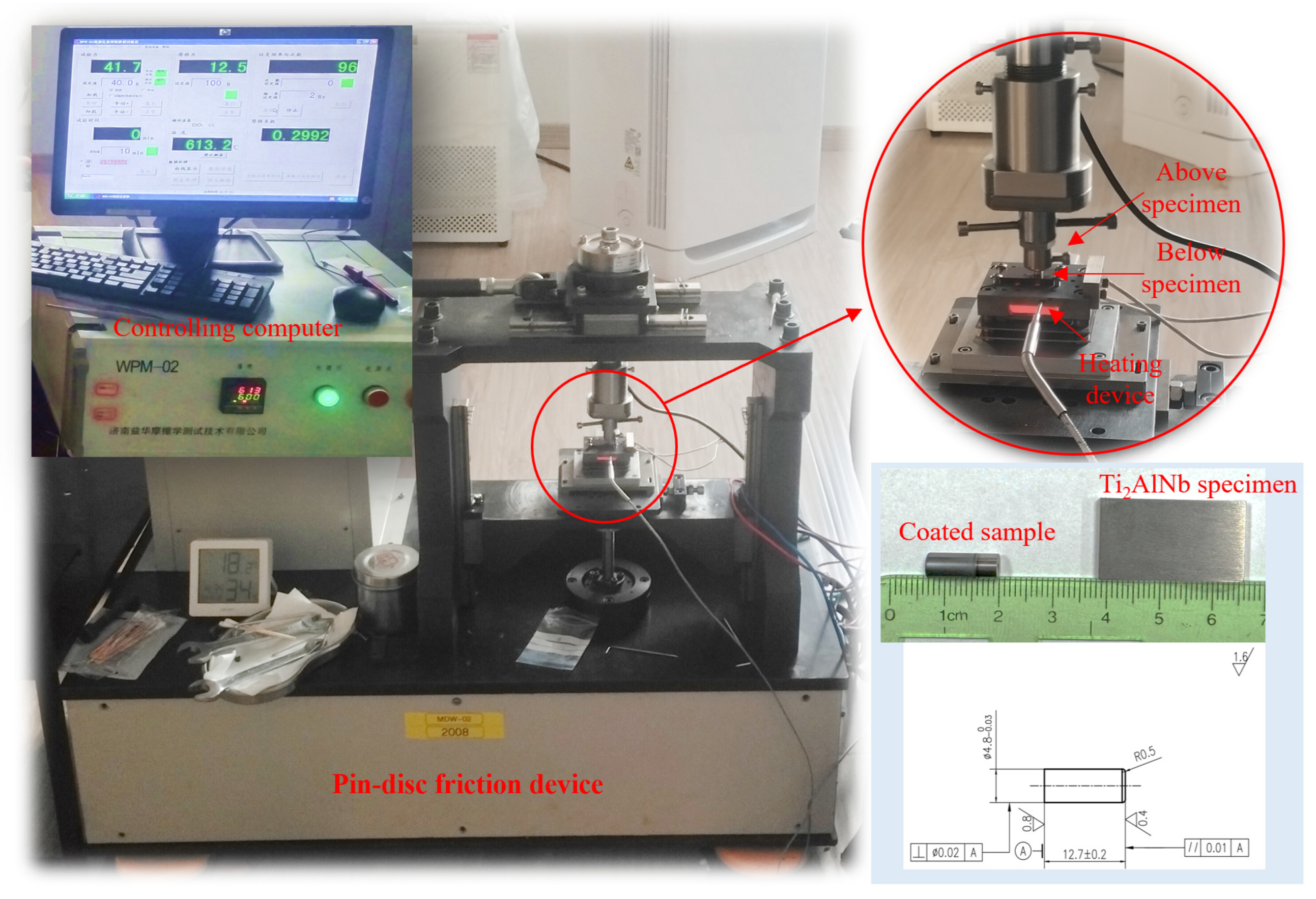

2.2. Design of Pin–Disc Friction Experiment

3. Results and Discussion

3.1. Coating Topography and Properties

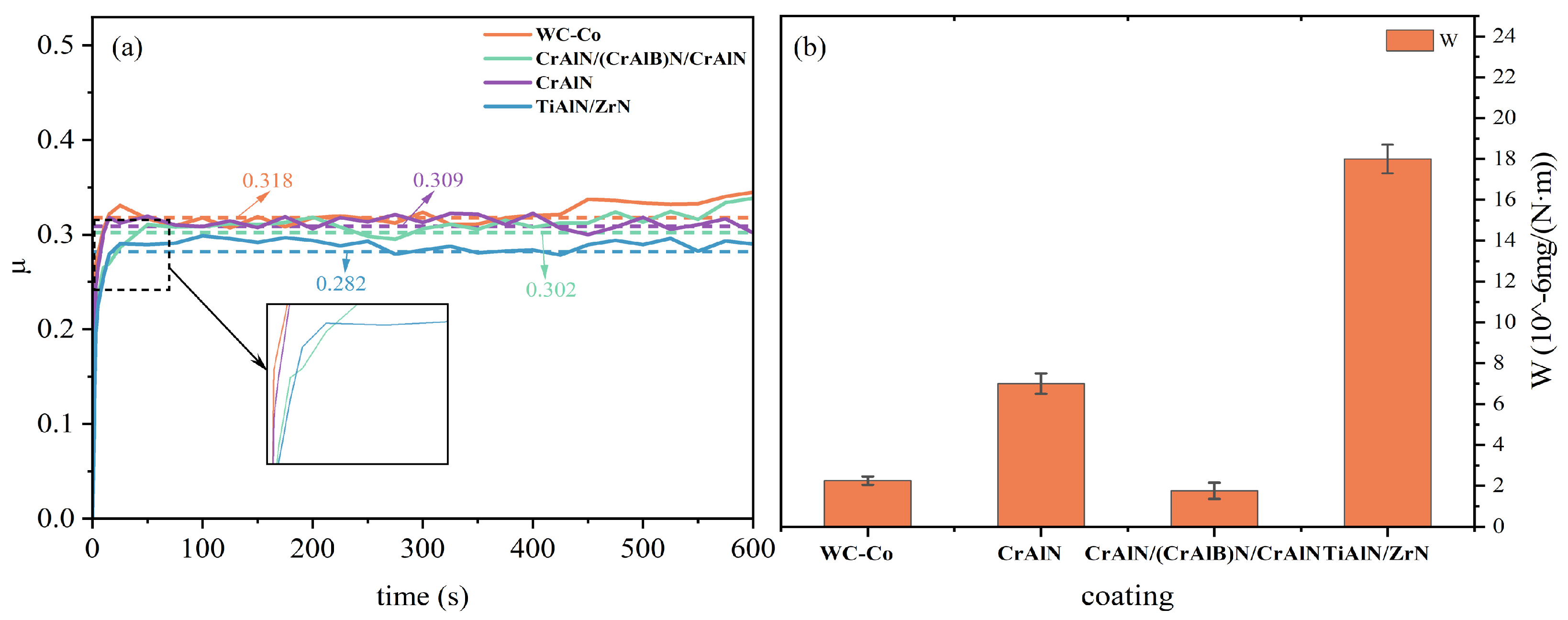

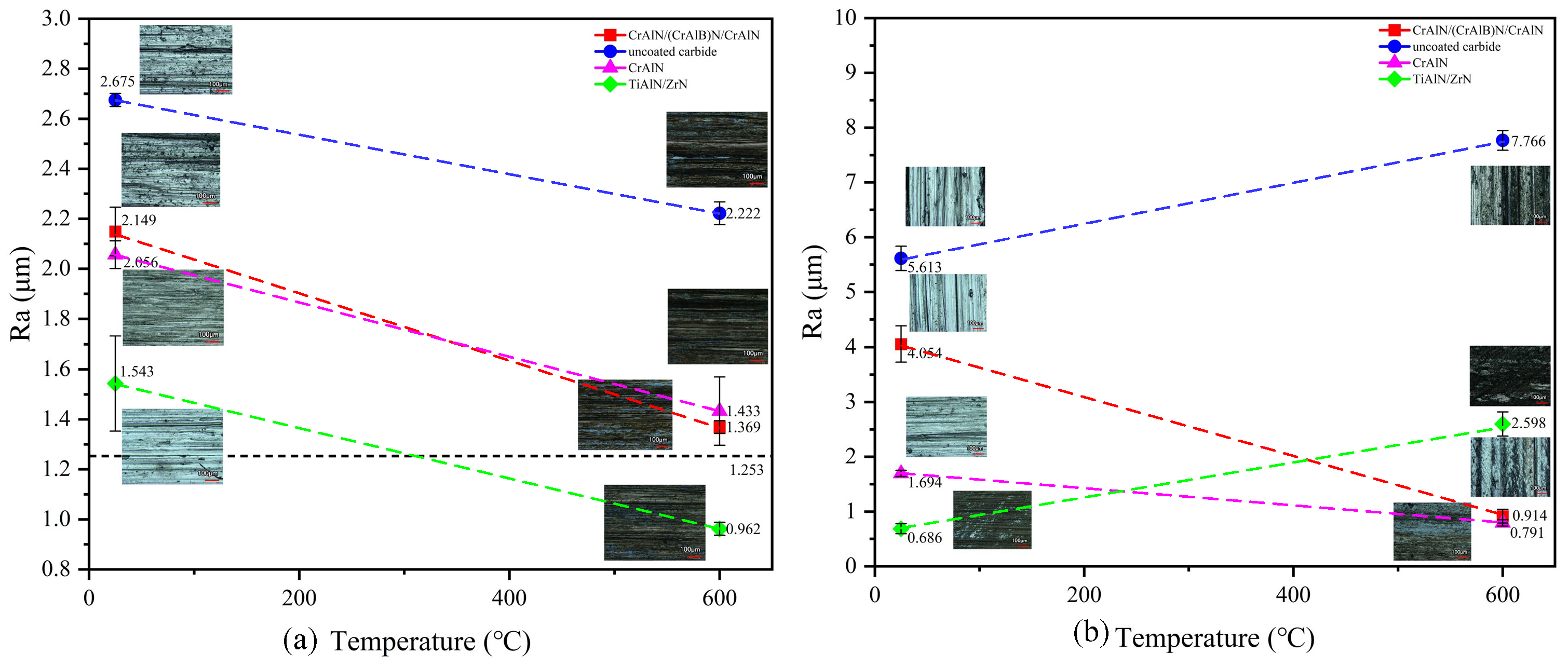

3.2. Friction Coefficient and Wear Rate

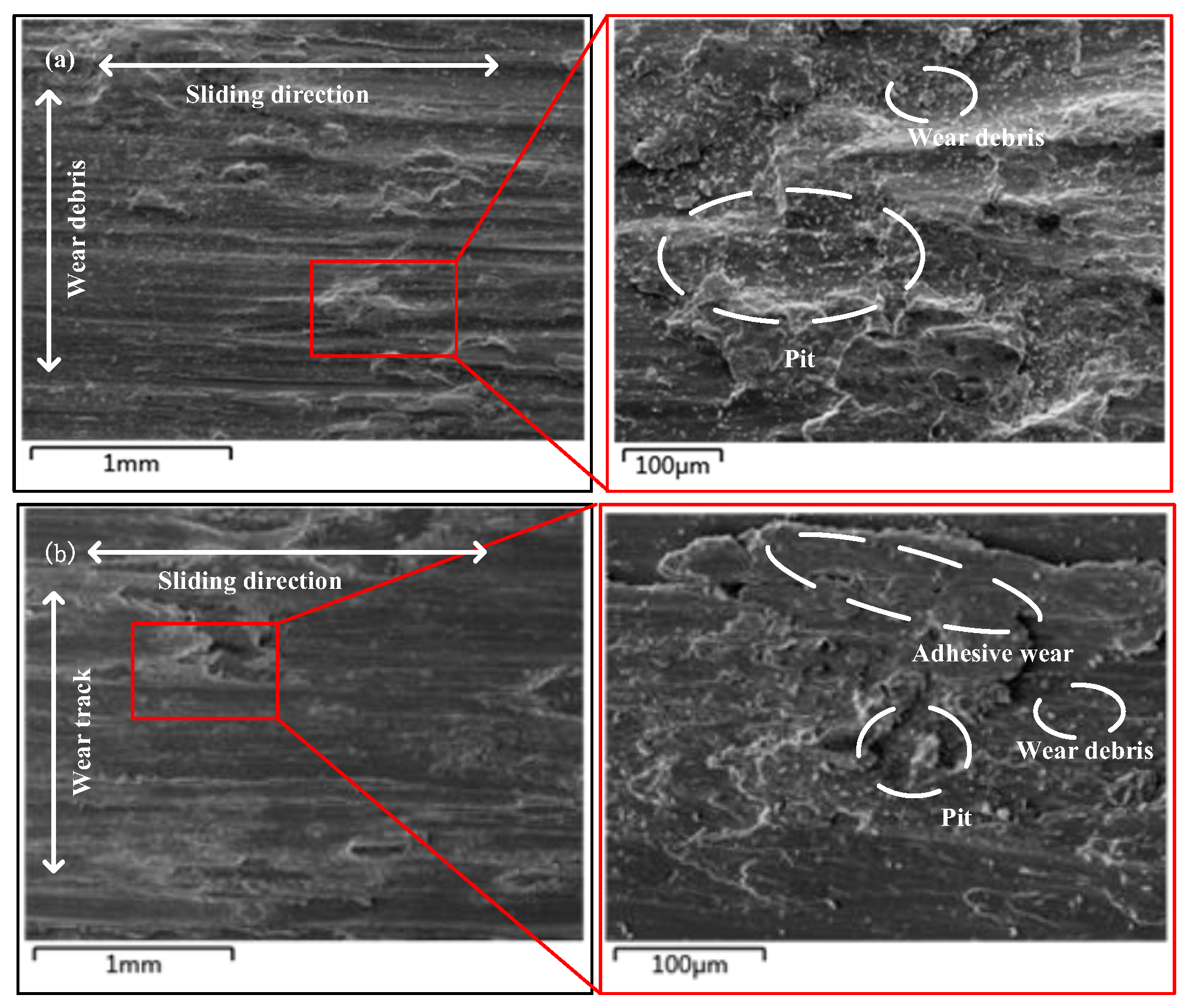

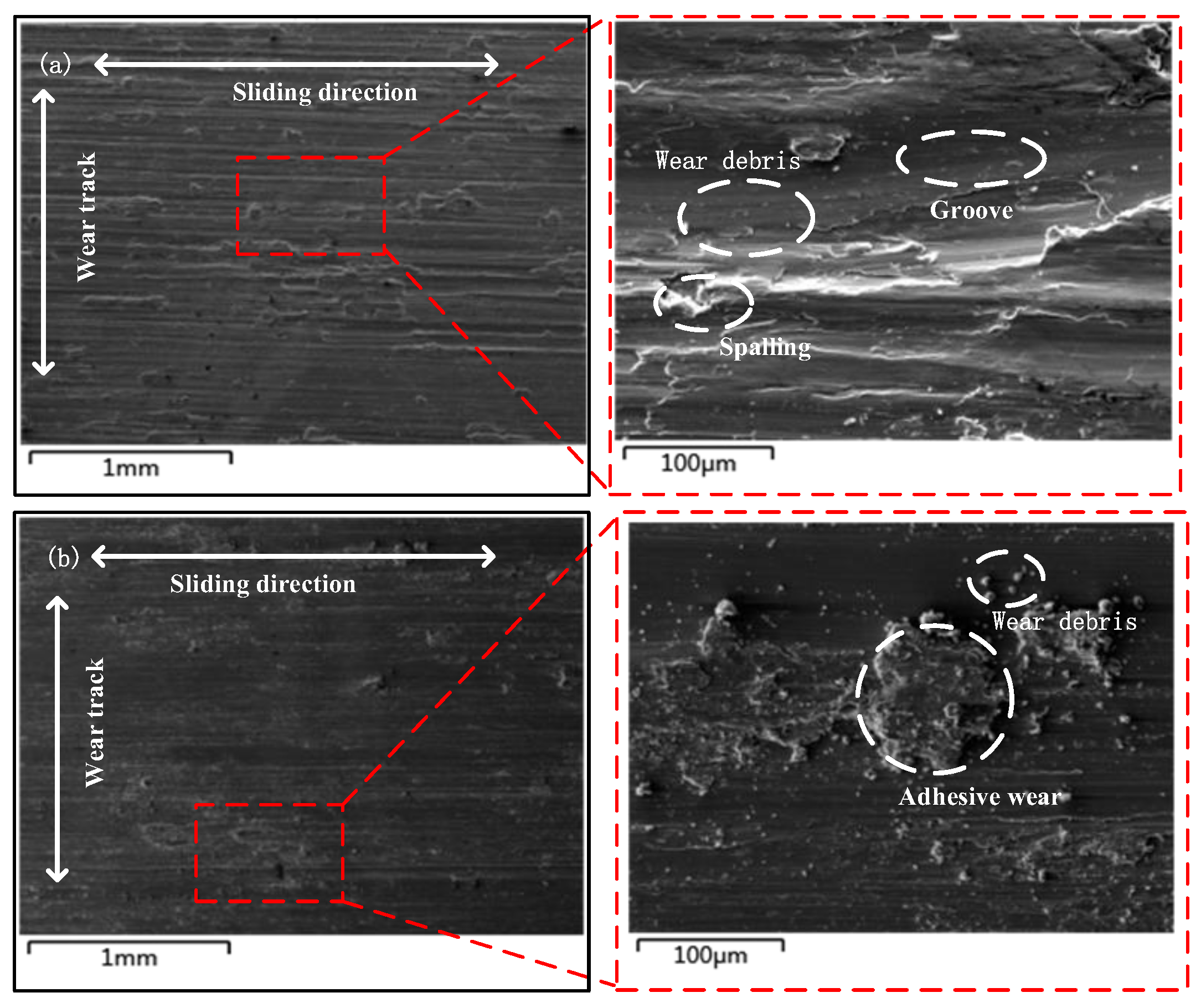

3.3. Surface Wear Morphology

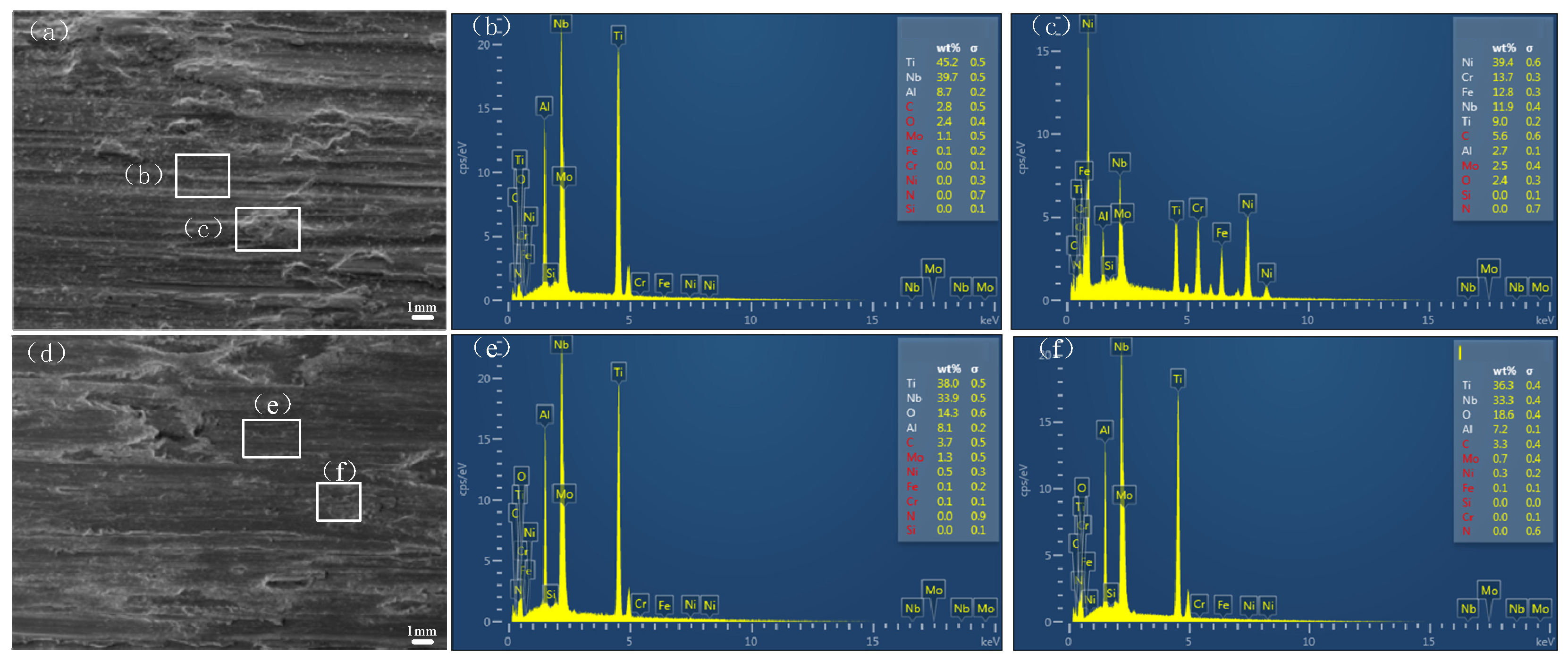

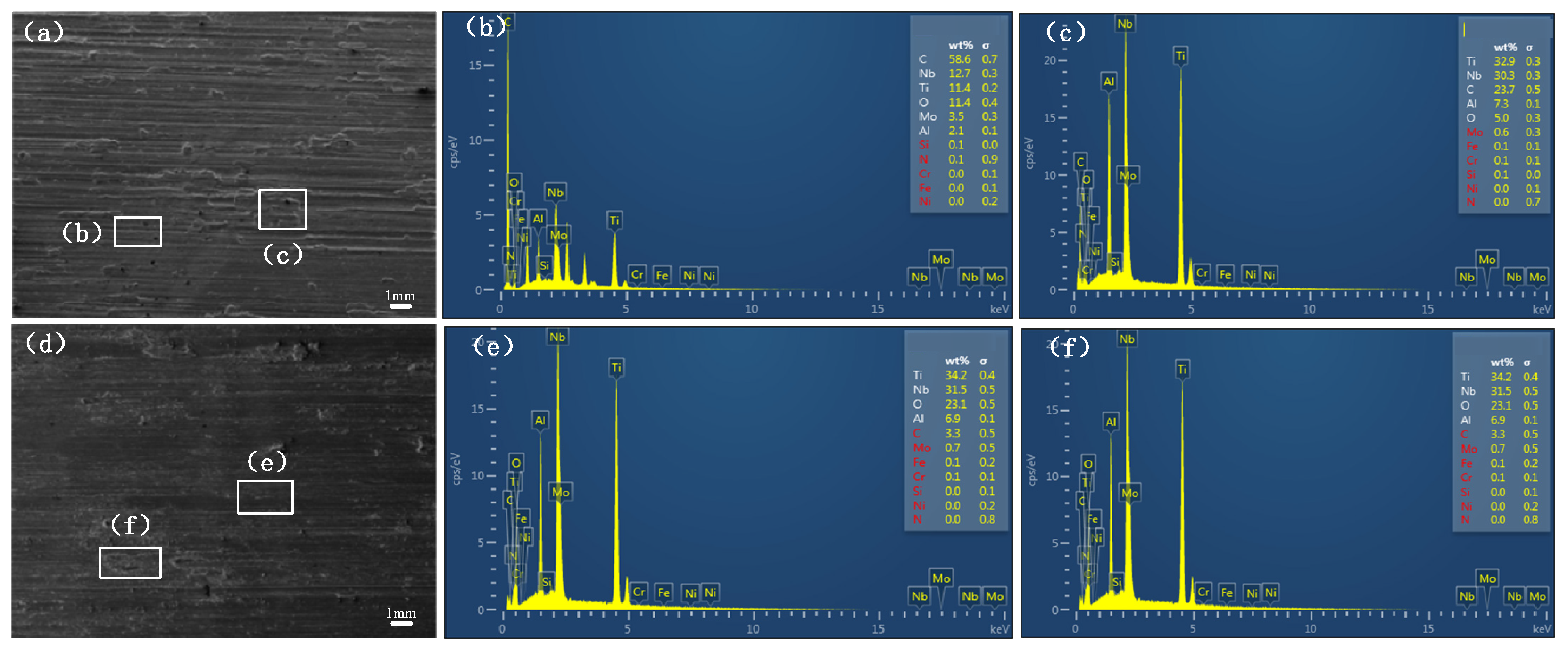

3.4. Analysis of Worn Surface Elements

4. Conclusions

- All three coatings exhibit a dense cubic B1-NaCl structure and maintain good phase stability under high-temperature conditions. The CrAlN coating showed a uniform microstructure and stable (200) texture, while B incorporation in CrAlN/(CrAlB)N/CrAlN refined grains and enhanced oxidation resistance through solid-solution and grain-boundary strengthening. The TiAlN/ZrN multilayer coating presented a well-defined nanoscale lamellar interface, achieving the highest hardness and adhesion strength due to synergistic effects between Ti(Al)N and ZrN layers. These structural and mechanical differences laid the foundation for distinct tribological responses during high-temperature sliding.

- Under 600 °C pin–disc tests, all coatings reduced the friction coefficient compared with uncoated WC/Co carbide, indicating effective suppression of adhesive wear. The Ti2AlNb counter-face exhibited smoother worn surfaces at elevated temperature, attributed to the formation of lubricious oxide films (Al2O3, ZrO2, and Cr2O3). Among the tested coatings, TiAlN/ZrN demonstrated the lowest steady-state friction coefficient, while CrAlN/(CrAlB)N/CrAlN maintained superior thermal stability with minimal oxidation-induced degradation. These results confirm that friction behaviour is governed by both coating microstructure and dynamic oxide film evolution at elevated temperature.

- Wear mechanisms transitioned from abrasive and adhesive wear at room temperature to oxidative wear at 600 °C. TiAlN/ZrN exhibited the highest resistance to coating delamination and retained smooth surface morphology after testing, indicating superior load-bearing capacity and interfacial cohesion. In contrast, CrAlN/(CrAlB)N/CrAlN minimized material removal from the Ti2AlNb counter-face by forming protective oxide layers on both surfaces. Therefore, TiAlN/ZrN is the most promising coating for enhancing tool-side durability and friction reduction, while CrAlN/(CrAlB)N/CrAlN offers advantages in reducing counterpart wear. Future work should couple high-temperature friction results with cutting tests to establish quantitative correlations between tribological performance and machining service life.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, W.; Zeng, W.; Li, D.; Zhu, B.; Zheng, Y.; Liang, X. Microstructural Evolution and Tensile Behavior of Ti2AlNb Alloys Based A2-Phase Decomposition. Mater. Sci. Eng. A 2016, 662, 120–128. [Google Scholar] [CrossRef]

- Wang, L.; Liang, W.; Miao, Q.; Ren, B.; Pan, X. High Temperature Oxidation Behaviors of Ti2AlNb Alloy at Different Temperatures. Jinshu Rechuli/Heat Treat. Met. 2015, 40, 51–57. [Google Scholar] [CrossRef]

- Dadé, M.; Esin, V.A.; Nazé, L.; Sallot, P. Short- and Long-Term Oxidation Behaviour of an Advanced Ti2AlNb Alloy. Corros. Sci. 2019, 148, 379–387. [Google Scholar] [CrossRef]

- Zu, R.; Wang, W.; Lin, N.; Tian, L.; Wu, T.; Li, X. High-Temperature Oxidation Behavior of Double Glow Plasma Cr-Y Alloyed Layers on Ti2AlNb Alloy. Mater. Lett. 2024, 370, 136706. [Google Scholar] [CrossRef]

- Man, J.; Huang, L.; He, J.; Yang, H.; Lin, X. Effect of Heat Treatment on Microstructure and Properties of Ti2AlNb Alloy Formed by Selective Laser Melting. J. Mater. Res. Technol. 2024, 33, 2549–2559. [Google Scholar] [CrossRef]

- Bello, M.; Shanmugan, S. Achievements in Mid and High-Temperature Selective Absorber Coatings by Physical Vapor Deposition (PVD) for Solar Thermal Application-A Review. J. Alloys Compd. 2020, 839, 155510. [Google Scholar] [CrossRef]

- Bobzin, K. High-Performance Coatings for Cutting Tools. CIRP J. Manuf. Sci. Technol. 2017, 18, 1–9. [Google Scholar] [CrossRef]

- Khadem, M.; Penkov, O.V.; Yang, H.K.; Kim, D.E. Tribology of Multilayer Coatings for Wear Reduction: A Review. Friction 2017, 5, 248–262. [Google Scholar] [CrossRef]

- Krella, A. Resistance of PVD Coatings to Erosive and Wear Processes: A Review. Coatings 2020, 10, 921. [Google Scholar] [CrossRef]

- Panjan, P.; Drnovšek, A.; Gselman, P.; Čekada, M.; Panjan, M. Review of Growth Defects in Thin Films Prepared by PVD Techniques. Coatings 2020, 10, 447. [Google Scholar] [CrossRef]

- Baptista, A.; Silva, F.J.G.; Porteiro, J.; Míguez, J.L.; Pinto, G.; Fernandes, L. On the Physical Vapour Deposition (PVD): Evolution of Magnetron Sputtering Processes for Industrial Applications. Procedia Manuf. 2018, 17, 746–757. [Google Scholar] [CrossRef]

- Chen, Y.H.; Roa, J.J.; Yu, C.H.; Johansson-Jõesaar, M.P.; Andersson, J.M.; Anglada, M.J.; Odén, M.; Rogström, L. Enhanced Thermal Stability and Fracture Toughness of TiAlN Coatings by Cr, Nb and V-Alloying. Surf. Coatings Technol. 2018, 342, 85–93. [Google Scholar] [CrossRef]

- Wang, Q.; Jin, Z.; Zhao, Y.; Niu, L.; Guo, J. A Comparative Study on Tool Life and Wear of Uncoated and Coated Cutting Tools in Turning of Tungsten Heavy Alloys. Wear 2021, 482–483, 203929. [Google Scholar] [CrossRef]

- Khosrowshahi, J.H.; Aramesh, M. Application of Novel Soft Solid Lubricant Coatings on Turning Tools for Sustainable and High-Performance Machining of INC 718 Alloy: A New Efficient Fluid-Free Method. J. Manuf. Process. 2025, 143, 387–398. [Google Scholar] [CrossRef]

- Chen, X.; Gao, H.; Bai, Y.; Yang, H. Thermal Failure Mechanism of Multilayer Brittle TiN/CrAlN Films. Ceram. Int. 2018, 44, 8138–8144. [Google Scholar] [CrossRef]

- Lin, J.; Mishra, B.; Moore, J.J.; Sproul, W.D. Microstructure, Mechanical and Tribological Properties of Cr1-XAlxN Films Deposited by Pulsed-Closed Field Unbalanced Magnetron Sputtering (P-CFUBMS). Surf. Coat. Technol. 2006, 201, 4329–4334. [Google Scholar] [CrossRef]

- Bouamerene, M.S.; Atmani, T.D.; Aissani, L.; Nouveau, C.; Belgroune, A.; Aknouche, H. Optimizing CrAlN Coatings: Effects of Deposition Temperature on Mechanical, Tribological, and Wettability Properties. Mater. Today Commun. 2025, 42, 111347. [Google Scholar] [CrossRef]

- Yu, C.; Wang, S.; Tian, L.; Li, T.; Xu, B. Microstructure and Mechanical Properties of CrAlN Coatings Deposited by Modified Ion Beam Enhanced Magnetron Sputtering on AISI H13 Steel. J. Mater. Sci. 2009, 44, 300–305. [Google Scholar] [CrossRef]

- Hu, C.; Chen, L.; Moraes, V. Structure, Mechanical Properties, Thermal Stability and Oxidation Resistance of Arc Evaporated CrAlBN Coatings. Surf. Coat. Technol. 2021, 417, 127191. [Google Scholar] [CrossRef]

- Chen, W.; Hu, T.; Hong, Y.; Zhang, D.; Meng, X. Comparison of Microstructures, Mechanical and Tribological Properties of Arc-Deposited AlCrN, AlCrBN and CrBN Coatings on Ti-6Al-4V Alloy. Surf. Coat. Technol. 2020, 404, 126429. [Google Scholar] [CrossRef]

- Cai, F.; Wang, J.; Zhou, Q.; Xue, H.; Zheng, J.; Wang, Q.; Kim, K.H. Microstructure Evolution and High-Temperature Tribological Behavior of AlCrBN Coatings with Various B Contents. Surf. Coat. Technol. 2022, 430, 127994. [Google Scholar] [CrossRef]

- Chavee, L.; Serag, E.; da Silva Pires, M.; Lucas, S.; Haye, E. A Mechanistic Approach of Oxidation Resistance, Structural and Mechanical Behaviour of TiAlN Coatings. Appl. Surf. Sci. 2022, 586, 152851. [Google Scholar] [CrossRef]

- Sousa, V.F.C.; Silva, F.J.G.; Alexandre, R.; Fecheira, J.S.; Silva, F.P.N. Study of the Wear Behaviour of TiAlSiN and TiAlN PVD Coated Tools on Milling Operations of Pre-Hardened Tool Steel. Wear 2021, 476, 203695. [Google Scholar] [CrossRef]

- Huang, J.H.; Ho, C.H.; Yu, G.P. Effect of Nitrogen Flow Rate on the Structure and Mechanical Properties of ZrN Thin Films on Si(1 0 0) and Stainless Steel Substrates. Mater. Chem. Phys. 2007, 102, 31–38. [Google Scholar] [CrossRef]

- Chang, Y.Y.; Wu, C.J. Mechanical Properties and Impact Resistance of Multilayered TiAlN/ZrN Coatings. Surf. Coat. Technol. 2013, 231, 62–66. [Google Scholar] [CrossRef]

- Lei, Z.; Liu, Y.; Ma, F.; Song, Z.; Li, Y. Oxidation Resistance of TiAlN/ZrN Multilayer Coatings. Vacuum 2016, 127, 22–29. [Google Scholar] [CrossRef]

- Wang, L.P.; Qi, J.L.; Cao, Y.Q.; Zhang, K.; Zhang, Y.; Hao, J.; Ren, P.; Wen, M. N-Rich Zr3N4 Nanolayers-Dependent Superhard Effect and Fracture Behavior in TiAlN/Zr3N4 Nanomultilayer Films. Ceram. Int. 2020, 46, 19111–19120. [Google Scholar] [CrossRef]

- Zhao, J.; Zheng, L.; Li, W.; Liu, Z.; Li, L.; Wang, B.; Cai, Y.; Ren, X.; Liang, X. Effects of PVD CrAlN/(CrAlB)N/CrAlN Coating on Pin–Disc Friction Properties of Ti2AlNb Alloys Compared to WC/Co Carbide at Evaluated Temperatures. Metals 2024, 14, 662. [Google Scholar] [CrossRef]

- Maksakova, O.V.; Simoẽs, S.; Pogrebnjak, A.D.; Bondar, O.V.; Kravchenko, Y.O.; Koltunowicz, T.N.; Shaimardanov, Z.K. Multilayered ZrN/CrN Coatings with Enhanced Thermal and Mechanical Properties. J. Alloys Compd. 2019, 776, 679–690. [Google Scholar] [CrossRef]

- Devarajan, D.K.; Rangasamy, B.; Amirtharaj Mosas, K.K. State-of-the-Art Developments in Advanced Hard Ceramic Coatings Using PVD Techniques for High-Temperature Tribological Applications. Ceramics 2023, 6, 301–329. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Pan, X.; Mu, J.; Zhao, J.; Li, W.; Liu, Z.; Wang, J. Effect of PVD Nitride Coating Deposition on the High-Temperature Pin–Disc Friction Properties Between WC/Co Carbide and Ti2AlNb Alloy. Metals 2025, 15, 1279. https://doi.org/10.3390/met15121279

Li L, Pan X, Mu J, Zhao J, Li W, Liu Z, Wang J. Effect of PVD Nitride Coating Deposition on the High-Temperature Pin–Disc Friction Properties Between WC/Co Carbide and Ti2AlNb Alloy. Metals. 2025; 15(12):1279. https://doi.org/10.3390/met15121279

Chicago/Turabian StyleLi, Liangliang, Xin Pan, Jianwei Mu, Jinfu Zhao, Wenqian Li, Zhifeng Liu, and Jiru Wang. 2025. "Effect of PVD Nitride Coating Deposition on the High-Temperature Pin–Disc Friction Properties Between WC/Co Carbide and Ti2AlNb Alloy" Metals 15, no. 12: 1279. https://doi.org/10.3390/met15121279

APA StyleLi, L., Pan, X., Mu, J., Zhao, J., Li, W., Liu, Z., & Wang, J. (2025). Effect of PVD Nitride Coating Deposition on the High-Temperature Pin–Disc Friction Properties Between WC/Co Carbide and Ti2AlNb Alloy. Metals, 15(12), 1279. https://doi.org/10.3390/met15121279