Mechanism of Grain Structure Formation in Pure Copper Wire During Directional Heat Treatment

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

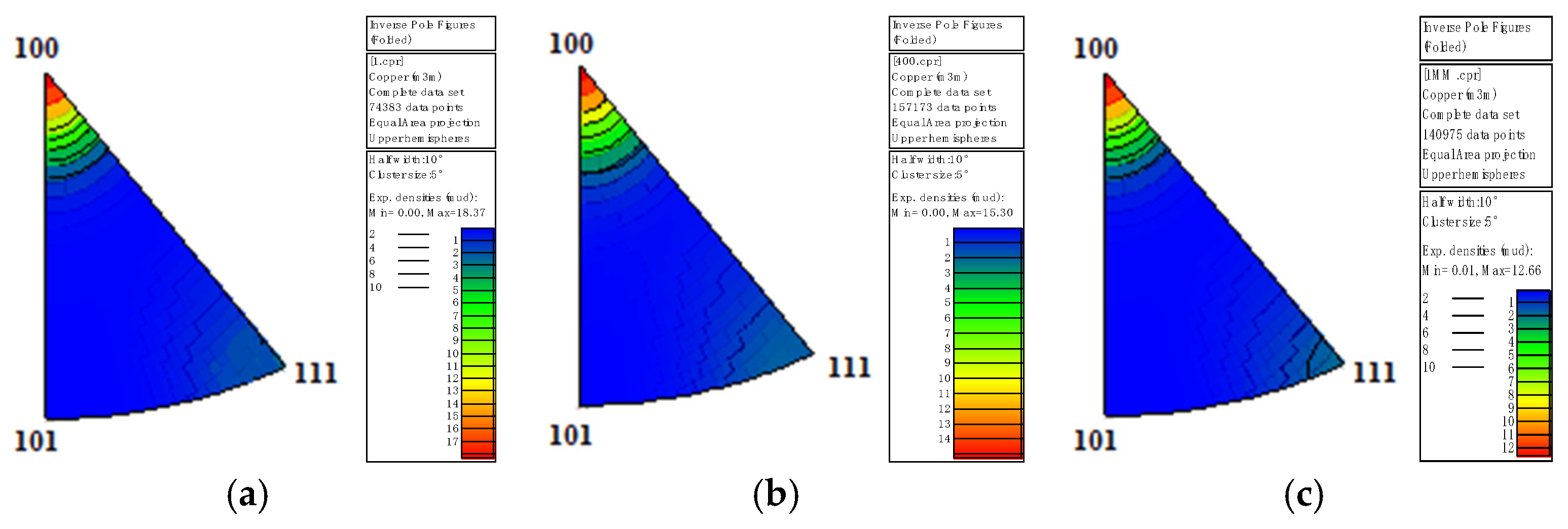

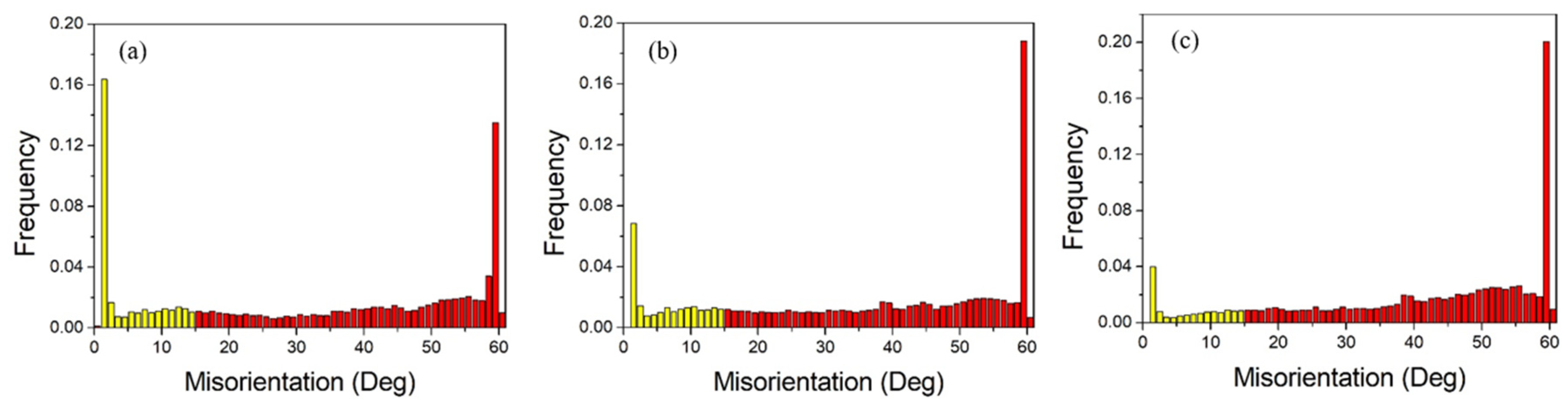

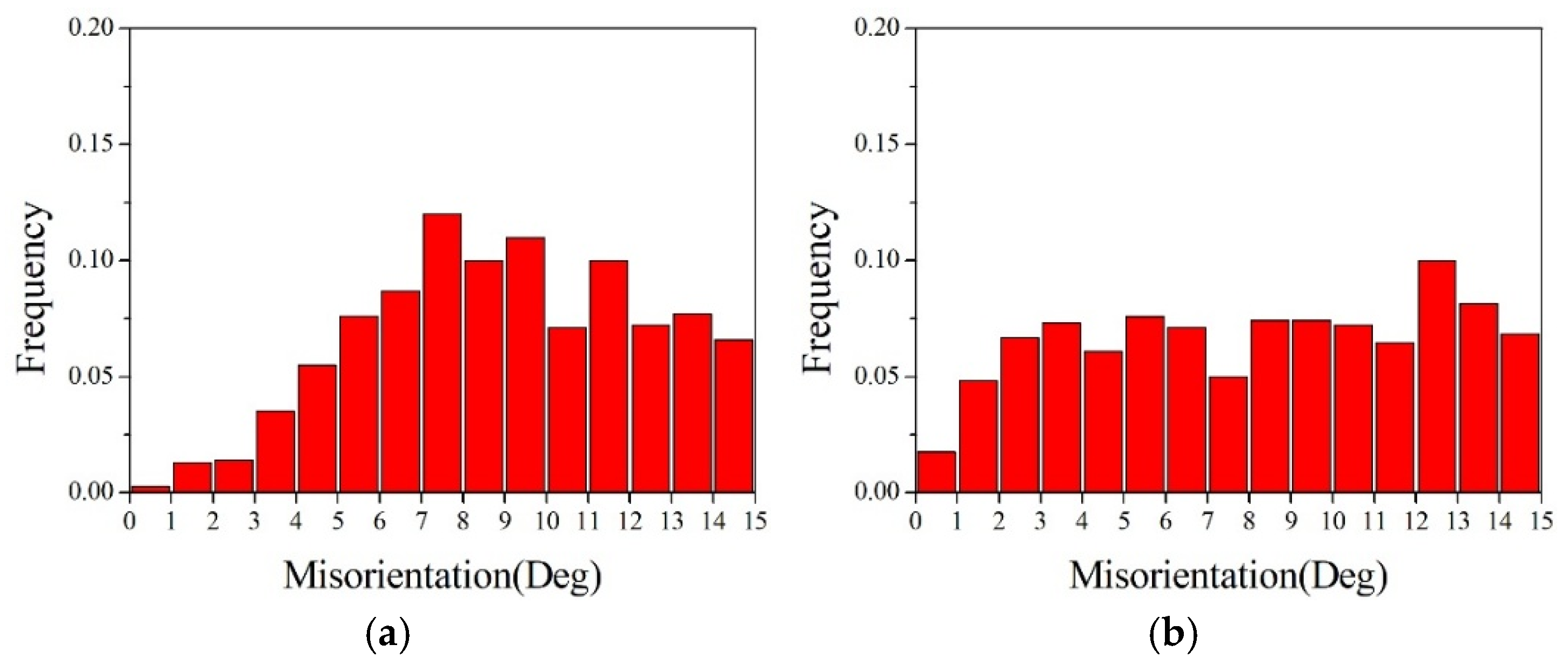

3.1. Crystallographic Texture of Initial Microstructure in Pure Copper Wire

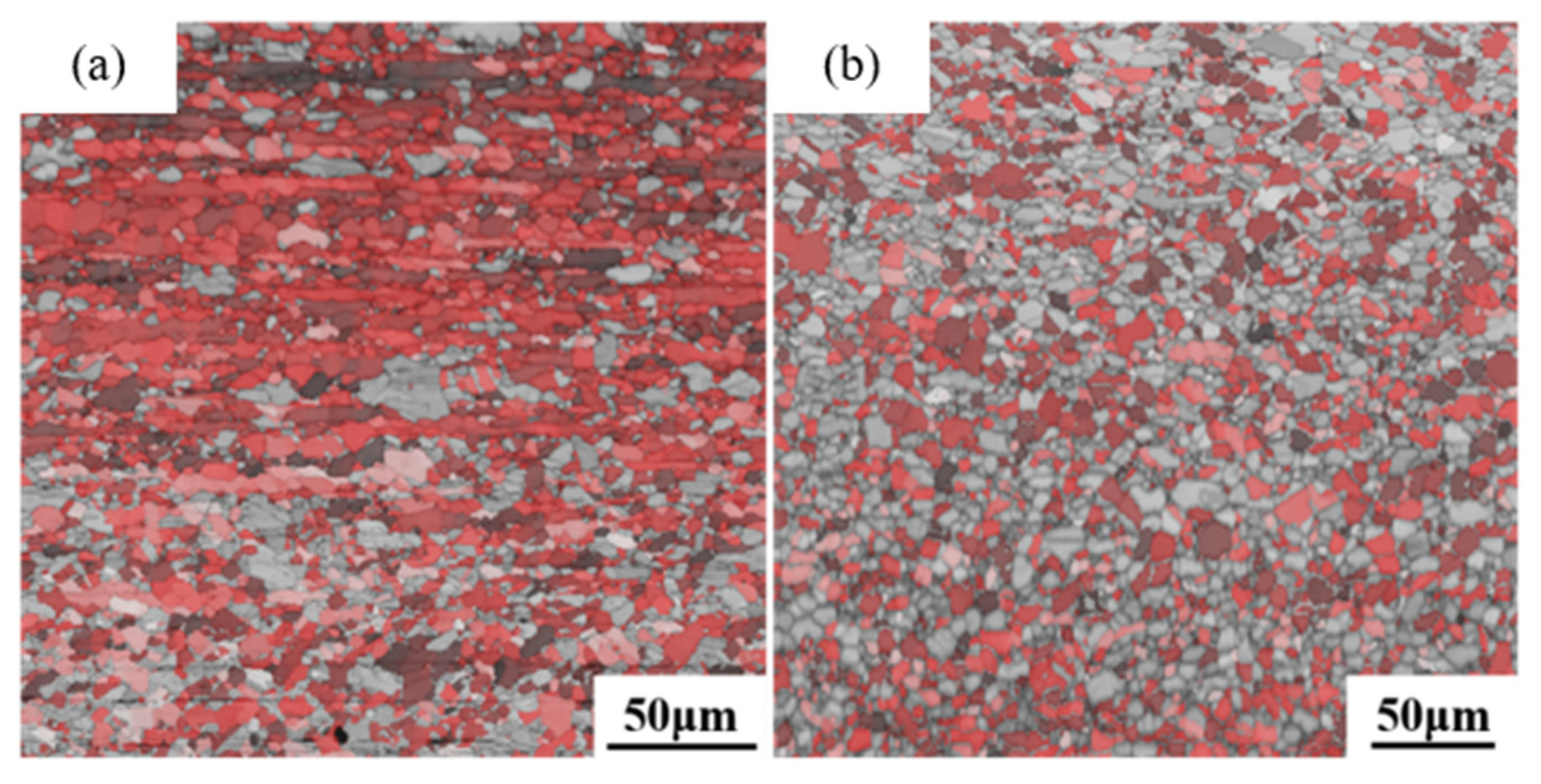

3.2. Grain Boundary Structure and Crystallographic Texture After Directional Heat Treatment

3.3. Columnar Grain Orientation and Grain Boundary Structure

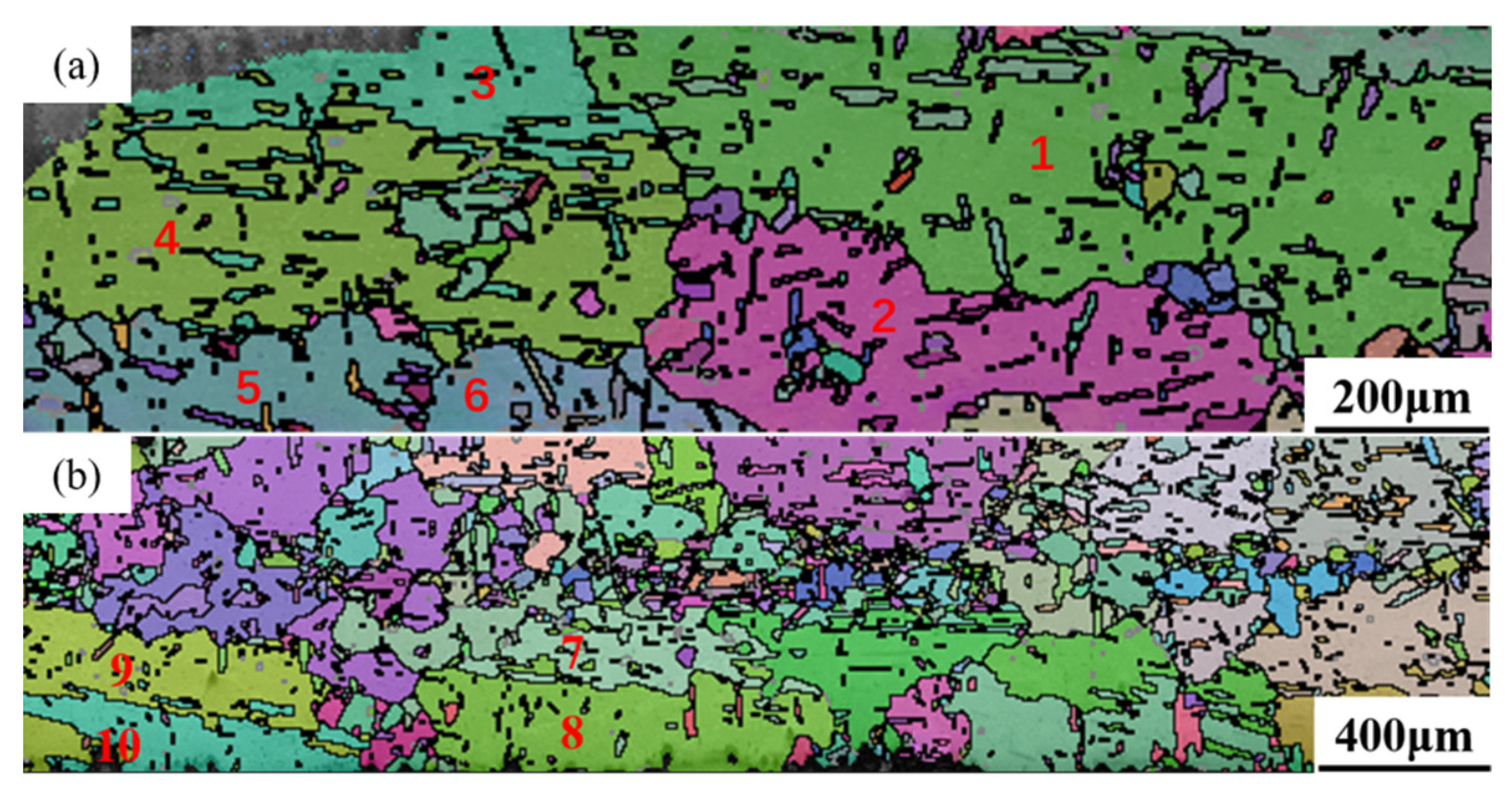

3.3.1. Columnar Grain Orientation

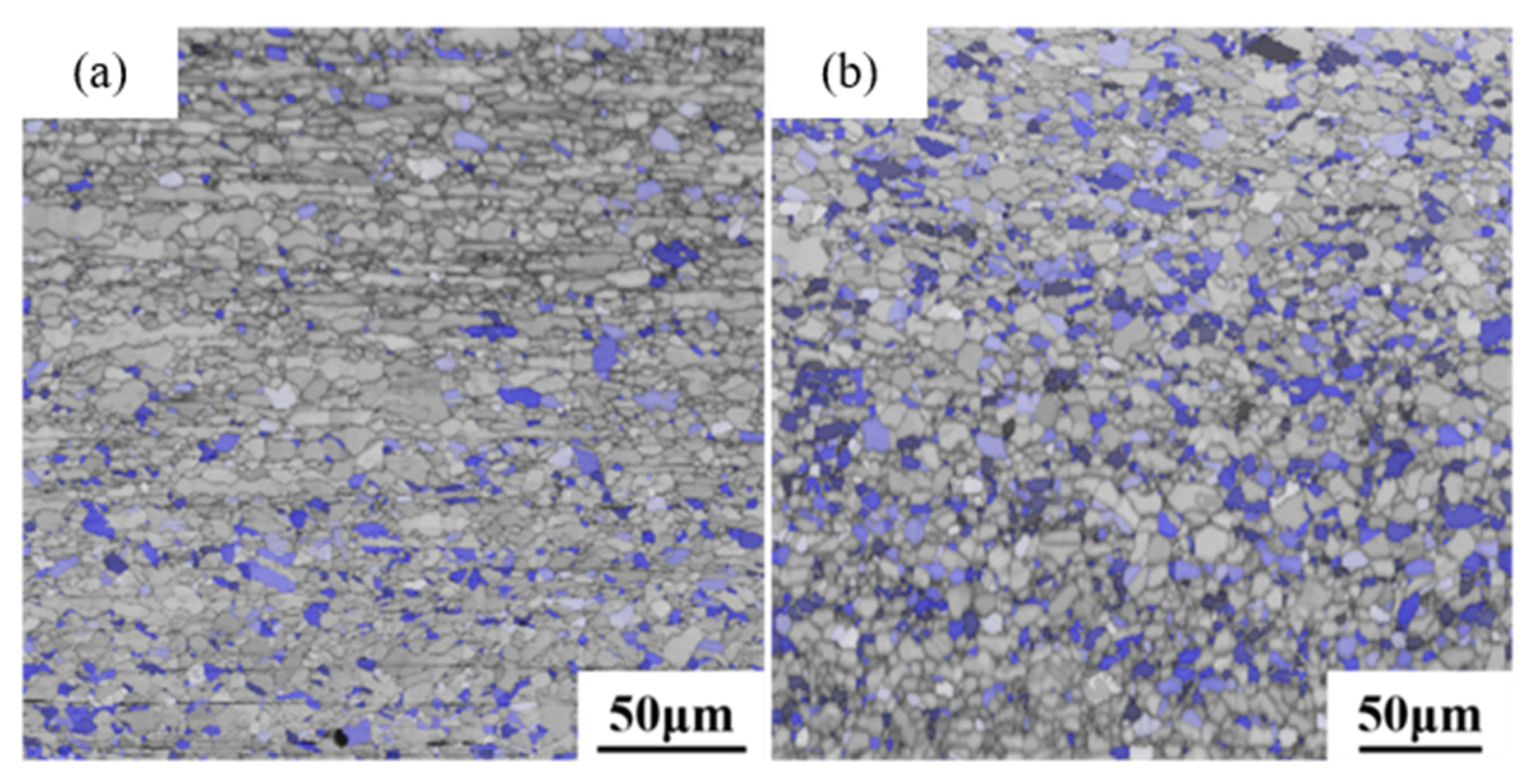

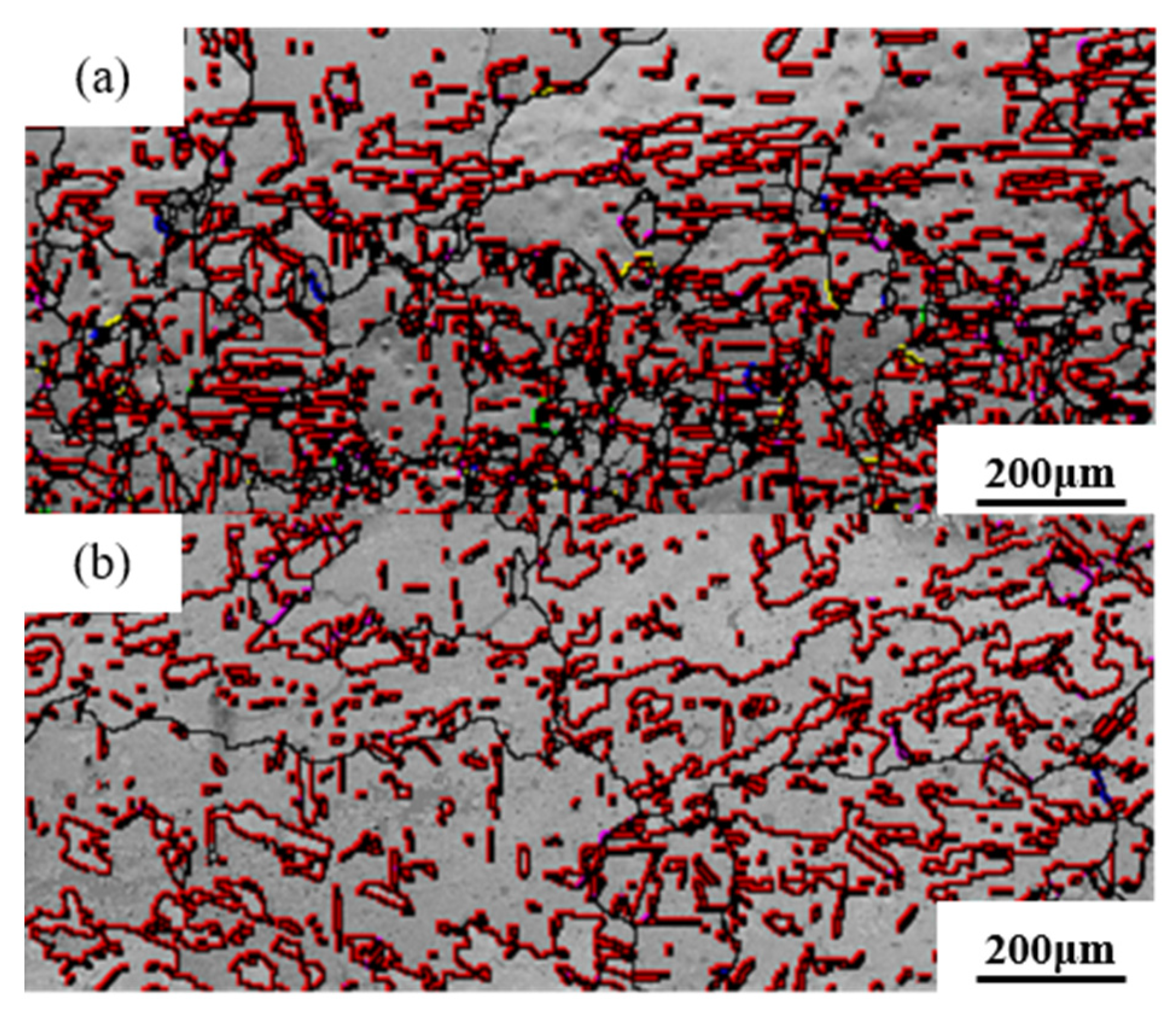

3.3.2. Grain Boundary Structure Between Columnar Crystals

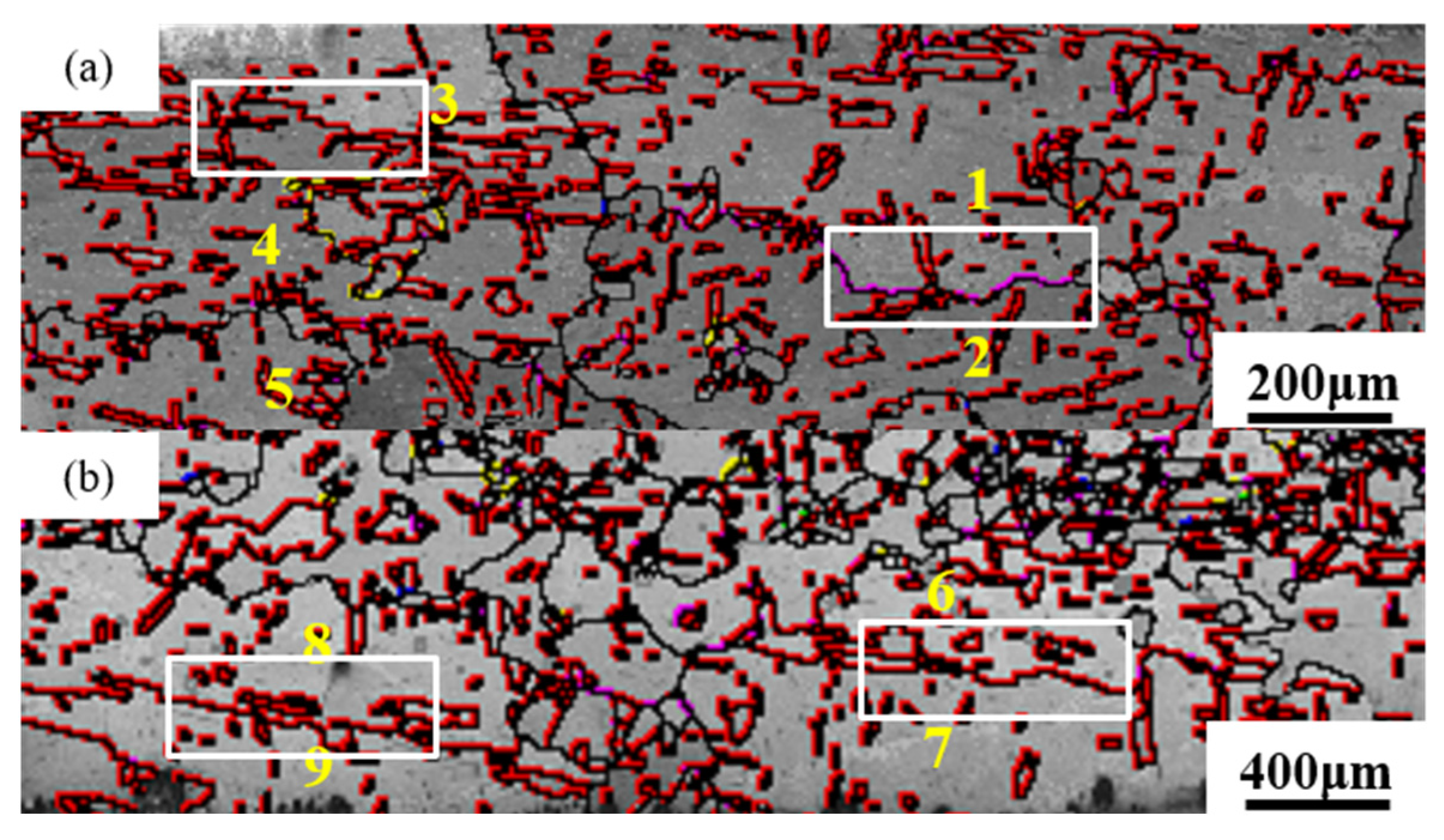

3.3.3. Grain Boundary Structure Between Columnar Crystals and Their Front Equiaxed Crystals

3.4. Mechanism of Directional Heat Treatment in Pure Copper Wires

4. Conclusions

- The 89% deformed pure copper wire exhibits a stronger and more concentrated <100> texture along the drawing direction than the 87% deformed wire. The increased stored energy induced by greater deformation facilitates enhanced grain rotation and alignment, which in turn leads to a stronger <100> fiber texture.

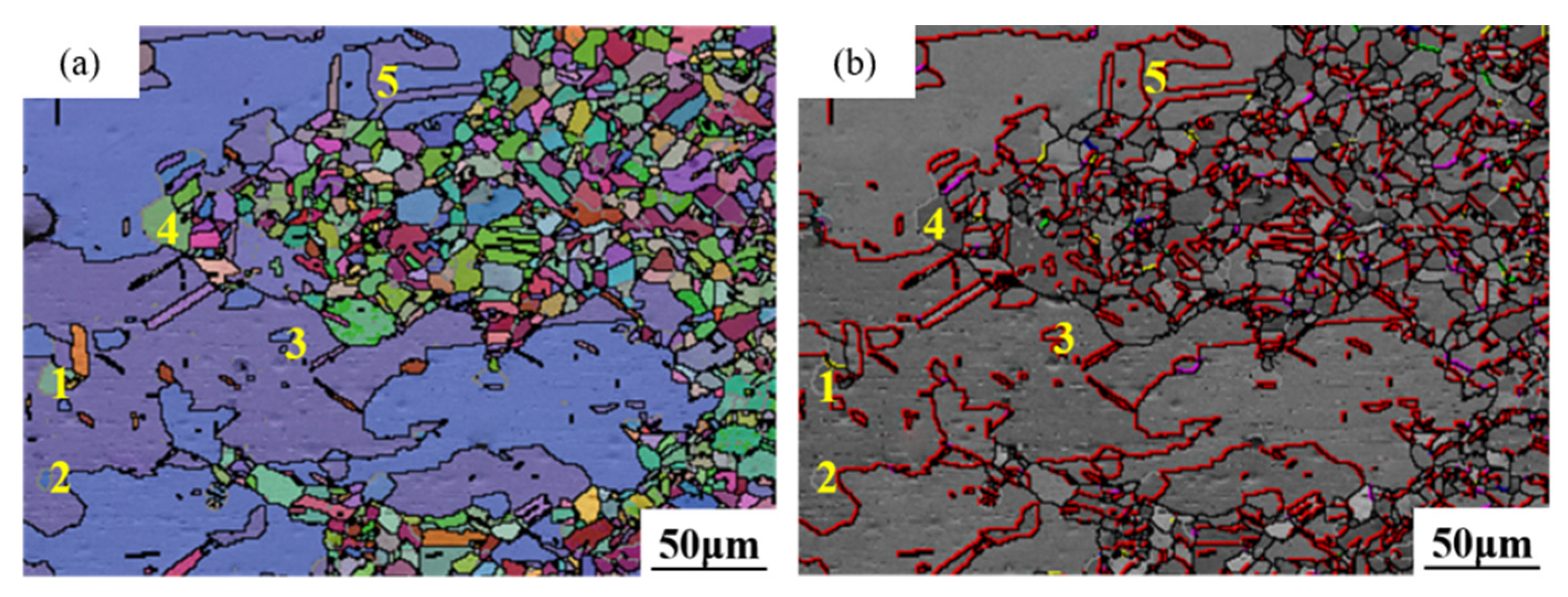

- Grains with a <112> orientation possess a distinct growth advantage, enabling them to evolve into columnar grains during directional heat treatment. The competitive growth of <112>-oriented grains is driven by their high-mobility boundaries with the <100>-textured matrix under the applied temperature gradient, enabling rapid consumption of surrounding equiaxed grains.

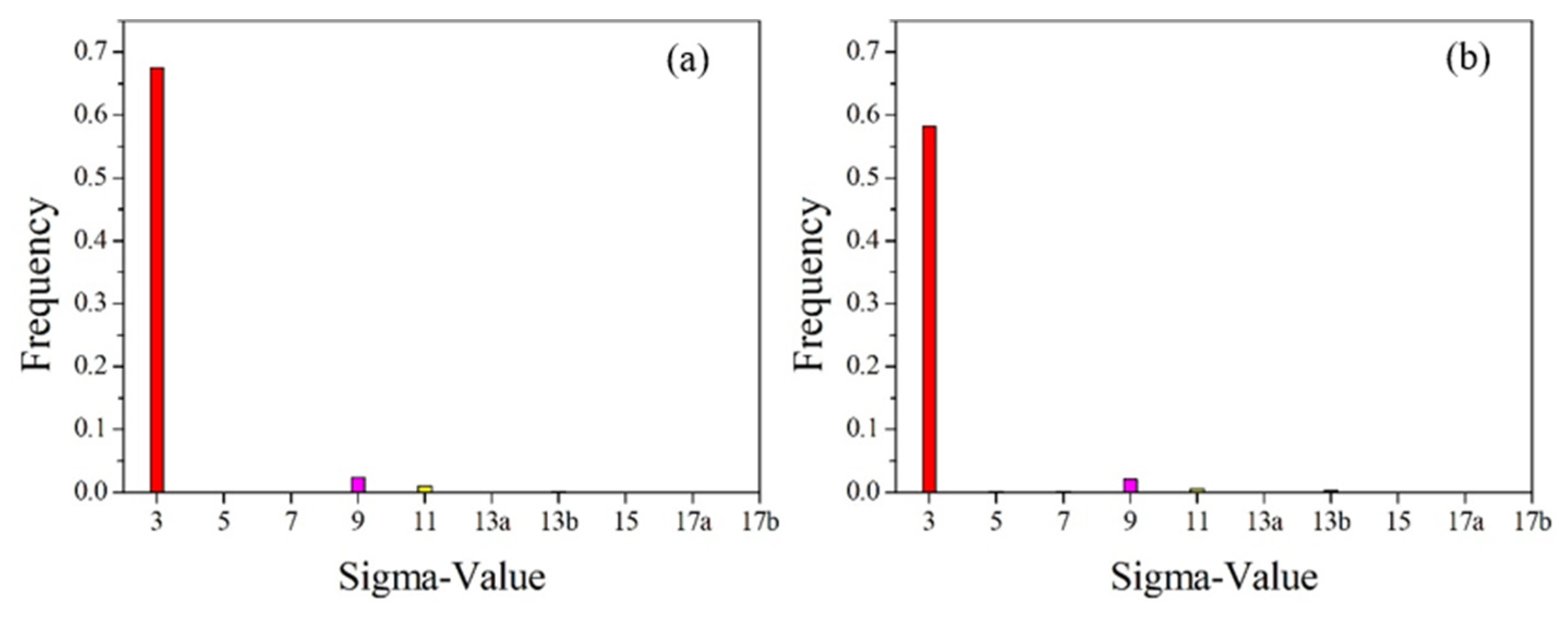

- The columnar grain boundaries in oriented pure copper wires are low-energy Σ 3 and Σ 9 grain boundaries. The preferential retention of Σ 3 and Σ 9 boundaries in the final columnar structure results from their low energy nature, which minimizes system energy during abnormal grain growth.

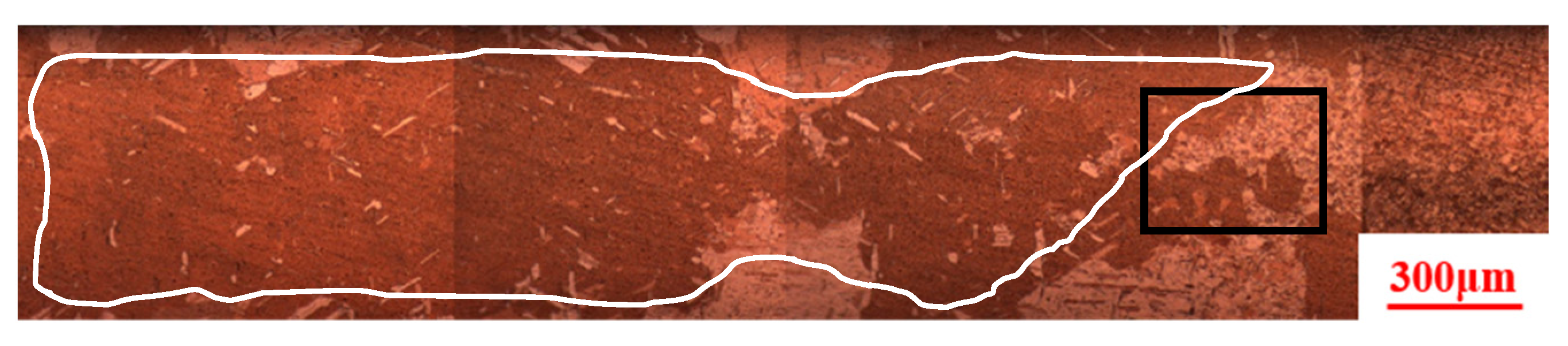

- Large columnar grains in pure copper wires contain “island grains.” Before directional heat treatment, there are small grains with low-angle grain boundaries or twin boundaries in pure copper wires. Since low-angle grain boundaries and twin boundaries are relatively stable and difficult to migrate, these small grains are bypassed by the directional migration interface, forming isolated “island grains” within the columnar grains. Due to their negligible mobility, low-energy boundaries pin small grains, causing the migration front to detour and selectively envelop them as “island grains” within the growing columnar crystal.

- During the directional migration of grain boundaries, large-angle grain boundaries at the leading edge of the interface, which generally migrate faster, promote the continuous growth of columnar crystals, while longer low-angle grain boundaries or twin boundaries at the leading edge hinder the interface from continuing to migrate forward. The migration rate of grain boundaries is governed by their energy: high-energy boundaries enable continuous columnar growth through rapid migration, whereas extensive low-energy boundaries act as potent pinning sites that impede microstructural development.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alaraji, N.; Altamimi, M.H.; Alshammari, T.W. The role of cold drawing on electrical and mechanical properties of copper cables. Int. J. Adv. Technol. Eng. Explor. 2015, 2, 122. [Google Scholar]

- Zhang, H.; Xie, X.J.; Wang, D.Z. Fabrication of pure copper rods containing continuous columnar crystals by continuous unidirectional solidification technology. J. Univ. Sci. Technol. B 2004, 11, 240–243. [Google Scholar]

- Ge, T.S. Fundamentals of Solid Internal Friction Theory—Grain Boundary Relaxation and Grain Boundary Structure; Science Press: Beijing, China, 2000. [Google Scholar]

- Tian, S.; Li, X.C.; Liu, Z.T. Metal Physical Properties; Aviation Industry Press: Beijing, China, 1994. [Google Scholar]

- Fan, X.H.; Yan, W. Research progress and application prospects of high-fidelity single-crystal metal wires. Ordnance Mater. Sci. Eng. 2000, 23, 62–65. [Google Scholar]

- Yan, C.; Hu, L.; Li, J.Y.; Li, W.L.; Xu, Y.H.; Chen, A.H. Microstructure and Mechanical Property Evolution in Cold-Drawn Copper Wire. World Nonferrous Met. 2020, 15, 177–178. [Google Scholar]

- Soda, H.; McLean, A.; Motoyasu, G. A note on casting speed of Ohno continuous casting process. Mater. Sci. Technol. 2010, 26, 1015–1016. [Google Scholar] [CrossRef]

- Rao, L.; Zhu, B.L.; Hu, Y.Q. Microstructure morphology evolution of single crystal copper rod by Ohno continuous casting in copper manufacturing system. Appl. Mech. Mater. 2012, 252, 360–363. [Google Scholar] [CrossRef]

- Gan, L.G.; Liu, F.X.; Xie, X.J. Room temperature tensile property and fracture behavior of CuNi10Fe1Mn alloy rods produced by O.C.C. process. Mater. Sci. Technol. 2013, 29, 374–377. [Google Scholar] [CrossRef]

- Guo, P.Y.; Guo, H.X.; Deng, P.J. Study on the mechanical properties of single crystal aluminum by Ohno continuous casting. Mater. Sci. Forum 2014, 809, 358–362. [Google Scholar] [CrossRef]

- Hu, W.; Wang, H.Y.; Zhao, J.X. Preparation of aluminum wire by Ohno continuous casting and its microstructure and properties. Chin. J. Nonferrous Met. 2015, 25, 1882. [Google Scholar]

- Feng, L.C.; Fan, X.G.; Qiu, L.S. Development and application of horizontal Ohno continuous casting equipment. Spec. Cast. Nonferrous Alloys 2015, 35, 737. [Google Scholar]

- Chen, J.; Yan, W.; Li, W.; Miao, J.; Fan, X.H. Texture evolution and its simulation of cold drawing copper wires produced by continuous casting. Tran. Nonferrous Met. Soc. China 2011, 21, 152–158. [Google Scholar] [CrossRef]

- Chen, J.; Yan, W.; Wang, Y.X.; Fan, X.H. Microstructure evolution of single crystal copper wires in cold drawing. Sci. China Ser. E Technol. Sci. 2007, 50, 736–748. [Google Scholar] [CrossRef]

- Wang, H.Y.; Xiao, R.L.; Zhao, J.X. Microstructure and mechanical properties of columnar-grained copper produced by the Ohno continuous casting technique. Mater. Sci. Eng. 2015, 639, 122–130. [Google Scholar] [CrossRef]

- Mao, X.Q.; Xiao, Q.L.; Ou, M.G.; Liang, Y.; Long, W. Effect of annealing process on microstructure and properties of pure copper wire T2. Heat Treat. Met. 2020, 45, 7–11. [Google Scholar]

- Fan, X.Y.; Hou, J.P.; Wang, S.; Liu, Z.Q.; Gong, B.S.; Zhou, X.H.; Duan, Q.Q.; Zhang, Z.J.; Zhang, Z.F. Achieving extraordinary strength and conductivity in copper wire by constructing highly consistent hard texture and ultra-high aspect ratio. J. Mater. Sci. Technol. 2025, 220, 14–22. [Google Scholar] [CrossRef]

- Jia, H.W. Effect of Heat Treatment on the Microstructure and Properties of Copper-Based Micro-Fine Wires with Different Deformation Behaviors; Henan Polytechnic University: Jiaozuo, China, 2024. [Google Scholar]

- Mao, Q.Z.; Zhang, Y.S.; Guo, Y.Z.; Zhao, Y.H. Enhanced electrical conductivity and mechanical properties in thermally stable fine-grained copper wire. Commun. Mater. 2021, 2, 46. [Google Scholar] [CrossRef]

- Randle, V. The coincidence site lattice and the ‘sigma enigma’. Mater. Charact. 2001, 47, 411–416. [Google Scholar] [CrossRef]

- Randle, V. Twinning-related grain boundary engineering. Acta Mater. 2004, 52, 4067–4081. [Google Scholar] [CrossRef]

- Humphreys, J.F.; Hatherly, M. Recrystallization and Related Annealing Phenomena; Elsevier Science Ltd.: Oxford, UK, 2004. [Google Scholar]

- Zhou, Z.Q. Influence of grain boundary structure on grain boundary migration. Ordnance Mater. Sci. Eng. 1998, 21, 3–8. [Google Scholar]

- Zasadzińska, M.; Knych, T.; Strzępek, P.; Jurkiewicz, B.; Franczak, K. Analysis of the strengthening and recrystallization of electrolytic copper (Cu-ETP) and oxygen free copper (Cu-OF). Arch. Civ. Mech. Eng. 2019, 19, 186–193. [Google Scholar] [CrossRef]

- Kim, N.B. Atomic jump model for migration of curved grain boundary. Scr. Mater. 1997, 8, 1111–1116. [Google Scholar] [CrossRef]

- Straumal, B.B.; Gust, W.; Dardinier, L. Abnormal grain growth in A1 of different purity. Mater. Des. 1997, 18, 293–295. [Google Scholar] [CrossRef]

- Rios, R.P. Abnormal grain growth in materials containing particles. Acta Mater. 1994, 42, 839. [Google Scholar] [CrossRef]

- Rios, R.P. Abnormal grain growth development from uniform grain size distribution in the presence of stable particales. Scr. Mater. 1998, 39, 1725–1730. [Google Scholar] [CrossRef]

- Rajmohan, N.; Szpunar, A.J. An analytical method for characterizing grain boundaries around growing Goss grains during secondary recrystallization. Scr. Mater. 2001, 44, 2387–2392. [Google Scholar] [CrossRef]

- Hayakawa, Y.; Szpunar, A.J. A new model of Goss texture development during secondary recrystallization of electrical steel. Acta Mater. 1997, 45, 4713–4720. [Google Scholar] [CrossRef]

- Yang, C.; Baker, I. Effect of solute on microstructural evolution during directional recrystallization. J. Alloys Compd. 2019, 815, 152358. [Google Scholar] [CrossRef]

- Yang, C.; Baker, I. Effect of soluble particles on microstructural evolution during directional recrystallization. Acta Mater. 2020, 188, 288–301. [Google Scholar] [CrossRef]

- Yang, C.; Baker, I. Breakdown of growth front at elevated drawing velocity during directional recrystallization. J. Philos. Mag. Lett. 2019, 99, 167–172. [Google Scholar] [CrossRef]

- Yang, C.; Baker, I. Elevated temperature directional recrystallization of high-purity nickel. J. Philos. Mag. 2019, 99, 1057–1078. [Google Scholar] [CrossRef]

- Ukai, S.; Taya, K.; Nakamura, K.; Aghamiri, M.S.; Oono, N.; Hayashi, S.; Okuda, T. Directional recrystallization by zone annealing in a Ni-based ODS superalloy. J. Alloys Compd. 2018, 744, 204–210. [Google Scholar] [CrossRef]

- Sugino, Y.; Ukai, S.; Hayashi, S.; Tang, Q.X.; Leng, B. Directional recrystallization of ODS alloys by means of zone annealing. J. Nucl. Mater. 2011, 417, 171–175. [Google Scholar] [CrossRef]

- Zhou, Y.J.; Liu, Y.H.; Song, K.X.; Li, S.L.; Feng, C.L.; Zhu, Q.Q.; Peng, X.W.; Yang, S.D.; Li, X.; Zhang, P.F. Mechanisms for high strength and ultra-high electrical conductivity of Cu-3.5wt.%Ag alloy prepared by thermomechanical treatment. Mater. Today Commun. 2022, 33, 104819. [Google Scholar] [CrossRef]

- Zhu, T.; Lu, X.; Yang, S. Effect of annealing on grain boundary characteristics distribution and conductivity of copper wire. Heat Treat. Met. 2021, 46, 85–90. [Google Scholar]

- Liu, R.X.; Mao, X.Q.; Ou, G.M.; Liang, Y.; Xiao, Q.L. Effect of Cold Drawing Deformation on the Microstructure and Properties of Pure Copper. J. Nonferrous Met. Sci. Eng. 2022, 13, 67–75. [Google Scholar]

- Lei, Y.; Li, Y.S.; Jiang, Y.B.; Zhao, F.; Liu, X.H.; Xie, J.X. Effects of Annealing on the Microstructure and Mechanical Properties of Brass-Clad Pure Copper Strands. Chin. J. Nonferrous Met. 2023, 33, 702–714. [Google Scholar]

- Banganayi, C.; Nyembwe, K.; Mageza, K. Annealer curve characteristics of electrolytically refined tough pitch copper (Cu-ETP) and oxygen free up-cast copper (Cu-OF) for electrical cable wires. Results Mater. 2020, 8, 100146. [Google Scholar] [CrossRef]

- Cao, J.; Wu, X.F.; Su, C.H.; Jia, H.W.; Sun, Y.Z. Processing and Properties of Single-Crystal Copper Wire. Micromachines 2023, 14, 2080. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.; Dong, L.M.; Cai, L.; Wang, L.F.; Xie, Z.H.; Fang, F. Effect of cold drawing strain on the microstructure, mechanical properties and electrical conductivity of low-oxygen copper wires. Mater. Sci. Eng. A 2021, 818, 141348. [Google Scholar] [CrossRef]

- Li, J.; Baker, I. An EBSP study of directionally recrystallized cold-rolled nickel. Mater. Sci. Eng. 2005, 392, 8. [Google Scholar] [CrossRef]

- Kang, X.; Li, Z.L.; Cen, S.D.; Bao, X.R.; Zhang, J.F.; Ding, G. Effect of Cold Rolling and Heat Treatment on the Texture and Hardness of a Spray-Deposited Al-Cu-Mg Alloy. Heat Treat. Met. 2025, 50, 99–108. [Google Scholar]

- Zhang, Z.W. Study on Oriented Recrystallization and Its Kinetics. Ph.D. Thesis, Nanjing University of Science and Technology, Nanjing, China, 2008. [Google Scholar]

| Element | Selenium Tellurium Bismuth | Chromium Manganese Antimony Cadmium Arsenic Phosphorus | Lead | Sulfur | Tin Nickel Iron | Silver | Total Content |

|---|---|---|---|---|---|---|---|

| content | <0.00018 | <0.00064 | <0.0001 | <0.0004 | <0.00121 | 0.0015 | <0.00403 |

| Grain No. | Test Euler Angle (°) | Miller Indices | ||

|---|---|---|---|---|

| φ1 | Φ | φ2 | (hkl)[uvw] | |

| 1 | 134.9 | 37.8 | 12.3 | (156)[-2-11] |

| 2 | 272.4 | 29.2 | 37.0 | (113)[11-1] |

| 3 | 38.0 | 36.3 | 87.1 | (19 1 27)[-1-21] |

| 4 | 317.2 | 41.7 | 10.9 | (156)[21-1] |

| 5 | 232.0 | 46.7 | 27.3 | (122)[-13-2] |

| 6 | 68.1 | 34.4 | 67.9 | (314)[-1-11] |

| 7 | 324.7 | 44.5 | 80.7 | (717)[12-1] |

| 8 | 204.9 | 39.6 | 5.2 | (1 12 14)[321] |

| 9 | 312.1 | 37.4 | 3.3 | (1 19 26)[21-1] |

| 10 | 32.8 | 40.9 | 79.7 | (617)[-1-41] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, H.; Dong, X.; Ruan, H.; Zheng, G.; Chen, G. Mechanism of Grain Structure Formation in Pure Copper Wire During Directional Heat Treatment. Metals 2025, 15, 1264. https://doi.org/10.3390/met15111264

Xu H, Dong X, Ruan H, Zheng G, Chen G. Mechanism of Grain Structure Formation in Pure Copper Wire During Directional Heat Treatment. Metals. 2025; 15(11):1264. https://doi.org/10.3390/met15111264

Chicago/Turabian StyleXu, Hao, Xin Dong, Huihui Ruan, Gong Zheng, and Guang Chen. 2025. "Mechanism of Grain Structure Formation in Pure Copper Wire During Directional Heat Treatment" Metals 15, no. 11: 1264. https://doi.org/10.3390/met15111264

APA StyleXu, H., Dong, X., Ruan, H., Zheng, G., & Chen, G. (2025). Mechanism of Grain Structure Formation in Pure Copper Wire During Directional Heat Treatment. Metals, 15(11), 1264. https://doi.org/10.3390/met15111264