Evaluation of Filter Cake Washing Processes in Hydrometallurgical Battery Recycling of Lithium-Ion Batteries to Optimize Recoveries

Abstract

1. Introduction

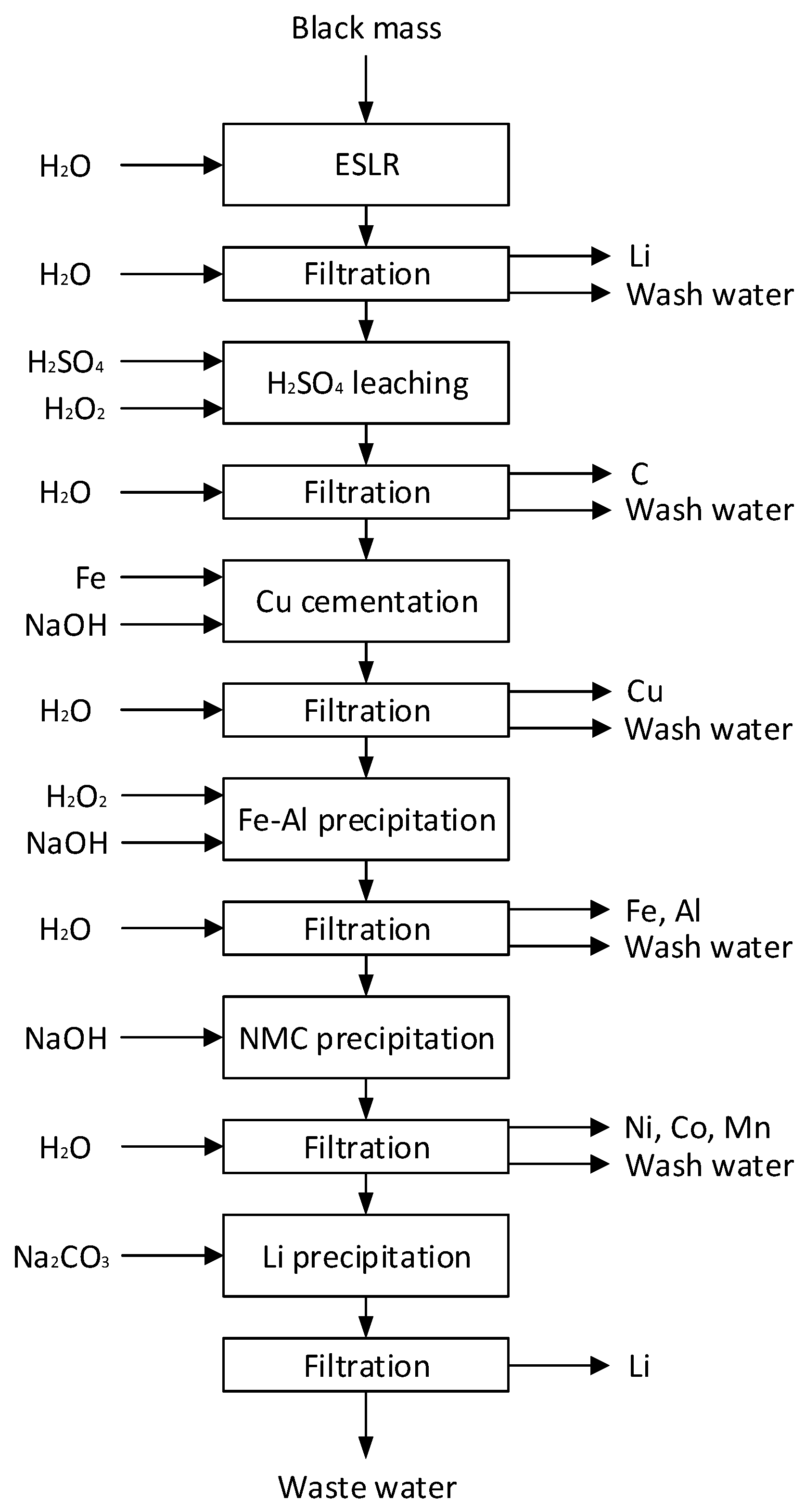

2. Materials and Methods

3. Results and Discussion

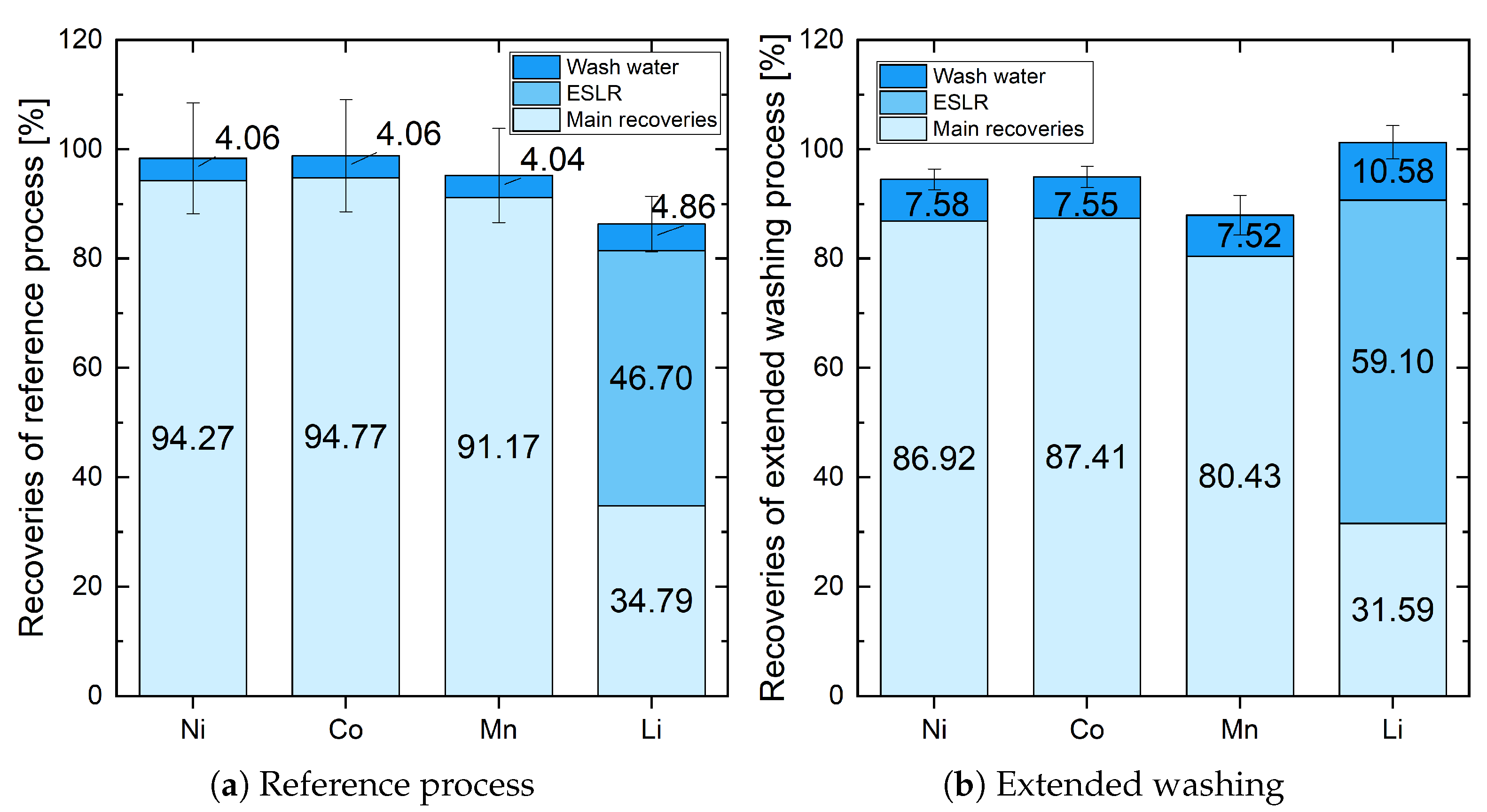

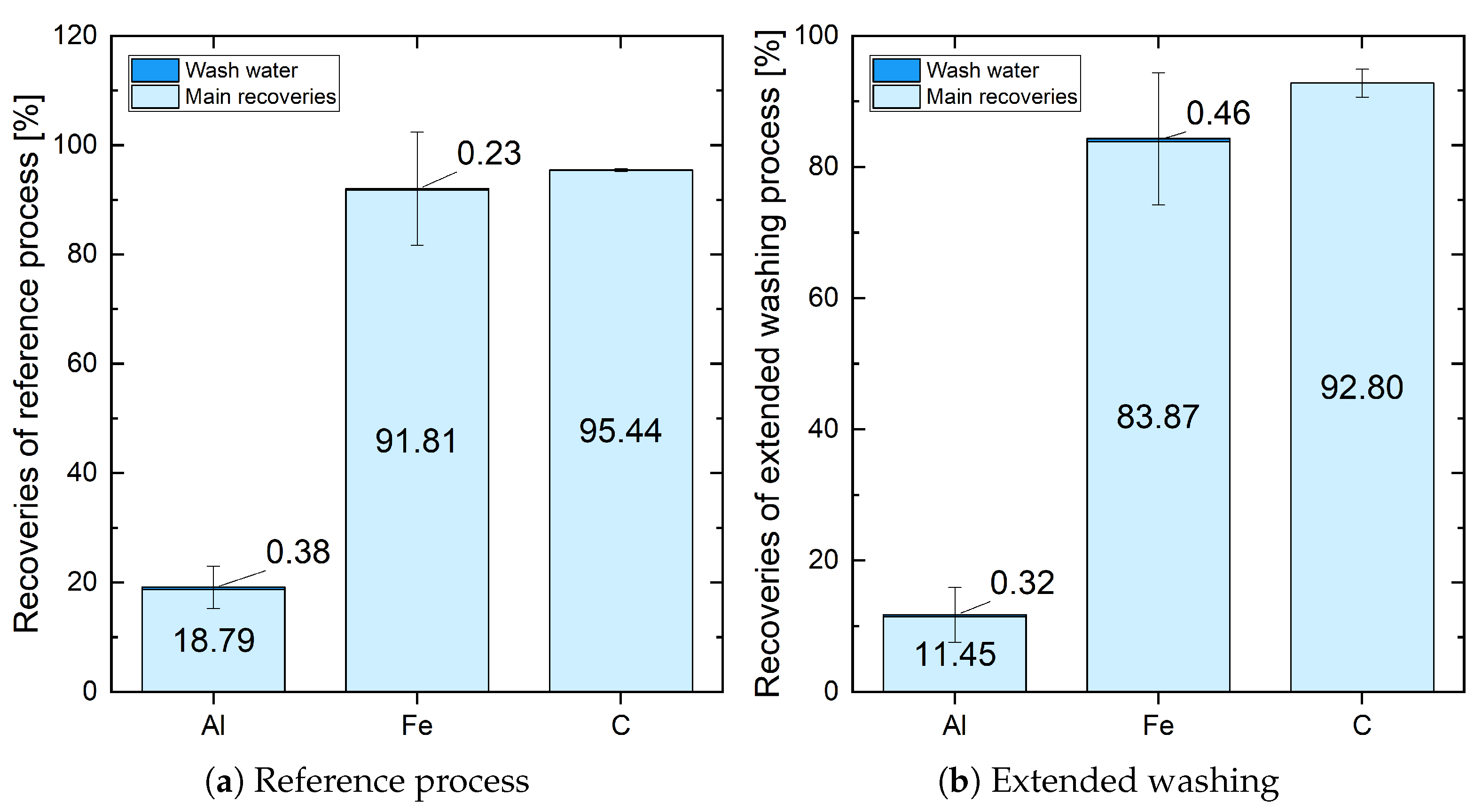

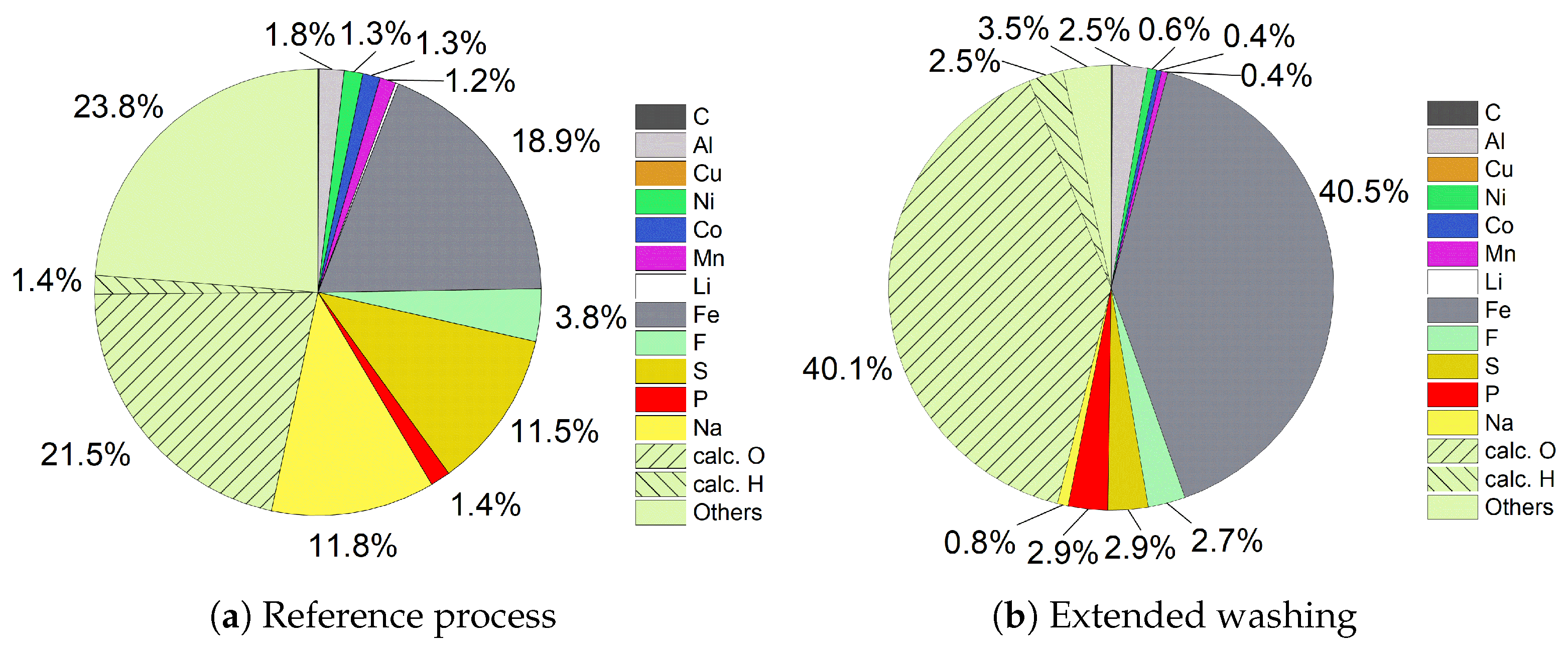

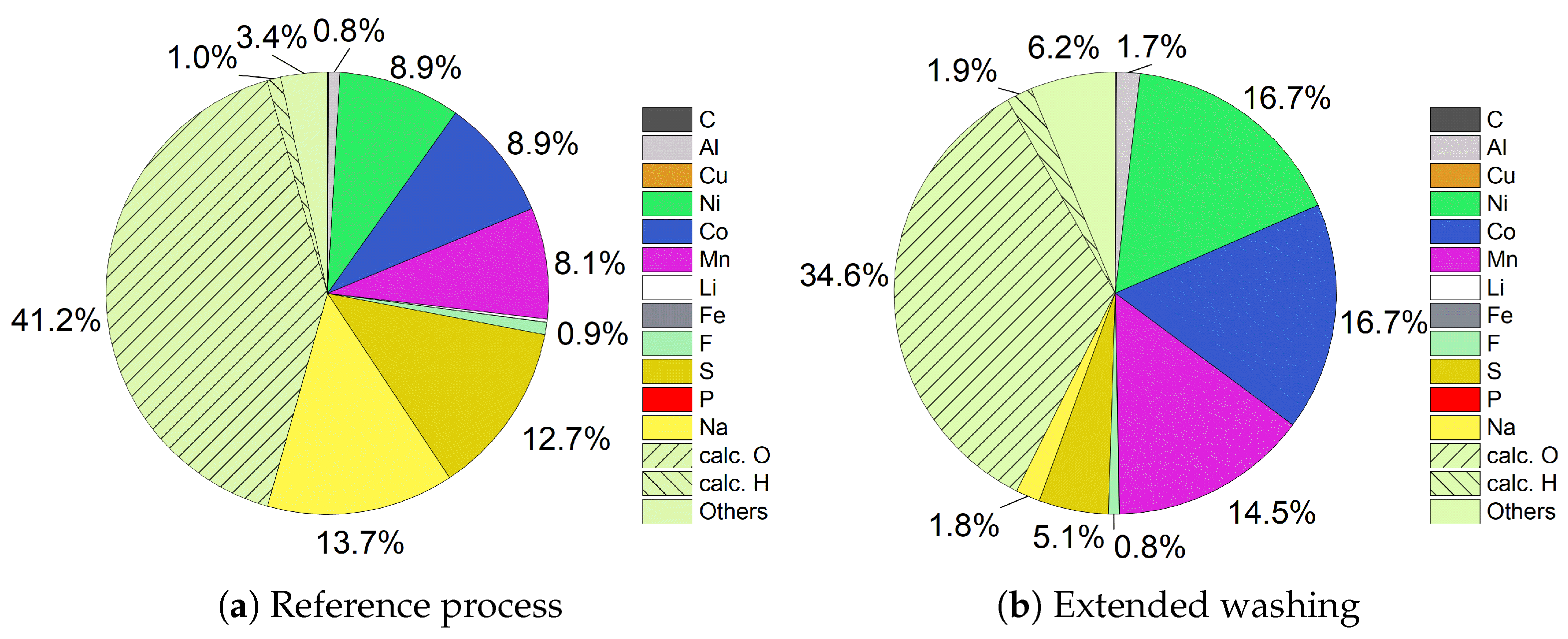

3.1. Comparison of Reference Process and Extended Washing

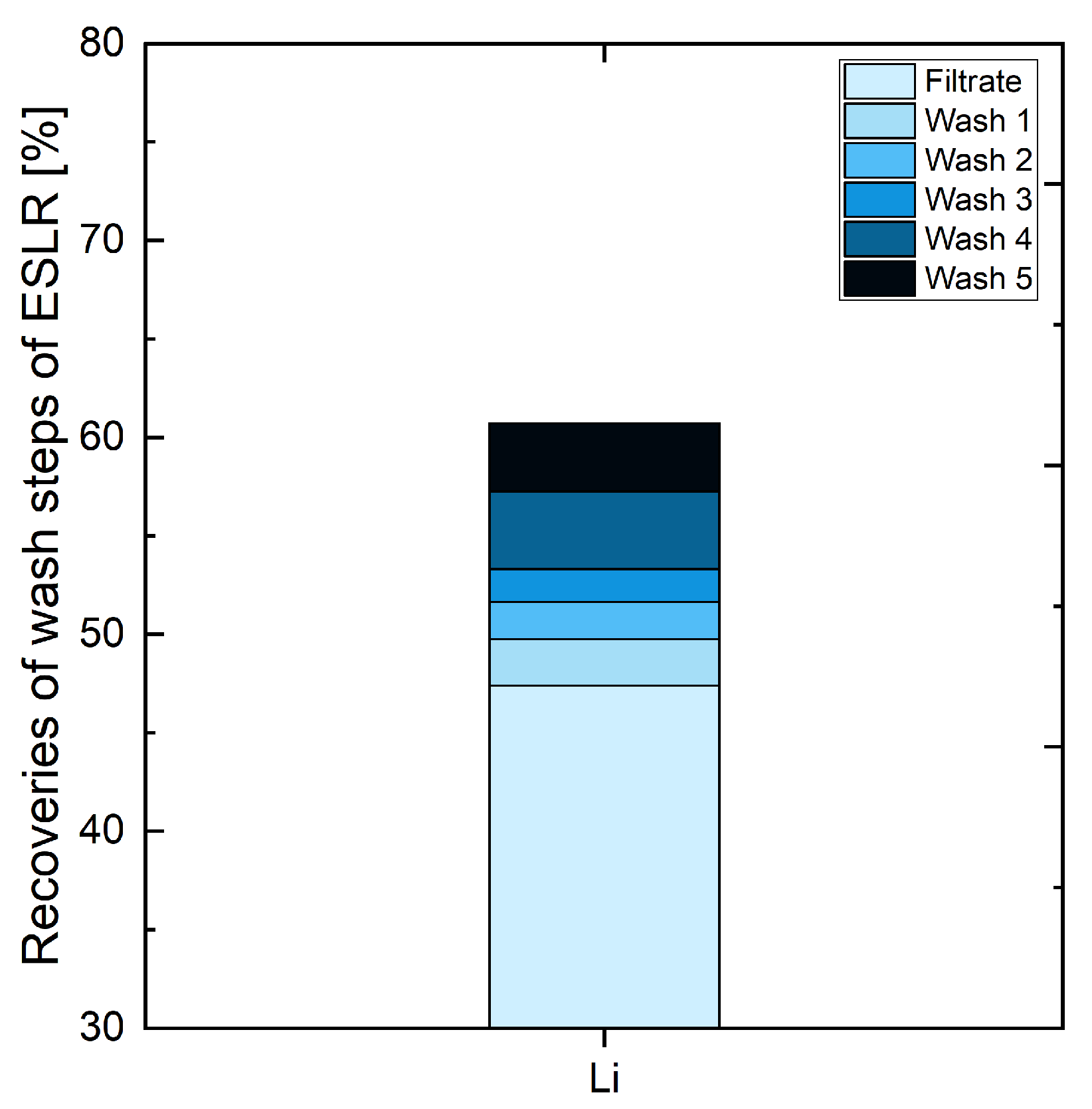

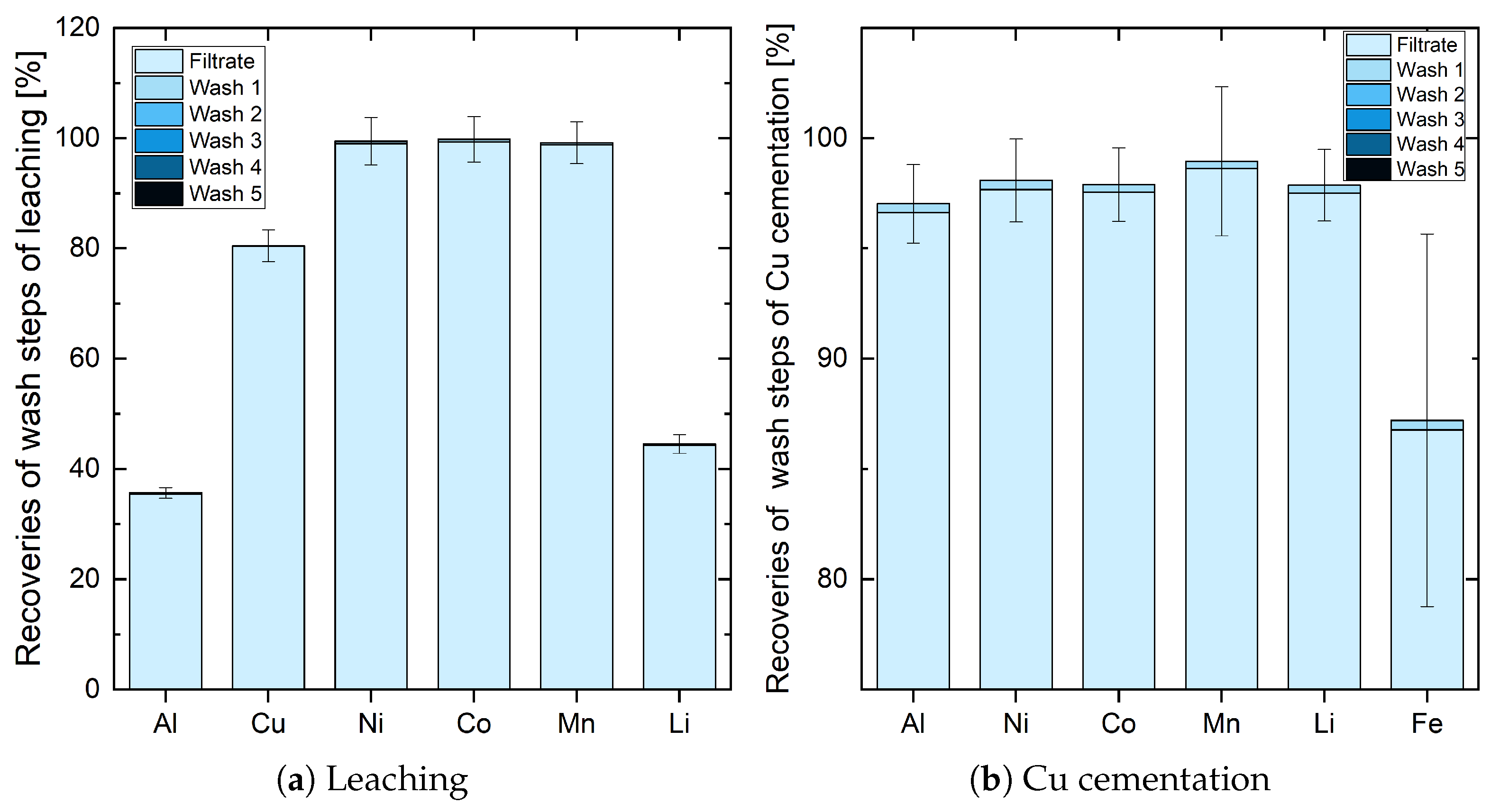

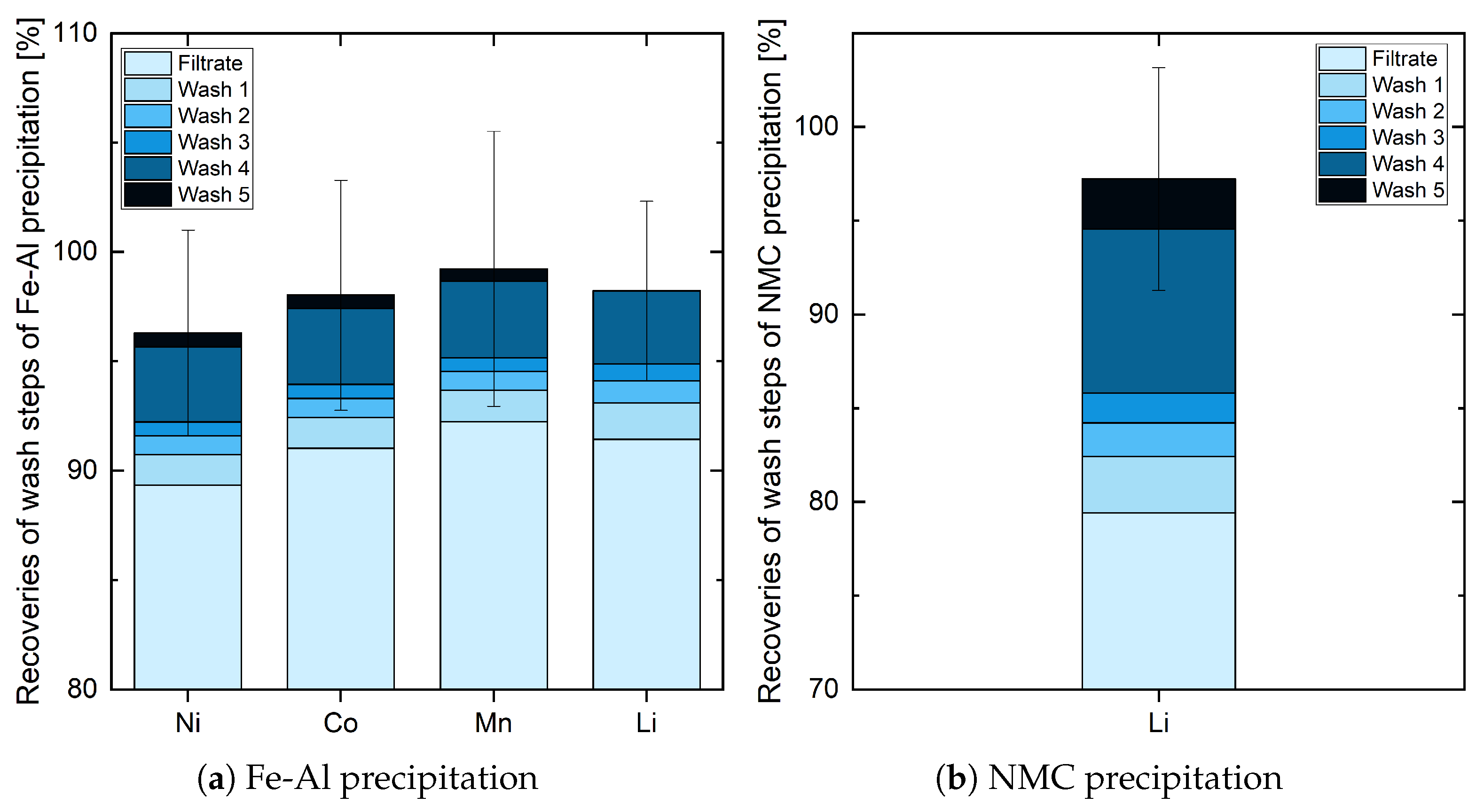

3.2. Efficiency of Substeps of Extended Washing

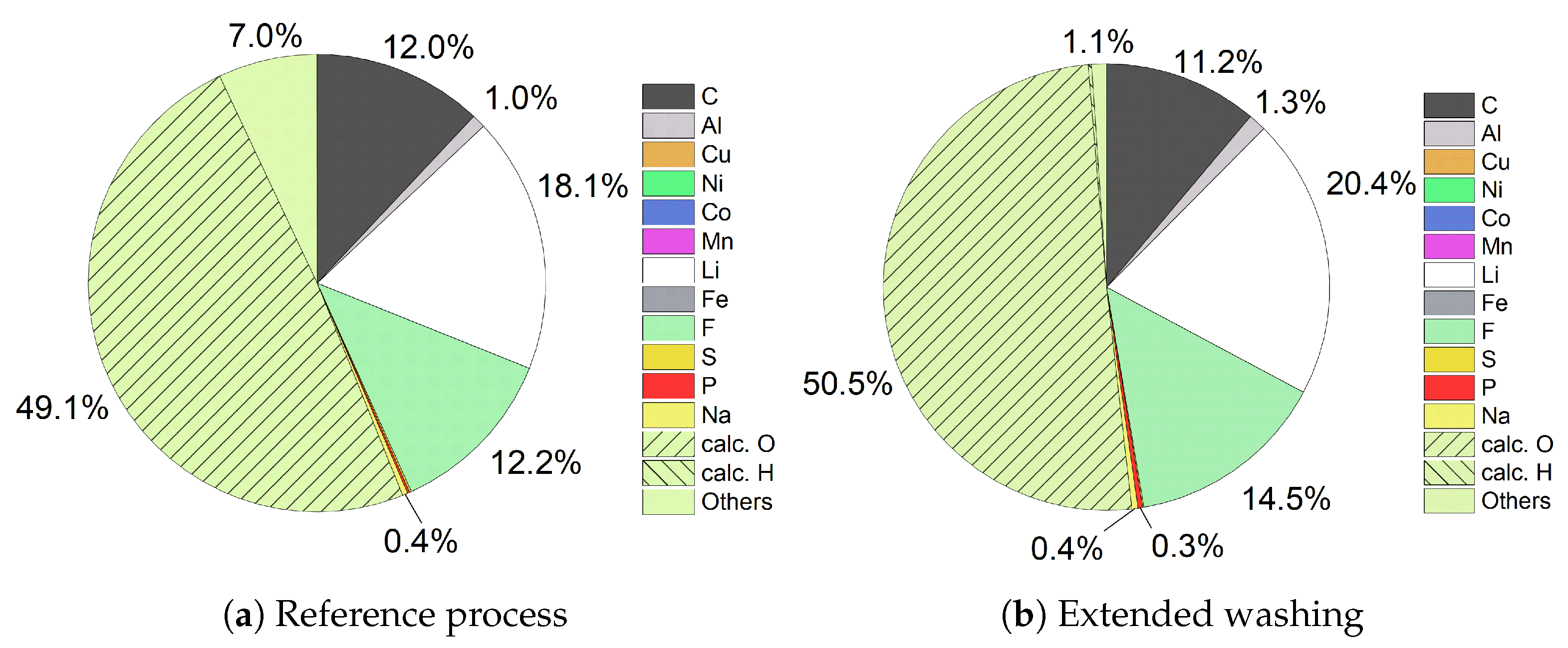

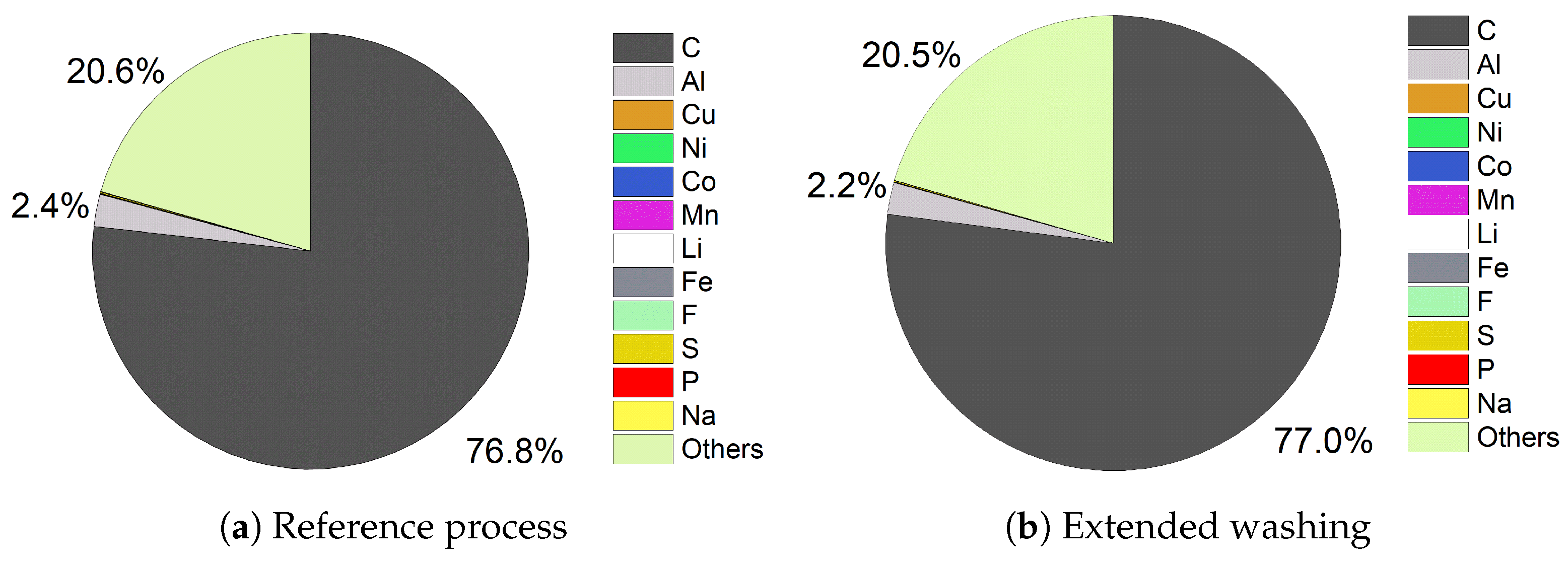

3.3. Impact of Extended Washing on the Purity of Filter Cakes

4. Conclusions

- One wash step is sufficient after H2SO4 leaching and Cu cementation.

- Extended washing with five wash steps is recommended after Fe-Al precipitation and NMC precipitation for improved recovery.

- Single wash steps of extended washing are able to recover 0.5% to 3.5% of Ni, Co, and Mn and 1.6% to 8.7% of Li.

- Extended washing improved the purity of Fe-Al compounds in the Fe-Al filter cake from 41.3% to 84.8% and the purity of NMC compounds in the NMC filter cake from 41.3% to 76.2%

- Nearly 100% of Li can be recovered by using extended washing, if wash water is recirculated.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kresse, C.; Bastian, D.; Bookhagen, B.; Frenzel, M. Lithium-Ionen-Batterierecycling in Deutschland und Europa. 2022. Available online: https://savearchive.zbw.eu/bitstream/11159/12253/1/180609875X_0.pdf (accessed on 13 November 2025).

- Jármai, K.; Cservenák, Á. Vehicle and Automotive Engineering 4; Springer International Publishing: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- Alanazi, F. Electric Vehicles: Benefits, Challenges, and Potential Solutions for Widespread Adaptation. Appl. Sci. 2023, 13, 6016. [Google Scholar] [CrossRef]

- König, A.; Nicoletti, L.; Schröder, D.; Wolff, S.; Waclaw, A.; Lienkamp, M. An Overview of Parameter and Cost for Battery Electric Vehicles. World Electr. Veh. J. 2021, 12, 21. [Google Scholar] [CrossRef]

- Baum, Z.J.; Bird, R.E.; Yu, X.; Ma, J. Lithium-Ion Battery Recycling—Overview of Techniques and Trends. ACS Energy Lett. 2022, 7, 712–719. [Google Scholar] [CrossRef]

- Davis, K.; Demopoulos, G.P. Hydrometallurgical recycling technologies for NMC Li-ion battery cathodes: Current industrial practice and new R&D trends. RSC Sustain. 2023, 1, 1932–1951. [Google Scholar] [CrossRef]

- Wang, Y.; An, N.; Wen, L.; Wang, L.; Jiang, X.; Hou, F.; Yin, Y.; Liang, J. Recent progress on the recycling technology of Li-ion batteries. J. Energy Chem. 2021, 55, 391–419. [Google Scholar] [CrossRef]

- Chen, X.; Cao, L.; Kang, D.; Li, J.; Li, S.; Wu, X. Hydrometallurgical Processes for Valuable Metals Recycling from Spent Lithium-Ion Batteries. In Recycling of Spent Lithium-Ion Batteries; An, L., Ed.; Springer International Publishing: Cham, Switzerland, 2019; pp. 93–139. [Google Scholar] [CrossRef]

- Xu, C.; Dai, Q.; Gaines, L.; Hu, M.; Tukker, A.; Steubing, B. Future material demand for automotive lithium-based batteries. Commun. Mater. 2020, 1, 99. [Google Scholar] [CrossRef]

- Maisel, F.; Neef, C.; Marscheider-Weidemann, F.; Nissen, N.F. A forecast on future raw material demand and recycling potential of lithium-ion batteries in electric vehicles. Resour. Conserv. Recycl. 2023, 192, 106920. [Google Scholar] [CrossRef]

- Hu, S.; He, S.; Jiang, X.; Wu, M.; Wang, P.; Li, L. Forecast and Suggestions on The Demand of Lithium, Cobalt, Nickel and Manganese Resources in China’s New Energy Automobile Industry. IOP Conf. Ser. Earth Environ. Sci. 2021, 769, 042018. [Google Scholar] [CrossRef]

- Tang, C.; Tukker, A.; Mogollón, J.M. The demand and recycling potential for lithium, cobalt, and nickel in the European electric-mobility transition. Environ. Res. Commun. 2025, 7, 061007. [Google Scholar] [CrossRef]

- Europäische Union. VERORDNUNG (EU) 2023/1542 DES EUROPÄISCHEN PARLAMENTS UND DES RATES vom 12. Juli 2023 über Batterien und Altbatterien, zur Änderung der Richtlinie 2008/98/EG und der Verordnung (EU) 2019/1020 und zur Aufhebung der Richtlinie 2006/66/EG. 12 July 2023. Available online: https://eur-lex.europa.eu/legal-content/DE/TXT/?uri=CELEX%3A32023R1542 (accessed on 13 November 2025).

- van Hoof, G.; Robertz, B.; Verrecht, B. Towards Sustainable Battery Recycling: A Carbon Footprint Comparison between Pyrometallurgical and Hydrometallurgical Battery Recycling Flowsheets. Metals 2023, 13, 1915. [Google Scholar] [CrossRef]

- Fahimi, A.; Ducoli, S.; Federici, S.; Ye, G.; Mousa, E.; Frontera, P.; Bontempi, E. Evaluation of the sustainability of technologies to recycle spent lithium-ion batteries, based on embodied energy and carbon footprint. J. Clean. Prod. 2022, 338, 130493. [Google Scholar] [CrossRef]

- An, L. (Ed.) Recycling of Spent Lithium-Ion Batteries; Springer International Publishing: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- Nayl, A.A.; Elkhashab, R.A.; Badawy, S.M.; El-Khateeb, M.A. Acid leaching of mixed spent Li-ion batteries. Arab. J. Chem. 2017, 10, S3632–S3639. [Google Scholar] [CrossRef]

- Wang, H.; Friedrich, B. Development of a Highly Efficient Hydrometallurgical Recycling Process for Automotive Li–Ion Batteries. J. Sustain. Metall. 2015, 1, 168–178. [Google Scholar] [CrossRef]

- Agrawal, R.; Kapoor, M.L. Theoretical considerations on the cementation of copper with iron. J. S. Afr. Inst. Min. Metall. 1982, 82, 106–111. [Google Scholar]

- Gupta, C.K.; Mukherjee, T.K. Hydrometallurgy in Extraction Processes; CRC Press: Boca Raton, FL, USA, 1990. [Google Scholar]

- Chernyaev, A.; Zhang, J.; Seisko, S.; Louhi-Kultanen, M.; Lundström, M. Fe3+ and Al3+ removal by phosphate and hydroxide precipitation from synthetic NMC Li-ion battery leach solution. Sci. Rep. 2023, 13, 21445. [Google Scholar] [CrossRef]

- Cai, G.; Fung, K.Y.; Ng, K.M.; Wibowo, C. Process Development for the Recycle of Spent Lithium Ion Batteries by Chemical Precipitation. Ind. Eng. Chem. Res. 2014, 53, 18245–18259. [Google Scholar] [CrossRef]

- Tawonezvi, T.; Zide, D.; Nomnqa, M.; Madondo, M.; Petrik, L.; Bladergroen, B.J. Recovery of NixMnyCoz(OH)2 and Li2CO3 from spent Li-ionB cathode leachates using non-Na precipitant-based chemical precipitation for sustainable recycling. Chem. Eng. J. Adv. 2024, 17, 100582. [Google Scholar] [CrossRef]

- Monhemius, A.J. Precipitation diagrams for metal hydroxides, sulphides, arsenates and phosphates. Trans. Inst. Min. Metall. 1977, 86, C202–C206. [Google Scholar]

- Anwar Ul Haq, R. Thermodynamics and Precipitation Kinetics of Lithium Carbonate (Li2CO3). Master’s Thesis, School of Chemical Enginering, Aalto University, Espoo, Finland, 2019. [Google Scholar]

- Schwich, L.; Schubert, T.; Friedrich, B. Early-Stage Recovery of Lithium from Tailored Thermal Conditioned Black Mass Part I: Mobilizing Lithium via Supercritical CO2-Carbonation. Metals 2021, 11, 177. [Google Scholar] [CrossRef]

- Yan, Z.; Sattar, A.; Li, Z. Priority Lithium recovery from spent Li-ion batteries via carbothermal reduction with water leaching. Resour. Conserv. Recycl. 2023, 192, 106937. [Google Scholar] [CrossRef]

- Anlauf, H. (Ed.) Wet Cake Filtration: Fundamentals, Equipment, and Strategies; Wiley-VCH: Hoboken, NJ, USA, 2019. [Google Scholar]

- Noerpel, S.; Siauw, V.; Nirschl, H. Filter Cake Washing of Mesoporous Particles. Chem. Eng. Technol. 2012, 35, 661–667. [Google Scholar] [CrossRef]

- Seupel, S.; Peuker, U.A. Displacement washing of filter cakes from porous particles. Sep. Purif. Technol. 2021, 274, 118141. [Google Scholar] [CrossRef]

- Ruslim, F.; Nirschl, H.; Stahl, W.; Carvin, P. Optimization of the wash liquor flow rate to improve washing of pre-deliquored filter cakes. Chem. Eng. Sci. 2007, 62, 3951–3961. [Google Scholar] [CrossRef]

- Huhtanen, M.; Salmimies, R.; Kinnarinen, T.; Häkkinen, A.; Ekberg, B.; Kallas, J. Empirical Modelling of Cake Washing in a Pressure Filter. Sep. Sci. Technol. 2012, 47, 1102–1112. [Google Scholar] [CrossRef]

- Svarovsky, L. (Ed.) Solid-Liquid Seperation, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2000. [Google Scholar]

- Emmett, R.C.; Dahlstrom, D.A. Liquid-solid separation factors in hydrometallurgical leach circuit design. Can. J. Chem. Eng. 1959, 37, 3–8. [Google Scholar] [CrossRef]

- Kuo, M.T. Filter cake washing performance. AIChE J. 1960, 6, 566–568. [Google Scholar] [CrossRef]

- Mocellin, J. COM 2015: Hosting AMCAA: 54th Annual Conference of Metallurgists Hosting America’s Conference on Aluminium Alloys: August 23–26, Fairmont Royal York Hotel, Toronto, ON, Canada: Proceedings; Canadian Institute of Mining Metallurgy and Petroleum: Westmount, QC, Canada, 2015. [Google Scholar]

- Choudhury, A.P.R.; Dahlstrom, D.A. Prediction of cake–washing results with continuous filtration equipment. AIChE J. 1957, 3, 433–438. [Google Scholar] [CrossRef]

- Kinnarinen, T.; Lubieniecki, B.; Holliday, L.; Helsto, J.J.; Häkkinen, A. Recovery of sodium from bauxite residue by pressure filtration and cake washing. Int. J. Miner. Process. 2015, 141, 20–26. [Google Scholar] [CrossRef]

- Sauer, F.; Löwer, E.; Henn, H.; Peuker, U.; Hoffner, B. Displacement Washing of Filter Cakes With a Fine Particle Top Layer. Chem. Eng. Technol. 2025, 48, e202400394. [Google Scholar] [CrossRef]

- Brückner, A.; Sprott, T.; Peuker, U.A.; Hoffner, B. Influence of pre-dewatering on the success of cake washing. Sep. Sci. Technol. 2023, 58, 175–187. [Google Scholar] [CrossRef]

| Al | Cu | Ni | Co | Mn | Li | Fe | F | S | P | Na | C | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [%] | 3.90 | 0.04 | 8.06 | 8.01 | 7.58 | 2.97 | <0.01 | 4.08 | 0.07 | 0.59 | 0.04 | 42.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dittmer, D.; Andary, M.; Diaz, F.; Friedrich, B. Evaluation of Filter Cake Washing Processes in Hydrometallurgical Battery Recycling of Lithium-Ion Batteries to Optimize Recoveries. Metals 2025, 15, 1262. https://doi.org/10.3390/met15111262

Dittmer D, Andary M, Diaz F, Friedrich B. Evaluation of Filter Cake Washing Processes in Hydrometallurgical Battery Recycling of Lithium-Ion Batteries to Optimize Recoveries. Metals. 2025; 15(11):1262. https://doi.org/10.3390/met15111262

Chicago/Turabian StyleDittmer, Dominic, Maya Andary, Fabian Diaz, and Bernd Friedrich. 2025. "Evaluation of Filter Cake Washing Processes in Hydrometallurgical Battery Recycling of Lithium-Ion Batteries to Optimize Recoveries" Metals 15, no. 11: 1262. https://doi.org/10.3390/met15111262

APA StyleDittmer, D., Andary, M., Diaz, F., & Friedrich, B. (2025). Evaluation of Filter Cake Washing Processes in Hydrometallurgical Battery Recycling of Lithium-Ion Batteries to Optimize Recoveries. Metals, 15(11), 1262. https://doi.org/10.3390/met15111262