Overcoming Processability Limitations in Al6082 Alloy by Using Laser Powder Bed Fusion of Aluminum Matrix Composites with Titanium Carbide/Silicon Carbide Reinforcements

Abstract

1. Introduction

2. Materials and Methods

3. Results

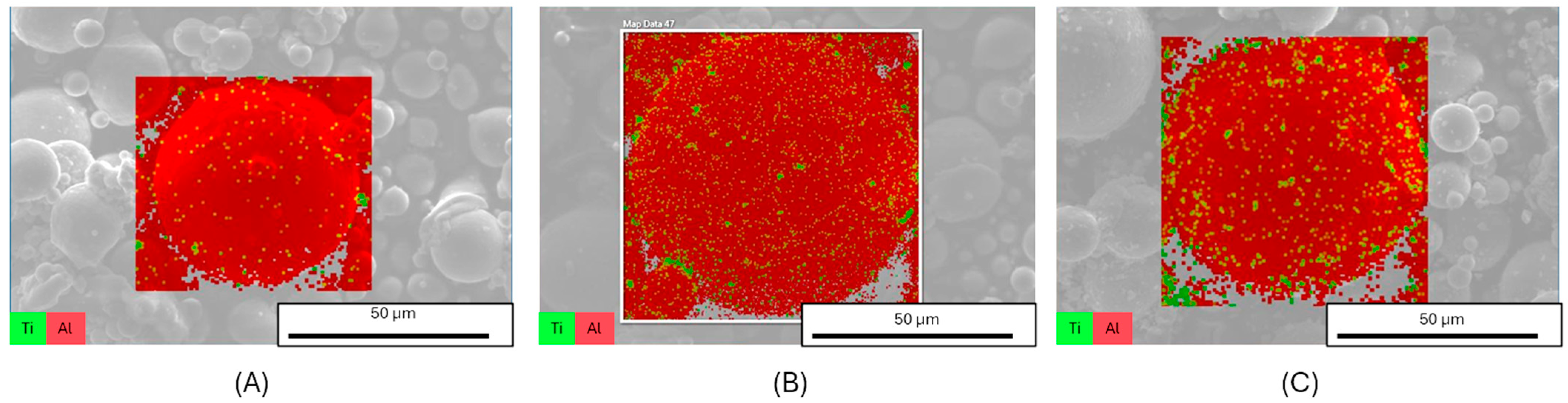

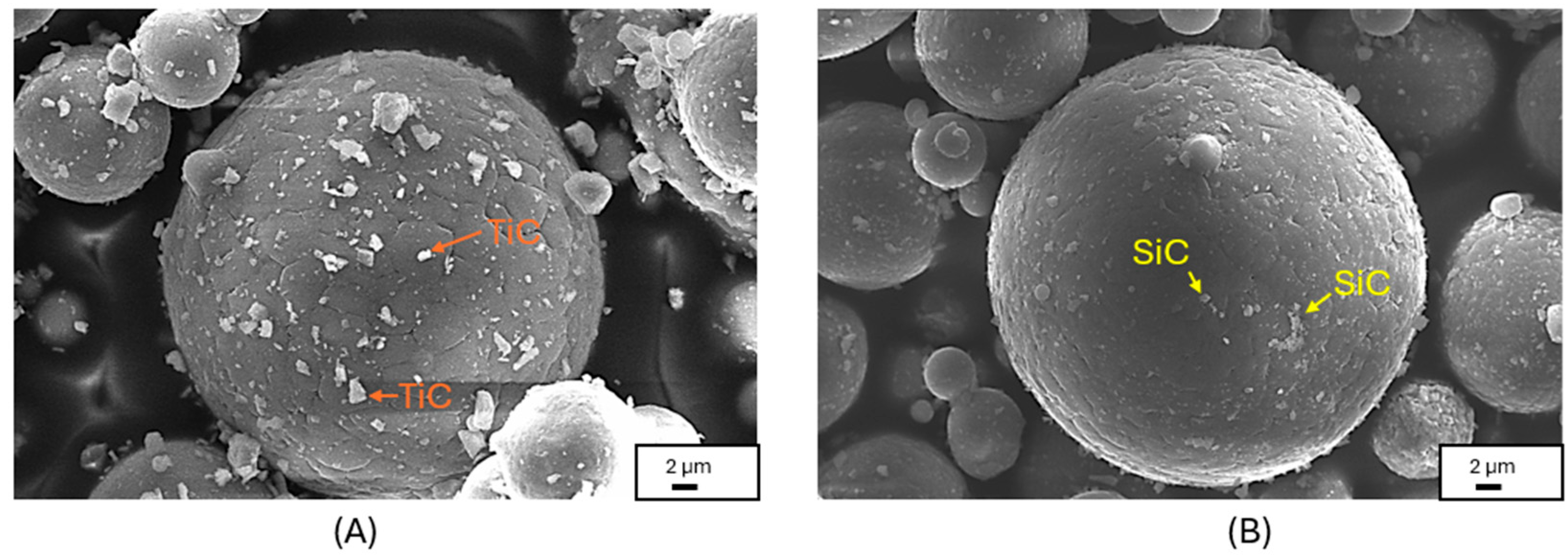

3.1. Al6082 Mixtures of Powders

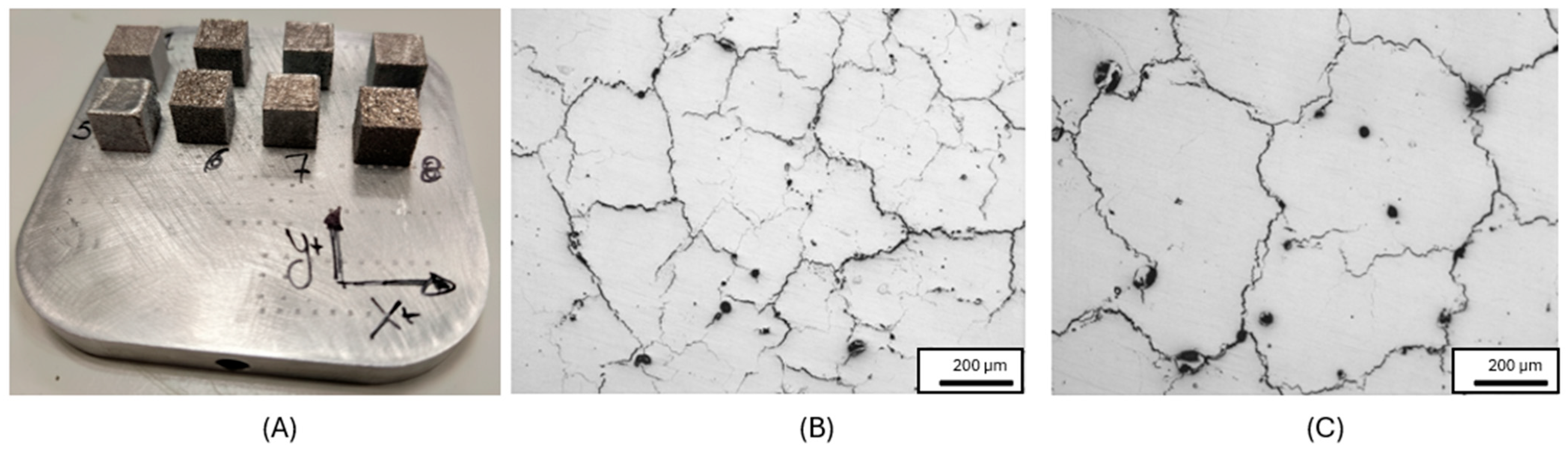

3.2. Processability of Unreinforced Al6082 Alloy

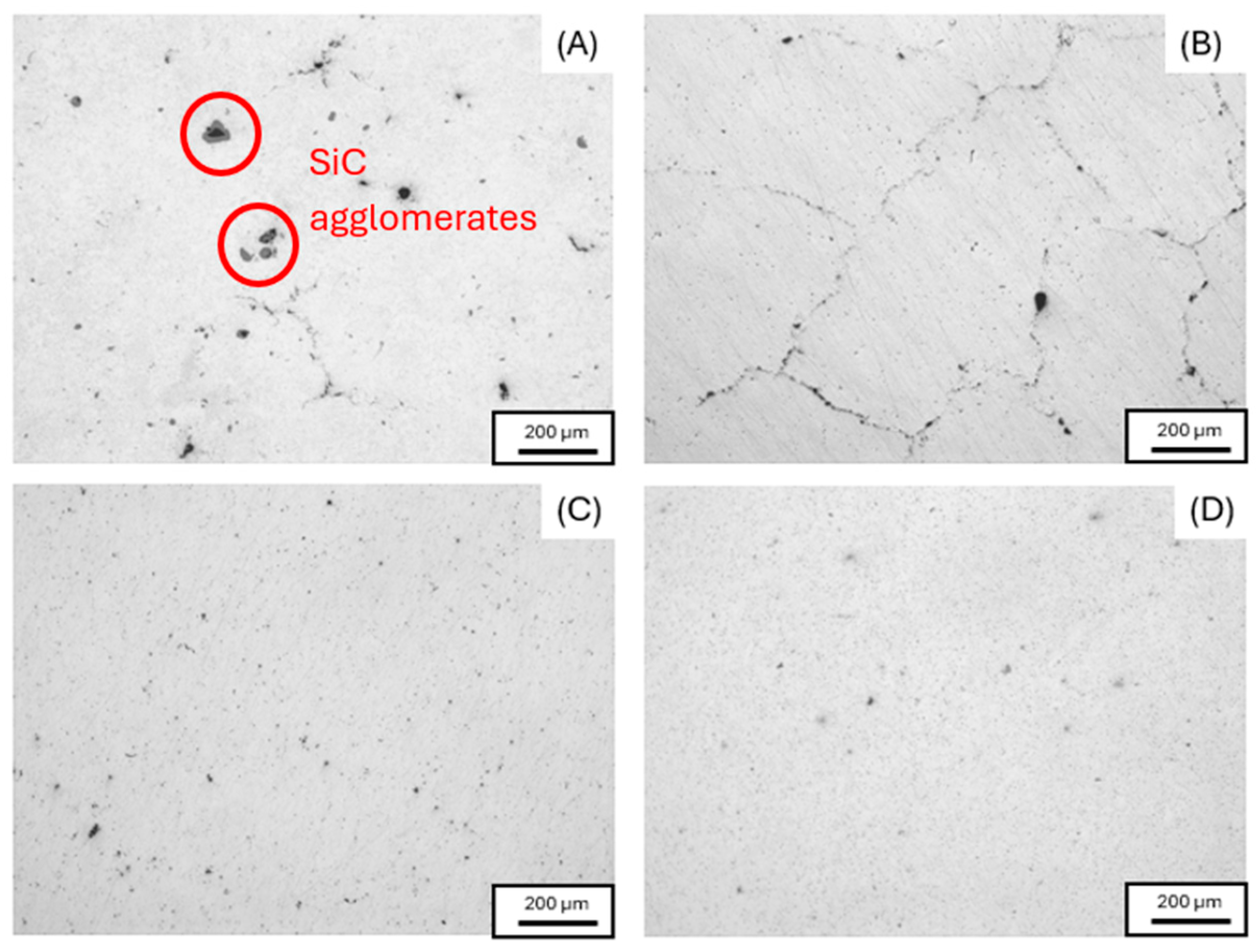

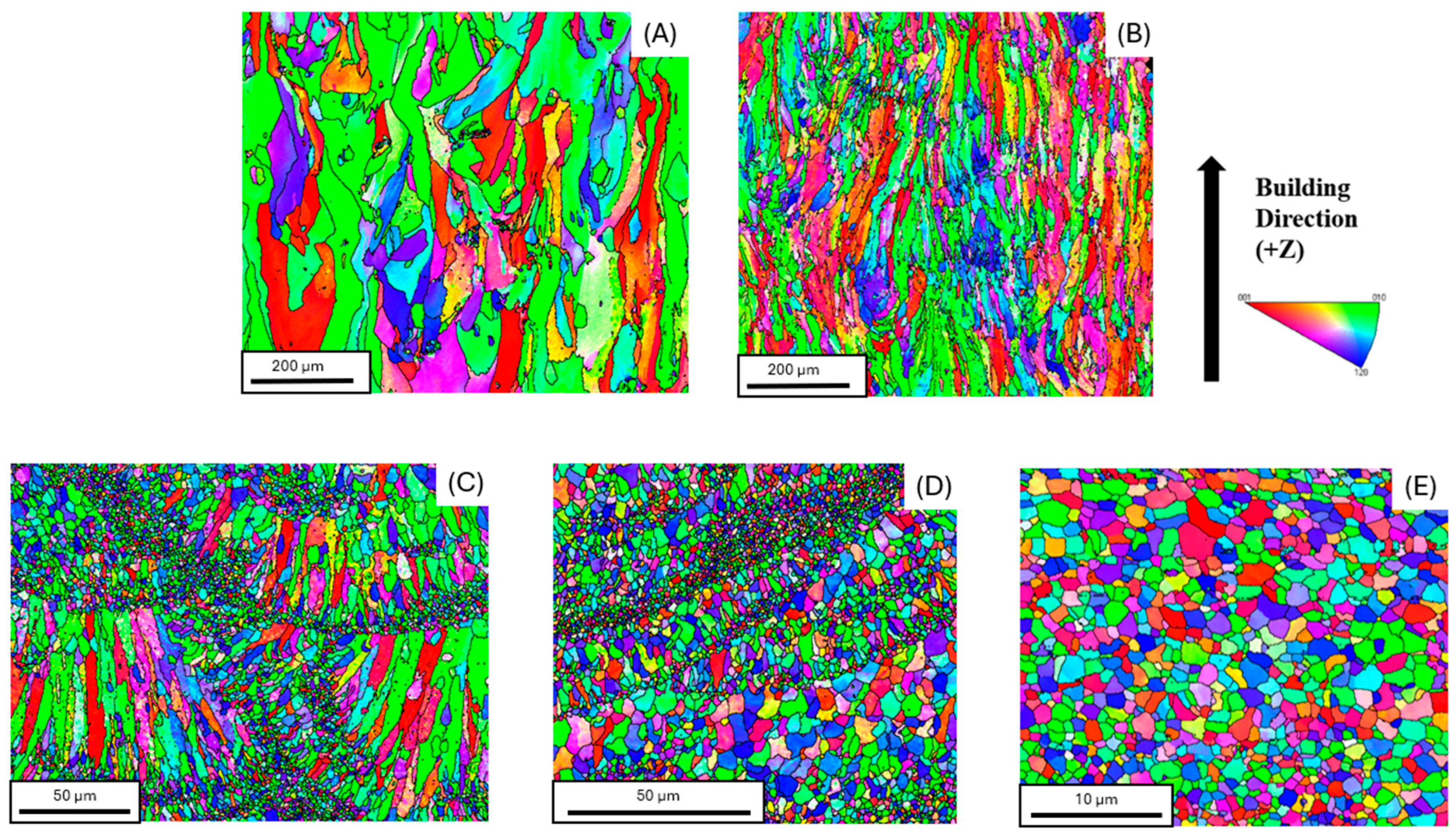

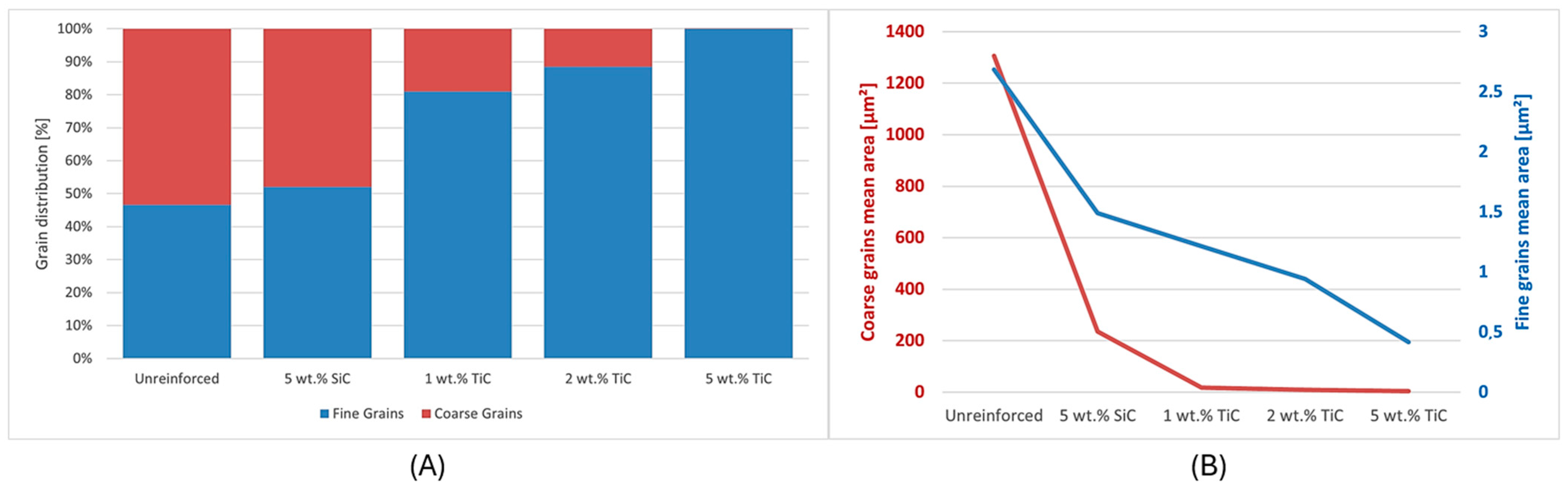

3.3. Crack Mitigation of Al6082 Alloy Through Reinforcements and Microstructural Evolution

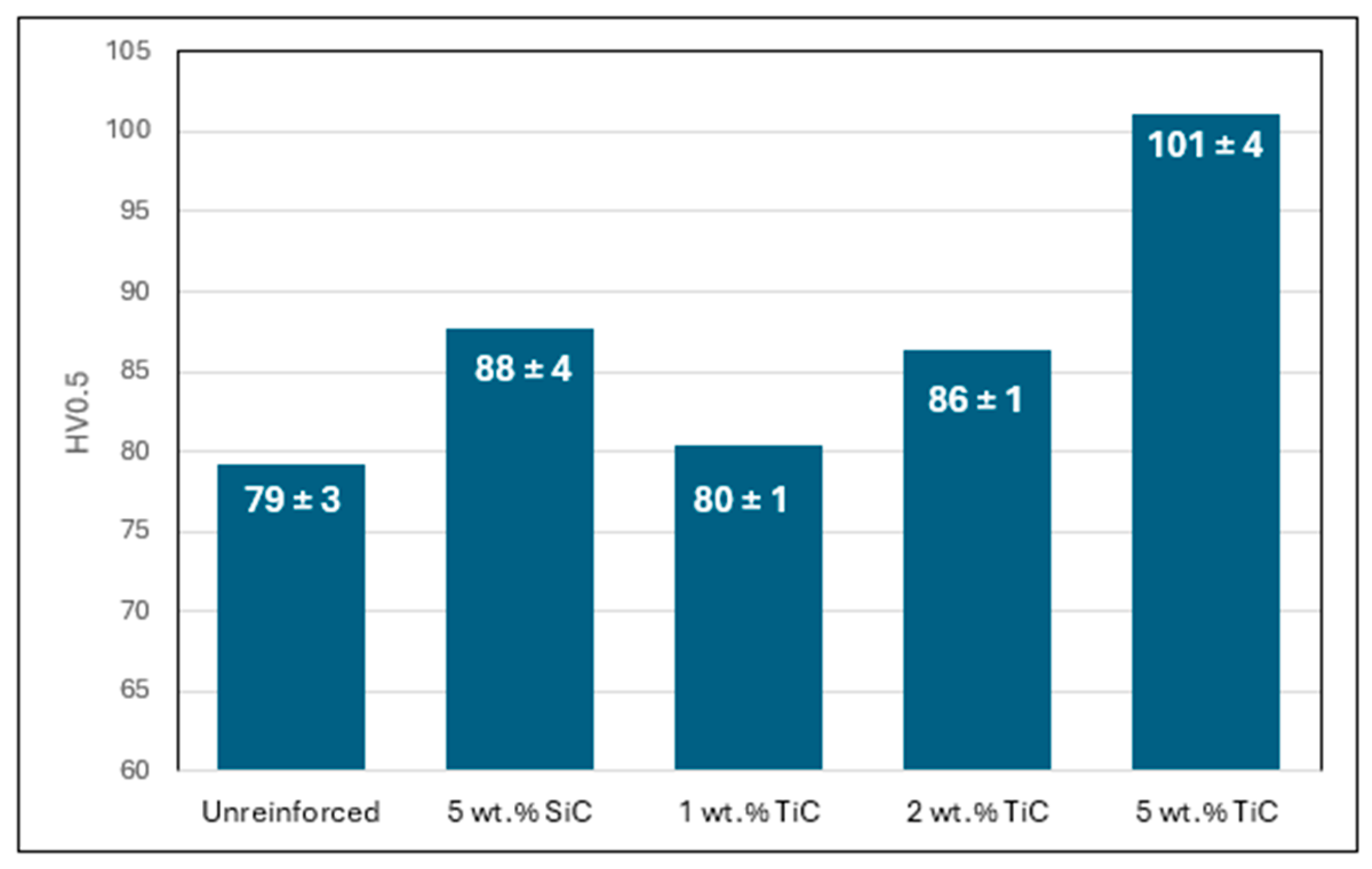

3.4. Mechanical Properties of Al6082 and Al6082-SiC/TiC Mixtures

4. Discussion

4.1. Effect of Processing Parameters on Processability

4.2. Effect of the Reinforcing Phase on Processability

4.3. Effect of the Reinforcements on the Mechanical Properties

4.4. Industrial Implications and Limitations

5. Conclusions

- The addition of TiC at 2 wt.% and 5 wt.% completely eliminated crack formation, achieving high relative densities over 99.9%. In contrast, 5 wt.% SiC and 1 wt.% TiC only reduced cracking and resulted in lower final relative densities.

- TiC proved to be a more potent grain refiner than SiC, transforming the coarse columnar structure into a fully fine-grained, equiaxed microstructure. SiC, while capable of reducing grain size, was insufficient to trigger a complete CET.

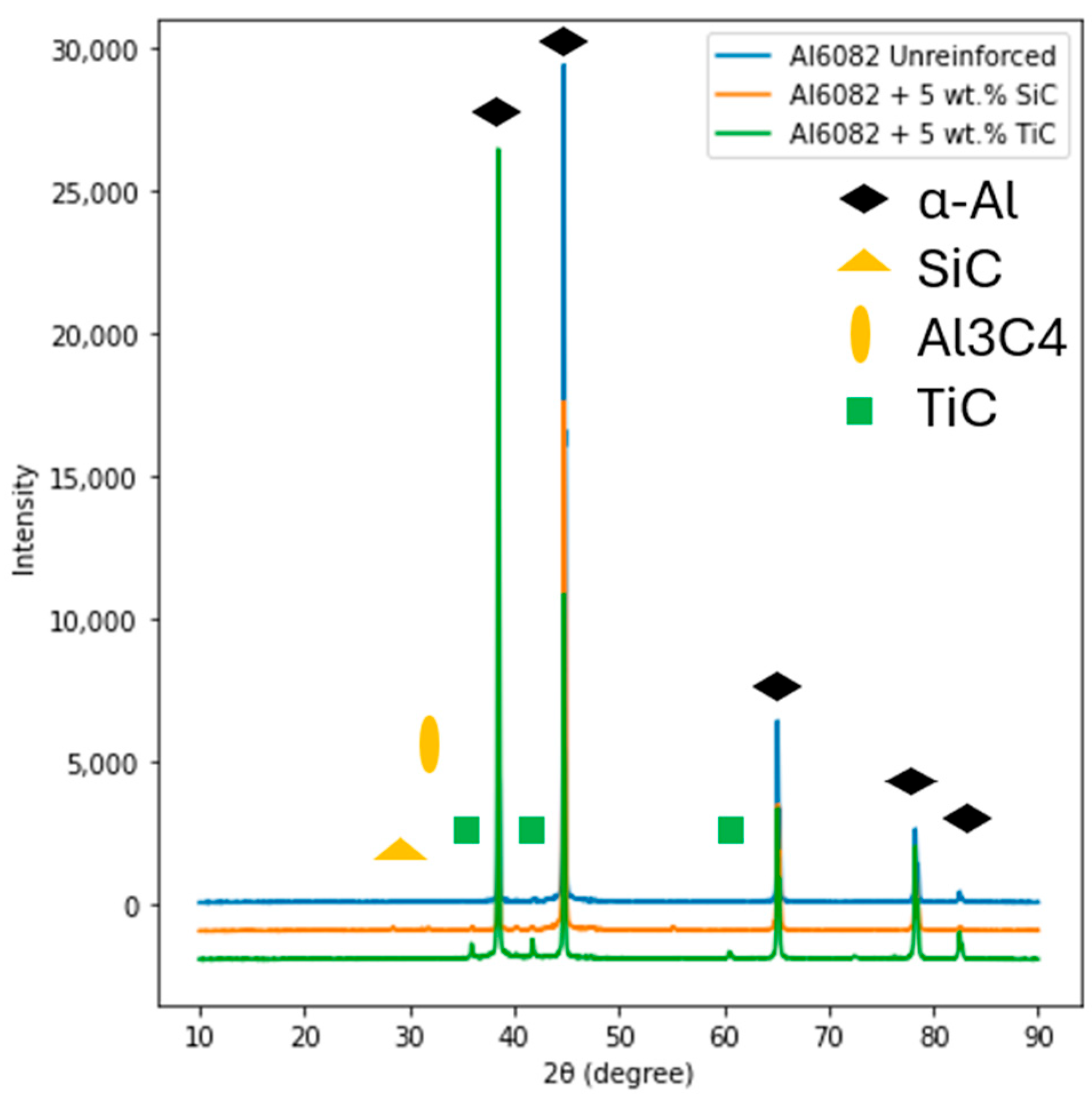

- A crucial finding regarding phase stability was observed in the Al6082 + 5 wt.% SiC composite, which showed the formation of the brittle intermetallic phase Al4C3 in the X-ray diffraction analysis. This suggests that detrimental chemical reactions were not fully suppressed in this specific composition, potentially compromising its long-term integrity, even though it achieved comparable hardness to the 2 wt.% TiC composite.

- The mechanical hardness of the composites increased significantly due to grain refinement (Hall-Petch effect) and dispersion strengthening. A clear dose–response was established with TiC, with hardness peaking at 101 ± 4 HV0.5 in the 5 wt.% TiC composite.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PBF/LB-M | Powder Bed Fusion/Laser Beam—Metal |

| AM | Additive Manufacturing |

| SiC | Silicon Carbide |

| TiC | Titanium Carbide |

| AMMC | Aluminum Metal Matrix Composites |

| VED | Volumetric Energy Density |

| EDS | Energy Dispersive X-ray Spectroscopy |

| EBSD | Electron Backscatter Diffraction |

References

- Uddin, S.Z.; Murr, L.E.; Terrazas, C.A.; Morton, P.; Roberson, D.A.; Wicker, R.B. Processing and characterization of crack-free aluminum 6061 using high-temperature heating in laser powder bed fusion additive manufacturing. Addit. Manuf. 2018, 22, 405–415. [Google Scholar] [CrossRef]

- Del Guercio, G.; Faron, S.; McCartney, D.G.; Robertson, S.; Aboulkhair, N.T.; Tuck, C.; Clare, A.T.; Simonelli, M. Experimental and computational studies on hot cracking in single laser tracks of aluminium alloy AA2024 and related implications for laser powder bed fusion. Discov. Mater 2024, 4, 83. [Google Scholar] [CrossRef]

- Del Guercio, G.; McCartney, D.; Aboulkhair, N.; Robertson, S.; Maclachlan, R.; Tuck, C.; Simonelli, M. Cracking behaviour of high-strength AA2024 aluminium alloy produced by Laser Powder Bed Fusion. Addit. Manuf. 2022, 54, 102776. [Google Scholar] [CrossRef]

- Sonawane, A.; Roux, G.; Blandin, J.J.; Despres, A.; Martin, G. Cracking mechanism and its sensitivity to processing conditions during laser powder bed fusion of a structural aluminum alloy. Materialia 2021, 15, 100976. [Google Scholar] [CrossRef]

- Heiland, S.; Milkereit, B.; Hoyer, K.P.; Zhuravlev, E.; Kessler, O.; Schaper, M. Requirements for Processing High-Strength AlZnMgCu Alloys with PBF-LB/M to Achieve Crack-Free and Dense Parts. Materials 2021, 14, 7190. [Google Scholar] [CrossRef]

- Chen, H.H.; Lo, Y.L.; Hsu, Y.Y.; Lai, K.L. Systematic optimization of L-PBF processing parameters for Al alloy 6061 with YSZ nanoparticles. Opt. Laser Technol. 2023, 167, 109676. [Google Scholar] [CrossRef]

- Liu, R.P.; Dong, Z.J.; Pan, Y.M. Solidification crack susceptibility of aluminum alloy weld metals. Trans. Nonferrous Met. Soc. China (Engl. Ed.) 2006, 16, 110–116. [Google Scholar] [CrossRef]

- Di Schino, A.; Patel, S.K.; Shi, L. Recent Advances in Ceramic-Reinforced Aluminum Metal Matrix Composites: A Review. Alloys 2025, 4, 18. [Google Scholar] [CrossRef]

- Nartu, M.S.K.K.Y.; Agrawal, P. Additive manufacturing of metal matrix composites. Mater Des. 2025, 252, 113609. [Google Scholar] [CrossRef]

- Zenz, C.; Durán, C.; Florian, T.; Bielak, R.; Otto, A. Multiphysical simulation of hot cracking in Laser-Based Powder Bed Fusion. Procedia CIRP 2024, 124, 341–346. [Google Scholar] [CrossRef]

- Huber, F.; Rasch, M.; Schmidt, M. Laser Powder Bed Fusion (PBF-LB/M) Process Strategies for In-Situ Alloy Formation with High-Melting Elements. Metals 2021, 11, 336. [Google Scholar] [CrossRef]

- Larini, F.; Casati, R.; Marola, S.; Vedani, M. Microstructural Evolution of a High-Strength Zr-Ti-Modified 2139 Aluminum Alloy for Laser Powder Bed Fusion. Metals 2023, 13, 924. [Google Scholar] [CrossRef]

- Iams, A.D.; Weaver, J.S.; Lane, B.M.; Giannuzzi, L.A.; Yi, F.; LaPlant, D.L.; Martin, J.H.; Zhang, F. Microstructural features and metastable phase formation in a high-strength aluminum alloy fabricated using additive manufacturing. J. Alloys Compd. 2025, 1025, 180281. [Google Scholar] [CrossRef]

- Martin, J.H.; Barnes, J.E.; Rogers, K.A.; Hundley, J.; LaPlant, D.L.; Ghanbari, S.; Tsai, J.-T.; Bahr, D.F. Additive manufacturing of a high-performance aluminum alloy from cold mechanically derived non-spherical powder. Commun. Mater. 2023, 4, 39. [Google Scholar] [CrossRef]

- Singh, P.; Singh, R.K.; Das, A.K. Influence of ceramic reinforcements on mechanical properties and high-temperature sliding wear behaviour of heat-treated Al6082–SiC–TiO2 composites developed by stir-casting process. Multiscale Multidiscip. Model. Exp. Des. 2023, 7, 1339–1356. [Google Scholar] [CrossRef]

- Gowda, Y. Characterizing the effects of SiC and Al2 O3 on the mechanical properties of Al6082 hybrid metal matrix composites: An experimental and neural network approach. Adv. Prod. Eng. Manag. 2024, 19, 281–292. [Google Scholar] [CrossRef]

- Hassan, A.; Altaf, K.; Ismail, M.C.; Pedapati, S.R.; Marode, R.V.; Soomro, I.A.; Ahmed, N. Development of Carbide-Reinforced Al-7075 Multi-Layered Composites via Friction Stir Additive Manufacturing. J. Compos. Sci. 2025, 9, 568. [Google Scholar] [CrossRef]

- Ramesh, S.; Nordin, A.F.; Osman, S.A.; Osman, S.A.; Yaakub, K.A.; Nasir, N.F. A Review on the Effect of Titanium Carbide (TiC) as Reinforcement Composites in Aluminium-Based Metal Matrix Composites on the Microstructure and Mechanical Properties using Stir Casting Process. J. Adv. Res. 2026, 39, 43–56. [Google Scholar]

- Gao, Z.; Li, D.; Zhao, Y.; He, C.; Lin, H. Microstructure and Mechanical Properties of TiB2/AlSi10Mg Composites Fabricated by Laser Metal Deposition. JOM 2025, 77, 2392–2404. [Google Scholar] [CrossRef]

- Khrustalyov, A.; Vorozhtsov, A.; Rocha, F.; Simões, S. Production and Characterization of Aluminum Reinforced with SiC Nanoparticles. Metals 2023, 13, 1626. [Google Scholar] [CrossRef]

- Gómez, R.; Aranzabe, J.; Garciandia, F.; Mancisidor, A.M.; Sebastian, M.S. Investigation of the impact of process parameters and thermal treatments on mechanical properties and microstructure of ScanCromAl ® manufactured via powder bed fusion laser beam process. J. Mater. Res. Technol. 2024, 33, 1961–1970. [Google Scholar] [CrossRef]

- Schimbäck, D.; Mair, P.; Kaserer, L.; Perfler, L.; Leichtfried, G. An improved process scan strategy to obtain high-performance fatigue properties for Scalmalloy®. Mater Des. 2022, 224, 111410. [Google Scholar] [CrossRef]

- Bärtl, M.; Xiao, X.; Brillo, J.; Palm, F. Influence of Surface Tension and Evaporation on Melt Dynamics of Aluminum Alloys for Laser Powder Bed Fusion. J. Mater. Eng. Perform. 2022, 31, 6221–6233. [Google Scholar] [CrossRef]

- Aversa, A.; Marchese, G.; Saboori, A.; Bassini, E. New aluminum alloys specifically designed for laser powder bed fusion: A review. Materials 2019, 12, 1007. [Google Scholar] [CrossRef] [PubMed]

- Stoll, T.; Schmitt, M.; Lohr, L.; Lürbke, R.; Müller, A.V.; Pinomaa, T.; Grünewald, J.; Laukkanen, A.; Wudy, K.; Neu, R. Influence of laser beam shaping on the cracking behavior of tungsten at single weld lines. Int. J. Refract. Met. Hard Mater. 2024, 125, 106864. [Google Scholar] [CrossRef]

- Qbau, N.; Nam, N.D.; Ca, N.X.; Hien, N.T. The crack healing effect of scandium in aluminum alloys during laser additive manufacturing. J. Manuf. Process. 2020, 50, 241–246. [Google Scholar] [CrossRef]

- Yue, D.; Zhang, X.; Li, D.; Li, Z.; Wang, Z.; Chen, B. Effect of remelting strategy on forming mechanism of selective laser melted AlSi10Mg. J. Mater. Res. Technol. 2024, 30, 4283–4293. [Google Scholar] [CrossRef]

- Li, L.; Dong, T.; Jiang, F.; Ru, Y.; Guo, C.; Diao, M.; Song, H. A novel method enhanced mechanical properties of a selective laser melted Mar-M247 superalloy by progressive remelting. J. Mater. Res. Technol. 2024, 33, 4968–4980. [Google Scholar] [CrossRef]

- Zhang, H.; Guo, H.C.; Hu, X.; Tao, J.Y.; She, W.H.; Zhao, C. Effect of laser remelting and ultrasonic irradiation on crack suppression and properties of Ni-WC laser cladding layer. Sci. Rep. 2025, 15, 19277. [Google Scholar] [CrossRef]

- Minasyan, T.; Hussainova, I. Laser Powder-Bed Fusion of Ceramic Particulate Reinforced Aluminum Alloys: A Review. Materials 2022, 15, 2467. [Google Scholar] [CrossRef]

- Yao, L.; Wang, L.; Cui, R.; Lv, Q.; Zhao, C.; Wang, X.; Guan, S.; Luo, L.; Lai, Q.; Chen, R.; et al. Enhancing strength and toughness of 7xxx aluminum alloys via TiC nanoparticles in electron beam rapid additive manufacturing. Mater. Sci. Eng. A 2025, 931, 148195. [Google Scholar] [CrossRef]

- Wang, K.; Jiang, H.; Wang, Q.; Wang, Y. Grain Refinement Mechanisms of TiC0.5N0.5 Nanoparticles in Aluminum. Materials 2023, 16, 1214. [Google Scholar] [CrossRef] [PubMed]

- Zuo, M.; Sokoluk, M.; Cao, C.; Yuan, J.; Zheng, S.; Li, X. Microstructure Control and Performance Evolution of Aluminum Alloy 7075 by Nano-Treating. Sci. Rep. 2019, 9, 10671. [Google Scholar] [CrossRef]

- Shin, S.; Park, H.; Park, B.; Lee, S.-B.; Lee, S.-K.; Kim, Y.; Cho, S.; Jo, I. Dispersion Mechanism and Mechanical Properties of SiC Reinforcement in Aluminum Matrix Composite through Stir- and Die-Casting Processes. Appl. Sci. 2021, 11, 952. [Google Scholar] [CrossRef]

- Mehdi, H.; Bhati, S.S.; Mouria, P.K.; Mishra, S.; Bhadana, M.; Batra, L. Effect of nanoparticles on metal matrix composites fabricated by ultrasonic stir casting. Int. J. Cast Met. Res. 2025, 38, 157–173. [Google Scholar] [CrossRef]

- Saravanamuthukumar, P.; Abdullah, A.B.; Poovazhagan, L.; Jayaram, R.S.; Murugan, S.S. Investigation of the Effect of Nano-SiC Particle Addition on the Structural and Thermal Properties of PEEK-SiC Nano Composite Made by Melt Cast Process. Natl. Acad. Sci. Lett. 2025, 1–6. [Google Scholar] [CrossRef]

- Lai, L.; Niu, B.; Bi, Y.; Li, Y.; Yang, Z. Advancements in SiC-Reinforced Metal Matrix Composites for High-Performance Electronic Packaging: A Review of Thermo-Mechanical Properties and Future Trends. Micromachines 2023, 14, 1491. [Google Scholar] [CrossRef]

- Shi, Y.; Wang, S.; Jian, Y. Inhibition Mechanism of the Interface Reaction in the Molten Pool of SiCp/Al Composites by Pulsed Laser Welding with Powder-Filling. Chin. J. Mech. Eng. (Engl. Ed.) 2024, 37, 154. [Google Scholar] [CrossRef]

- Hua, Z.; Xiang, Y.; Wang, C.; Jiang, P.; Zhang, M.; Hu, Y.; Mi, G.; Zhu, Q. Investigation of Ti alloying for microstructural evolution and strengthening mechanism: Avoiding Al4C3 formation in SiCp/Al composites via laser directed energy deposition. J. Alloys Compd. 2024, 970, 172371. [Google Scholar] [CrossRef]

- Lu, Z.; Wei, N.; Li, P.; Guo, C.; Jiang, F. Microstructure and mechanical properties of intermetallic Al 3 Ti alloy with residual aluminum. Mater. Des. 2016, 110, 466–474. [Google Scholar] [CrossRef]

- Sun, G.; Du, W.; Chen, C.; Zhao, X. Hybrid additive manufacturing of ceramic/aluminum-titanium gradient composites via arc and laser cladding eutectic pools. Virtual Phys. Prototyp. 2024, 19, e2419950. [Google Scholar] [CrossRef]

- Tang, S.; Ummethala, R.; Suryanarayana, C.; Eckert, J.; Prashanth, K.G.; Wang, Z. Additive Manufacturing of Aluminum-Based Metal Matrix Composites—A Review. Adv. Eng. Mater. 2021, 23, 2100053. [Google Scholar] [CrossRef]

- Loucif, A.; Figueiredo, R.B.; Baudin, T.; Brisset, F.; Chemam, R.; Langdon, T.G. Ultrafine grains and the Hall–Petch relationship in an Al–Mg–Si alloy processed by high-pressure torsion. Mater. Sci. Eng. A 2012, 532, 139–145. [Google Scholar] [CrossRef]

- Cordero, Z.C.; Knight, B.E.; Schuh, C.A. Six decades of the Hall–Petch effect—A survey of grain-size strengthening studies on pure metals. Int. Mater. Rev. 2016, 61, 495–512. [Google Scholar] [CrossRef]

- Tornabene, F.; Brischetto, S.; Triantafillou, T.; Maddaiah, K.C.; Kumar, G.B.V.; Pramod, R. Studies on the Mechanical, Strengthening Mechanisms and Tribological Characteristics of AA7150-Al2O3 Nano-Metal Matrix Composites. J. Compos. Sci. 2024, 8, 97. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Clough, E.C.; Mayer, J.A.; Hundley, J.M.; Schaedler, T.A. Additive manufacturing of metal matrix composites via nanofunctionalization. MRS Commun. 2018, 8, 297–302. [Google Scholar] [CrossRef]

- Simchi, A.; Godlinski, D. Effect of SiC particles on the laser sintering of Al–7Si–0.3Mg alloy. Scr. Mater. 2008, 59, 199–202. [Google Scholar] [CrossRef]

- Grima, D.; Layeb, N.; Li, R.; Zammit, B.; Attard, B.; Zammit, A.; Cassar, G. Enhancing fatigue resistance in WAAM AZ80 magnesium and wrought Al6082 through shot peening: A comparative study. Prog. Addit. Manuf. 2025. [Google Scholar] [CrossRef] [PubMed]

- Pan, S.; Yuan, J.; Jin, K.; Murali, N.; Gladstein, A.; Zeng, Y.; Taub, A.; Li, X. Influence of Mg on reaction and properties of Al–Si/TiC nanocomposites. Mater. Sci. Eng. A 2022, 840, 142992. [Google Scholar] [CrossRef]

- Joseph, O.O.; Afolalu, A.S.; Abioye, A.A.; Agbo, S.E.; Olatunde, S.F.; Omotehinwa, O.S. Effect of TiC addition on the mechanical properties and microstructure of Al-Si alloy. Mater. Today Proc. 2021, 38, 784–788. [Google Scholar] [CrossRef]

- Jacumasso, S.C.; Martins, J.d.P.; de Carvalho, A.L.M. Analysis of precipitate density of an aluminium alloy by TEM and AFM. Rev. Esc. Minas 2016, 69, 451–457. [Google Scholar] [CrossRef][Green Version]

- Dadkhah, M.; Mosallanejad, M.H.; Iuliano, L.; Saboori, A. A Comprehensive Overview on the Latest Progress in the Additive Manufacturing of Metal Matrix Composites: Potential, Challenges, and Feasible Solutions. Acta Metall. Sin. (Engl. Lett.) 2021, 34, 1173–1200. [Google Scholar] [CrossRef]

- Talebi, F.A.; Haydari, Z.; Salehi, H.; Mehrabi, M.; Gardy, J.; Bradley, M.; Bayly, A.E.; Hassanpour, A. Spreadability of powders for additive manufacturing: A critical review of metrics and characterisation methods. Particuology 2024, 93, 211–234. [Google Scholar] [CrossRef]

| Laser Power (W) | Scanning Speed (mm/s) | Hatch Distance (µm) | VED (J/mm3) |

|---|---|---|---|

| 370 | 1100 | 190 | 59 |

| 250 | 900 | 80 | 116 |

| 400 | 1000 | 100 | 133 |

| 400 | 900 | 160 | 93 |

| 400 | 700 | 120 | 159 |

| 250 | 900 | 80 | 116 |

| 400 | 1000 | 100 | 133 |

| 250 | 800 | 100 | 104 |

| Reference | Crack Density (mm/mm2) | Relative Density (%) |

|---|---|---|

| Al6082 unreinforced | 3.06 | 96.95 |

| Al6082 + 5 wt.% SiC | 1.34 | 99.25 |

| Al6082 + 1 wt.% TiC | 0.27 | 98.81 |

| Al6082 + 2 wt.% TiC | 0 | 99.93 |

| Al6082 + 5 wt.% TiC | 0 | 99.98 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gómez, R.; San Sebastian, M.; Guraya, T.; Mancisidor, A.M. Overcoming Processability Limitations in Al6082 Alloy by Using Laser Powder Bed Fusion of Aluminum Matrix Composites with Titanium Carbide/Silicon Carbide Reinforcements. Metals 2025, 15, 1232. https://doi.org/10.3390/met15111232

Gómez R, San Sebastian M, Guraya T, Mancisidor AM. Overcoming Processability Limitations in Al6082 Alloy by Using Laser Powder Bed Fusion of Aluminum Matrix Composites with Titanium Carbide/Silicon Carbide Reinforcements. Metals. 2025; 15(11):1232. https://doi.org/10.3390/met15111232

Chicago/Turabian StyleGómez, Raúl, Maria San Sebastian, Teresa Guraya, and Ane Miren Mancisidor. 2025. "Overcoming Processability Limitations in Al6082 Alloy by Using Laser Powder Bed Fusion of Aluminum Matrix Composites with Titanium Carbide/Silicon Carbide Reinforcements" Metals 15, no. 11: 1232. https://doi.org/10.3390/met15111232

APA StyleGómez, R., San Sebastian, M., Guraya, T., & Mancisidor, A. M. (2025). Overcoming Processability Limitations in Al6082 Alloy by Using Laser Powder Bed Fusion of Aluminum Matrix Composites with Titanium Carbide/Silicon Carbide Reinforcements. Metals, 15(11), 1232. https://doi.org/10.3390/met15111232