Differences in Yield Behavior in the Thickness Direction of TMCP-Processed HSLA Thick Steel Plates and the Evolution of Microstructure Property Gradients

Abstract

1. Introduction

2. Experimental Procedures

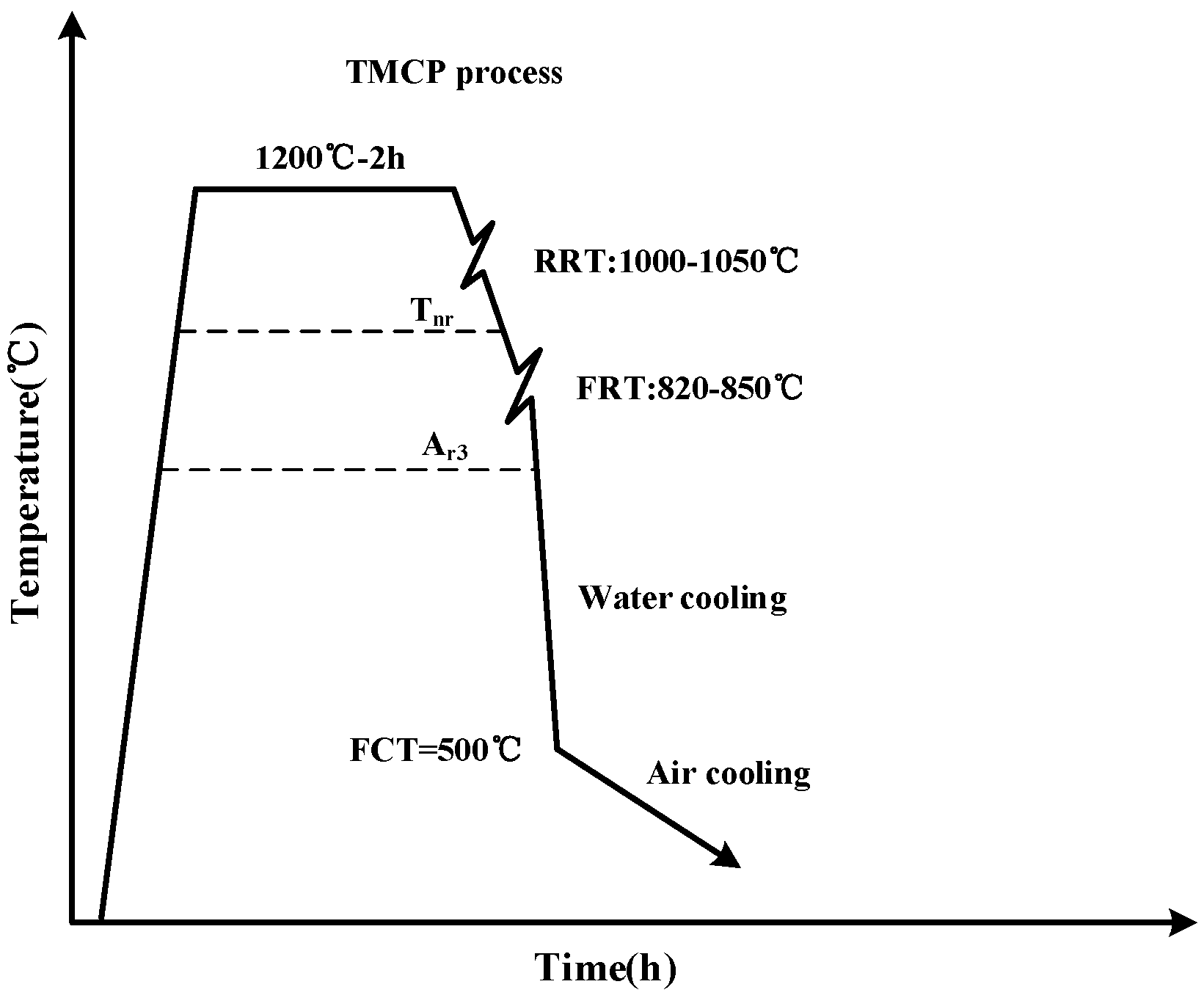

2.1. Material and Processing

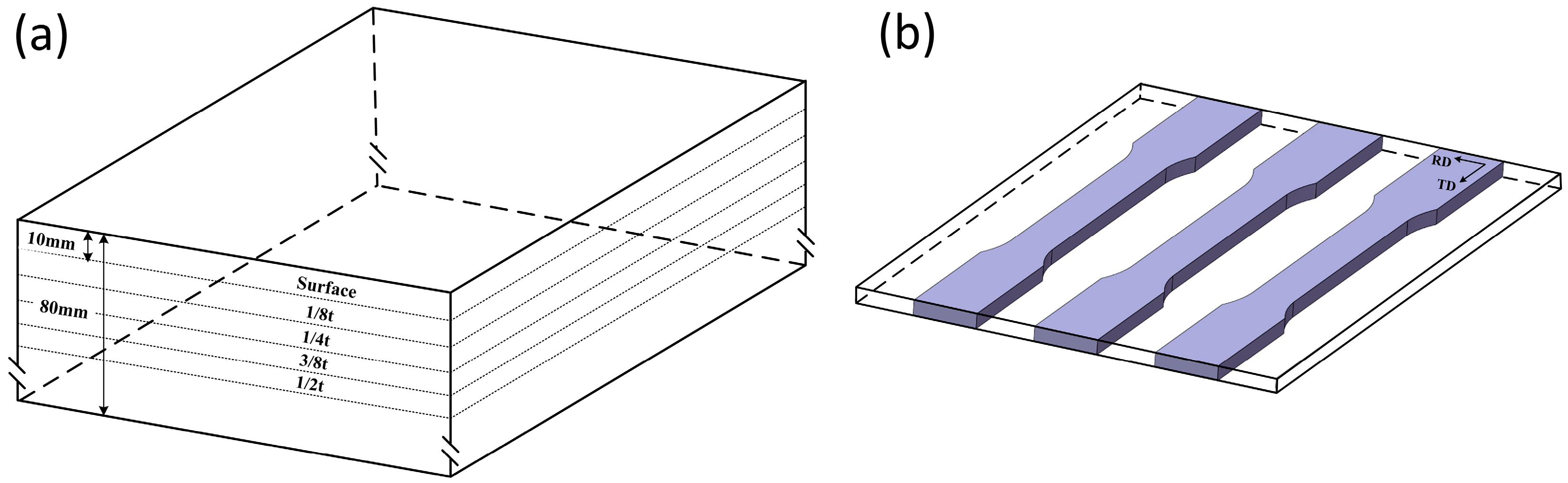

2.2. Microstructural Characterization

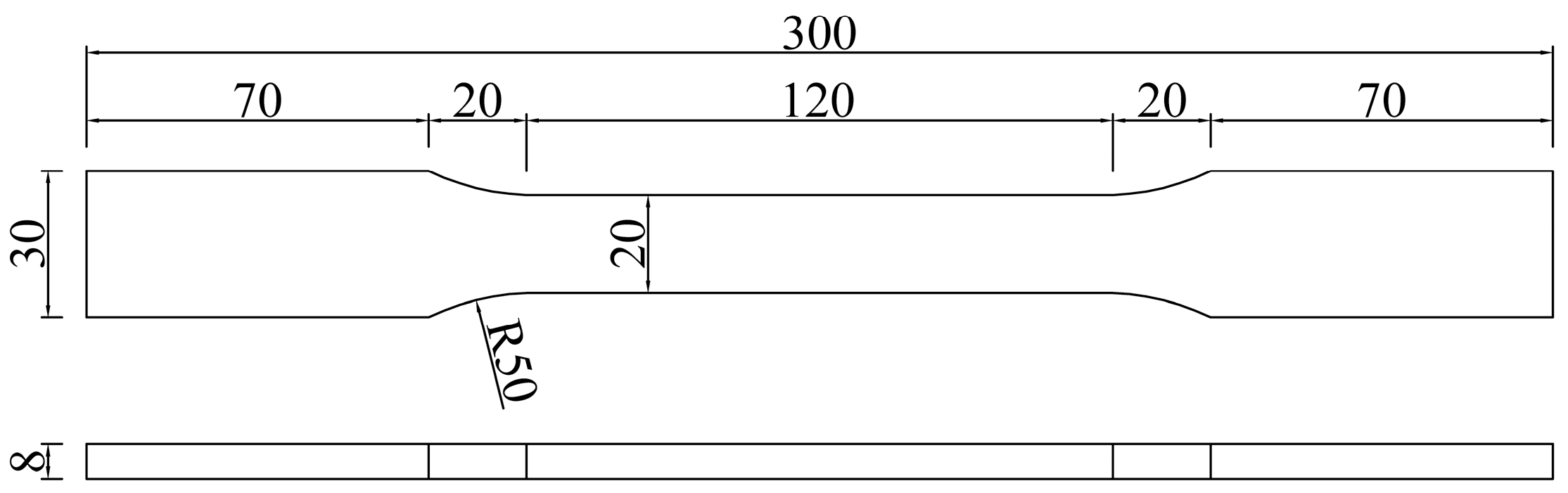

2.3. Mechanical Tests

3. Results

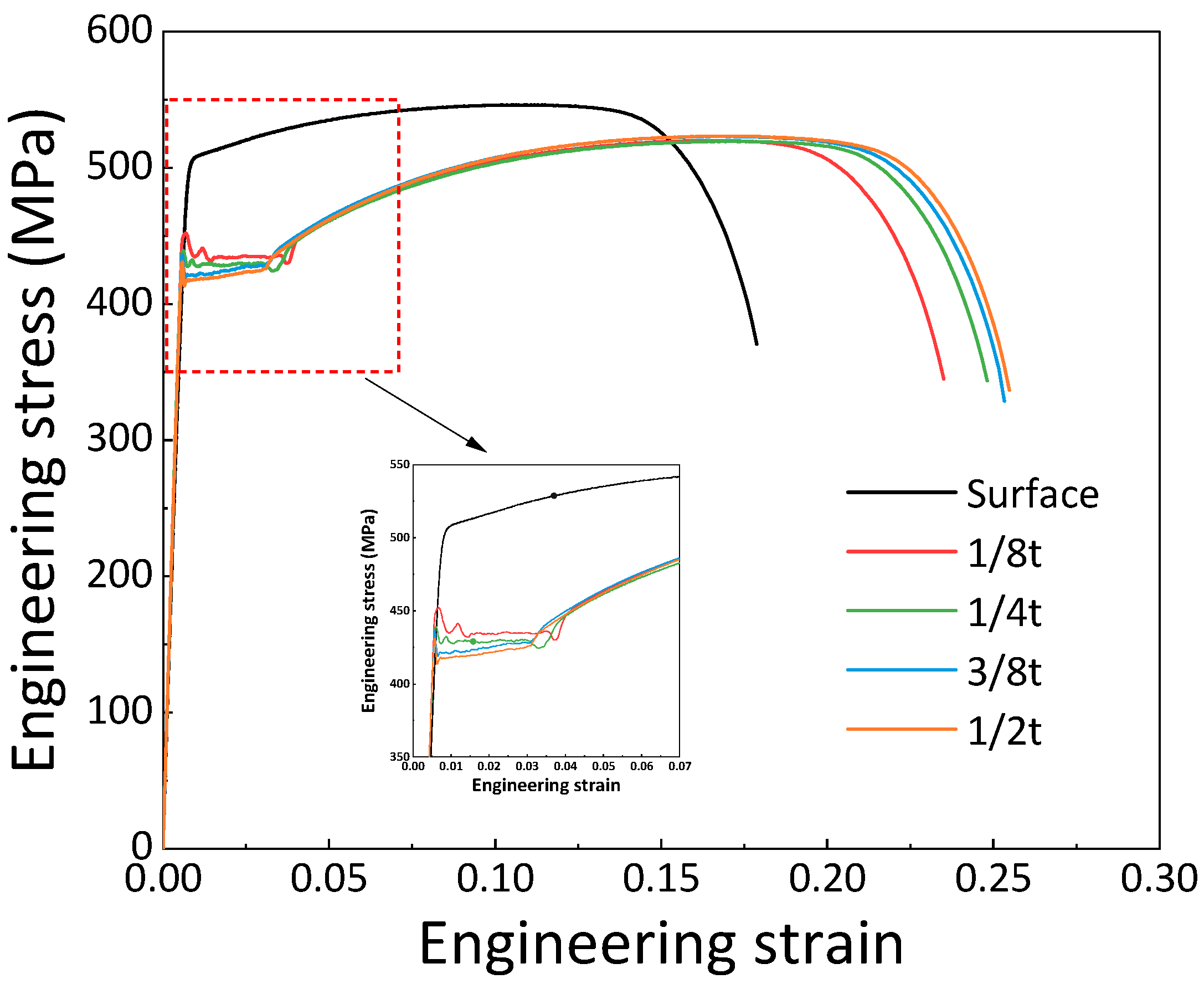

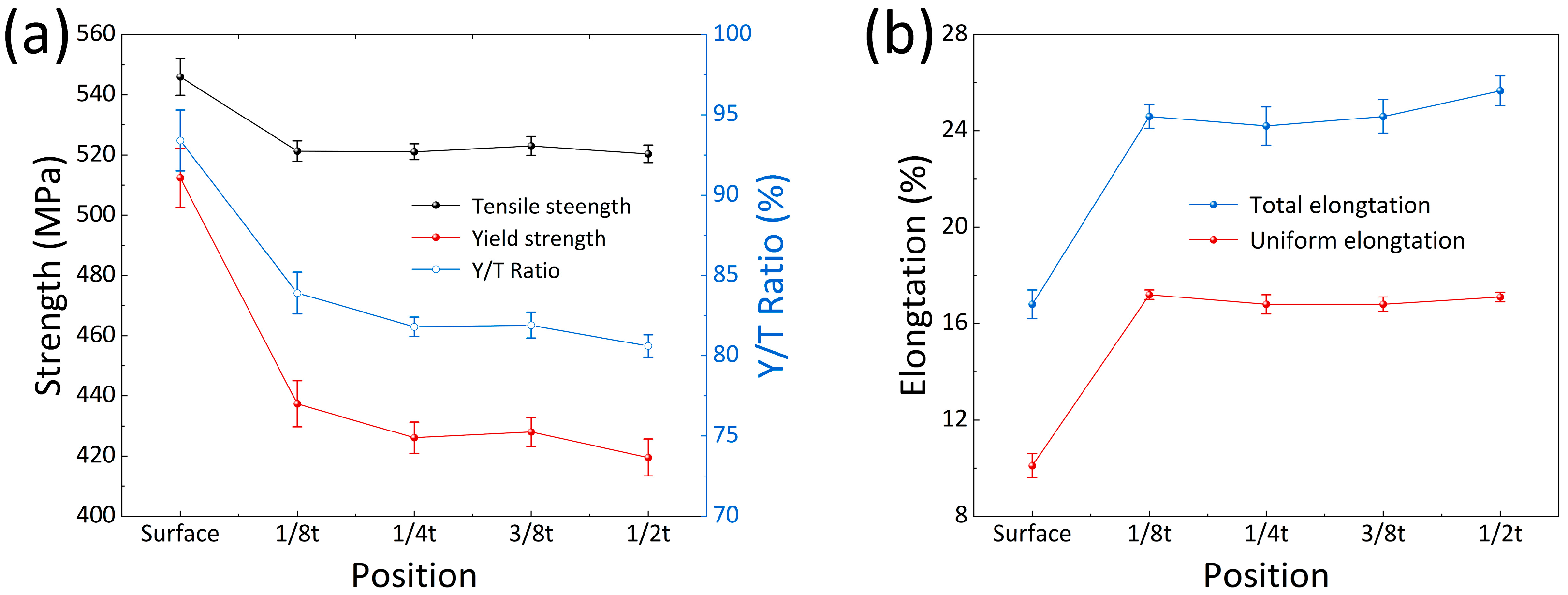

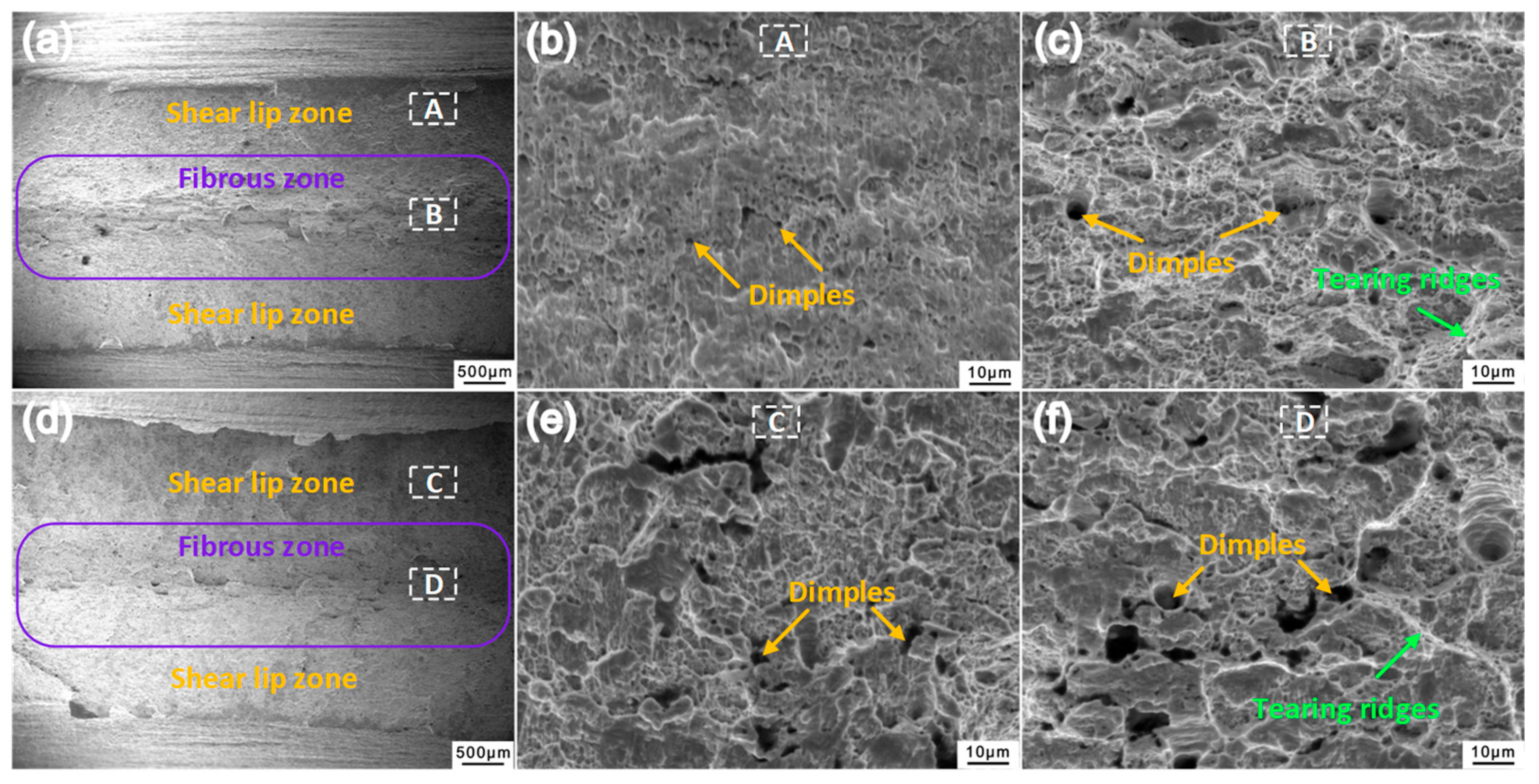

3.1. Tensile Properties

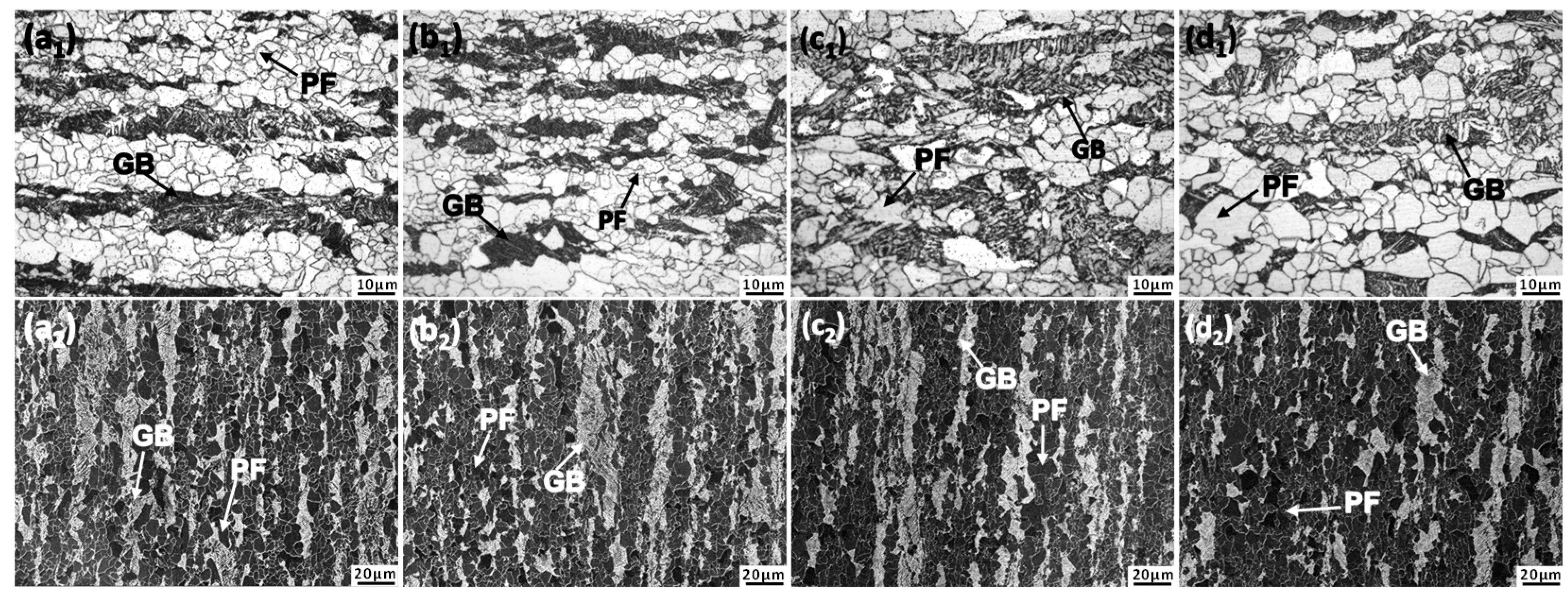

3.2. Microstructures

4. Discussion

4.1. Microscopic Mechanism of Yielding Behavior

4.1.1. Microscopic Mechanism of Discontinuous Yielding in Core Regions

4.1.2. Microscopic Mechanism of Continuous Yielding in Surface Layer

4.2. Microstructure Evolution at Different Thickness Positions

4.3. Strengthening Mechanism Analysis

5. Conclusions

- (1)

- The TMCP-processed thick steel plate exhibited continuous yielding at the surface layer, while the 1/8t–1/2t region displayed discontinuous yielding, whicn was characterized by a distinct yield drop and Lüders strain in the curve.

- (2)

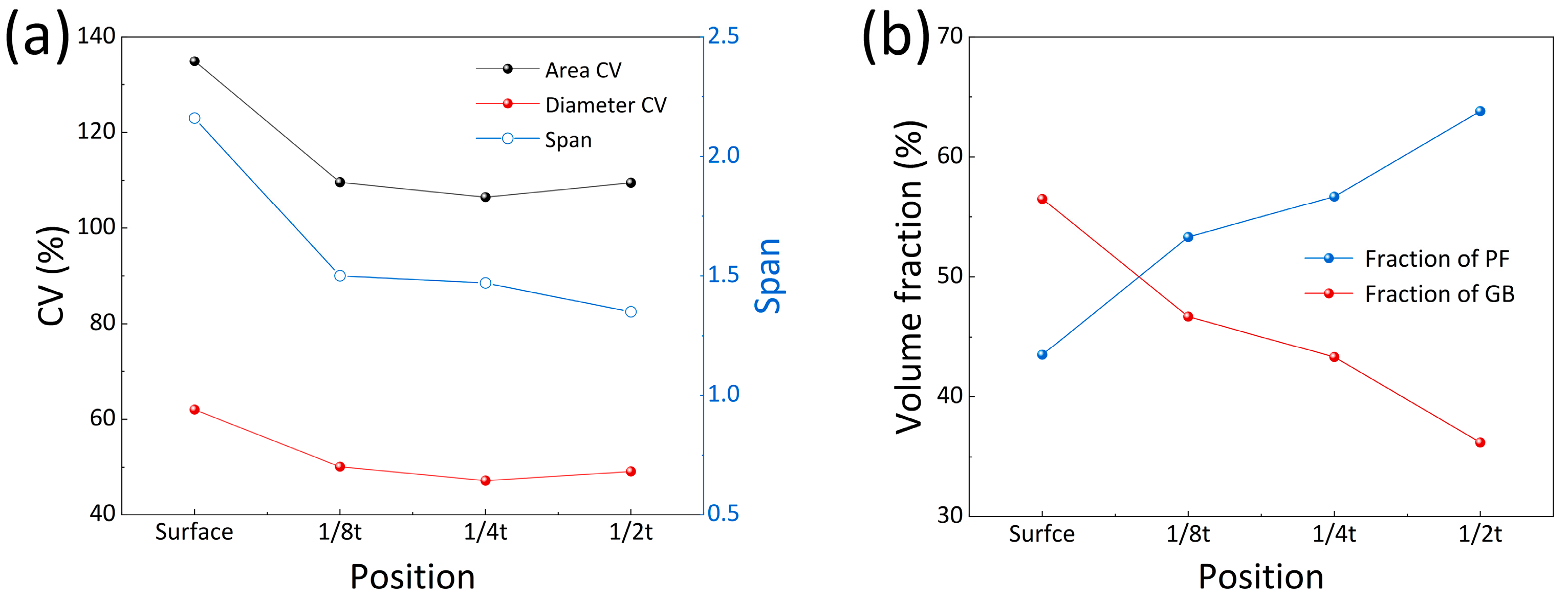

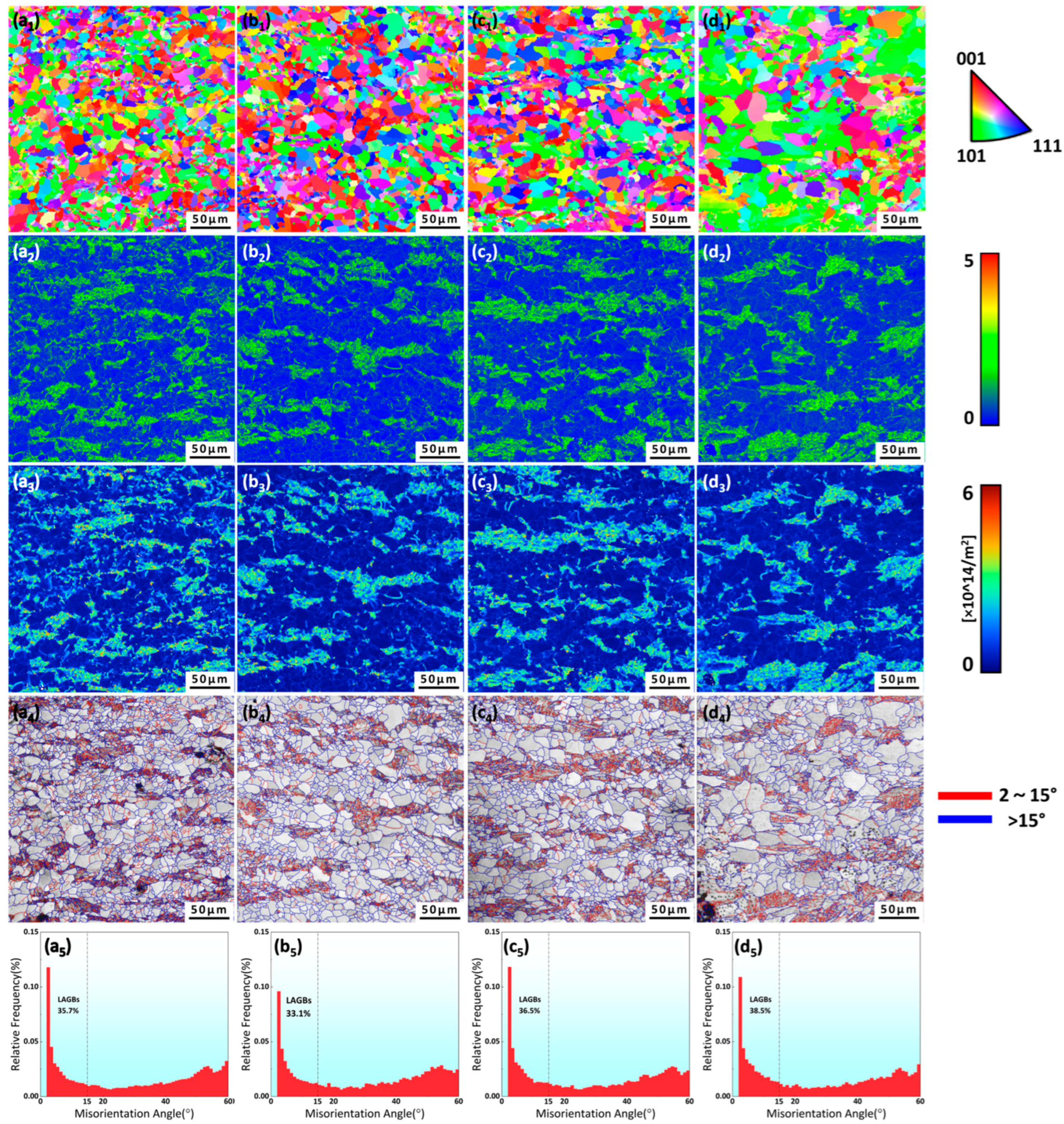

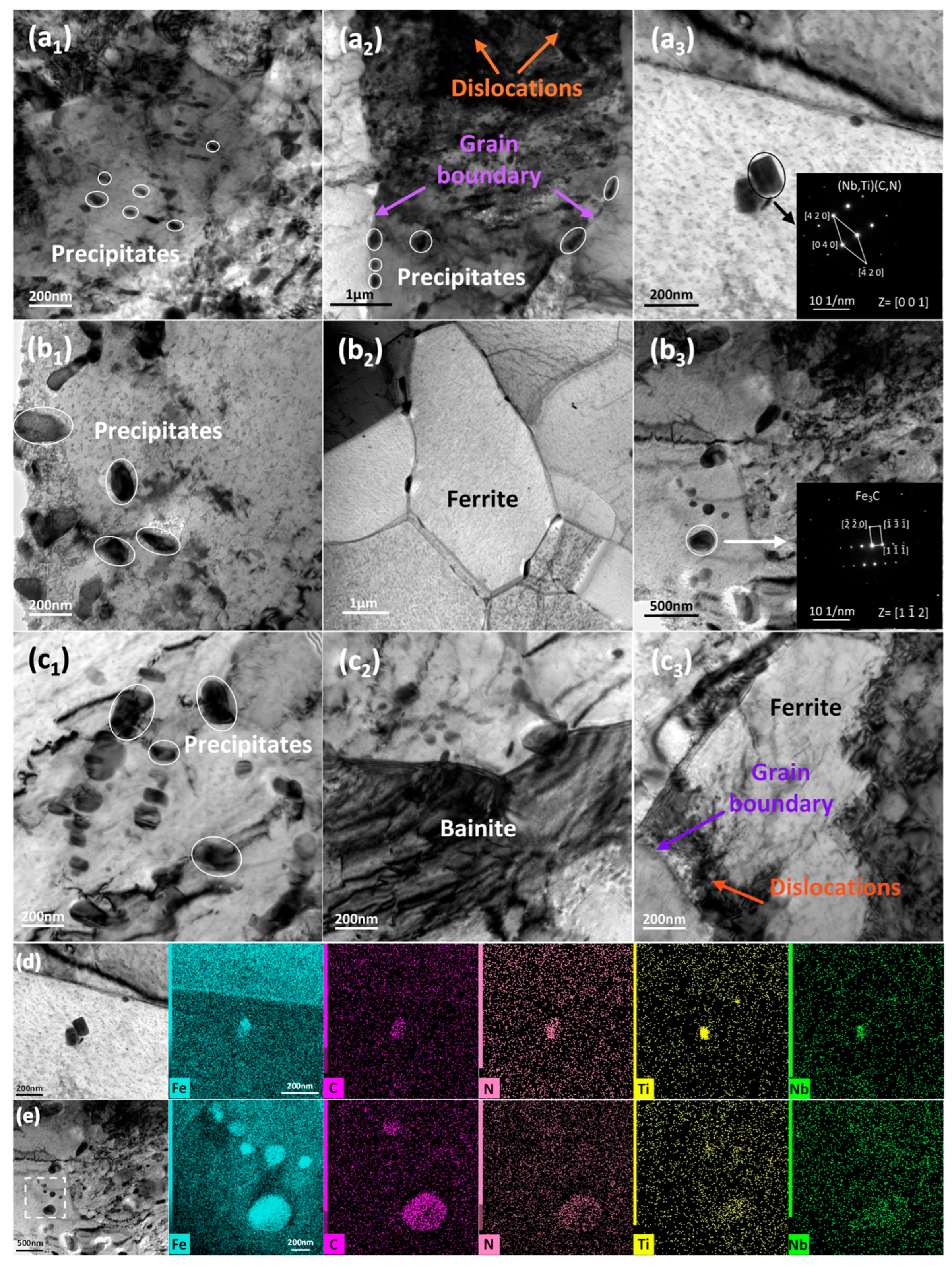

- The average grain size progressively increased progressively from 6.86 μm at the surface to 11.57 μm at the 1/2t position. The surface layer contained ultrafine particles and showed greater heterogeneity in grain size distribution. Precipitates were identified as two types: Fe3C cementite and (Nb, Ti) (C, N) complex carbonitrides.

- (3)

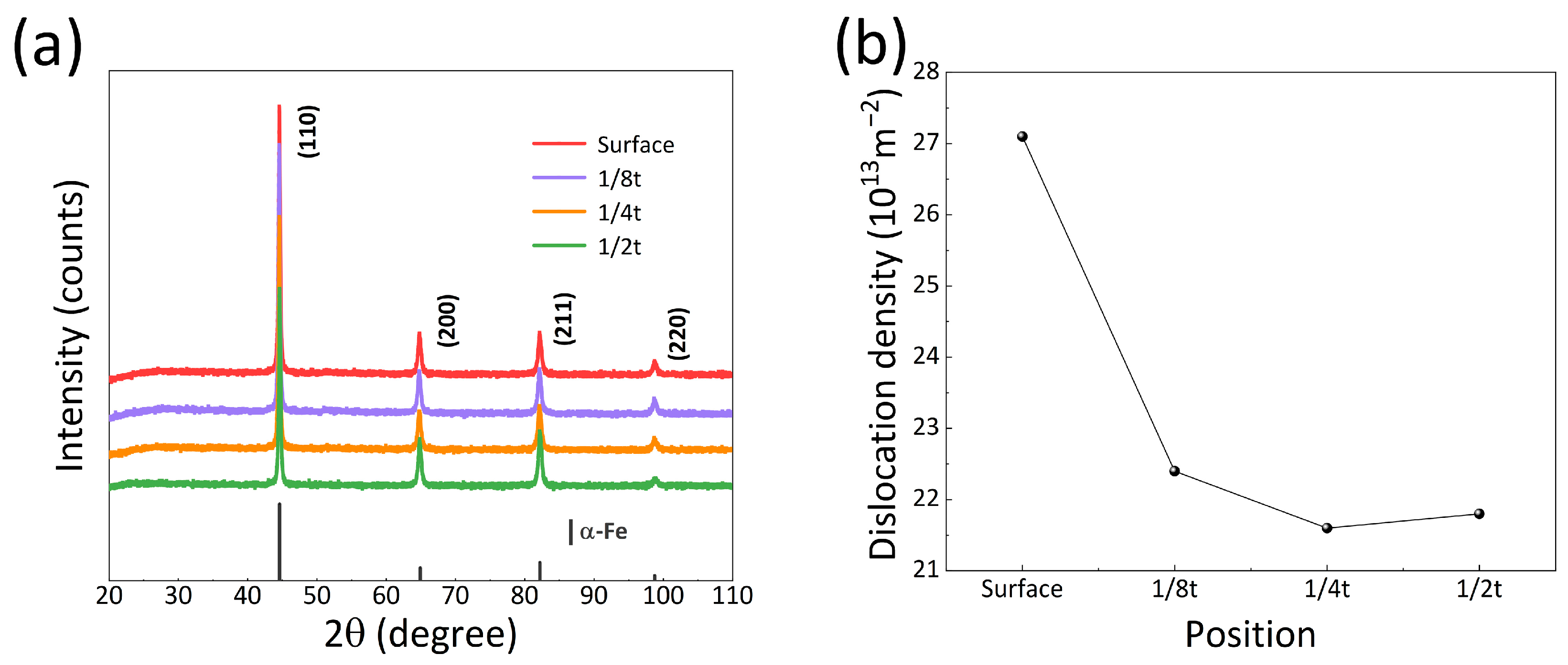

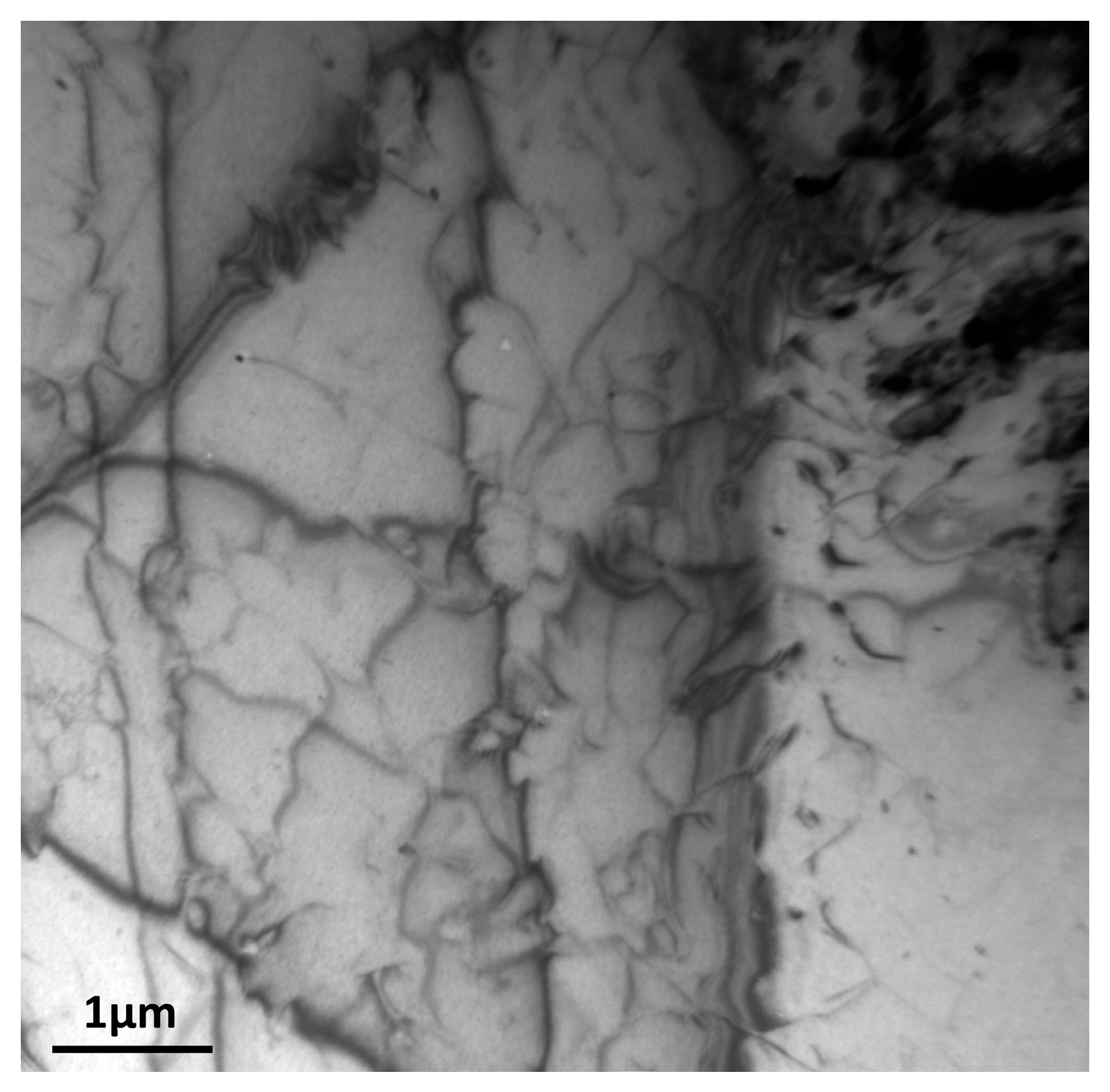

- The continuous yielding at the surface was mainly due to its higher initial dislocation density (27.1 × 1013 m−2), which suppressed dislocation unpinning and promoted homogeneous deformation. In contrast, discontinuous yielding in the core region resulted from the dislocation pinning–unpinning under lower dislocation densities (~21.8 × 1013 m−2). Grain refinement and microstructural heterogeneity further stabilized the continuous yielding at the surface.

- (4)

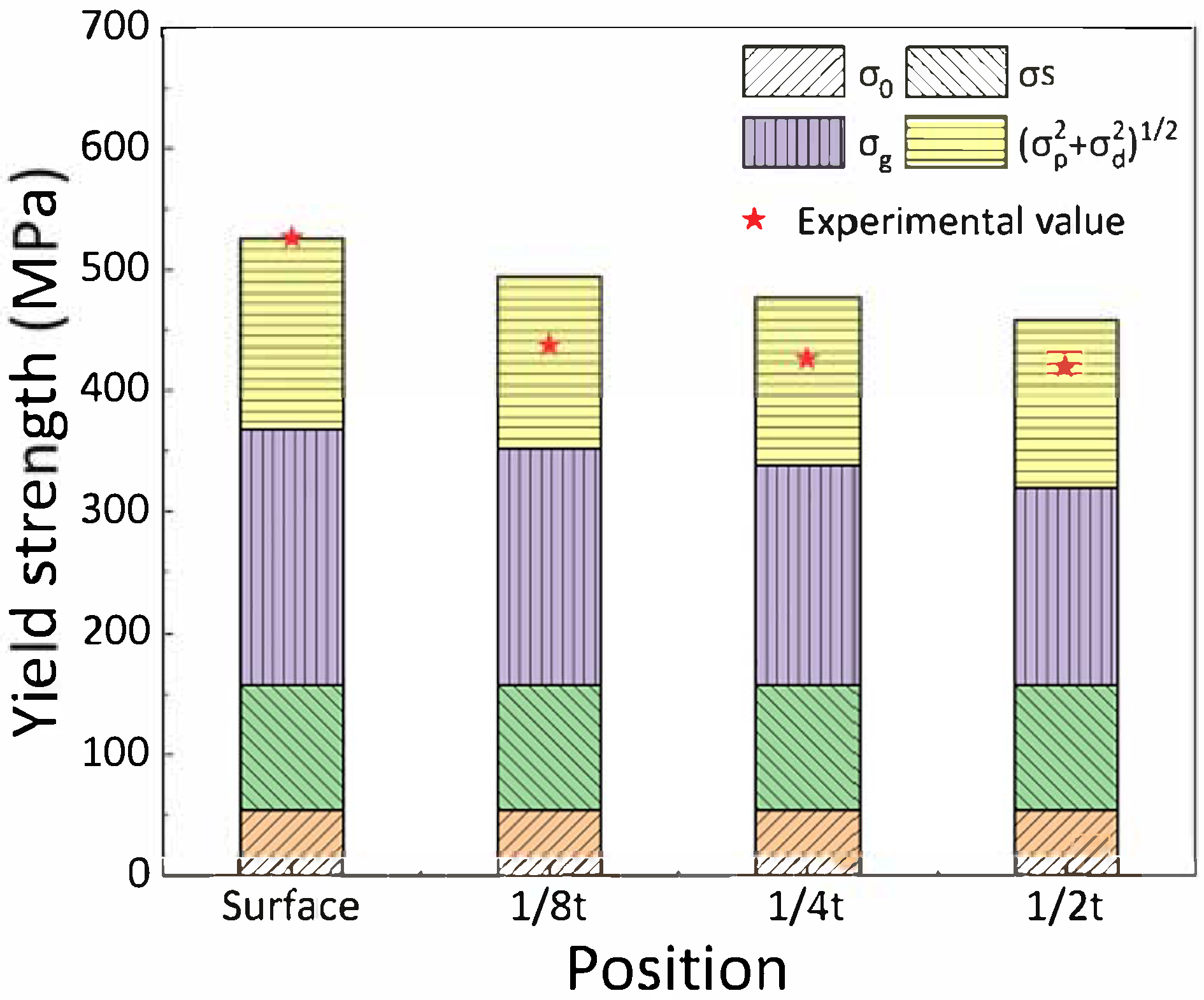

- The thick steel plate displayed gradual decreases in both the yield strength and tensile strength from the surface to the 1/2t position, and most of the strength drop occurs between the surface and 1/8t. Grain refinement strengthening played a major role and varied significantly across thicknesses. Therefore, alloy design and processing should prioritize austenite grain conditioning during rolling and transformation control to obtain a fine, uniform microstructure throughout the thickness.

- (5)

- The cooling rate gradient strongly influenced the resultant microstructure. Improving property uniformity in thick plates requires precise cooling control. To alleviate discontinuous yielding and strength loss in the core, TMCP strategies should aim to increase the cooling rate or apply interrupted cooling for microstructural refinement.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qin, X.; Huang, X.; Li, Y.; Kaewunruen, S. Sustainable design framework for enhancing shear capacity in beams using recycled steel fiber-reinforced high-strength concrete. Construct. Build. Mater. 2024, 411, 134509. [Google Scholar] [CrossRef]

- Karmakar, A.; Biswas, S.; Mukherjee, S.; Chakrabarti, D.; Kumar, V. Effect of composition and thermo-mechanical processing schedule on the microstructure, precipitation and strengthening of Nb-microalloyed steel. Mater. Sci. Eng. A 2017, 690, 158–169. [Google Scholar] [CrossRef]

- Wang, J.; Sun, L.; Ma, H.; Cheng, X.; Li, X. Comparative study on mechanical and corrosion fatigue properties of high-strength bridge steels produced by TMCP and intercritical quenching & tempering process. Mater. Sci. Eng. A 2022, 853, 143771. [Google Scholar] [CrossRef]

- Sun, X.J.; Yuan, S.F.; Xie, Z.J.; Dong, L.L.; Shang, C.J.; Misra, R.D.K. Microstructure-property relationship in a high strength-high toughness combination ultra-heavy gauge offshore plate steel: The significance of multiphase microstructure. Mater. Sci. Eng. A 2017, 689, 212–219. [Google Scholar] [CrossRef]

- Kyada, T.; Shant, J.R.; Goyal, R.K.; Kathayat, T.S. Understanding the Delamination and Its Effect on Charpy Impact Energy in Thick Wall Linepipe Steel. J. Mater. Metall. Eng. 2014, 4, 31–39. [Google Scholar]

- Zhang, X.; Li, G.; Zhao, H.; Gao, J.; Wu, H.; Zhang, C.; Huang, Y.; Wu, G.; Wang, S.; Mao, X. Evolution of microstructure and mechanical properties along the thickness direction of 500 MPa HSLA steel heavy plates. Mater. Sci. Eng. A 2024, 913, 147097. [Google Scholar] [CrossRef]

- Cui, S.; Gu, G.; Shi, C.; Xiao, G.; Lu, Y. Variations in microstructure and mechanical properties along thickness direction in a heavy high strength low alloy steel plate. J. Mater. Res. Technol. 2023, 26, 9190–9202. [Google Scholar] [CrossRef]

- Li, Z.; Fu, L.; Fu, B.; Shan, A. Yield point elongation in fine-grained titanium. Mater. Lett. 2013, 96, 1–4. [Google Scholar] [CrossRef]

- Nakahigashi, J.; Takahata, K.; Tsuru, K.; Sumimoto, T.; Yoshimura, H.; Horimura, H. Ultra-fine grain refinement of titanium materials by hydrogen treatment. J. Jpn. Inst. Mater. 2006, 70, 204–211. [Google Scholar]

- Bayona-Carrillo, N.; Bozzolo, N.; Fundenberger, J.; Thomas, B.; Camelin, P.; Lenarduzzi, E.; Wagner, F. Effect of Recrystallization on Tensile Behavior, Texture, and Anisotropy of Ti-3Al-2.5V Cold Pilgered Tubes. Adv. Eng. Mater. 2011, 13, 383–387. [Google Scholar] [CrossRef]

- Tian, Y.Z.; Gao, S.; Zhao, L.J.; Lu, S.; Pippan, R.; Zhang, Z.F.; Tsuji, N. Remarkable transitions of yield behavior and Lüders deformation in pure Cu by changing grain sizes. Scr. Mater. 2018, 142, 88–91. [Google Scholar] [CrossRef]

- Shi, H.; Guo, X.; Li, J.; Mao, J.; Lu, W. The gradual disappearance of yield plateau in Zr–Sn–Nb–Fe–Mo alloy by the trace addition of Cr and V. Mater. Sci. Eng. A 2019, 760, 407–414. [Google Scholar] [CrossRef]

- Fan, Y.R.; Chen, R.; Yan, D.S.; Xue, X.Y.; Luo, T.; Li, J.S.; Lai, M.J. Discontinuous yielding behavior in the near-α Ti-3Al-2.5V alloy. Mater. Sci. Eng. A 2025, 923, 147701. [Google Scholar] [CrossRef]

- Zhang, Y.; Ding, H.; Zhu, H.; Zhou, X.; Zhang, Y.; Jia, N.; Zhang, N. Influence of microstructural morphology on the continuous/discontinuous yielding behavior in a medium manganese steel. Mater. Sci. Eng. A 2021, 824, 141746. [Google Scholar] [CrossRef]

- Shen, X.J.; Li, D.Z.; Tang, S.; Chen, J.; Fang, H.; Wang, G.D. Delamination toughening in a low carbon microalloyed steel plate rolled in the dual-phase region. Mater. Sci. Eng. A 2019, 766, 138342. [Google Scholar] [CrossRef]

- Zhang, C.; Zhou, X.; Chu, X.; Shi, Z.; Zhang, C.; Luo, J. Fractal of tensile fracture morphology of 5083 aluminum alloy sheet and its relationship with tensile properties. Eng. Fail. Anal. 2024, 165, 108819. [Google Scholar] [CrossRef]

- Qin, W.; Li, J.; Liu, Y.; Kang, J.; Zhu, L.; Shu, D.; Peng, P.; She, D.; Meng, D.; Li, Y. Effects of grain size on tensile property and fracture morphology of 316L stainless steel. Mater. Lett. 2019, 254, 116–119. [Google Scholar] [CrossRef]

- Xiong, L.; You, Z.S.; Qu, S.D.; Lu, L. Fracture behavior of heterogeneous nanostructured 316L austenitic stainless steel with nanotwin bundles. Acta Mater. 2018, 150, 130–138. [Google Scholar] [CrossRef]

- Peng, S.Y.; Tian, Y.Z.; Ni, Z.Y.; Lu, S.; Li, S. Effect of grain size on the deformation mechanism and fracture behavior of a non-equiatomic CoCrNi alloy with low stacking fault energy. Int. J. Plast. 2024, 182, 104129. [Google Scholar] [CrossRef]

- Xiao, J.; Yan, L.; Zhang, P.; Li, G.; BLi Zhao, T.; Wang, H.; Chen, L.; Wang, D. Effects of minor Ce doping on the microstructure and mechanical performances of a EH47 grade HSLA steel for ship and ocean engineering. Mater. Char. 2023, 201, 112931. [Google Scholar] [CrossRef]

- He, S.H.; He, B.B.; Zhu, K.Y.; Huang, M.X. Evolution of dislocation density in bainitic steel: Modeling and experiments. Acta Mater. 2018, 149, 46–56. [Google Scholar] [CrossRef]

- Kishor, R.; Sahu, L.; Dutta, K.; Mondal, A. Assessment of dislocation density in asymmetrically cyclic loaded non-conventional stainless steel using X-ray diffraction profile analysis. Mater. Sci. Eng. A 2014, 598, 299–303. [Google Scholar] [CrossRef]

- Ungár, T.; Ott, S.; Sanders, P.; Borbély, A.; Weertman, J. Weertman, Dislocations, grain size and planar faults in nanostructured copper determined by high resolution X-ray diffraction and a new procedure of peak profile analysis. Acta Mater. 1998, 46, 3693–3699. [Google Scholar] [CrossRef]

- Shintani, T.; Murata, Y. Evaluation of the dislocation density and dislocation character in cold rolled Type 304 steel determined by profile analysis of X-ray diffraction. Acta Mater. 2011, 59, 4314–4322. [Google Scholar] [CrossRef]

- Jannat, M.R.; Biswas, B.; Rahman, L.; Ahmed, F.; Hossain, J.; Khanam, J.; Sharmin, N. Validity of crystallite size determination methods based on XRD peak broadening in pure and metal-doped nickel ferrites. Results Mater. 2025, 28, 100762. [Google Scholar] [CrossRef]

- Ribárik, G.; Ungár, T. Characterization of the microstructure in random and textured polycrystals and single crystals by diffraction line profile analysis. Mater. Sci. Eng. A 2010, 528, 112–121. [Google Scholar] [CrossRef]

- Ungár, T. Dislocation densities, arrangements and character from X-ray diffraction experiments. Mater. Sci. Eng. A 2001, 309, 14–22. [Google Scholar] [CrossRef]

- Kan, L.; Ye, Q.; Wang, Z.; Zhao, T. Improvement of strength and toughness of 1 GPa Cu-bearing HSLA steel by direct quenching. Mater. Sci. Eng. A 2022, 855, 143875. [Google Scholar] [CrossRef]

- Ungár, T.; Dragomir, I.; Révész, Á.; Borbély, A. The contrast factors of dislocations in cubic crystals: The dislocation model of strain anisotropy in practice. J. Appl. Cryst. 1999, 32, 992–1002. [Google Scholar] [CrossRef]

- Cottrell, A.H.; Bilby, B.A. Dislocation Theory of Yielding and Strain Ageing of Iron. Proc. Phys. Soc. Lond. Sect. A 1949, 62, 49–62. [Google Scholar] [CrossRef]

- Schoeck, G.; Seeger, A. The flow stress of iron and its dependence on impurities. Acta Metall. 1959, 7, 469–477. [Google Scholar] [CrossRef]

- Hahn, G. A model for yielding with special reference to the yield-point phenomena of iron and related bcc metals. Acta Metall. 1962, 10, 727–738. [Google Scholar] [CrossRef]

- Johnston, W.G.; Gilman, J.J. Dislocation Velocities, Dislocation Densities, and Plastic Flow in Lithium Fluoride Crystals. J. Appl. Phys. 1959, 30, 129–144. [Google Scholar] [CrossRef]

- Shi, J.; Huang, C.; Deng, S.; Tan, Z.; Lu, H.; Hao, J.; Shen, F.; Jia, Y.; Chen, J.; Wang, Q.; et al. In-situ neutron diffraction study of the strengthening mechanism and deformation behavior of cellular structure in high-entropy alloys by additive manufacturing. Int. J. Plast. 2024, 181, 104081. [Google Scholar] [CrossRef]

- Yuzbekova, D.; Mogucheva, A.; Zhemchuzhnikova, D.; Lebedkina, T.; Lebyodkin, M.; Kaibyshev, R. Effect of microstructure on continuous propagation of the Portevin–Le Chatelier deformation bands. Int. J. Plast. 2017, 96, 210–226. [Google Scholar] [CrossRef]

- Singh, P.P.; Mula, S.; Ghosh, S. Grain refinement, strain hardening and fracture in thermomechanically processed ultra-strong microalloyed steel. Mater. Today Commun. 2024, 38, 107582. [Google Scholar] [CrossRef]

- Shi, X.; Cao, Z.; Fan, Z.; Guo, R.; Qiao, J. Probing into the yield plateau phenomenon in commercially pure titanium during tensile tests. Acta Metall. Sin. 2020, 34, 701–709. [Google Scholar] [CrossRef]

- Hall, E.O. Variation of Hardness of Metals with Grain Size. Nature 1954, 173, 948–949. [Google Scholar] [CrossRef]

- Xiong, W.; Song, R.; Huo, W.; Yu, P.; Qin, S.; Liu, Z. Microstructure characteristics and impact fracture mechanisms of Nb and V–Ti micro-alloyed offshore platform steels. Vacuum 2022, 195, 110709. [Google Scholar] [CrossRef]

- Shi, G.; Zhao, H.; Zhang, S.; Wang, Q.; Zhang, F. Microstructural characteristics and impact fracture behaviors of low-carbon vanadium-microalloyed steel with different nitrogen contents. Mater. Sci. Eng. A 2020, 769, 138501. [Google Scholar] [CrossRef]

- Lan, L.; Qiu, C.; Zhao, D.; Gao, X.; Du, L. Microstructural characteristics and toughness of the simulated coarse grained heat affected zone of high strength low carbon bainitic steel. Mater. Sci. Eng. A 2011, 529, 192–200. [Google Scholar] [CrossRef]

- Zhao, W.; Chen, M.; Chen, S.; Qu, J. Static strain aging behavior of an X100 pipeline steel. Mater. Sci. Eng. A 2012, 550, 418–422. [Google Scholar] [CrossRef]

- Jung, J.; Park, J.; Kim, J.; Lee, Y. Carbide precipitation kinetics in austenite of a Nb–Ti–V microalloyed steel. Mater. Sci. Eng. A 2011, 528, 5529–5535. [Google Scholar] [CrossRef]

- Gao, G.; Gao, B.; Gui, X.; Hu, J.; He, J.; Tan, Z.; Bai, B. Correlation between microstructure and yield strength of as-quenched and Q&P steels with different carbon content (0.06–0.42 wt%C). Mater. Sci. Eng. A 2019, 753, 1–10. [Google Scholar]

- Liu, G.; Li, Y.; Liao, T.; Wang, S.; Lv, B.; Guo, H.; Huang, Y.; Yong, Q.; Mao, X. Revealing the precipitation kinetics and strengthening mechanisms of a 450 MPa grade Nb-bearing HSLA steel. Mater. Sci. Eng. A 2023, 884, 145506. [Google Scholar] [CrossRef]

- Yen, H.-W.; Chen, P.-Y.; Huang, C.-Y.; Yang, J.-R. Interphase precipitation of nanometer-sized carbides in a titanium –molybdenum-bearing low-carbon steel. Acta Mater. 2011, 59, 6264–6274. [Google Scholar] [CrossRef]

- Singh, N.; Casillas, G.; Wexler, D.; Killmore, C.; Pereloma, E. Application of advanced experimental techniques to elucidate the strengthening mechanisms operating in microalloyed ferritic steels with interphase precipitation. Acta Mater. 2020, 201, 386–402. [Google Scholar] [CrossRef]

- Iza-Mendia, A.; Gutiérrez, I. Generalization of the existing relations between microstructure and yield stress from ferrite–pearlite to high strength steels. Mater. Sci. Eng. A 2013, 561, 40–51. [Google Scholar] [CrossRef]

- Funakawa, Y.; Shiozaki, T.; Tomita, K.; Yamamoto, T.; Maeda, E. Development of high strength hot-rolled sheet steel consisting of ferrite and nanometer-sized carbides. ISIJ Int. 2004, 44, 1945–1951. [Google Scholar] [CrossRef]

- Shen, Y.; Wang, C.; Sun, X. A micro-alloyed ferritic steel strengthened by nanoscale precipitates. Mater. Sci. Eng. A 2011, 528, 8150–8156. [Google Scholar] [CrossRef]

- Soto, R.; Saikaly, W.; Bano, X.; Issartel, C.; Rigaut, G.; Charai, A. Statistical and theoretical analysis of precipitates in dual-phase steels microalloyed with titanium and their effect on mechanical properties. Acta Mater. 1999, 47, 3475–3481. [Google Scholar] [CrossRef]

- Yong, Q.L. Secondary Phases in Steels; Press of Metallurgy Industry: Beijing, China, 2006; p. 47. (In Chinese) [Google Scholar]

- Taylor, K. Solubility products for titanium-, vanadium-, and niobium-carbide in ferrite. Scr. Metall. Mater. 1995, 32, 7–12. [Google Scholar] [CrossRef]

| C | Si | Mn | Nb | V | Ti | Cr | Ni | Co | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.18 | 0.55 | 1.8 | 0.06 | 0.14 | 0.06 | 0.35 | 0.85 | 0.6 | 0.0027 | Bal. |

| Position | Surface | 1/8t | 1/4t | 3/8t | 1/2t |

|---|---|---|---|---|---|

| RP0.2 & YS (MPa) | 512.4 ± 9.8 | 437.4 ± 7.6 | 426.1 ± 5.2 | 428.0 ± 4.8 | 419.5 ± 6.1 |

| TS (MPa) | 545.9 ± 6.1 | 521.3 ± 3.4 | 521.1 ± 2.6 | 523.0 ± 3.1 | 520.4 ± 2.9 |

| Y/T Ratio (%) | 93.4 ± 1.9 | 83.9 ± 1.3 | 81.8 ± 0.6 | 81.9 ± 0.8 | 80.6 ± 0.7 |

| UE (%) | 10.1 ± 0.5 | 17.2 ± 0.2 | 16.8 ± 0.4 | 16.8 ± 0.3 | 17.1 ± 0.2 |

| TE (%) | 16.8 ± 0.6 | 24.6 ± 0.5 | 24.2 ± 0.8 | 24.6 ± 0.7 | 25.8 ± 0.4 |

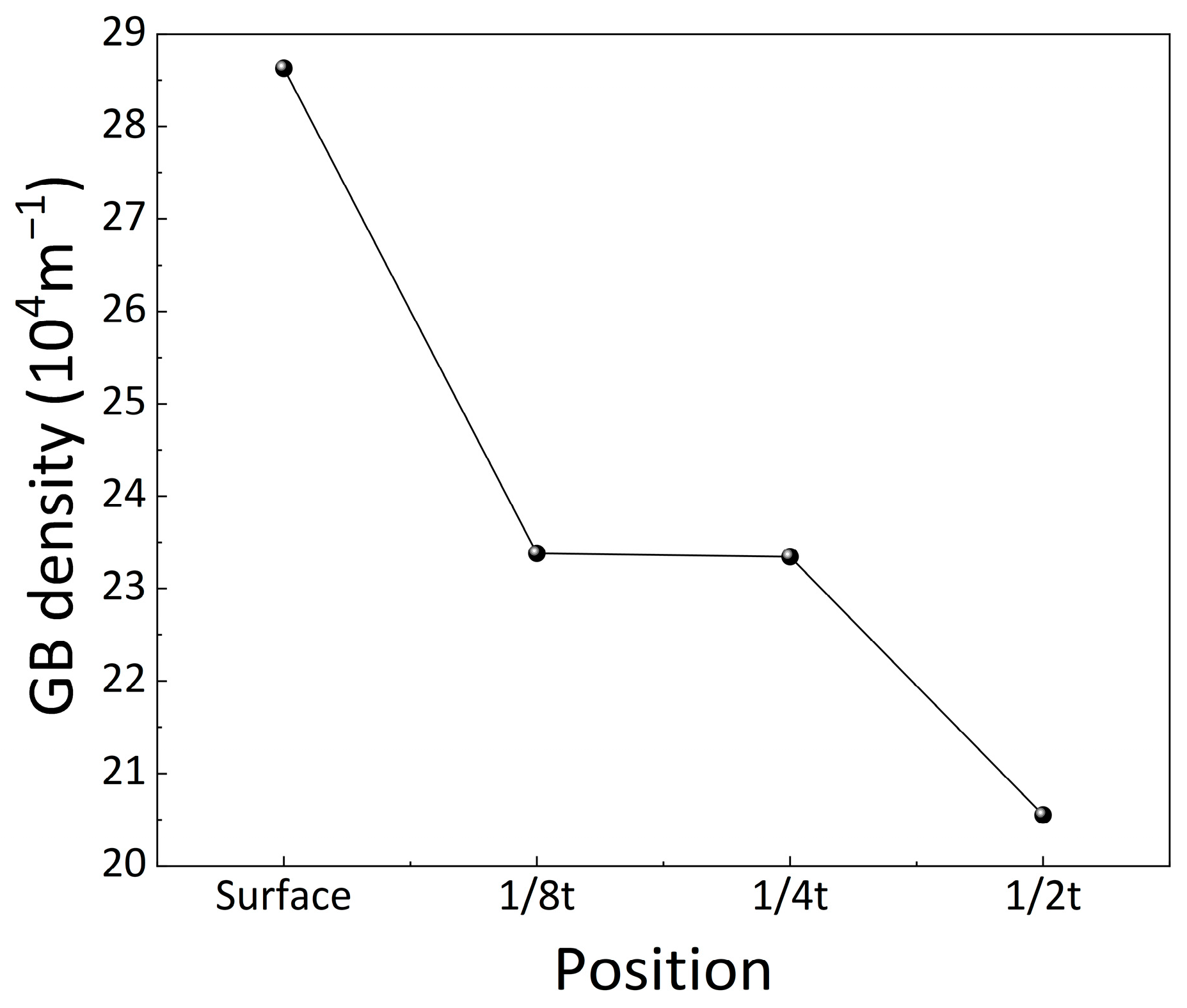

| Position | Surface | 1/8t | 1/4t | 1/2t |

|---|---|---|---|---|

| A (104 μm2) | 9 | 9 | 9 | 9 |

| LA (μm) | 40,457.3 | 33,020.1 | 32,985.0 | 29,037.5 |

| SV (104 m−1) | 28.63 | 23.38 | 23.34 | 20.55 |

| Position | σ0/MPa | σg/MPa | σd/MPa | σp/MPa | σs/MPa | σy/MPa |

|---|---|---|---|---|---|---|

| Surface | 54 | 210.1 | 146.6 | 58.9 | 103.5 | 525.6 |

| 1/8t | 54 | 194.3 | 133.3 | 49.6 | 103.5 | 494.0 |

| 1/4t | 54 | 180.4 | 130.9 | 46.3 | 103.5 | 476.7 |

| 1/2t | 54 | 161.8 | 131.5 | 44.2 | 103.5 | 458.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, C.; Lu, W.; Su, H.; Zhu, M. Differences in Yield Behavior in the Thickness Direction of TMCP-Processed HSLA Thick Steel Plates and the Evolution of Microstructure Property Gradients. Metals 2025, 15, 1229. https://doi.org/10.3390/met15111229

Qu C, Lu W, Su H, Zhu M. Differences in Yield Behavior in the Thickness Direction of TMCP-Processed HSLA Thick Steel Plates and the Evolution of Microstructure Property Gradients. Metals. 2025; 15(11):1229. https://doi.org/10.3390/met15111229

Chicago/Turabian StyleQu, Chuxiao, Wenliang Lu, Han Su, and Mengqi Zhu. 2025. "Differences in Yield Behavior in the Thickness Direction of TMCP-Processed HSLA Thick Steel Plates and the Evolution of Microstructure Property Gradients" Metals 15, no. 11: 1229. https://doi.org/10.3390/met15111229

APA StyleQu, C., Lu, W., Su, H., & Zhu, M. (2025). Differences in Yield Behavior in the Thickness Direction of TMCP-Processed HSLA Thick Steel Plates and the Evolution of Microstructure Property Gradients. Metals, 15(11), 1229. https://doi.org/10.3390/met15111229