Influence of LPBF Parameters and Post-Annealing Temperature on Martensitic Transformation and Superelasticity of Ni-Rich Ni51.9Ti48.1 Alloy

Abstract

1. Introduction

2. Fabrication and Experimental Procedure

2.1. Powder

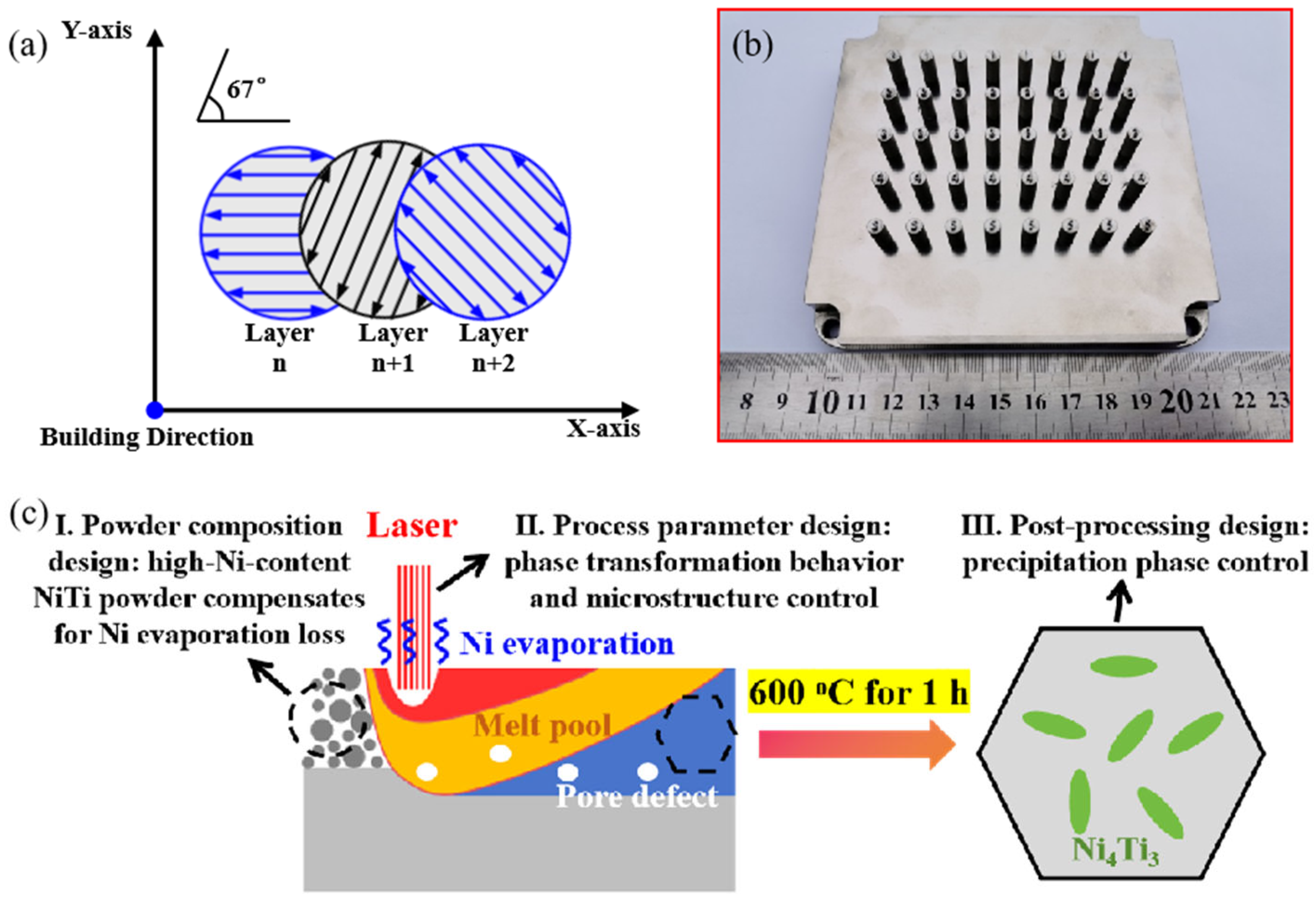

2.2. Fabrication Process

2.3. Property and Microstructure Characterization

3. Results

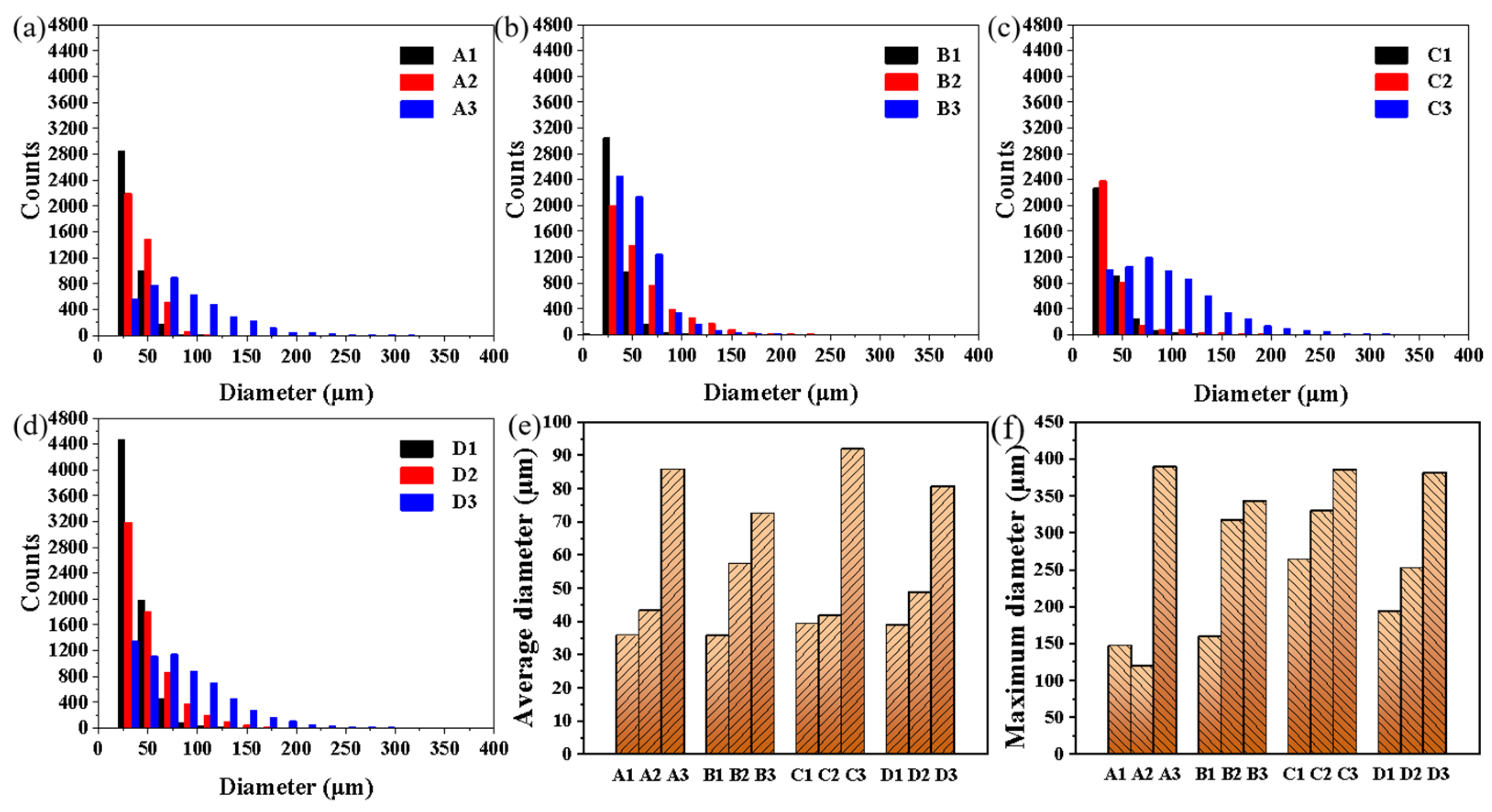

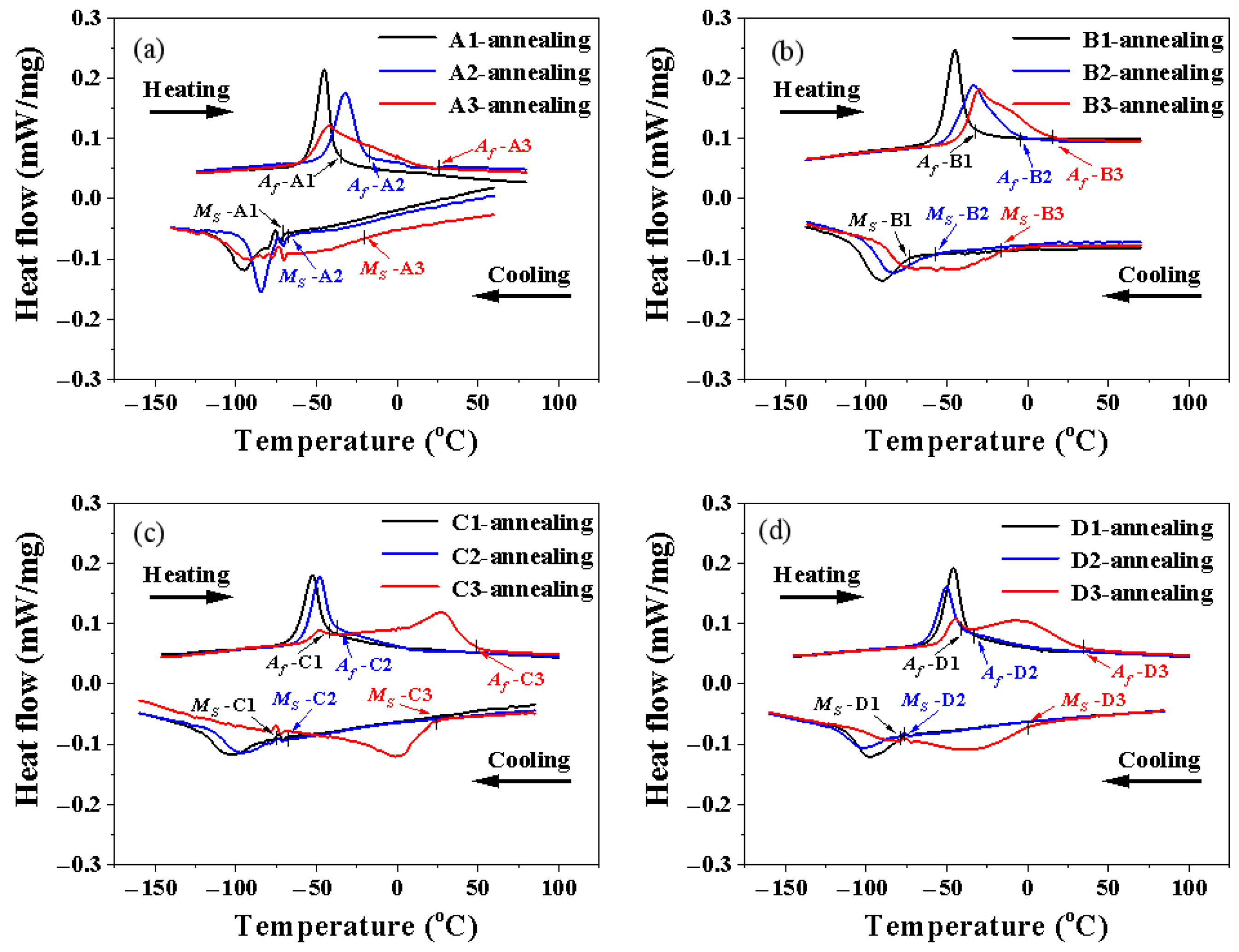

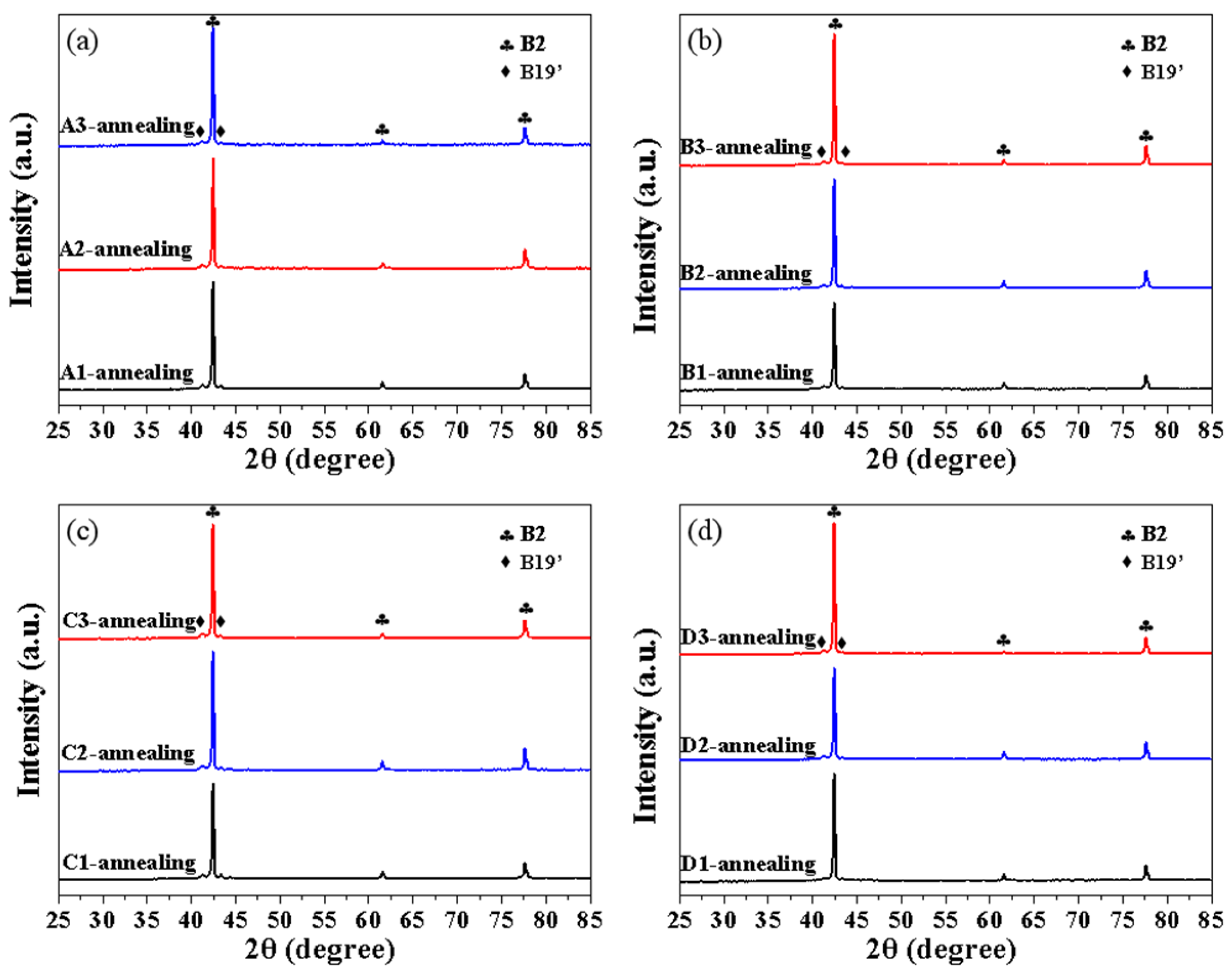

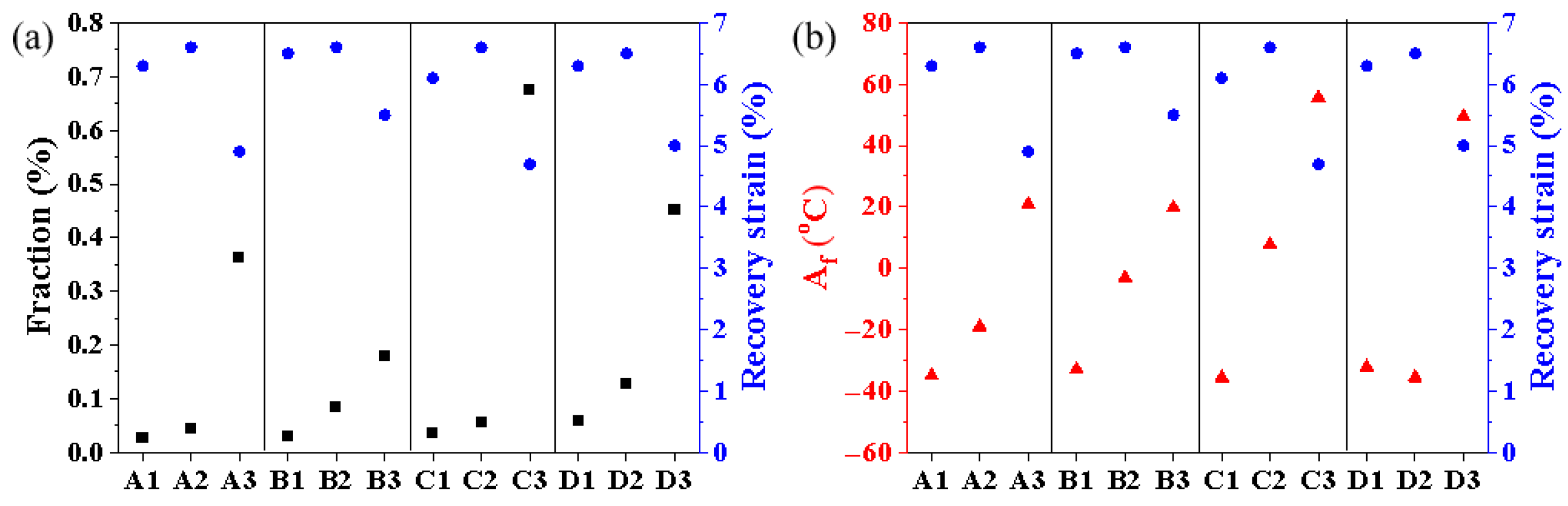

3.1. Defect and Martensitic Transformation Behavior

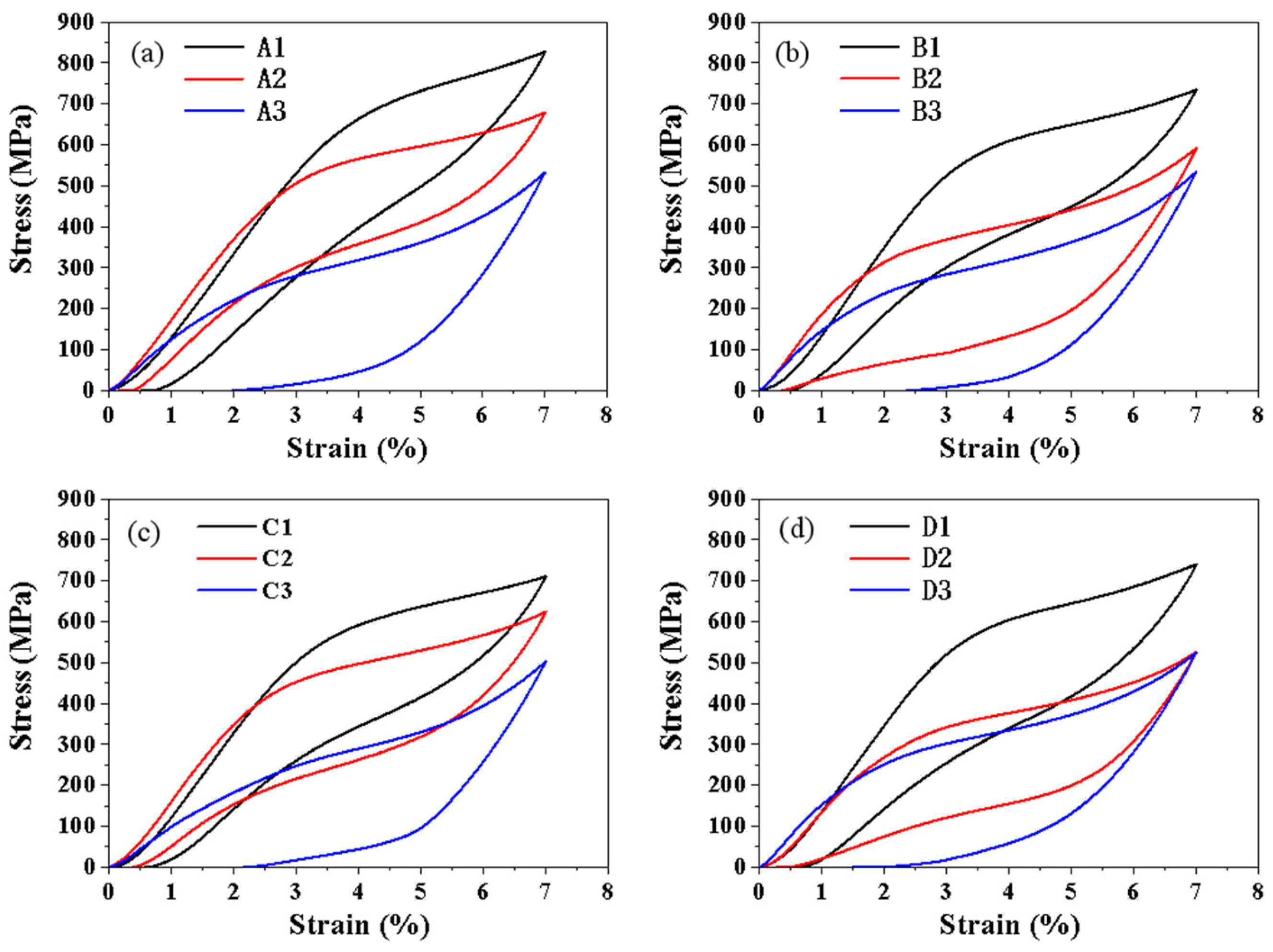

3.2. Hardness and Superelasticity

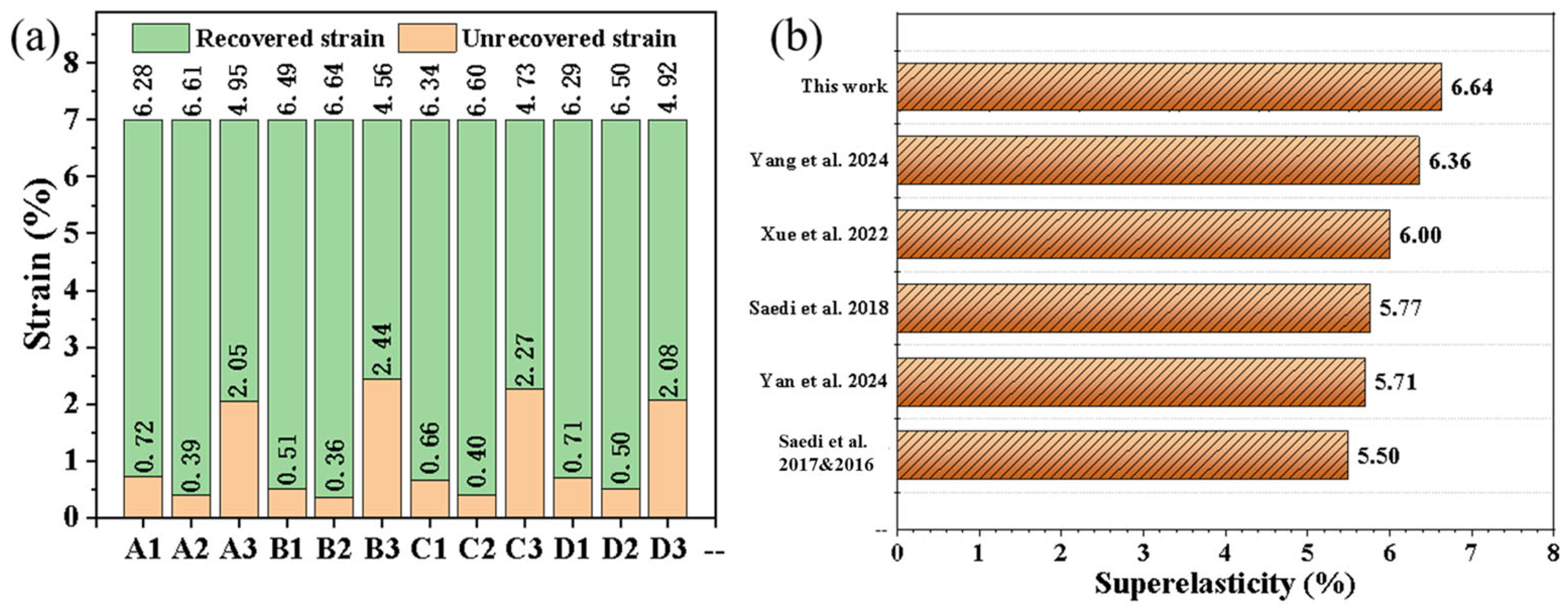

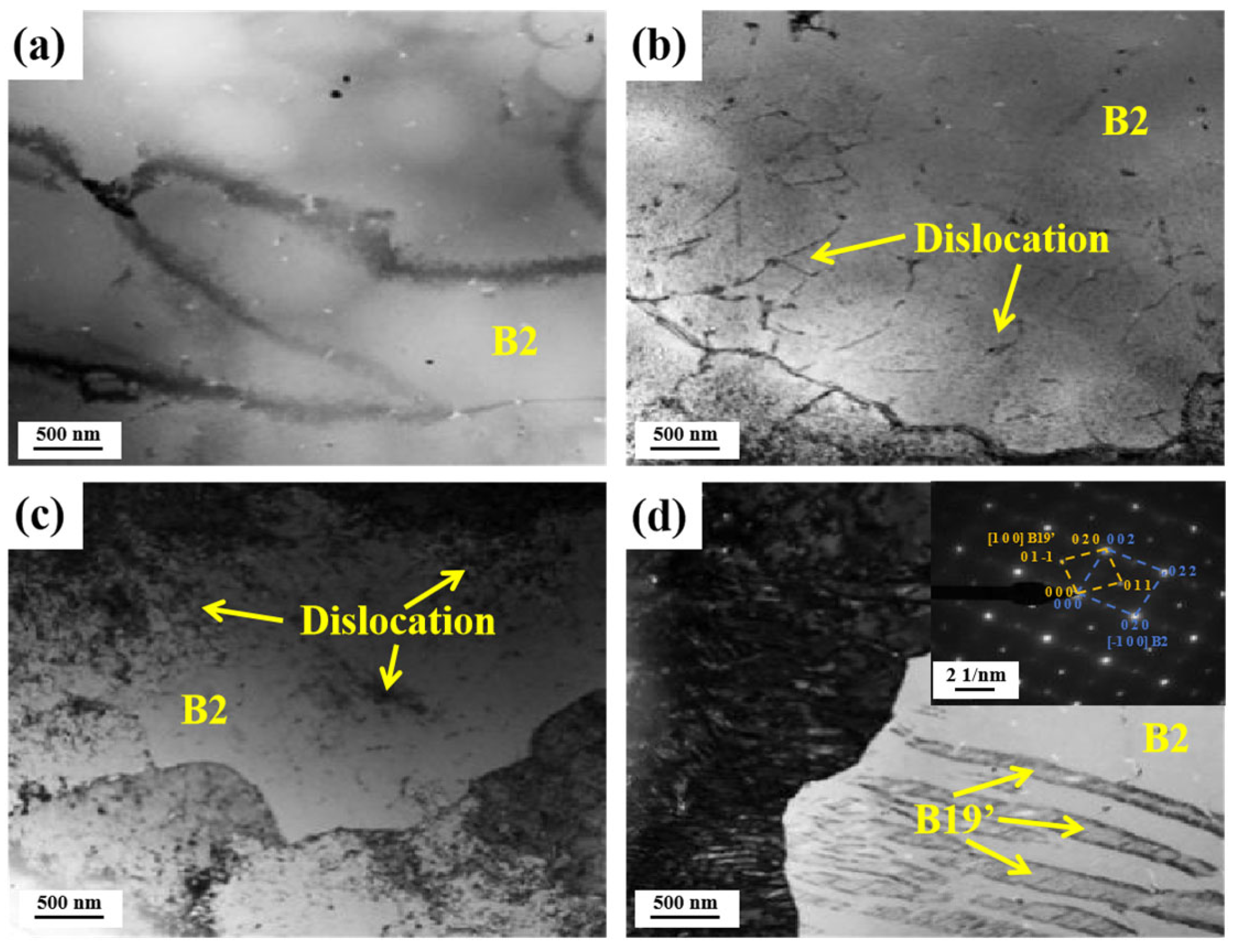

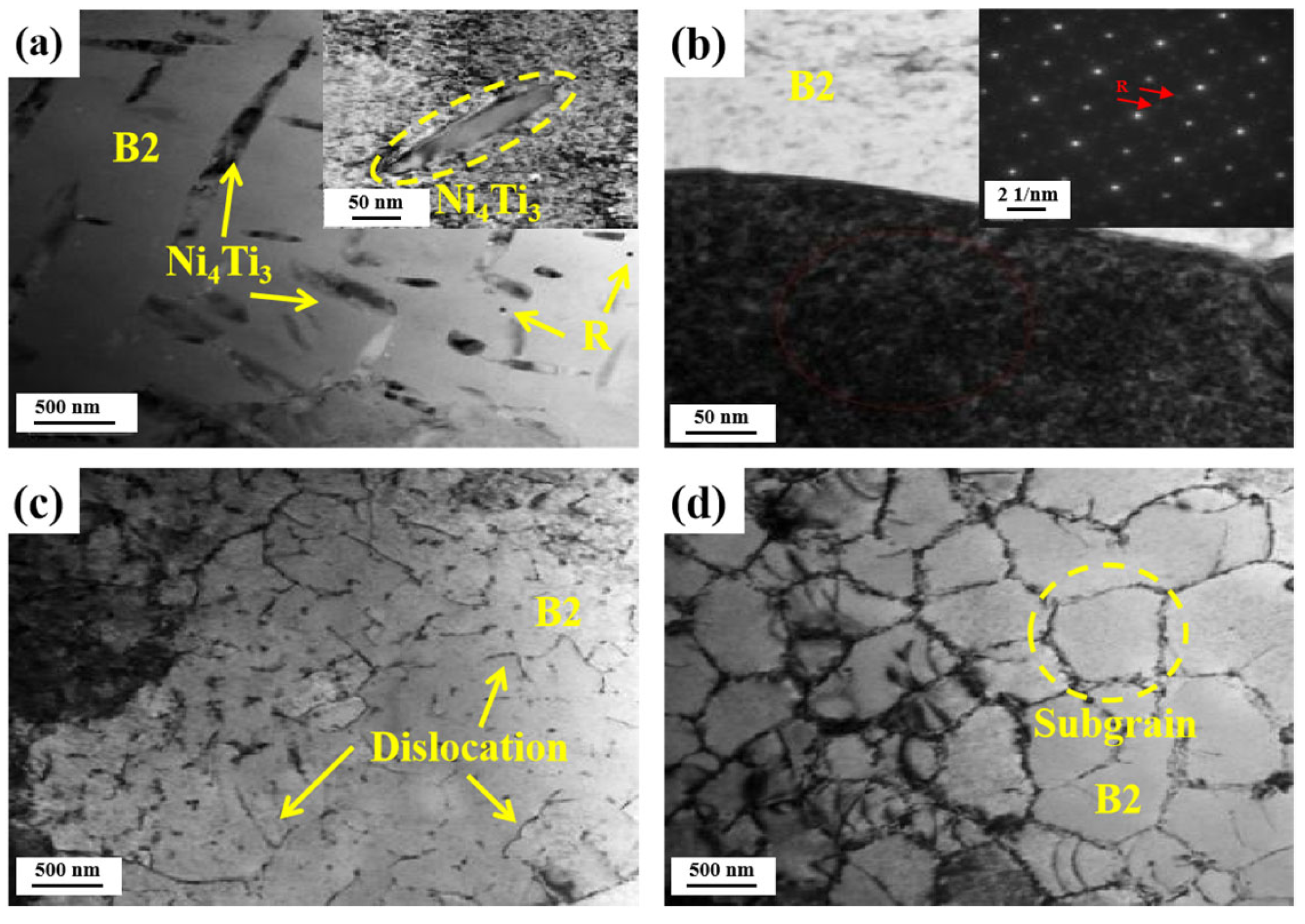

3.3. Microstructure

4. Discussion

4.1. Effects of Laser Parameters and Annealing on Martensitic Transformation Behavior

4.2. Factors Influencing Recovery Strain

5. Conclusions

- (1)

- As energy density increases, the number and volume of pore defects in the LPBFed Ni51.9Ti48.1 alloy increase, the phase transition temperature rises, and the hardness decreases. After annealing at 600 °C, the phase transition temperature of the LPBFed Ni51.9Ti48.1 alloy decreases, the thermal hysteresis increases, and the hardness improves.

- (2)

- The Ni51.9Ti48.1 alloy prepared at lower energy density exhibits relatively fewer dislocations and forms Ni4Ti3 precipitates and R-phase after annealing. The Ni51.9Ti48.1 alloy prepared at higher energy density contains more dislocations, which aggregate to form subgrains after annealing.

- (3)

- Due to a large number of pore defects, a high phase transformation temperature, and the formation of subgrains after annealing, the Ni51.9Ti48.1 alloy prepared using high energy density exhibits deteriorated superelastic properties, with a recovery strain after compression of less than 5%.

- (4)

- The Ni51.9Ti48.1 alloy prepared at a lower energy density exhibits a high matrix Ni content. After annealing, it forms Ni4Ti3 precipitates and R-phase, demonstrating outstanding superelastic properties with a recovery strain of up to 6.64% after compression.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Biesiekierski, A.; Wang, J.; Abdel-Hady Gepreel, M.; Wen, C. A new look at biomedical Ti-based shape memory alloys. Acta Biomater. 2012, 8, 1661–1669. [Google Scholar] [CrossRef]

- Mohd Jani, J.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Zhang, Y.; Attarilar, S.; Wang, L.; Lu, W.; Yang, J.; Fu, Y. A Review on Design and Mechanical Properties of Additively Manufactured NiTi Implants for Orthopedic Applications. Int. J. Bioprinting 2024, 7, 340. [Google Scholar] [CrossRef]

- Safaei, K.; Abedi, H.; Nematollahi, M.; Kordizadeh, F.; Dabbaghi, H.; Bayati, P.; Javanbakht, R.; Jahadakbar, A.; Elahinia, M.; Poorganji, B. Additive Manufacturing of NiTi Shape Memory Alloy for Biomedical Applications: Review of the LPBF Process Ecosystem. JOM 2021, 73, 3771–3786. [Google Scholar] [CrossRef]

- Gangil, N.; Siddiquee, A.N.; Maheshwari, S. Towards applications, processing and advancements in shape memory alloy and its composites. J. Manuf. Process. 2020, 59, 205–222. [Google Scholar] [CrossRef]

- Dash, B.; Das, M.; Das, M.; Mahapatra, T.R.; Mishra, D. A Concise Review on Machinability of NiTi Shape Memory Alloys. Mater. Today Proc. 2019, 18, 5141–5150. [Google Scholar] [CrossRef]

- Wei, S.; Zhang, J.; Zhang, L.; Zhang, Y.; Song, B.; Wang, X.; Fan, J.; Liu, Q.; Shi, Y. Laser powder bed fusion additive manufacturing of NiTi shape memory alloys: A review. Int. J. Extrem. Manuf. 2023, 5, 032001. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Masood, S.H.; Xu, W. Nickel-titanium shape memory alloys made by selective laser melting: A review on process optimisation. Adv. Manuf. 2022, 10, 24–58. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Speirs, M.; Van Humbeeck, J.; Kruth, J.-P. Laser additive manufacturing of bulk and porous shape-memory NiTi alloys: From processes to potential biomedical applications. MRS Bull. 2016, 41, 765–774. [Google Scholar] [CrossRef]

- Farber, E.; Zhu, J.-N.; Popovich, A.; Popovich, V. A review of NiTi shape memory alloy as a smart material produced by additive manufacturing. Mater. Today Proc. 2020, 30, 761–767. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Frenzel, J.; Wieczorek, A.; Opahle, I.; Maaß, B.; Drautz, R.; Eggeler, G. On the effect of alloy composition on martensite start temperatures and latent heats in Ni–Ti-based shape memory alloys. Acta Mater. 2015, 90, 213–231. [Google Scholar] [CrossRef]

- Lu, H.Z.; Ma, H.W.; Cai, W.S.; Luo, X.; Qu, S.G.; Wang, J.; Lupoi, R.; Yin, S.; Yang, C. Altered phase transformation behaviors and enhanced bending shape memory property of NiTi shape memory alloy via selective laser melting. J. Mater. Process. Technol. 2022, 303, 117546. [Google Scholar] [CrossRef]

- Ranaiefar, M.; Honarmandi, P.; Xue, L.; Zhang, C.; Elwany, A.; Karaman, I.; Schwalbach, E.J.; Arroyave, R. A differential evaporation model to predict chemistry change of additively manufactured metals. Mater. Des. 2022, 213, 110328. [Google Scholar] [CrossRef]

- Wang, X.; Yu, J.; Liu, J.; Chen, L.; Yang, Q.; Wei, H.; Sun, J.; Wang, Z.; Zhang, Z.; Zhao, G.; et al. Effect of process parameters on the phase transformation behavior and tensile properties of NiTi shape memory alloys fabricated by selective laser melting. Addit. Manuf. 2020, 36, 101545. [Google Scholar] [CrossRef]

- Tan, C.; Li, S.; Essa, K.; Jamshidi, P.; Zhou, K.; Ma, W.; Attallah, M.M. Laser Powder Bed Fusion of Ti-rich TiNi lattice structures: Process optimisation, geometrical integrity, and phase transformations. Int. J. Mach. Tools Manuf. 2019, 141, 19–29. [Google Scholar] [CrossRef]

- Saedi, S.; Shayesteh Moghaddam, N.; Amerinatanzi, A.; Elahinia, M.; Karaca, H.E. On the effects of selective laser melting process parameters on microstructure and thermomechanical response of Ni-rich NiTi. Acta Mater. 2018, 144, 552–560. [Google Scholar] [CrossRef]

- Shen, F.L.; Li, H.Q.; Guo, H.; Guo, N.N.; Fang, X.Y. Effect of energy density on the superelastic property of Ni-rich NiTi alloy fabricated by laser powder bed fusion. Mater. Sci. Eng. A 2022, 854, 143874. [Google Scholar] [CrossRef]

- Xue, L.; Atli, K.C.; Zhang, C.; Hite, N.; Srivastava, A.; Leff, A.C.; Wilson, A.A.; Sharar, D.J.; Elwany, A.; Arroyave, R.; et al. Laser Powder Bed Fusion of Defect-Free NiTi Shape Memory Alloy Parts with Superior Tensile Superelasticity. Acta Mater. 2022, 229, 117781. [Google Scholar] [CrossRef]

- Yan, A.; Cai, W.S.; Li, H.Z.; Lu, H.Z.; Lin, J.M.; Wang, J.; Zhang, L.C.; Yang, C. Stable superelasticity with large recoverable strain in NiTi alloy via additive manufacturing. Mater. Sci. Eng. A 2024, 911, 146935. [Google Scholar] [CrossRef]

- Saedi, S.; Turabi, A.S.; Andani, M.T.; Moghaddam, N.S.; Elahinia, M.; Karaca, H.E. Texture, aging, and superelasticity of selective laser melting fabricated Ni-rich NiTi alloys. Mater. Sci. Eng. A 2017, 686, 1–10. [Google Scholar] [CrossRef]

- Saedi, S.; Turabi, A.S.; Taheri Andani, M.; Haberland, C.; Karaca, H.; Elahinia, M. The influence of heat treatment on the thermomechanical response of Ni-rich NiTi alloys manufactured by selective laser melting. J. Alloys Compd. 2016, 677, 204–210. [Google Scholar] [CrossRef]

- Safdel, A.; Zaker, N.; Botton, G.A.; Elbestawi, M.A. The role of texture and restoration mechanisms in defining the tension-compression asymmetry behavior of aged NiTi alloys fabricated by laser powder bed fusion. Mater. Sci. Eng. A 2023, 864, 144592. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Y.Q.; Lu, H.Z.; Luo, Y.; Long, T.H.; Tong, W.T.; Zhang, Y.; Yu, X.; Yang, C. Relationship between the superelasticity and strain field around Ni4Ti3 nano-precipitates in NiTi shape memory alloy via laser powder bed fusion. J. Manuf. Process. 2024, 127, 698–708. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Z.; Wang, S.; Xiang, Z.; Shen, X.; Huang, S.; Yang, Q. Mechanical and functional properties of HfH2-decorated NiTi shape memory alloy fabricated by laser powder-bed fusion. J. Alloys Compd. 2022, 913, 165296. [Google Scholar] [CrossRef]

- Jamshidi, P.; Panwisawas, C.; Langi, E.; Cox, S.C.; Feng, J.; Zhao, L.; Attallah, M.M. Development, characterisation, and modelling of processability of nitinol stents using laser powder bed fusion. J. Alloys Compd. 2022, 909, 164681. [Google Scholar] [CrossRef]

- Chen, W.; Yang, Q.; Huang, S.; Huang, S.; Kruzic, J.J.; Li, X. Laser power modulated microstructure evolution, phase transformation and mechanical properties in NiTi fabricated by laser powder bed fusion. J. Alloys Compd. 2021, 861, 157959. [Google Scholar] [CrossRef]

- Haberland, C.; Elahinia, M.; Walker, J.M.; Meier, H.; Frenzel, J. On the development of high quality NiTi shape memory and pseudoelastic parts by additive manufacturing. Smart Mater. Struct. 2014, 23, 104002. [Google Scholar] [CrossRef]

- Sequeda Leon, E.M.; Singamneni, S.; Guraya, T.; Chen, Z.W. Effect of laser power in laser powder bed fusion on Ni content and structure of Nitinol. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Xiang, Z.; Zhu, T.; Yang, Q.; Tang, J.; Shen, X.; Hao, S.; Zhang, J.; Chen, J.; Huang, S. Optimization of repetitive energy absorption properties of LPBF NiTi porous structures by compositional gradient design. Mater. Sci. Eng. A 2025, 946, 149148. [Google Scholar] [CrossRef]

- Lu, H.Z.; Liu, L.H.; Luo, X.; Ma, H.W.; Cai, W.S.; Lupoi, R.; Yin, S.; Yang, C. Formation mechanism of heterogeneous microstructures and shape memory effect in NiTi shape memory alloy fabricated via laser powder bed fusion. Mater. Des. 2023, 232, 112107. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, S.; Guo, Z.; Peng, G.; Wang, L.; Yan, W. Defects caused by powder spattering and entrainment in laser powder bed fusion process: High-fidelity modeling of gas, melt pool and powder dynamics. Acta Mater. 2025, 288, 120816. [Google Scholar] [CrossRef]

- Wang, L.; Guo, Z.; Peng, G.; Wu, S.; Zhang, Y.; Yan, W. Evaporation-Induced Composition Evolution in Metal Additive Manufacturing. Adv. Funct. Mater. 2024, 35, 2412071. [Google Scholar] [CrossRef]

- Tang, D.; Hu, Y.; Yang, L.; Yan, C.; Shi, Y. Melt Pool Simulation Technology of Laser Powder Bed Fusion: A Review. Jom 2024, 76, 4663–4682. [Google Scholar] [CrossRef]

- Cunningham, R.; Zhao, C.; Parab, N.; Kantzos, C.; Pauza, J.; Fezzaa, K.; Sun, T.; Rollett, A. Keyhole threshold and morphology in laser melting revealed by ultrahigh-speed x-ray imaging. Science 2019, 363, 849–852. [Google Scholar] [CrossRef]

- Zhao, C.; Guo, Q.; Li, X.; Parab, N.; Fezzaa, K.; Tan, W.; Chen, L.; Sun, T. Bulk-Explosion-Induced Metal Spattering During Laser Processing. Phys. Rev. X 2019, 9, 021052. [Google Scholar] [CrossRef]

- Lu, H.Z.; Ma, H.W.; Cai, W.S.; Luo, X.; Wang, Z.; Song, C.H.; Yin, S.; Yang, C. Stable tensile recovery strain induced by a Ni4Ti3 nanoprecipitate in a Ni50.4Ti49.6 shape memory alloy fabricated via selective laser melting. Acta Mater. 2021, 219, 117261. [Google Scholar] [CrossRef]

| Elements | Ni | Ti | Fe | C | O | N |

|---|---|---|---|---|---|---|

| at.% | 51.89 | Bal. | <0.01 | 0.003 | 0.050 | 0.003 |

| Sample | Laser Power P (W) | Scanning Speed v (mm/s) | Hatch Spacing h (mm) | Layer Thickness t (mm) | Energy Density E (J/mm3) |

|---|---|---|---|---|---|

| A1 | 190 | 700 | 0.05 | 0.03 | 180 |

| A2 | 190 | 600 | 0.05 | 0.03 | 211 |

| A3 | 190 | 500 | 0.05 | 0.03 | 253 |

| B1 | 170 | 600 | 0.05 | 0.03 | 188 |

| B2 | 170 | 500 | 0.05 | 0.03 | 226 |

| B3 | 170 | 450 | 0.05 | 0.03 | 252 |

| C1 | 150 | 550 | 0.05 | 0.03 | 181 |

| C2 | 150 | 500 | 0.05 | 0.03 | 200 |

| C3 | 150 | 400 | 0.05 | 0.03 | 250 |

| D1 | 130 | 500 | 0.05 | 0.03 | 173 |

| D2 | 130 | 400 | 0.05 | 0.03 | 217 |

| D3 | 130 | 350 | 0.05 | 0.03 | 248 |

| Sample | LPBF Fabrication | 600 °C Annealing | ||||

|---|---|---|---|---|---|---|

| Ms (°C) | Af (°C) | Δ(Af − Ms) (°C) | Ms (°C) | Af (°C) | Δ(Af − Ms) (°C) | |

| A1 | −2 | −10 | −8 | −72 | −36 | 36 |

| A2 | 12 | 17 | 5 | −73 | −20 | 53 |

| A3 | 17 | 43 | 26 | −12 | 19 | 31 |

| B1 | −6 | 9 | 15 | −73 | −33 | 40 |

| B2 | 0 | 15 | 15 | −58 | −6 | 52 |

| B3 | 22 | 45 | 23 | −16 | 15 | 31 |

| C1 | 5 | 22 | 17 | −75 | −43 | 32 |

| C2 | 8 | 23 | 15 | −65 | −40 | 25 |

| C3 | 15 | 40 | 25 | 25 | 48 | 23 |

| D1 | 6 | 28 | 22 | −77 | −35 | 32 |

| D2 | 6 | 29 | 23 | −75 | −41 | 34 |

| D3 | 23 | 50 | 27 | 0 | 30 | 30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiang, Z.; Yang, Q.; Zhang, S.; Zhang, T.; Xia, Z.; Huang, M.; Chen, J.; Huang, S. Influence of LPBF Parameters and Post-Annealing Temperature on Martensitic Transformation and Superelasticity of Ni-Rich Ni51.9Ti48.1 Alloy. Metals 2025, 15, 1180. https://doi.org/10.3390/met15111180

Xiang Z, Yang Q, Zhang S, Zhang T, Xia Z, Huang M, Chen J, Huang S. Influence of LPBF Parameters and Post-Annealing Temperature on Martensitic Transformation and Superelasticity of Ni-Rich Ni51.9Ti48.1 Alloy. Metals. 2025; 15(11):1180. https://doi.org/10.3390/met15111180

Chicago/Turabian StyleXiang, Zheng, Qin Yang, Shengwang Zhang, Tianhao Zhang, Zhihui Xia, Ming Huang, Jie Chen, and Shuke Huang. 2025. "Influence of LPBF Parameters and Post-Annealing Temperature on Martensitic Transformation and Superelasticity of Ni-Rich Ni51.9Ti48.1 Alloy" Metals 15, no. 11: 1180. https://doi.org/10.3390/met15111180

APA StyleXiang, Z., Yang, Q., Zhang, S., Zhang, T., Xia, Z., Huang, M., Chen, J., & Huang, S. (2025). Influence of LPBF Parameters and Post-Annealing Temperature on Martensitic Transformation and Superelasticity of Ni-Rich Ni51.9Ti48.1 Alloy. Metals, 15(11), 1180. https://doi.org/10.3390/met15111180