High-Temperature Tensile Properties in the Curved Continuous Casting of M2 High-Speed Steel

Abstract

1. Introduction

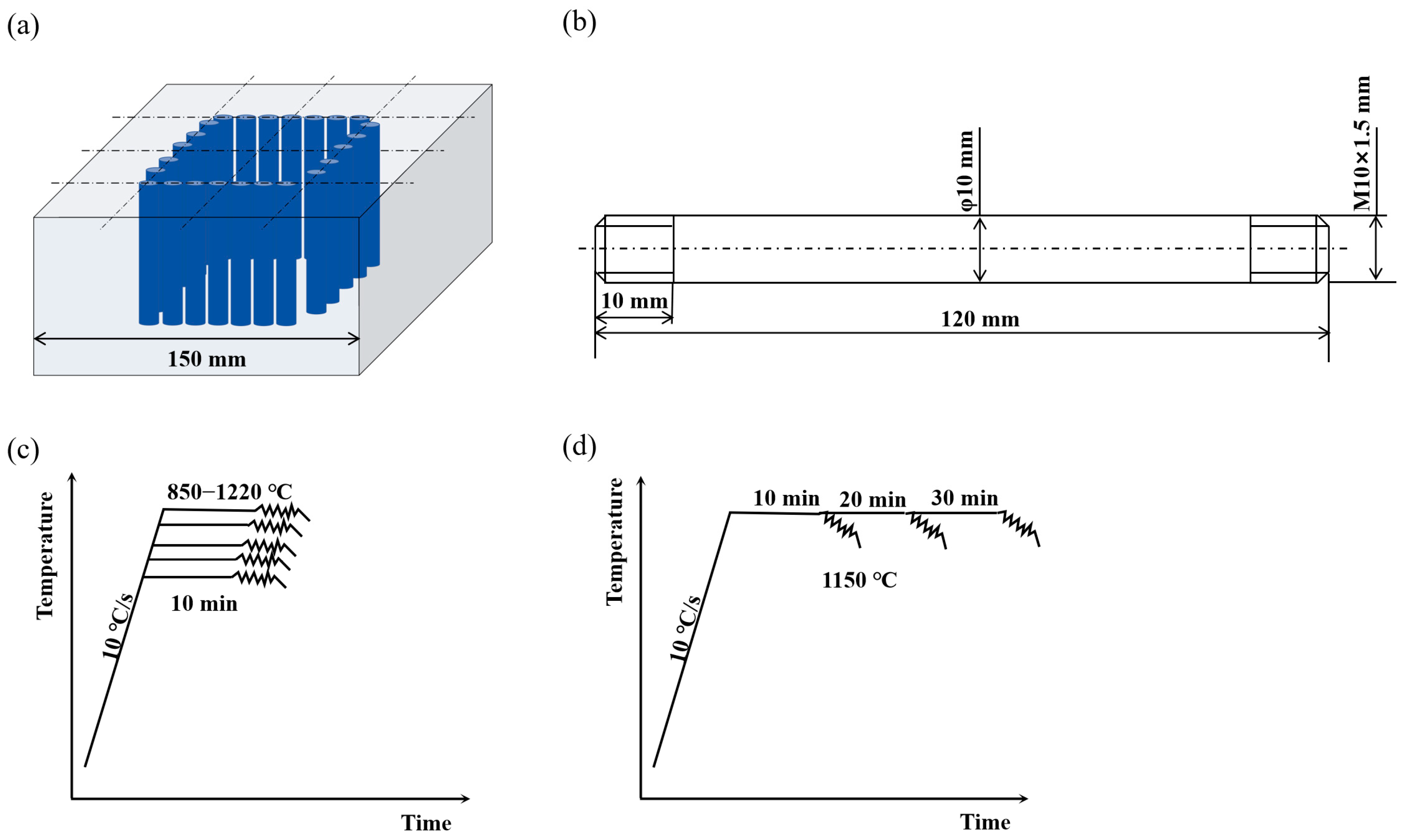

2. Materials and Experiments

3. Results and Discussion

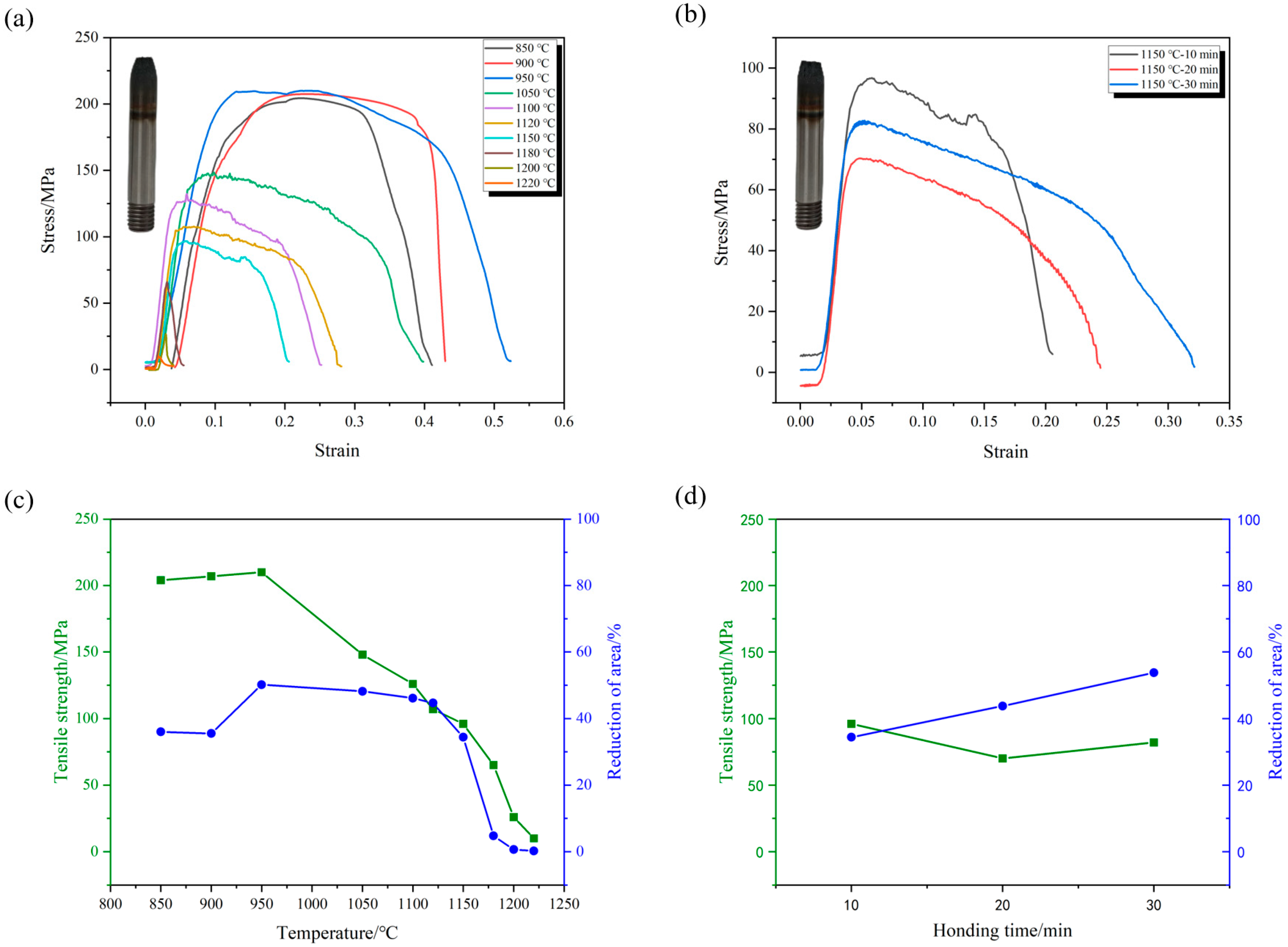

3.1. High-Temperature Tensile Properties

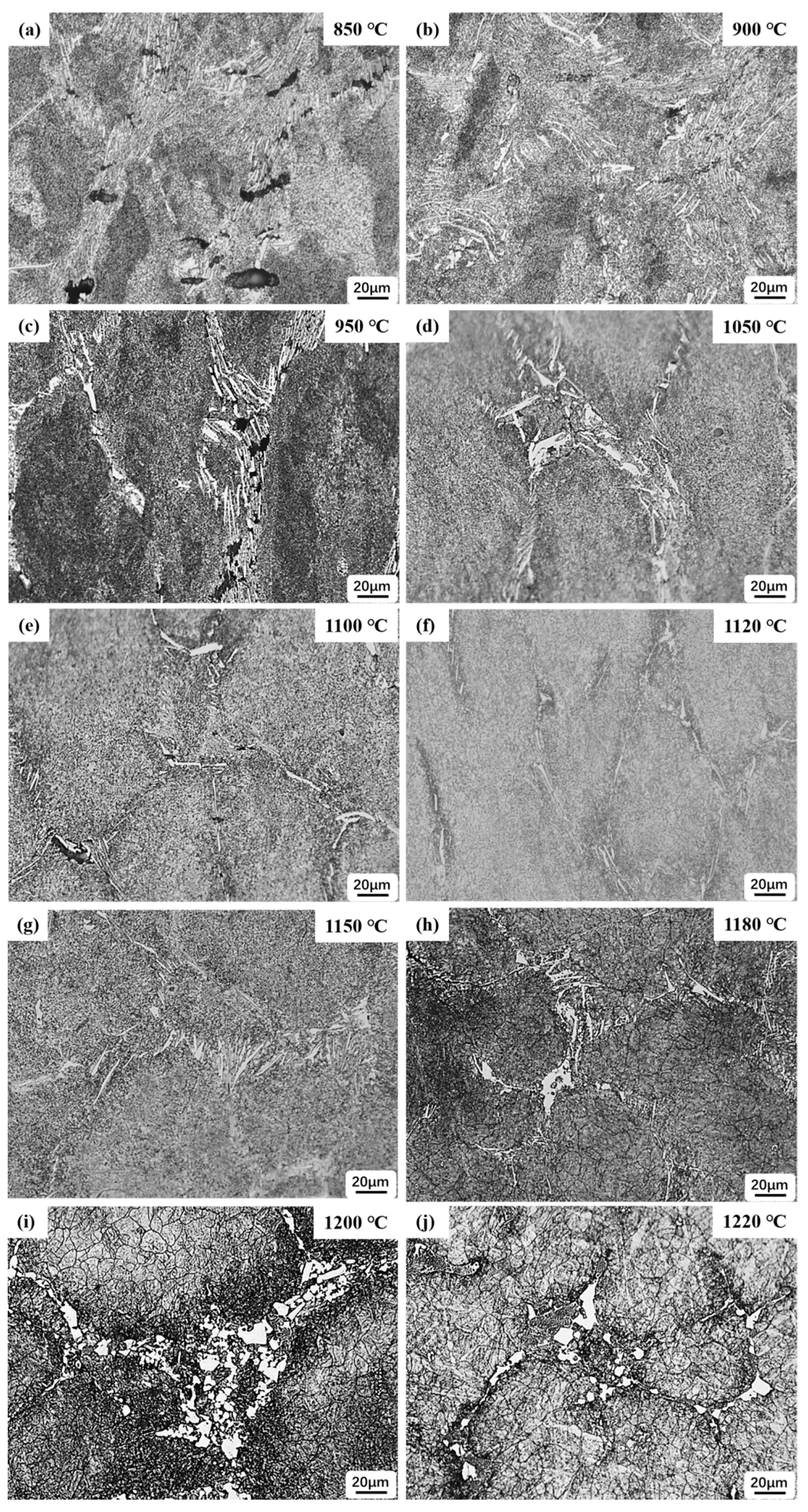

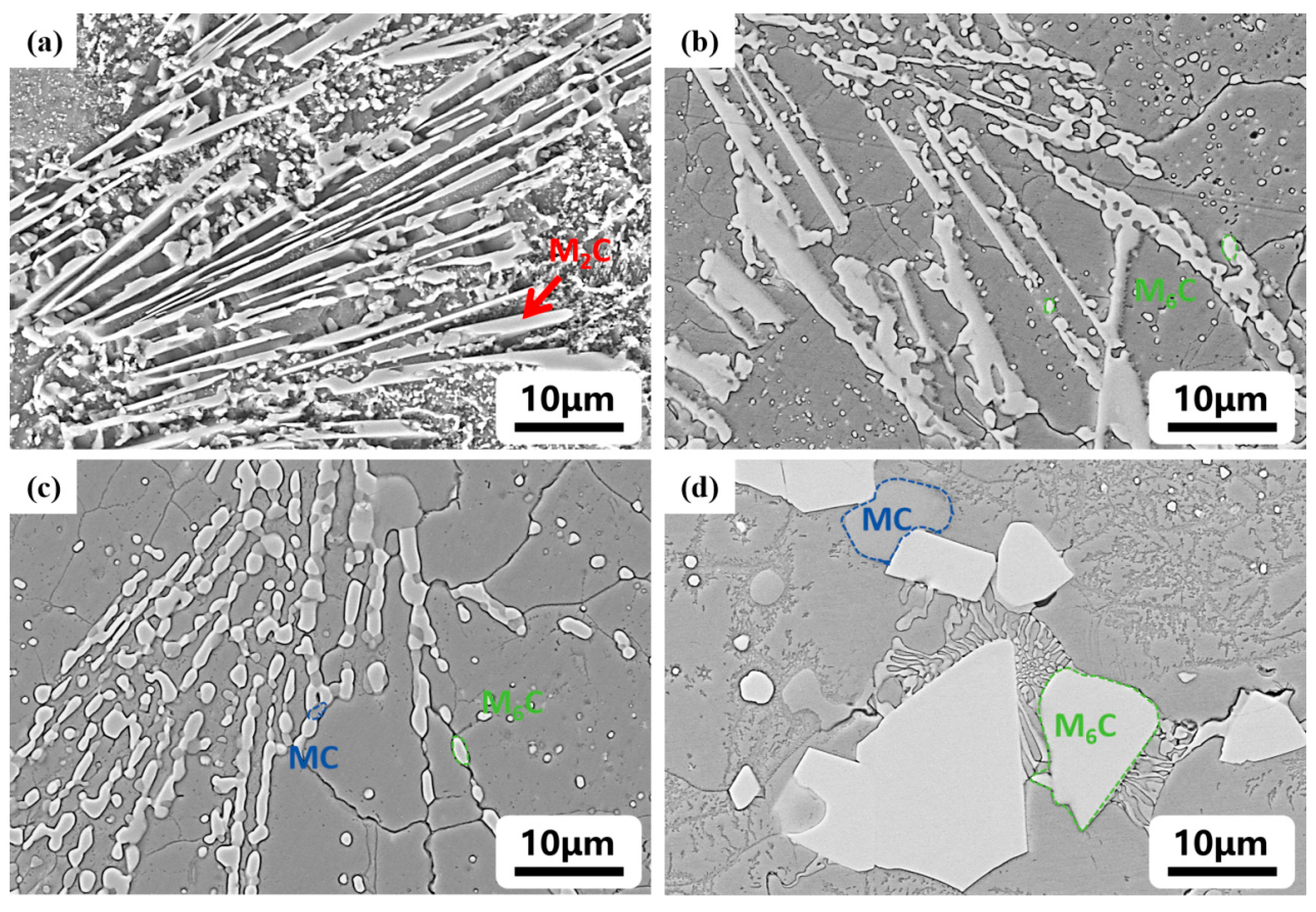

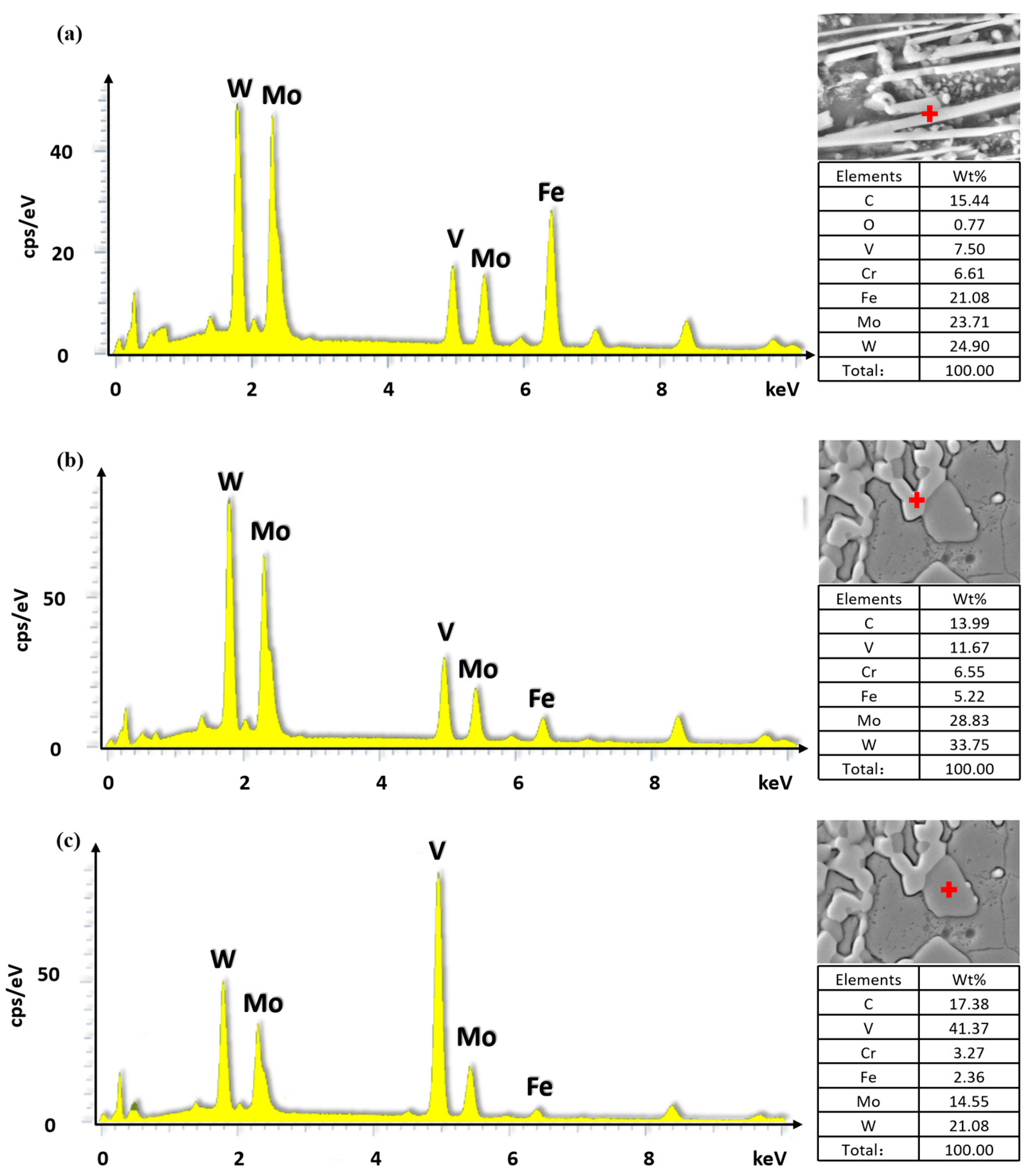

3.2. Carbide Morphology During High-Temperature Tensile Process

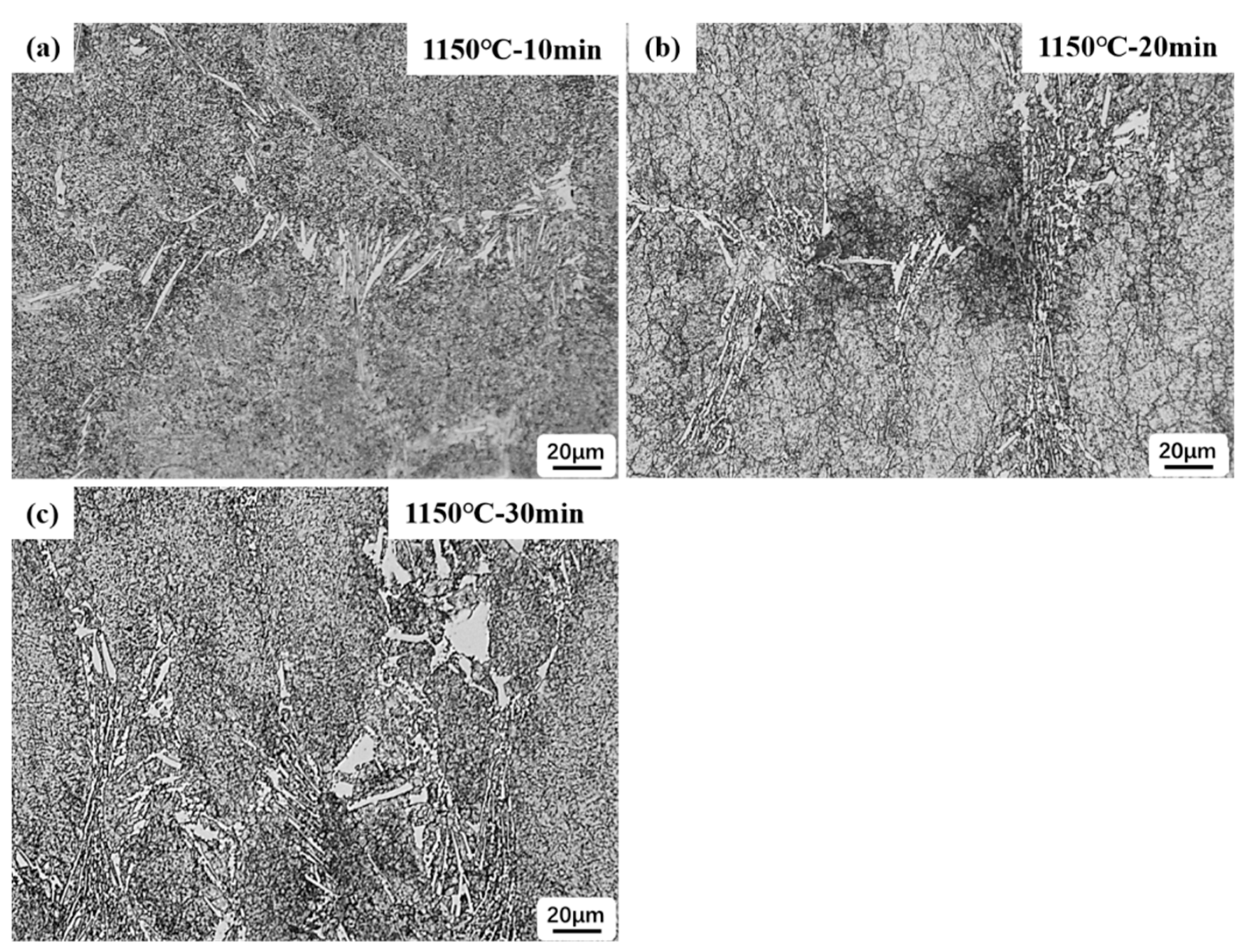

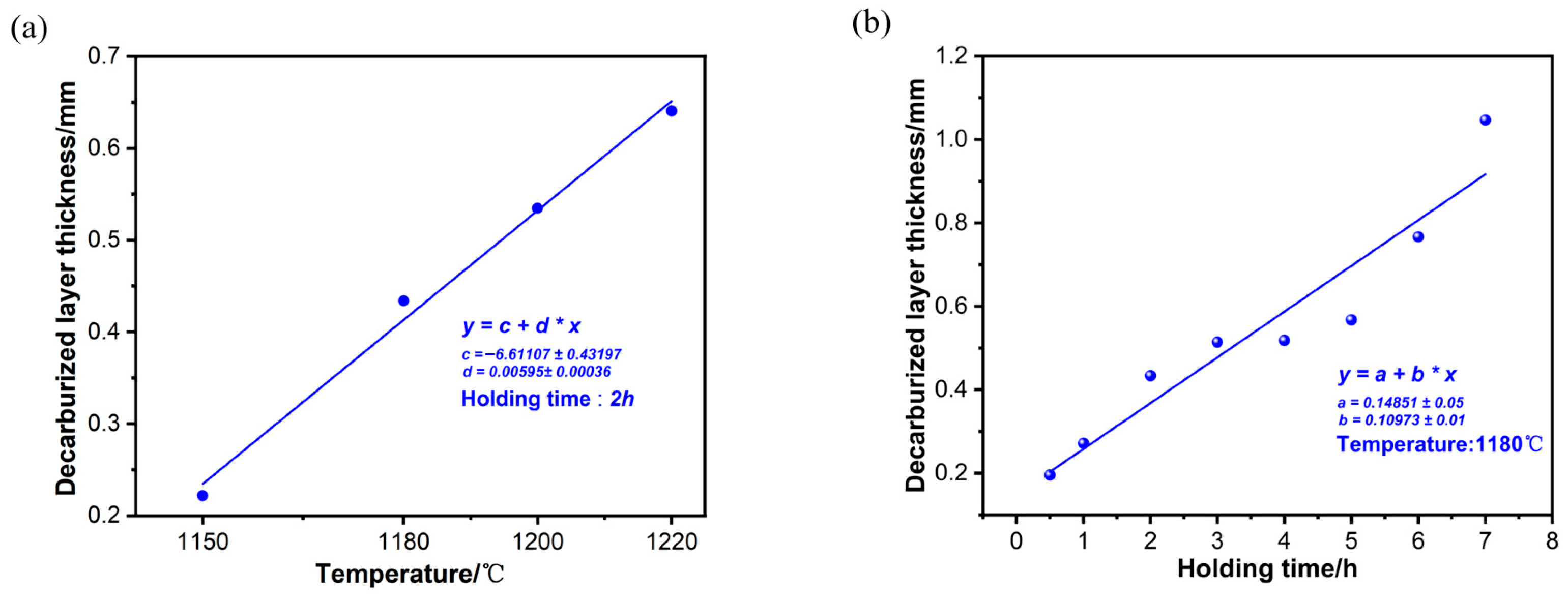

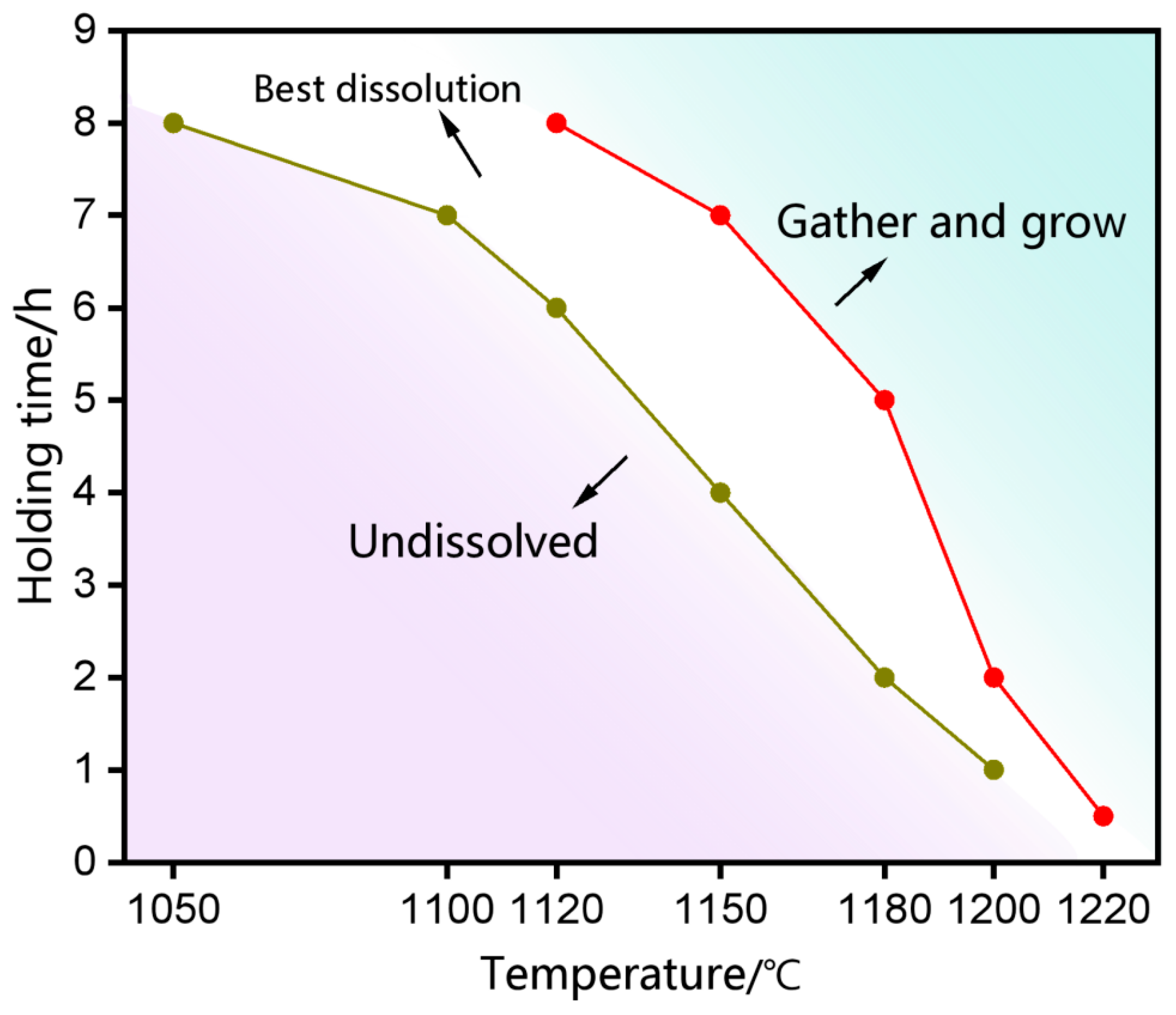

3.3. Carbide Evolution During High-Temperature Diffusion

4. Conclusions

- (1)

- With the increase in temperature with holding time of 10 min, the tensile strength and reduction of area increase at a temperature from 850 °C to 950 °C. Up to a range of 950 °C to 1120 °C, the tensile strength decreases while the reduction of area reaches a plateau area at 45% to 50%. At 1120 °C, a decrease in reduction of area begins to occur, and at 1180 °C, a sudden drop occurs, leading to a reduction of area below 5%. The zero-strength temperature and plastic temperature are 1220 °C and 1200 °C, respectively. With the increase in holding time at 1150 °C, the reduction of area increases from 34% to 54%. In addition, the tensile strength decreases from 92 MPa to 70 MPa and then increases to 82 MPa.

- (2)

- A range of PHJ value of about 28.0 to 30.5 exhibits the best solution for carbides. With the increase in PHJ value, the shape of carbides gradually changes from fibrous to short rod-like and blocky during high-temperature diffusion.

- (3)

- The hot working process includes high-temperature diffusion at 1120 °C to 1180 °C, with a holding time of 2 h to 5 h, and then forging or hot rolling at 1000 °C to 1120 °C.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hoyle, G. High Speed Steels; Butterworths: London, UK, 1988. [Google Scholar]

- Deng, Y.K.; Chen, J.R.; Wang, S.Z. High Speed Tool Steel; Metallurgical Industry Press: Beijing, China, 2002. [Google Scholar]

- Xu, G.L.; Huang, P.; Sun, X.; Zu, G.Y. Research status and development trend of high-speed-steel’s preparation and heat treatment process. Mater. China 2020, 39, 70–77. [Google Scholar]

- Chaus, A.S.; Kryshtal, A.P. New insights into the microstructure of M2 high-speed steel. Mater. Charact. 2023, 205, 113313. [Google Scholar] [CrossRef]

- ParenKov, S.L.; Kakabadze, R.V.; Pavlov, V.P.; Supov, A.V.; Aleksandrova, N.M. Integrated technology for casting-crystallization heat treatment in the continuous casting of high speed steels. Metallurgist 1999, 43, 485–489. [Google Scholar] [CrossRef]

- Zhou, X.F.; Fang, F.; Jiang, J.J. A study on the microstructure of AISI M2 high speed steel manufactured by continuous casting. Adv. Mater. Res. 2010, 146/147, 1211–1215. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, Z.; Wang, W.; Wang, Y. Comparison of the microstructure of M2 steel fabricated by continuous casting and with a sand mould. Metals 2019, 9, 560. [Google Scholar] [CrossRef]

- Zhou, X.; Fang, F.; Jiang, J. Solidification microstructure of M2 high speed steel by different casting technologies. China Foundry 2011, 8, 290–294. [Google Scholar]

- Lee, E.-S.; Park, W.-J.; Jung, J.Y.; Ahn, S. Solidification microstructure and M2C carbide decomposition in a spray-formed high-speed steel. Metall. Mater. Trans. A 1998, 29, 1395–1404. [Google Scholar] [CrossRef]

- Zhang, C.D.; Jiang, B.; Yang, Q.; Ding, P.-D. The evolution of eutectic carbide in M2 high speed steel cast strip. Trans. Mater. Heat Treat. 2009, 30, 107–110. [Google Scholar]

- Wang, Q.M.; Cheng, G.G.; Huang, Y. Morphology and precipitation mechanism of large carbides in M2 high speed steel. Iron Steel 2018, 53, 65–71. [Google Scholar]

- Chausa, A.S.; Sahu, M.l. On origin of delta eutectoid carbide in M2 high-speed steel and its behaviour at high temperature. Mater. Lett. 2019, 256, 126605. [Google Scholar] [CrossRef]

- Mintz, B.; Yue, S.; Jonas, J.J. Hot ductility of steels and its relationship to the problem of transverse cracking during continuous casting. Int. Mater. Rev. 1991, 36, 185–216. [Google Scholar] [CrossRef]

- Chi, H.X.; Xu, H.X.; Fang, F. High temperature mechanical properties of M2 high speed steel. China Metall. 2016, 26, 31–34. [Google Scholar]

- Sun, S.H.; Xu, J.; Wang, S.Z. Study of hot plasticity and hot working technology of HSS. J. Iron Steel Res. 1988, 8, 47–53. [Google Scholar]

- Wang, J.; Ma, D.S.; Zhou, Y.; Chi, H. Hot ductility behavior of M35 high speed steel. Heat Treat. Met. 2016, 41, 66–70. [Google Scholar]

- Hadian, A.; Zamani, C.; Gorjan, L.; Clemens, F.J. Thermoplastic processing and debinding behavior of NbC-M2 high speed steel cemented carbide. J. Mater. Process. Technol. 2019, 263, 91–100. [Google Scholar] [CrossRef]

- Chang, Y.; Zhao, F.; Ran, J.; Gan, L.; Zhao, F. Numerical simulation of thermal behavior and analysis of microstructure evolution during laser melting deposition of M2 high-speed steel powder. Vacuum 2024, 224, 113188. [Google Scholar] [CrossRef]

- Qu, M.-G.; Sun, S.-H.; Bai, X.-H.; Shi, Z.-P.; Gao, Y.; Fu, W.-T. Hot deformation behavior of as-cast AISI M2 high-speed steel containing Mischmetal. J. Iron Steel Res. Int. 2014, 21, 60–68. [Google Scholar] [CrossRef]

- Qu, M.-G.; Sun, S.-H.; Bai, X.-H.; Shi, Z.-P.; Gao, Y.; Fu, W.-T. Hot deformation behavior of as-cast AISI M2 high-speed steel. Trans. Mater. Heat Treat. 2013, 34, 47–50. [Google Scholar]

- Wei, Y.; Zhang, Y.; Chu, X.; Yang, S.; Wang, J.; Jia, W.; Zhu, J.; Liu, S. Enhanced red hardness through fine carbides in M2 high-speed steel fabricated via electron beam powder bed fusion. J. Mater. Res. Technol. 2025, 36, 1562–1571. [Google Scholar] [CrossRef]

- Imbert, C.; McQueen, H.J. Peak strength, strain hardening and dynamic restoration of A2 and M2 tool steels in hot deformation. Mater. Sci. Eng. A 2001, 313, 88–103. [Google Scholar] [CrossRef]

- Zhu, L.; Zhang, W.; Shi, R.; Wang, G. In-situ SEM analysis of plastic deformation, crack initiation, crack propagation behaviors in M2 high speed steel. J. Mater. Res. Technol. 2025, 35, 1265–1282. [Google Scholar] [CrossRef]

- Hao, Y.; Cheng, G.G.; Xie, Y. Precipitation behavior of carbides in W4Mo3Cr4VSi high-speed steel. Iron Steel 2018, 53, 73–82. [Google Scholar]

- Damon, J.; Schüßler, P.; Mühl, F.; Dietrich, S.; Schulze, V. Short-time induction heat treatment of high speed steel AISI M2: Laboratory proof of concept and application-related component tests. Mater. Des. 2023, 230, 111991. [Google Scholar] [CrossRef]

- Liu, Q.-X.; Lu, D.-P.; Lu, L.; Hu, Q.; Fu, Q.-F.; Zhou, Z. Effect of mischmetal on as-cast microstructure and mechanical properties of M2 high speed steel. J. Iron Steel Res. Int. 2015, 22, 245–249. [Google Scholar] [CrossRef]

- Zhou, X.F.; Fang, F.; Jiang, J.Q.; Zhu, W.L.; Xu, H.X. Study on decomposition behaviour of M2C eutectic carbide in high speed steel. Mater. Sci. Technol. 2012, 28, 1499–1504. [Google Scholar] [CrossRef]

- Zhou, X.-F.; Liu, D.; Zhu, W.-L.; Fang, F.; Tu, Y.-Y.; Jiang, J.-Q. Morphology, microstructure and decomposition behavior of M2C carbides in high speed steel. J. Iron Steel Res. Int. 2017, 24, 43–49. [Google Scholar] [CrossRef]

- Dai, Y.; Miao, H.; Peng, J.; Wang, B.; Dong, H.; Liu, Y.; Man, T.; Wei, X. Refinement mechanism of cerium addition on carbides in low-oxygen high-speed steel. J. Mater. Sci. Technol. 2025, 254, 180–195. [Google Scholar] [CrossRef]

- Yao, J.; Man, T.H.; Liu, Y.; Dong, H. Effect of continuous casting on segregation and carbide of M2 high speed steel. China Metall. 2023, 33, 77–84. [Google Scholar]

- Tamura, M.; Abe, F.; Shiba, K.; Sakasegawa, H.; Tanigawa, H. Larson–Miller Constant of Heat-Resistant Steel. Metall. Mater. Trans. A 2013, 44A, 2645–2661. [Google Scholar] [CrossRef]

- Nagasaka, T.; Ando, M.; Tanigawa, H.; Sakasegawa, H.; Tanaka, T.; Muroga, T.; Sagara, A. Tensile properties of F82H steel after aging at 400–650 °C for 1000–30000 h. Fusion Eng. Des. 2017, 124, 1011–1014. [Google Scholar] [CrossRef]

- Man, T.; Dai, Y.; Yao, J.; Xu, L.; Li, P.; Zhao, M.; Liu, Y.; Zhao, H. Segregation and carbide evolution in AISI D2 tool steel produced by curved continuous casting. J. Mater. Res. Technol. 2023, 26, 8254–8262. [Google Scholar] [CrossRef]

| C | P | S | Cr | Mo | Al | V | W | Ca | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 0.85 | 0.022 | 0.003 | 4.08 | 4.7 | 0.0111 | 1.92 | 5.65 | 0.0019 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, M.; Dai, Y.; Si, X.; Man, T.; Liu, Y.; Dong, H. High-Temperature Tensile Properties in the Curved Continuous Casting of M2 High-Speed Steel. Metals 2025, 15, 1178. https://doi.org/10.3390/met15111178

Pan M, Dai Y, Si X, Man T, Liu Y, Dong H. High-Temperature Tensile Properties in the Curved Continuous Casting of M2 High-Speed Steel. Metals. 2025; 15(11):1178. https://doi.org/10.3390/met15111178

Chicago/Turabian StylePan, Meichen, Yuheng Dai, Xuejie Si, Tinghui Man, Yu Liu, and Han Dong. 2025. "High-Temperature Tensile Properties in the Curved Continuous Casting of M2 High-Speed Steel" Metals 15, no. 11: 1178. https://doi.org/10.3390/met15111178

APA StylePan, M., Dai, Y., Si, X., Man, T., Liu, Y., & Dong, H. (2025). High-Temperature Tensile Properties in the Curved Continuous Casting of M2 High-Speed Steel. Metals, 15(11), 1178. https://doi.org/10.3390/met15111178