Effect of Aging Treatment on the Mechanical Properties and Impact Abrasive Wear Property of High-Manganese Steel

Abstract

1. Introduction

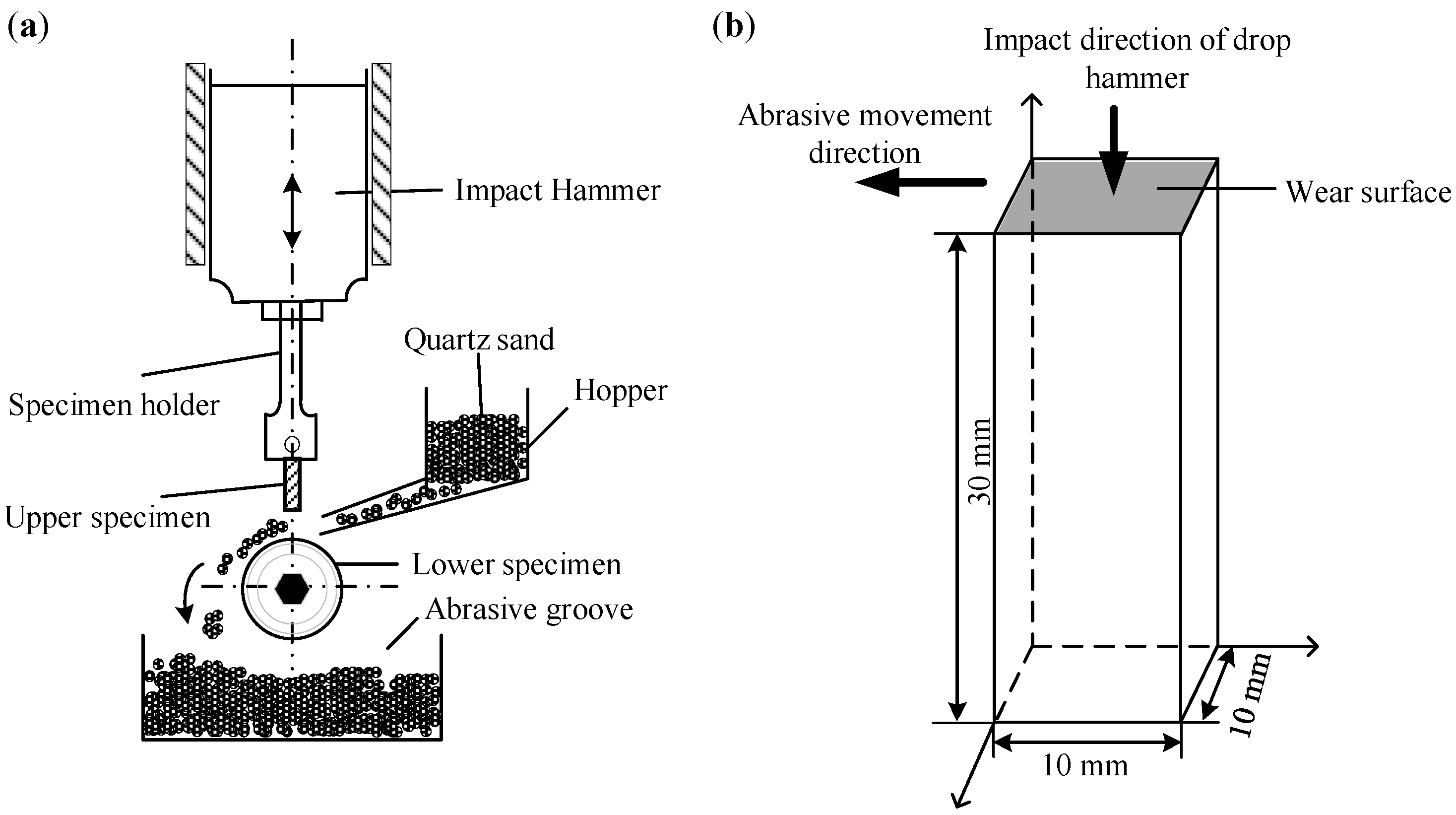

2. Experimental

3. Results and Discussion

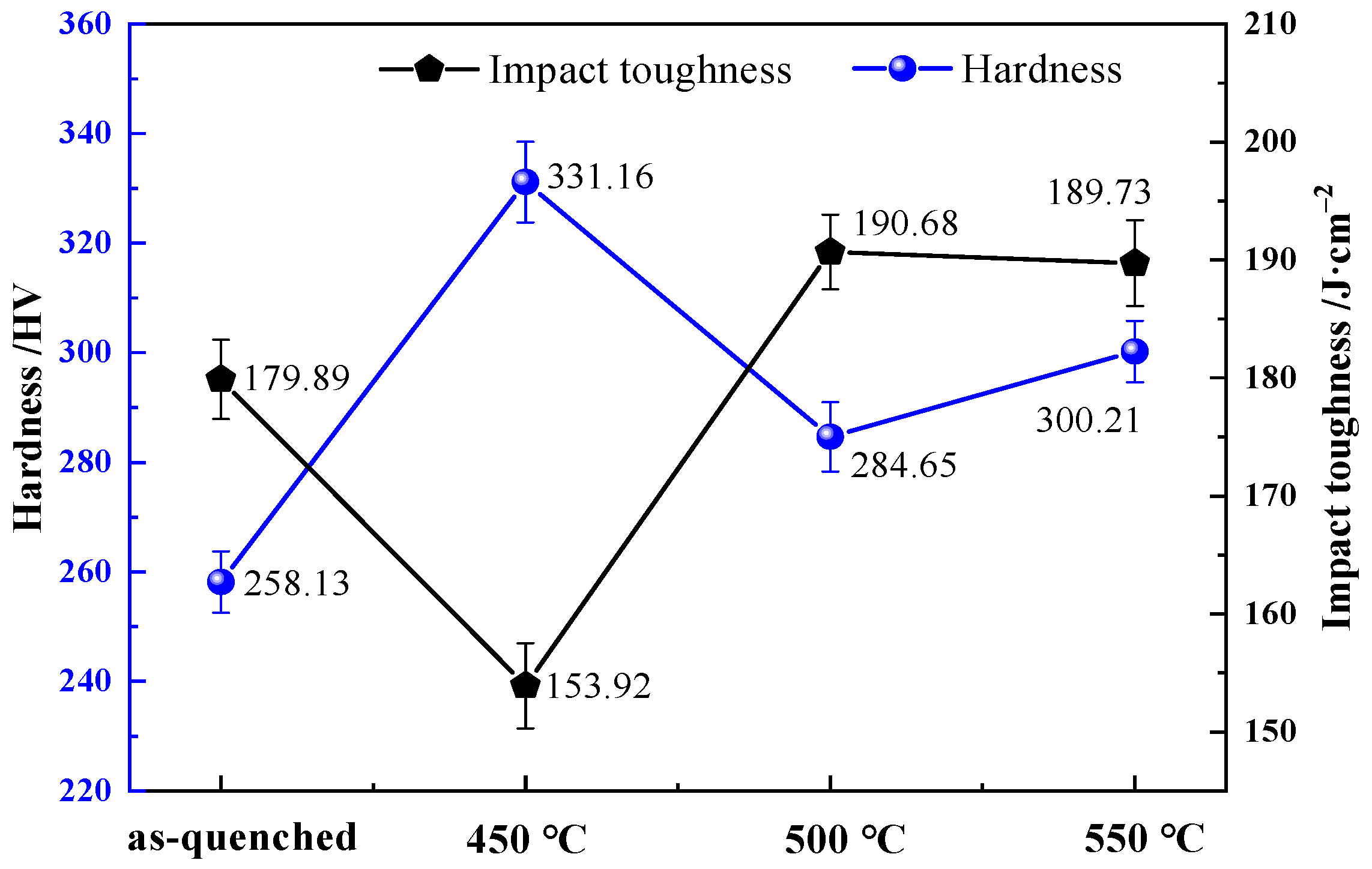

3.1. Effect of Aging Temperature on Mechanical Properties of High Manganese Steel

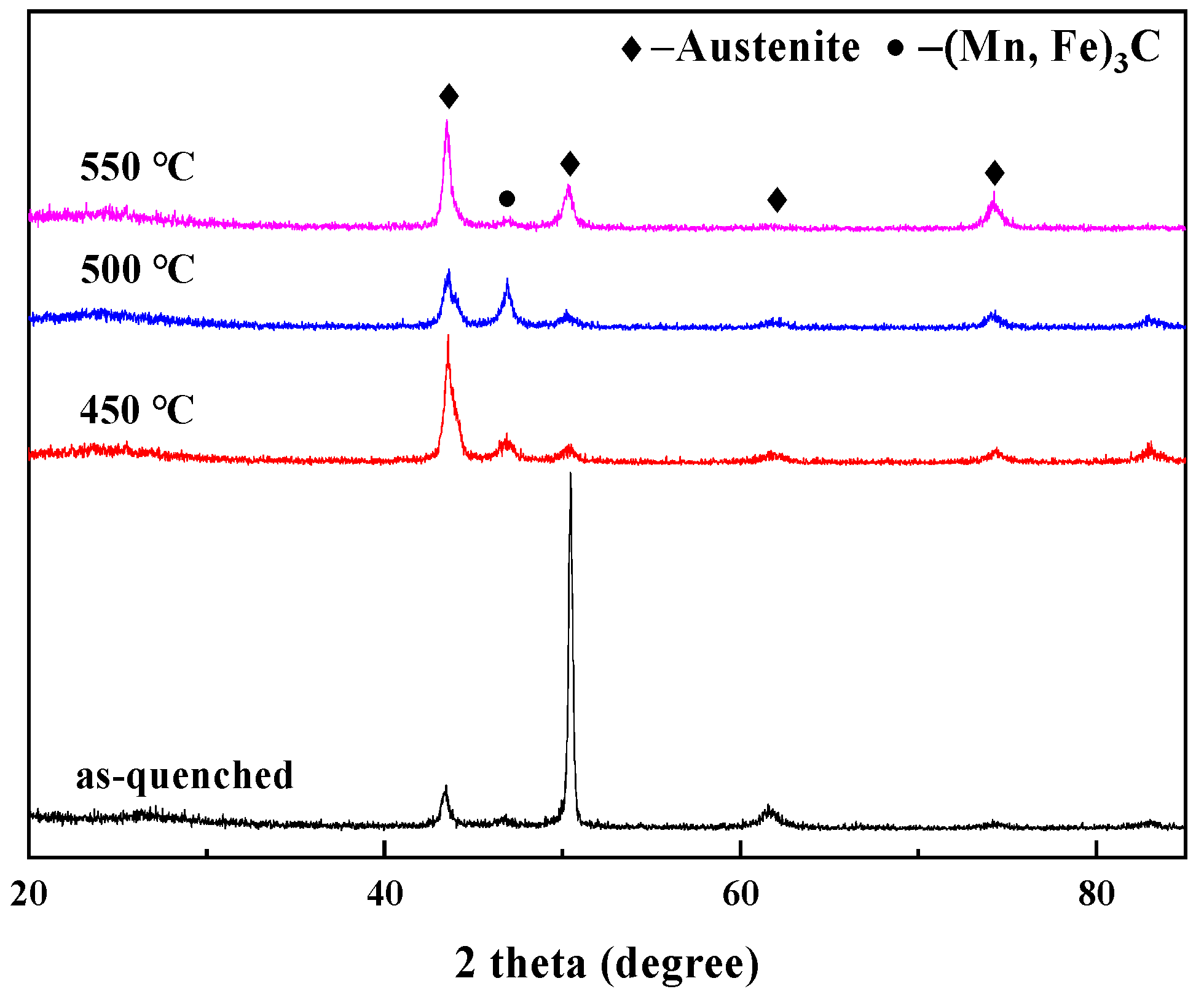

3.2. Effect of Aging Temperature on X-Ray Diffraction Analysis of High-Manganese Steel

3.3. Effect of Aging Temperature on Wear Characteristics and Work Hardening of High Manganese Steel

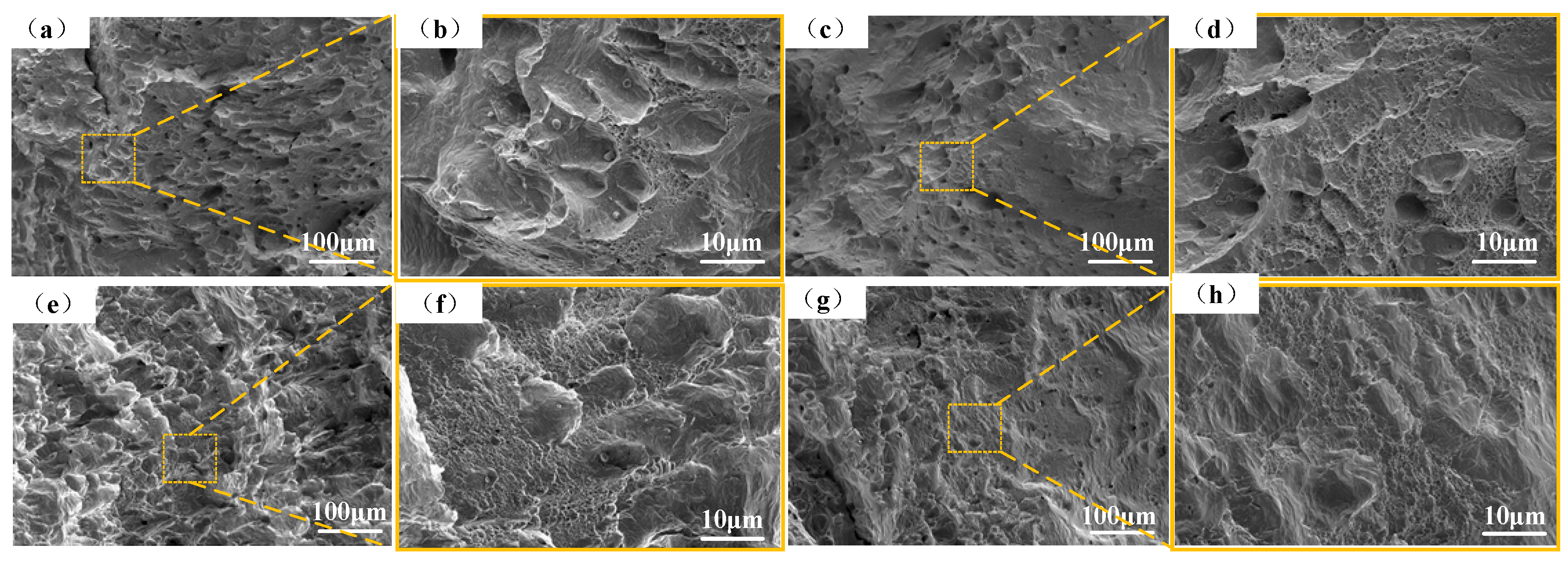

3.4. Effect of Aging Temperature on Wear Mechanism of High Manganese Steel

4. Conclusions

- (1)

- With the aging temperature increases, the impact toughness first sharply reduced and then increased, while the corresponding hardness was first increased and then decreased. When the aging temperature is 400 °C, the surface hardness of Mn25 steel reaches the maximum value 331.16 HV, while its impact toughness value is the smallest at 153.92 J. When the aging temperature is 550 °C, the impact toughness and hardness match better. Combining the XRD patterns, the precipitation phase is uniformly dispersed in the matrix, which can improve the initial hardness of high manganese steel, while the toughness is not reduced.

- (2)

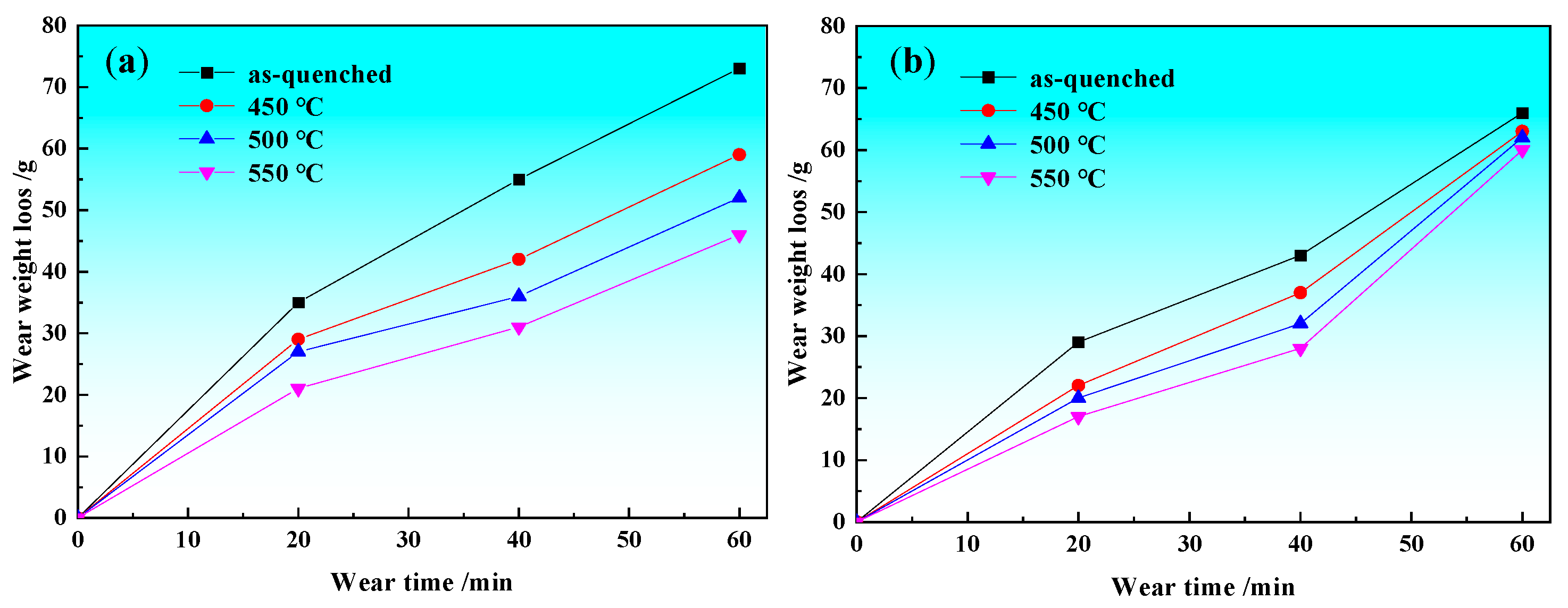

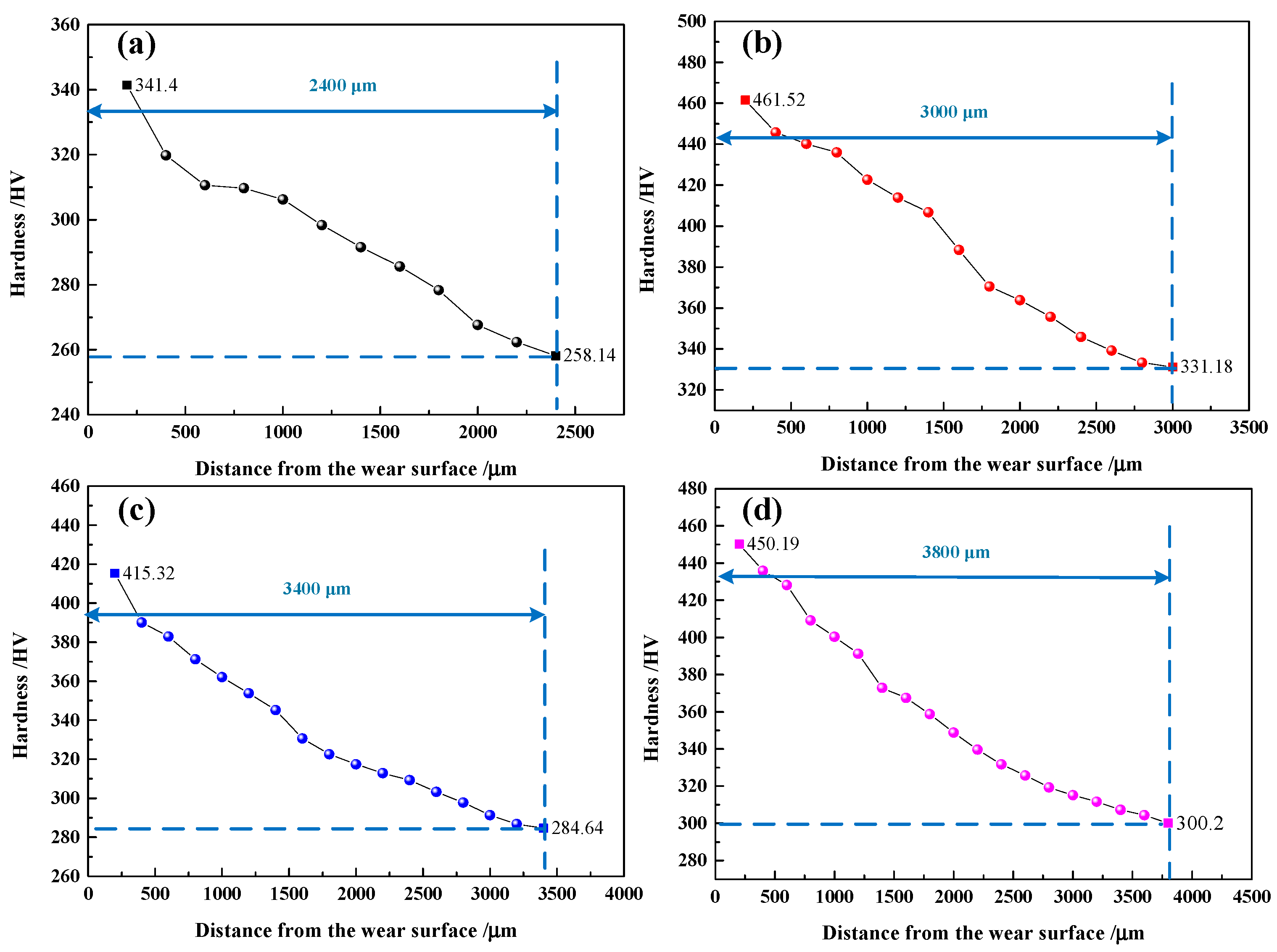

- Under different impact wear conditions, with the increase in aging temperature, wear loss of Mn25 steel was a decreasing trend. As the aging temperature increases, the effective hardening layer of Mn25 steel becomes deeper, the microhardness value of the wear section increases significantly, and the magnitude of the increase in the microhardness of the wear section relative to the initial hardness value increases to varying degrees. Under 5.0 J high-impact load abrasive wear conditions, when at an aging temperature of 550 °C, with an increase of 245 HV relative to the initial hardness, the percentage of hardening of the high manganese steel specimens is up to 49.96 percent, and the depth of the hardened layer is up to 3800 μm. For aging temperatures of 450 °C and 500 °C, the affected layers are about 3000 μm and 3400 μm, respectively.

- (3)

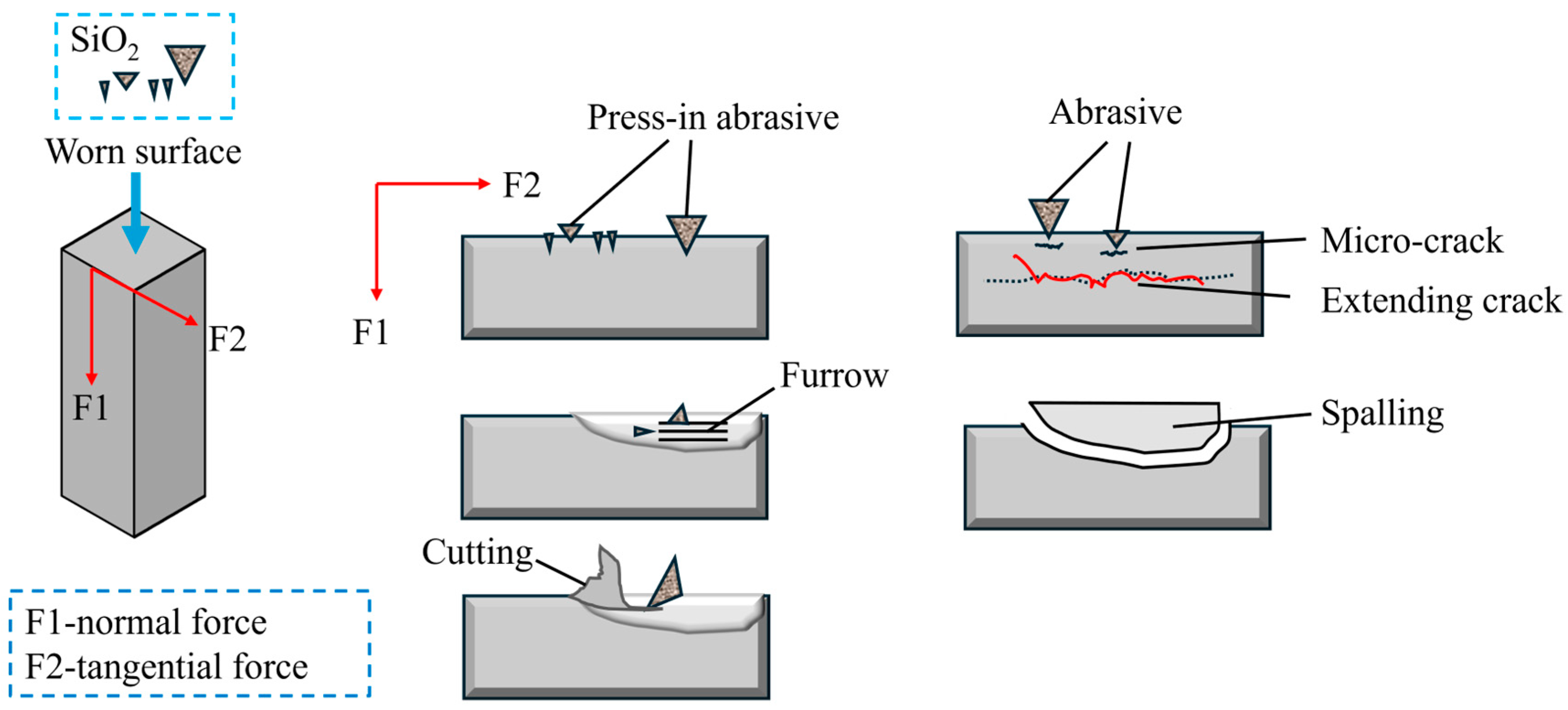

- For Mn25 steel in different impact load conditions, its wear mechanism is micro-cutting and fatigue-spalling at the same time. Specifically, under 2.0 J low impact load abrasive wear conditions, Mn25 steel wear is dominated by micro-cutting; with the aging temperature increases, the degree of steel wear hardening increases, and micro-cutting resistance is stronger. Under 5.0 J high impact load abrasive wear conditions, the Mn25 steel wear tends to plastic fatigue-spalling; with the aging temperature increases, the degree of steel wear hardening and the toughness of the wear layer and subsurface layer increases. When at an aging temperature of 550 °C, the wear surface morphology of Mn25 steel fatigue-spalling pit is shallow, which shows better wear resistance. This is related to the better matching of hardness and impact toughness of Mn25 steel after aging treatment, as well as better work-hardening ability.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wen, Y.H.; Peng, H.B.; Si, H.T.; Xiong, R.; Raabe, D. A novel high manganese austenitic steel with higher work hardening capacity and much lower impact deformation than Hadfield manganese steel. Mater. Des. 2014, 55, 798–804. [Google Scholar] [CrossRef]

- El Fawkhry, M.K. Feasibility of new ladle-treated Hadfield steel for mining purposes. Int. J. Miner. Metall. Mater. 2018, 25, 300–309. [Google Scholar] [CrossRef]

- Efstathiou, C.; Sehitoglu, H. Strain hardening and heterogeneous deformation during twinning in Hadfield steel. Acta Mater. 2010, 58, 1479–1488. [Google Scholar] [CrossRef]

- Barbangelo, A. Influence of alloying elements and heat treatment on impact toughness of chromium steel surface deposits. J. Mater. Sci. 1990, 25, 2975–2984. [Google Scholar] [CrossRef]

- Scott, C.; Remy, B.; Collet, J.L.; Cael, A.; Bao, C.; Danoix, F.; Malard, B.; Curfs, C. Precipitation strengthening in high manganese austenitic TWIP steels. Int. J. Mater. Res. 2011, 102, 538–549. [Google Scholar] [CrossRef]

- Reyes-Calderón, F.; Mejía, I.; Boulaajaj, A.; Cabrera, J. Effect of microalloying elements (Nb, V and Ti) on the hot flow behavior of high-Mn austenitic twinning induced plasticity (TWIP) steel. Mater. Sci. Eng. A 2013, 560, 552–560. [Google Scholar] [CrossRef]

- Feng, X.Y.; Zhang, F.C.; Yang, Z.N.; Zhang, M. Wear behaviour of nanocrystallised Hadfield steel. Wear 2013, 305, 299–304. [Google Scholar] [CrossRef]

- Beheshti, M.; Zabihiazadboni, M.; Ismail, M.C.; Kakooei, S.; Shahrestani, S. Investigation on simultaneous effects of shot peen and austenitizing time and temperature on grain size and microstructure of austenitic manganese steel (Hadfield). IOP Conf. Ser.: Mater. Sci. Eng. 2018, 328, 012006. [Google Scholar]

- Meng, S.; Cui, C.Y.; Chen, K.; Zhao, K. Microstructure and mechanical properties of laser-shock-peened high-manganese steel. Electroplat. Finish. 2020, 39, 760–765. [Google Scholar]

- Hu, X.; Shen, Z.; Liu, Y.; Liu, T.; Wang, F. Influence of explosive density on mechanical properties of high manganese steel explosion hardened. J. Appl. Phys. 2013, 114, 213507. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, Y.; Chen, C.; Li, Y.; Yang, Z.; Lv, B.; Zhang, F. Effect of surface impacting parameters on wear resistance of high manganese steel. Coatings 2023, 13, 539. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhang, Z.; Shan, Q.; Li, Z.; Jiang, Y.; Ge, R. Influence of heat-treatment on enhancement of yield strength and hardness by Ti-V-Nb alloying in high-manganese austenitic steel. Metals 2019, 9, 299. [Google Scholar] [CrossRef]

- Feng, Y.; Song, R.; Peng, S.; Song, R. Microstructures and impact wear behavior of Al-alloyed high-Mn austenitic cast steel after aging treatment. J. Mater. Eng. Perform. 2019, 28, 4845–4855. [Google Scholar] [CrossRef]

- Lee, K.; Park, S.J.; Lee, J.; Moon, J.; Kang, J.Y.; Kim, D.I.; Suh, J.Y.; Han, H.N. Effect of aging treatment on microstructure and intrinsic mechanical behavior of Fe-31.4 Mn-11.4 Al-0.89 C lightweight steel. J. Alloys Compd. 2016, 656, 805–811. [Google Scholar] [CrossRef]

- Feng, Y.; Song, R.; Wang, Y.; Liu, M.; Li, H.; Liu, X. Aging hardening and precipitation behavior of Fe-31.6 Mn-8.8 Al-1.38 C austenitic cast steel. Vacuum 2020, 181, 109662. [Google Scholar] [CrossRef]

- Shin, J.H.; Rim, G.Y.; Kim, S.D.; Jang, J.H.; Park, S.-J.; Lee, J. Effects of aging heat-treatment on dynamic strain aging behavior in high-Mn lightweight steel. Mater. Charact. 2020, 164, 110316. [Google Scholar] [CrossRef]

- Shan, Q.; Zhang, T.; Li, Z.; Zhou, Z.; Jiang, Y.; Lee, Y.S.; Luo, X. Effect of Aging Treatment on Precipitates and Intrinsic Mechanical Behavior of Austenitic Matrix in Ti-V-Nb-Alloyed High-Manganese Steel. Steel Res. Int. 2021, 92, 2000650. [Google Scholar] [CrossRef]

- Ren, J.; Li, Z.; Zhou, X.; Wu, S.; Chen, J.; Liu, Z. Interpretation of microstructure evolution and mechanical properties under aging treatments of a Fe–24Mn-0.6 C–2Al-0.6 V austenitic steel for cryogenic application. J. Mater. Res. Technol. 2023, 24, 4661–4677. [Google Scholar] [CrossRef]

- GB/T 229-2020; Metallic Materials—Charpy Pendulum Impact Test Method. Standards Press of China: Beijing, China, 2021.

- Peng, S.; Song, R.; Sun, T.; Pei, Z.; Cai, C.; Feng, Y.; Tan, Z. Wear behavior and hardening mechanism of novel lightweight Fe–25.1 Mn–6.6 Al–1.3 C steel under impact abrasion conditions. Tribol. Lett. 2016, 64, 13. [Google Scholar] [CrossRef]

- Babichev, M.A.; Velikanova, A.A. Effect of the concentration of manganese on the wearability of steel. Met. Sci. Heat Treat. 1964, 6, 289–292. [Google Scholar] [CrossRef]

- Primig, S.; Leitner, H. Transformation from continuous-to-isothermal aging applied on amaraging steel. Mater. Sci. Eng. 2010, 527, 4399–4405. [Google Scholar] [CrossRef]

- Bouaziz, O.; Allain, S.; Scott, C.P.; Cugy, P.; Barbier, D. High manganese austenitic twinning induced plasticity steels: A review of the microstructure properties relationships. Solid State Mater. Sci. 2011, 15, 141–166. [Google Scholar] [CrossRef]

- Mazancová, E.; Ružiak, I.; Schindler, I. Influence of rolling conditions and aging process on mechanical properties of high manganese steels. Arch. Civ. Mech. Eng. 2012, 12, 142–147. [Google Scholar] [CrossRef]

- Petrov, Y.N.; Gavriljuk, V.G.; Berns, H.; Schmalt, F. Surface structure of stainless and Hadfield steel after impact wear. Wear 2005, 260, 687–691. [Google Scholar] [CrossRef]

- Efremenko, V.G.; Shimizu, K.; Noguchi, T.; Efremenko, A.; Chabak, Y.G. Impact–abrasive–corrosion wear of Fe-based alloys: Influence of microstructure and chemical composition upon wear resistance. Wear 2013, 305, 155–165. [Google Scholar] [CrossRef]

- Ba, L.; Gao, Q.; Cen, W.; Wang, J.; Wen, Z. The impact-abrasive wear behavior of high wear resistance filling pipeline with explosion treatment. Vacuum 2021, 192, 110427. [Google Scholar] [CrossRef]

- Guo, Y.; Wang, Y.; Ma, Z.; Han, J. Microstructure Characteristic and Impact Wear Behavior of Nb-Alloyed High Manganese Steels. J. Mater. Eng. Perform. 2023, 32, 9040–9050. [Google Scholar] [CrossRef]

- Ma, H.; Chen, C.; Li, J.; Wang, X.; Qi, X.; Zhang, F.; Tang, T. Effect of pre-deformation degree on tensile properties of high carbon high manganese steel at different strain rates. Mater. Sci. Eng. A 2022, 829, 142146. [Google Scholar] [CrossRef]

- Bedolla-Jacuinde, A.; Guerra, F.V.; Rainforth, M.; Mejía, I.; Maldonado, C. Sliding wear behavior of austempered ductile iron microalloyed with boron. Wear 2015, 330, 23–31. [Google Scholar] [CrossRef]

- Khun, N.W.; Liu, E.; Tan, A.W.Y.; Senthilkumar, D.; Albert, B.; Lal, D.M. Effects of deep cryogenic treatment on mechanical and tribological properties of AISI D3 tool steel. Friction 2015, 3, 234–242. [Google Scholar] [CrossRef]

| Elements | C | Si | Mn | Cr | Ni | Cu | Mo | P | S | Al | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Weight (wt%) | 0.35 | 0.15 | 24.98 | 3.58 | 0.014 | 0.48 | 0.0079 | 0.007 | 0.0083 | 0.009 | Balance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiao, X.; Yan, L.; Han, X.; Qi, X.; Yang, X.; Xin, Y. Effect of Aging Treatment on the Mechanical Properties and Impact Abrasive Wear Property of High-Manganese Steel. Metals 2025, 15, 909. https://doi.org/10.3390/met15080909

Qiao X, Yan L, Han X, Qi X, Yang X, Xin Y. Effect of Aging Treatment on the Mechanical Properties and Impact Abrasive Wear Property of High-Manganese Steel. Metals. 2025; 15(8):909. https://doi.org/10.3390/met15080909

Chicago/Turabian StyleQiao, Xiya, Ling Yan, Xiao Han, Xiangyu Qi, Xin Yang, and Yu Xin. 2025. "Effect of Aging Treatment on the Mechanical Properties and Impact Abrasive Wear Property of High-Manganese Steel" Metals 15, no. 8: 909. https://doi.org/10.3390/met15080909

APA StyleQiao, X., Yan, L., Han, X., Qi, X., Yang, X., & Xin, Y. (2025). Effect of Aging Treatment on the Mechanical Properties and Impact Abrasive Wear Property of High-Manganese Steel. Metals, 15(8), 909. https://doi.org/10.3390/met15080909