Effects of Multi-Crack Initiation in High-Speed Railway Wheel Subsurface on Tread Peeling Lifetime

Abstract

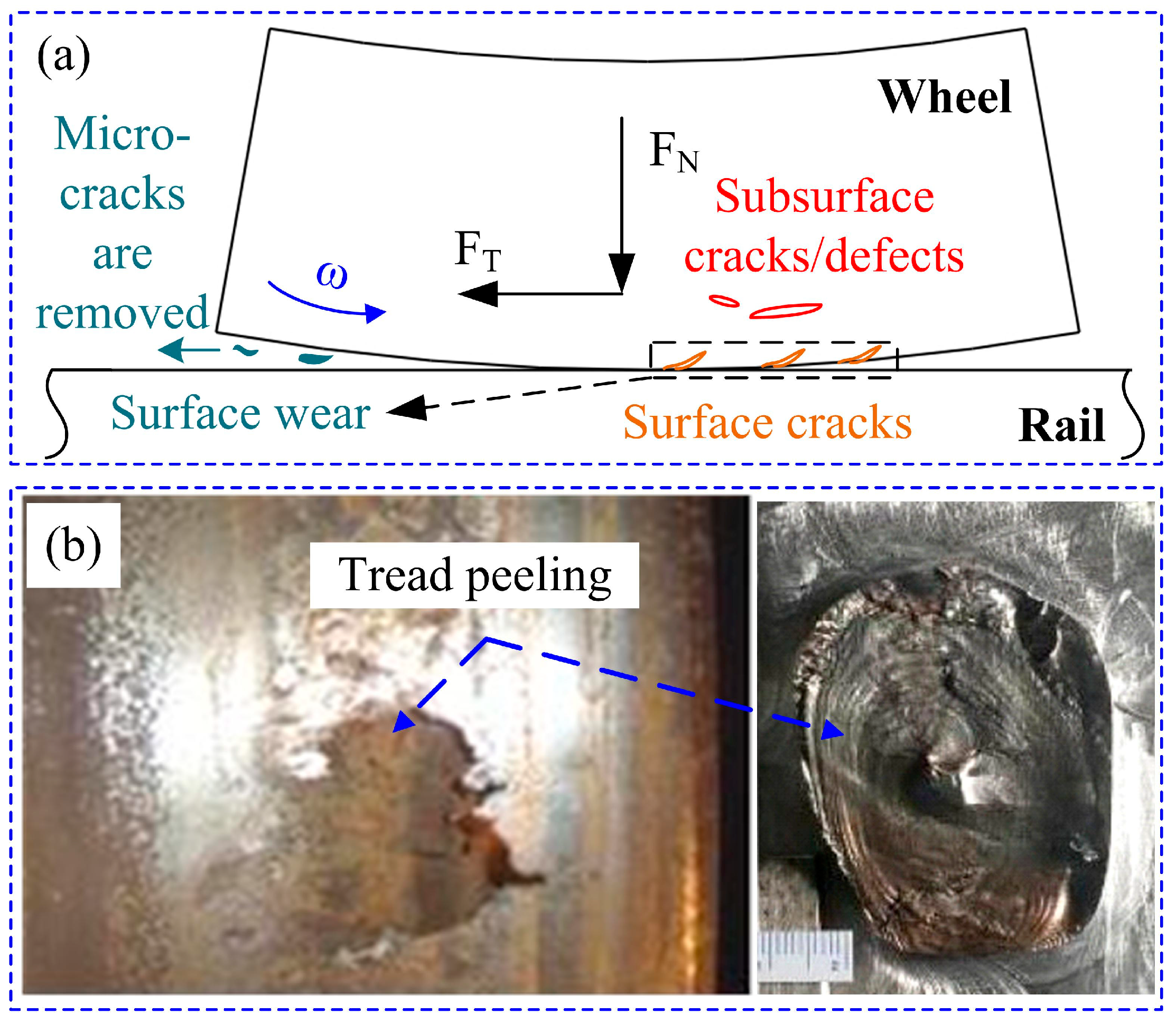

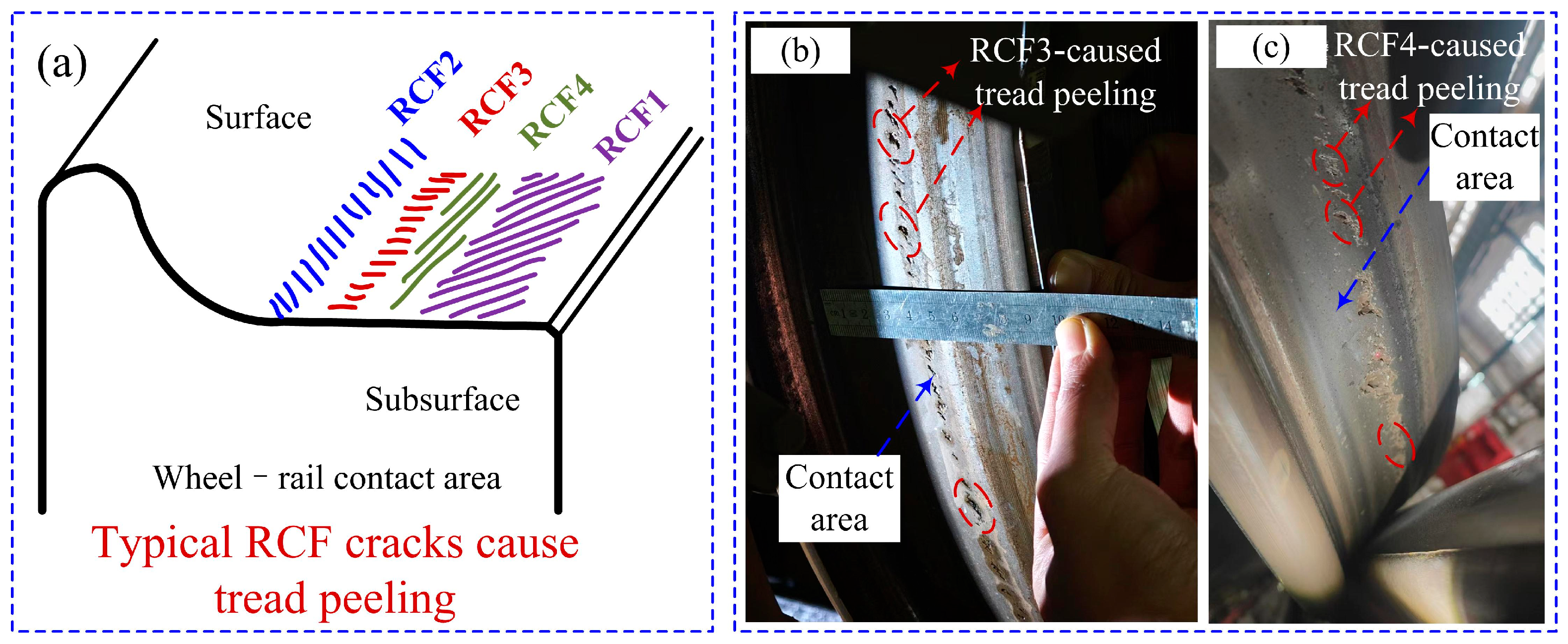

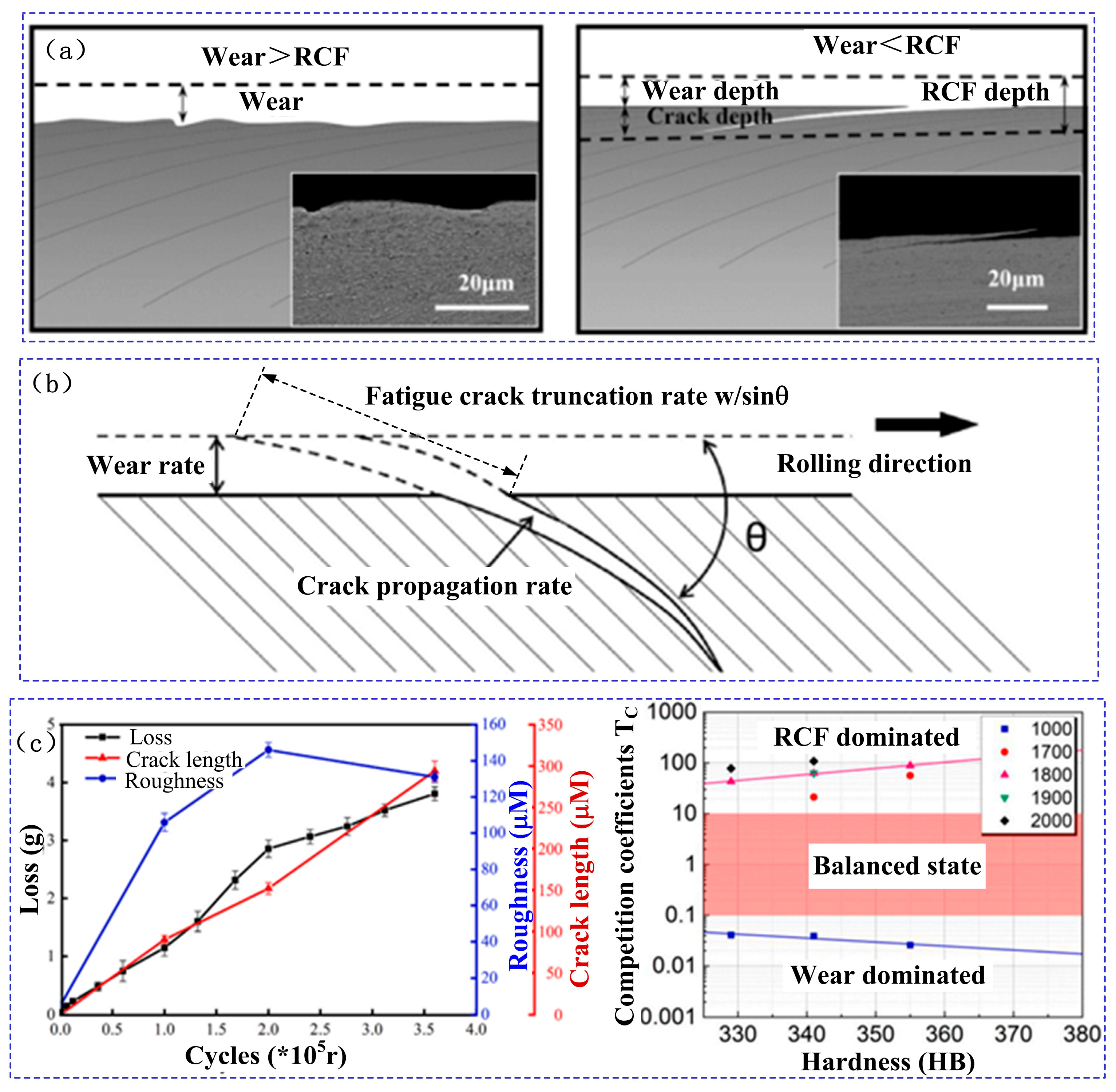

1. Introduction

2. Analysis of the Peeling of the Wheel Tread

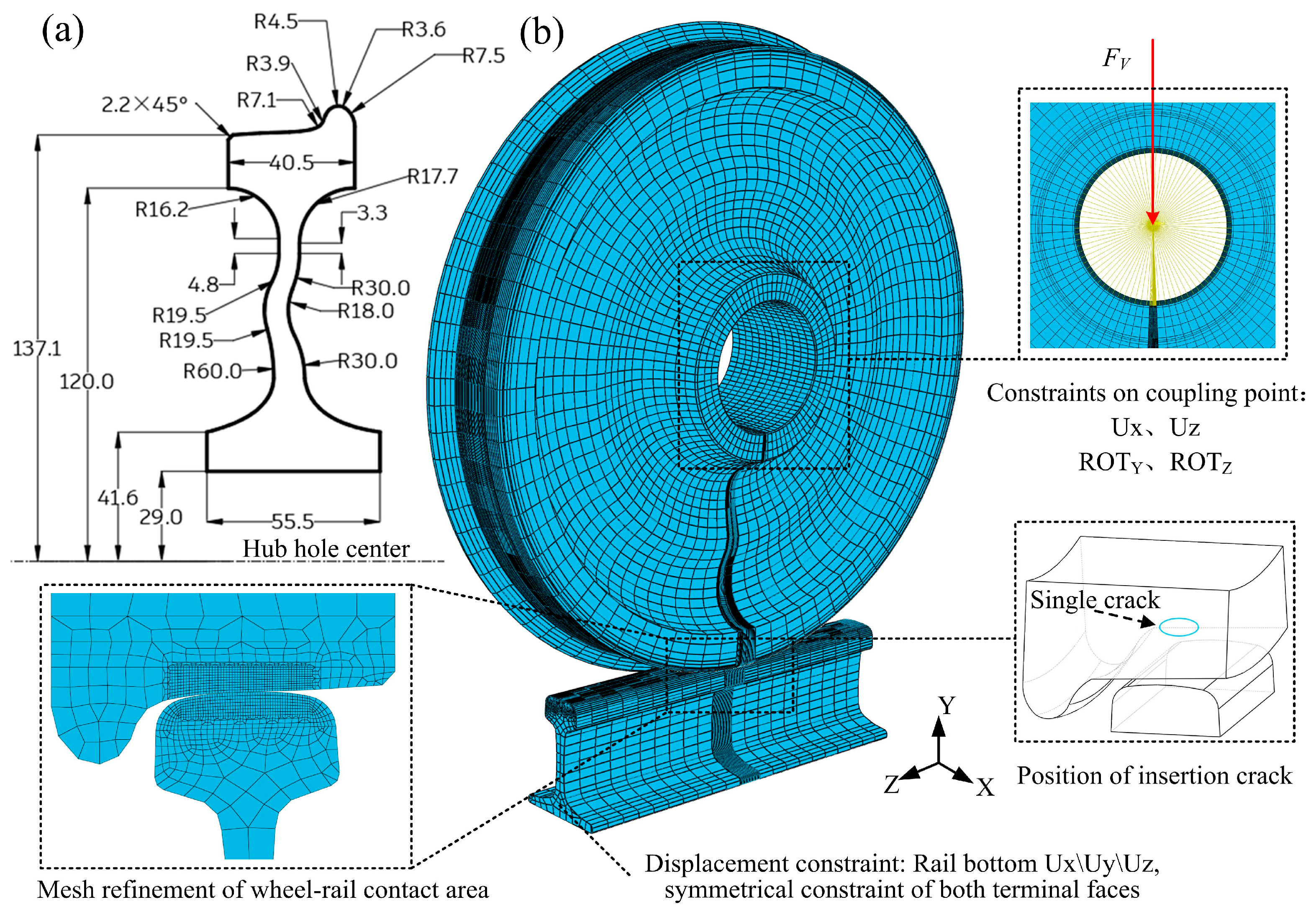

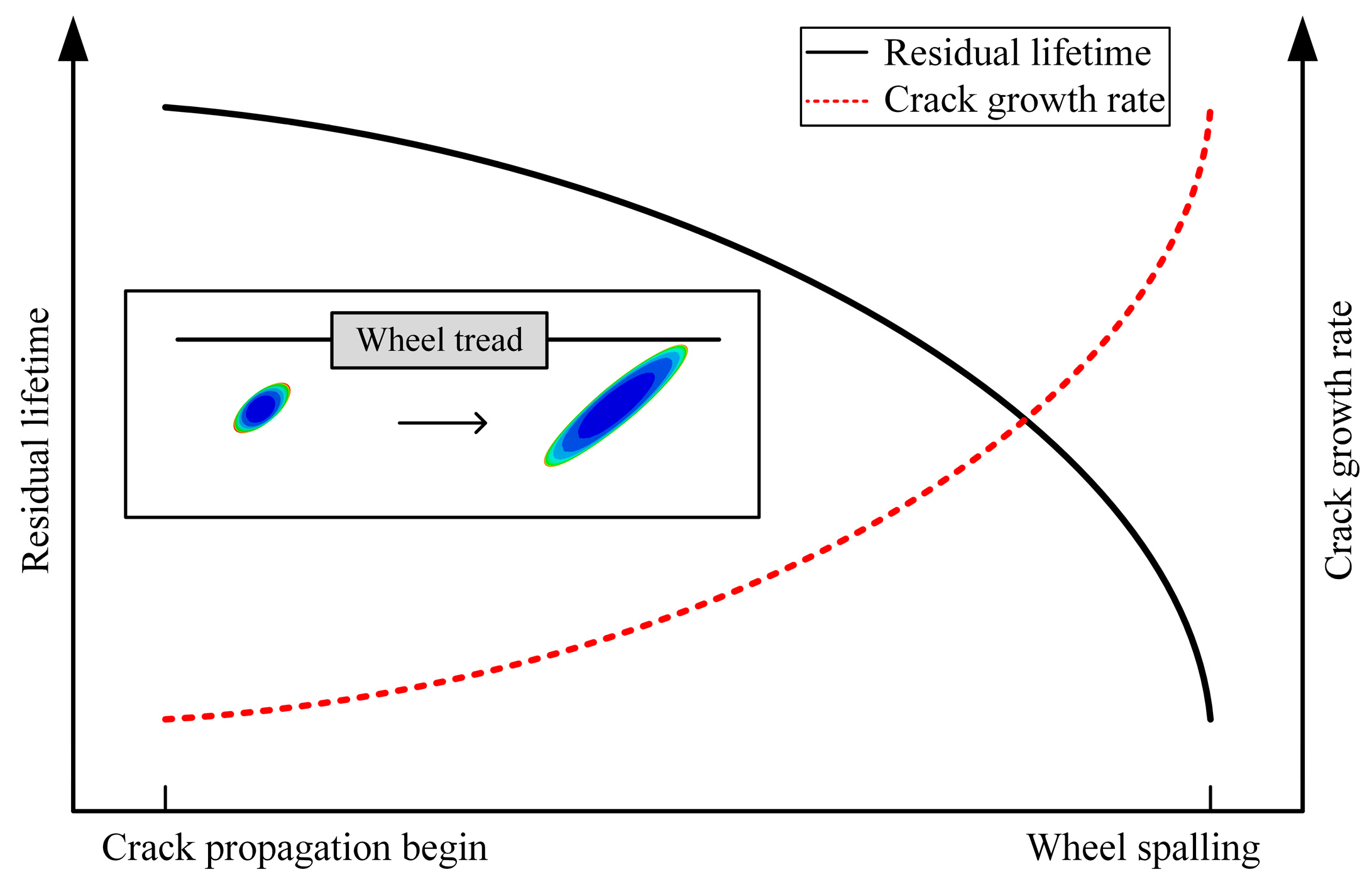

3. Simulation Analysis Method of Fatigue Crack Propagation

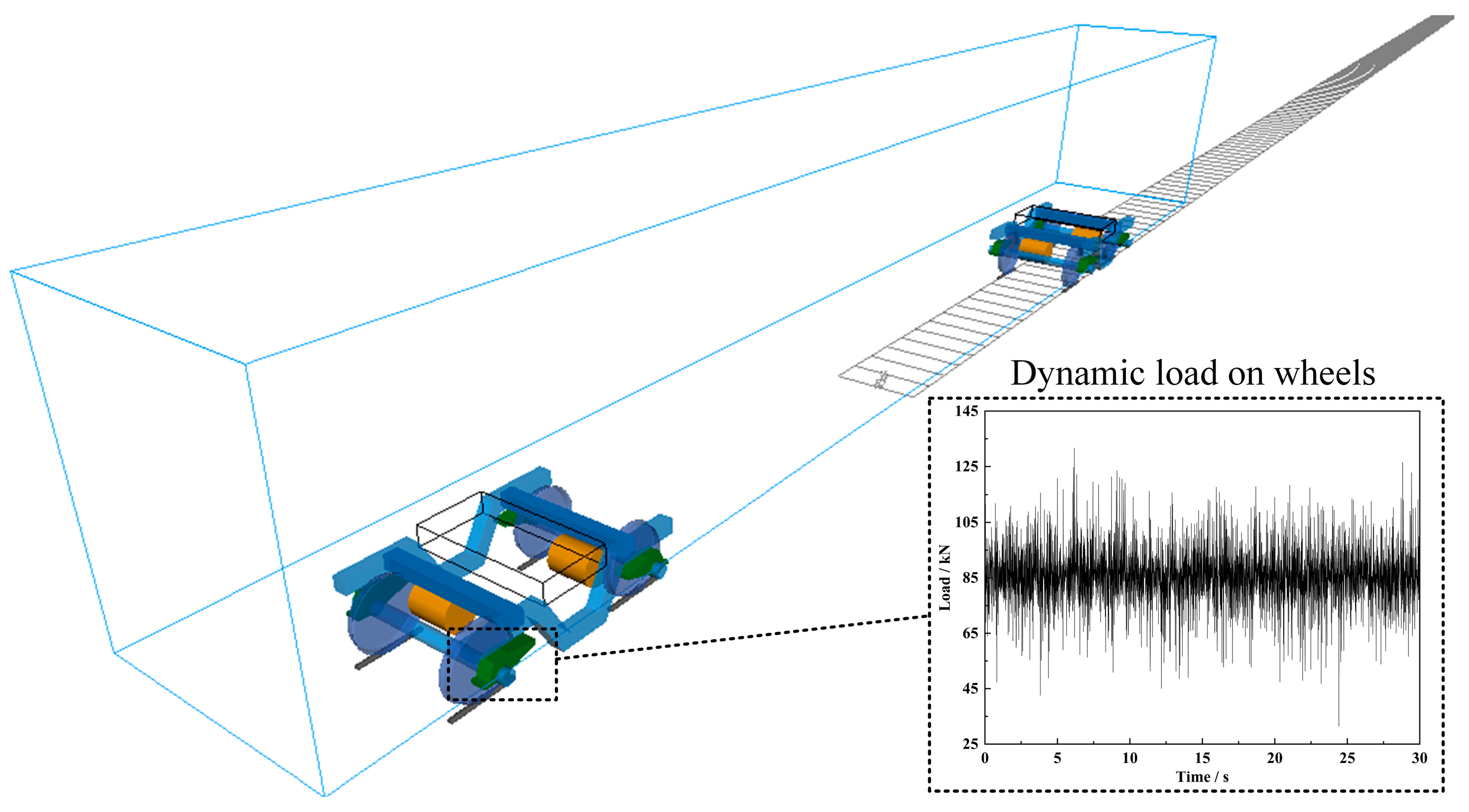

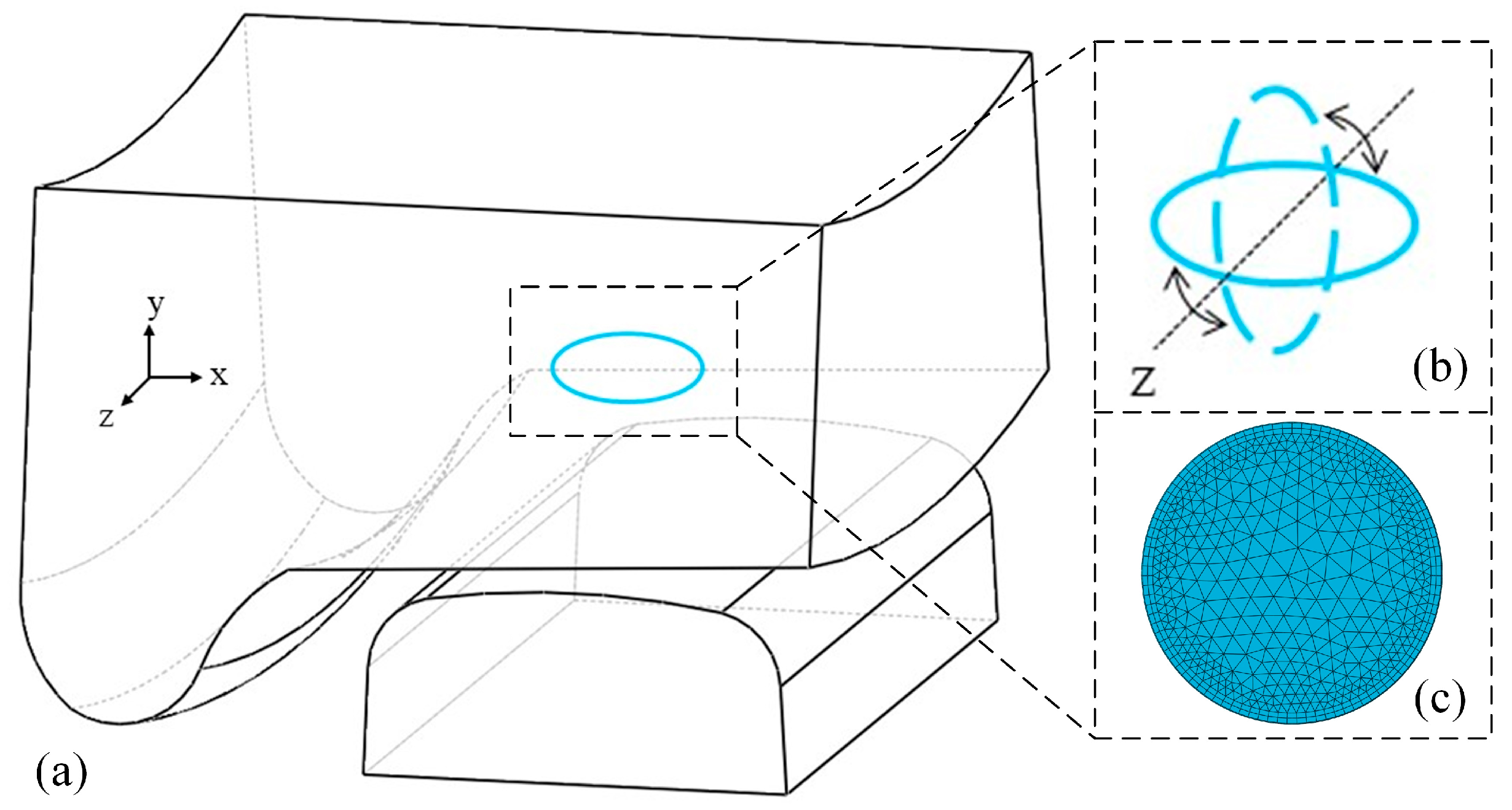

3.1. FE Models

3.2. Boundary Conditions

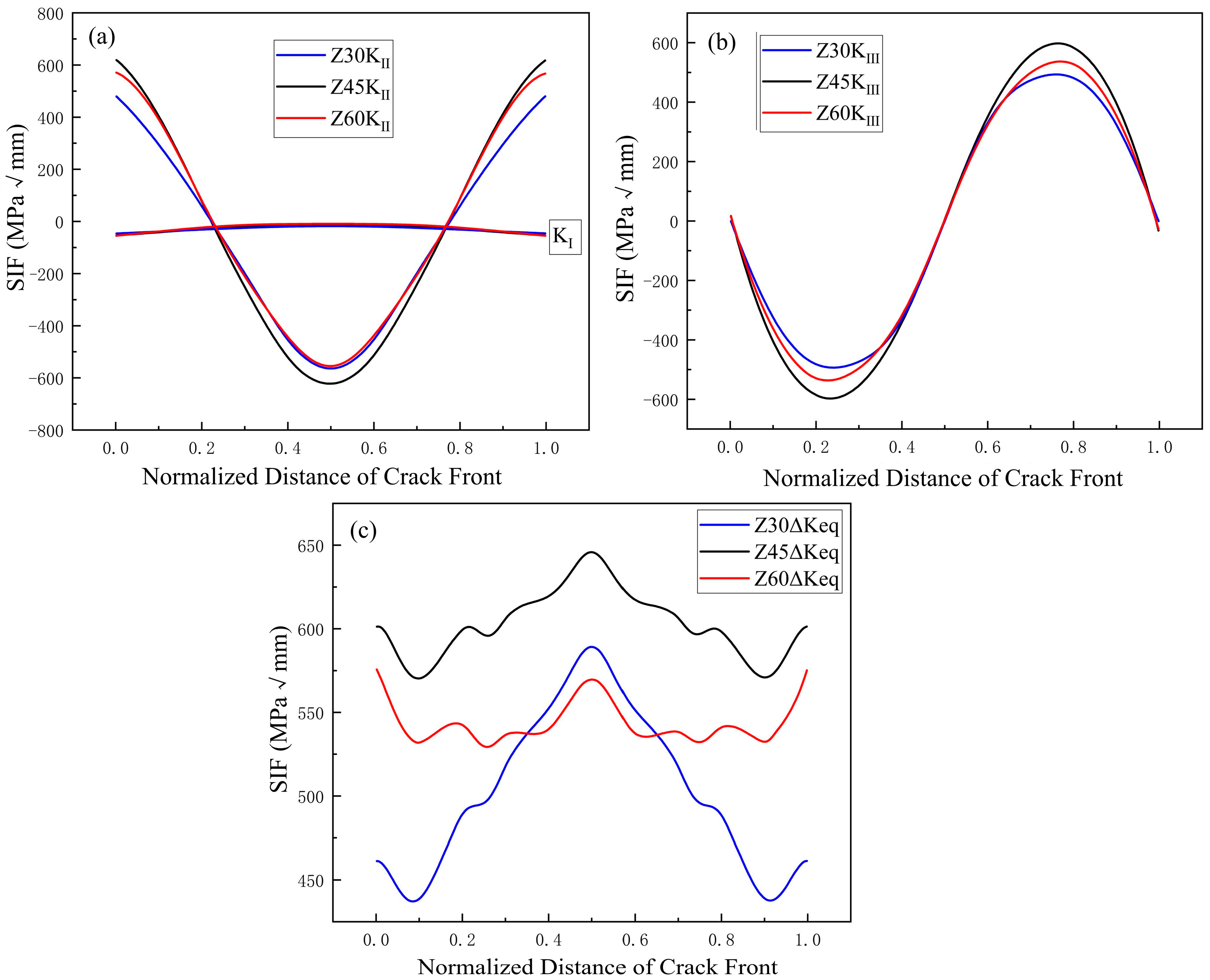

3.3. Determination Method of SIFs

4. Analysis of Fatigue Crack Propagation in the Dangerous Area of the Wheel

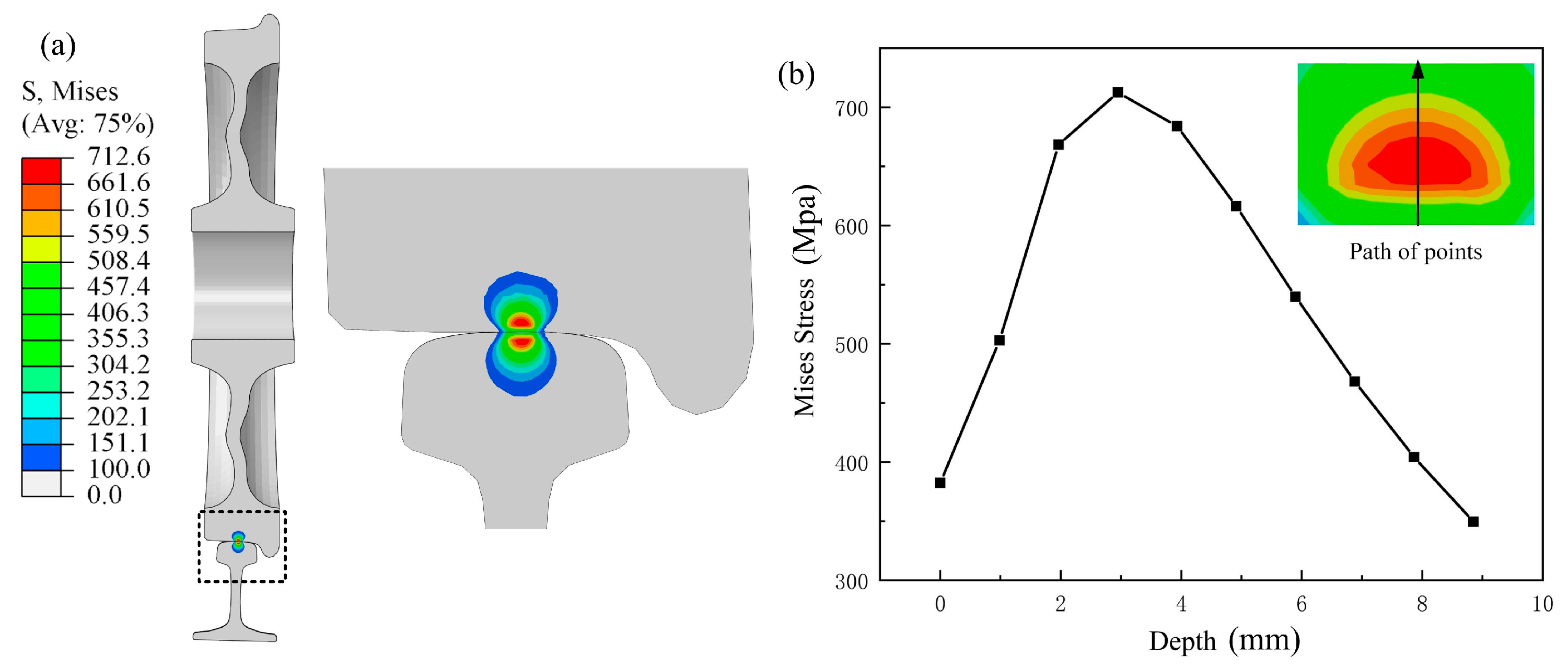

4.1. Determination of the Dangerous Area of the Wheel

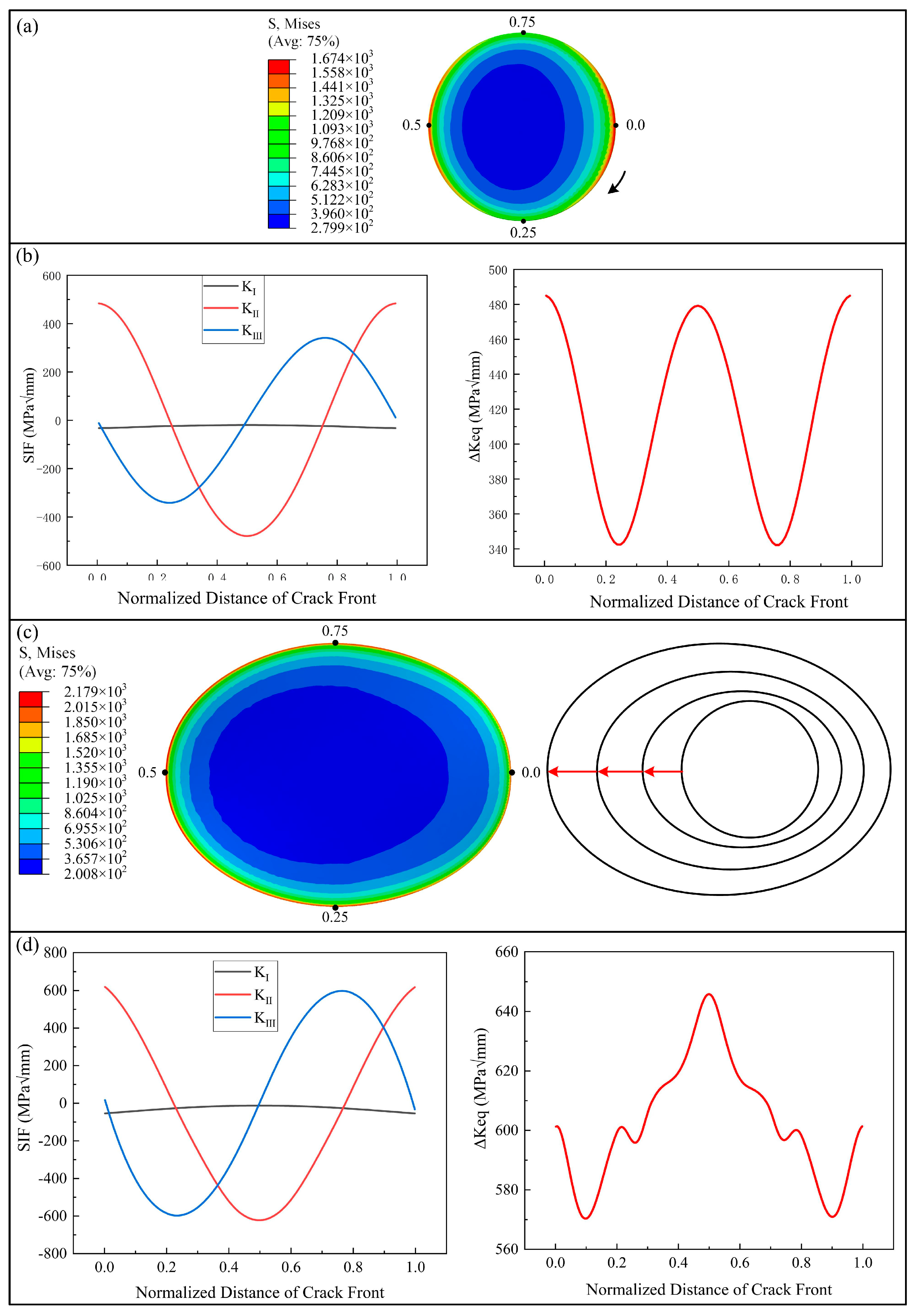

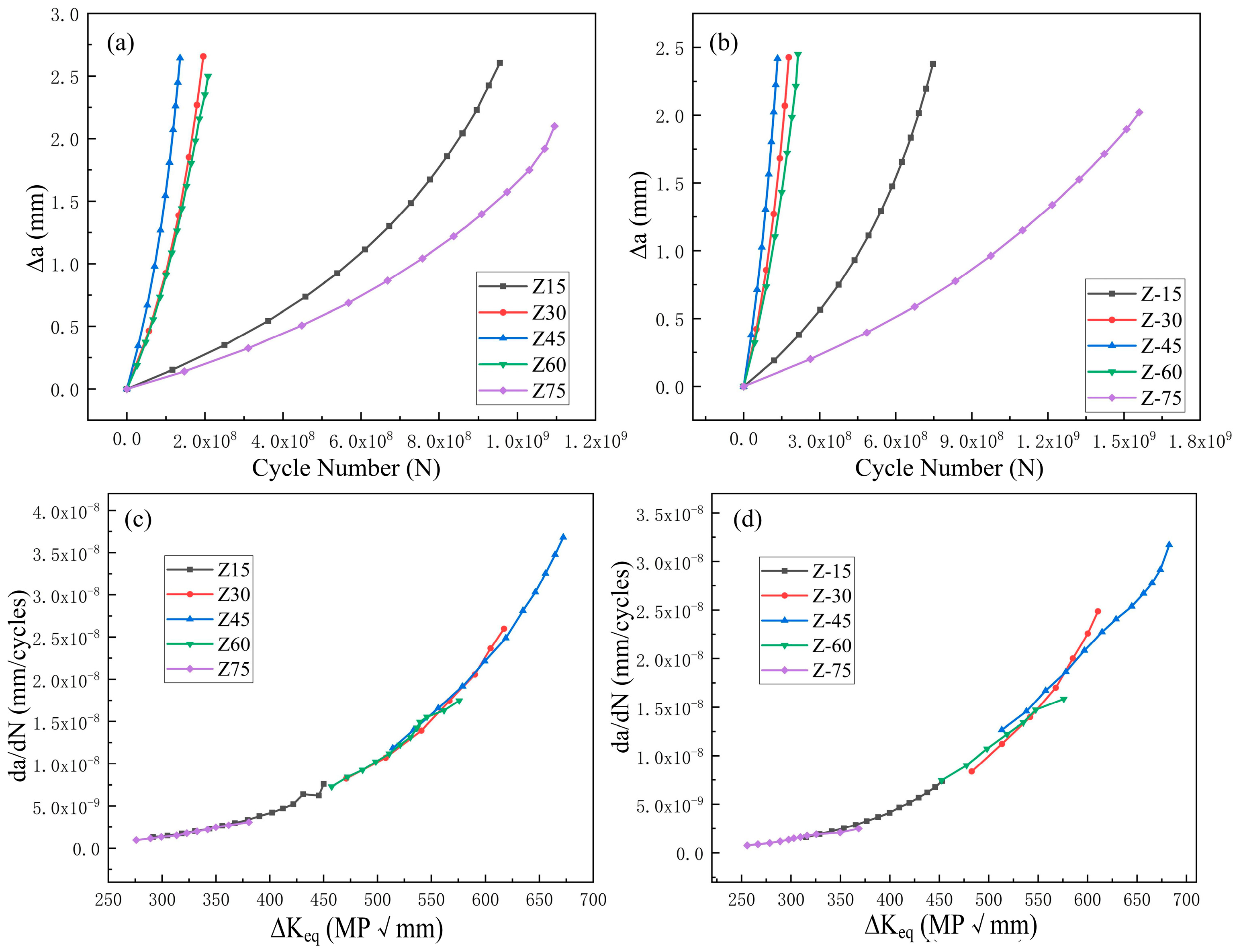

4.2. Effects of Initial Crack on Propagation

4.2.1. The Influence of the Crack Distribution Pattern on the Remaining Life of Wheel Peeling

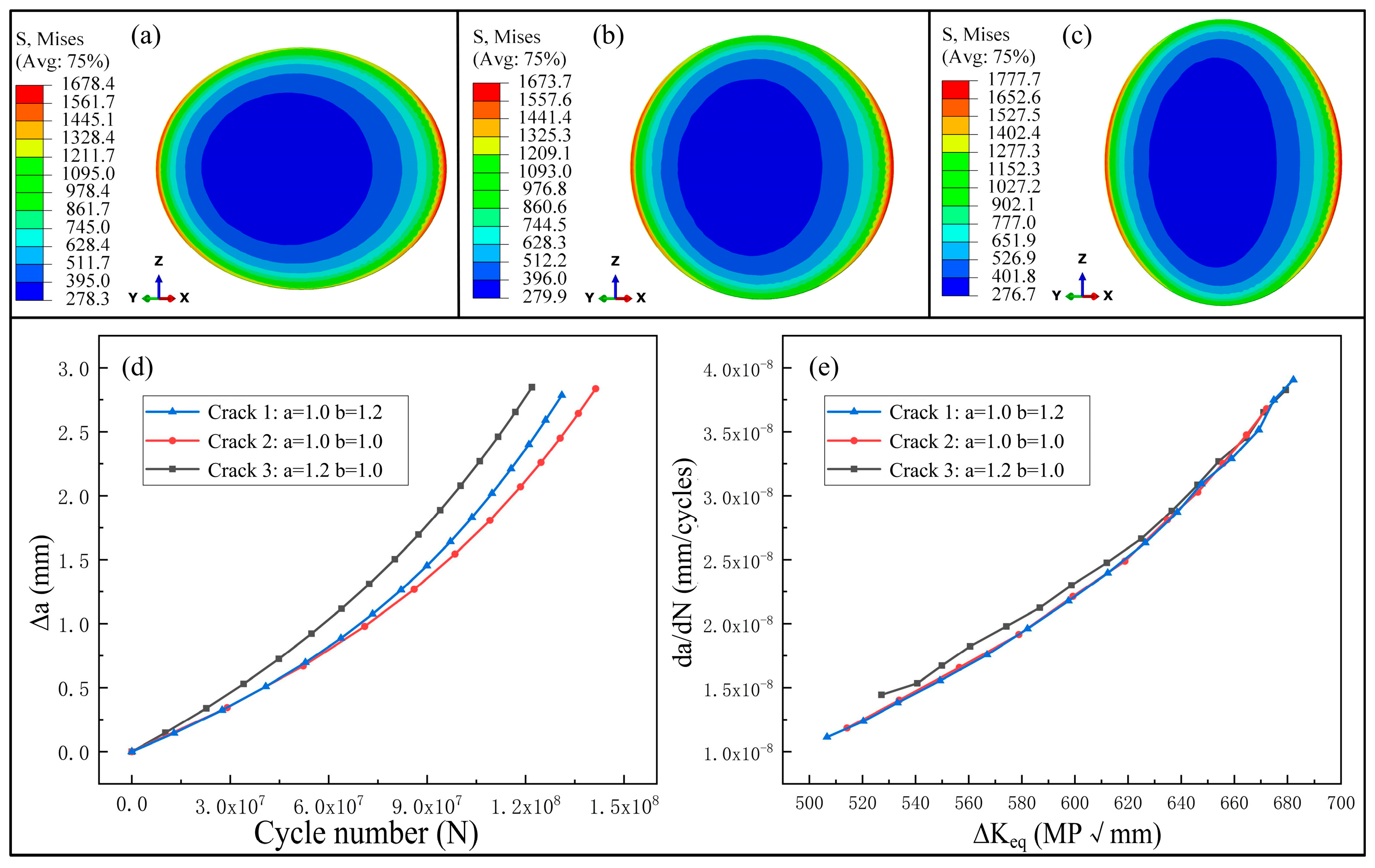

4.2.2. Influence of Crack Shape on the Remaining Life of Wheel Peeling

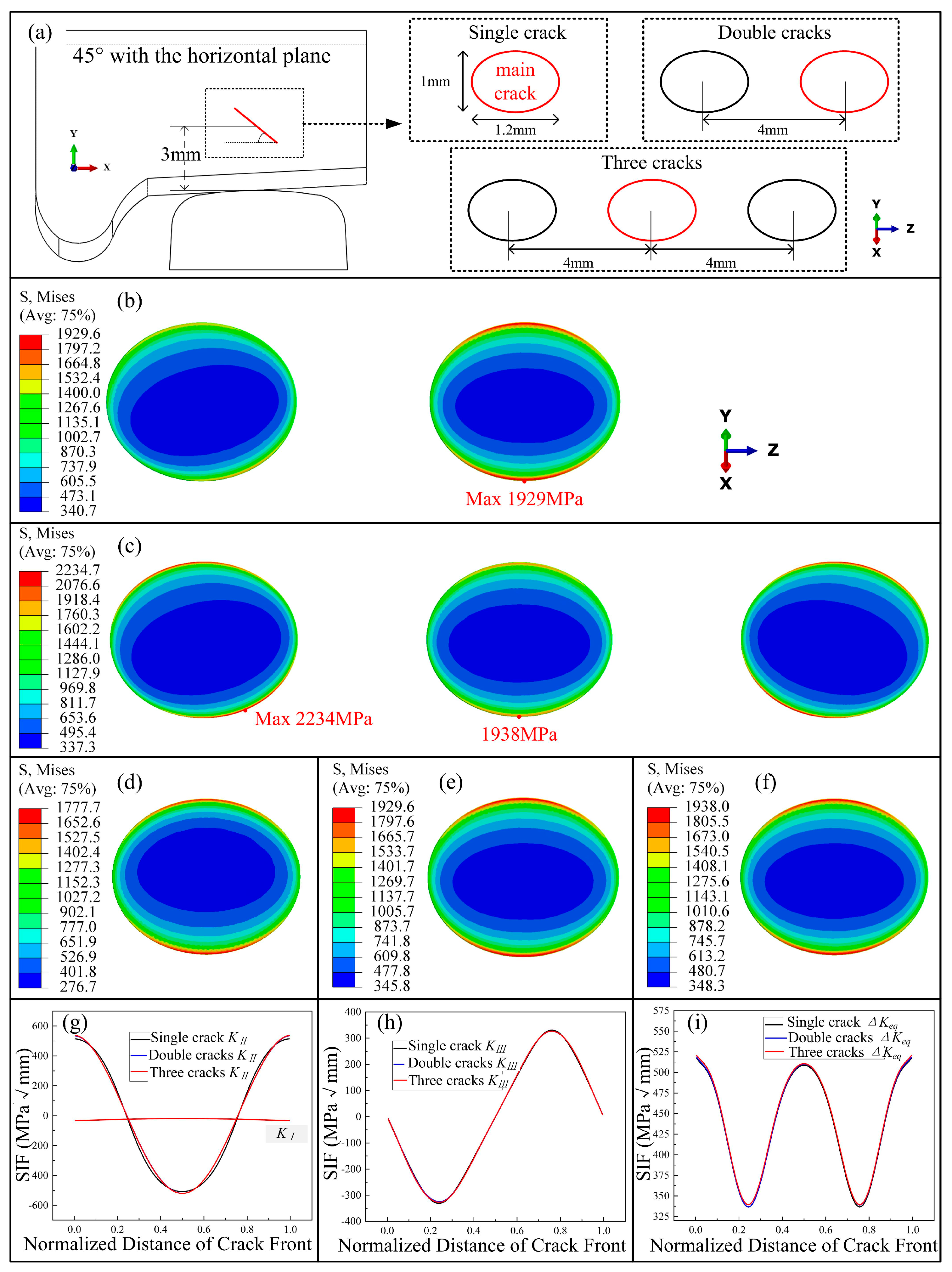

4.3. The Influence of Secondary Cracks on Primary-Crack Propagation

4.3.1. The Influence on the Propagation Rate of the Main Crack

4.3.2. Influence on the Propagation Path of the Main Crack

4.4. Discussion on Residual Peeling Lifetime

5. Conclusions

- (1)

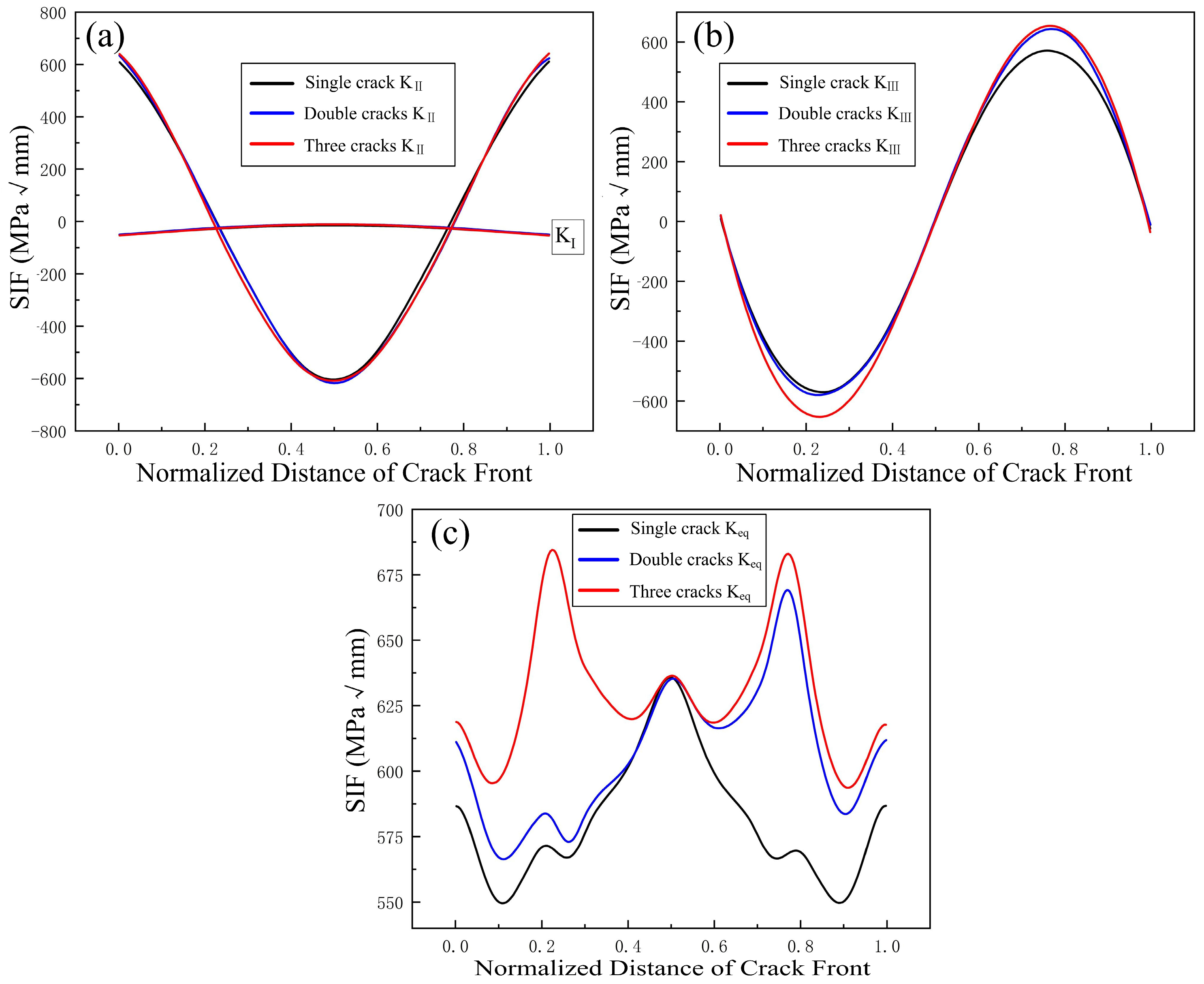

- Under the complex loads acting on the wheel, the propagation mode of subsurface cracks in wheels is mainly a mixture of modes II and III caused by shear stress, with mode II propagation being dominant. This is consistent with the authors’ previous work on rails. Since the cracks remain in a closed state during propagation, the influence of the mode I SIF on crack propagation is minimal.

- (2)

- When the fatigue crack inside the wheel forms a 45° angle with the wheel–rail contact horizontal plane, it represents the most dangerous condition. Cracks at this angle propagate the fastest, resulting in the shortest remaining life of the wheel. Compared with circular cracks, elliptical cracks exhibit a greater driving force in the early stage of crack propagation, leading to an accelerated crack growth rate and a reduced remaining peeling life of the wheel.

- (3)

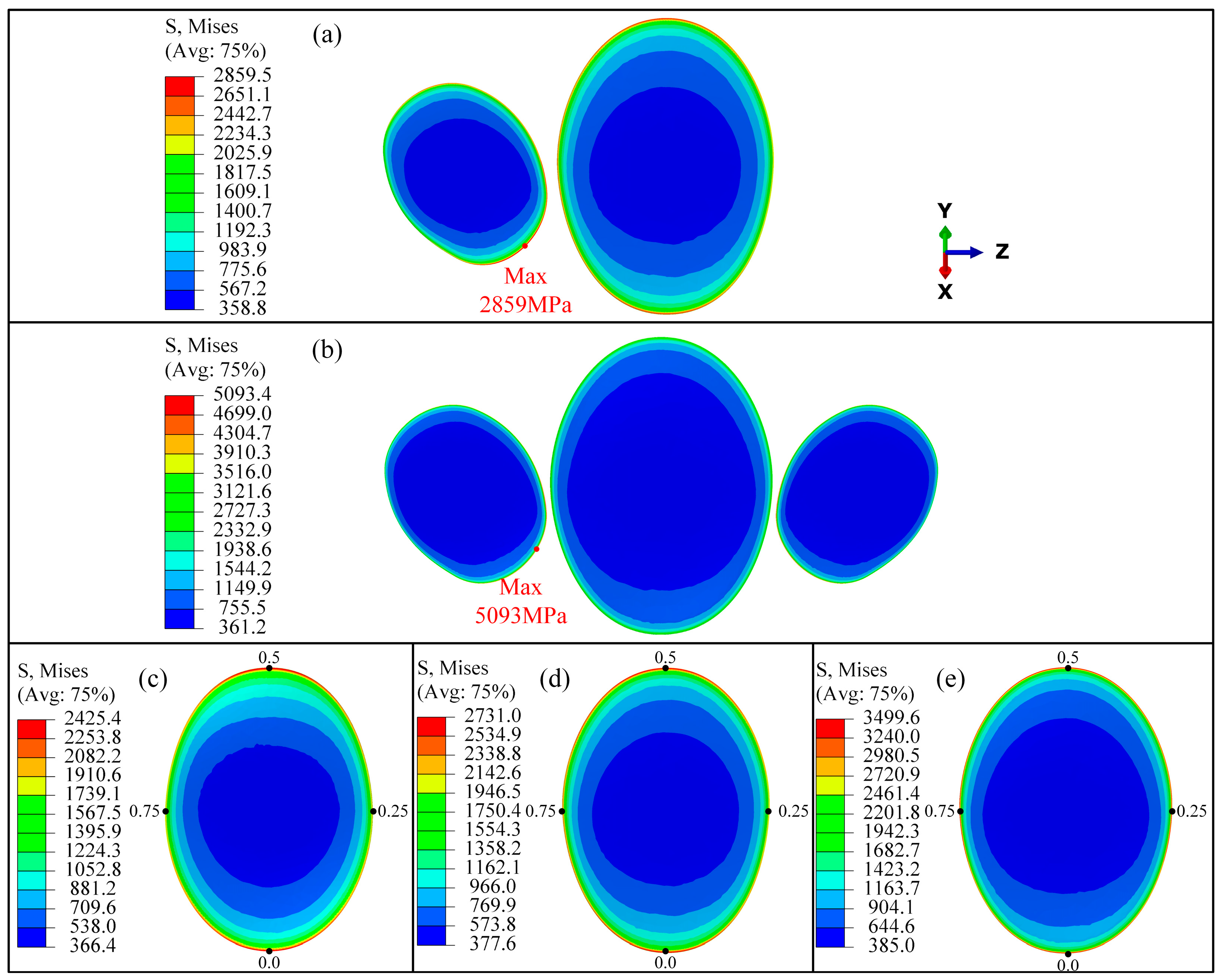

- The presence of secondary cracks has little influence on the initial stress distribution of the main crack, but it makes the stress singularity at the crack tip more prominent. The maximum von Mises stress of the wheel increases as the number of multi-source cracks increases. In the multi-crack model, the reference crack exhibits a stress distribution different from that in the single-crack model in the direction of secondary cracks, which proves that the reference crack gradually propagates toward the secondary cracks before crack coalescence occurs.

- (4)

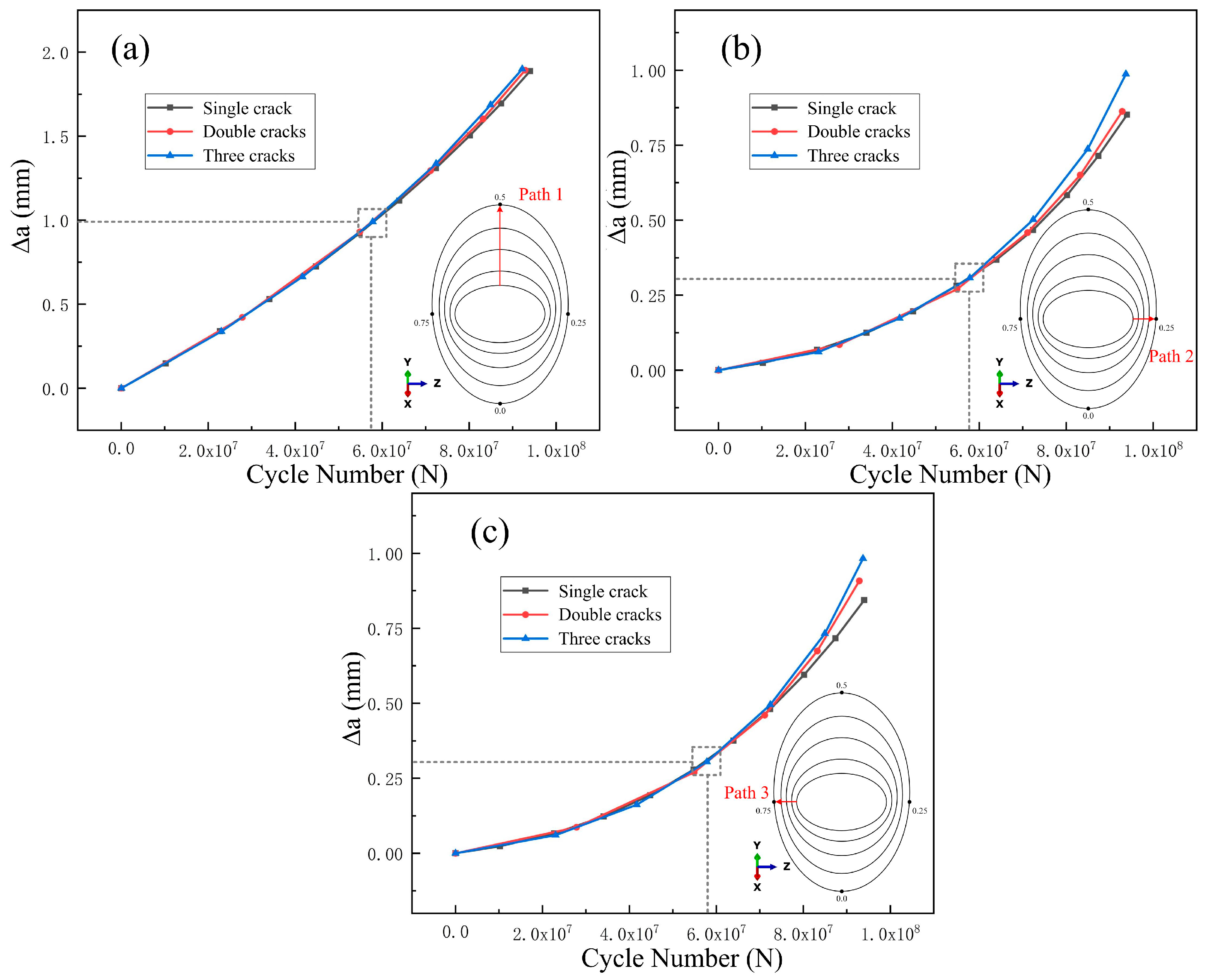

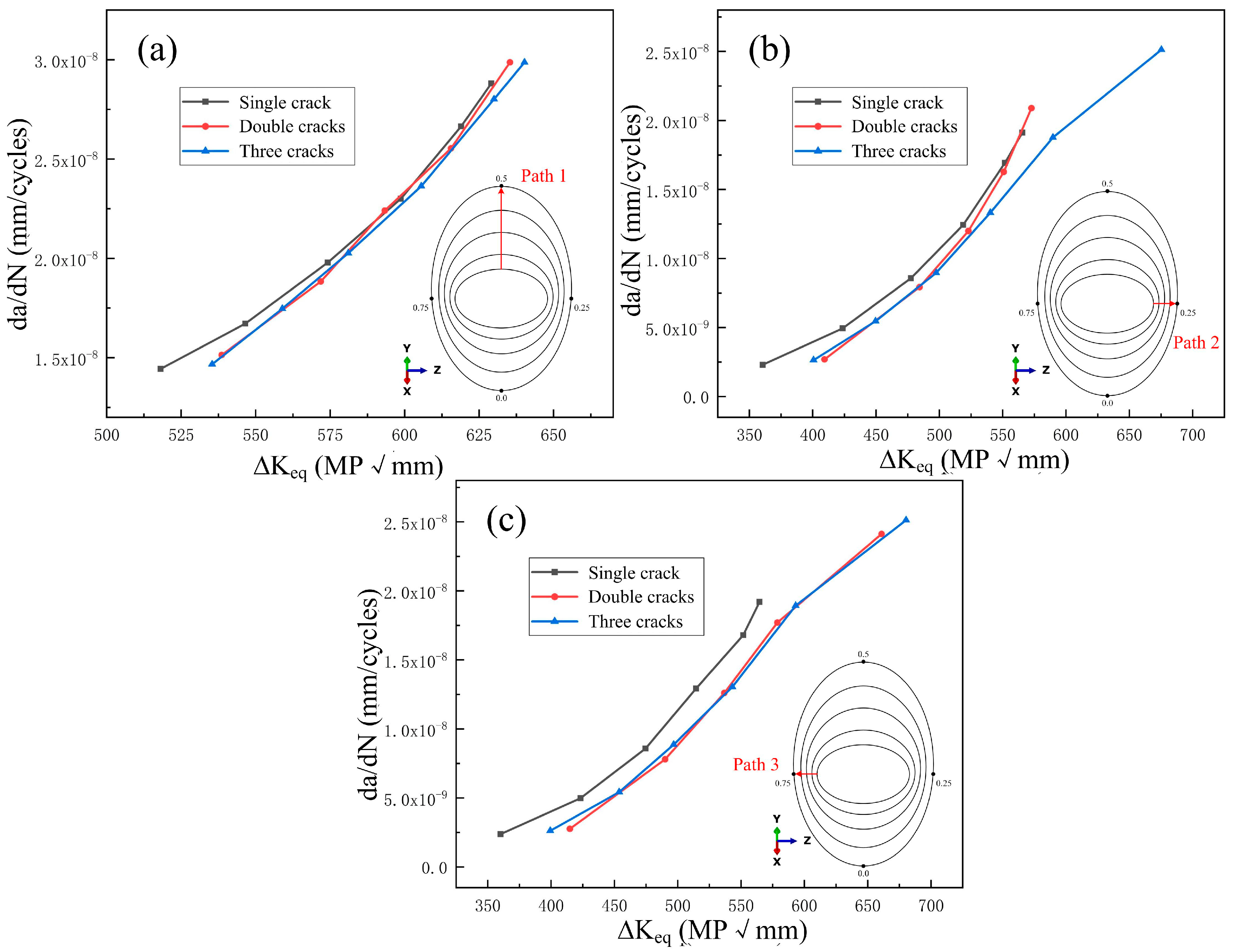

- The presence of multi-source cracks has little effect on the mode I and mode II propagation of the main crack but has a significant impact on mode III propagation. Additionally, it increases the overall equivalent SIF of the crack and enhances the driving force for crack propagation, making fatigue cracks more prone to propagation and reducing the peeling life of the wheel.

- (5)

- The presence of secondary cracks increases the initial driving force ΔKeq for crack propagation. During crack propagation, secondary cracks have little influence on the original propagation path of the crack. After a certain number of cycles, the original crack rapidly propagates toward the secondary cracks until crack coalescence occurs, making the cracks more dangerous.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Symbol | Meaning |

| SIF | Stress intensity factor |

| FE | Finite element |

| FEM | Finite element method |

| RCF | Rolling contact fatigue |

| FV | Vertical load |

| Δa/ΔN | Crack growth rate |

| ΔKeq | Equivalent stress intensity factor |

| KI | Mode I crack |

| KII | Mode II crack |

| KIII | Mode III crack |

References

- Reis, L.; Li, B.; de Freitas, M. A multiaxial fatigue approach to Rolling Contact Fatigue in railways. Int. J. Fatigue 2014, 67, 191–202. [Google Scholar] [CrossRef]

- Cong, T.; Han, J.M.; Hong, Y.S.; Domblesky, J.P.; Liu, X.L. Shattered rim and shelling of high-speed railway wheels in the very-high-cycle fatigue regime under rolling contact loading. Eng. Fract. Mech. 2019, 97, 556–567. [Google Scholar] [CrossRef]

- Cantini, S.; Cervello, S.J.W. The competitive role of wear and RCF: Full scale experimental assessment of artificial and natural defects in railway wheel treads. Wear 2016, 366, 325–337. [Google Scholar] [CrossRef]

- Gullers, P.; Dreik, P.; Nielsen, J.C.; Andersson, L. Track condition analyser: Identification of rail rolling surface defects, likely to generate fatigue damage in wheels, using instrumented wheelset measurements. Proceedings of the Institution of Mechanical Engineers, P.I. Mech. Eng. F.-J. Rai. 2011, 225, 1–13. [Google Scholar]

- Zhu, Z.Y.; Zhu, Y.L.; Wang, Q.Y. Fatigue mechanisms of wheel rim steel under off-axis loading. Mat. Sci. Eng. A-Struct. 2020, 773, 138731. [Google Scholar] [CrossRef]

- Yang, L.Q.; Hu, M.; Zhao, D.M.; Yang, J.; Zhou, X. A method for assessing wheel fatigue reliability considering multiaxial stress state. Adv. Mech. Eng. 2020, 12, 1–14. [Google Scholar] [CrossRef]

- Peixoto, D.F.; de Castro, P.M.S.T. Modelling of the fracture of a railway wheel. Procedia Struct. Integr. 2016, 2, 1904–1911. [Google Scholar] [CrossRef][Green Version]

- Nejad, R.M.; Farhangdoost, K.; Shariati, M.J.E.F.A. Numerical study on fatigue crack growth in railway wheels under the influence of residual stresses. Eng. Fail. Anal. 2015, 52, 75–89. [Google Scholar] [CrossRef]

- Yan, R.G.; Wang, W.J.; Guo, Y.T.; Liu, X.L.; Wu, S.C.; Zhang, Z.X. Influence of wheel out-of-roundness on the remaining life of railway wheels under mixed-mode fatigue loading. Fatigue Fract. Eng. Mater. Struct. 2022, 45, 2072–2085. [Google Scholar] [CrossRef]

- Zhang, Q.S.; Caraballo, I.T.; Li, Q.Z.; Han, J.C.; Han, J.; Zhao, J.W.; Dai, G.Z. Tension-shear multiaxial fatigue damage behavior of high-speed railway wheel rim steel. Int. J. Fatigue 2020, 133, 105416. [Google Scholar] [CrossRef]

- Zeng, D.F.; Xu, T.; Liu, W.D.; Lu, L.T.; Zhang, J.W.; Gong, Y.H. Investigation on rolling contact fatigue of railway wheel steel with surface defect. Wear 2020, 203207, 446–447. [Google Scholar] [CrossRef]

- Haidemenopoulos, G.; Sarafoglou, P.; Christopoulos, P.; Zervaki, A.D. Rolling contact fatigue cracking in rails subjected to in-service loading. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 1161–1172. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, L.; Mahadevan, S.J.E.F. Analysis of subsurface crack propagation under rolling contact loading in railroad wheels using FEM. Eng. Fract. Mech. 2007, 74, 2659–2674. [Google Scholar] [CrossRef]

- Cho, D.H.; Seong, H.; Kim, Y.J.; Choi, J.B.; Jun, H.K.; Seo, J.W.; Kim, D.S. Parametric study on the fatigue life of railways under rolling contact fatigue by three-dimensional numerical analysis. J. Mech. Sci. Technol. 2012, 26, 359–365. [Google Scholar] [CrossRef]

- Meray, F.; Chaise, T.; Gravouil, A.; Depouhon, P.; Descharrieres, B.; Nélias, D. A novel SAM/X-FEM coupling approach for the simulation of 3D fatigue crack growth under rolling contact loading. Finite Elem. Anal. Des. 2022, 206, 103752. [Google Scholar]

- Ringsberg, J.W.; Bergkvist, A.J.F.; Materials, F.O.E. On propagation of short rolling contact fatigue cracks. Fatigue Fract. Eng. Mater. Struct. 2003, 26, 969–983. [Google Scholar] [CrossRef]

- Butini, E.; Marini, L.; Meacc, M.; Meli, E.; Rindi, A.; Zhao, X.J.; Wang, W.J. An innovative model for the prediction of wheel-Rail wear and rolling contact fatigue. Wear 2019, 436, 203025. [Google Scholar] [CrossRef]

- Huang, Y.B.; Shi, L.B.; Zhao, X.J.; Cai, Z.B.; Liu, Q.Y.; Wang, W.J. On the formation and damage mechanism of rolling contact fatigue surface cracks of wheel/rail under the dry condition. Wear 2018, 400–401, 62–73. [Google Scholar] [CrossRef]

- Dubourg, M.; Villechaise, B. Analysis of multiple fatigue cracks—Part I: Theory. J. Tribol. T. Asme 1992, 114, 455–461. [Google Scholar] [CrossRef]

- Dubourg, M.; Godet, M.; Villechaise, B. Analysis of multiple fatigue cracks—Part II: Results. J. Tribol. T. Asme 1992, 114, 462–468. [Google Scholar] [CrossRef]

- Tao, G.Q.; Tan, M.S.; Yuan, X.Y.; Wen, B.G.; Wen, Z.F. Influence of wheel wear on the rolling contact fatigue of metro wheels in the central area of the wheel tread. Wear 2025, 571, 205777. [Google Scholar] [CrossRef]

- Deuce, R. Wheel Tread Damage-An Elementary Guide, Bombardier Transportation Gmbh, Netphen; Technical Report: Berlin, Germany, 2007. [Google Scholar]

- Luo, K.L.; Liu, X.L.; Yang, Y.; Cong, T.; Zhang, F.; Wang, W. Modeling the competitive relationship between wear and rolling contact fatigue of railway wheel steel. Wear 2025, 205615, 560–561. [Google Scholar] [CrossRef]

- Zhang, R.J.; Zheng, C.L.; Chen, C.; Lv, B.; Gao, G.; Yang, Z.; Yang, Y.; Zhang, F. Study on fatigue wear competition mechanism and microstructure evolution on the surface of a bainitic steel rail. Wear 2021, 203978, 482–483. [Google Scholar] [CrossRef]

- Liu, H.L.; Liu, H.J.; Zhu, C.C.; Tang, J. Study on gear contact fatigue failure competition mechanism considering tooth wear evolution. Tribol. Int. 2020, 147, 106277. [Google Scholar] [CrossRef]

- Wang, H.H.; Wang, W.J.; Han, Z.Y.; Wang, Y.; Ding, H.H.; Lewis, R.; Lin, Q.; Liu, Q.Y.; Zhou, Z.R. Wear and rolling contact fatigue competition mechanism of different types of rail steels under various slip ratios. Wear 2023, 522, 204721. [Google Scholar] [CrossRef]

- Basseville, S.; Cailletaud, G. An evaluation of the competition between wear and crack initiation in fretting conditions for Ti-6Al-4V alloy. Wear 2015, 328, 443–455. [Google Scholar] [CrossRef]

- Fang, X.Y.; Zhang, H.N.; Ma, D.W. Influence of initial crack on fatigue crack propagation with mixed mode in U71Mn rail subsurface. Eng. Fail. Anal. 2022, 136, 106220. [Google Scholar] [CrossRef]

- GB/T 5599-2019; Specification for Dynamic Performance Assessment and Testing Verification of Rolling Stock. State Administration for Market Regulation, Standardization Administration of China: Bei Jing, China, 2019.

- Ai-Mukhtar, A.M.; Biermann, H.; Hubner, P.; Henkel, S. Determination of some parameters for fatigue life in welded joints using fracture mechanics method. J. Mater. Eng. Perfor. 2010, 19, 1225–1234. [Google Scholar] [CrossRef]

- Fang, X.Y.; Zhang, H.N.; Ma, D.W.; Wu, Z.J.; Huang, W. Influence of welding residual stress on subsurface fatigue crack propagation of rail. Eng. Fract. Mech. 2022, 271, 108642. [Google Scholar] [CrossRef]

- Paris, P.C.; Gomez, R.E.; Anderson, W.E. A rational analytic theory of fatigue. Trend Eng. 1961, 13, 9–14. [Google Scholar]

- Fang, X.Y.; Cai, Z.B.; Wang, J.G.; Yang, X.F. Evaluation of temperature-sensitive fatigue crack propagation of a high-speed railway wheel rim material. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 815–1825. [Google Scholar] [CrossRef]

- Richard, H.A.; Fulland, M.; Sander, M.; Kullmer, G. Fracture in a rubber-sprung railway wheel. Eng. Fail. Anal. 2005, 6, 986–999. [Google Scholar] [CrossRef]

| Material Parameter | Elastic Modulus (GPa) | Poisson’s Ratio | Yield Limit (MPa) | Tensile Limit (MPa) | Threshold (MPa·m1/2) | Fracture Toughness (MPa·m1/2) |

|---|---|---|---|---|---|---|

| Wheel | 197 | 0.3 | 605 | 903 | 5.59 | 84 |

| Rail | 210 | 0.3 | 550 | 998 | 2.2 | 47 |

| Dynamic Parameter | Value | |

|---|---|---|

| Derailment coefficient | 0.11 | |

| Wheel unloading rate | 0.64 | |

| Wheel rail lateral force (kN) | 10.4 | |

| Stability index | Vertical index | 2.26 |

| Horizontal index | 2.39 | |

| Maximum acceleration (m·s−2) | Vertical acceleration | 1.96 |

| Transverse acceleration | 1.75 | |

| Load (kN) | 40 | 55 | 70 | 85 | 100 | 115 | 130 |

| Frequency (%) | 0.7 | 4.3 | 20.8 | 41.9 | 25.2 | 6.4 | 0.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, T.; Chen, B.; Fang, X. Effects of Multi-Crack Initiation in High-Speed Railway Wheel Subsurface on Tread Peeling Lifetime. Metals 2025, 15, 1148. https://doi.org/10.3390/met15101148

Guo T, Chen B, Fang X. Effects of Multi-Crack Initiation in High-Speed Railway Wheel Subsurface on Tread Peeling Lifetime. Metals. 2025; 15(10):1148. https://doi.org/10.3390/met15101148

Chicago/Turabian StyleGuo, Tao, Bingzhi Chen, and Xiuyang Fang. 2025. "Effects of Multi-Crack Initiation in High-Speed Railway Wheel Subsurface on Tread Peeling Lifetime" Metals 15, no. 10: 1148. https://doi.org/10.3390/met15101148

APA StyleGuo, T., Chen, B., & Fang, X. (2025). Effects of Multi-Crack Initiation in High-Speed Railway Wheel Subsurface on Tread Peeling Lifetime. Metals, 15(10), 1148. https://doi.org/10.3390/met15101148