Study on Double-Curvature Metal Plates Sequential Forming with Heat-Assisted Incremental Bending Based on Minimum Energy Method

Abstract

1. Introduction

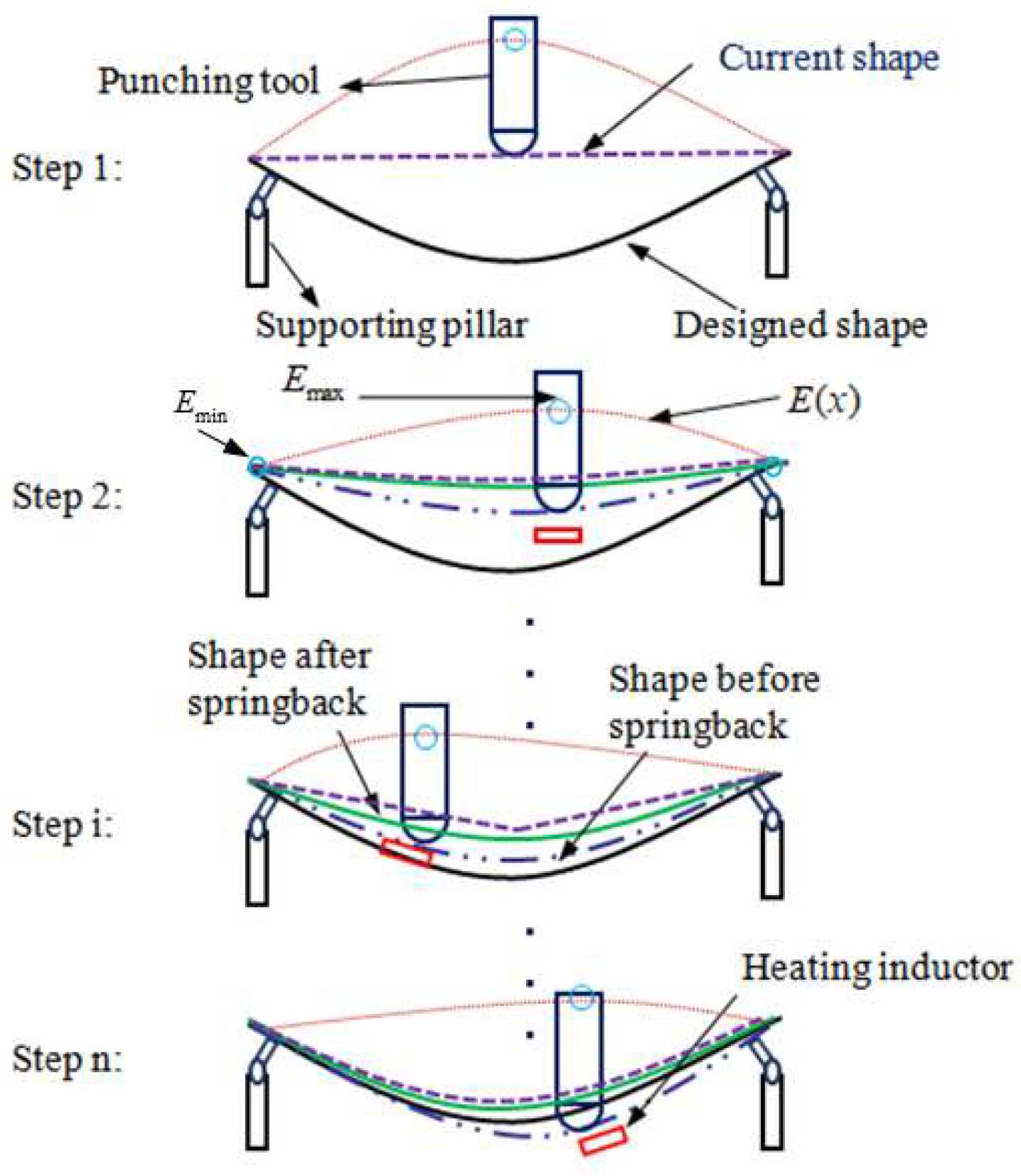

2. Principle of Heat-Assisted Incremental Bending

2.1. Minimum Energy Principle [23]

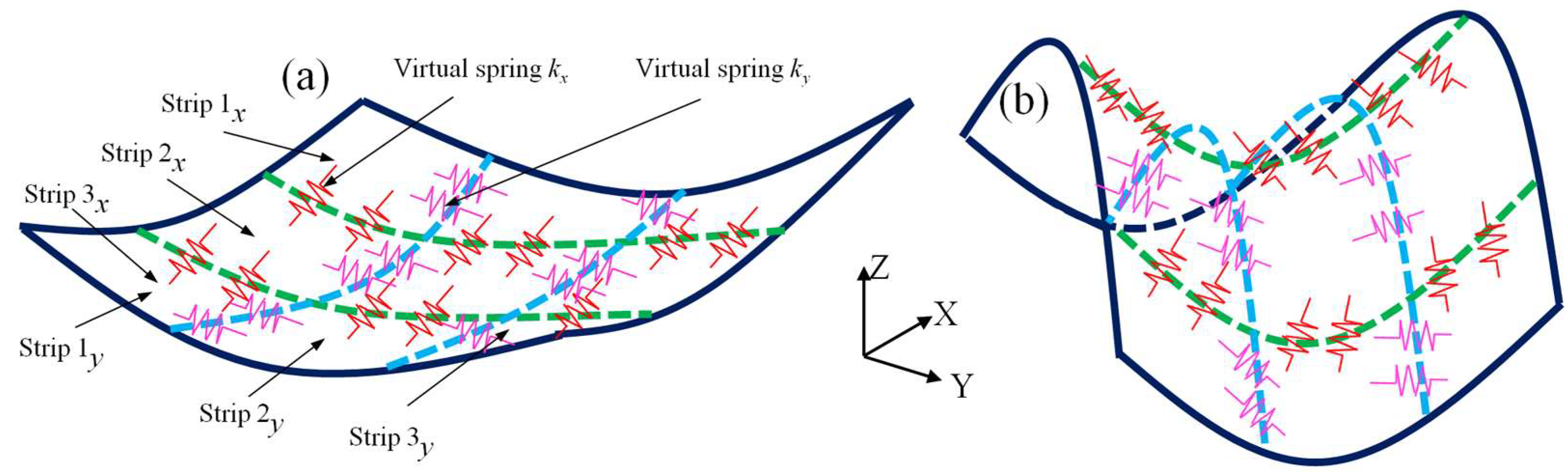

2.2. Virtual Spring Theory

2.3. Flexible Supporting System

3. Experiments and Simulations

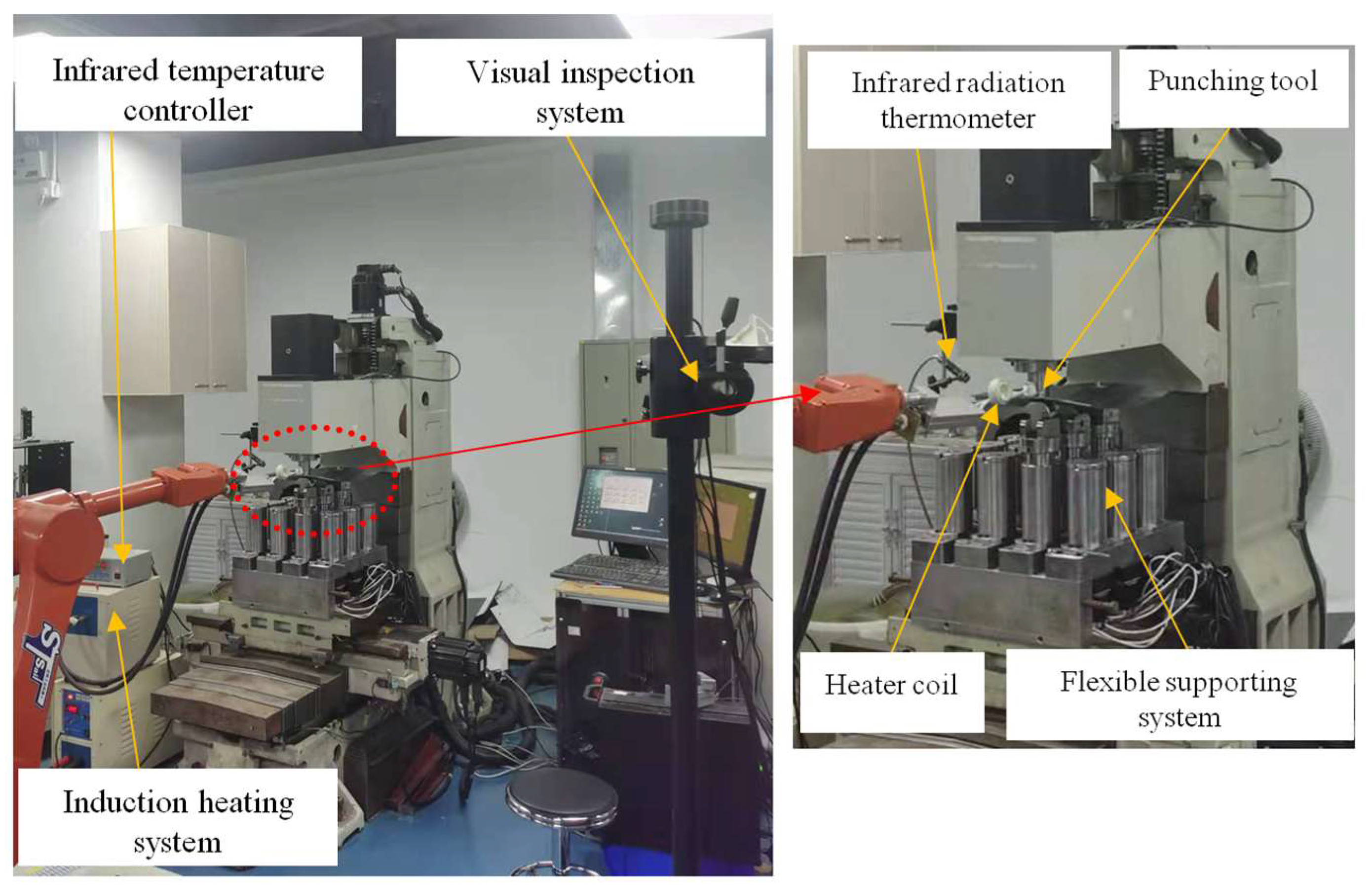

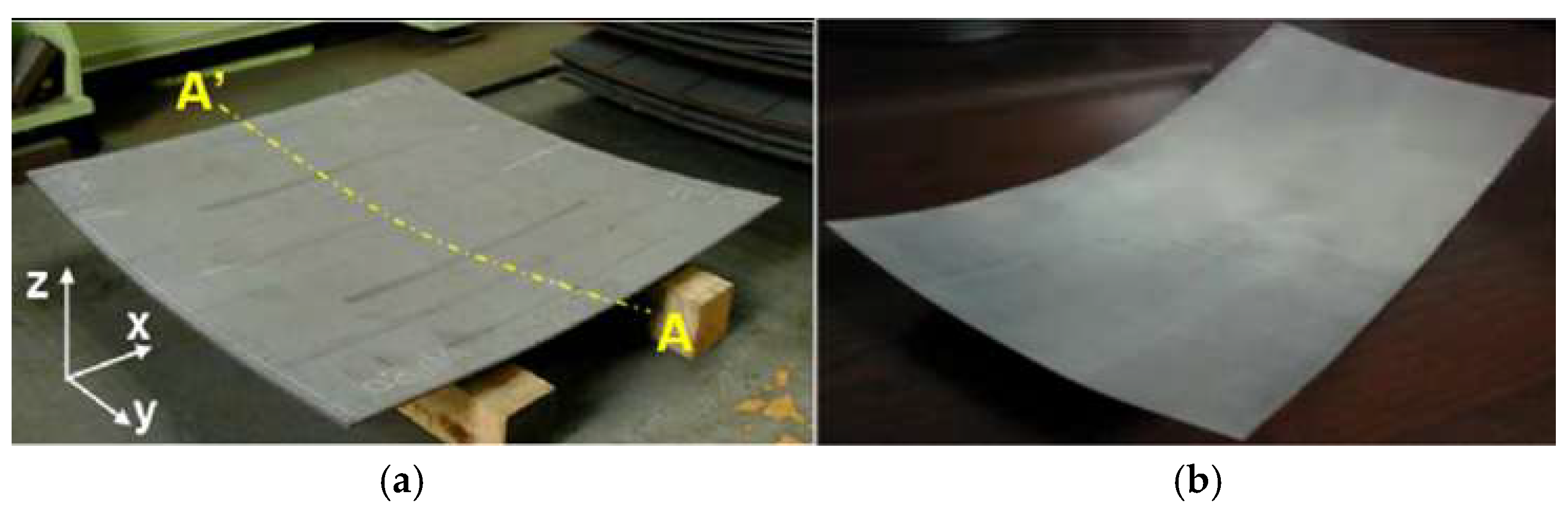

3.1. Experimental Setup

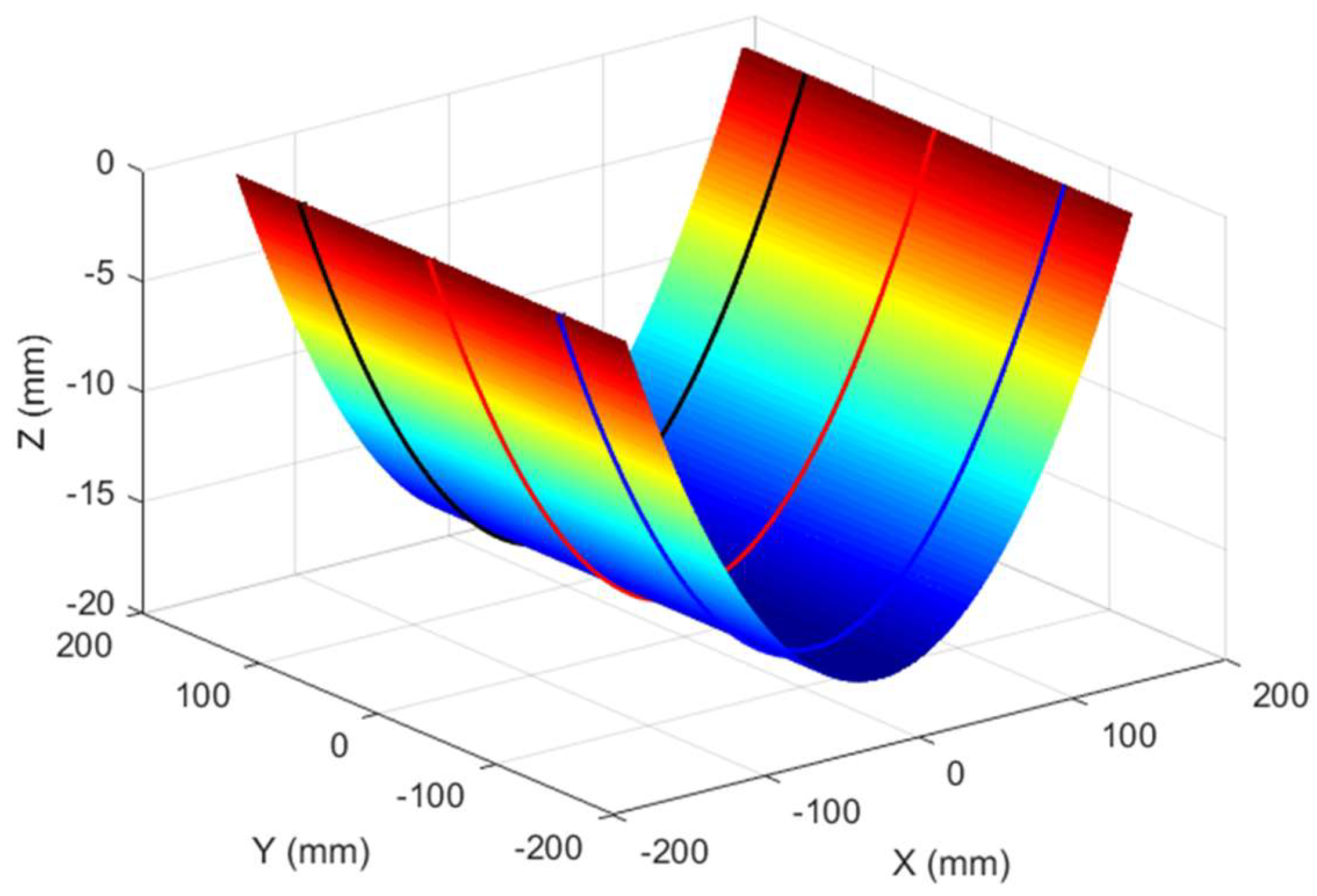

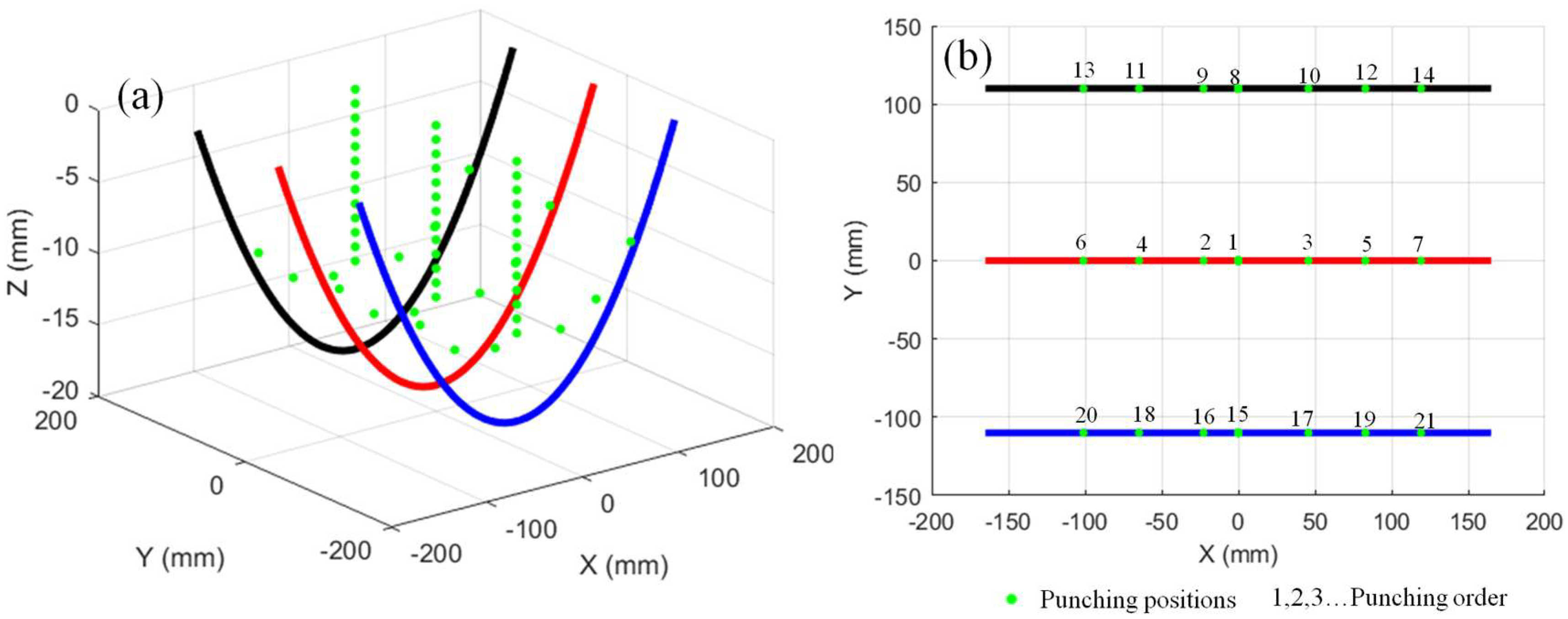

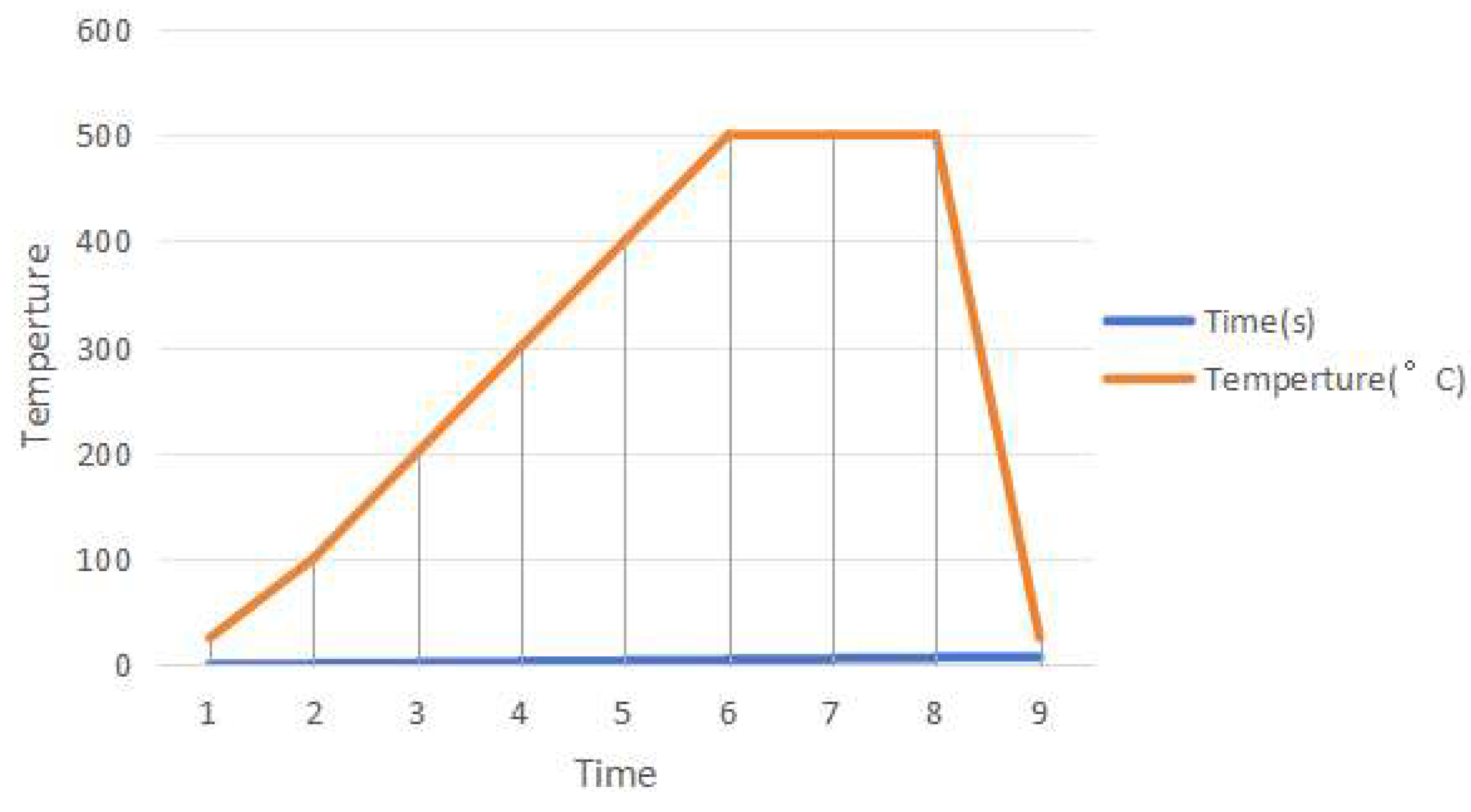

3.2. Experimental Procedure

3.3. Simulation

4. Results and Discussion

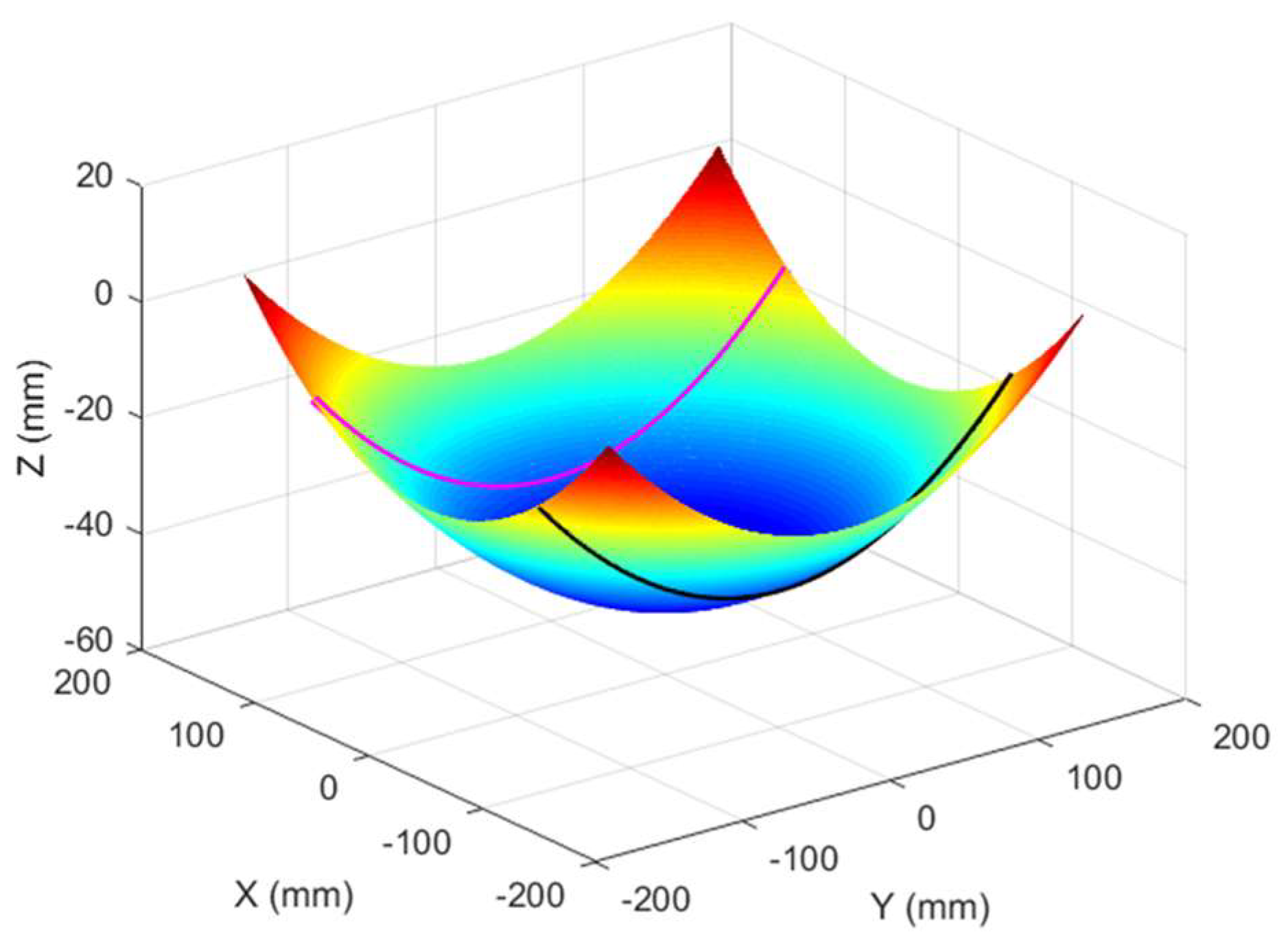

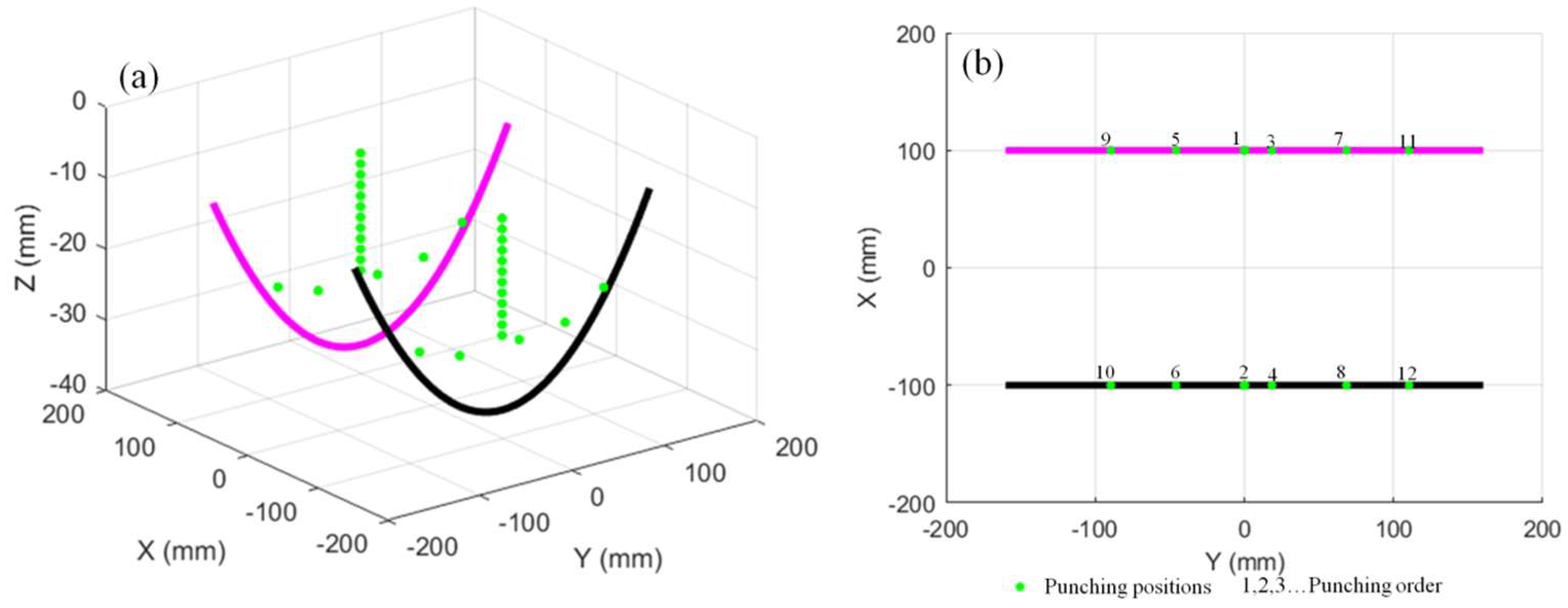

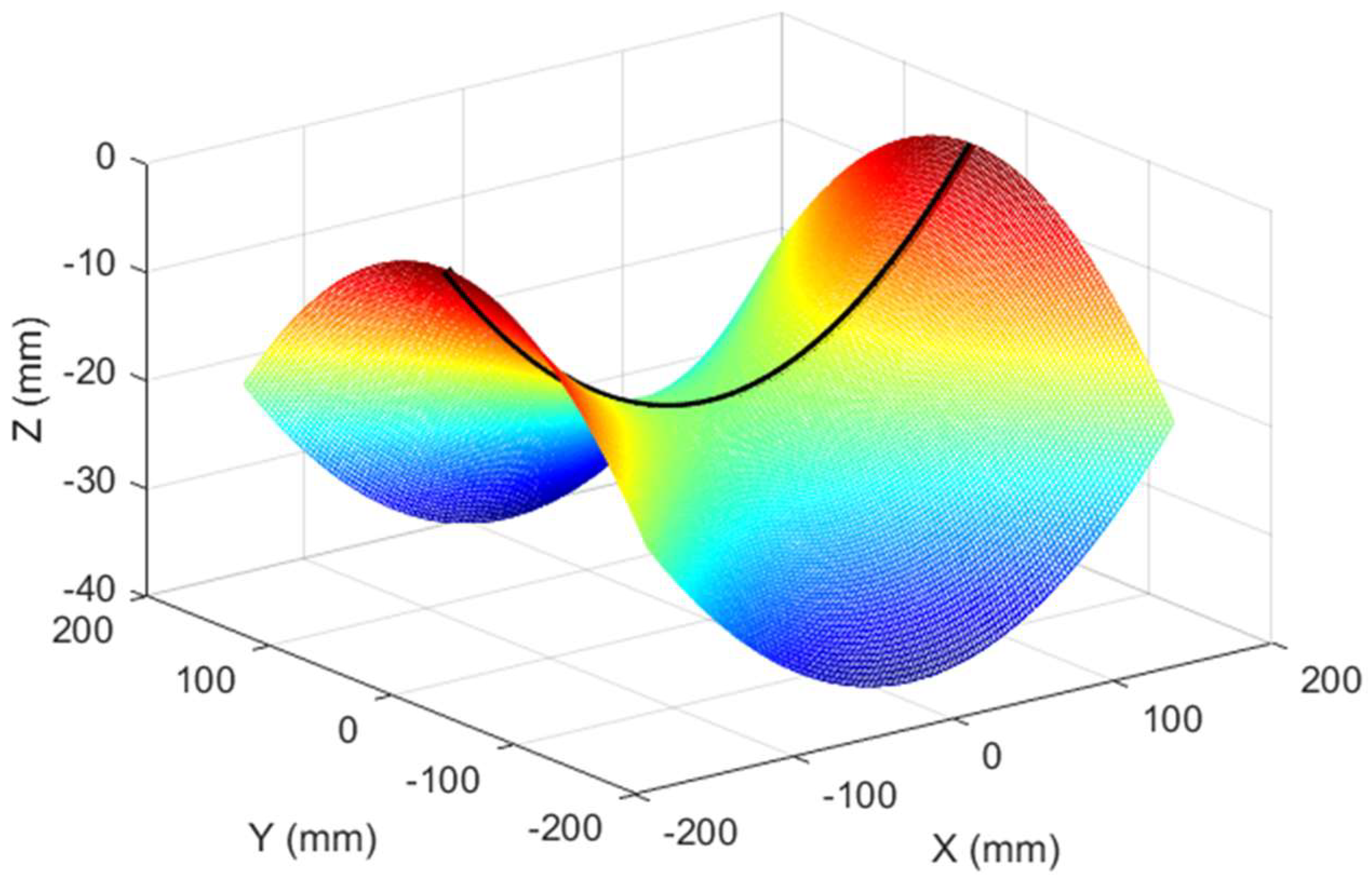

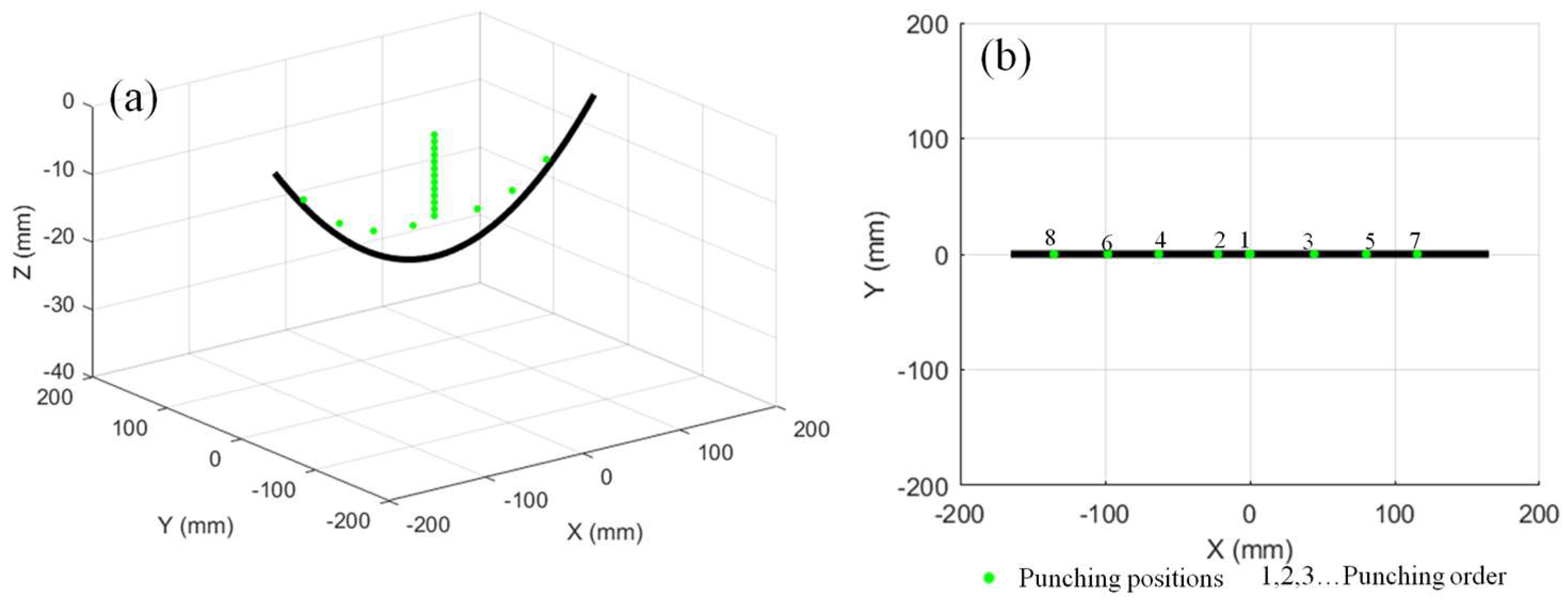

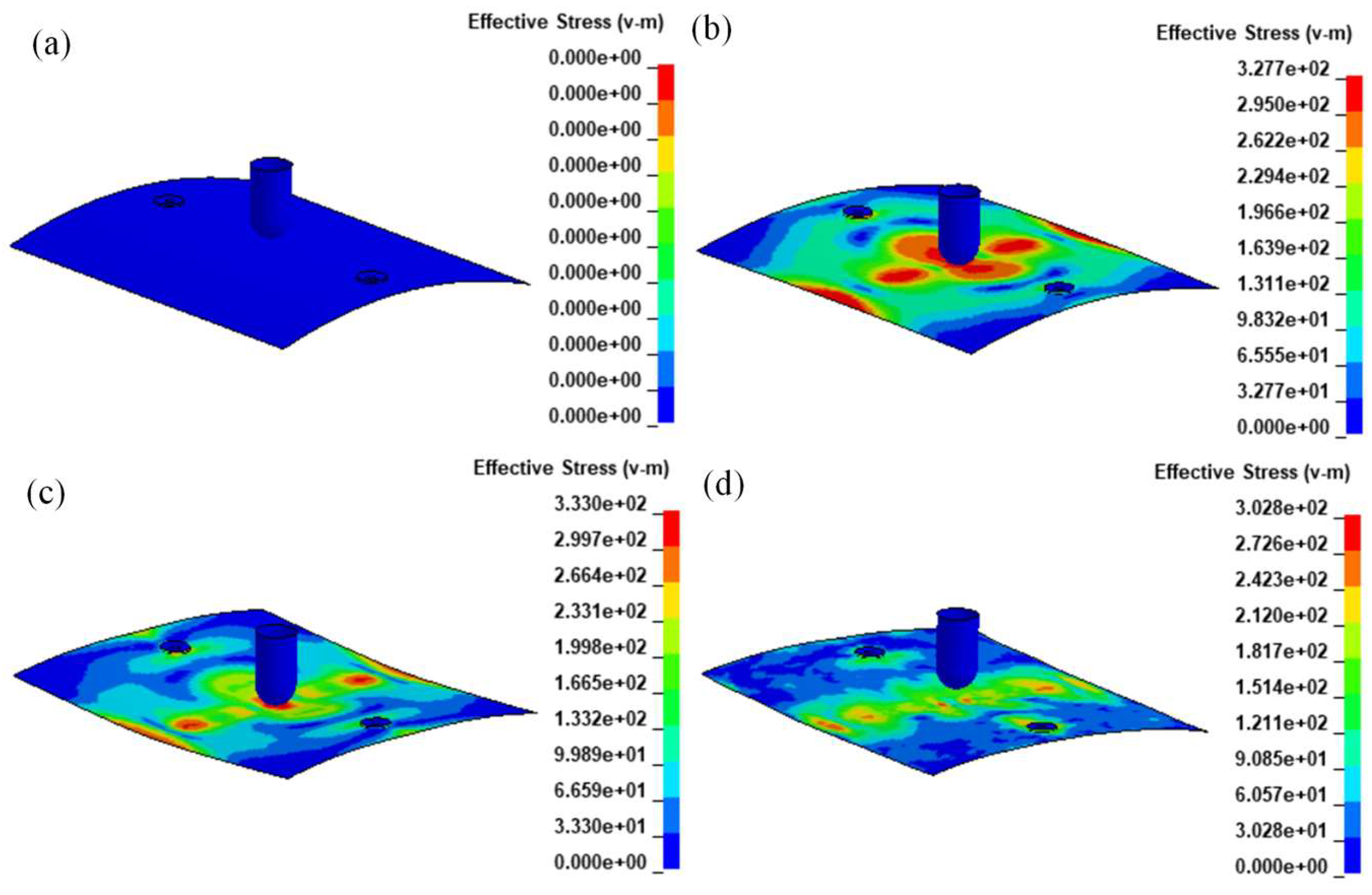

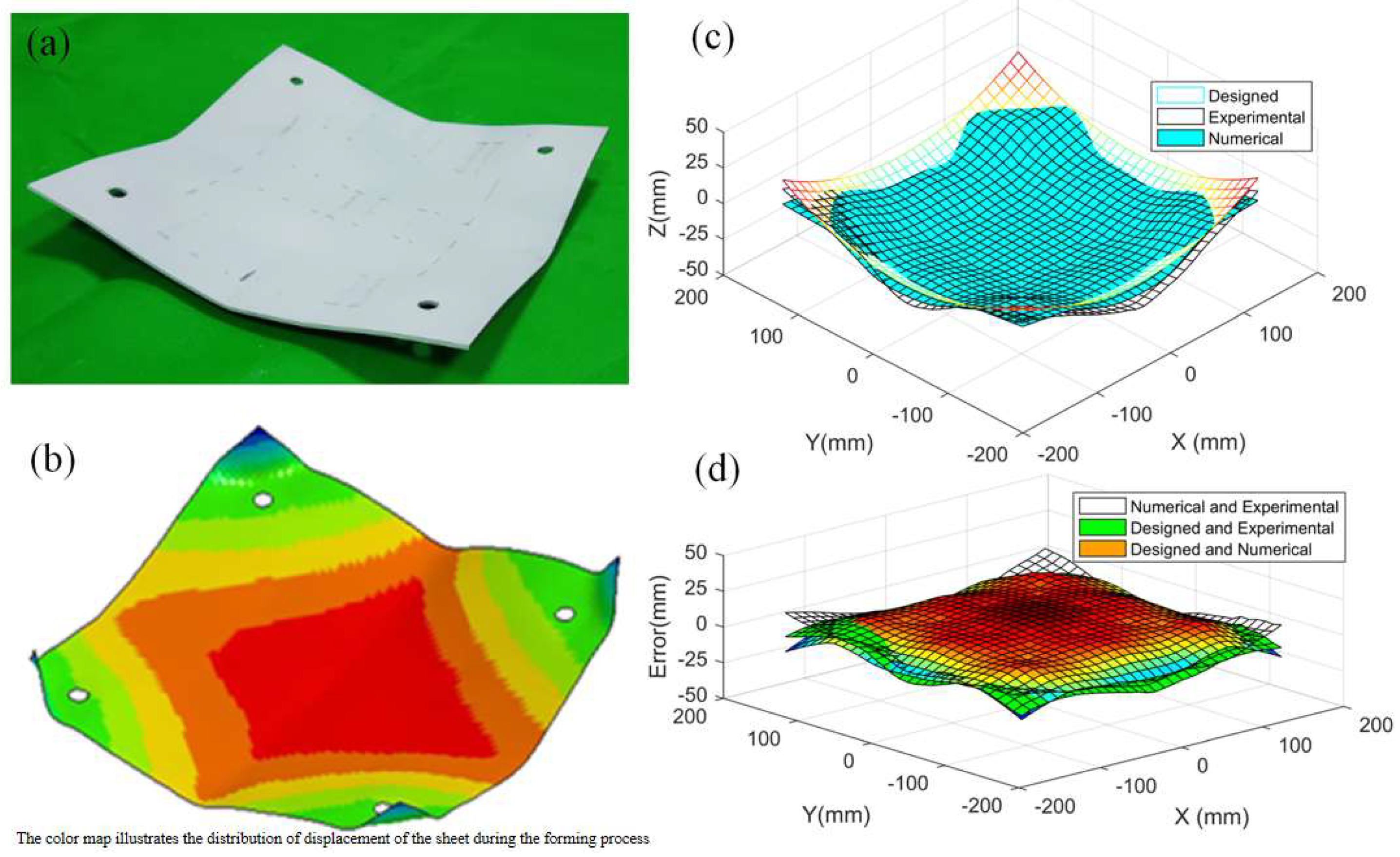

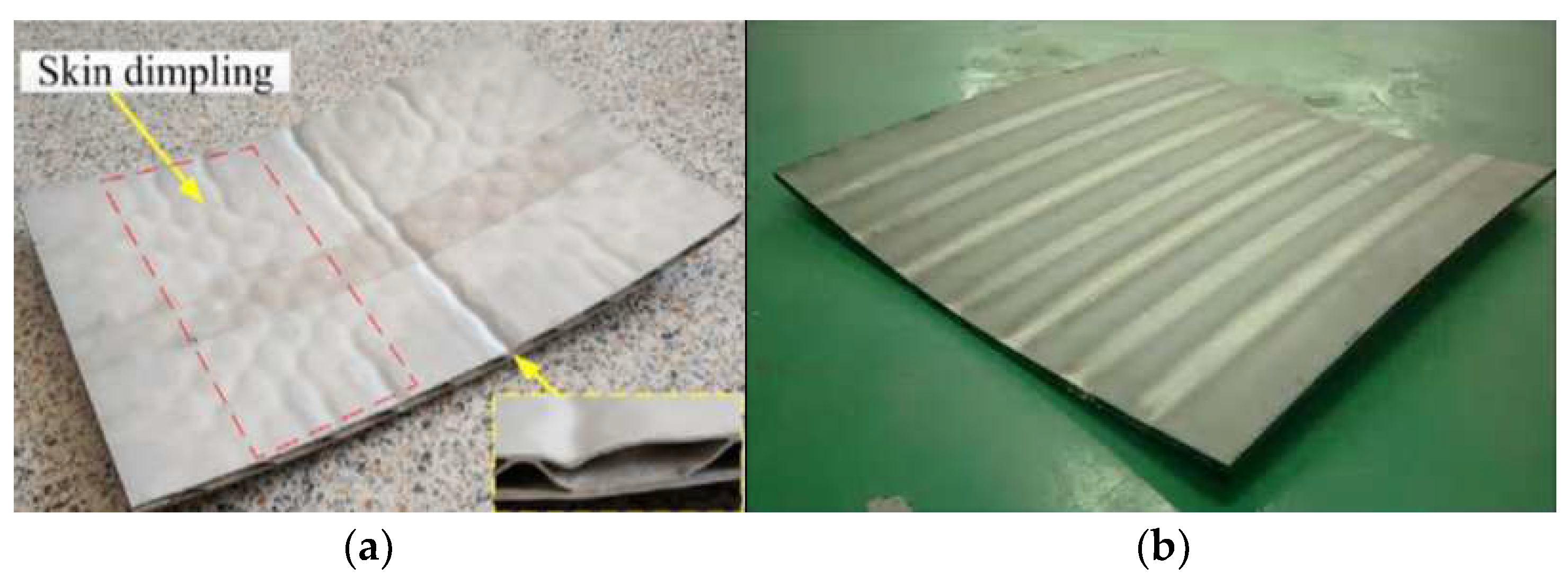

4.1. Comparative Study on Sequential Forming Process of Double-Curvature Plates

4.2. Comparison of Results for Forming Double-Curvature Plates Using Different Methods

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shin, J.G.; Woo, J.H. Analysis of heat transfer between the gas torch and the plate for the application of line heating. J. Manuf. Sci. Eng. 2003, 125, 794–800. [Google Scholar] [CrossRef]

- Shin, J.G.; Lee, J.M.; Nam, J.H. An efficient algorithm for measurement and comparison of large-scale hull pieces in the line-heating process. J. Ship Prod. 2004, 20, 60–67. [Google Scholar] [CrossRef]

- Li, M.Z.; Cai, Z.Y.; Sui, Z.; Yan, Q. Multi-point forming technology for sheet metal. J. Mater. Process. Technol. 2002, 129, 333–338. [Google Scholar] [CrossRef]

- Liu, Y.J.; Li, M.Z.; Ju, F.F. Research on the process of flexible blank holder in multi-point forming for spherical surface parts. Int. J. Adv. Manuf. Technol. 2017, 89, 2315–2322. [Google Scholar] [CrossRef]

- Qu, E.H.; Li, M.Z.; Li, R.; Zhao, L.; Yi, Z. Inhibitory effects of a flexible steel pad on wrinkling in multi-point die forming. Int. J. Adv. Manuf. Technol. 2018, 95, 2413–2420. [Google Scholar]

- Shim, D.S.; Yang, D.Y.; Kim, K.H.; Han, M.; Chung, S. Numerical and experimental investigation into cold incremental rolling of doubly curved plates for process design of a new LARS (line array roll set) rolling process. CIRP Ann. 2009, 58, 239–242. [Google Scholar] [CrossRef]

- Shim, D.S.; Yang, D.Y.; Kim, K.H.; Chung, S.; Han, M. Investigation into forming sequences for the incremental forming of doubly curved plates using the line array roll set process. Int. J. Mach. Tools Manuf. 2010, 50, 214–218. [Google Scholar] [CrossRef]

- Cai, Z.Y.; Li, L.L.; Wang, M.; Li, M.-Z. Process design and longitudinal deformation prediction in continuous sheet metal roll forming for three-dimensional surface. Int. J. Precis. Eng. Manuf. 2014, 15, 1889–1895. [Google Scholar] [CrossRef]

- Cai, Z.Y.; Li, M.Z.; Lan, Y.W. Three-dimensional sheet metal continuous forming process based on flexible roll bending: Principle and experiments. J. Mater. Process. Technol. 2012, 212, 120–127. [Google Scholar] [CrossRef]

- Li, R.J.; Li, M.Z.; Qiu, N.J.; Cai, Z.-Y. Surface flexible rolling for three-dimensional sheet metal parts. J. Mater. Process. Technol. 2014, 214, 380–389. [Google Scholar] [CrossRef]

- Kim, J.; Na, S.J. Development of irradiation strategies for free curve laser forming. Opt. Laser Technol. 2003, 35, 605–611. [Google Scholar] [CrossRef]

- Kim, J.; Na, S.J. Feedback control for 2D free curve laser forming. Opt. Laser Technol. 2005, 37, 139–146. [Google Scholar] [CrossRef]

- Yang, L.J.; Wang, M.L.; Wang, Y.; Chen, Y. Dynamic analysis on laser forming of square metal sheet to spherical dome. Int. J. Adv. Manuf. Technol. 2010, 51, 519–539. [Google Scholar] [CrossRef]

- Safari, M.; Farzin, M. Experimental investigation of laser forming of a saddle shape with spiral irradiating scheme. Opt. Laser Technol. 2015, 66, 146–150. [Google Scholar] [CrossRef]

- Chakraborty, S.S.; More, H.; Nath, A.K. Laser forming of a bowl shaped surface with a stationary laser beam. Opt. Lasers Eng. 2016, 77, 126–136. [Google Scholar] [CrossRef]

- Hong, S.; Zhou, W.T.; Wang, H. Laser forming of doubly curved plates using minimum energy principle and comprehensive strain control. Int. J. Mech. Sci. 2018, 14, 542–552. [Google Scholar]

- Guan, Y.J.; Sun, S.; Zhao, G.Q.; Luan, Y.G. Finite element modeling of laser bending of pre-loaded sheet metals. J. Mater. Process. Technol. 2003, 142, 400–407. [Google Scholar]

- Yao, Z.Q.; Hong, S.; Shi, Y.J.; Hu, J. Numerical study on laser forming of metal plates with pre-loads. Comput. Mater. Sci. 2007, 40, 27–32. [Google Scholar] [CrossRef]

- Liu, J.; Sun, S.; Guan, Y.J. Numerical investigation on the laser bending of stainless steel foil with pre-stresses. J. Mater. Process. Technol. 2009, 209, 1580–1587. [Google Scholar] [CrossRef]

- Gisario, A.; Barletta, M.; Venettacci, S.; Veniali, F. Laser-assisted bending of sharp angles with small fillet radius on stainless steel sheets: Analysis of experimental set-up and processing parameters. Lasers Manuf. Mater. Process. 2015, 2, 57–73. [Google Scholar] [CrossRef]

- Gisario, A.; Barletta, M.; Venettacci, S. Improvements in springback control by external force laser-assisted sheet bending of titanium and aluminum alloys. Opt. Laser Technol. 2016, 86, 46–53. [Google Scholar] [CrossRef]

- Gisario, A.; Barletta, M.; Venettacci, S.; Veniali, F. External force-assisted Laser Origami (LO) bending: Shaping of 3D cubes and edge design of stainless steel chairs. J. Manuf. Process. 2015, 18, 159–166. [Google Scholar] [CrossRef]

- Dang, X.B.; He, K.; Li, W.; Zuo, Q.; Du, R. Incremental bending of three-dimensional free form metal plates using minimum energy principle and model-less control. J. Manuf. Sci. Eng. 2017, 139, 071009. [Google Scholar] [CrossRef]

- Hill, R. The Mathematical Theory of Plasticity; Oxford University Press: Oxford, UK, 1998. [Google Scholar]

- Gendron, M.; Hazel, B.; Boudreault, E.; Champliaud, H.; Pham, X.-T. Coupled thermo-electromagnetic model of a new robotic high-frequency local induction heat treatment system for large steel components. Appl. Therm. Eng. 2019, 150, 372–385. [Google Scholar] [CrossRef]

- Wei, B.; Zhang, F.F.; He, K.; Li, Z.; Du, R. Deformation and Springback Behavior of Sheet Metal With Convex-Shaped Surfaces in Heat-Assisted Incremental Bending Process Based on Minimum Energy Method. J. Manuf. Sci. Eng. 2023, 145, 031003. [Google Scholar] [CrossRef]

- Liang, X.B.; Cai, Z.Y.; Zhang, X.; Gao, J.-X. Plastic forming of the doubly curved surfaces of sandwich plates with bi-directionally trapezoidal cores of different sizes. Thin-Walled Struct. 2020, 146, 478–488. [Google Scholar] [CrossRef]

- Seong, W.J.; Jeon, Y.C.; Na, S.J. Ship-hull plate forming of saddle shape by geometrical approach. J. Mater. Process. Technol. 2013, 213, 1885–1893. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, B.; Zhang, F.; Cheng, Z.; Yuan, B. Study on Double-Curvature Metal Plates Sequential Forming with Heat-Assisted Incremental Bending Based on Minimum Energy Method. Metals 2025, 15, 1124. https://doi.org/10.3390/met15101124

Wei B, Zhang F, Cheng Z, Yuan B. Study on Double-Curvature Metal Plates Sequential Forming with Heat-Assisted Incremental Bending Based on Minimum Energy Method. Metals. 2025; 15(10):1124. https://doi.org/10.3390/met15101124

Chicago/Turabian StyleWei, Bo, Feifei Zhang, Zhun Cheng, and Bo Yuan. 2025. "Study on Double-Curvature Metal Plates Sequential Forming with Heat-Assisted Incremental Bending Based on Minimum Energy Method" Metals 15, no. 10: 1124. https://doi.org/10.3390/met15101124

APA StyleWei, B., Zhang, F., Cheng, Z., & Yuan, B. (2025). Study on Double-Curvature Metal Plates Sequential Forming with Heat-Assisted Incremental Bending Based on Minimum Energy Method. Metals, 15(10), 1124. https://doi.org/10.3390/met15101124