Microstructure Control for Enhancing the Combination of Strength and Elongation in Ti-6Al-4V through Heat Treatment

Abstract

1. Introduction

2. Materials and Experimental Procedures

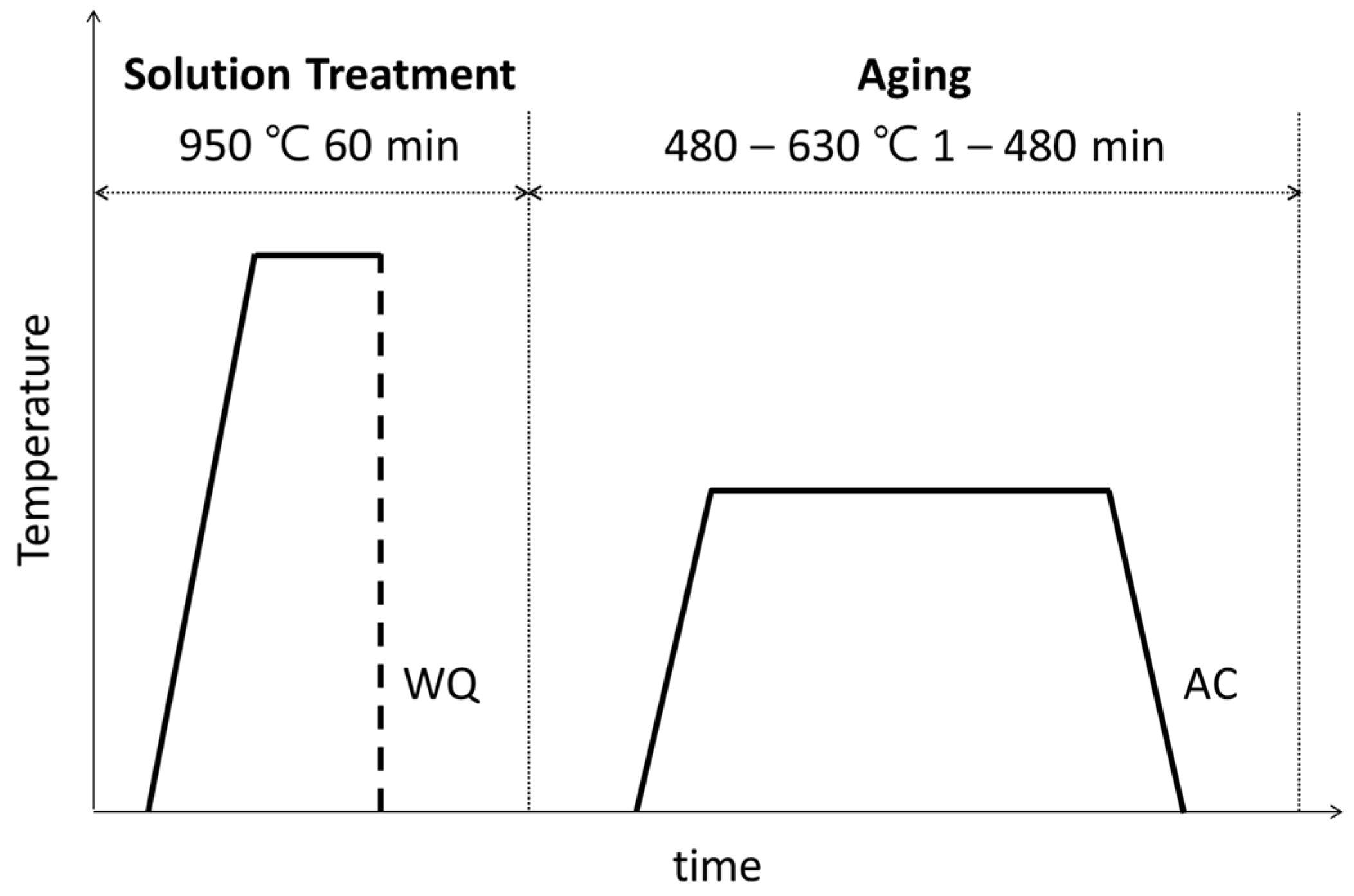

2.1. Material and Heat Treatment Conditions

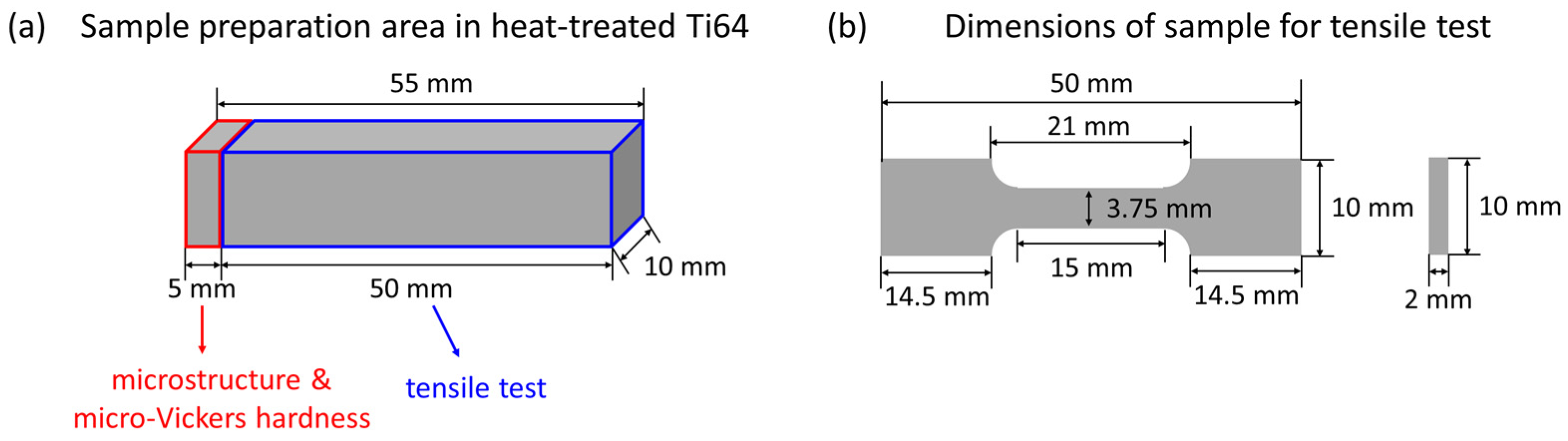

2.2. Characterization

3. Results and Discussion

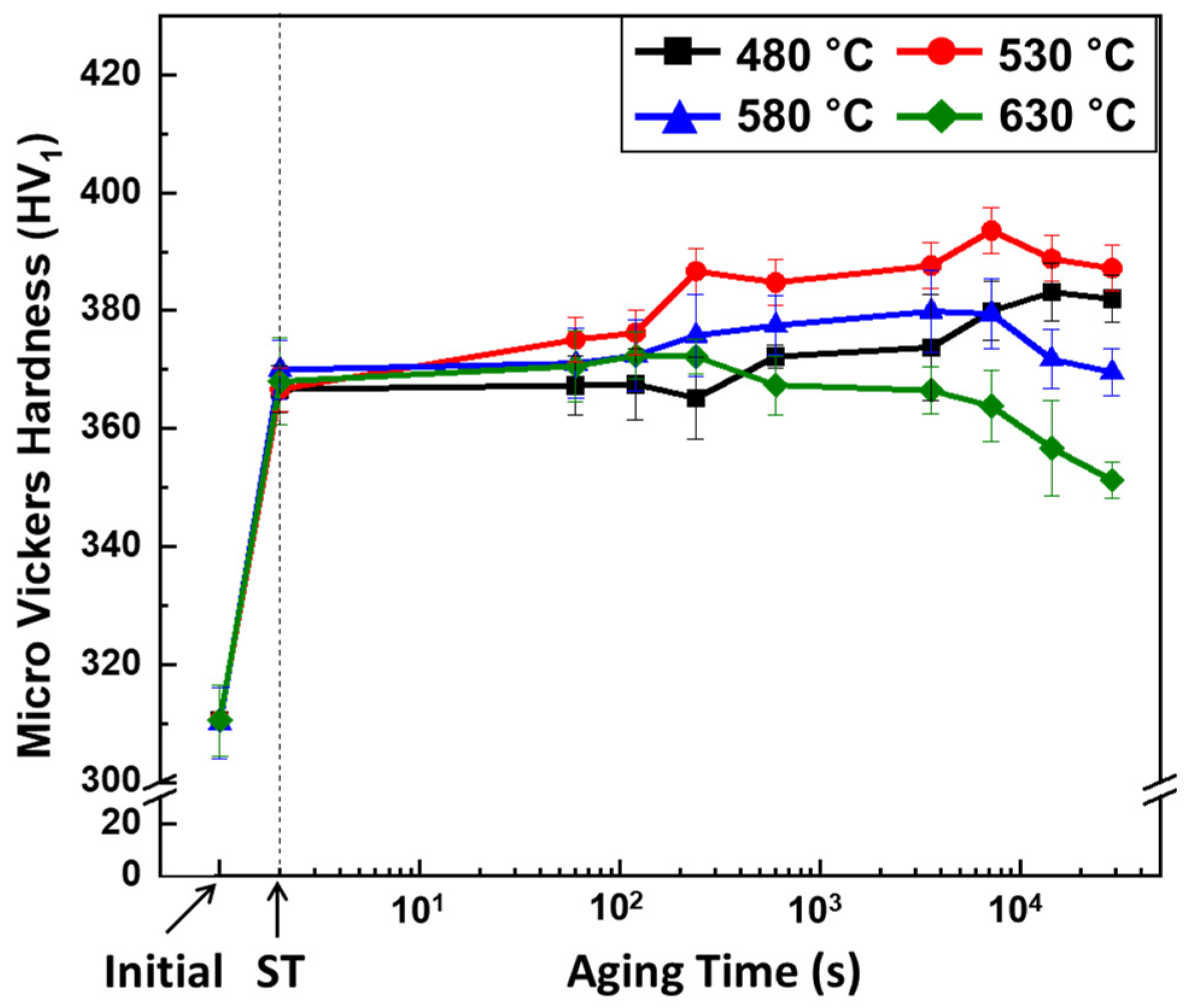

3.1. Hardness Profile

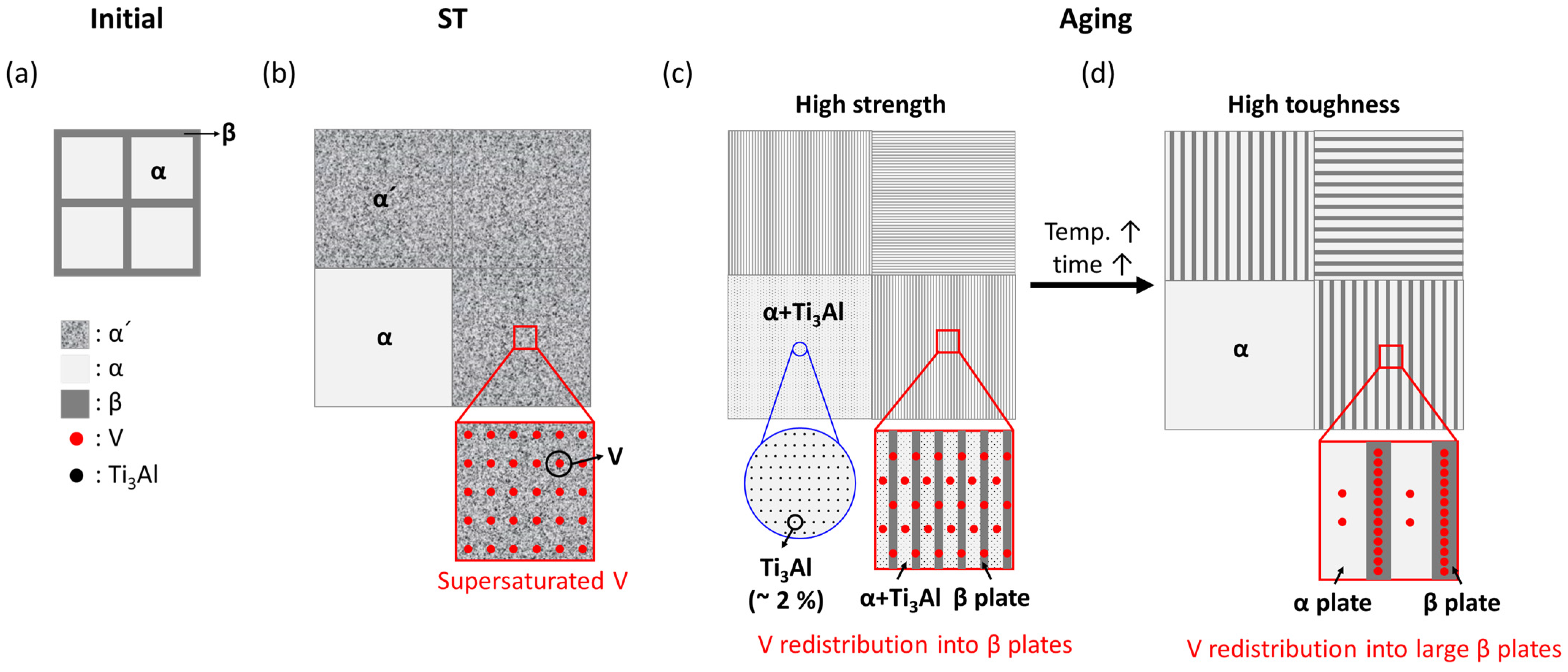

3.2. Microstructure Model

3.3. Microstructure Characterization

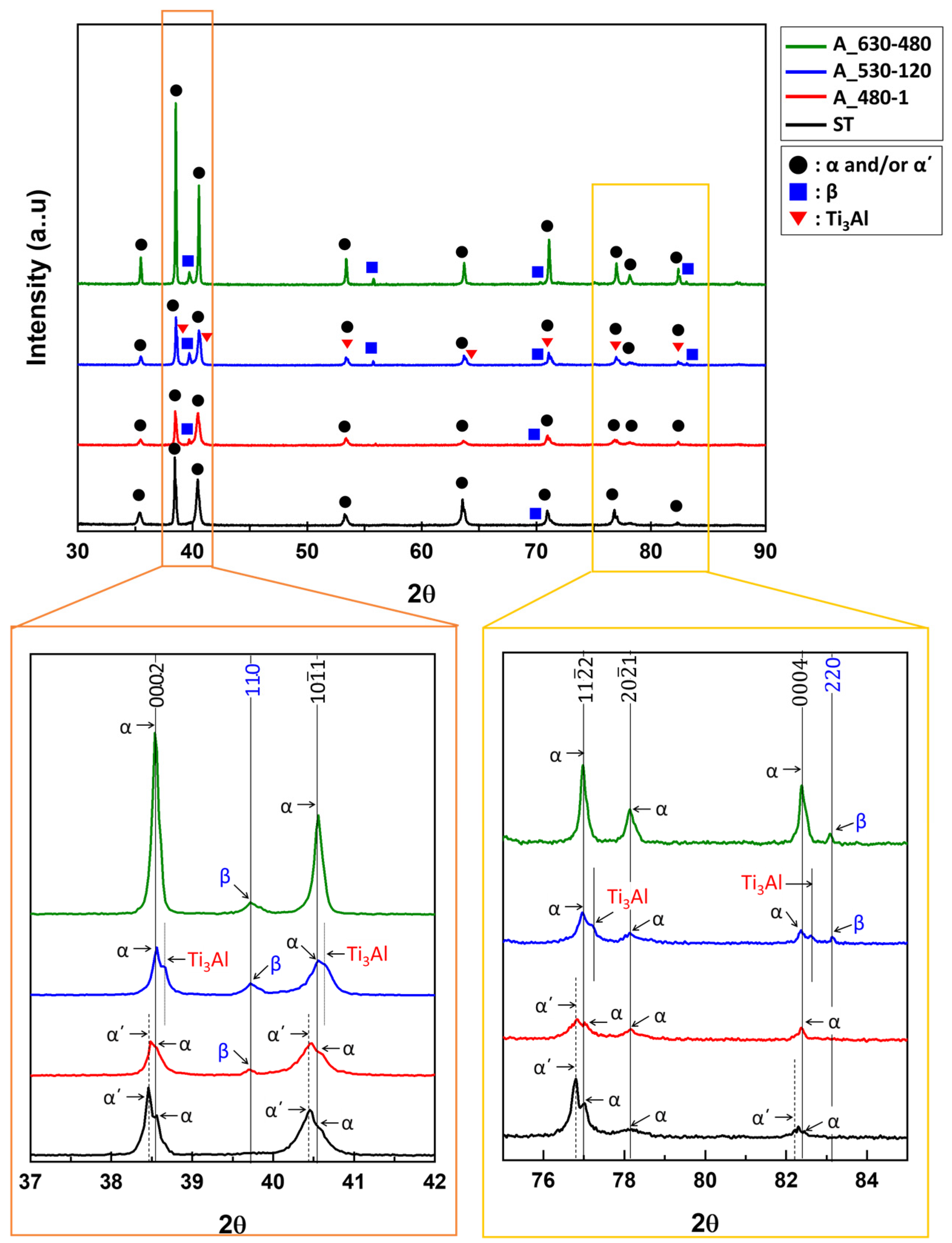

3.3.1. X-ray Diffraction and Phase Evolution

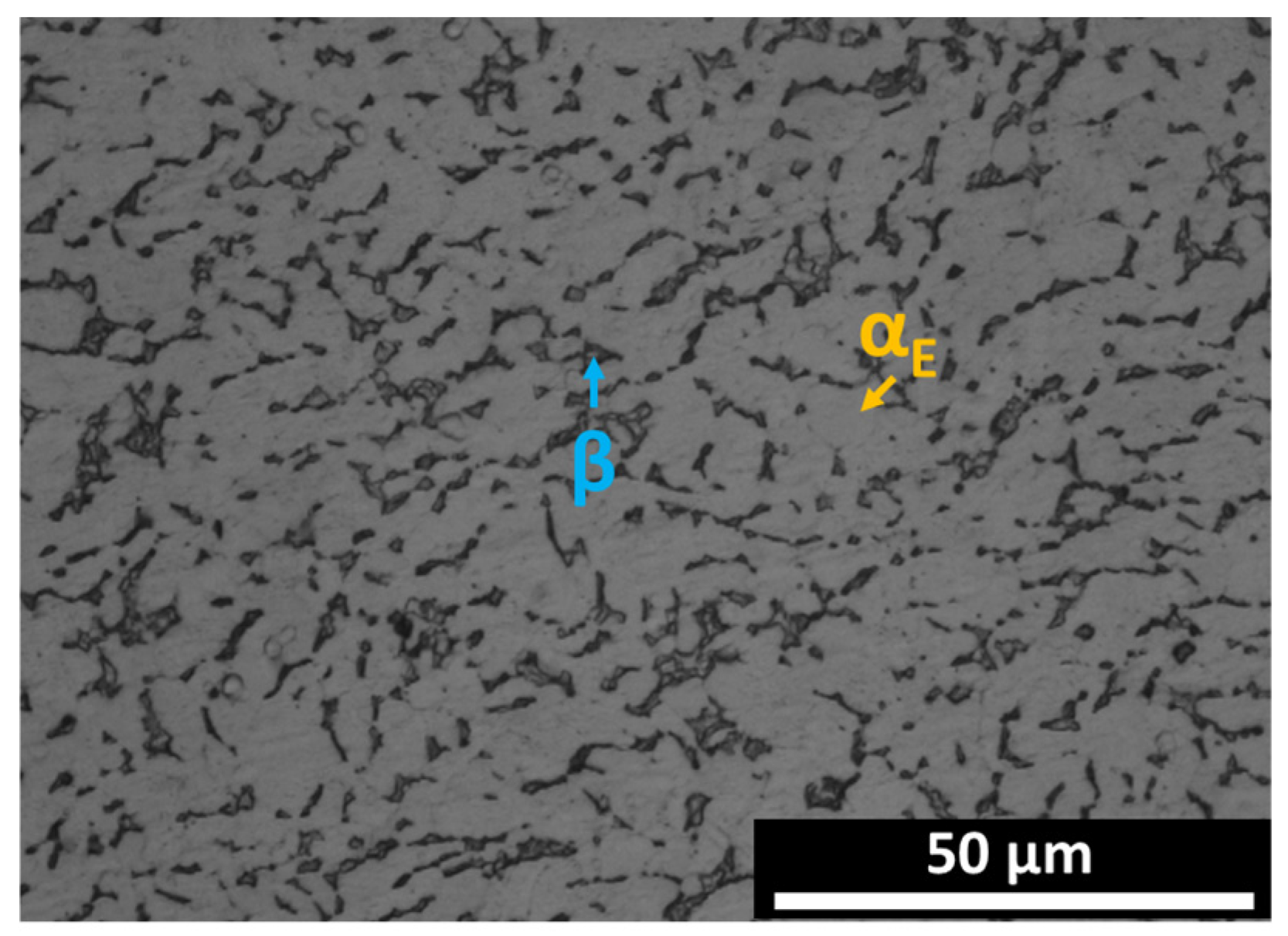

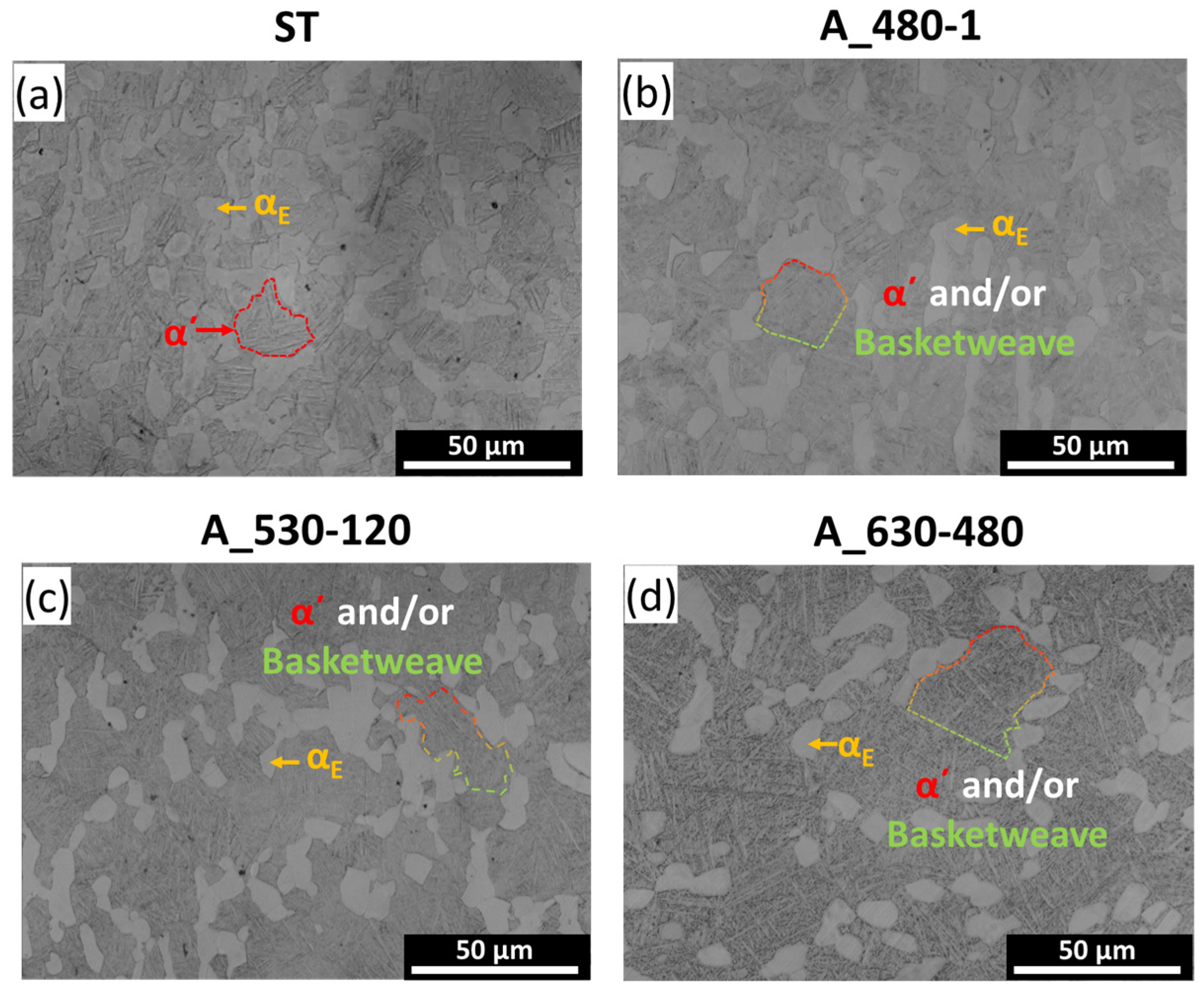

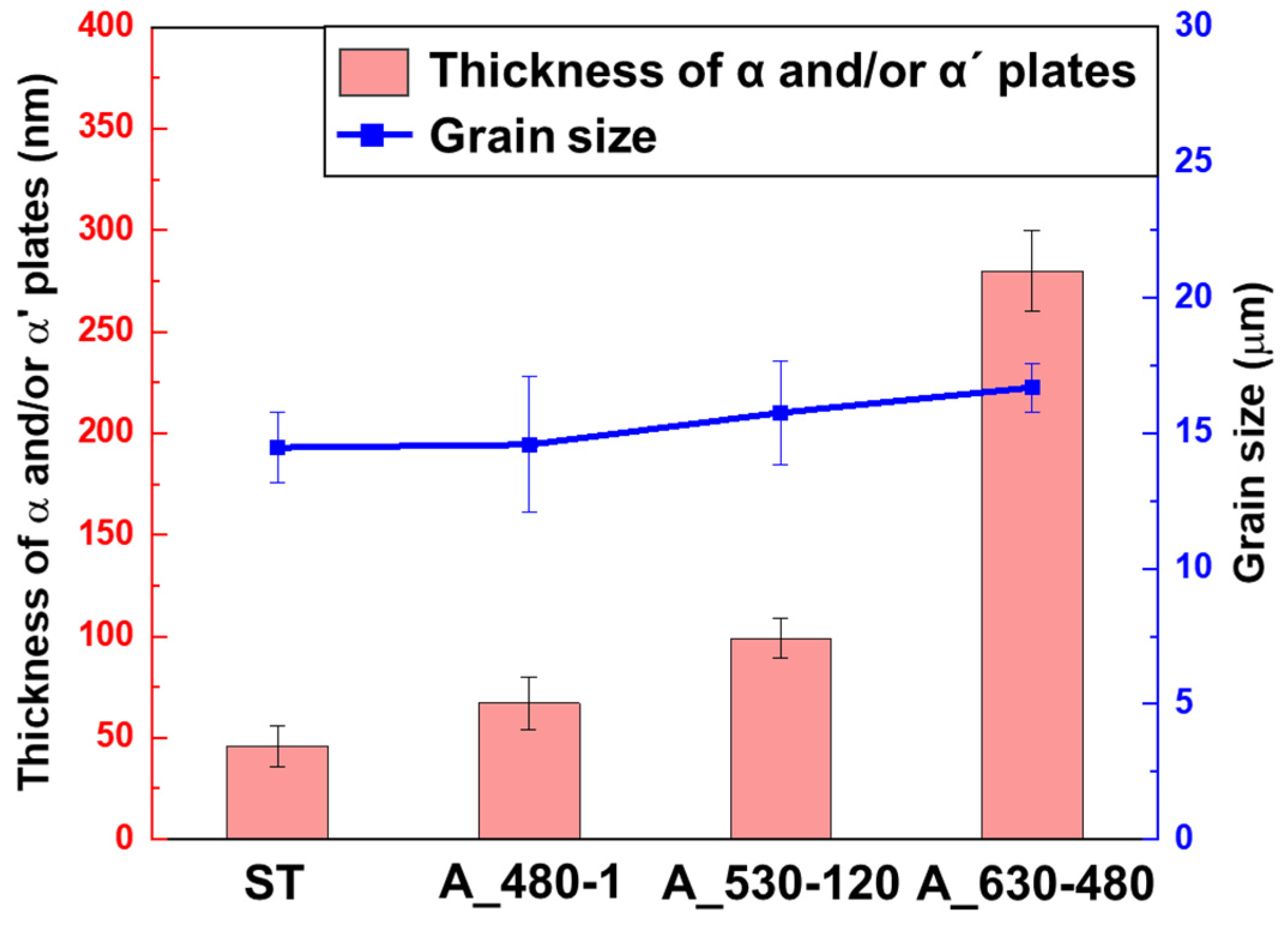

3.3.2. Microstructure

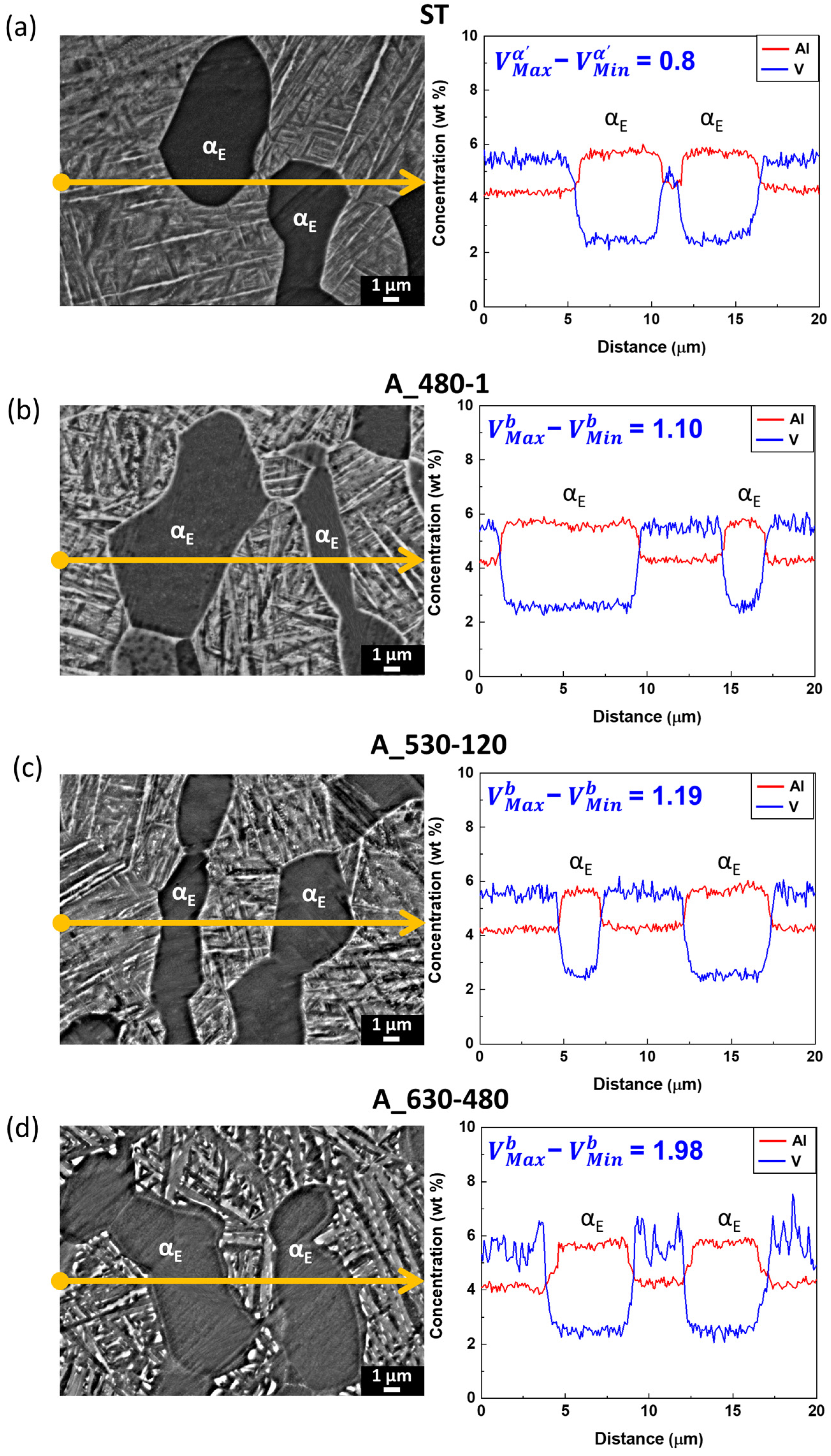

3.3.3. Element Redistribution

3.4. Mechanical Properties

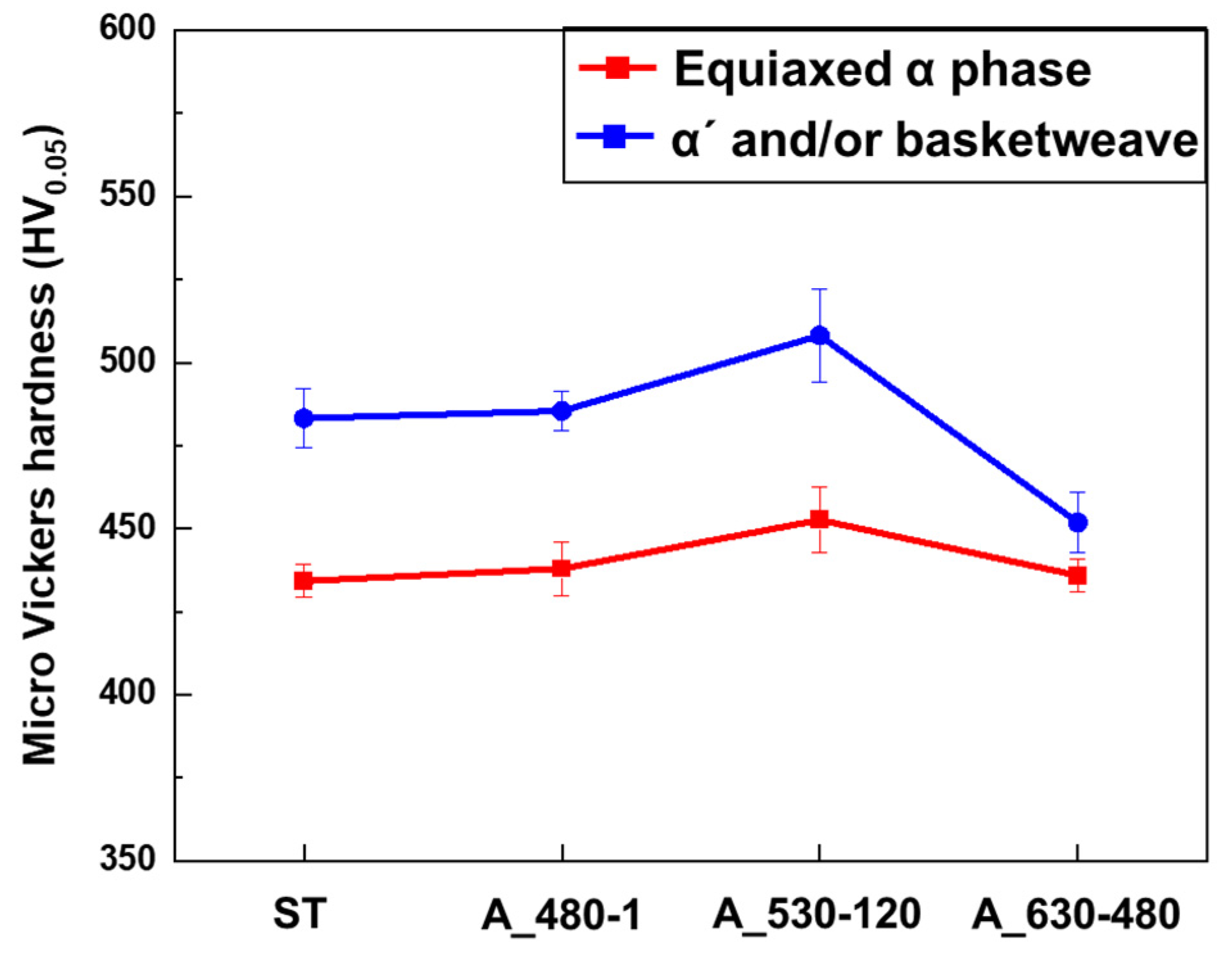

3.4.1. Change in Phase Hardness

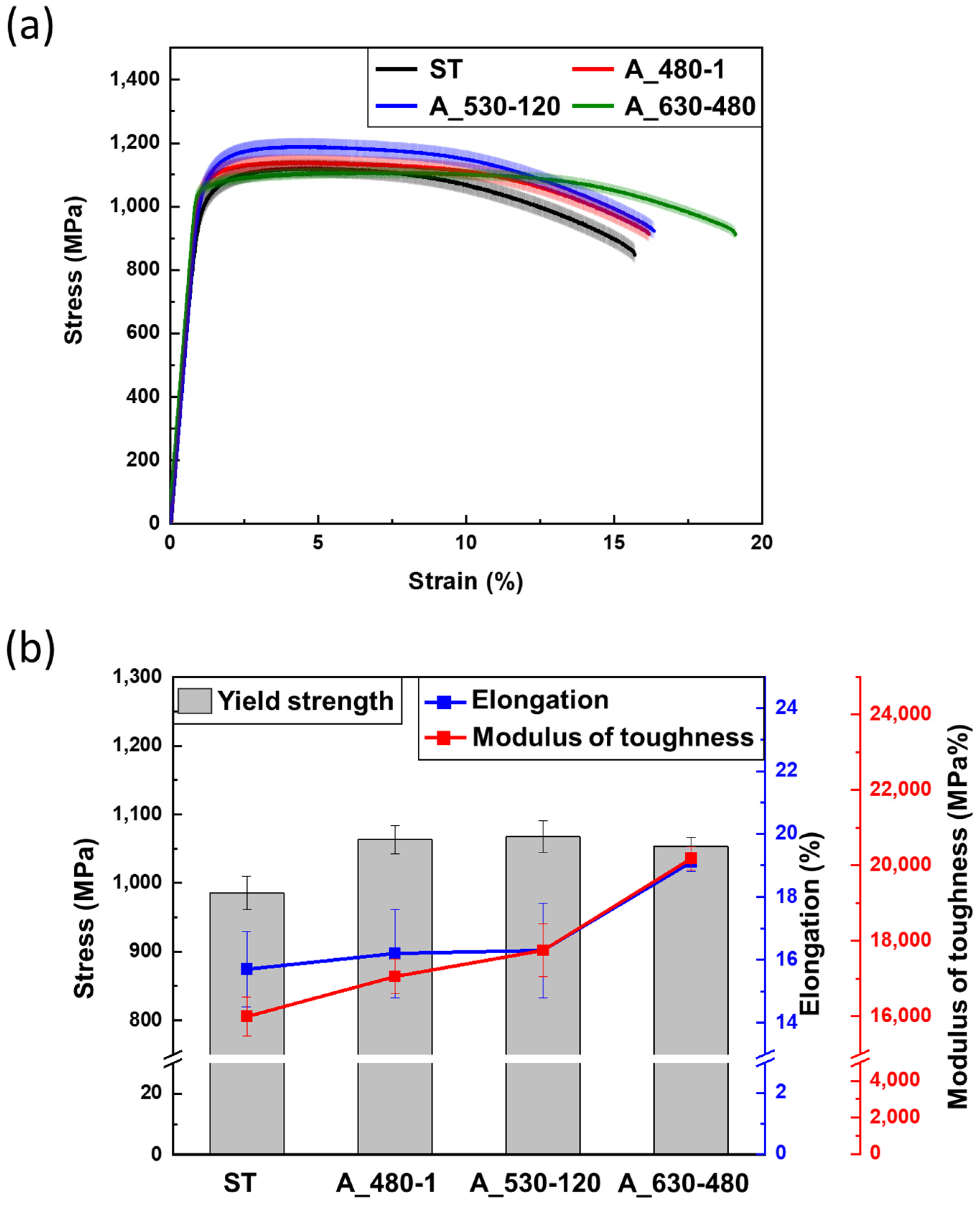

3.4.2. Tensile Properties

3.4.3. Fractographies

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Afonso, F.; Ferreira, A.; Ribeiro, I.; Lau, F.; Suleman, A. On the design of environmentally sustainable aircraft for urban air mobility. Transp. Res. Part D 2021, 91, 102688. [Google Scholar] [CrossRef]

- Pak, H.; Asmer, L.; Kokus, P.; Schuchardt, B.I.; End, A.; Meller, F.; Schweiger, K.; Torens, C.; Barzantny, C.; Becker, D.; et al. Can Urban Air Mobility become reality? Opportunities and challenges of UAM as innovative mode of transport and DLR contribution to ongoing research. CEAS Aeronaut. J. 2024, 7, 1–31. [Google Scholar] [CrossRef]

- Thipphavong, D.P.; Apaza, R.; Barmore, B.; Battiste, V.; Burian, B.; Dao, Q.; Feary, M.; Go, S.; Goodrich, K.H.; Homola, J.; et al. Urban air mobility airspace integration concepts and considerations. In Proceedings of the 2018 Aviation Technology, Integration, and Operations Conference, Atlanta, Georgia, 25–29 June 2018. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Y.; Hu, J. Recent advances in the development of aerospace materials. Prog. Aerosp. Sci. 2018, 97, 22–34. [Google Scholar] [CrossRef]

- Eswara, P.N.; Wanhill, R.J.H. Aerospace Materials and Material Technologies; Springer: Singapore, 2017; Volume 1. [Google Scholar]

- Callister, W.D.; Rethwisch, D.G. Materials Science and Engineering, 8th ed.; WILEY: New York, NY, USA, 2017. [Google Scholar]

- Zhang, W.; Yang, P.; Liang, X.; Cao, Y.; Ouyang, S.; Liu, Y.; Wu, Z. Strength-ductility trade-off deviation in a pre-deformed metastable β titanium alloy. J. Alloys Compd. 2020, 835, 155332. [Google Scholar] [CrossRef]

- Jia, M.T.; Zhang, D.L.; Gabbitas, B.; Liang, J.M.; Kong, C. A novel Ti–6Al–4V alloy microstructure with very high strength and good ductility. Scripta. Mater. 2015, 107, 10–13. [Google Scholar] [CrossRef]

- Boyer, R.; Collings, E.W.; Welsch, G. (Eds.) Materials Properties Handbook: Titanium Alloys; ASM international: Novelty, OH, USA, 1994; pp. 528–530. [Google Scholar]

- Inagaki, I.; Takechi, T.; Shirai, Y.; Ariyasu, N. Application and features of titanium for the aerospace industry. Nippon. Steel Sumitomo Met. Tech. Rep. 2014, 106, 22–27. [Google Scholar]

- Lütjering, G.; Williams, J.C. Titanium, 2nd ed.; Derby, B., Ed.; Springer: Berlin, Germany, 2007; pp. 1–14. [Google Scholar]

- Boyer, R. An overview on the use of titanium in the aerospace industry. Mater. Sci. Eng. A 1996, 213, 103–114. [Google Scholar] [CrossRef]

- Boyer, R.; Foltz, J. Metallurgy of titanium alloy heat treatment. In ASM Handbook Volume 4e Heat Treating of Nonferrous Alloys; Totten, G.E., Mechenzie, D.S., Eds.; ASM International: Materials Park, OH, USA, 2016; pp. 498–509. [Google Scholar]

- Seo, S.; Choi, H.; Lee, G.; Lee, K.A.; Han, J.; Jung, M. Effect of cooling rate on microstructure and hardness during solution treatment and aging process of Ti-6Al-4V alloy for aerospace components. J. Mater. Eng. Perform. 2021, 30, 3406–3415. [Google Scholar] [CrossRef]

- Gupta, A.; Khatirkar, R.K.; Kumar, A.; Parihar, M.S. Investigations on the effect of heating temperature and cooling rate on evolution of microstructure in an α+ β titanium alloy. J. Mater. Res. 2018, 33, 946–957. [Google Scholar] [CrossRef]

- Carreon, H.; Ruiz, A.; Santoveña, B. Study of aging effects in a Ti-6Al-4V alloy with Widmanstätten and equiaxed microstructures by non-destructive means. AIP Conf. Proc. 2014, 1581, 739–745. [Google Scholar]

- Gupta, R.K.; Kumar, V.A.; Chhangani, S. Study on variants of solution treatment and aging cycle of titanium alloy Ti6Al4V. J. Mater. Eng. Perform. 2016, 25, 1492–1501. [Google Scholar] [CrossRef]

- Huang, S.; Zhang, J.; Ma, Y.; Zhang, S.; Youssef, S.S.; Qi, M.; Wang, H.; Qiu, J.; Xu, D.; Lei, J.; et al. Influence of thermal treatment on element partitioning in α+ β titanium alloy. J. Alloys Compd. 2019, 791, 575–585. [Google Scholar] [CrossRef]

- Lin, Y.C.; Tang, Y.; Jiang, Y.Q.; Chen, J.; Wang, D.; He, D.G. Precipitation of Secondary Phase and Phase Transformation Behavior of a Solution-Treated Ti–6Al–4V Alloy during High-Temperature Aging. Adv. Eng. Mat. 2020, 22, 1901436. [Google Scholar] [CrossRef]

- Kherrouba, N.; Carron, D.; Kouba, R.; Bouabdallah, M.; Badji, R. Gleeble-assisted investigation and thermokinetics simulation of α phase isothermal precipitation during short-time duplex heat treatment of Ti-6Al-4V alloy. J. Mater. Eng. Perform. 2022, 31, 7517–7526. [Google Scholar] [CrossRef]

- Morita, T.; Hatsuoka, K.; Iizuka, T.; Kawasaki, K. Strengthening of Ti–6Al–4V alloy by short-time duplex heat treatment. Mater. Trans. 2005, 46, 1681–1686. [Google Scholar] [CrossRef]

- Tanaka, S.; Morita, T.; Shinoda, K. Effects of short-time duplex heat treatment on microstructure and fatigue strength of Ti-6Al-4V alloy. In Proceedings of the 13th International Conference on Fracture, Beijing, China, 16–21 June 2013; Curran Associates Inc.: New York, NY, USA, 2013; pp. 16–21. [Google Scholar]

- Ajiz, A.; Affi, J. The effects of short-time solution treatment and short-time aging on mechanical properties of Ti-6Al-4V for orthopaedic applications. Int. J. Adv. Sci. Eng. Inf. Technol. 2015, 5, 329–334. [Google Scholar] [CrossRef]

- Oh, S.T.; Woo, K.D.; Kim, J.H.; Kwak, S.M. Effect of retained β phase on mechanical properties of cast Ti-6Al-4V alloy. Mater. Trans. 2017, 58, 1145–1149. [Google Scholar] [CrossRef]

- Vahidshad, Y.; Khodabakhshi, A.H. Effect of solution treatment and aging temperature on α′ and Ti3Al (α2) phase formation and mechanical properties of water-quenched Ti–6Al–4V. MMA 2022, 11, 59–71. [Google Scholar] [CrossRef]

- Perumal, G.; Senthilkumar, N.; Subramaniyan, C.; Ramasamy, R.; Satheshkumar, D. Tailoring the mechanical and tribological properties of Ti-6Al-4 V alloy through duplex heat treatment. J. Mater. Eng. Perform. 2023, 9, 1–18. [Google Scholar] [CrossRef]

- Zhu, Q.; Yang, X.; Lan, H.; Wang, D.; Lou, H.; Li, J. Effect of solution treatments on microstructure and mechanical properties of Ti–6Al–4V alloy hot rolled sheet. J. Mater. Res. Technol. 2023, 23, 5760–5771. [Google Scholar] [CrossRef]

- Elshaer, R.N.; El-Hadad, S.; Nofalm, A. Influence of heat treatment processes on microstructure evolution, tensile and tribological properties of Ti6Al4V alloy. Sci. Rep. 2023, 13, 11292. [Google Scholar] [CrossRef]

- Qiao, P.; Xie, J.; Jiang, Y.; Tang, P.; Liang, B.; Lu, Y.; Gong, J. Mechanical properties of σ-phase and its effect on the mechanical properties of austenitic stainless steel. Coatings 2022, 12, 1917. [Google Scholar] [CrossRef]

- ASTM E8/E8M-16a; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2016.

- Shi, X.; Zeng, W.; Sun, Y.; Han, Y.; Zhao, Y.; Guo, P. Microstructure-tensile properties correlation for the Ti-6Al-4V titanium alloy. J. Mater. Eng. Perform. 2015, 24, 1754–1762. [Google Scholar] [CrossRef]

- Vikas, K.S.R.; Rahul, V.S.N.; Reddy, G.M.; Rao, K.S. Effect of Heat Treatments on Tensile Fracture Behaviour of Ti-6Al-4V Alloy Friction Welds. J. Ins. Eng. India Series D 2023, 105, 929–947. [Google Scholar] [CrossRef]

- JMatPro, Version 7.0, Sente Software Corp.: Guildford, UK, 2021.

- Chen, J.; Wang, L.; Fan, Q. Effect of aging temperature on microstructure and mechanical properties of a novel Ti-6121 alloy. J. Alloys Compd. 2023, 947, 169612. [Google Scholar] [CrossRef]

- Welsch, G.; Lütjering, G.; Gazioglu, K.; Bunk, W. Deformation characteristics of age hardened Ti-6Al-4V. Metall. Mater. Trans. A 1977, 8, 169–177. [Google Scholar] [CrossRef]

- Lee, D.G.; Lee, S. Effects of nano-sized α2 (Ti3Al) particles on quasi-static and dynamic deformation behavior of Ti-6Al-4V alloy with bimodal microstructure. J. Mater. Sci. 2005, 40, 4077–4084. [Google Scholar] [CrossRef]

- Andani, M.T.; Lakshmanan, A.; Karamooz-Ravari, M.; Sundararaghavan, V.; Allison, J.; Misra, A. A quantitative study of stress fields ahead of a slip band blocked by a grain boundary in unalloyed magnesium. Sci. Rep. 2020, 10, 3084. [Google Scholar] [CrossRef]

- Oh, J.M.; Lim, J.W.; Lee, B.G.; Suh, C.Y.; Cho, S.W.; Lee, S.W.; Choi, G.S. Grain refinement and hardness increase of titanium via trace element addition. Mater. Trans. 2010, 51, 2009–2012. [Google Scholar] [CrossRef]

- Liu, D.; Pons, D.J. Crack propagation mechanisms for creep fatigue: A consolidated explanation of fundamental behaviours from initiation to failure. Metals 2018, 8, 623. [Google Scholar] [CrossRef]

- Dang, N.; Chen, S.; Liu, L.; Maire, E.; Adrien, J.; Cazottes, S.; Xiao, W.; Ma, C.; Zhou, L. Analysis of hybrid fracture in α/β titanium alloy with lamellar microstructure. Mater. Sci. Eng. A 2019, 744, 54–63. [Google Scholar] [CrossRef]

| Ti | Al | V | Fe | O | N | C | H |

|---|---|---|---|---|---|---|---|

| Balance | 6.56 | 4.15 | 0.19 | 0.19 | 0.021 | 0.027 | 0.003 |

| Yield Strength (MPa) | Elongation (%) | Modulus of Toughness (MPa%) | |

|---|---|---|---|

| ST | 985.97 (±24.2) | 15.71 (±1.8) | 15,996 (±117.4) |

| A_480-1 | 1063.13 (±21.3) | 16.22 (±1.7) | 17,056 (±159.6) |

| A_530-120 | 1067.42 (±23.1) | 16.28 (±1.9) | 17,752 (±200.8) |

| A_630-480 | 1053.40 (±13.4) | 19.10 (±0.3) | 19,803 (±112.3) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seo, S.; Jung, M.; Park, J. Microstructure Control for Enhancing the Combination of Strength and Elongation in Ti-6Al-4V through Heat Treatment. Metals 2024, 14, 985. https://doi.org/10.3390/met14090985

Seo S, Jung M, Park J. Microstructure Control for Enhancing the Combination of Strength and Elongation in Ti-6Al-4V through Heat Treatment. Metals. 2024; 14(9):985. https://doi.org/10.3390/met14090985

Chicago/Turabian StyleSeo, Seongji, Minsu Jung, and Jiyong Park. 2024. "Microstructure Control for Enhancing the Combination of Strength and Elongation in Ti-6Al-4V through Heat Treatment" Metals 14, no. 9: 985. https://doi.org/10.3390/met14090985

APA StyleSeo, S., Jung, M., & Park, J. (2024). Microstructure Control for Enhancing the Combination of Strength and Elongation in Ti-6Al-4V through Heat Treatment. Metals, 14(9), 985. https://doi.org/10.3390/met14090985