Effect of Power on Structural and Mechanical Properties of DC Magnetron Sputtered Cr Coatings

Abstract

1. Introduction

2. Experimental

2.1. Coating Preparation

2.2. Characterization

3. Results and Discussion

3.1. Deposition Rate

3.2. Crystal Structure

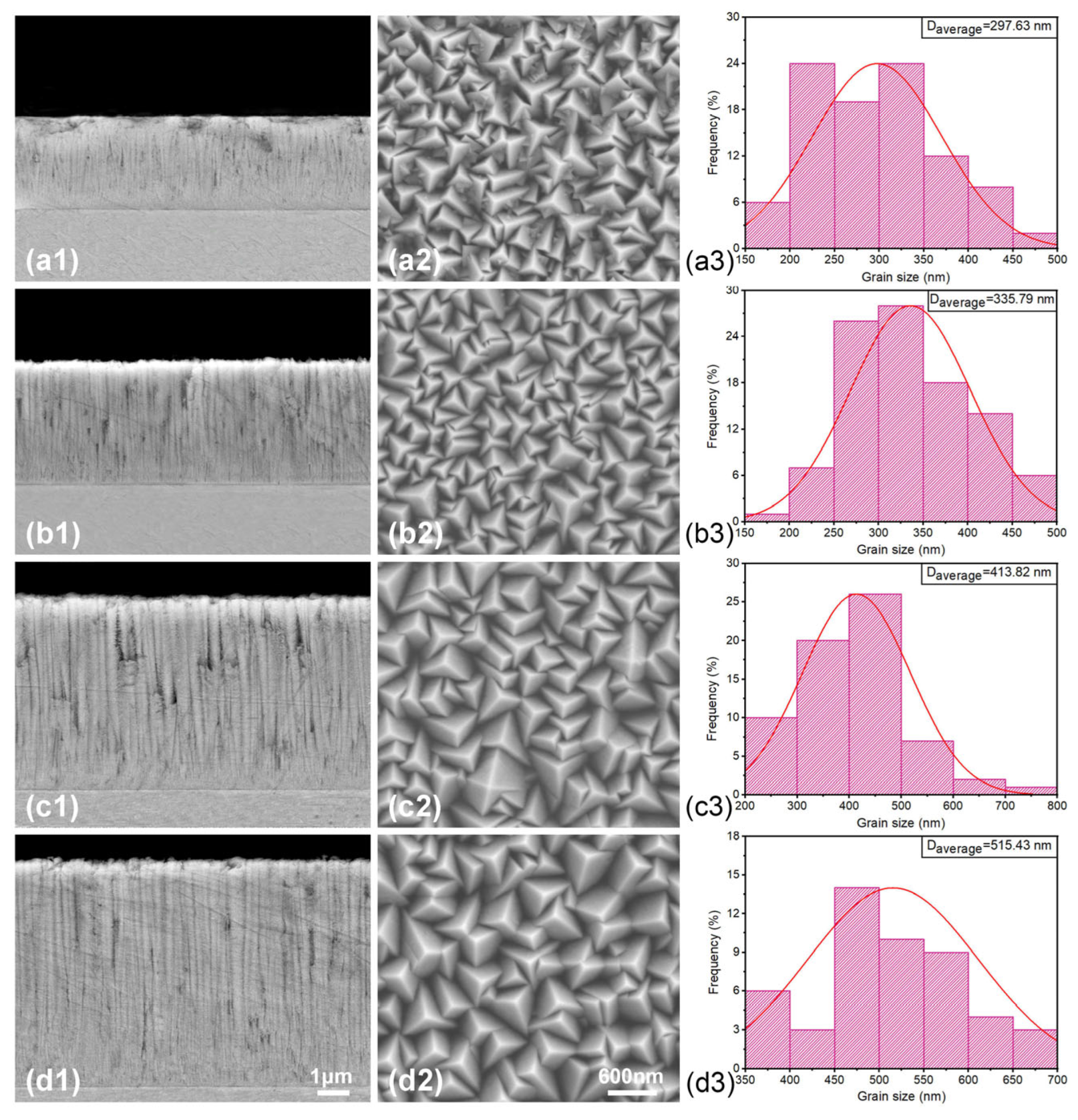

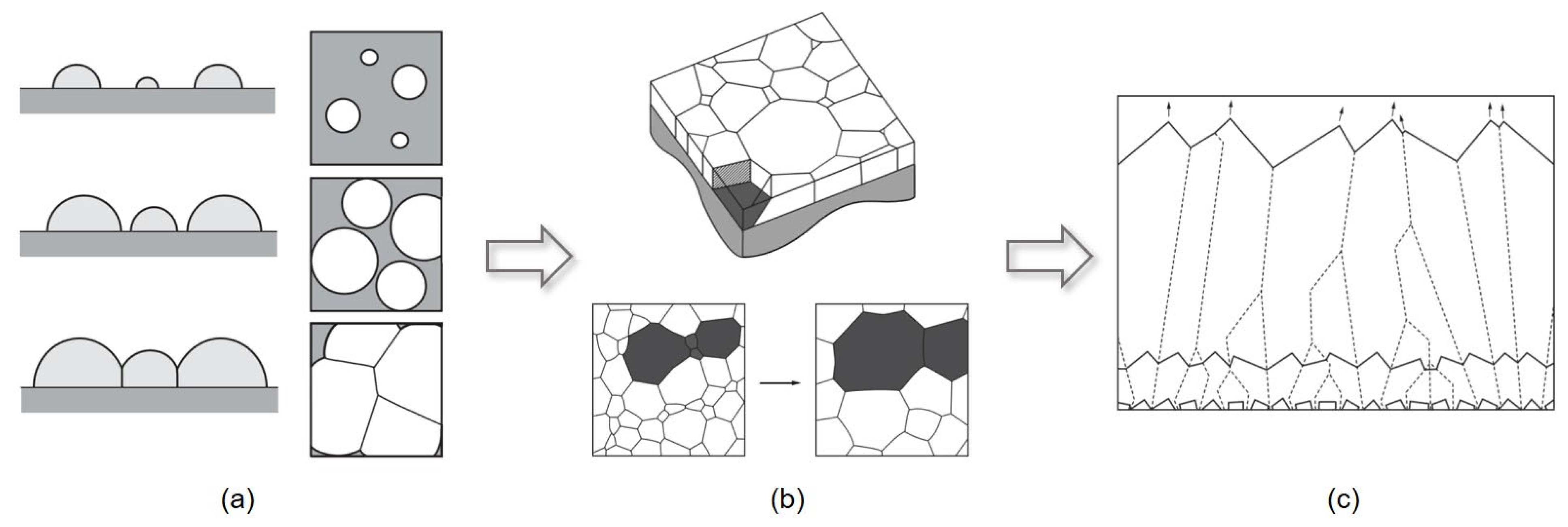

3.3. Microstructure

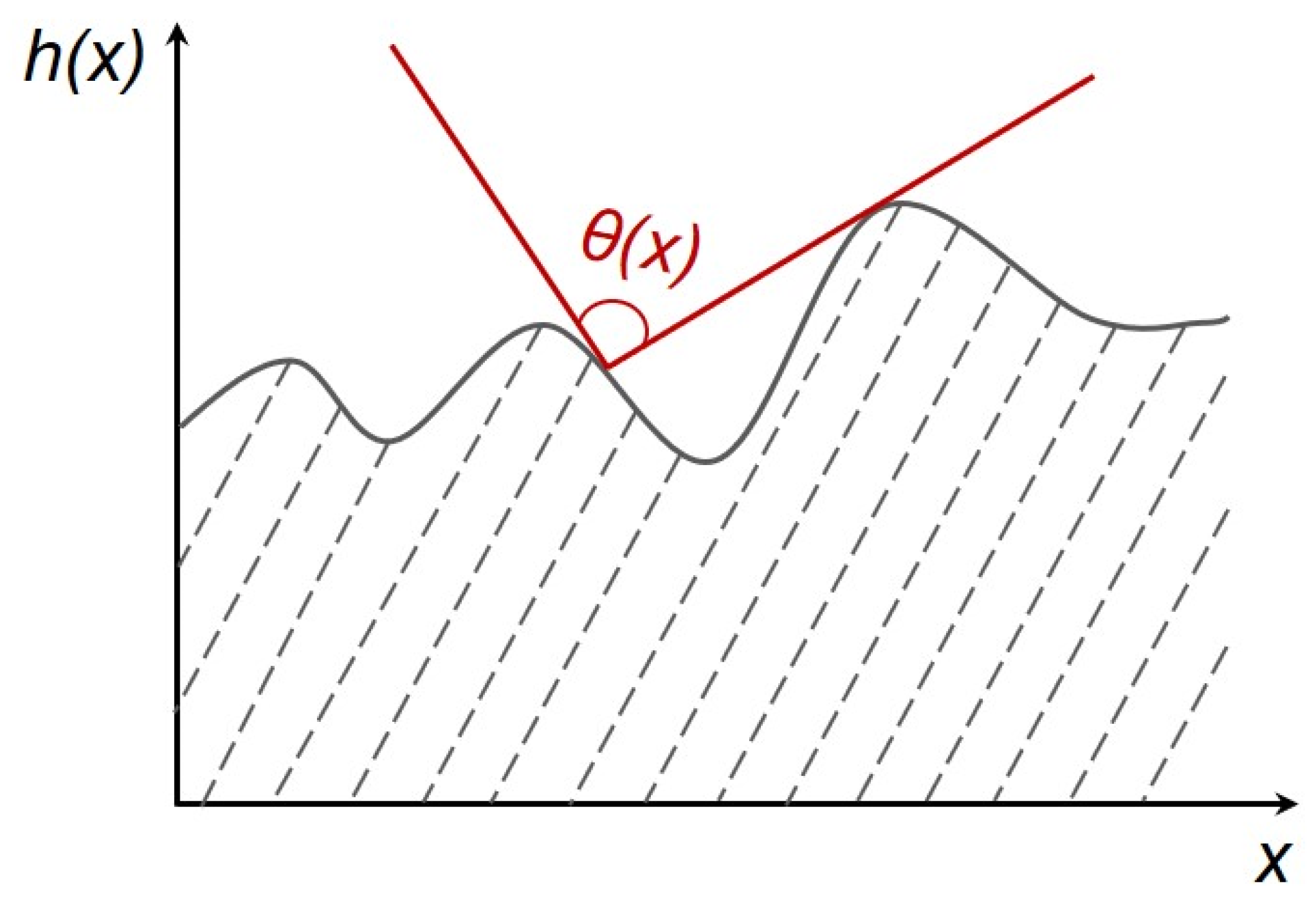

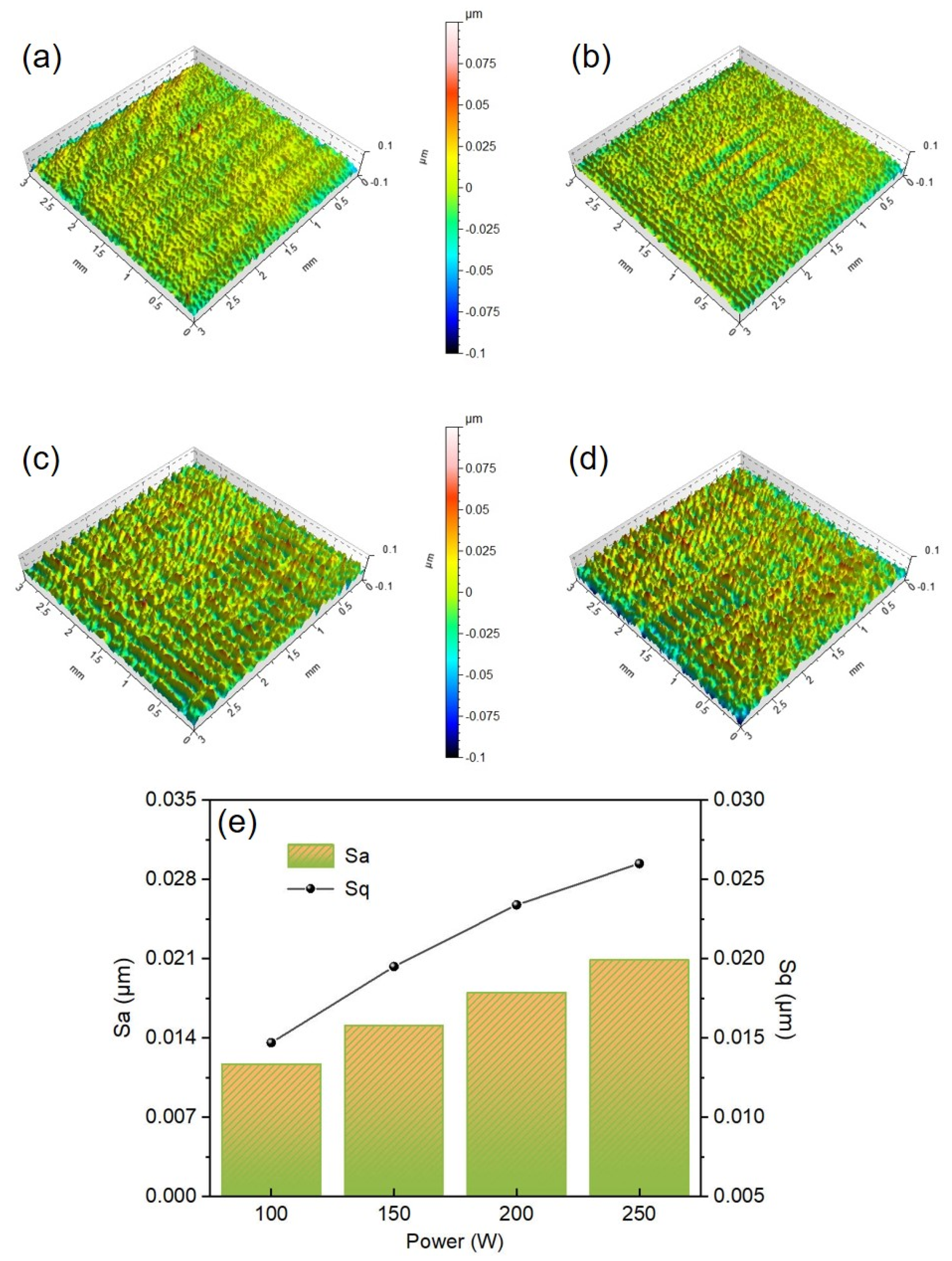

3.4. Surface Roughness

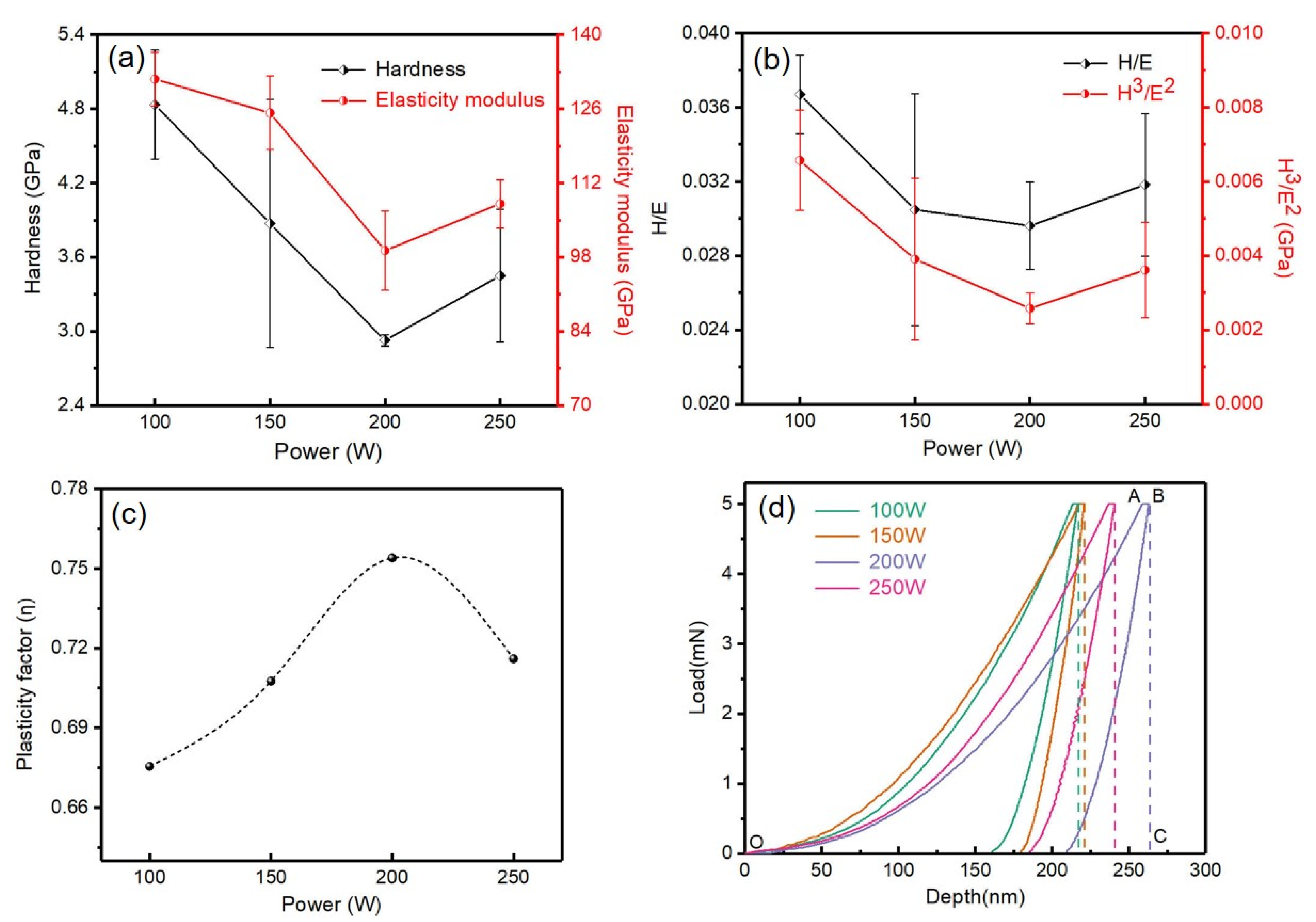

3.5. Nano-Indentation Behavior

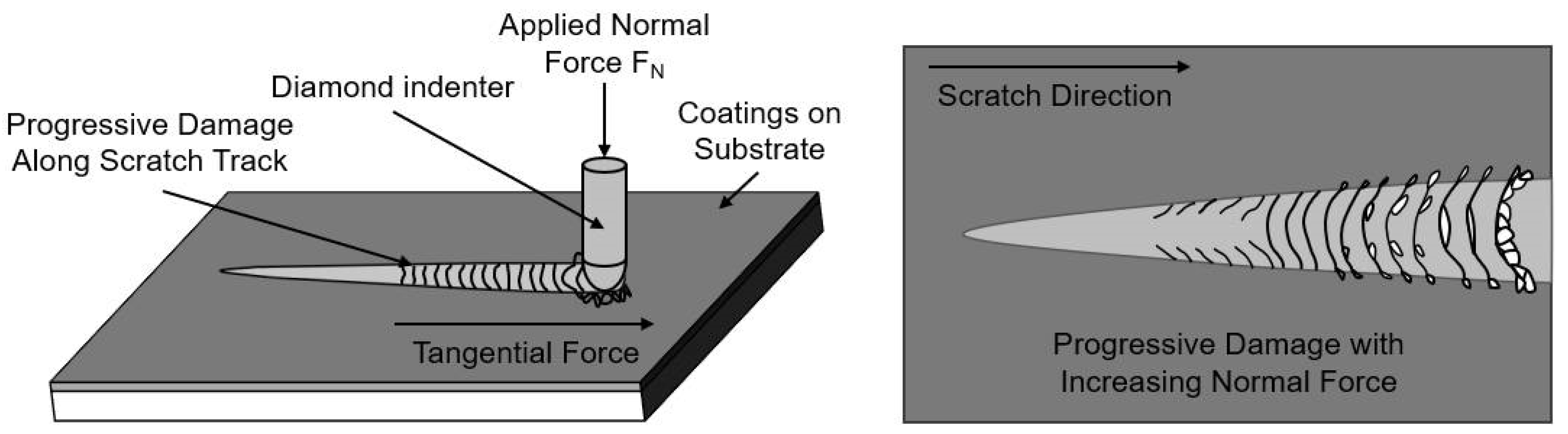

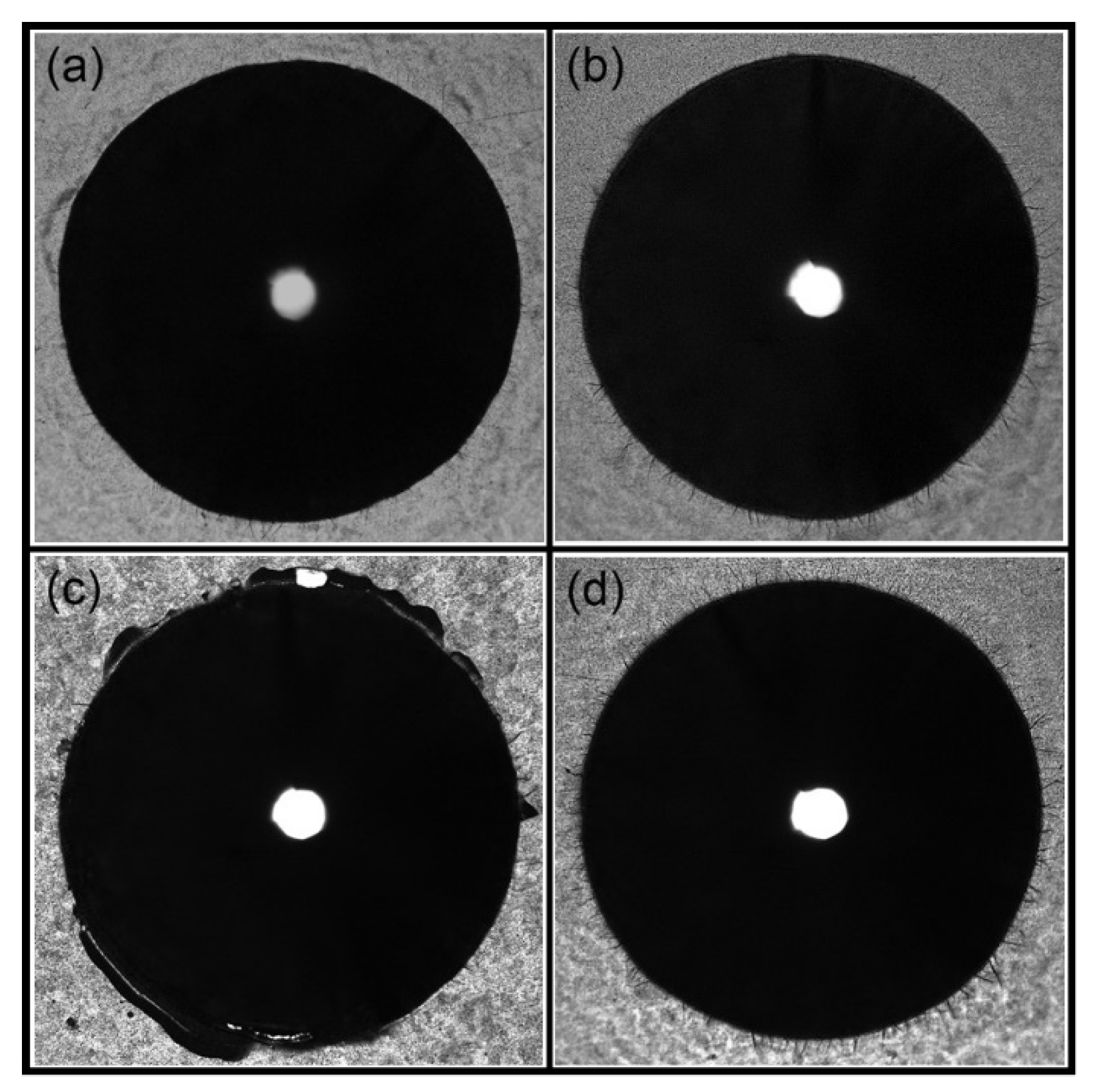

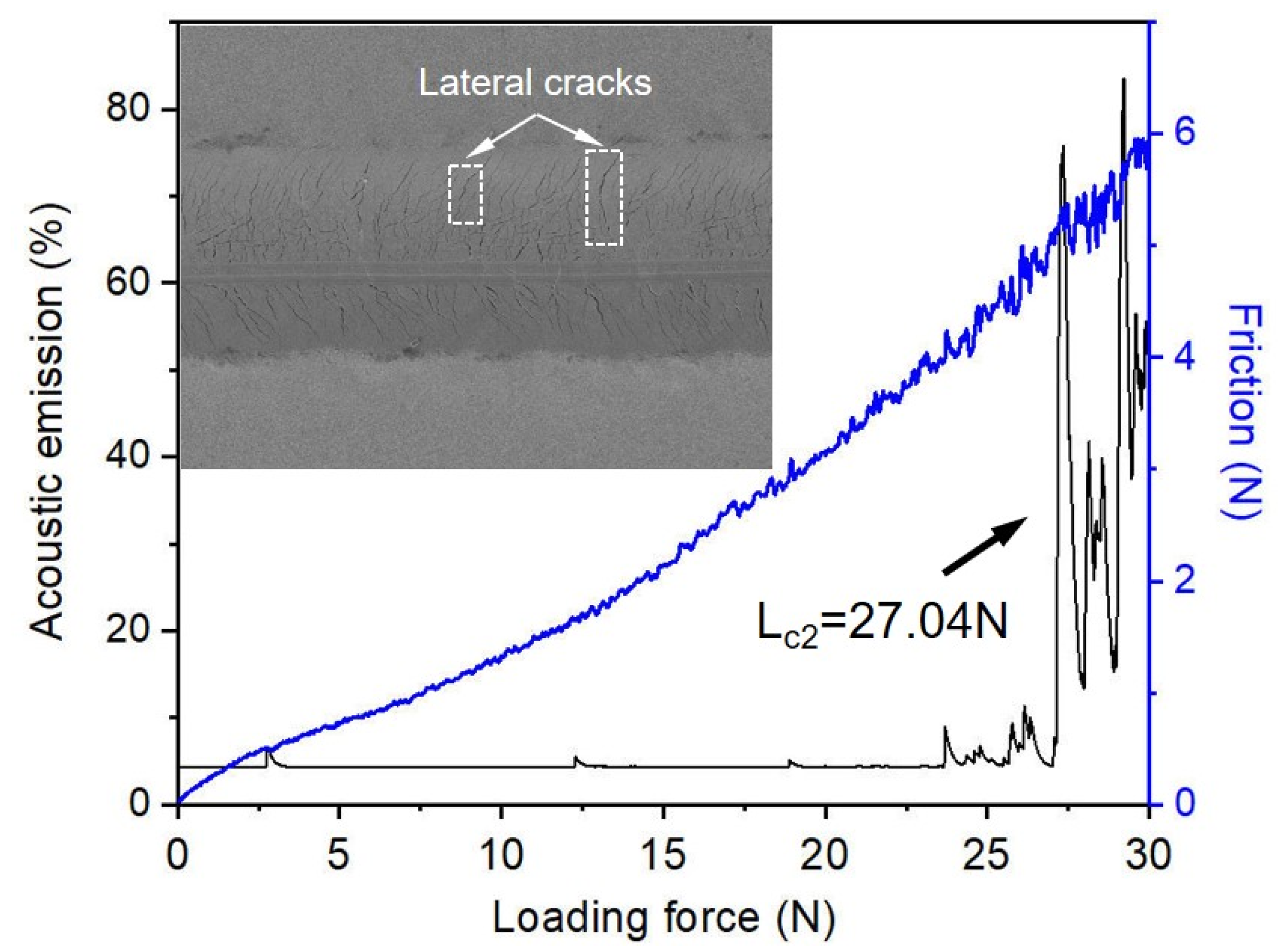

3.6. Micro-Scratch Behavior

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mello, C.B.; Mansur, R.A.F.; Santos, N.M.; Viana, W.E.S.S.; Ueda, M. Experimental study of mechanical and tribological behavior of nitrogen ion-implanted chromium thin films. Surf. Coat. Technol. 2017, 312, 123–127. [Google Scholar] [CrossRef]

- Bikulčius, G.; Češunienė, A.; Selskienė, A.; Pakštas, V.; Matijošius, T. Dry sliding tribological behavior of Cr coatings electrodeposited in trivalent chromium sulphate baths. Surf. Coat. Technol. 2017, 315, 130–138. [Google Scholar] [CrossRef]

- Liang, A.; Ni, L.; Liu, Q.; Zhang, J. Structure characterization and tribological properties of thick chromium coating electrodeposited from a Cr(III) electrolyte. Surf. Coat. Technol. 2013, 218, 23–29. [Google Scholar] [CrossRef]

- Hu, M.; Shen, M.; Liu, Z.; Guo, C.; Li, Q.; Zhu, S. Self-ion bombarded Cr films: Crystallographic orientation and oxidation behaviour. Corros. Sci. 2018, 143, 212–220. [Google Scholar] [CrossRef]

- Panjan, P.; Drnovšek, A.; Kovač, J. Tribological aspects related to the morphology of PVD hard coatings. Surf. Coat. Technol. 2018, 343, 138–147. [Google Scholar] [CrossRef]

- Navinšek, B.; Peter, P.; Milošev, I. PVD coatings as an environmentally clean alternative to electrocoating and electroless processes. Surf. Coat. Technol. 1999, 116, 476–487. [Google Scholar] [CrossRef]

- Paturaud, C.; Farges, G.; Sainte Catherine, M.C.; Machet, J. Correlation between hardness and embedded argon content of magnetron sputtered chromium films. Thin Solid Film. 1999, 347, 46–55. [Google Scholar] [CrossRef]

- Legg, K.O.; Graham, M.; Chang, P.; Rastagar, F.; Gonzales, A.; Sartwell, B. The replacement of electrocoating. Surf. Coat. Technol. 1996, 81, 99–105. [Google Scholar] [CrossRef]

- Wang, S.F.; Lin, H.C.; Bor, H.Y.; Tsai, Y.L.; Wei, C.N. Characterization of chromium thin films by sputter deposition. J. Alloys Compd. 2011, 509, 10110–10114. [Google Scholar] [CrossRef]

- Daure, J.L.; Carrington, M.J.; Shipway, P.H.; McCartney, D.G.; Stewart, D.A. A comparison of the galling wear behaviour of PVD Cr and electroplated hard Cr thin films. Surf. Coat. Technol. 2018, 350, 40–47. [Google Scholar] [CrossRef]

- Sidelev, D.V.; Bestetti, M.; Bleykher, G.A.; Krivobokov, V.P.; Grudinin, V.A.; Franz, S.; Vicenzo, A.; Shanenkova, Y.L. Deposition of Cr films by hot target magnetron sputtering on biased substrates. Surf. Coat. Technol. 2018, 350, 560–568. [Google Scholar] [CrossRef]

- Savisalo, T.; Lewis, D.B.; Hovsepian, P.E.; Münz, W.D. Influence of ion bombardment on the properties and microstructure of unbalanced magnetron deposited niobium coatings. Thin Solid Film. 2004, 460, 94–100. [Google Scholar] [CrossRef]

- Adjaottor, A.A.; Meletis, E.I.; Logothetidis, S.; Alexandrou, I.; Kokkou, S. Effect of substrate bias on sputter-deposited TiCx, TiNy and TiCxNy thin films. Surf. Coat. Technol. 1995, 76–77, 142–148. [Google Scholar] [CrossRef]

- Yang, Z.T.; Yang, B.; Guo, L.P.; Fu, D.J. Effect of bias voltage on the structure and hardness of TiSiN composite coatings synthesized by cathodic arc assisted middle-frequency magnetron sputtering. J. Alloys Compd. 2009, 473, 437–441. [Google Scholar] [CrossRef]

- Ferreira, F.; Serra, R.; Cavaleiro, A.; Oliveira, J.C. Additional control of bombardment by deep oscillation magnetron sputtering: Effect on the microstructure and topography of Cr thin films. Thin Solid Film. 2016, 619, 250–260. [Google Scholar] [CrossRef]

- Li, H.; Jiang, B.; Yang, B. Study on crystalline to amorphous structure transition of Cr coatings by magnetron sputtering. Appl. Surf. Sci. 2011, 258, 935–939. [Google Scholar] [CrossRef]

- Ferrec, A.; Keraudy, J.; Jacq, S.; Schuster, F.; Jouan, P.Y.; Djouadi, M.A. Correlation between mass-spectrometer measurements and thin film characteristics using dcMS and HiPIMS discharges. Surf. Coat. Technol. 2014, 250, 52–56. [Google Scholar] [CrossRef]

- Feng, Y.C.; Laughlin, D.E.; Lambeth, D.N. Formation of crystallographic texture in rf sputter-deposited Cr thin films. J. Appl. Phys. 1994, 76, 7311–7316. [Google Scholar] [CrossRef]

- Shtanskii, D.V.; Kulinich, S.A.; Levashov, E.A.; Moore, J.J. Structure and physical-mechanical properties of nanostructured thin films. Phys. Solid State 2003, 45, 1177–1184. [Google Scholar] [CrossRef]

- Glechner, T.; Hahn, R.; Wojcik, T.; Holec, D. Assessment of ductile character in superhard Ta-C-N thin films. Acta Mater. 2019, 179, 17–25. [Google Scholar] [CrossRef]

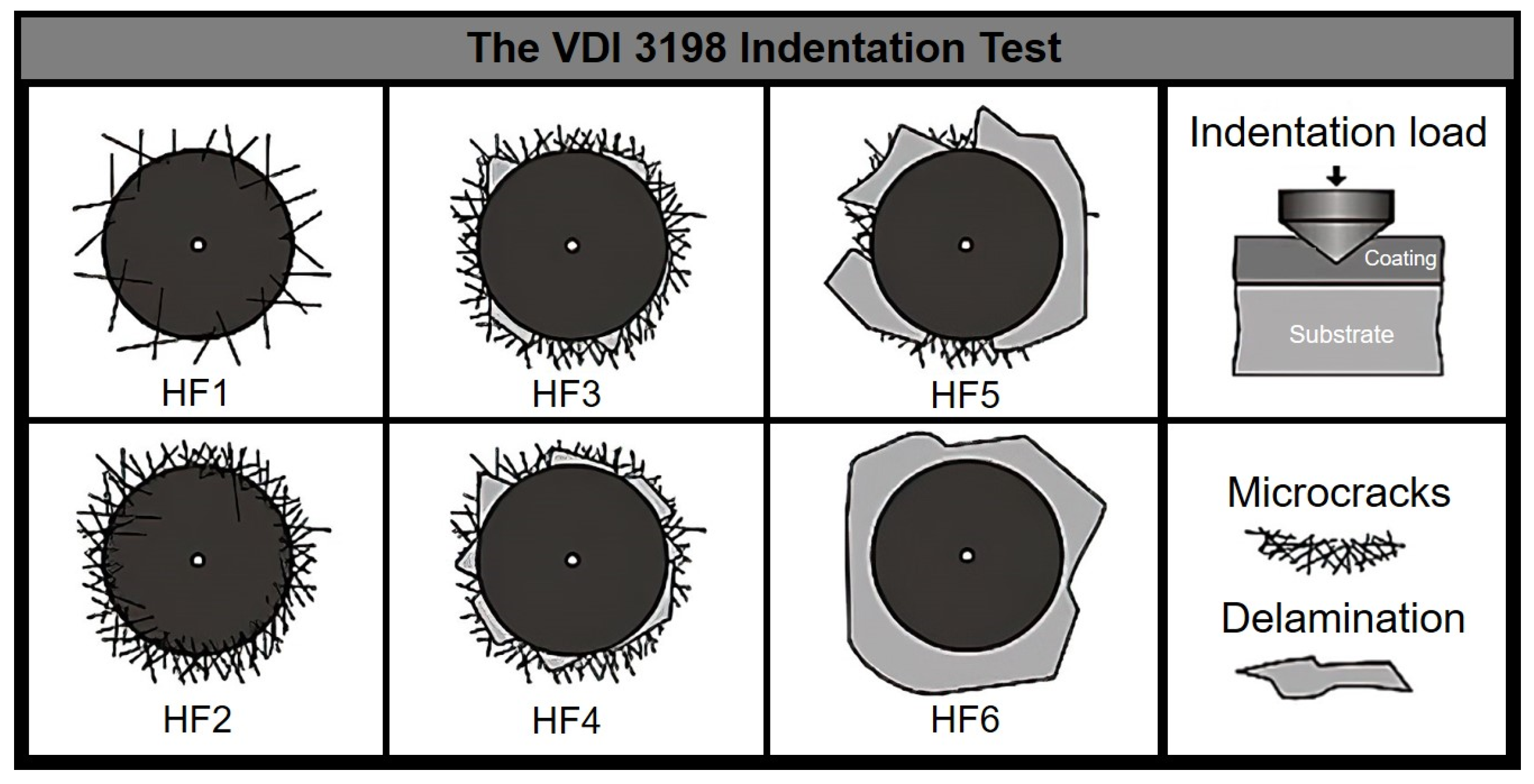

- Vidakis, N.; Antoniadis, A.; Bilalis, N. The VDI 3198 indentation test evaluation of a reliable qualitative control for layered compounds. J. Mater. Process. Technol. 2003, 143–144, 481–485. [Google Scholar] [CrossRef]

- Ferreira, F.; Serra, R.; Oliveira, J.C.; Cavaleiro, A. Effect of peak target power on the properties of Cr thin films sputtered by HiPIMS in deep oscillation magnetron sputtering (DOMS) mode. Surf. Coat. Technol. 2014, 258, 249–256. [Google Scholar] [CrossRef]

- Thompson, C.V. Structure evolution during processing of polycrystalline films. Annu. Rev. Mater. Sci. 2000, 30, 159–190. [Google Scholar] [CrossRef]

- Tu, K.N.; Smith, D.A.; Weiss, B.Z. Hyperbolic grain boundaries. Phys. Rev. B 1987, 36, 8948–8950. [Google Scholar] [CrossRef]

- Knuyt, G.; Quaeyhaegens, C.; Haen, J.D. A quantitative model for the evolution from random orientation to a unique texture in PVD thin film growth. Thin Solid Film. 1995, 258, 159–169. [Google Scholar] [CrossRef]

- Longworth, H.P.; Thompson, C.V. Abnormal grain growth in aluminum alloy thin films. J. Appl. Phys. 1991, 69, 3929–3940. [Google Scholar] [CrossRef]

- Janssen, G.C.A.M.; Alkemade, P.F.A.; Sivel, V.G.M. Anisotropic growth of chromium films during sputter deposition on substrates in planetary motion. J. Vac. Sci. Technol. A 2004, 22, 1773–1777. [Google Scholar] [CrossRef]

- Greczynski, G.; Jensen, J.; Hultman, L. Mitigating the geometrical limitations of conventional sputtering by controlling the ion-to-neutral ratio during high power pulsed magnetron sputtering. Thin Solid Film. 2011, 519, 6354–6361. [Google Scholar] [CrossRef]

- Zhao, Z.B.; Yalisove, S.M.; Rek, Z.U. Evolution of anisotropic microstructure and residual stress in sputtered Cr films. J. Appl. Phys. 2002, 92, 7183–7192. [Google Scholar] [CrossRef]

- Sakharova, N.A.; Prates, P.A.; Oliveira, M.C.; Fernandes, J.V.; Antunes, J.M. A Simple Method for Estimation of Residual Stresses by Depth-Sensing Indentation. Strain 2012, 48, 75–87. [Google Scholar] [CrossRef]

- Lintymer, J.; Martin, N.; Chappé, J.M.; Delobelle, P.; Takadoum, J. Nanoindentation of chromium zigzag thin films sputter deposited. Surf. Coat. Technol. 2005, 200, 269–272. [Google Scholar] [CrossRef]

- Bondarev, A.V.; Kiryukhantsev-Korneev, P.V.; Sidorenko, D.A.; Shtansky, D.V. A new insight into hard low friction MoCN–Ag coatings intended for applications in wide temperature range. Mater. Des. 2016, 93, 63–72. [Google Scholar] [CrossRef]

- Ju, H.; Xu, J. Influence of vanadium incorporation on the microstructure, mechanical and tribological properties of Nb–V–Si–N films deposited by reactive magnetron sputtering. Mater. Charact. 2015, 107, 411–418. [Google Scholar] [CrossRef]

- Macías, H.A.; Yate, L.; Coy, L.E.; Olaya, J.J.; Aperador, W. Effect of nitrogen flow ratio on microstructure, mechanical and tribological properties of TiWSiNx thin film deposited by magnetron co-sputtering. Appl. Surf. Sci. 2018, 456, 445–456. [Google Scholar] [CrossRef]

| Sampleno. | Ar Pressure (Pa) | Substrate Temp (°C) | Deposition Time (min) | Flow Rate (sccm) | Cathode Current (A) | Cathode Voltage (V) | Sputtering Power (W) | Thickness (μm) |

|---|---|---|---|---|---|---|---|---|

| Cr-1 | 0.2 | 500 | 120 | 105.8 | 0.417 | 240 | 100 | 2.77 |

| Cr-2 | 0.2 | 500 | 120 | 105.8 | 0.591 | 254 | 150 | 4.12 |

| Cr-3 | 0.2 | 500 | 120 | 105.8 | 0.760 | 263 | 200 | 6.04 |

| Cr-4 | 0.2 | 500 | 120 | 105.8 | 0.923 | 271 | 250 | 7.10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, W.; Peng, J.; Xu, Z.; Shen, Q.; Wang, C. Effect of Power on Structural and Mechanical Properties of DC Magnetron Sputtered Cr Coatings. Metals 2023, 13, 691. https://doi.org/10.3390/met13040691

Shi W, Peng J, Xu Z, Shen Q, Wang C. Effect of Power on Structural and Mechanical Properties of DC Magnetron Sputtered Cr Coatings. Metals. 2023; 13(4):691. https://doi.org/10.3390/met13040691

Chicago/Turabian StyleShi, Wanyu, Jian Peng, Zhigang Xu, Qiang Shen, and Chuanbin Wang. 2023. "Effect of Power on Structural and Mechanical Properties of DC Magnetron Sputtered Cr Coatings" Metals 13, no. 4: 691. https://doi.org/10.3390/met13040691

APA StyleShi, W., Peng, J., Xu, Z., Shen, Q., & Wang, C. (2023). Effect of Power on Structural and Mechanical Properties of DC Magnetron Sputtered Cr Coatings. Metals, 13(4), 691. https://doi.org/10.3390/met13040691