Casting Process at Roll Bite in Strip Cast Using Vertical-Type High-Speed Twin-Roll Caster

Abstract

1. Introduction

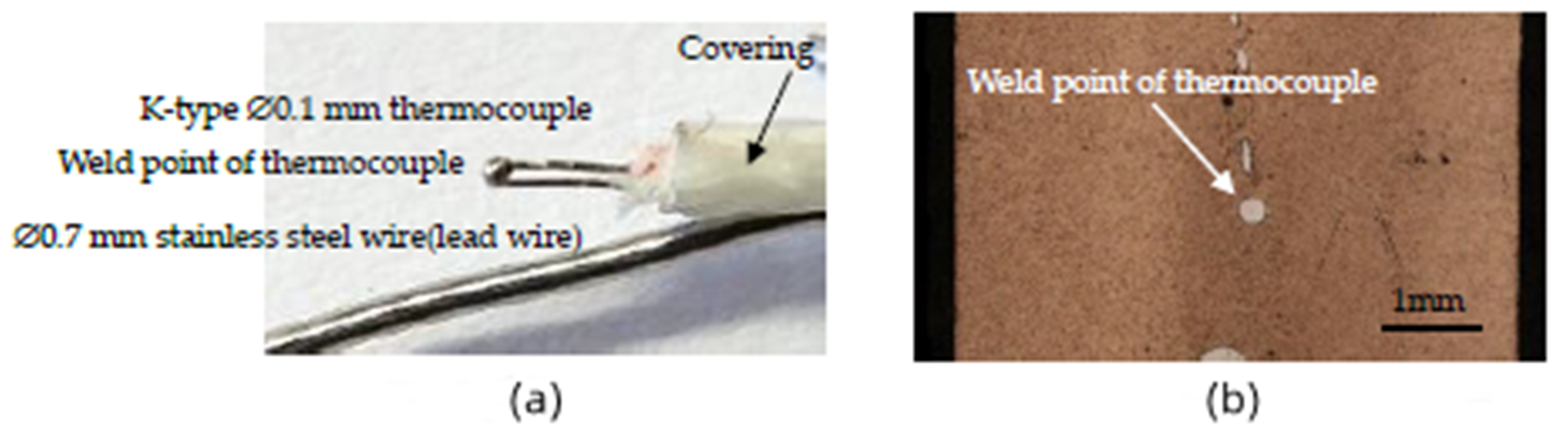

2. Experimental Methods

3. Results

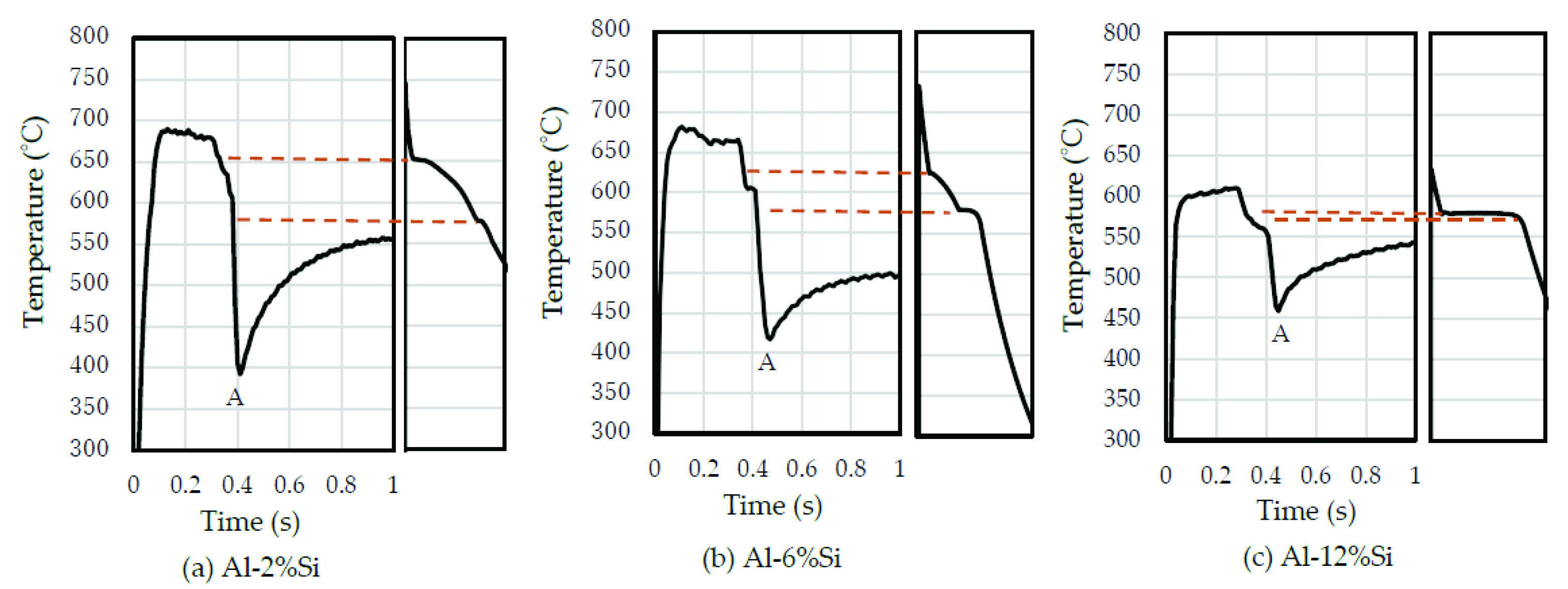

3.1. Cooling Curves

3.2. Strip Thickness

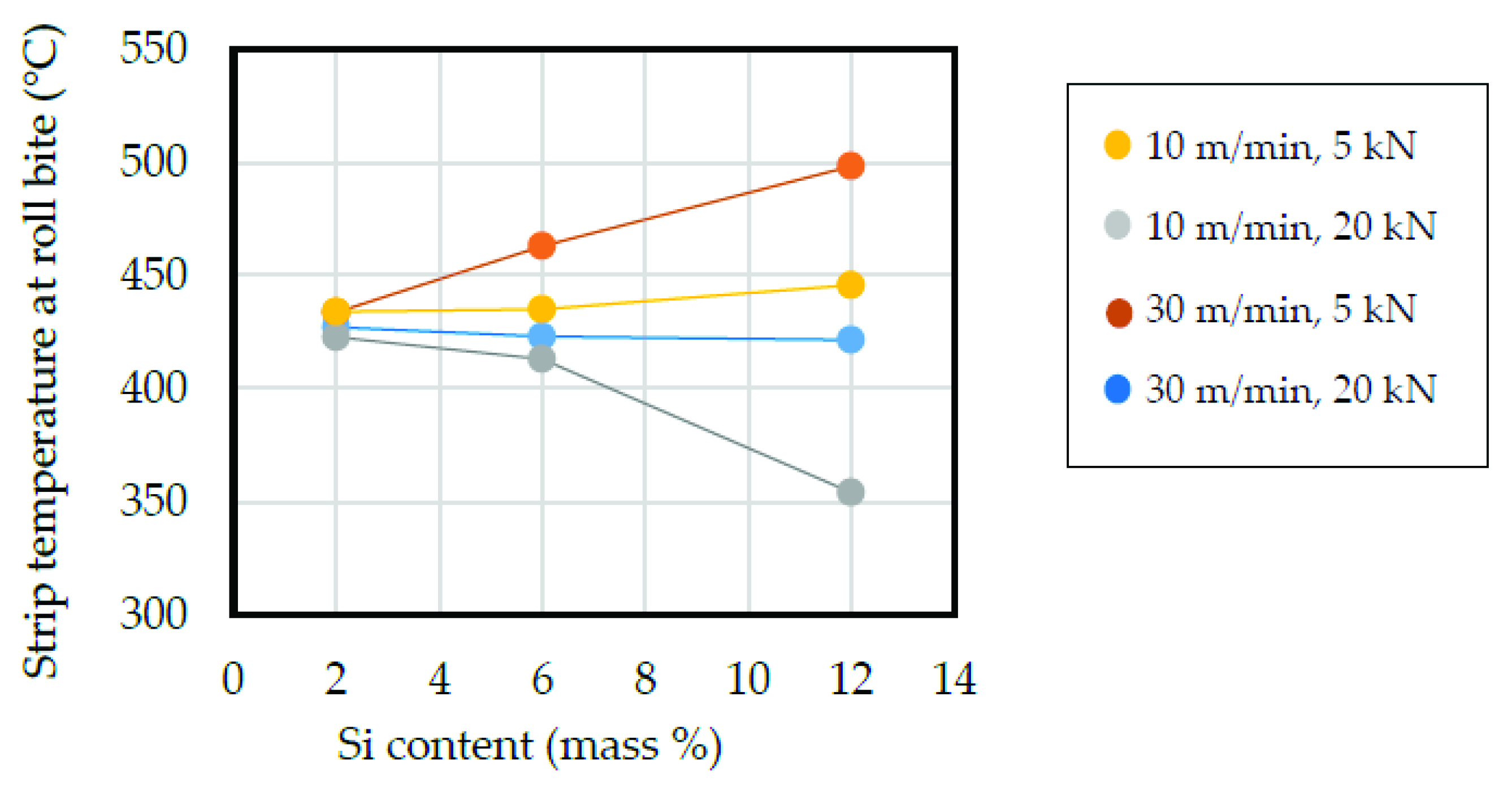

3.3. Strip Temperature at Roll Bite

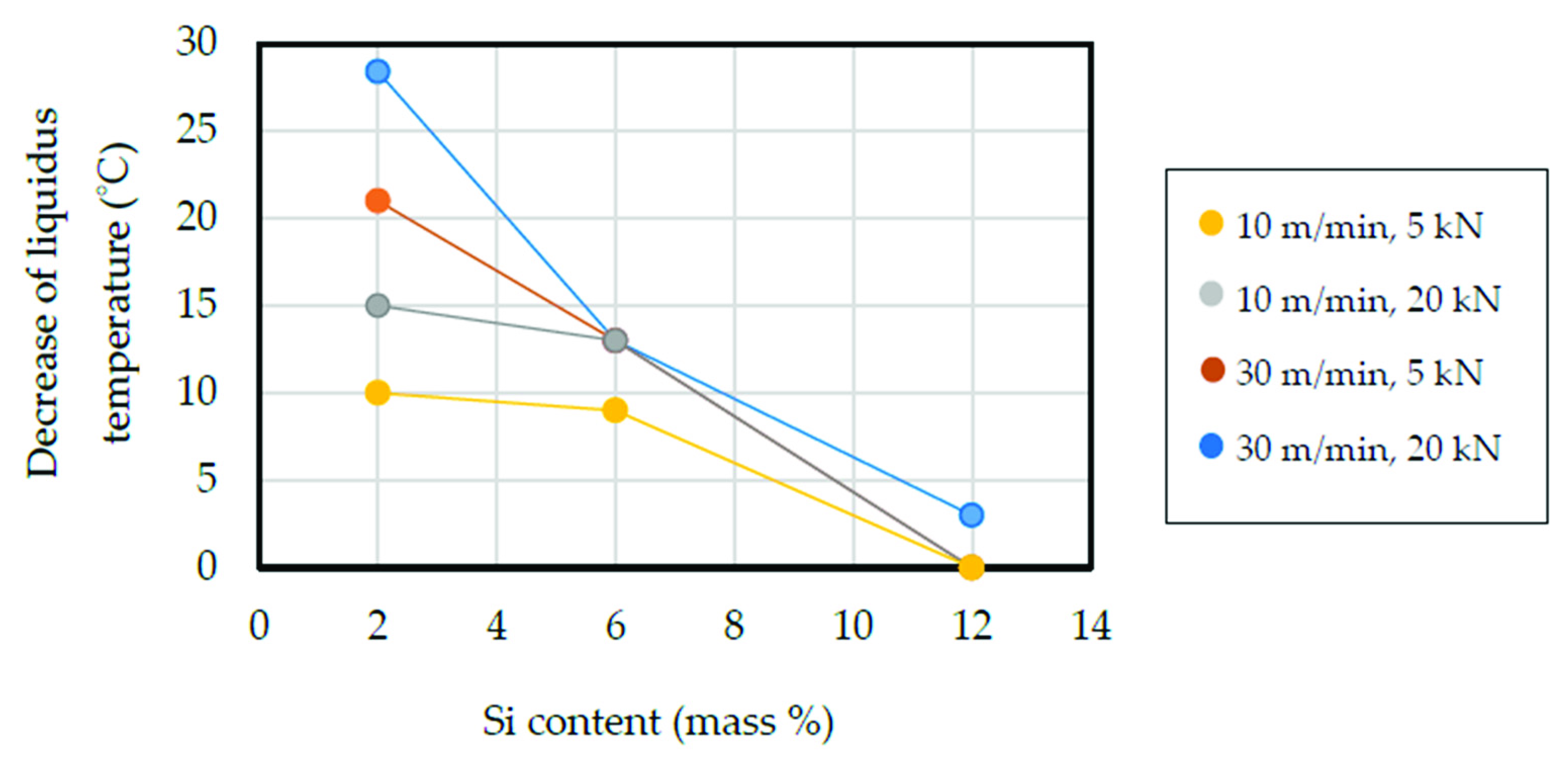

3.4. Decrease in Liquidus Temperature

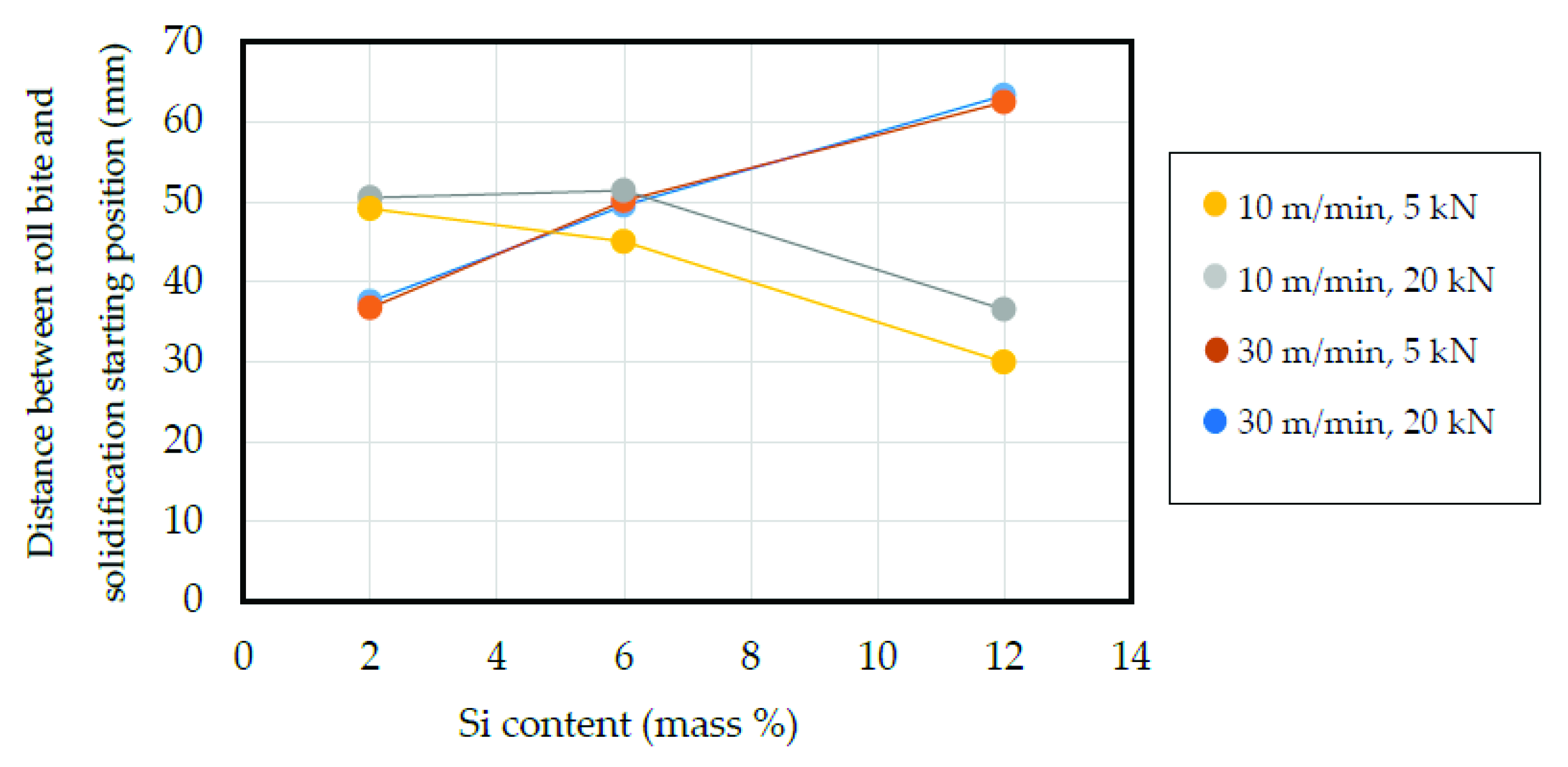

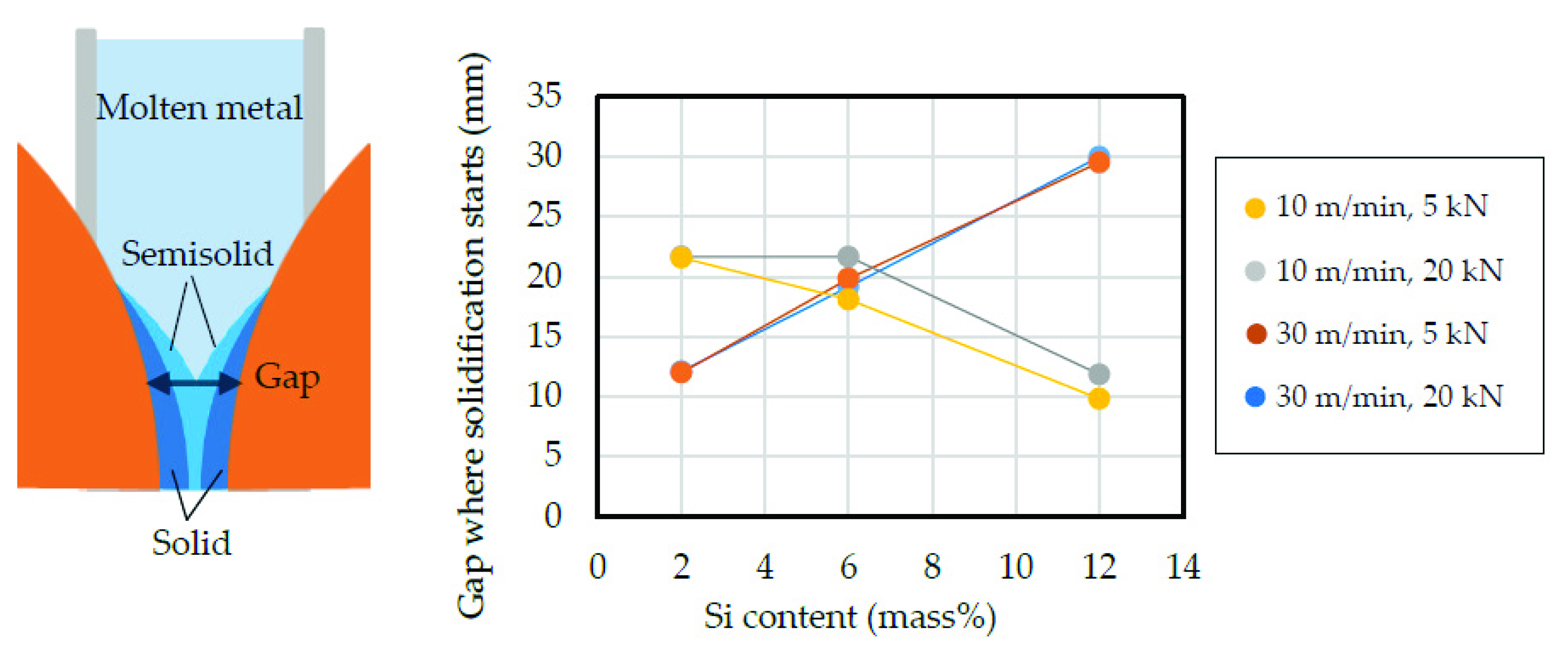

3.5. Solidification Starting Position

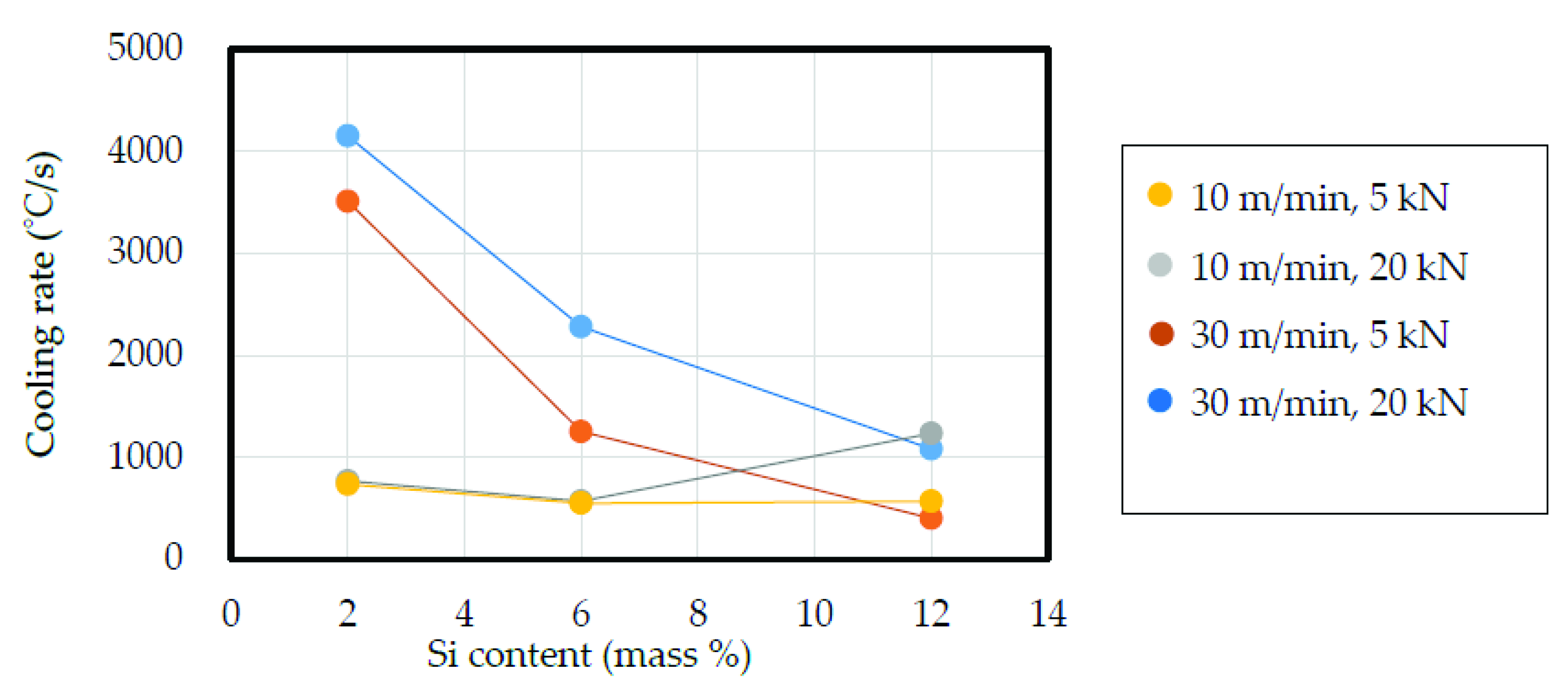

3.6. Cooling Rate

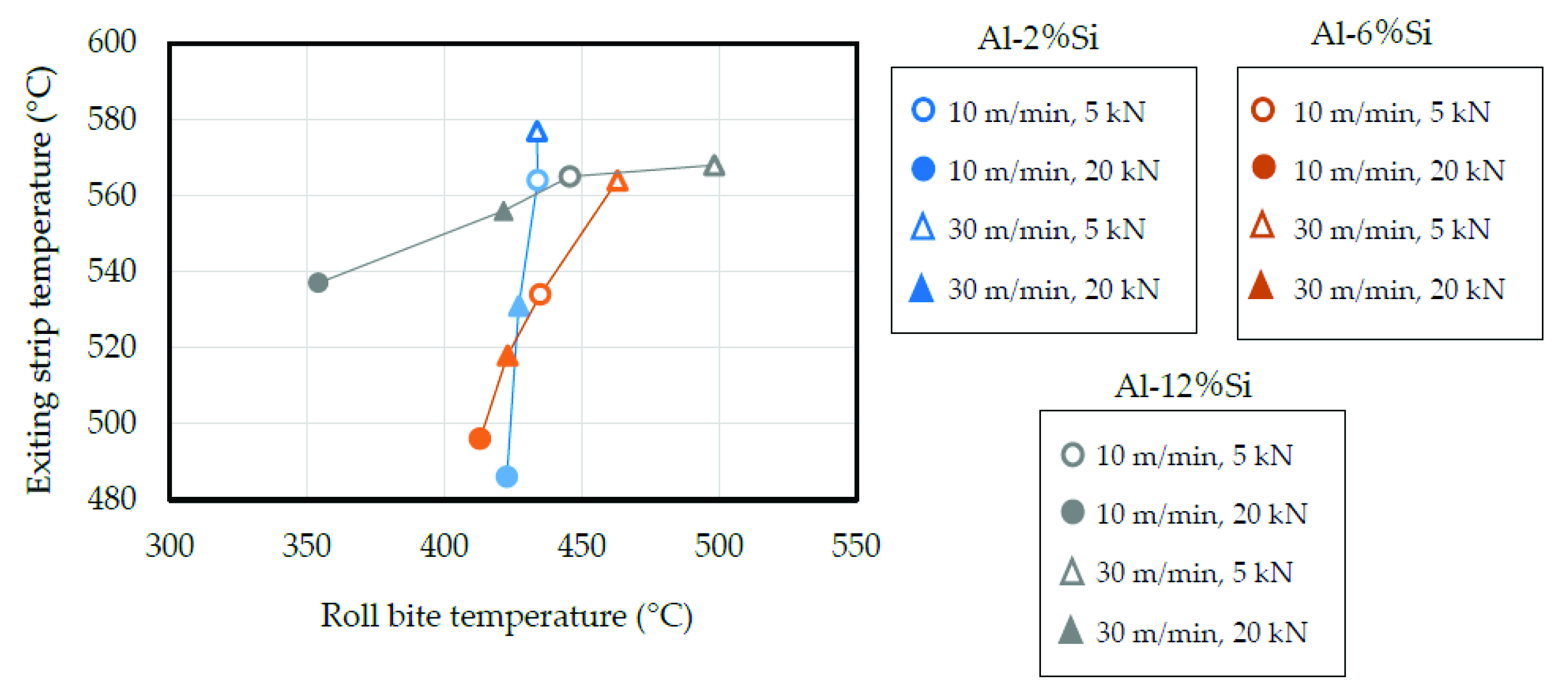

3.7. Strip Temperature after Exiting the Rolls

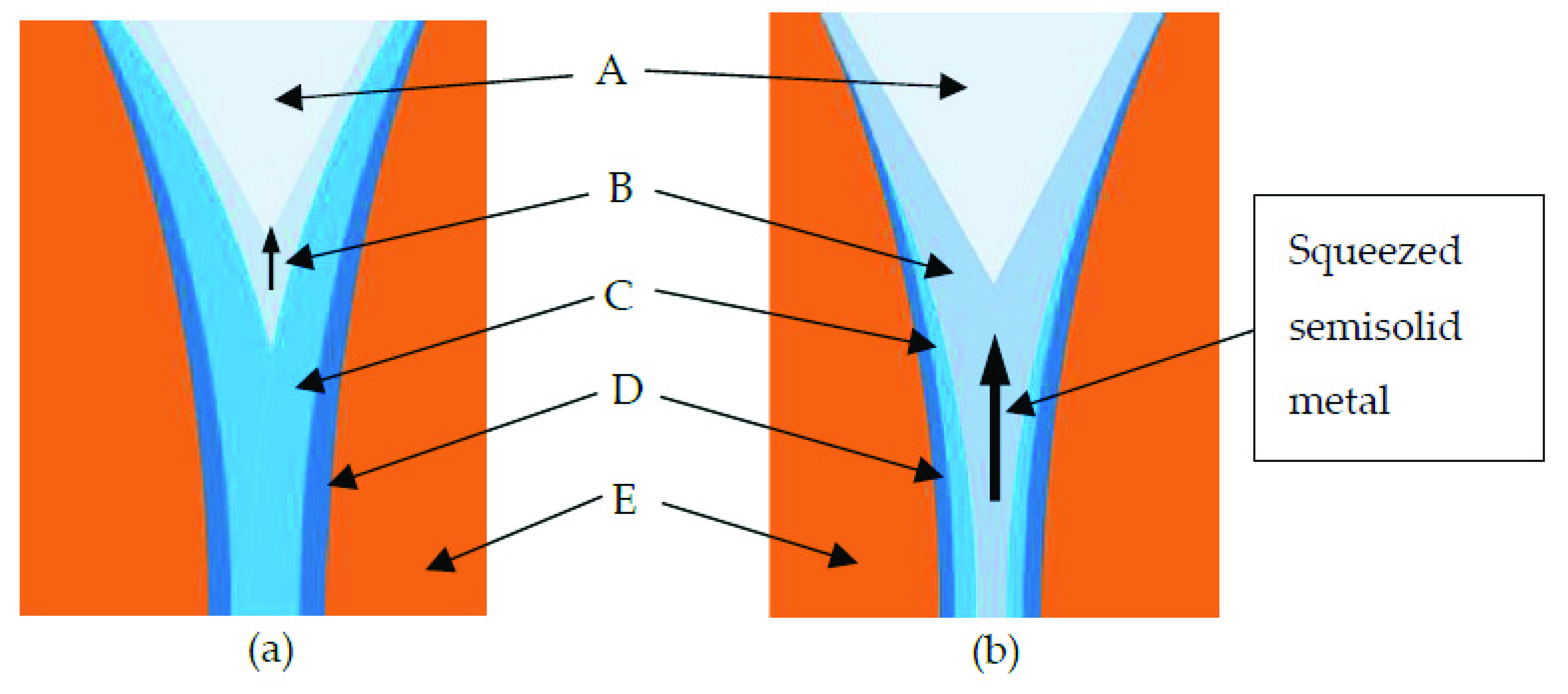

4. Discussion

4.1. Cooling Curves

4.2. Solidification Starting Position

4.3. Decrease in Liquidus Temperature

4.4. Cooling Rate

4.5. Strip Temperature at Roll Bite

4.6. Strip Temperature after Exiting Rolls

5. Conclusions

- (1)

- The Al-Si strip temperature after exiting the rolls increased to exceed the strip temperature at the roll bite.

- (2)

- The strip interior was not yet solidified when the strip exited the rolls.

- (3)

- The degree of supercooling of the liquidus temperature was lower than 30 °C, and that of the solidus temperature was higher than 180 °C. The supercooling of the liquidus temperature of the Al-Si alloy decreased as the Si content increased.

- (4)

- The strip temperature at the roll bite decreased as the roll speed decreased and the roll load increased.

- (5)

- The cooling rate increased as the Si content decreased, the roll speed increased, and the roll load increased.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Cook, R.; Cook, P.G.; Thomas, P.M.; Edmonds, D.V.; Hunt, J.D. Development of the twin-roll casting process. J. Mater. Process. Technol. 1995, 55, 76–84. [Google Scholar] [CrossRef]

- Taraglio, B.; Romanowski, C. Thin-gage/high-speed roll casting technology for foil production. Light Met. (TMS) 1995, 1165–1182. [Google Scholar]

- Cortes, M. Pechiney-Jumbo 3 CM the new demands of thin strip casting. Light Met. (TMS) 1995, 1161–1164. [Google Scholar]

- Nussbaum, A.I. Three-state-of-the-art Thin -gage high-speed roll caster for aluminum alloy sheet products. Light Met. Age 1996, 12, 8–19. [Google Scholar]

- Nussbaum, A.I. Three-state-of-the-art Thin-gage high-speed roll caster for aluminum alloy sheet products Part III. Light Met. Age 1997, 55, 34–39. [Google Scholar]

- Thomas, P.M.; Grocock, P.G.; Bouzendorffer, J.M. Dynamic strip caster- an update on the operation of the roll caster at Eurofoil. Melall. Plant Technol. Int. 1997, 20, 44–52. [Google Scholar]

- Hamer, S.; Romanowski, C.; Taraglio, B. Continuous casting and rolling of aluminum: Analysis of capacities, Product ranges and technology. Light Met. Age 2002, 60, 6–17. [Google Scholar]

- Gras, C.; Meredith, N.; Hunt, J.D. Microdefects for mation during the roll casting of Al-Mg-Mn aluminum alloys. J. Mater. Process. Technol. 2005, 167, 62–72. [Google Scholar] [CrossRef]

- Daaland, O.; Espedal, A.B.; Nedreberg, M.L.; Alvestad, I. Thin gage twin-roll casting, process capabilities and product quality. Light Met. (TMS) 2016, 3, 989–996. [Google Scholar] [CrossRef]

- Li, Y.; He, C.; Li, J.; Wang, Z.; Wu, D.; Xu, G. A novel approach to improve the microstructure and mechanical properties of Al-Mg-Si aluminum alloys during twin-roll casting. Metals 2020, 13, 1713. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, S.; Wang, H.; Song, H.; Li, S.; Chen, X. Effect of cooling rate on Microstructure and properties of twin-roll casting 6061 aluminum alloy sheet. Metals 2020, 10, 1168. [Google Scholar] [CrossRef]

- Haga, T.; Takahashi, K.; Ikawa, M.; Watari, H. A vertical type twin roll caster for aluminum alloy strip. J. Mater. Proc. Technol. 2003, 140, 610–615. [Google Scholar] [CrossRef]

- Haga, T.; Suzuki, S. Study on high-speed twin roll caster for aluminum alloys. J. Mater. Proc. Technol. 2003, 143–144, 895–900. [Google Scholar] [CrossRef]

- Haga, T.; Takahashi, K.; Ikawa, M.; Watari, H. Twin roll casting of aluminum alloy strips. J. Mater. Proc. Technol. 2004, 153, 42–47. [Google Scholar] [CrossRef]

- Haga, T. High Speed Roll Caster for Aluminum Alloy. Metals 2021, 11, 520. [Google Scholar] [CrossRef]

- Nakamura, R.; Haga, T.; Kumai, S.; Watari, H. Casting of aluminum alloy clad strip using a vertical type tandem twin roll caster. Adv. Mar. Res. 2010, 97–101, 1053–1056. [Google Scholar] [CrossRef]

- Haga, T.; Kumai, S.; Watari, H. Casting of Al-25%Si strip using a vertical type twin roll caster. Adv. Mar. Res. 2011, 239–242, 1944–1947. [Google Scholar] [CrossRef]

- Haga, T.; Ikawa, M.; Watari, H.; Suzuki, K.; Kumai, S. High-speed twin roll casting of thin aluminum alloy strips containing Fe impurities. Mater. Trans. 2005, 46, 2596–2601. [Google Scholar] [CrossRef]

- Harada, Y.; Jiang, N.; Kumai, S. Mechanical Properties of Cold-Rolled and Annealed Al-12%Mg alloy Sheet with High Mg Solid Solubility Fabricated from Vertical-Type High-Speed Twin Roll Cast Strip. Mater. Trans. 2019, 60, 2435–2441. [Google Scholar] [CrossRef]

- Kim, M.S.; Kim, H.E.; Kim, S.H.; Kumai, S. Role of Roll Separating Force in High-Speed Twin-Roll Casting of Aluminum Alloys. Metals 2019, 9, 645. [Google Scholar] [CrossRef]

- Kim, M.S.; Kim, H.E.; Kumai, S. Direct Temperature Measurement of Al-2mass%Si Alloys Strips during High-Speed Twin-Roll Casting and Its Applications in Determining Melt/Roll Heat Transfer Coefficient for Simulation. Mater. Trans. 2017, 58, 967–970. [Google Scholar] [CrossRef]

- Song, R.; Harada, Y.; Kumai, S. Influence of Cooling Rate on Primary Particle Solute Distribution in High-Speed Twin-Roll Cast Al-Mn Based Alloy Strip. Mater. Trans. 2018, 59, 110–116. [Google Scholar] [CrossRef]

- Itamura, M.; Yamamoto, N. Effects of Silicon Content on Latent Heat of Al-Si Alloys. J. Jpn. Foundry Eng. Soc. 1996, 66, 493–498. [Google Scholar] [CrossRef]

- Sugiyama, M.; Fukusako, T.; Sato, A. Direct-rolling of Molten Pure Aluminum. J. Jpn. Inst. Met. Mater. 1968, 32, 731–735. [Google Scholar] [CrossRef]

- Isobe, T.; Kubota, M.; Kitaoka, M. Criteria for Subdivision of Liquid-Solid Zone in Aluminum Alloys on the Basis of Contraction and Measurements. J. JFS 1978, 50, 235–239. [Google Scholar] [CrossRef]

- Isobe, T.; Kubota, M.; Kitaoka, M. Influence of Semi-solid Temperature Range and the Rate Influence in Strength during the Solidification Process on the Hot Tearing of Cast Aluminum Alloys. J. JFS 1978, 50, 425–430. [Google Scholar] [CrossRef]

- Haga, T.; Yamashiki, T.; Watari, H.; Nishida, S. Investigation of Burr on Strips Cast by Vertical-Type High-Speed Twin Roll Caster. Key Eng. Mater. 2020, 831, 40–45. [Google Scholar] [CrossRef]

- Haga, T.; Yamashiki, T.; Watari, H.; Nishida, S. Burr Formation in Casting Using Vertical-Type High-Speed Twin-Roll. Key Eng. Mater. 2020, 846, 146–151. [Google Scholar] [CrossRef]

- Miwa, K.; Ichikawa, R. Apparent Viscosity and Structure in Al-Si Alloys Partially Solidified under Stirring. J. Jpn. Inst. Met. 1981, 45, 853–859. [Google Scholar] [CrossRef][Green Version]

- Ichikawa, R.; Ikeda, T.; Ohashi, T. Effects of Cooling Rate and Supercooling on the Solidified Structure of Various Aluminum alloys. J. JFS 1974, 46, 25–35. [Google Scholar] [CrossRef]

- Haga, T.; Kapranos, P. Thixoforming of laminate made from semisolid cast strips. J. Mater. Process. Technol. 2004, 157, 508–512. [Google Scholar] [CrossRef]

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Ni |

|---|---|---|---|---|---|---|---|---|---|

| Al-2%Si | 2.04 | 0.11 | <0.01 | <0.01 | <0.01 | < 0.01 | <0.01 | 0.01 | 0.01 |

| Al-6%Si | 6.00 | 0.13 | <0.01 | <0.01 | 0.01 | 0.01 | <0.01 | 0.01 | 0.01 |

| Al-12%Si | 12.10 | 0.17 | <0.01 | <0.01 | 0.01 | 0.01 | <0.01 | 0.01 | <0.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haga, T.; Kurahashi, Y. Casting Process at Roll Bite in Strip Cast Using Vertical-Type High-Speed Twin-Roll Caster. Metals 2022, 12, 1169. https://doi.org/10.3390/met12071169

Haga T, Kurahashi Y. Casting Process at Roll Bite in Strip Cast Using Vertical-Type High-Speed Twin-Roll Caster. Metals. 2022; 12(7):1169. https://doi.org/10.3390/met12071169

Chicago/Turabian StyleHaga, Toshio, and Yukihiro Kurahashi. 2022. "Casting Process at Roll Bite in Strip Cast Using Vertical-Type High-Speed Twin-Roll Caster" Metals 12, no. 7: 1169. https://doi.org/10.3390/met12071169

APA StyleHaga, T., & Kurahashi, Y. (2022). Casting Process at Roll Bite in Strip Cast Using Vertical-Type High-Speed Twin-Roll Caster. Metals, 12(7), 1169. https://doi.org/10.3390/met12071169