Use of Molding Mixtures for the Production of Cast Porous Metals

Abstract

:1. Introduction

1.1. Properties and Applications of Metallic Foams

1.2. Production Possibilities of Porous Metals

2. Materials and Methods

2.1. Composition and Preparation of the Mixture for the Production of Cores and Precursors

2.2. Procedure for Evaluating the Properties of Cores and Precursors

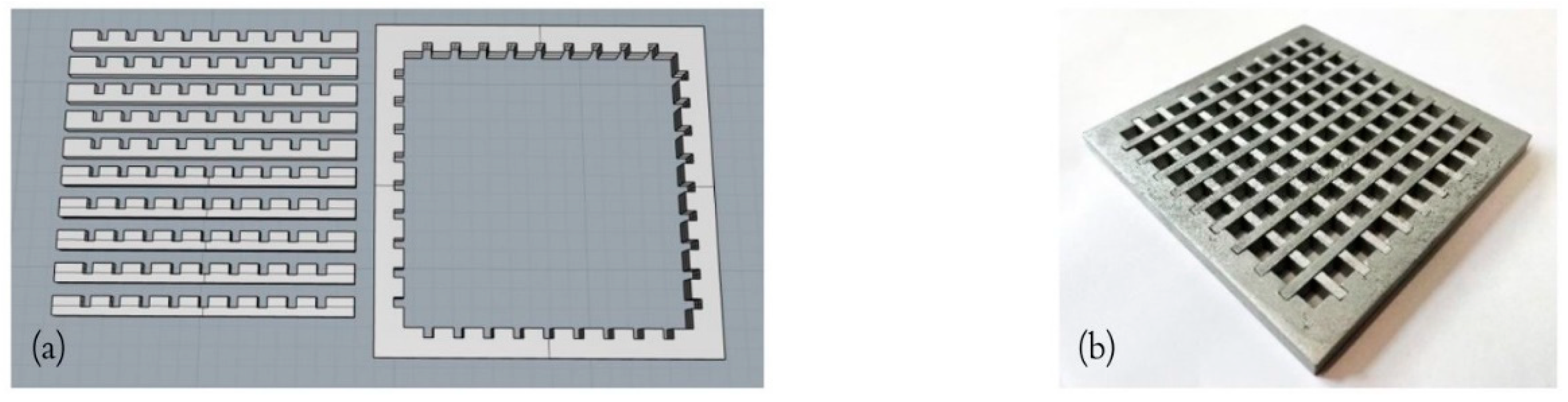

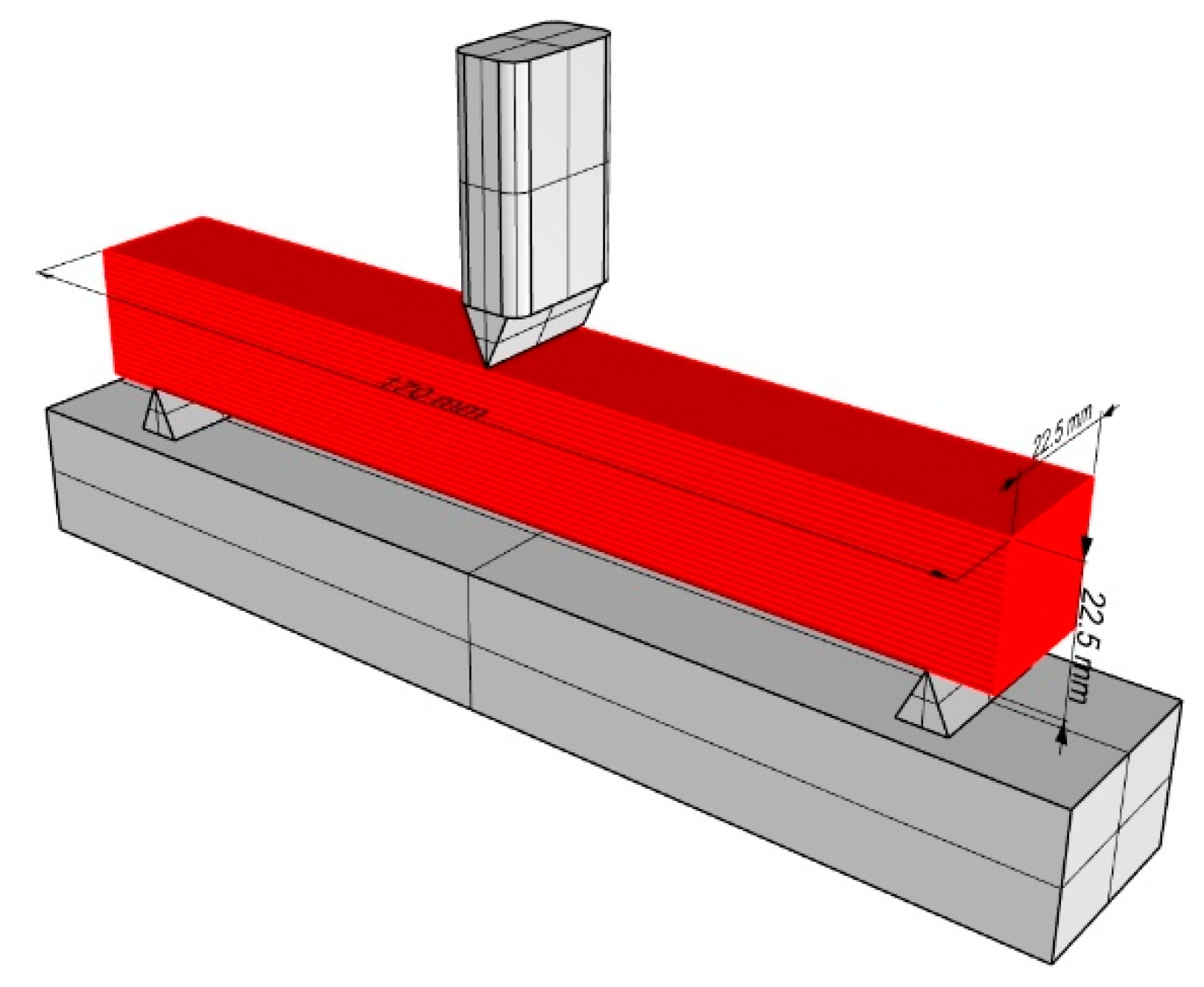

- Beams—Standardized test specimens (beams) with dimensions of 22.5 mm × 22.5 mm × 170 mm (Figure 3a) were made by compacting the mixture into the core box;

2.2.1. Three-Point Bending Strength (Beams)

2.2.2. Abrasion Loss (Beams)

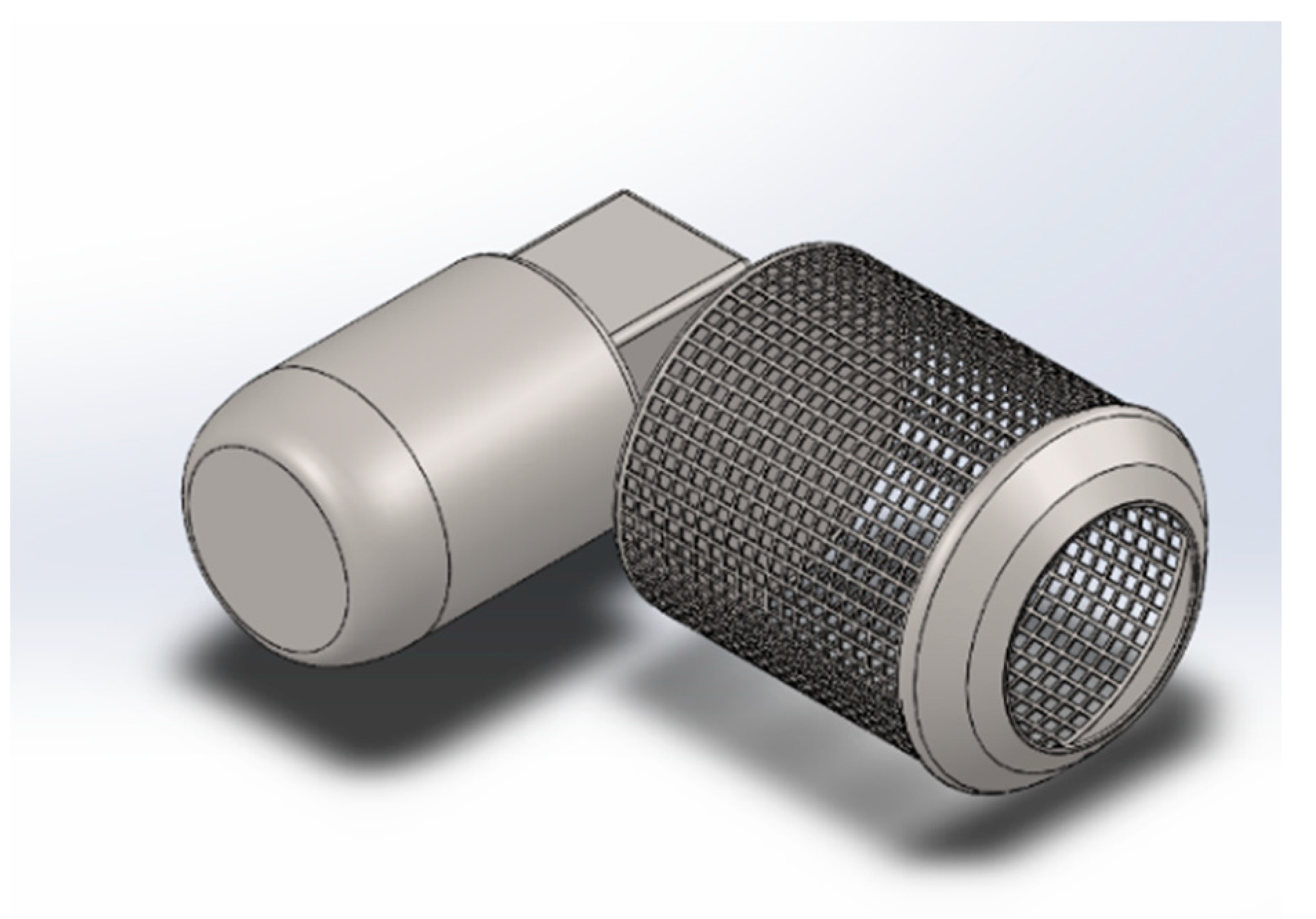

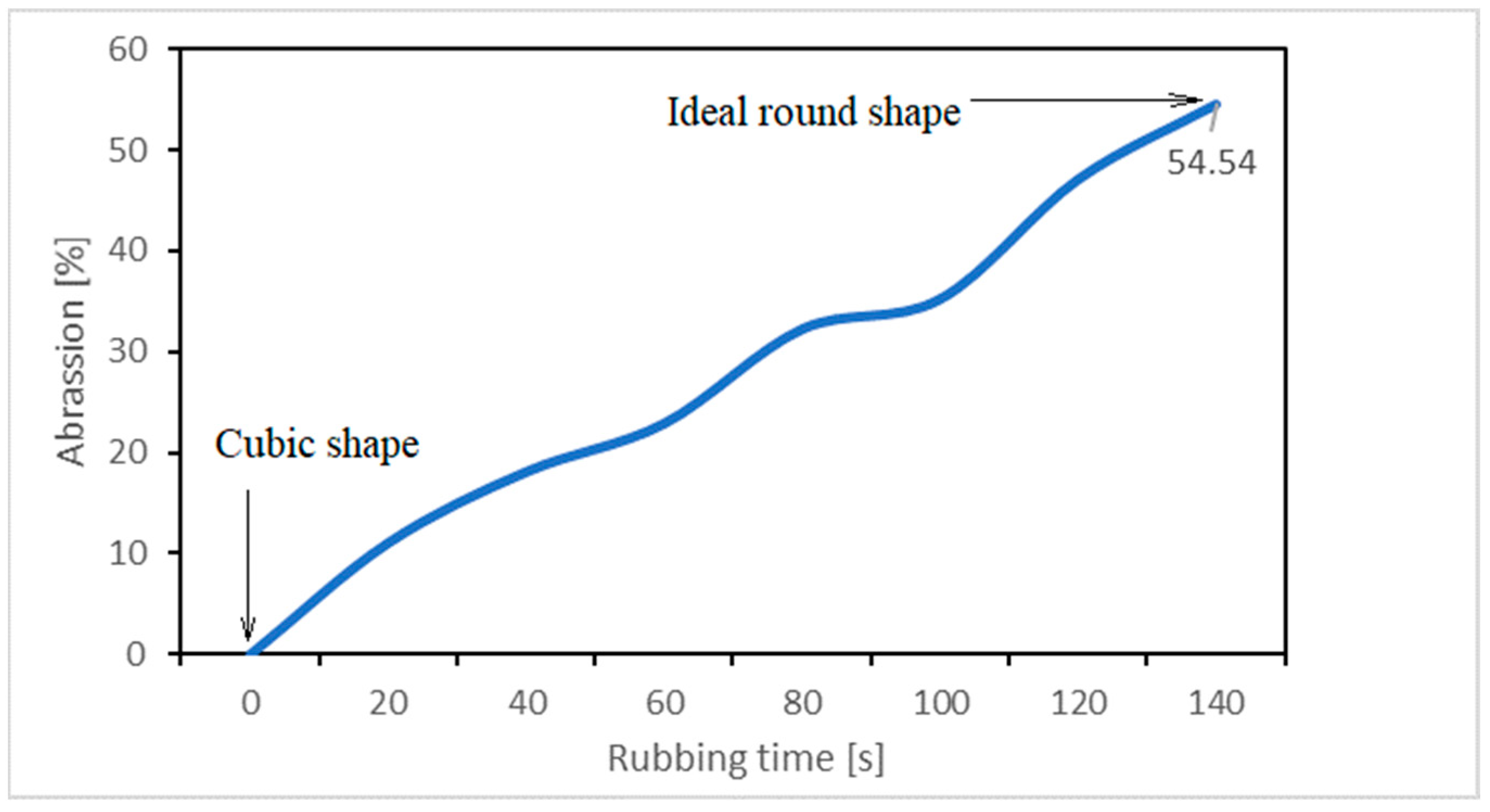

2.2.3. Abrasion Loss (Precursors)

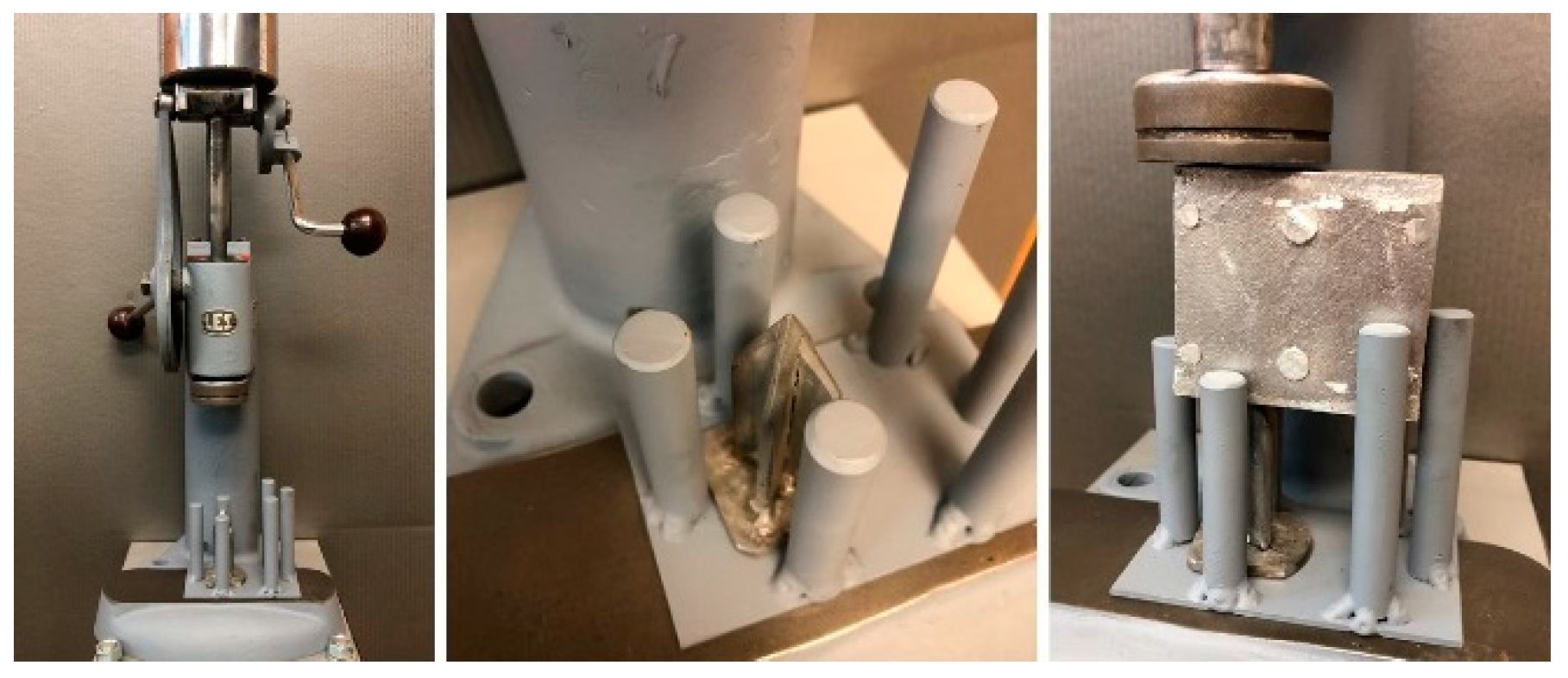

2.2.4. Collapsibility of Cores after Casting (Beams)

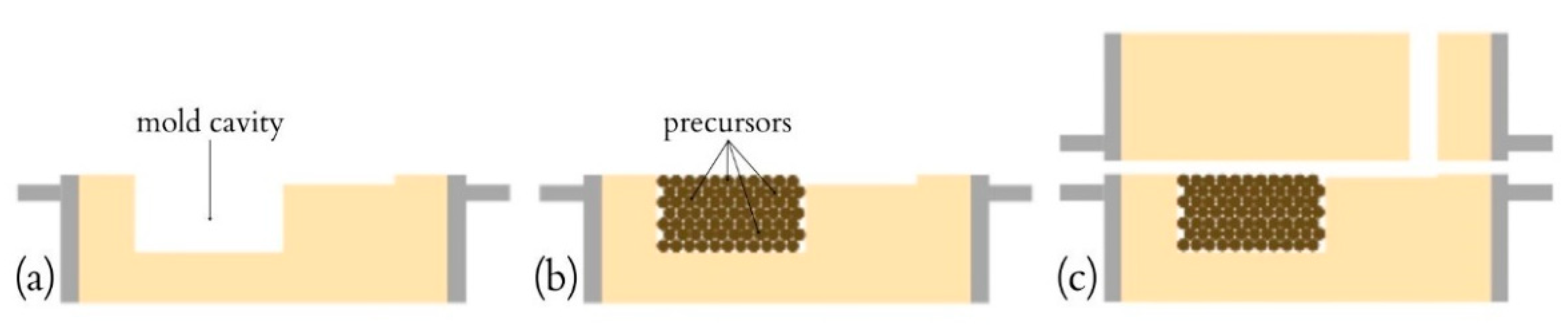

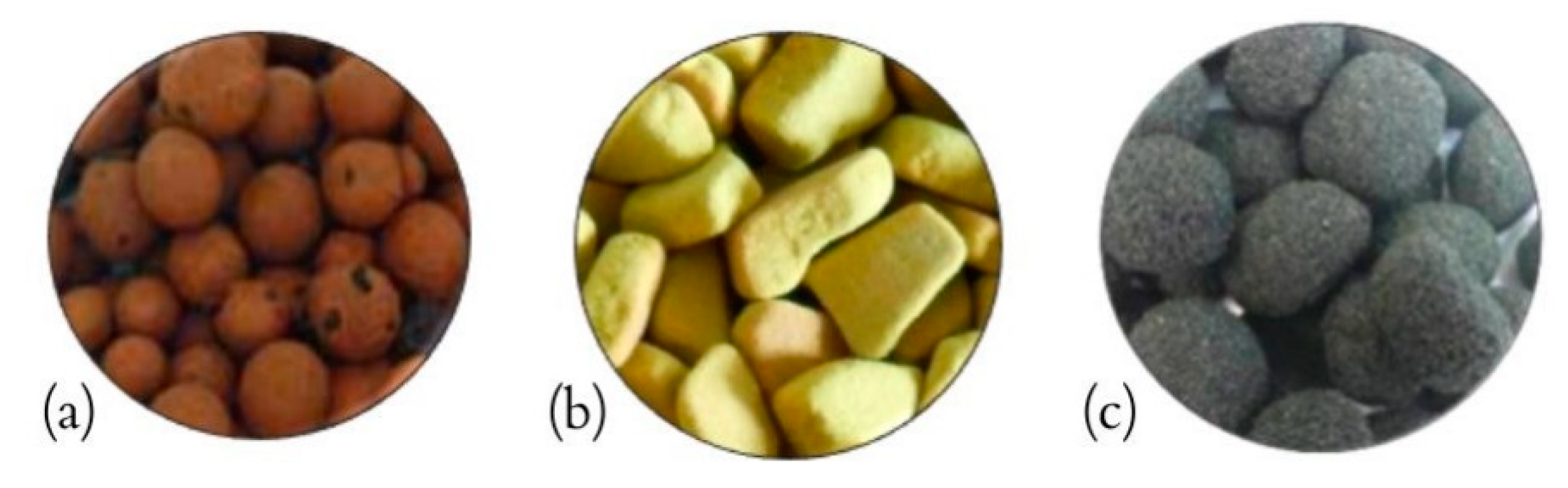

2.2.5. Evaluation of the Possibility of Using Studied Precursors for Metallic Foams Casting

3. Results

3.1. Three-Point Bending Strength (Beams)

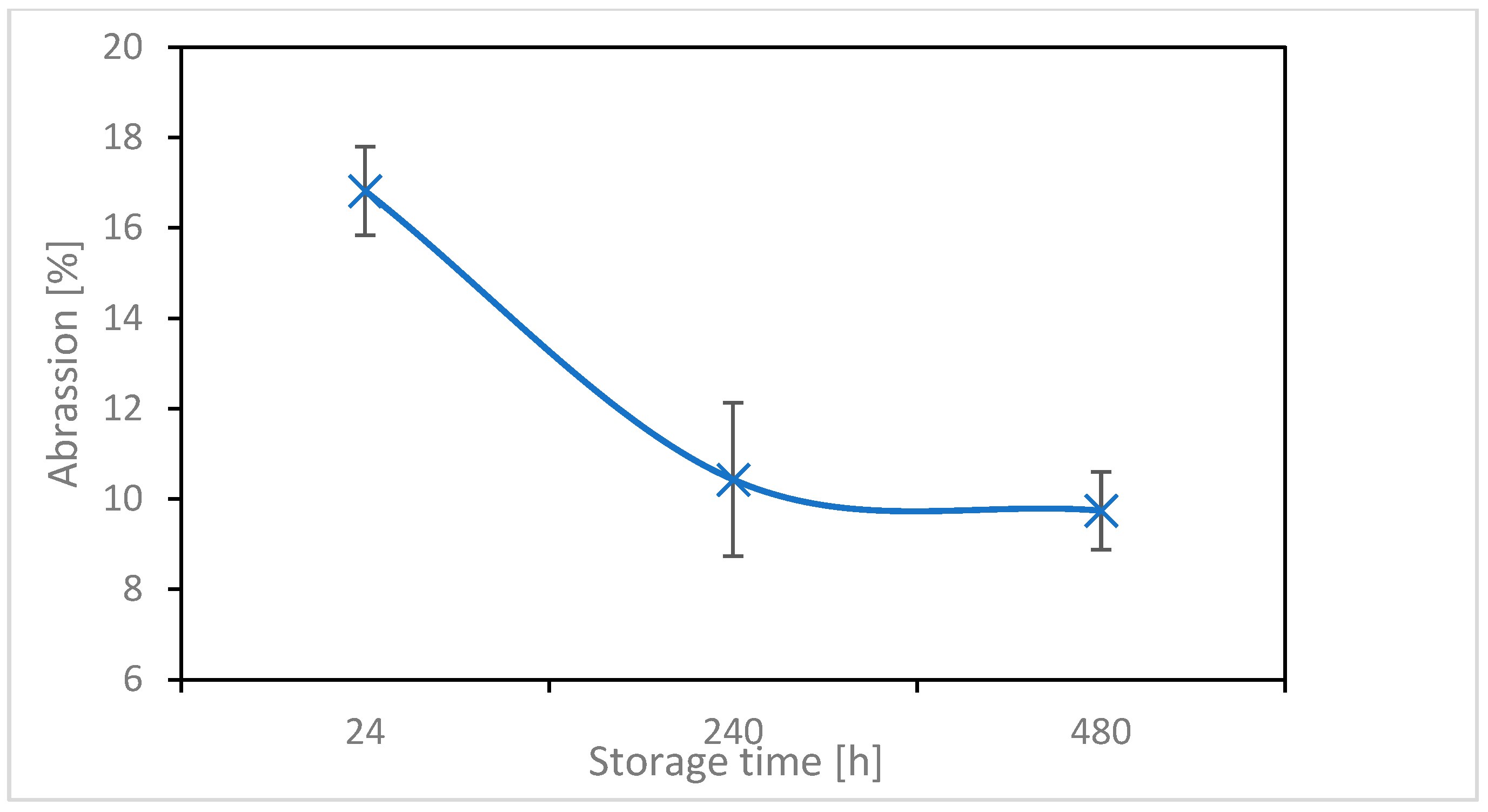

3.2. Abrasion Loss (Beams)

3.3. Abrasion Loss (Precursors)

3.4. Collapsibility of Cores after Casting (Beams)

3.5. Evaluation of the Possibility of Using Studied Precursors for Metallic Foams Casting

4. Discussion

- Bending strength evaluation area: Since the core mixture is an inhomogeneous system, the bending strength was always measured for five specimens. The measurements were carried out 24 h, 240 h, and 480 h after the curing of the mixture (or test beams). The measured values clearly show that the beam strength increases with increasing storage time and does not decrease further even after a long storage period (20 days). This is a significant result because one of the requirements for precursors is the possibility of storing them without affecting their quality;

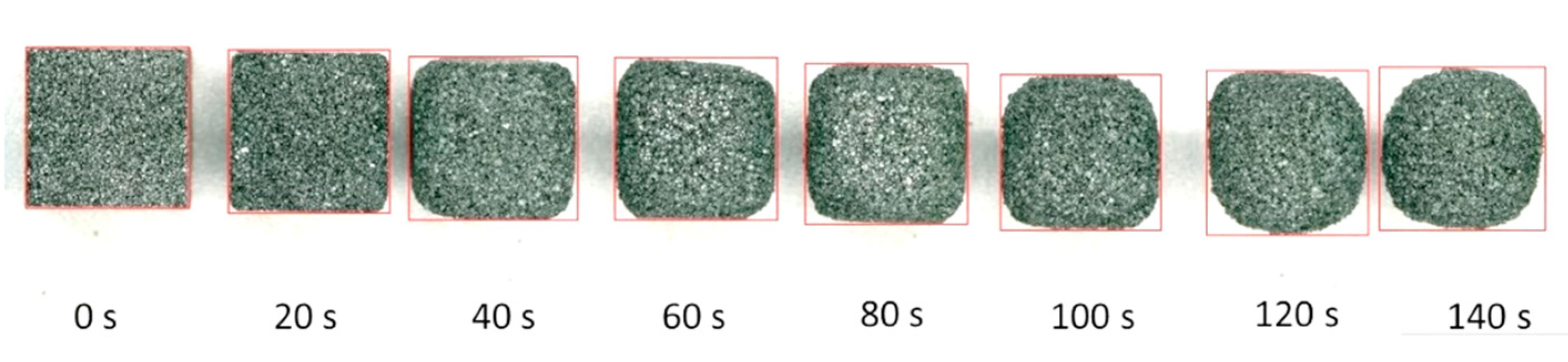

- Abrasion loss area: This property was evaluated on two types of specimens: test beams and precursors. The evaluation of the abrasion loss of the beams aimed to verify the change in abrasion resistance as a function of storage time. It was found that the abrasion resistance increases with storage time (and increasing strength). The aim of the precursor rubbing was to verify whether it is possible to create precursors of different shapes in this way, especially precursors that are close to the shape of a sphere. It has been shown that this process can produce precursors of various shapes. Moreover, the assumption that the size of the resulting precursor would change significantly with increasing abrasion time was refuted. It has been shown that the corners and edges of the original cube are rounded during the rubbing process. The diameter of the resulting round precursor is almost identical to the edge length of the original cube;

- Area of assessment of collapsibility after casting: The material under study proved to be excellent in terms of collapsibility after casting. Thanks to a specially designed apparatus and procedure, it was found that the removal (knock-out) of the cores from the casting required a knock-out energy of 0–6.6 J. These results demonstrate a very good collapsibility of the studied material after casting. This is one of our fundamental results. To be able to cast metallic foams by liquid metal infiltration into a mold cavity filled with precursors, the precursor material must be easily removable from the complex inner cavity of the casting. If this is not the case, or if the precursors remain embedded inside the casting, it is already a different type of material, known as so-called syntactic foams [58];

- Area of cast metallic foam production using precursors: It has been verified that the proposed technology to produce precursors allows their subsequent use in the cast metallic foam production process. By changing the shape of the precursor used, we can easily change the shape of the internal cavities of the cast metallic foam and thus change its final properties. These parameters will be addressed by further research in this area. Future research will also focus on materials for the production of metallic foams (alloys), particularly aluminum alloys [59], which represent the greatest potential in this area.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yan, G.; Zou, H.-X.; Wang, S.; Zhao, L.-C.; Wu, Z.-Y.; Zhang, W.-M. Bio-Inspired Vibration Isolation: Methodology and Design. Appl. Mech. Rev. 2021, 73, 020801. [Google Scholar] [CrossRef]

- Tan, C.; Zou, J.; Li, S.; Jamshidi, P.; Abena, A.; Forsey, A.; Moat, R.J.; Essa, K.; Wang, M.; Zhou, K.; et al. Additive manufacturing of bio-inspired multi-scale hierarchically strengthened lattice structures. Int. J. Mach. Tools Manuf. 2021, 167, 103764. [Google Scholar] [CrossRef]

- Guan, Q.-F.; Han, Z.-M.; Zhu, Y.; Xu, W.-L.; Yang, H.-B.; Ling, Z.-C.; Yan, B.-B.; Yang, K.-P.; Yin, C.-H.; Wu, H.; et al. Bio-Inspired Lotus-Fiber-like Spiral Hydrogel Bacterial Cellulose Fibers. Nano Lett. 2021, 21, 952–958. [Google Scholar] [CrossRef]

- Banhart, J. Light-Metal Foams—History of Innovation and Technological Challenges. Adv. Eng. Mater. 2013, 15, 82–111. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Cellular Solids—Structures and Properties; Cambridge University Press: Cambridge, UK, 1997; 515p, ISBN 0-521-49560-1. [Google Scholar]

- Banhart, J. Manufacture, characterisation and application of cellular metals and metal foams. Prog. Mater. Sci. 2001, 46, 559–632. [Google Scholar] [CrossRef]

- Banhart, J. Manufacturing Routes for Metallic Foams. JOM 2000, 52, 22–27. [Google Scholar] [CrossRef]

- Vahodgolpayegani, A.; Wen, C.; Hodgson, P.; Li, Y. Metallic Foam Bone: Processing, Modification and Characterization and Properties—Production Methods and Characterization of Porous Mg and Mg Alloys for Biomedical Application; Woodhead Publishing: Sawston, UK, 2017; pp. 25–81. ISBN 978-0-08-101290-1. [Google Scholar]

- Salehi, M.; Mirbagheri, S.M.H.; Jafari Ramiani, A. Efficient energy absorption of functionally-graded metallic foam-filled tubes under impact loading. Trans. Nonferrous Met. Soc. China 2021, 31, 92–110. [Google Scholar] [CrossRef]

- García-Peláez, J.; Rego-Junco, J.M.; Sánchez-Ricart, L. Reduction of Underwater Noise Radiated by Ships: Design of Metallic Foams for Diesel Tanks. IEEE J. Ocean. Eng. 2017, 43, 444–456. [Google Scholar] [CrossRef]

- Sharma, S.S.; Yadav, S.; Joshi, A.; Khatri, R. Application of metallic foam in vehicle structure: A review. Mater. Today Proc. 2022, 60, 7. [Google Scholar] [CrossRef]

- Zhang, H.; Zou, Z.; Qi, L.; Liu, H. Investigation of metallic foam in the application of turbine cooling. Procedia Eng. 2012, 27, 752–761. [Google Scholar] [CrossRef] [Green Version]

- Wejrzanowski, T.; Cwieka, K.; Skibinski, J.; Brynk, T.; Haj Ibrahim, S.; Milewskji, J.; Xing, W. Metallic foam supported electrodes, for molten carbonate fuel cells. Mater. Des. 2020, 193, 3. [Google Scholar] [CrossRef]

- Agbedor, S.-O.; Yang, D.; Chen, J.; Wang, L.; Wu, H. Low-Temperature Reactive Sintered Porous Mg-Al-Zn Alloy Foams. Metals 2022, 12, 692. [Google Scholar] [CrossRef]

- Cañadilla, A.; Romero, A.; Rodríguez, G.P. Sustainable Production of Powder Metallurgy Aluminum Foams Sintered by Concentrated Solar Energy. Metals 2021, 11, 1544. [Google Scholar] [CrossRef]

- Marri, G.K.; Balaji, C. Experimental and numerical investigations on the effect of porosity and PPI gradients of metal foams on the thermal performance of a composite phase change material heat sink. Int. J. Heat Mass Transfer 2021, 164, 15. [Google Scholar] [CrossRef]

- Santos, C.A.; Quaresma, J.M.V.; Garcia, A. Determination of Transient Interfacial Heat Transfer Coefficients in Chill Mold Castings. J. Alloy. Compd. 2001, 319, 174–186. [Google Scholar] [CrossRef]

- Donelan, P. Modelling microstructural and mechanical properties of ferritic ductile cast iron. Mater. Sci. Technol. 2000, 16, 261–269. [Google Scholar] [CrossRef]

- Osório, W.R.; Cheung, N.; Spinelli, J.E.; Goulart, P.R.; Garcia, A. The effects of a eutectic modifier on microstructure and surface corrosion behavior of Al-Si hypoeutectic alloys. J. Solid State Electrochem. 2007, 11, 1421–1427. [Google Scholar] [CrossRef]

- Osorio, W.R.; Siqueira, C.A.; Santos, C.A.; Garcia, A. The Correlation between Electrochemical Corrosion Resistance and Mechanical Strength of as-cast Al-Cu and Al-Si Alloys. Int. J. Electrochem. Sci. 2011, 6, 6275–6289. [Google Scholar]

- Bonatti, R.S.; Meyer, Y.A.; Bortolozo, A.D.; Costa, D.; Osório, W.R. Morphology and size effects on densification and mechanical behavior of sintered powders from Al-Si and Al-Cu casting alloys. J. Alloy. Compd. 2019, 786, 717–732. [Google Scholar] [CrossRef]

- Szklarz, Z.; Krawiec, H.; Rogal, L. Effect of the cooling rate on the electrochemical behaviour of 2017 aluminium alloy. Ann. De Chim. Sci. Des Mater. 2016, 40, 25–32. [Google Scholar] [CrossRef]

- Yadav, R.Y.; Prakash, E.S. Experimental Determination of Relative Density and Percentage Porosity of Open Cell Aluminium foam Produced from Sand Salt Mould Method. Int. J. Eng. Res. Technol. 2016, 5, 152–154. [Google Scholar]

- Sun, G.; Wang, Z.; Yu, H.; Gong, Z.; Li, Q. Experimental and numerical investigation into the crashworthiness of metal-foam-composite hybrid structures. Compos. Struct. 2019, 209, 535–547. [Google Scholar] [CrossRef]

- Banhart, J.; Baumeister, J. Deformation characteristics of metal foams. J. Mater. Sci. 1998, 33, 1431–1440. [Google Scholar] [CrossRef]

- Strano, M.; Marra, A.; Mussi, V.; Goletti, M.; Bocher, P. Endurance of Damping Properties of Foam-Filled Tubes. Materials 2015, 8, 4061–4079. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Evans, A.G.; Hutchinson, J.W.; Ashby, M.F. Multifunctionality of cellular metal systems. Prog. Mater. Sci. 1998, 43, 171–221. [Google Scholar] [CrossRef]

- Stojanovic, B.; Bukvic, M.; Epler, I. Application of aluminum and aluminum alloys in engineering. Appl. Eng. Lett. 2018, 3, 52–62. [Google Scholar] [CrossRef]

- Weiler, J.P. A review of magnesium die-castings for closure applications. J. Magnes. Alloy 2019, 7, 297–304. [Google Scholar] [CrossRef]

- Garai, F.; Béres, G.; Weltsch, Z. Development of tubes filled with aluminium foams for lightweight vehicle manufacturing. Mater. Sci. Eng. A 2020, 790, 9. [Google Scholar] [CrossRef]

- Rogala, M.; Ferdynus, M.; Gawdzińska, K.; Kochmański, P. The Influence of Different Length Aluminum Foam Filling on Mechanical Behavior of a Square Thin-Walled Column. Materials 2021, 14, 3630. [Google Scholar] [CrossRef]

- Ghiani, C.; Linul, E.; Porcu, M.C.; Marsavina, L.; Movahedi, N.; Aymerich, F. Metal Foam-Filled Tubes as Plastic Dissipaters in Earthquake-Resistant Steel Buildings. IOP Conf. Ser. Mater. Sci. Eng. 2018, 416, 8. [Google Scholar] [CrossRef]

- Abishek, S.; King, A.J.C.; Nadim, N.; Mullis, B.J. Effect of microstructure on melting in metal-foam/paraffin composite phase change materials. Int. J. Heat Mass Transf. 2018, 127, 135–144. [Google Scholar] [CrossRef]

- Feng, Y.; Zheng, H.; Zhu, Z.; Zu, F. The microstructure and electrical condictivity of aluminum alloy foams. Mater. Chem. Phys. 2003, 78, 196–201. [Google Scholar] [CrossRef]

- Kuruneru, S.T.W.; Vafai, K.; Sauret, E.; Gu, Y.T. Application of porous metal foam heat exchangers and the implications of particulate fouling for energy-intensive industries. Chem. Eng. Sci. 2020, 228, 23. [Google Scholar] [CrossRef]

- Chen, K.; Guo, L.; Wang, H. A review on thermal application of metal foam. Sci. China Technol. Sci. 2020, 63, 2469–2490. [Google Scholar] [CrossRef]

- Teruna, C.; Manegar, F.; Avallone, F.; Ragni, D.; Casalino, D.; Carolus, T. Noise reduction mechanisms of an open-cell metal-foam trailing edge. J. Fluid Mech. 2020, 898, 36. [Google Scholar] [CrossRef]

- Gibson, L.J. Biomechanics of cellular solids. J. Biomech. 2005, 38, 377–399. [Google Scholar] [CrossRef] [PubMed]

- García-Moreno, F. Commercial Applications of Metal Foams: Their Properties and Production. Materials 2016, 85, 85. [Google Scholar] [CrossRef] [PubMed]

- Chino, Y. Processing of a porous 7075 Al alloy by bubble expansion in a semi-solid state. Acta Mater. 2002, 47, 769–773. [Google Scholar] [CrossRef]

- Wadley, H.N.G. Cellular Metals Manufacturing. Adv. Eng. Mater. 2002, 4, 726–733. [Google Scholar] [CrossRef]

- Rajak, D.K.; Kumaraswamidhas, L.A.; Das, S. Technical overview of aluminum alloy foam. Rev. Adv. Mater. Sci. 2017, 48, 68–86. [Google Scholar]

- Shim, D. Effects of process parameters on additivemanufacturing of aluminum porous materials andtheir optimization using response surface method. J. Mater. Res. Technol. 2021, 15, 119–134. [Google Scholar] [CrossRef]

- Rabiei, A.; O’Neill, A.T. A study on processing of a composite metalfoam via casting. Mater. Sci. Eng. A 2005, 404, 159–164. [Google Scholar] [CrossRef]

- Queheillalt, D.T.; Hass, D.D.; Sypeck, D.J.; Wadley, H.N.G. Synthesis of open-cell metal foams by templated directed vapor deposition. J. Mater. Res. 2011, 16, 1028–1036. [Google Scholar] [CrossRef] [Green Version]

- Hernández-Nava, E.; Smith, C.j.; Derguti, F.; Tammas-Williams, S.; Léonard, F.; Withers, P.J.; Todd, I.; Goodall, R. The effect of density and feature size on mechanical properties of isostructural metallic foams produced by additive manufacturing. Acta Mater. 2015, 85, 387–395. [Google Scholar] [CrossRef] [Green Version]

- Almonti, D.; Baiocco, G.; Tagliaferri, V.; Ucciardello, N. Design and Mechanical Characterization of Voronoi Structures Manufactured by Indirect Additive Manufacturing. Materials 2020, 13, 85. [Google Scholar] [CrossRef] [Green Version]

- Lakes, R.S. Composites and Metamaterials; World Scientific: Singapore, 2020; ISBN 9789811216367. [Google Scholar]

- Hangai, Y.; Zushida, K.; Fujii, H.; Ueji, R.; Kuwaruzu, O.; Yoshikawa, N. Friction powder compaction process for fabricating open-celled Cu foam by sintering-dissolution process route using NaCl space holder. Mater. Sci. Eng. A 2013, 585, 468–474. [Google Scholar] [CrossRef]

- Jha, N.; Mondal, D.P.; Majumdar, J.D.; Badkul, A.; Jha, A.K.; Khare, A.K. Highly porous open cell Ti-foam using NaCl as temporary space holder through powder metallurgy route. Mater. Design 2013, 47, 810–819. [Google Scholar] [CrossRef]

- Dahil, L.; Karabulut, A.; Baspinar, S. Damping properties of open pore aluminum foams produced by vacuum casting and NaCl dissolution process. Metalurgija 2013, 52, 489–492. [Google Scholar]

- Aida, S.F.; Hijrah, M.N.; Amirah, A.H.; Zuhailawati, H.; Anasyida, A.S. Effect of NaCl as a Space Holder in Producing Open Cell A356 Aluminium Foam by Gravity Die Casting Process. Procedia Chem. 2016, 19, 234–240. [Google Scholar] [CrossRef] [Green Version]

- Kroupová, I.; Gawronová, M.; Lichý, P.; Merta, V.; Radkovský, F.; Janovská, K.; Nguyenová, I.; Beňo, J.; Obzina, T.; Vasková, I.; et al. Preparation of Cast Metallic Foams with Irregular and Regular Inner Structure. Materials 2021, 14, 6989. [Google Scholar] [CrossRef]

- Sundarram, S.S.; Li, W. The effect of pore size and porosity on thermal management performance of phase change material infiltrated microcellular metal foams. Appl. Therm. Eng. 2014, 64, 147–154. [Google Scholar] [CrossRef]

- Bai, M.; Chung, J.N. Analytical and numerical prediction of heat transfer and pressure drop in open-cell metal foams. Int. J. Therm. Sci. 2011, 50, 869–880. [Google Scholar] [CrossRef]

- Heitor, D.; Duarte, I.; Dias-de-Oliveira, J. Aluminium Alloy Foam Modelling and Prediction of Elastic Properties Using X-ray Microcomputed Tomography. Metals 2021, 11, 925. [Google Scholar] [CrossRef]

- Merta, V.; Beňo, J.; Obzina, T.; Radkovský, F.; Kroupová, I.; Lichý, P.; Folta, M.; Janovská, K.; Nguyenová, I.; Dostál, M. Innovative Inorganic Binder Systems for the Production of Cores for Non-Ferrous Metal Alloys Reflecting the Product Quality Requirements. Metals 2021, 11, 733. [Google Scholar] [CrossRef]

- Orbulov, I.N.; Szlancsik, A. On the Mechanical Properties of Aluminum Matrix Syntactic Foams. Adv. Eng. Mater. 2018, 20, 12. [Google Scholar] [CrossRef] [Green Version]

- Matejka, M.; Bolibruchová, D.; Kasińska, J. The influence of remelting on the properties of AlSi9Cu3 alloy with higher iron content. Materials 2020, 13, 575. [Google Scholar] [CrossRef] [Green Version]

| Basic Sand | Binder | Catalyst | |

|---|---|---|---|

| Foundry silica sand | Furan resin <75% FFA | Based on p-toluensulfonic acid | |

| Name | BG 27 (Biala Góra) | Ecofur 2375 | 100T5D |

| Supplier | Sand Team | Mazzon | Hüttenes-Albertus |

| Dosage [wt. %] | 100 | 1 | 45 (to the binder content) |

| Dosage [g] | 5000 ± 5 | 50 ± 0.01 | 22.5 ± 0.01 |

| Basic Sand | Binder | Catalyst | |

|---|---|---|---|

| Name | Foundry silica sand BG 27 | GEOPOL 618 | SA 73 |

| Supplier | Sand Team | Sand Team | Sand Team |

| Dosage [wt. %] | 100 | 1.8 | 18 (to the binder content) |

| Dosage [g] | 4000 ± 5 | 72 ± 0.01 | 12.96 ± 0.01 |

| Sample Type | Total Pieces | Test | Time | Pieces per Test |

|---|---|---|---|---|

| Beams | 20 | Three-point bending strength test + abrasion loss | After 24 h | 5 |

| After 240 h | 5 | |||

| After 480 h | 5 | |||

| Determination of collapsibility of cores after casting | After 24 h | 5 (resp. 10 × 1/2) | ||

| Precursors | 1200 | Abrasion loss | For 0 s | 100 |

| For 20 s | 100 | |||

| For 40 s | 100 | |||

| For 60 s | 100 | |||

| For 80 s | 200 | |||

| For 100 s | 200 | |||

| For 120 s | 200 | |||

| For 140 s | 200 | |||

| Casting of metallic foam | 0–140 s | approx. 100 pcs/casting |

| Time [h] | Ø m of the Sample before Abrasion [g] | Sx [g] | Ø m of the Sample after Abrasion [g] | Sx [g] | Abrasion Loss [g] | Sx [g] |

|---|---|---|---|---|---|---|

| 24 | 128.48 | 1.32 | 106.87 | 1.74 | 21.612 | 1.26 |

| 240 | 128.46 | 2.68 | 115.06 | 2.42 | 13.402 | 2.33 |

| 480 | 127.91 | 1.74 | 115.45 | 1.85 | 12.464 | 1.13 |

| Time [s] | Ø m of the Batch (100 pcs) before Abrasion [g] | Ø m of the Batch (100 pcs) after Abrasion [g] | Abrasion Loss [g] |

|---|---|---|---|

| 0 | 153.56 | 153.56 | 0 |

| 20 | 155.40 | 138.18 | 17.22 |

| 40 | 157.34 | 128.82 | 28.52 |

| 60 | 149.18 | 115.01 | 34.17 |

| 80 | 148.27 | 100.36 | 47.90 |

| 100 | 144.87 | 93.79 | 51.08 |

| 120 | 148.95 | 78.77 | 70.18 |

| 140 | 146.60 | 66.81 | 79.79 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kroupová, I.; Gawronová, M.; Lichý, P.; Merta, V.; Radkovský, F. Use of Molding Mixtures for the Production of Cast Porous Metals. Metals 2022, 12, 1134. https://doi.org/10.3390/met12071134

Kroupová I, Gawronová M, Lichý P, Merta V, Radkovský F. Use of Molding Mixtures for the Production of Cast Porous Metals. Metals. 2022; 12(7):1134. https://doi.org/10.3390/met12071134

Chicago/Turabian StyleKroupová, Ivana, Martina Gawronová, Petr Lichý, Václav Merta, and Filip Radkovský. 2022. "Use of Molding Mixtures for the Production of Cast Porous Metals" Metals 12, no. 7: 1134. https://doi.org/10.3390/met12071134

APA StyleKroupová, I., Gawronová, M., Lichý, P., Merta, V., & Radkovský, F. (2022). Use of Molding Mixtures for the Production of Cast Porous Metals. Metals, 12(7), 1134. https://doi.org/10.3390/met12071134