Fatigue Performance of Laser Welds in Heavy-Gage Press Hardening Steels

Abstract

1. Introduction

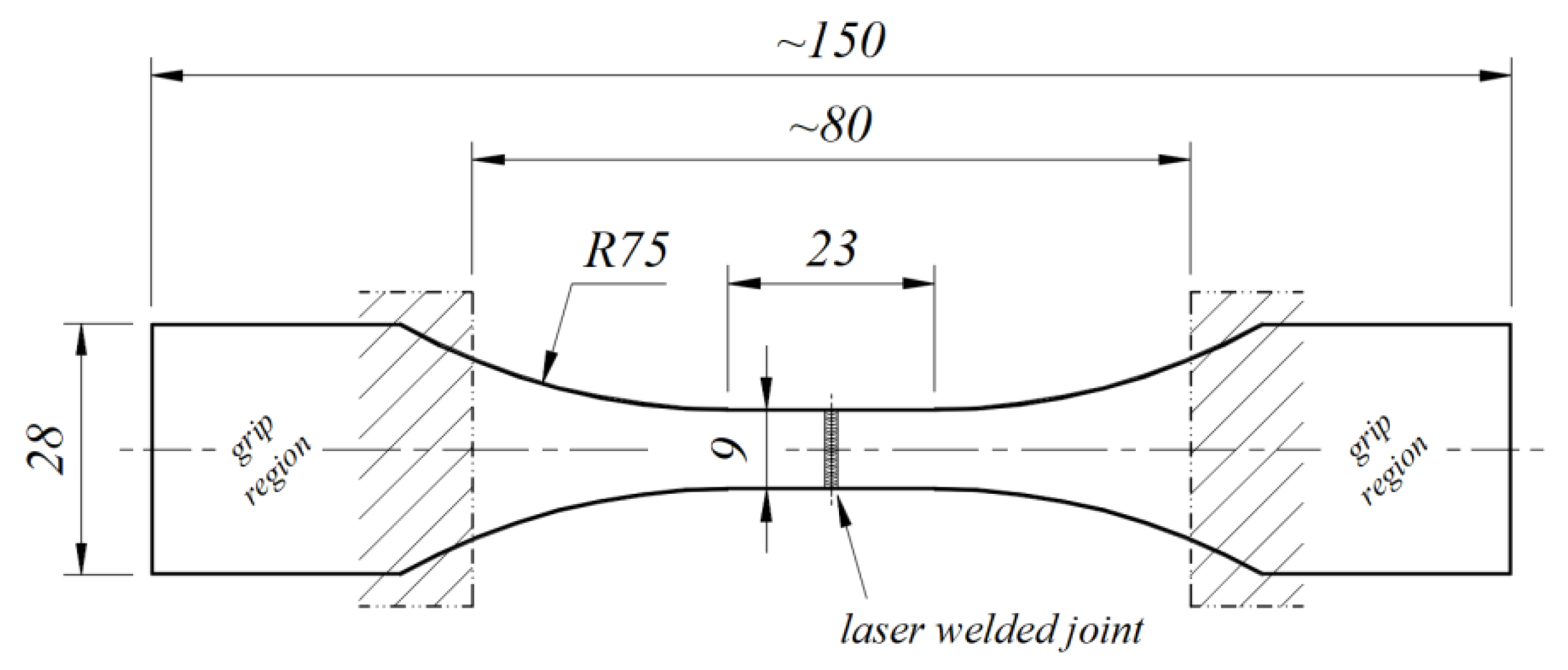

2. Materials and Methods

3. Results and Discussion of Fatigue Tests

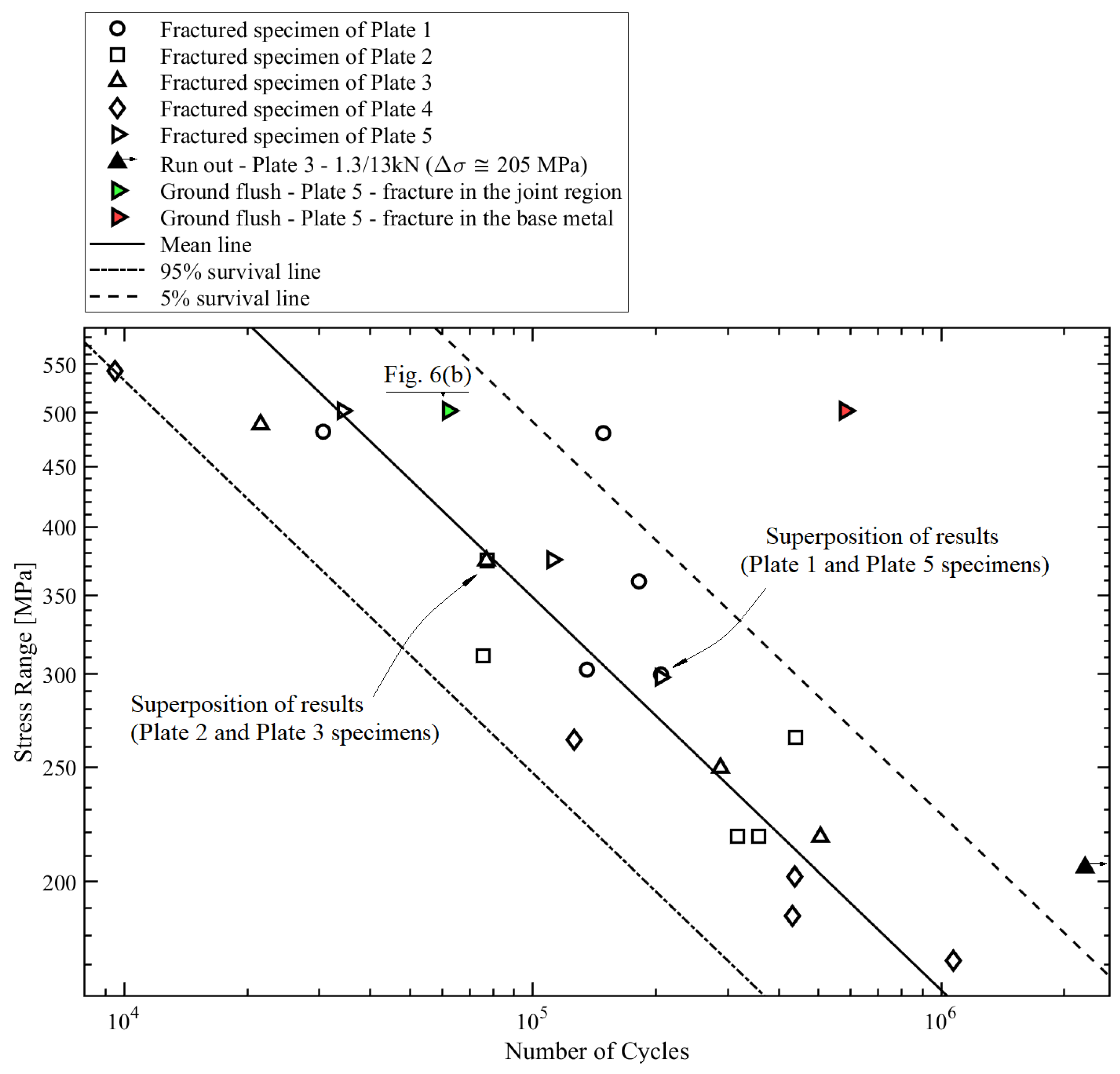

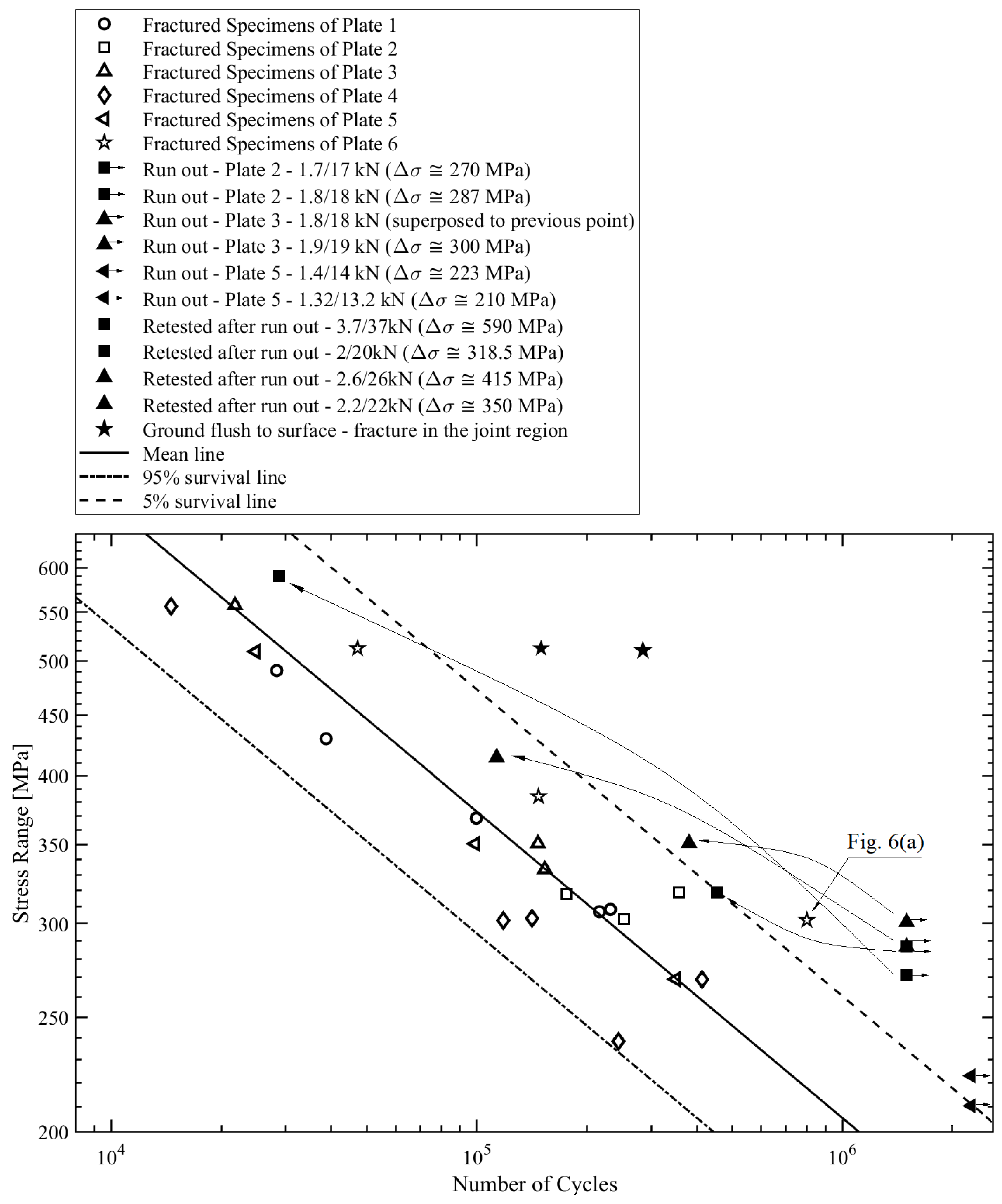

3.1. First Run Results

3.2. Retesting of Run Out Samples

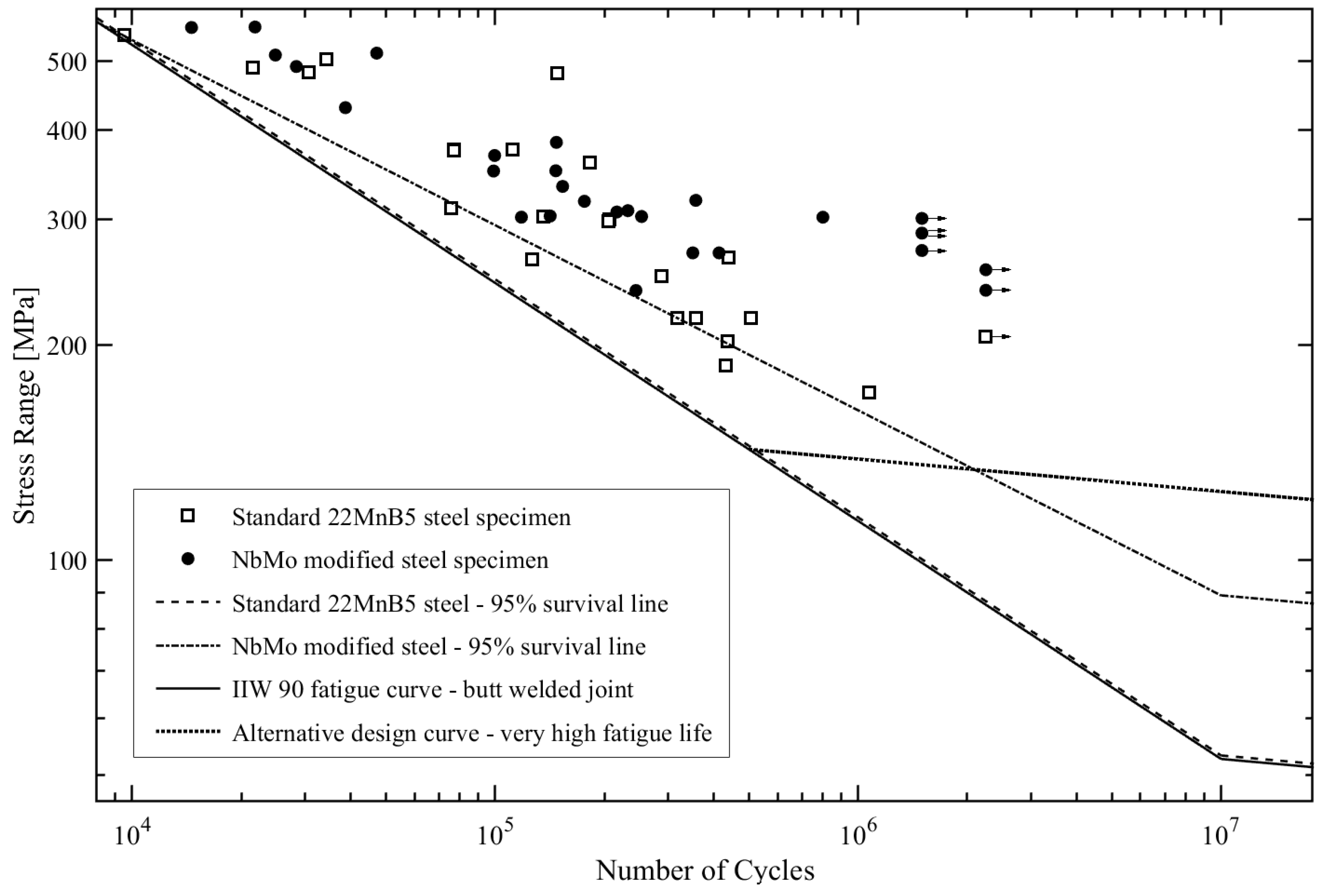

3.3. Comparison of Standard 22mnb5 and NbMo Modified Steels

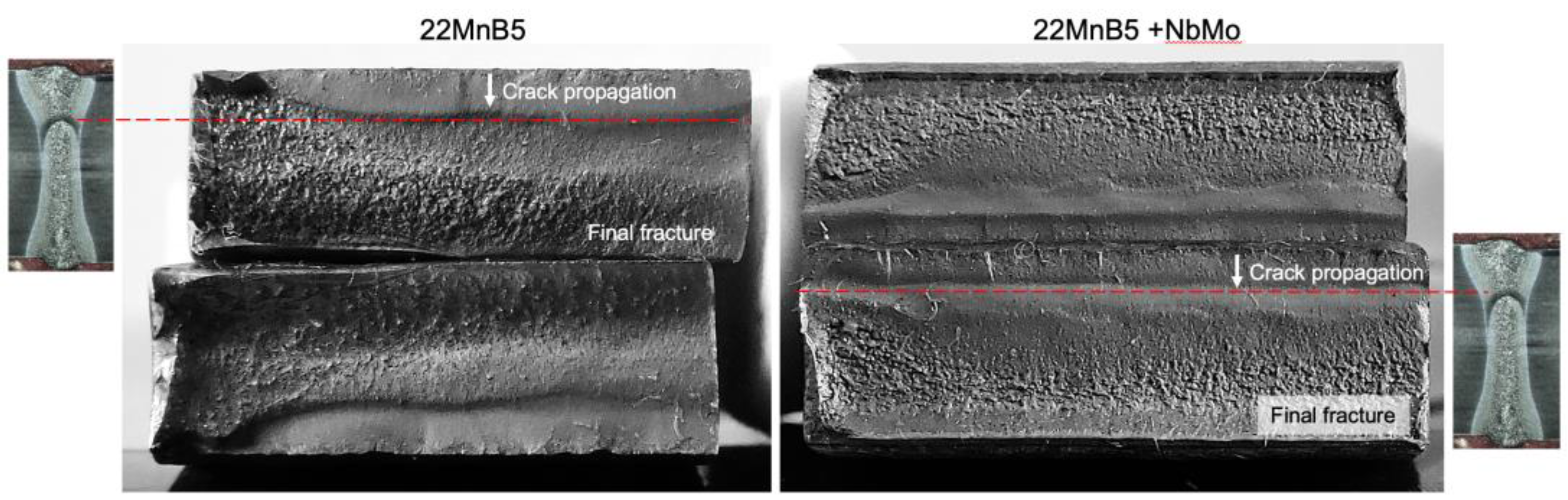

3.4. Analysis of Fatigue Fracture Surface

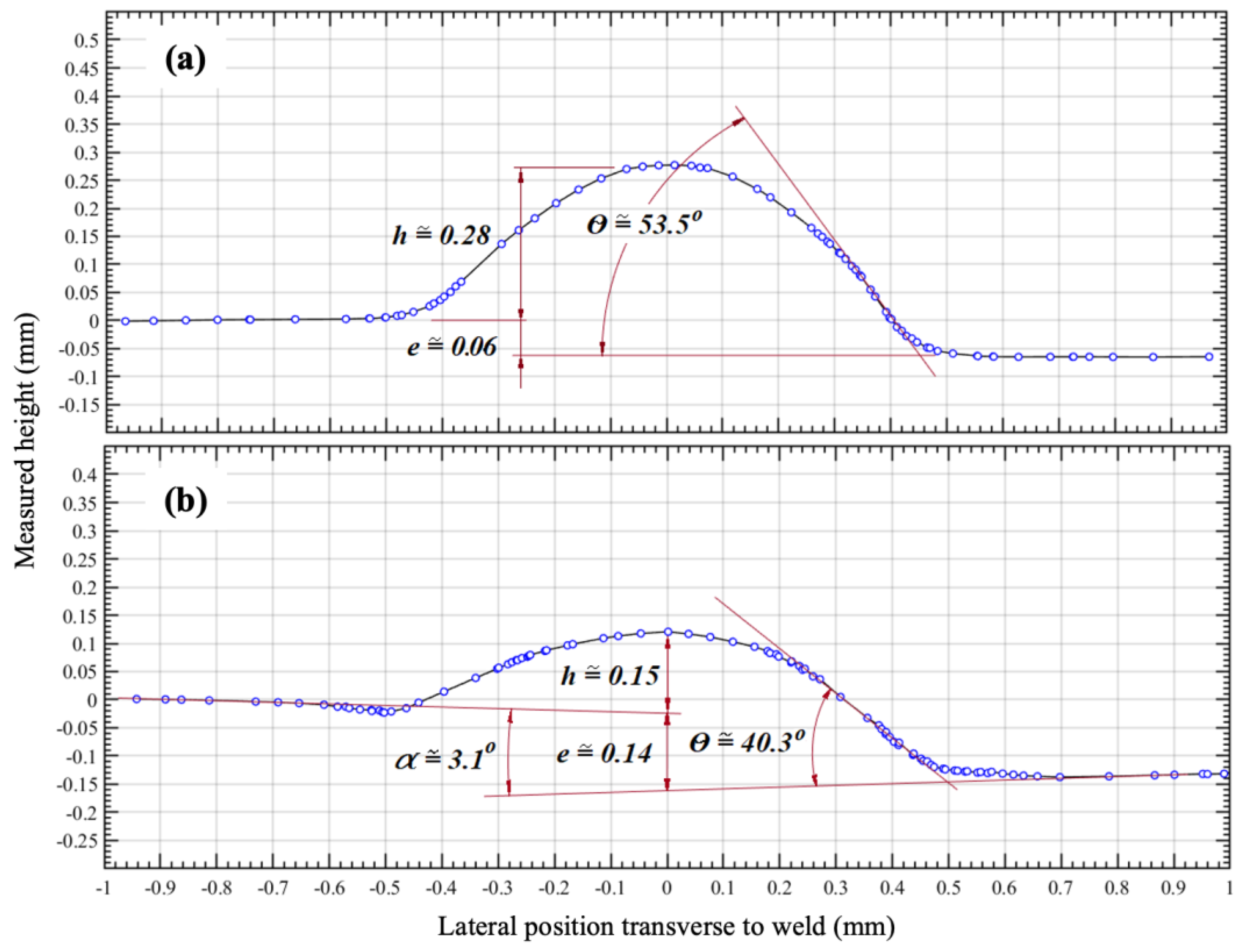

3.5. Analysis of Joint Geometry Effects

3.6. Transition to Fatigue Limit

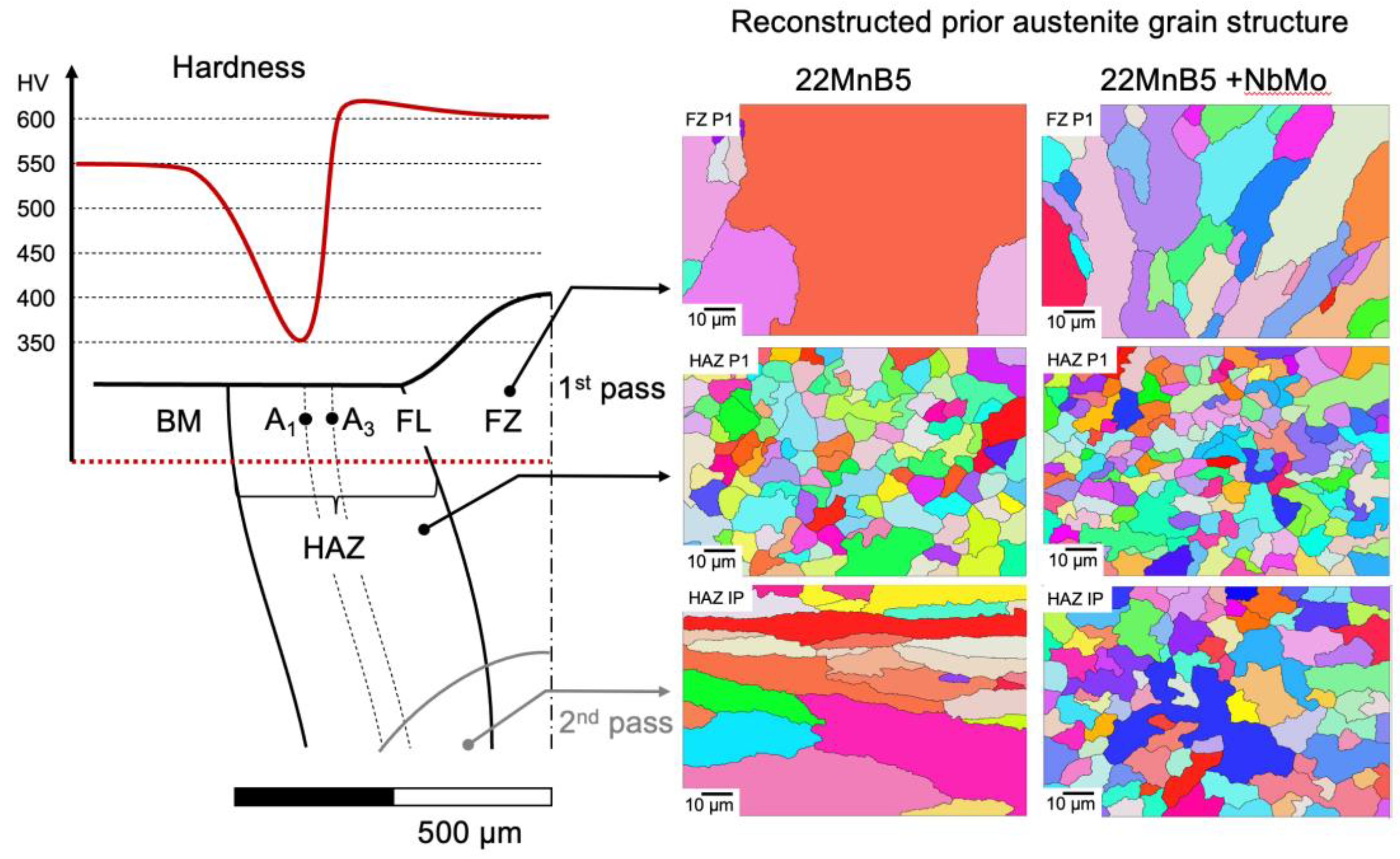

4. Microstructural Influences

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Golling, S.; Frómeta, D.; Casellas, D.; Jonsén, P. Influence of Microstructure on the Fracture Toughness of Hot Stamped Boron Steel. Mater. Sci. Eng. A 2019, 743, 529–539. [Google Scholar] [CrossRef]

- Wallin, K.; Pallaspuro, S.; Valkonen, I.; Karjalainen-Roikonen, P.; Suikkanen, P. Fracture Properties of High Performance Steels and Their Welds. Eng. Fract. Mech. 2015, 135, 219–231. [Google Scholar] [CrossRef]

- Parareda, S.; Casellas, D.; Frómeta, D.; Martínez, M.; Lara, A.; Barrero, A.; Pujante, J. Fatigue Resistance of Press Hardened 22MnB5 Steels. Int. J. Fatigue 2020, 130, 105262. [Google Scholar] [CrossRef]

- Pessard, E.; Abrivard, B.; Morel, F.; Abroug, F.; Delhaye, P. The Effect of Quenching and Defects Size on the HCF Behaviour of Boron Steel. Int. J. Fatigue 2014, 68, 80–89. [Google Scholar] [CrossRef][Green Version]

- Murakami, Y.; Nomoto, T.; Ueda, T. Factors Influencing the Mechanism of Superlong Fatigue Failure in Steels. Fatigue Fract. Eng. Mater. Struct. 1999, 22, 581–590. [Google Scholar] [CrossRef]

- Sonsino, C. Course of SN-Curves Especially in the High-Cycle Fatigue Regime with Regard to Component Design and Safety. Int. J. Fatigue 2007, 29, 2246–2258. [Google Scholar] [CrossRef]

- Fricke, W.; Remes, H.; Feltz, O.; Lillemäe, I.; Tchuindjang, D.; Reinert, T.; Nevierov, A.; Sichermann, W.; Brinkmann, M.; Kontkanen, T.; et al. Fatigue Strength of Laser-Welded Thin-Plate Ship Structures Based on Nominal and Structural Hot-Spot Stress Approach. Ships Offshore Struct. 2015, 10, 39–44. [Google Scholar] [CrossRef]

- Lillemäe, I.; Lammi, H.; Molter, L.; Remes, H. Fatigue Strength of Welded Butt Joints in Thin and Slender Specimens. Int. J. Fatigue 2012, 44, 98–106. [Google Scholar] [CrossRef]

- Maddox, S. Fatigue Strength of Welded Structures; Elsevier: Amsterdam, The Netherlands, 2002; ISBN 9781855730137. [Google Scholar]

- Maddox, S. Review of Fatigue Assessment Procedures for Welded Aluminium Structures. Int. J. Fatigue 2003, 25, 1359–1378. [Google Scholar] [CrossRef]

- Costa, J.D.M.; Ferreira, J.A.M.; Abreu, L.P.M. Fatigue Behaviour of Butt Welded Joints in a High Strength Steel. Procedia Eng. 2010, 2, 697–705. [Google Scholar] [CrossRef]

- Seyfried, P.; Taiss, E.J.M.; Calijorne, A.C.; Li, F.-P.; Song, Q.-F. Light Weighting Opportunities and Material Choice for Commercial Vehicle Frame Structures from a Design Point of View. Adv. Manuf. 2015, 3, 19–26. [Google Scholar] [CrossRef]

- He, X.; Qin, Y.; Jiang, W. Effect of Welding Parameters on Microstructure and Mechanical Properties of Laser Welded Al-Si Coated 22MnB5 Hot Stamping Steel. J. Mater. Processing Technol. 2019, 270, 285–292. [Google Scholar] [CrossRef]

- Hobbacher, A.F. Recommendations for Fatigue Design of Welded Joints and Components; Springer International Publishing: Cham, Switzerland, 2016; ISBN 978-3-319-23756-5. [Google Scholar]

- Radaj, D.; Sonsino, C.M.; Fricke, W. Introduction. In Fatigue Assessment of Welded Joints by Local Approaches; Elsevier: Amsterdam, The Netherlands, 2006; pp. 1–12. [Google Scholar]

- Tolotti de Almeida, D.; Rosauro Clarke, T.G.; Corrêa de Souza, J.H.; Haupt, W.; Fernandes de Lima, M.S.; Mohrbacher, H. The Effect of Laser Welding on Microstructure and Mechanical Properties in Heavy-Gage Press Hardening Steel Alloys. Mater. Sci. Eng. A 2021, 821, 141341. [Google Scholar] [CrossRef]

- Němeček, S.; Zikmund, D.; Černý, I.; Ganev, N. Stresses and Fatigue of Laser Welds. Procedia CIRP 2018, 74, 481–484. [Google Scholar] [CrossRef]

- Lillemäe, I.; Remes, H.; Liinalampi, S.; Itävuo, A. Influence of Weld Quality on the Fatigue Strength of Thin Normal and High Strength Steel Butt Joints. Weld. World 2016, 60, 731–740. [Google Scholar] [CrossRef]

- Zerbst, U.; Ainsworth, R.A.; Beier, H.T.; Pisarski, H.; Zhang, Z.L.; Nikbin, K.; Nitschke-Pagel, T.; Münstermann, S.; Kucharczyk, P.; Klingbeil, D. Review on Fracture and Crack Propagation in Weldments—A Fracture Mechanics Perspective. Eng. Fract. Mech. 2014, 132, 200–276. [Google Scholar] [CrossRef]

- Ottersböck, M.J.; Leitner, M.; Stoschka, M.; Maurer, W. Effect of Weld Defects on the Fatigue Strength of Ultra High-Strength Steels. Procedia Eng. 2016, 160, 214–222. [Google Scholar] [CrossRef]

- Thompson, R.E.; Matlock, D.K.; Speer, J.G. The Fatigue Performance of High Temperature Vacuum Carburized Nb Modified 8620 Steel. SAE Trans. 2007, 116, 392–407. [Google Scholar]

| Alloy Content | C | Si | Mn | S | Cr | Mo | Ti | Nb | B |

|---|---|---|---|---|---|---|---|---|---|

| 22MnB5 | 0.22 | 0.14 | 1.19 | 0.001 | 0.22 | n.a. | 0.035 | n.a. | 0.001 |

| NbMo mod. | 0.20 | 0.19 | 1.19 | 0.002 | 0.19 | 0.157 | 0.035 | 0.04 | 0.001 |

| Properties | Base Steel (as Quenched) | Transverse to Laser Weld | ||||

|---|---|---|---|---|---|---|

| YS (MPa) | TS (MPa) | El (%) | YS (MPa) | TS (MPa) | El (%) | |

| 22MnB5 | 1023 ± 2 | 1411 ± 7 | 9 ± 0.5 | 942 ± 91 | 1472 ± 119 | 4 ±1.6 |

| NbMo mod. | 1075 ± 2 | 1465 ± 9 | 10 ± 0.2 | 1090 ± 111 | 1598 ± 60 | 5 ±0.3 |

| Plate | Δσ [MPa] | Attained Life (Cycles) | Fracture Site | Remarks |

|---|---|---|---|---|

| 1 | 300 | 205,992 | weld toe | |

| 302.5 | 135,699 | weld toe | ||

| 360 | 181,921 | weld toe | ||

| 480.5 | 148,762 | weld toe | ||

| 482 | 30,667 | weld toe | ||

| 2 | 218 | 357,902 | weld toe | |

| 218.5 | 317,138 | weld toe | ||

| 265 | 440,407 | weld toe | ||

| 309.5 | 75,696 | weld toe | ||

| 375 | 77,238 | weld toe | ||

| 3 | 204.5 | 2.25(10)6 ♥ | → | run out |

| 218 | 506,041 ♥ | weld toe | ||

| 250 | 288,111 | weld toe | ||

| 375.5 | 77,026 | weld toe | ||

| 489 | 21,554 | weld toe | ||

| 4 | 171.5 | 1,072,767 ♥ | weld toe | |

| 187 | 432,672 | weld toe | ||

| 202 | 437,364 | weld toe | ||

| 263.5 | 126,215 | weld toe | ||

| 543 | 9,495 | weld toe | ||

| 5 * | 298 | 205,529 | weld toe | |

| 375 | 111,687 | weld toe | ||

| 500 | 581,294 | base metal | ground flush | |

| 502 | 62,045 | weld toe | ground flush | |

| 502 | 34,255 | weld toe |

| Plate | Δσ [MPa] | Attained Life (Cycles) | Fracture Site | Remarks |

|---|---|---|---|---|

| 1 * | 307 | 216,578 | weld toe | |

| 308.5 | 232,175 | weld toe | ||

| 368.5 | 99,760 | weld toe | ||

| 430 | 38,710 | weld toe | ||

| 491 | 28,358 | weld toe | ||

| 2 | 271 | 1.5(10)6 ♥♣ | → | run out |

| Retest: Δσ = 590 | 28,743♣ | weld toe | ||

| 287 | 1.5(10)6 ♥♣ | → | run out | |

| Retest: Δσ = 318.5 | 453,771 ♣ | weld toe | ||

| 302.5 | 253,349 | weld toe | ||

| 318 | 176,268 | weld toe | ||

| 319 | 357,346 | weld toe | ||

| 3 | 287 | 1.5(10)6 ♥♣ | → | run out |

| Retest: Δσ = 414.5 | 113,350 ♣ | weld toe | ||

| 303 | 1.5(10)6 ♥♣ | → | run out | |

| Retest: Δσ = 351 | 380,878 ♣ | base metal | ||

| 333.5 | 153,539 | weld toe | ||

| 351 | 147,028 | weld toe | ||

| 557.5 | 21,812 | weld toe | ||

| 4 | 238.5 | 244,450 | weld toe | |

| 269 | 414,152 | weld toe | ||

| 302 | 118,182 | weld toe | ||

| 303 | 141,845 | weld toe | ||

| 557 | 14,583 | weld toe | ||

| 5 | 210.5 | 2.25(10)6 ♥♣ | → | run out |

| 223 | 2.25(10)6 ♥♣ | → | run out | |

| 269 | 350,638 | weld toe | ||

| 350.5 | 99,085 | weld toe | ||

| 509.5 | 24,820 | weld toe | ||

| 6 * | 302 | 800,255 ♥ | weld toe | |

| 384.5 | 147,580 | weld toe | ||

| 510.5 | 284,941 ♣ | weld toe | ground flush | |

| 512.5 | 149,968 ♣ | weld toe | ground flush | |

| 512.5 | 47,200 | weld toe |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Almeida, D.T.; Bianchi, K.E.; Corrêa de Souza, J.H.; de Lima, M.S.F.; Clarke, T.G.R.; da Silva, F.P.; Mohrbacher, H. Fatigue Performance of Laser Welds in Heavy-Gage Press Hardening Steels. Metals 2022, 12, 580. https://doi.org/10.3390/met12040580

de Almeida DT, Bianchi KE, Corrêa de Souza JH, de Lima MSF, Clarke TGR, da Silva FP, Mohrbacher H. Fatigue Performance of Laser Welds in Heavy-Gage Press Hardening Steels. Metals. 2022; 12(4):580. https://doi.org/10.3390/met12040580

Chicago/Turabian Stylede Almeida, Diego Tolotti, Kleber Eduardo Bianchi, João Henrique Corrêa de Souza, Milton Sergio Fernandes de Lima, Thomas Gabriel Rosauro Clarke, Fabio Pinto da Silva, and Hardy Mohrbacher. 2022. "Fatigue Performance of Laser Welds in Heavy-Gage Press Hardening Steels" Metals 12, no. 4: 580. https://doi.org/10.3390/met12040580

APA Stylede Almeida, D. T., Bianchi, K. E., Corrêa de Souza, J. H., de Lima, M. S. F., Clarke, T. G. R., da Silva, F. P., & Mohrbacher, H. (2022). Fatigue Performance of Laser Welds in Heavy-Gage Press Hardening Steels. Metals, 12(4), 580. https://doi.org/10.3390/met12040580