Microstructures and Mechanical Properties of A356 Alloy and A6061 Alloy through Rheo, Upsetting, Thixo, Forming Process, and T6 Heat Treatment

Abstract

:1. Introduction

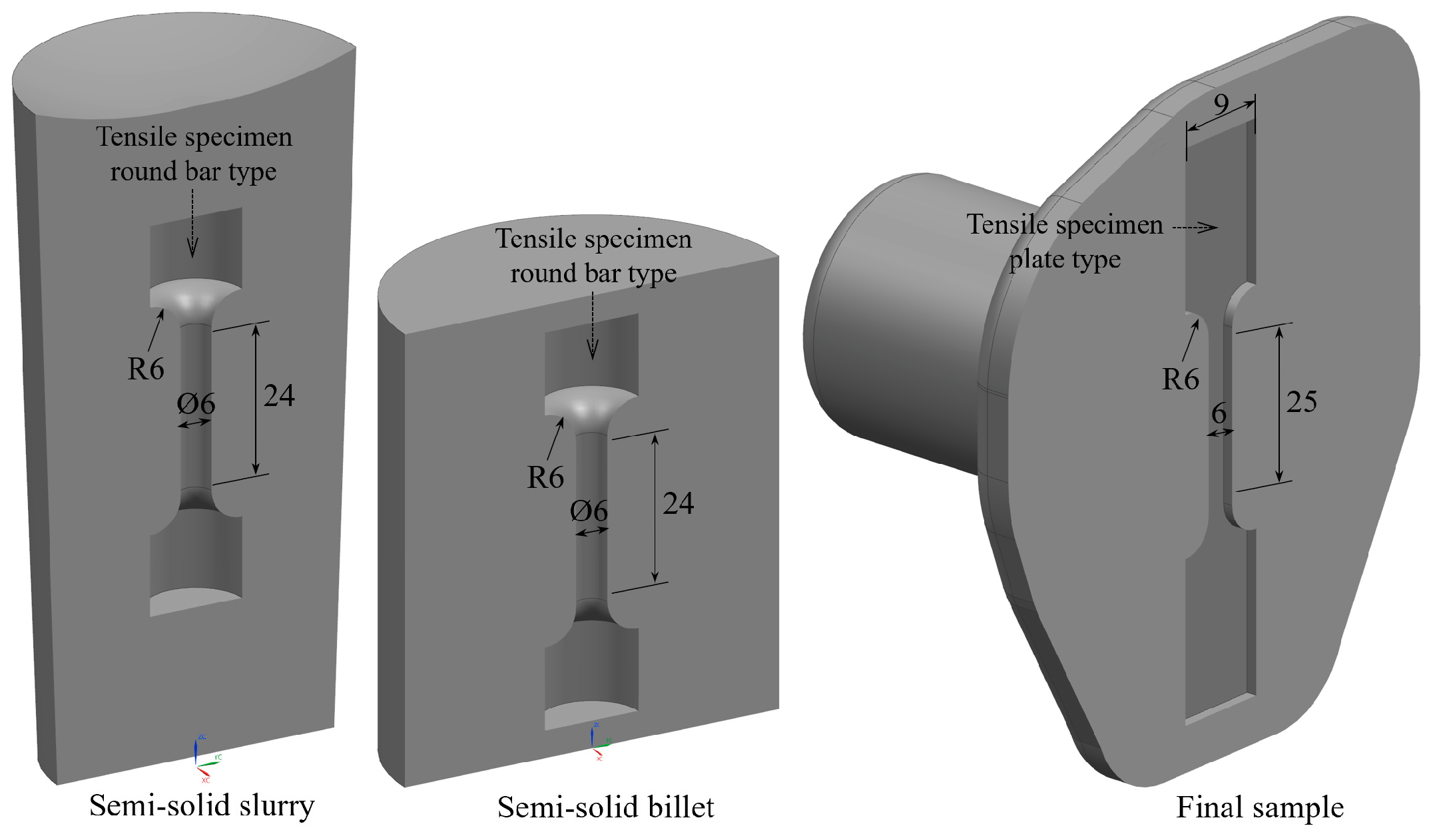

2. Experimental Method

2.1. Manufacturing Methods

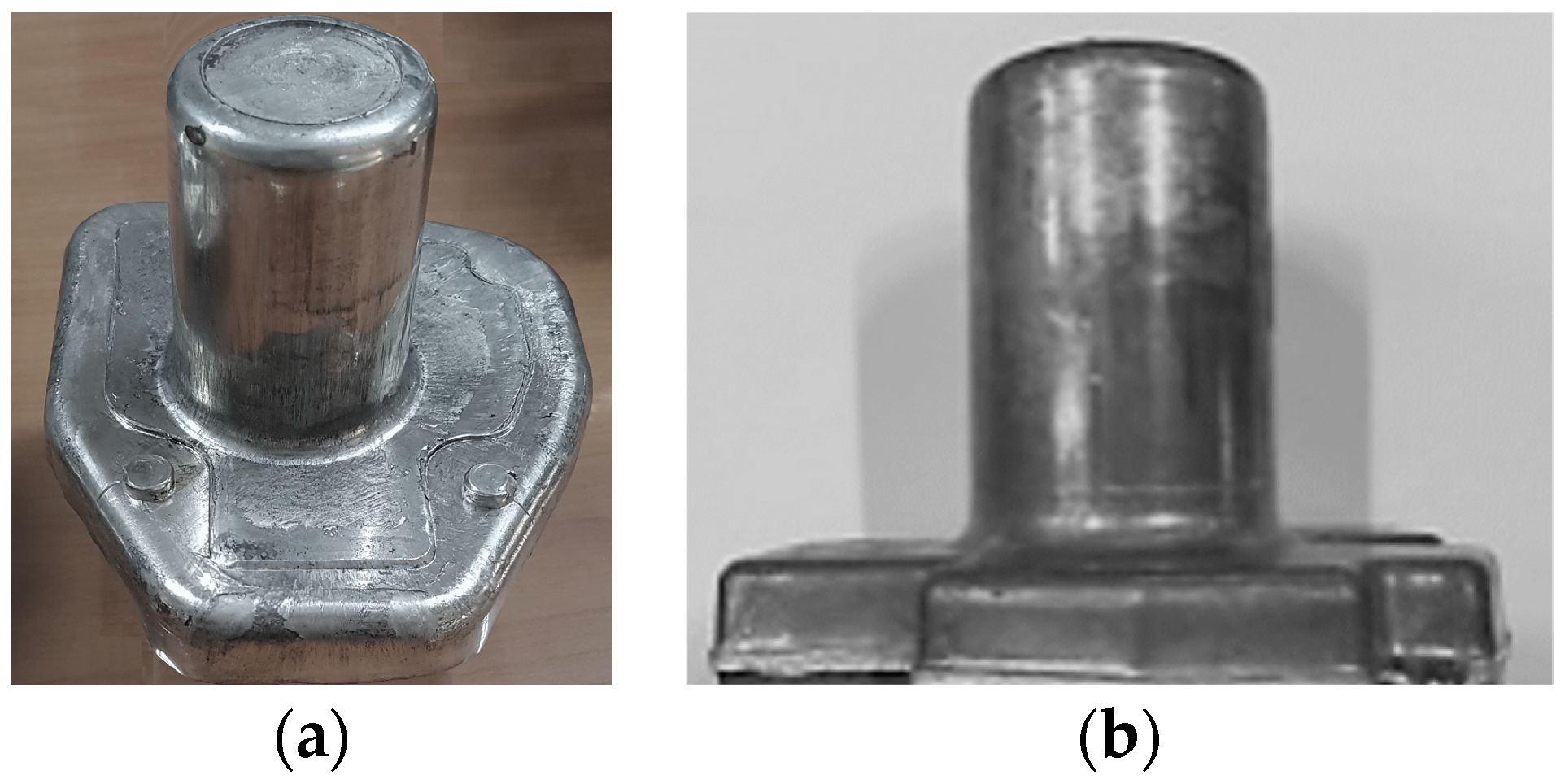

2.1.1. Rheo Process and Upsetting Process

2.1.2. Thixo Process and Forming Process

2.2. Analysis of Microstructures and Mechanical Properties

3. Experimental Results

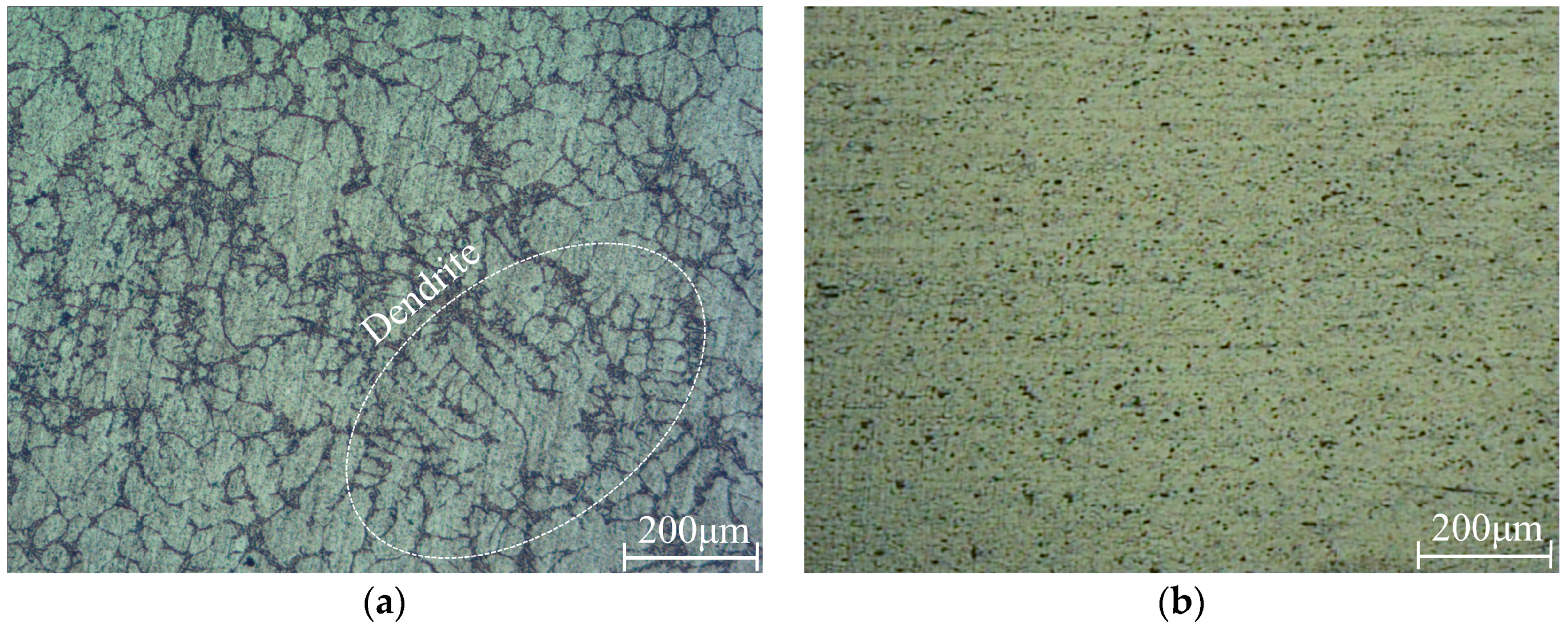

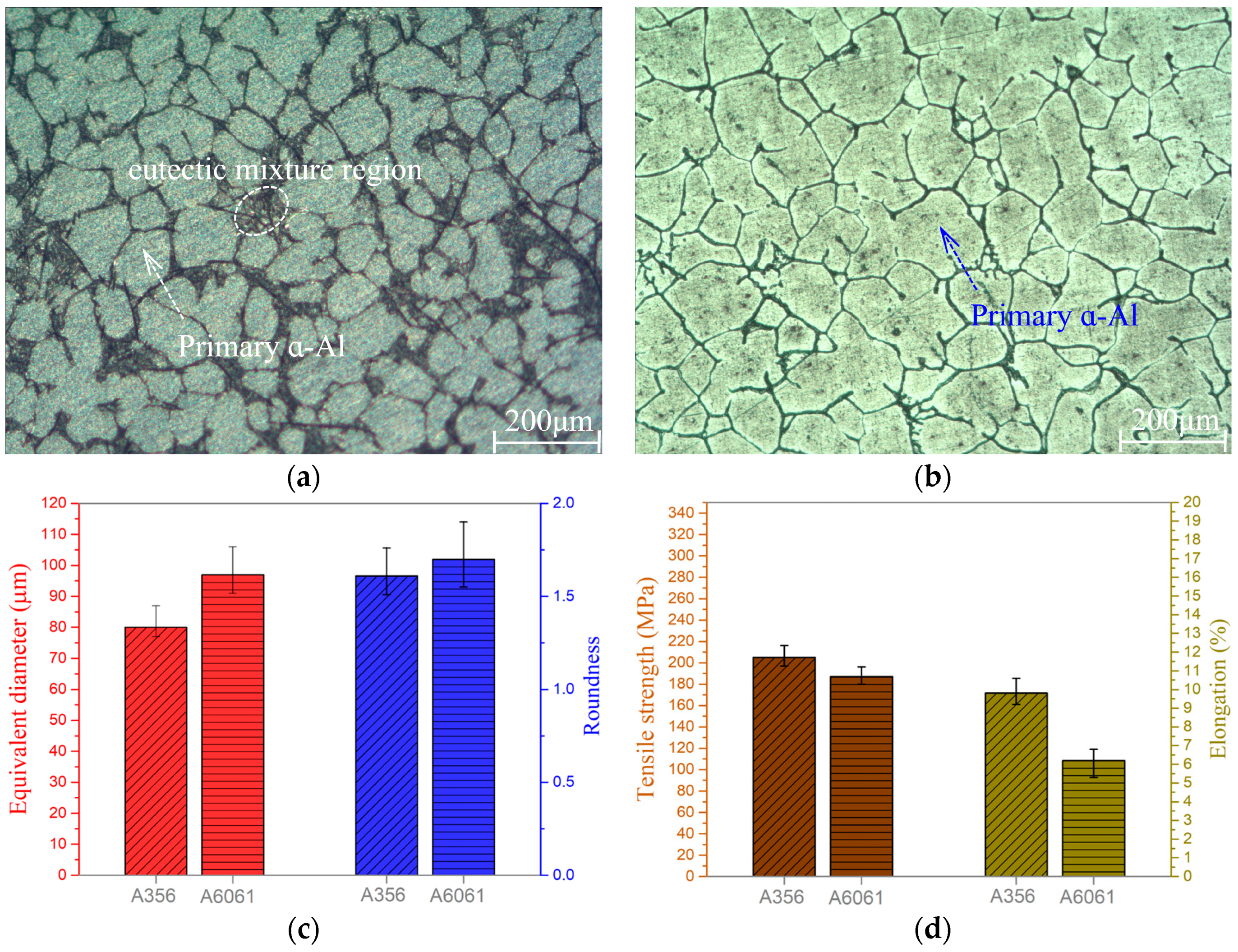

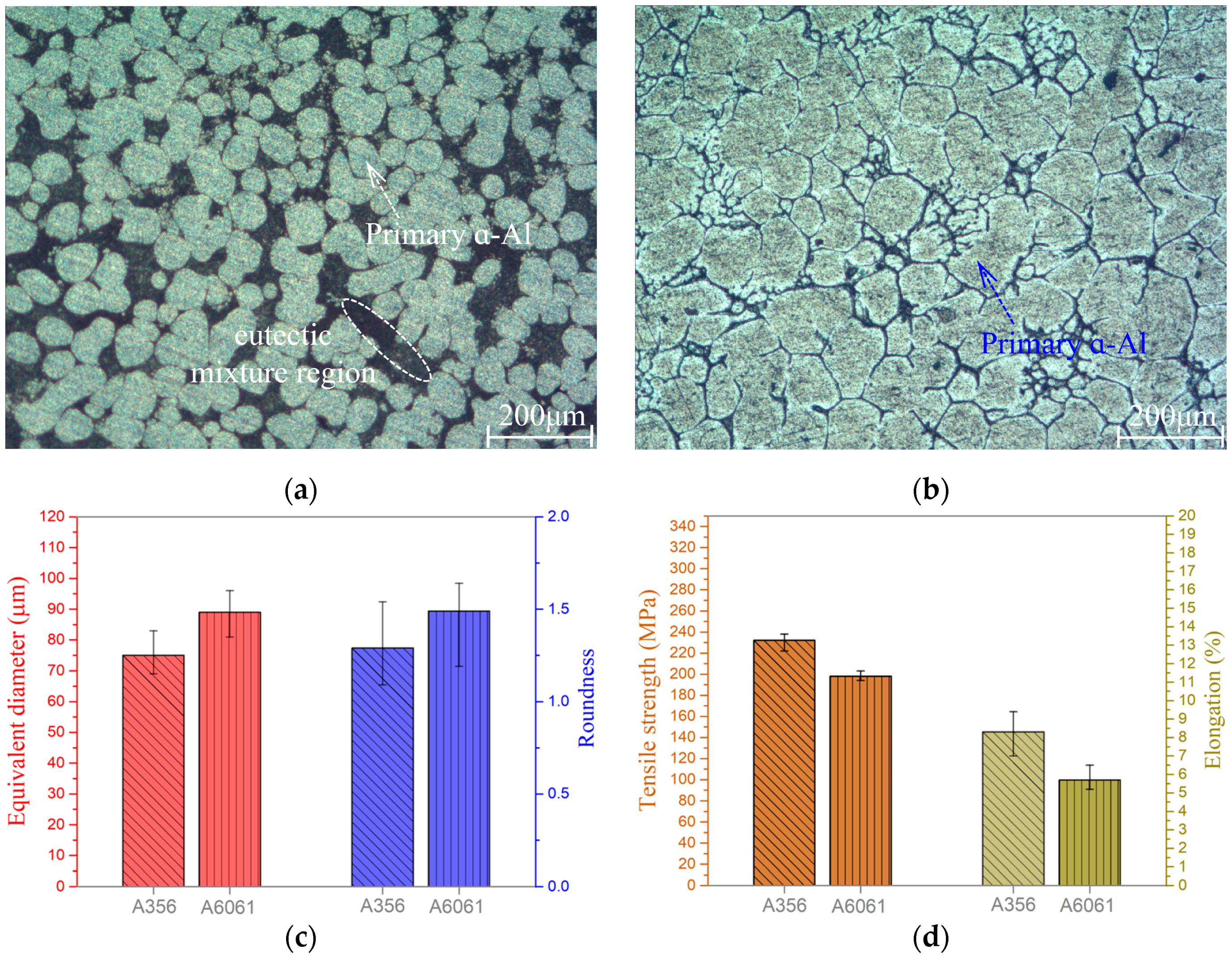

3.1. Rheo Process and Upsetting Process

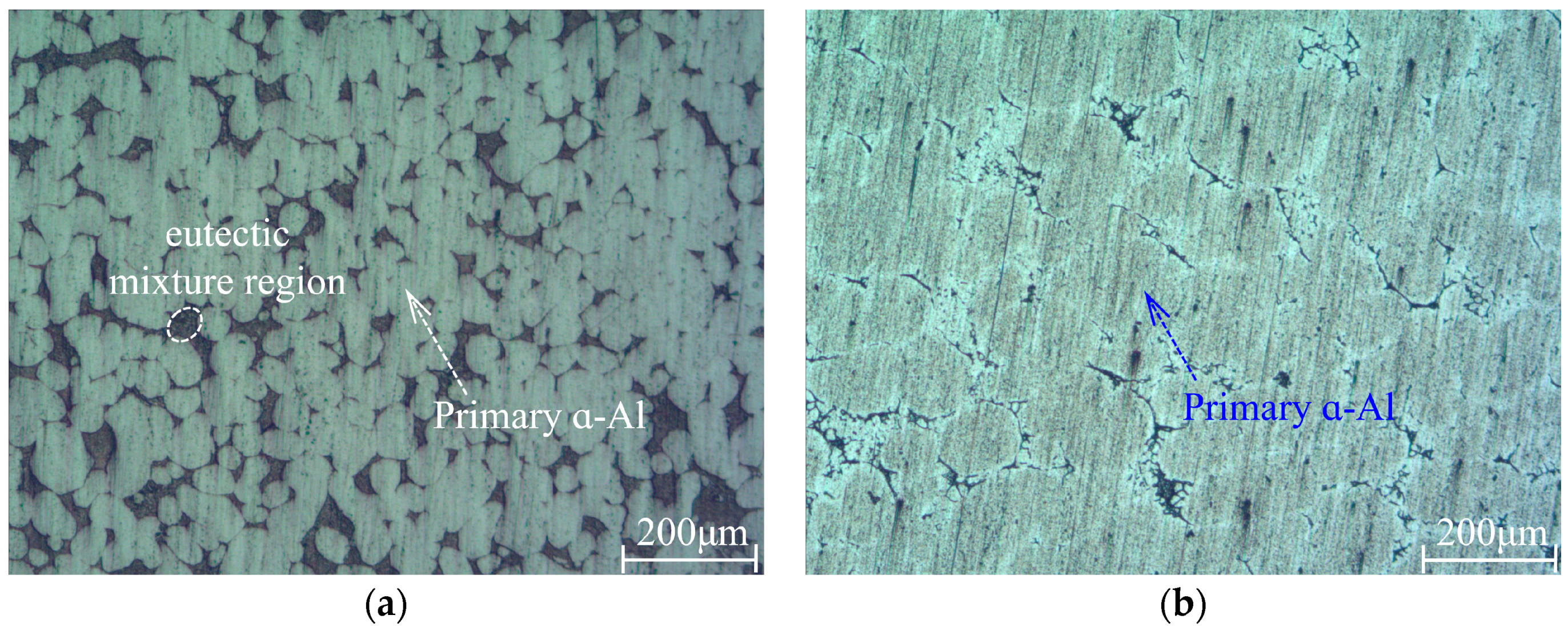

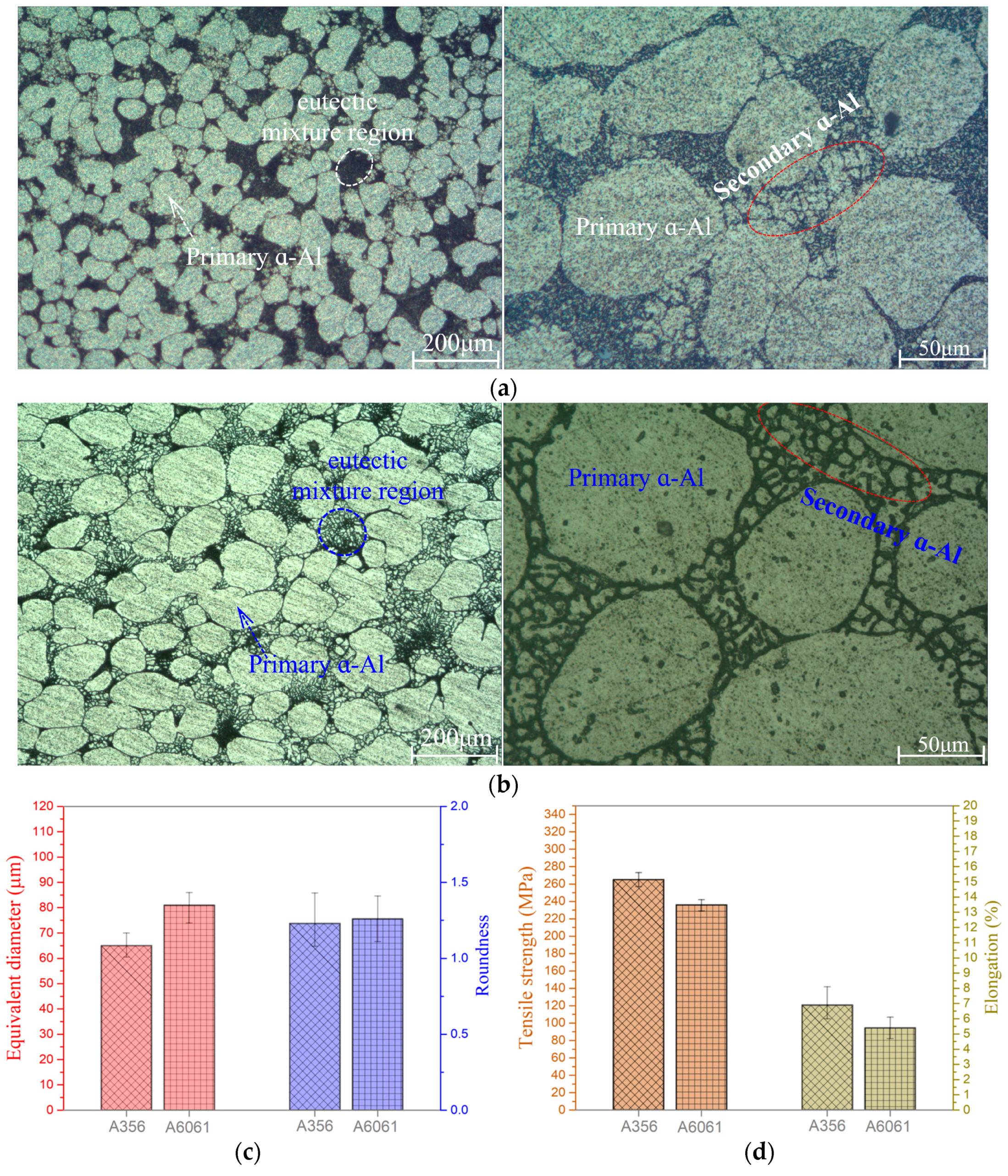

3.2. Thixo Process and Forming Process

4. Conclusions

- (1)

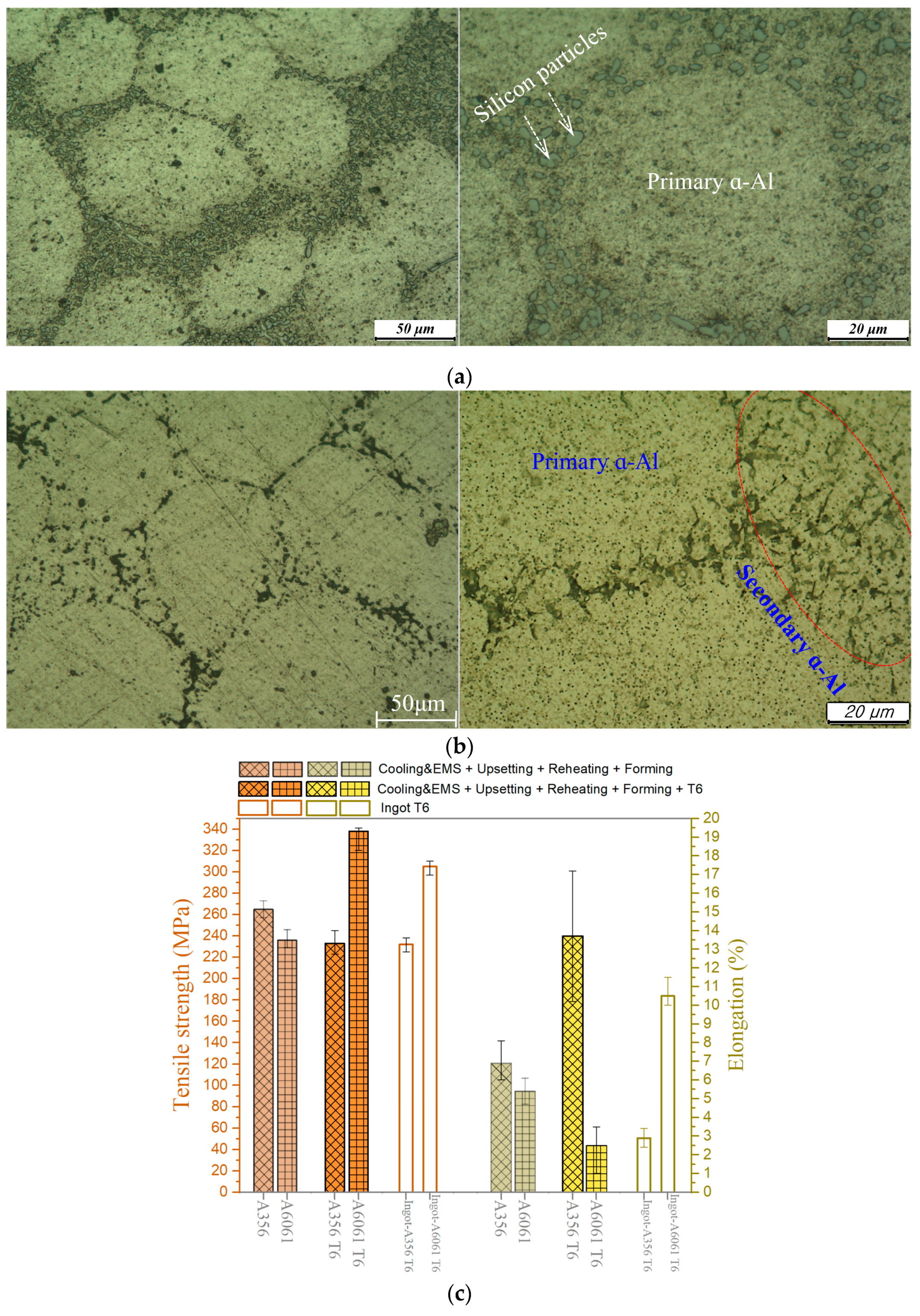

- Dendrite structure was dominant in A356 ingot, and it was changed to fine and globular microstructure through cooling and electromagnetic stirring process. A356 semi-solid slurry had an equivalent diameter and roundness of primary α-Al grains, of 80 μm and 1.61, respectively. Tensile strength and elongation were 205 MPa and 9.8%, respectively. After the upsetting, reheating, and forming processes, the equivalent diameter of the primary α-Al grains was reduced by 15 μm, and the roundness was 1.23, close to a spherical shape. The tensile strength was improved by 60 MPa and the elongation decreased by 2.9% due to the refinement and spheroidization effect of the primary α-Al grains. After T6 heat treatment, the tensile strength decreased by 32 MPa, but the elongation was improved by 6.8%.

- (2)

- A6061 ingot was a structure in which grain boundaries were not clear. The boundaries of primary α-Al grains became clear through cooling and electromagnetic stirring. The A6061 semi-solid slurry had an equivalent diameter and roundness of the primary α-Al grains, of 97 μm and 1.70, respectively. The tensile strength and elongation were 187 MPa and 6.2%, respectively. After the upsetting, reheating, and forming processes, the equivalent diameter of the primary α-Al grains decreased by 16 μm and became 81 μm, and the roundness was 1.26, close to a spherical shape. The tensile strength was improved by 49 MPa, and the elongation was decreased by 0.8%. After T6 heat treatment, the elongation decreased by 2.9%, but the tensile strength showed a fairly large increase of 102 MPa.

- (3)

- In the rheo process, upsetting process, thixo process, and forming process, A356 had a higher tensile strength than A6061. However, after T6 heat treatment, the tensile strength of A6061 was significantly increased, after which it became higher than that of A356.

Funding

Data Availability Statement

Conflicts of Interest

References

- Flemings, M.C.; Riek, R.G.; Young, K.P. Rheocasting. Mater. Sci. Eng. 1976, 25, 103–117. [Google Scholar] [CrossRef]

- Fan, Z. Semisolid metal processing. Int. Mater. Rev. 2002, 47, 49–84. [Google Scholar] [CrossRef]

- Kirkwood, D.H. Semisolid metal processing. Int. Mater. Rev. 1994, 39, 173–189. [Google Scholar] [CrossRef]

- Atkinson, H.K. Modelling the semisolid processing of metallic alloys. Prog. Mater. Sci. 2005, 50, 341–412. [Google Scholar] [CrossRef] [Green Version]

- Hirt, G.; Cremer, R.; Winkelmann, A.; Witulski, T.; Zillgen, M. Semi Solid Forming of Aluminium Alloys by Direct Forging and Lateral Extrusion. J. Mater. Process. Technol. 1994, 45, 359–364. [Google Scholar] [CrossRef]

- Kim, N.S.; Kang, C.G. An investigation of characteristics considering the effect of viscosity variation in the thixoforming process. J. Mater. Process. Technol. 2000, 103, 237–246. [Google Scholar] [CrossRef]

- Freitas, E.; Ferrante, M.; Ruckert, C.T.; Filho, W.B. Thixocasting of an A356 alloy: Fluidity, porosity distribution and thermo mechanical fatigue behavior. Mater. Sci. Eng. A 2008, 479, 171–180. [Google Scholar] [CrossRef]

- Youn, S.W.; Kang, C.G.; Seo, P.K. Mechanical characteristics evaluation of hollow shape part with metal matrix composites fabricated by thixoforging process. J. Mater. Process. Technol. 2002, 130–131, 574–580. [Google Scholar] [CrossRef]

- Lee, S.J.; Oh, S.I. Thixoforming characteristics of thermo-mechanically treated AA 6061 alloy for suspension parts of electric vehicles. J. Mater. Process. Technol. 2002, 130–131, 587–593. [Google Scholar] [CrossRef]

- Patel, J.B.; Liu, Y.Q.; Shao, G.; Fan, Z. Rheo-processing of an alloy specifically designed for semi-solid metal processing based on the Al–Mg–Si system. Mater. Sci. Eng. A 2008, 476, 341–349. [Google Scholar] [CrossRef]

- Fan, Z.; Fang, X.; Ji, S. Microstructure and mechanical properties of rheo-diecast (RDC) aluminium alloys. Mater. Sci. Eng. A 2005, 412, 298–306. [Google Scholar] [CrossRef]

- Canyook, R.; Wannasin, J.; Wisuthmethangkul, S.; Flemings, M.C. Characterization of the microstructure evolution of a semi-solid metal slurry during the early stages. Acta Mater. 2012, 60, 3501–3510. [Google Scholar] [CrossRef]

- Seo, P.K.; Youn, S.W.; Kang, C.G. The effect of test specimen size and strain-rate on liquid segregation in deformation behavior of mushy state material. J. Mater. Process. Technol. 2002, 130–131, 551–557. [Google Scholar] [CrossRef]

- Giraud, E.; Suery, M.; Coret, M. Mechanical Behavior of AA6061 Aluminum in the Semisolid State Obtained by Partial Melting and Partial Solidification Metall. Mater. Trans. A 2010, 41, 2257–2268. [Google Scholar] [CrossRef] [Green Version]

- Jin, C.K. Microstructure of Semi-Solid Billets Produced by Electromagnetic Stirring and Behavior of Primary Particles during the Indirect Forming Process. Metals 2018, 8, 271. [Google Scholar] [CrossRef] [Green Version]

- Hitchcock, M.; Wang, Y.; Fan, Z. Secondary solidification behaviour of the Al–Si–Mg alloy prepared by the rheo-diecasting process. Acta Mater. 2008, 55, 1589–1598. [Google Scholar] [CrossRef]

- Bolouri, A.; Jang, C.H.; Kang, C.G. Thixoforming A356 Aluminum Bipolar Plates at High Solid Fractions. Metall. Mater. Trans. B 2014, 45, 363–371. [Google Scholar] [CrossRef]

- Park, C.; Kim, S.S.; Kwon, Y.N.; Lee, Y.S.; Lee, J.H. Mechanical and corrosion properties of rheocast and low-pressure cast A356-T6 alloy. Mater. Sci. Eng. A 2005, 391, 86–94. [Google Scholar] [CrossRef]

| Heading | Si | Mg | Cu | Ti | Fe | Cr | Ni | Mn | Zn | Pb | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A356 | 7.08 | 0.35 | - | 0.17 | 0.08 | - | 0.07 | 0.01 | 0.01 | 0.01 | Bal. |

| A6061 | 0.68 | 1.0 | 0.23 | - | 0.2 | 0.2 | - | 0.05 | - | - | Bal. |

| EMS Stirring Current | Start Temperature °C | Finish Temperature °C | Solid Fraction % | Volume of Semi-Solid Billet | |||

|---|---|---|---|---|---|---|---|

| 60 A | A356 | A6061 | A356 | A6061 | A356 | A6061 | 333,860 mm3 |

| 622 | 671 | 583.8 | 648.3 | 50 | 50 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, C.K. Microstructures and Mechanical Properties of A356 Alloy and A6061 Alloy through Rheo, Upsetting, Thixo, Forming Process, and T6 Heat Treatment. Metals 2022, 12, 2051. https://doi.org/10.3390/met12122051

Jin CK. Microstructures and Mechanical Properties of A356 Alloy and A6061 Alloy through Rheo, Upsetting, Thixo, Forming Process, and T6 Heat Treatment. Metals. 2022; 12(12):2051. https://doi.org/10.3390/met12122051

Chicago/Turabian StyleJin, Chul Kyu. 2022. "Microstructures and Mechanical Properties of A356 Alloy and A6061 Alloy through Rheo, Upsetting, Thixo, Forming Process, and T6 Heat Treatment" Metals 12, no. 12: 2051. https://doi.org/10.3390/met12122051

APA StyleJin, C. K. (2022). Microstructures and Mechanical Properties of A356 Alloy and A6061 Alloy through Rheo, Upsetting, Thixo, Forming Process, and T6 Heat Treatment. Metals, 12(12), 2051. https://doi.org/10.3390/met12122051