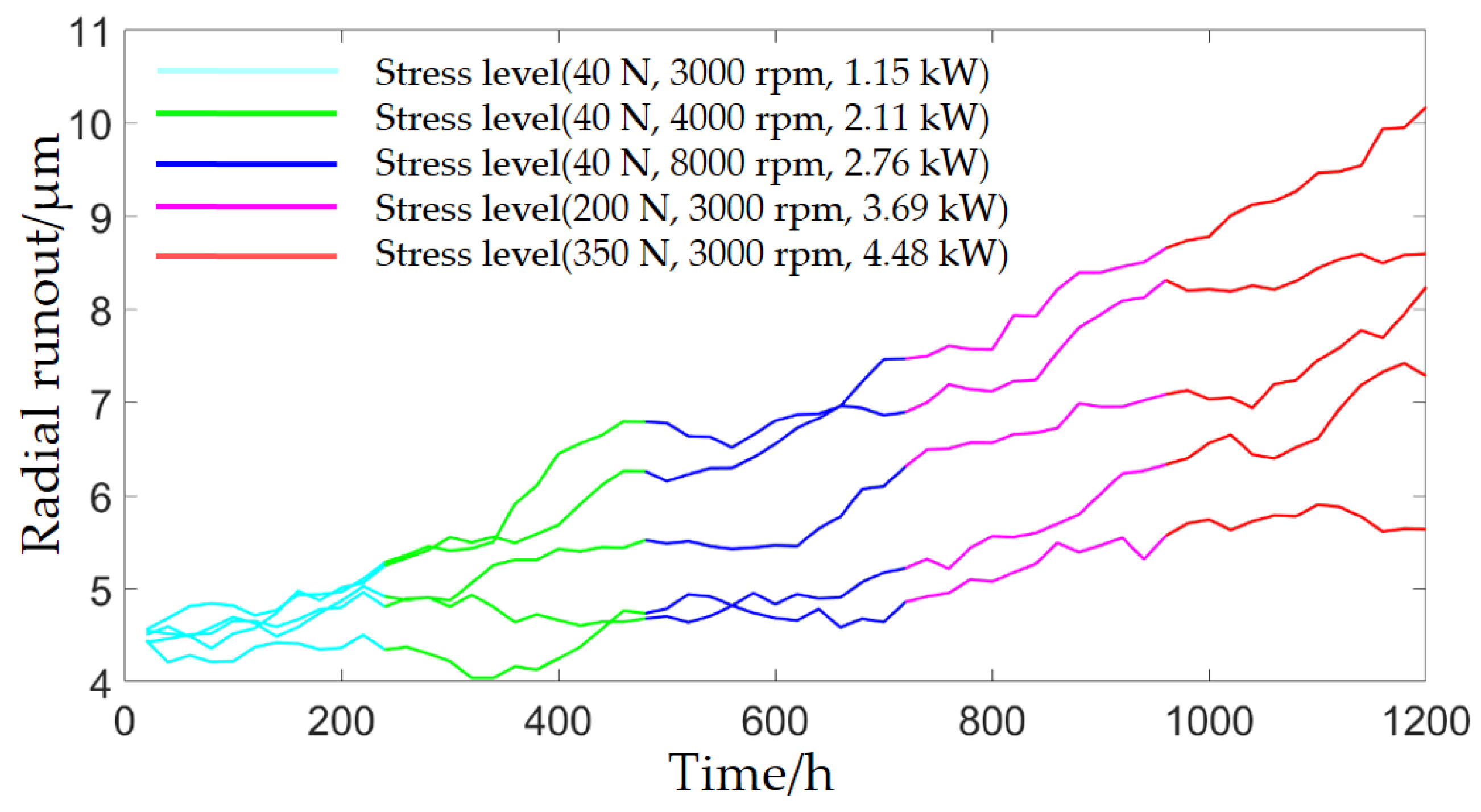

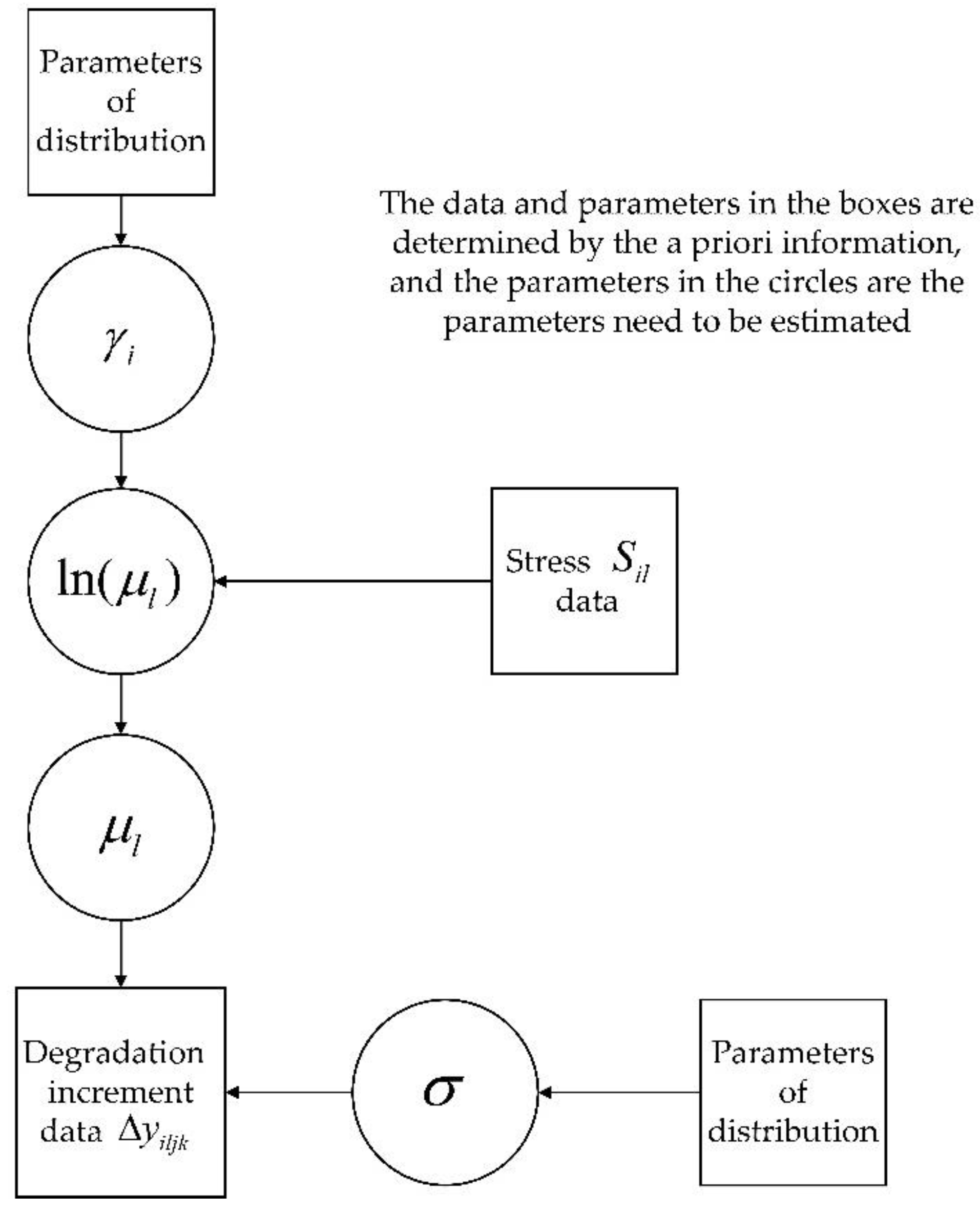

To verify the practicality of the proposed method, the optimal design of a three-stress ADT plan for a model of the motorized spindle manufactured in China was used as the research object, and the specific technical indicators of the tested motorized spindle are shown in

Table 3. Using the data in reference [

28] as the prior data for the example study, the accelerated degradation model of this model of the motorized spindle is Equation (14). The parameters in the model are solved by using the traditional model parameter solving method, and the specific values and 95% confidence intervals of each model parameter are obtained as shown in

Table 4. According to the specific values in

Table 4 and the form of the prior distribution of each model parameter in Equation (29), the specific prior distribution of each model parameter (Equation (41)) is obtained. The spindle 300 radial runout was used as the performance monitoring index.

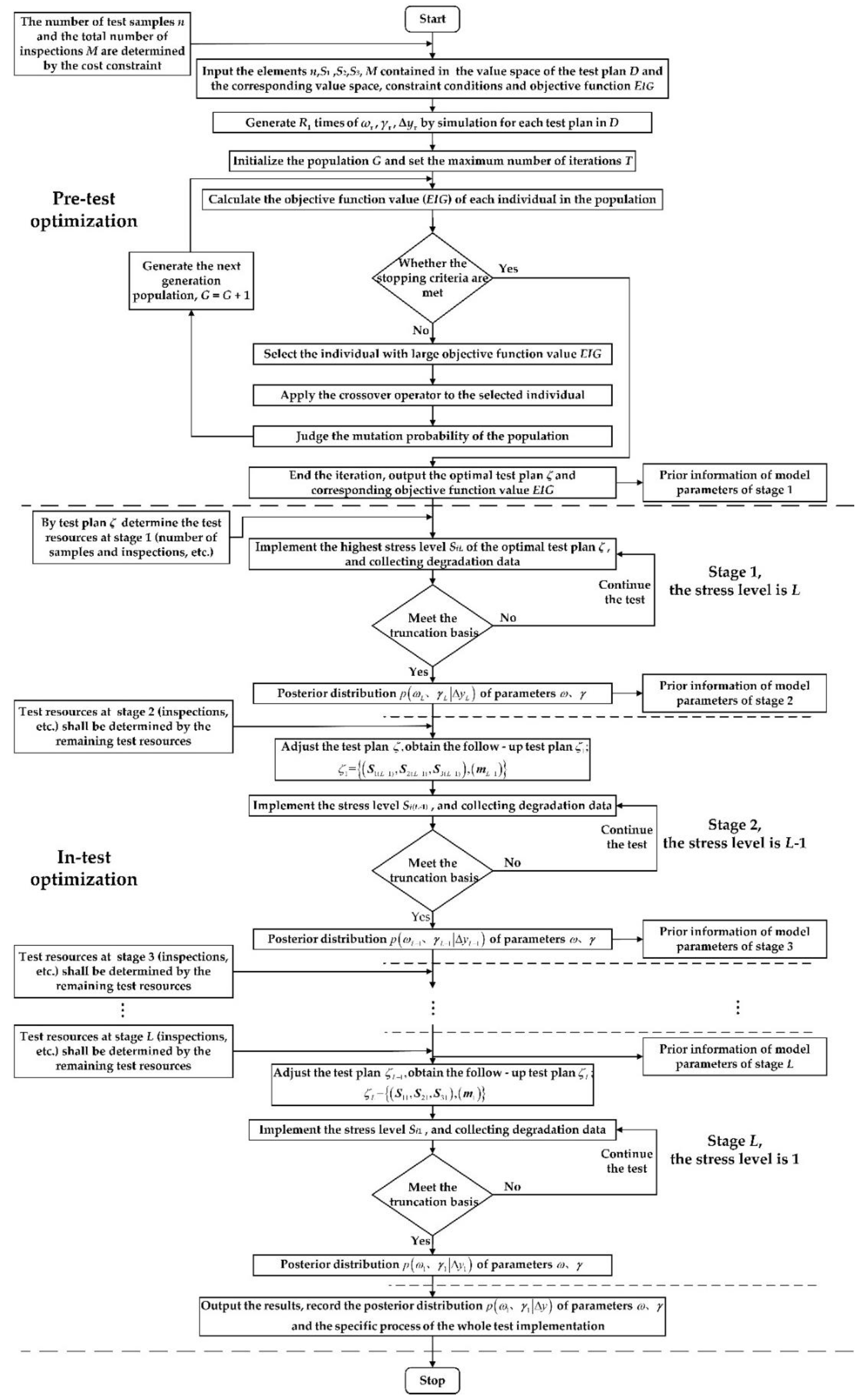

6.1. Pre-Test Optimization

According to the constraints in

Section 3.2, the main constraint in the optimal design of the plan is the test cost constraint, and the design variables are the number of samples

n, the specific value of each stress level

SiL, the number of tests

ml at each stress level, and the test interval

. However, since the constraint has averaged the single test cost into the unit implementation test cost

C0 and the implementation time of the test at each stress level is

ml, only one of

ml and

needs to be used as design a variable to complete the optimal solution under the constraint. According to engineering experience,

ml is chosen as the design variable and

is a constant, taking the value of 10 h, i.e., the optimized variables for pre-test optimization are

.

Based on Equation (37), the technical indicators of the tested motorized spindle, and the corresponding actual test equipment (

Figure 5), the specific values of the elements in the cost constraint were obtained, as shown in

Table 5.

C0 in

Table 4 includes an electricity cost of 0.00195 (10,000 yuan)/h and a water cost of 0.001 (10,000 yuan)/h for motorized spindle cooling water.

Reference [

37] determined the limit values of cutting force

S1 and spindle speed

S2 of machining center motorized spindle as 580 N and 10,000 rpm through the study, in order to save test resources, this conclusion was used as the reference for the maximum test stress value of the motorized spindle test in this subsection. However, the limit speed of the tested motorized spindle in reference [

37] is 10,000 rpm, while the limit speed

S2max of the tested motorized spindle in this article is 8000 rpm. Because the two motorized spindle models are different, there are also differences in the motorized spindle’s ability to withstand stresses. So in order to avoid changes in the motorized spindle failure mechanism, the values of cutting force

S1 and spindle speed

S2 maximum test stresses were selected as

S1L = 500 N and

S2L = 7500 rpm. For the cutting power

S3, the long-term full-load output of the motorized spindle under sufficient coolant does not change its own failure mechanism [

27]. However, since it is the first time that the power is used as a stress to carry out a study of ADT of the motorized spindle under consideration of stress coupling, the maximum test stress

S3L of the cutting power S3 is chosen to be 7.0 kW for safety reasons. According to the information on working conditions in the preliminary data, this model of the motorized spindle is used in a factory in Guangdong when processing the metal shells of cell phones. The spindle speed is 3000 rpm during normal operation, and the cutting force and cutting power fluctuate around 30 N and 2.1 kW, respectively, so the normal stress level of this motorized spindle is (30 N, 3000 rpm, 2.1 kW). Based on the above analysis, the value space of the test plan

D of the motorized spindle is determined as shown in

Table 6.

In order to ensure the exact analytical solution of the accelerated degradation model and the extrapolation accuracy of the solved model, the stress level

L in the test should be larger than or equal to the number of model parameters in the accelerated model. Taking into account the cost of the test and the number of model parameters in the established motorized spindle accelerated model, the number of stress levels

L in the test is chosen to be 7. The alternative solutions with different sample numbers are solved by genetic algorithm, the iterative process is shown in

Figure 6, and the optimal solutions are shown in

Table 7 and

Table 8.

From the comparison of the optimal solutions in

Table 6 and

Table 7, it can be concluded that the smaller the number of samples, the larger the value of

EIG for the same test cost. This is because as the number of samples decreases, the cost required for the test samples decreases, allowing more test costs to be spent on the implementation of the test. Conducting the test over a long period of time and collecting more degradation data of the tested motorized spindle, allows the obtaining of a stable posterior distribution of the model parameters. Moreover, the stress levels of the three optimal plans all fluctuate within the same range, indicating that the stress levels in the table are the sensitive stress levels for the accelerated degradation test of the spindle under this objective function, i.e., the optimal test stress levels for this model of the motorized spindle. Although the values of each stress level of the three optimal plans fluctuate in the same range, the values of the low sample size stress levels are all slightly lower than the values of the high sample size stress levels. That is because fewer resources are used to implement the test in the high sample size solution, and the high-stress level values can obtain the degradation information of the motorized spindle faster and thus obtain larger objective function values. The reason for the lower stress values in the low sample size optimal plan is, the closer to the normal stress level of the motorized spindle, the smaller the fluctuation of the a posteriori distribution of the obtained model parameters or even reaches stability, thus making the objective function reach its theoretical maximum.

Based on the above analysis, it is concluded that under the condition that the cost constraint is the main constraint, the sample size of the test should be minimized and the test time should be maximized to obtain a more accurate posterior distribution of the model parameters. Therefore, the optimal test plan with

n = 5 in

Table 6 is chosen as the initial plan of the test, and the values of each stress level and the

EIG at this stress level of this plan are shown in

Table 9.

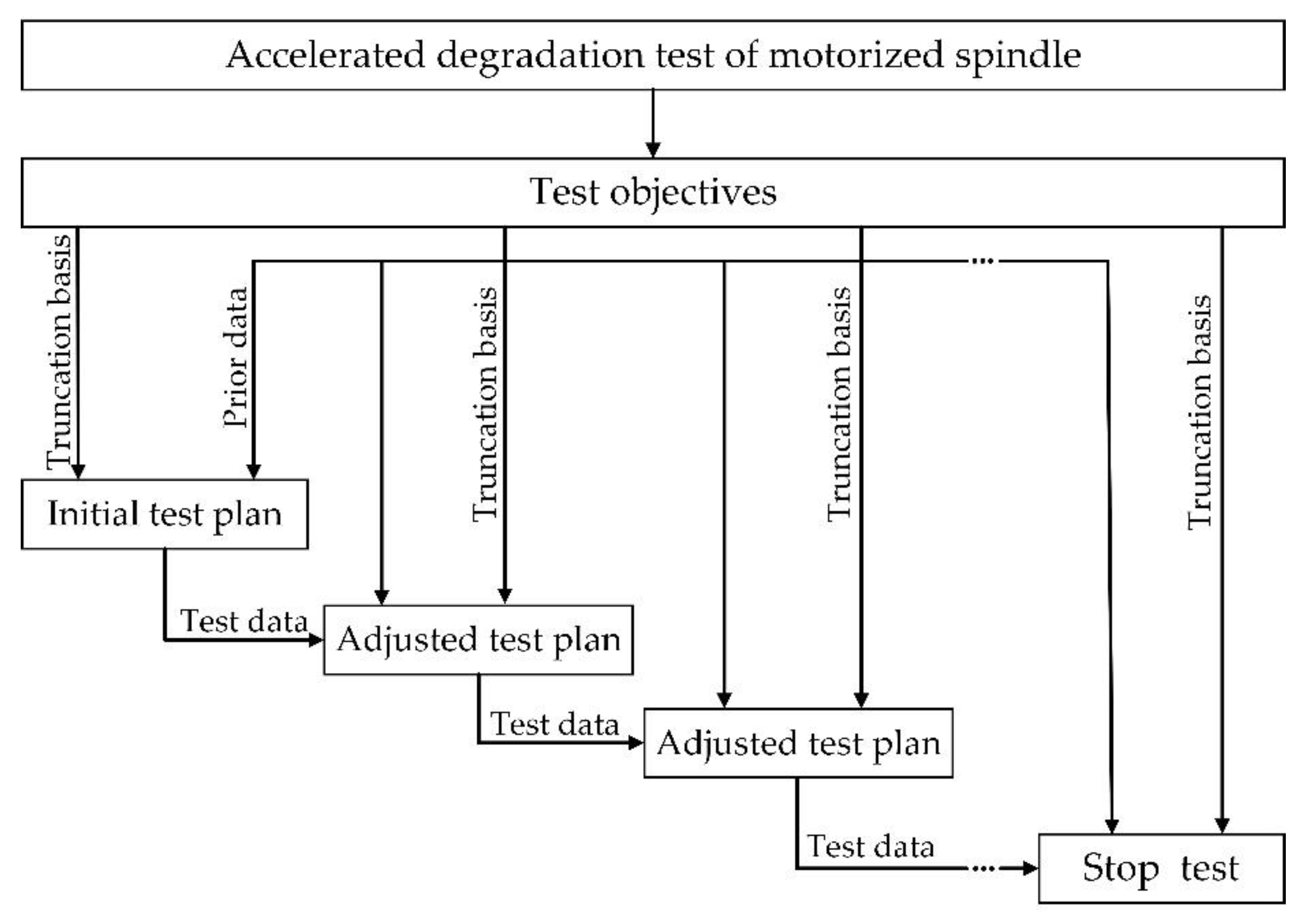

6.2. In-Test Optimization

According to the test plan obtained from pre-test optimization and the Optimization process of the test in

Section 5, the test was performed on the tested motor spindle at the highest stress level

Si7, and the test equipment is shown in

Figure 5. The posterior distribution of the parameters was calculated based on the obtained performance degradation increment data

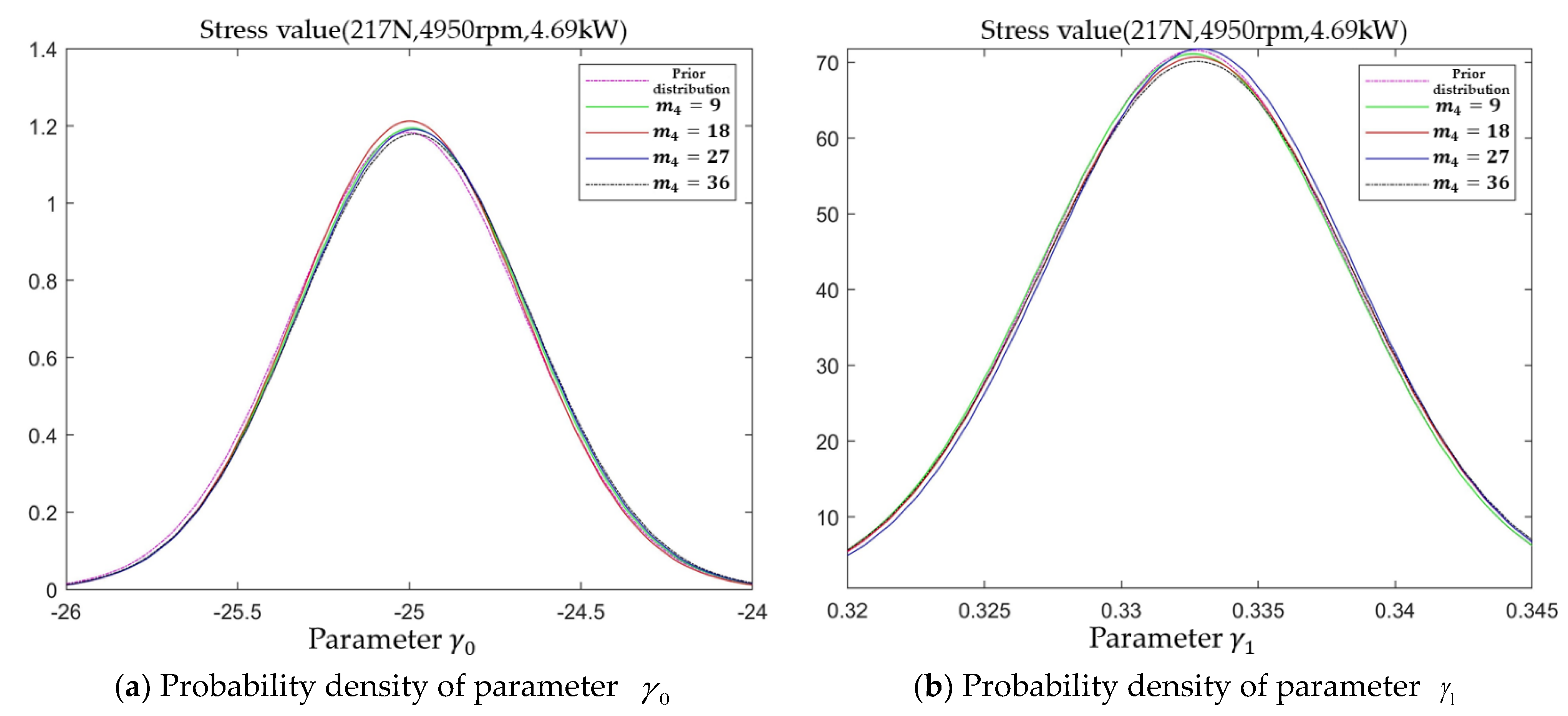

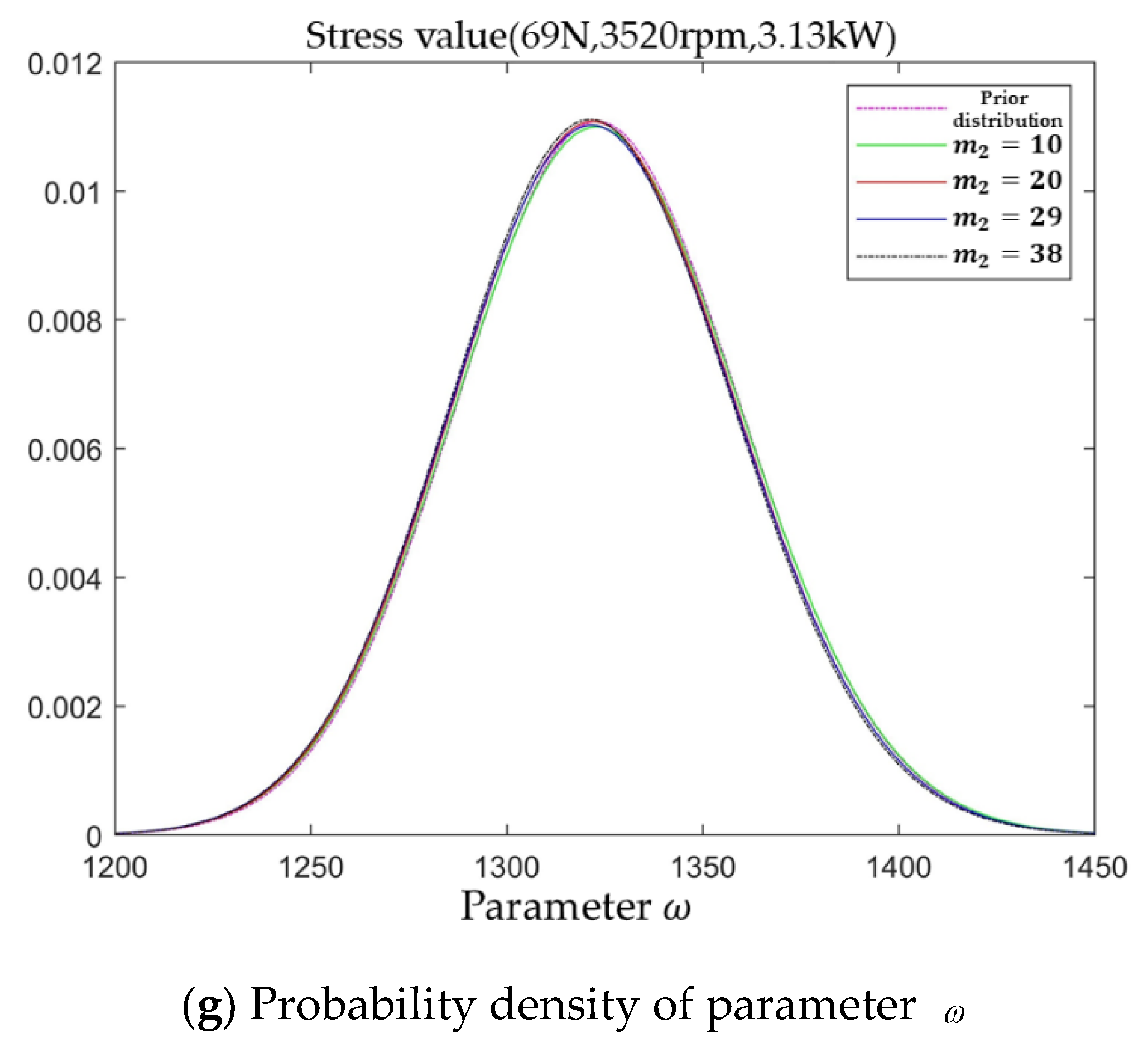

. The updated probability density function of the posterior distribution of the model parameters with the number of inspections was obtained, as shown in

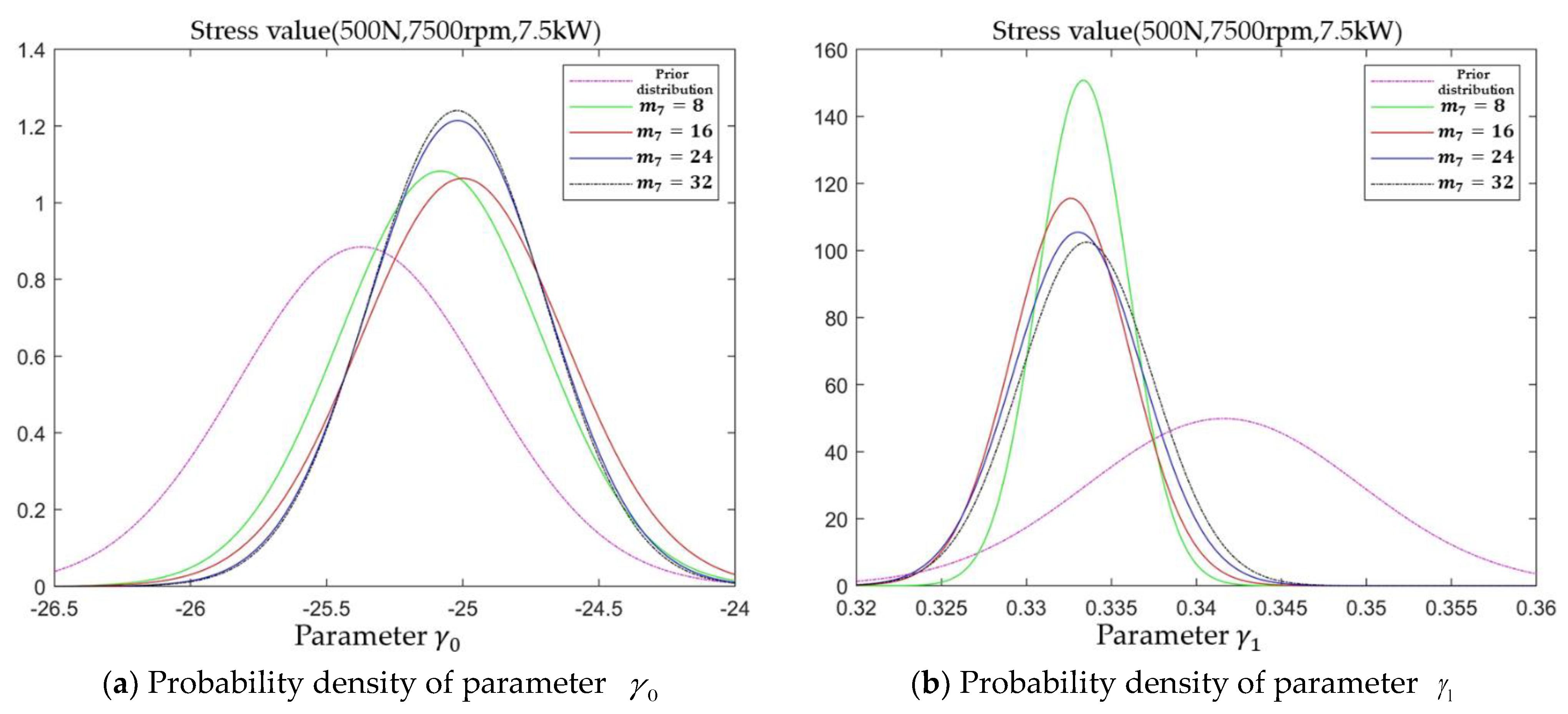

Figure 7.

From

Figure 7, it can be obtained that there is a certain deviation between the prior distribution probability density functions of the model parameters based on the prior data of different models of machining center motorized spindles and the tested motorized spindles. In addition, the posterior probability density function of each model parameter generally has the phenomenon of peak shift and variance increase of the distribution graph with the increase in the number of inspections. This is because the posterior distribution probability density function of each model parameter obtained by solving at

m7 = 8 has a certain chance due to the small amount of data, and usually has a certain distance between the true value of the parameter. As the number of tests increases (i.e., the amount of data increases), the chance of the probability density function is gradually eliminated, and the probability density function of the posterior distribution of the model parameters is gradually closer to the true value. At the end of this stress level test,

IG = 117.3 >

EIG = 43.1671, which satisfies the sequential truncation basis, and the next stress level test is carried out.

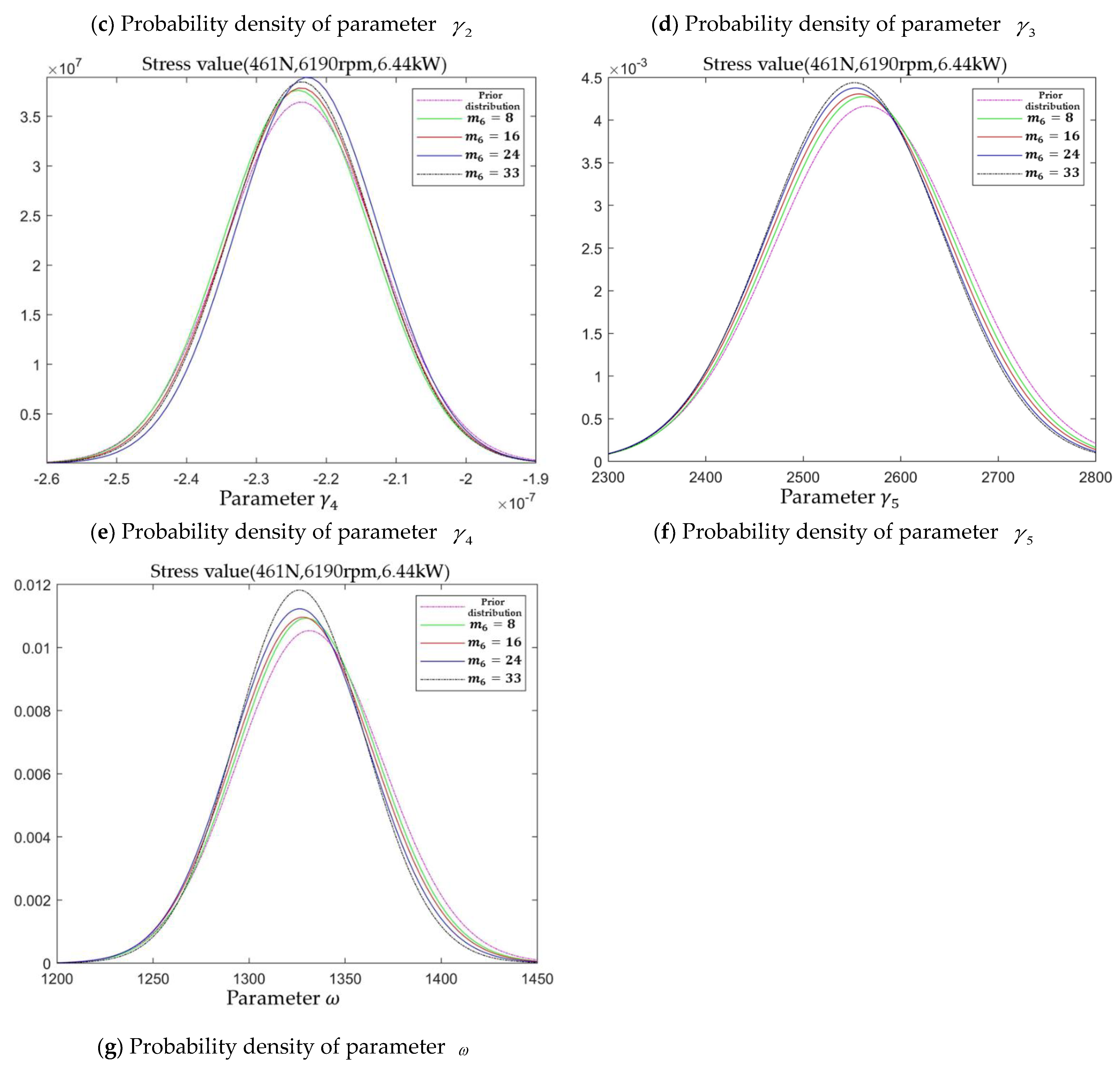

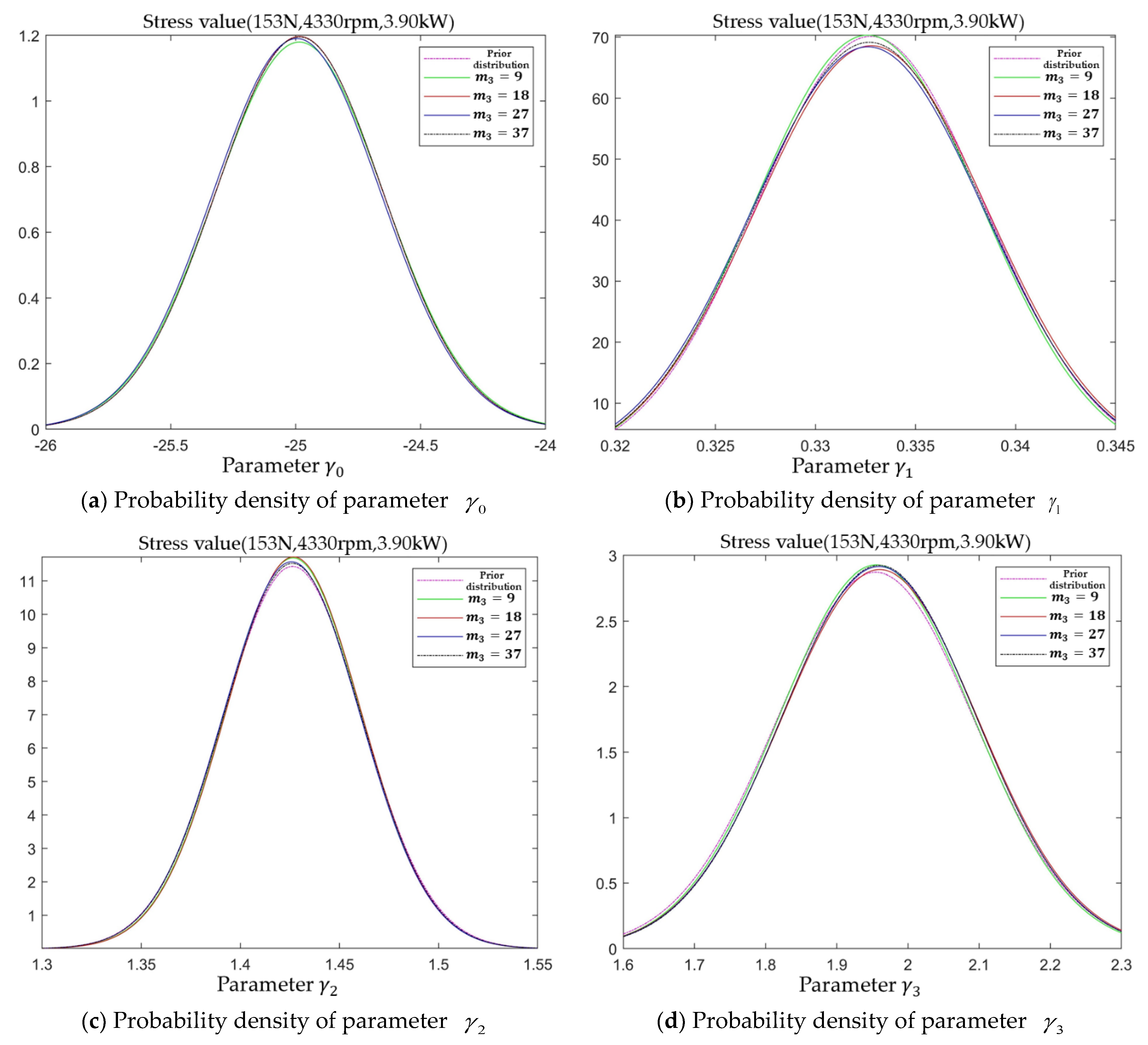

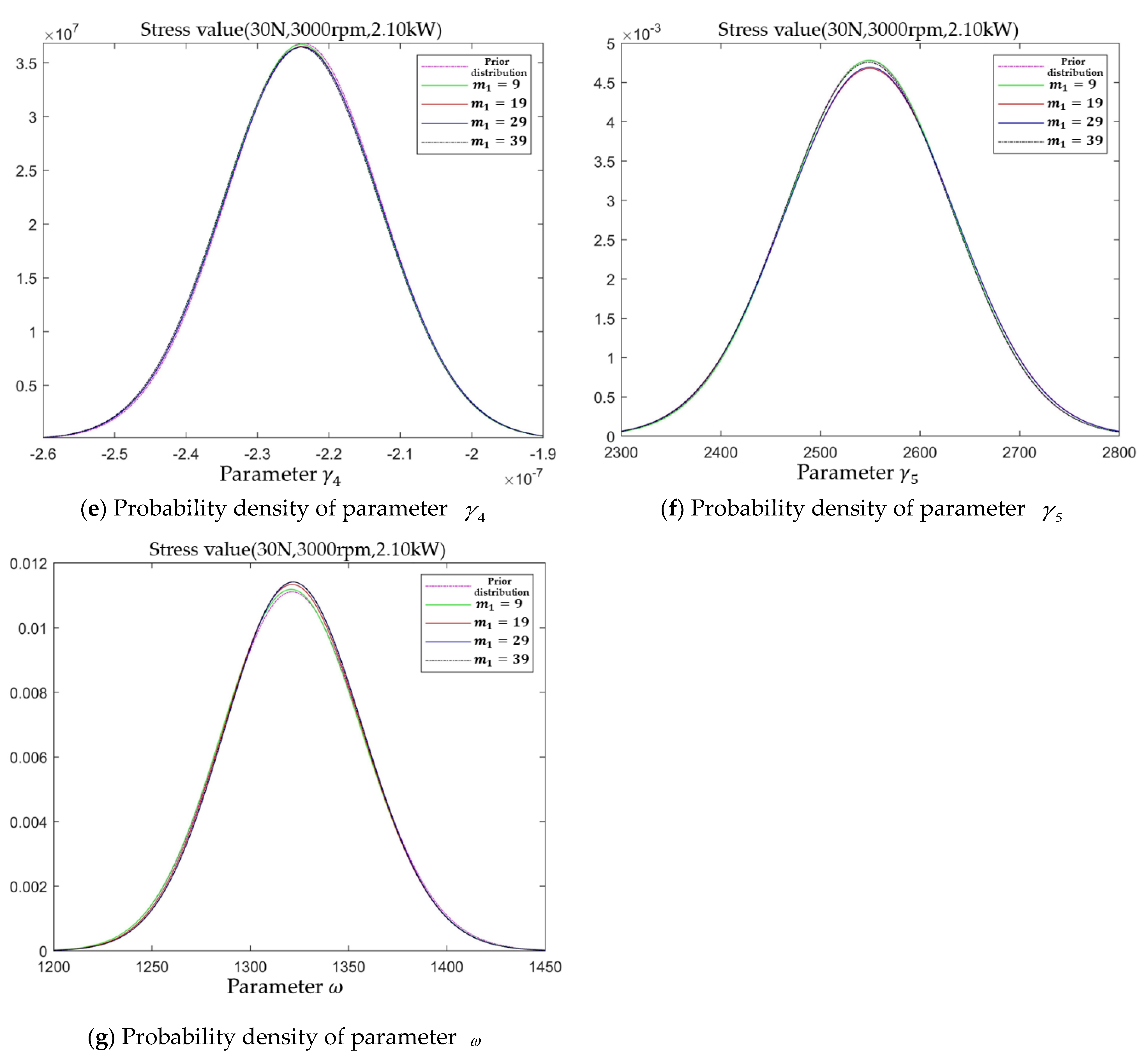

The posterior distribution probability density function of each model parameter obtained at

m7 = 32 is used as the prior distribution probability density of each model parameter at stress level

l = 6. The process of updating the posterior distribution of each model parameter with the increment data

of performance degradation is shown in

Figure 8.

At the end of the test for stress level

l = 6,

IG = 101.248 >

EIG = 35.4401, which satisfies the sequential truncation basis. It can also be seen from

Figure 8 that the shifting of the probability density function is weakened compared with the previous stress level. Nevertheless, the posterior distribution probability density function of each model parameter still has large variations, some of which are the shifting of the mean value of the model parameter and some of which are the fluctuations of the variance. This indicates that there are still deviations between the posterior distribution probability density of each model parameter and the true value at this stage, and the chance of the probability density function has not been completely eliminated, so it is necessary to continue the test.

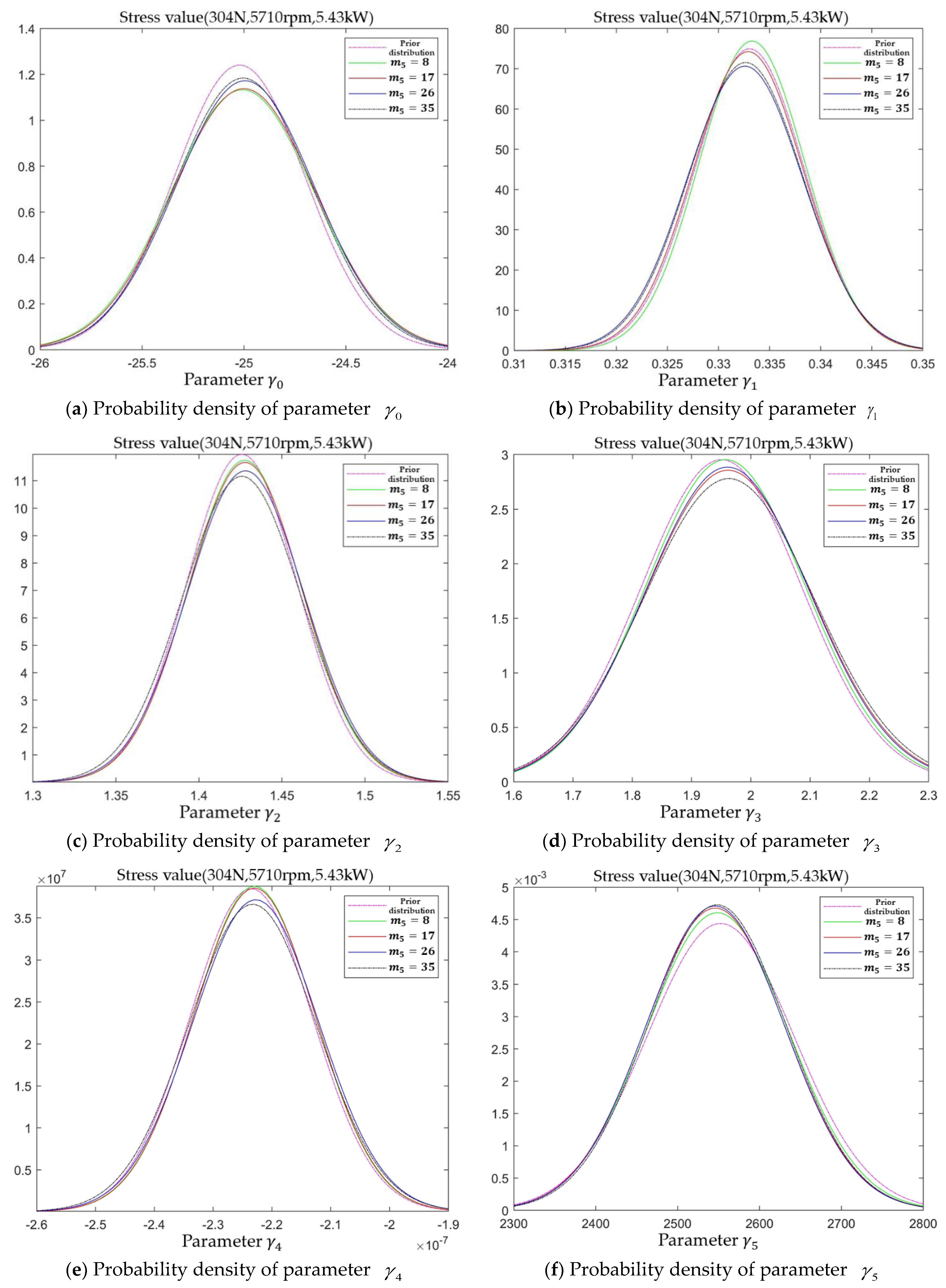

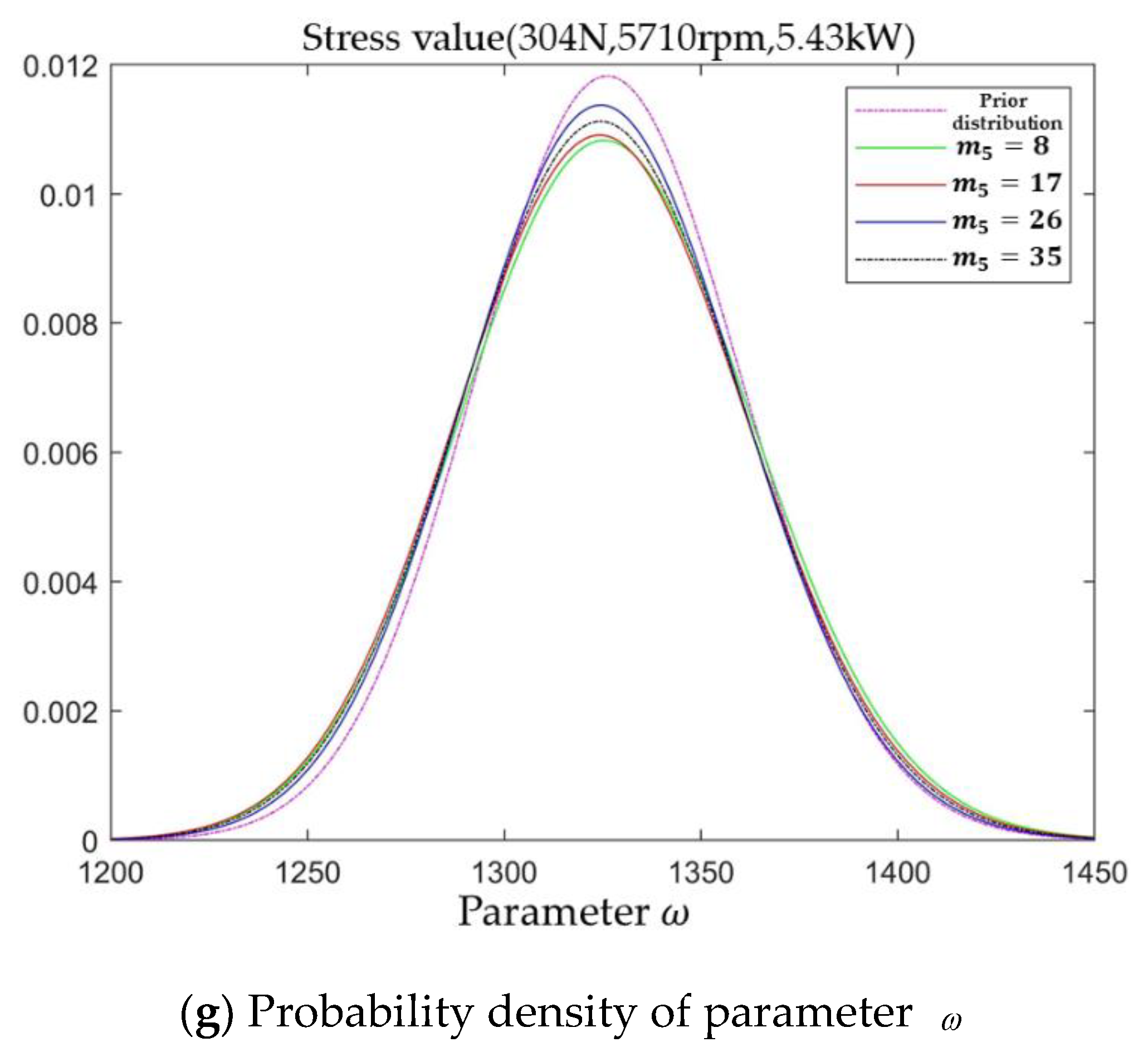

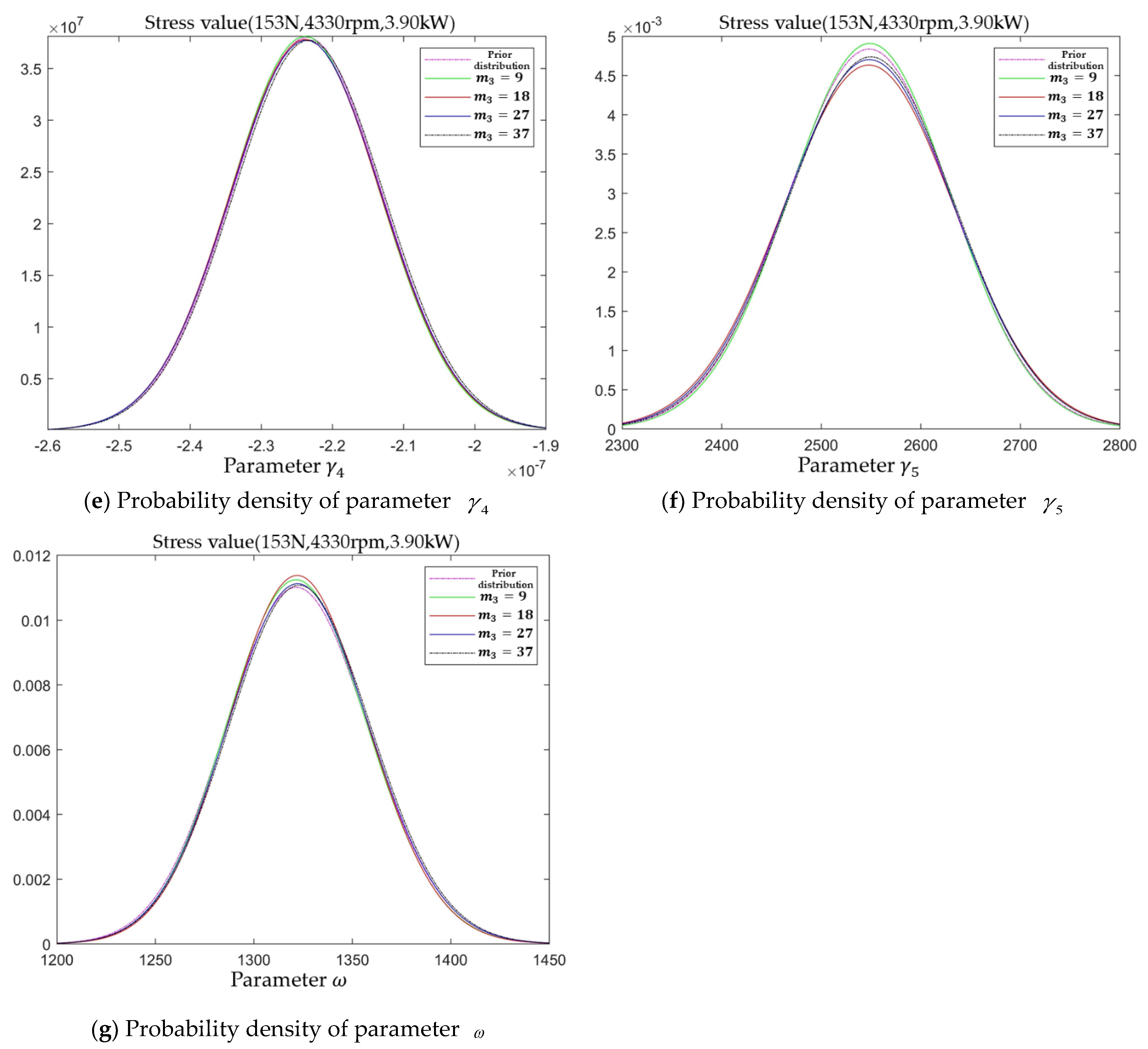

According to the selected test protocol, the test was conducted at stress level

l = 5, and the posterior distribution probability density of each model parameter was calculated based on the performance degradation increment data

. The updated posterior distribution probability density of each model parameter at stress level

l = 5 is shown in

Figure 9.

Compared with the probability density function plots of the posterior distribution of model parameters at the first two stress levels, the shifting of the probability density function of the posterior distribution of each model parameter in

Figure 9 is basically eliminated, and the fluctuations are mainly the up and down fluctuations of the function images, i.e., the changes of the variance of the posterior distribution. It indicates that the mean value of the posterior distribution has been close to the true value of the model parameters, but it is necessary to continue the test because the function graph is not stable. When the stress level

l = 5 ends,

IG = 87.661 >

EIG = 32.2650, which satisfies the sequential truncation basis for the next stress level, the test of stress level

l = 4 is carried out according to the selected test plan. In addition, the variation of the probability density of the posterior distribution of each model parameter with the performance degradation increment data

under this stress level is shown in

Figure 10.

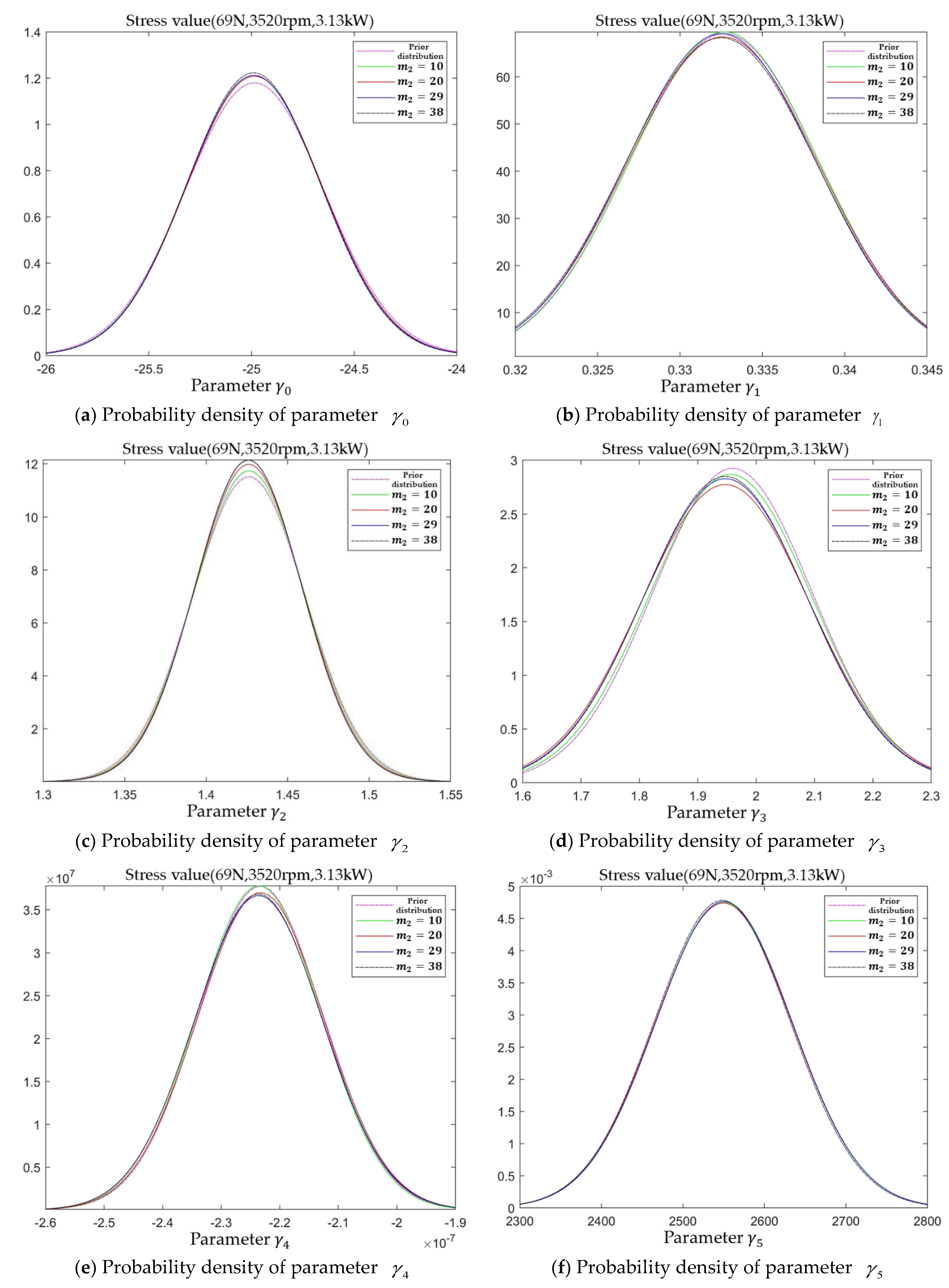

At the end of this stress level,

IG = 71.918 >

EIG = 28.0621, which satisfies the sequential truncation basis, and there are only minor fluctuations in the mean and variance of the posterior distribution probability density functions of the model parameters in

Figure 10. This indicates that the posterior distribution of each model parameter is close to the true value of the model parameters; especially the probability density function of the prior distribution of parameter

at this stress level basically coincides with the probability density function of the posterior distribution. However, because the accelerated model needs to be extrapolated to assess the reliability of the spindle at the normal stress level when evaluating the reliability of the spindle, some of the evaluation accuracy is lost. Therefore, although the fluctuation of the posterior distribution probability density of each model parameter is small at this time, the fluctuation of the posterior distribution probability density function needs to be completely eliminated in order to ensure the evaluation accuracy at the normal stress level, so the test at the next stress level is also required. According to the selected test plan, the test of stress level

l = 3 was conducted, and the posterior distribution of each model parameter is shown in

Figure 11.

Compared with

Figure 10, the posterior distribution probability density functions of the model parameters in

Figure 11 only have small fluctuations in the variance, especially the posterior distribution probability densities obtained for parameters

and

at each number of inspections at this stress level almost overlap. Although the variances of the posterior distributions of parameters

,

and

still have more obvious variations, the mean values have not changed significantly. Moreover, the value of

IG obtained in the test is 437.589, which is already larger than the

EIG = 205.5740 of the test plan. In addition, if the test efficiency is maximized, termination of the test can be considered according to the sequential design method. However, at this time, the distribution of the model parameters, for the first time, appears to stabilize, and in order to eliminate the chance of the test and thus ensure the scientific nature of the study, the next level of the test is conducted to verify it. At the end of this stress level,

IG = 59.462 >

EIG = 24.5134, which satisfies the sequential truncation basis for the next stress level. According to the selected test plan, the test for stress level

l = 2 was conducted, and the procedure is shown in

Figure 12.

In

Figure 12 there is a significant change between the posterior distribution probability density functions of parameters

,

,

and

the prior probability density functions, where

,

and

are variance fluctuations and

is the mean shift. In particular, the posterior distribution of parameter

at the previous two stress levels has converged to a steady state, but the variance of the experimental parameter

at this stress level again appears to fluctuate significantly. The above changes in the posterior probability density functions of the parameters indicate that after incorporating the incremental degradation data of the motorized spindle under this stress level, the steady state of the probability density function of each model parameter distribution after the end of the previous stress level is “breaks”. According to the analysis, the changes in the posterior distribution of

,

and

are because the randomness of the motorized spindle under this stress level is different from the previous stress level. The change of

is because the value reaches the false true value at the previous stress level, and continues to approach the true value under this stress level. The change of parameters

,

,

and

prove the necessity of continuing the test. However, as the number of inspections at this stress level increases, the change in the probability density function of the posterior distribution of the model parameters gradually decreases. This indicates that with the incorporation of the degradation increment data at this stress level, the posterior distribution of the model parameters at the performed stress level has converged to the true value, i.e., the model can be used to evaluate the reliability of the spindle within the performed stress level. However, there is a certain span between this stress level and the normal stress level. In order to avoid the recurrence of this phenomenon after incorporating the data at the normal stress level, and to ensure the extrapolation accuracy of the model at the normal stress level, a test at the normal stress level (

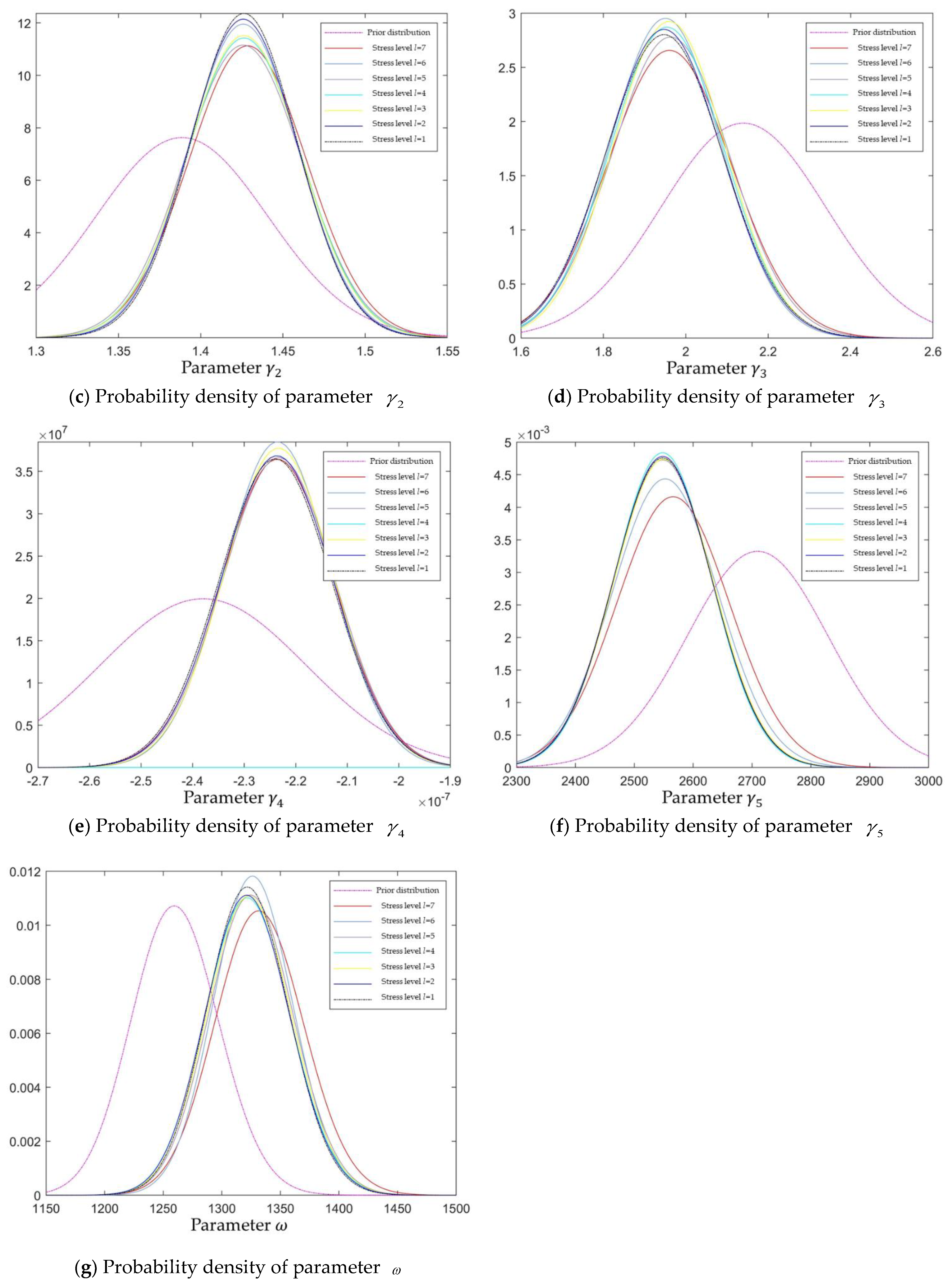

l = 1) is required. According to the test plan, the test of normal stress level (

l = 1) is implemented, and the probability density of the posterior distribution of each model parameter is shown in

Figure 13.

According to

Figure 13, it can be seen that the posterior distribution probability density of the model parameters also appears to fluctuate after incorporating the degradation increment data at normal levels. However, compared with

Figure 12, the fluctuations have diminished and there are basically no more fluctuations in the model parameters after incorporating some normal stress level data. It can also be concluded from

Figure 13 that the fluctuations of model parameters in

Figure 13 are mainly variance fluctuations. This fluctuation is mainly caused by the degradation randomness of samples of different motorized spindles at this stress level. In addition, according to the nature of sequential design, the test can be stopped after 19 data tests (

m1 = 19), and although the

IG <

EIG at this time, the posterior distribution has not changed significantly. In addition, according to the complete test process of the stress level

l = 1, the posterior distribution of the model parameters in the subsequent test has tended to the steady state (as shown in

Table 10). So the probability density function of the posterior distribution of each model parameter at

m1 = 19 satisfies the second basis of the sequential truncation basis, and the end of the test can be stopped.

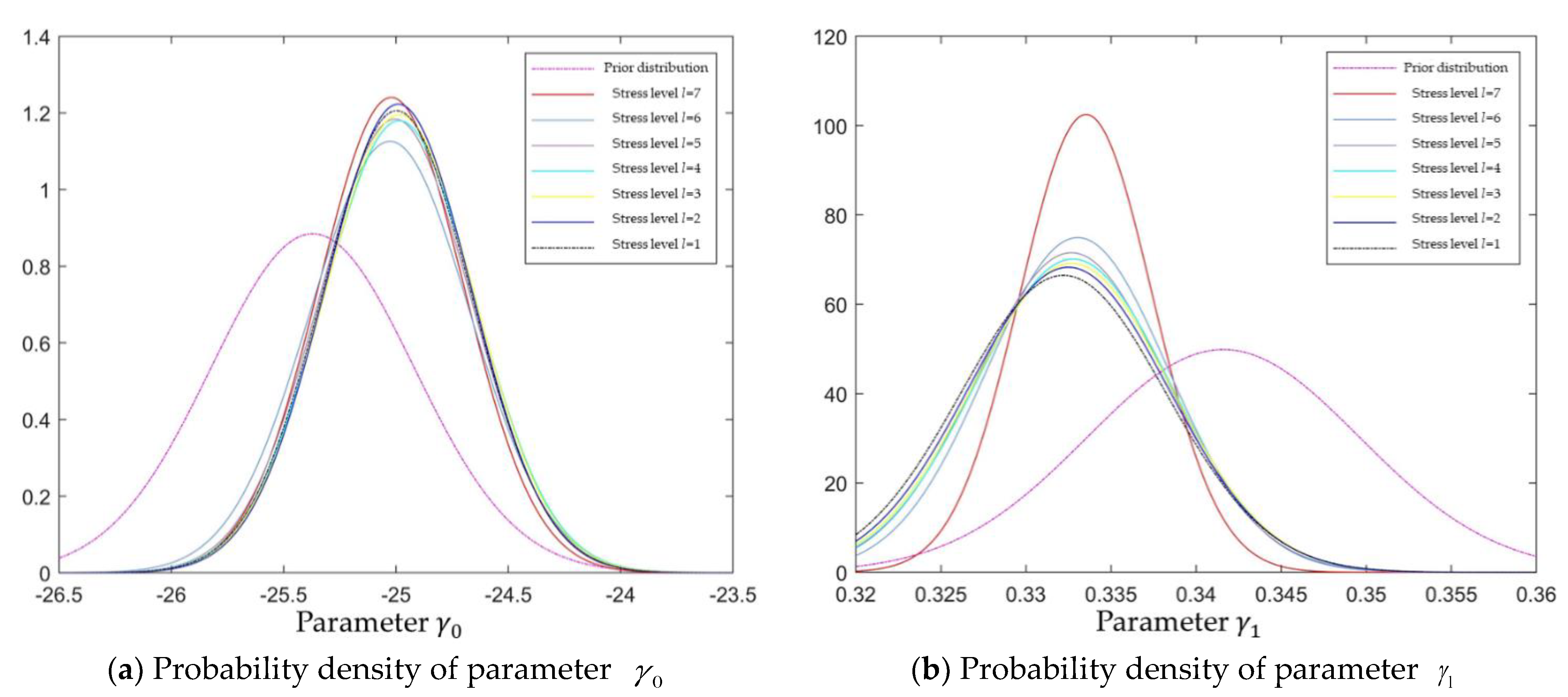

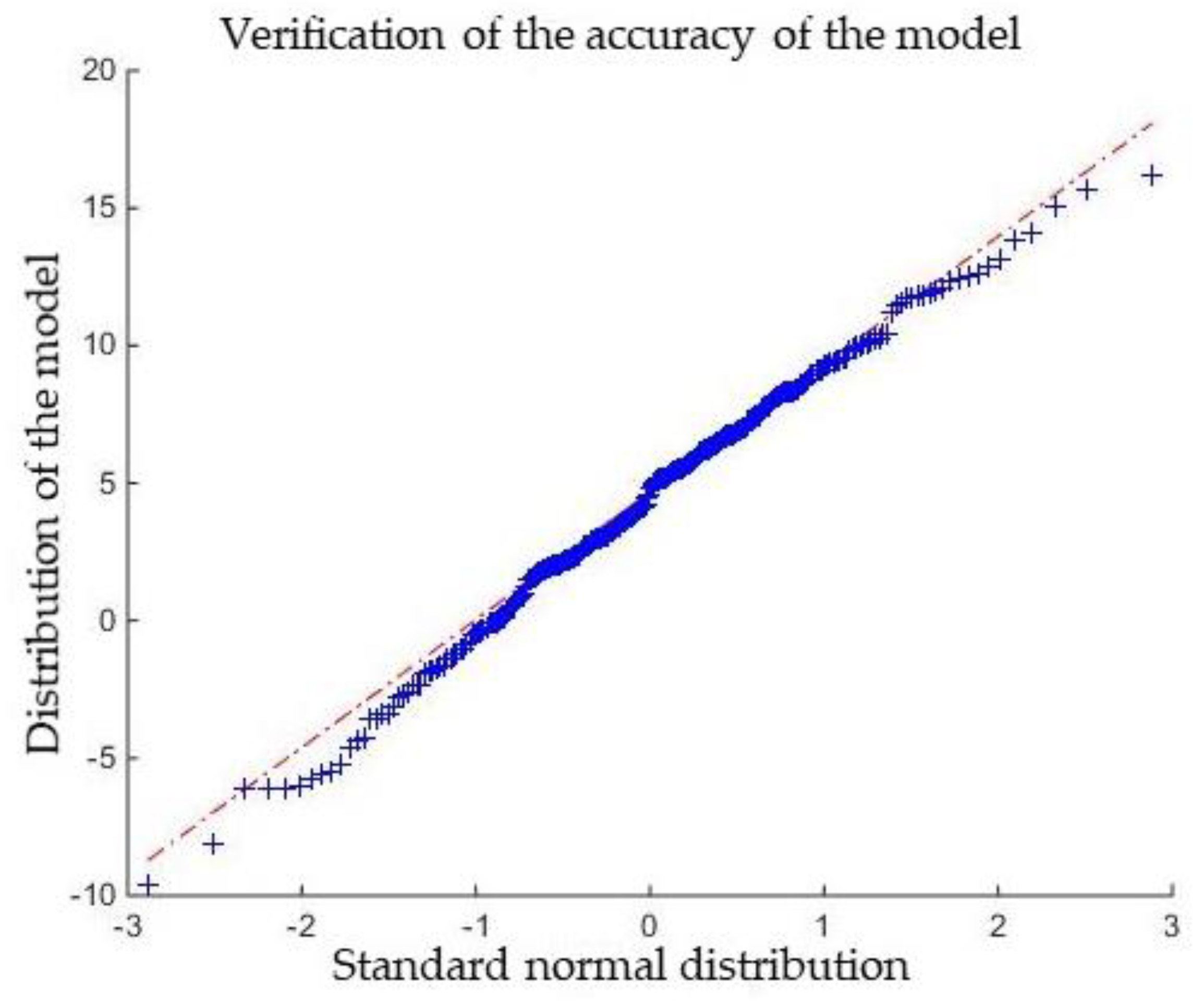

The complete test process was compiled as shown in

Table 11, and the posterior distribution of each model parameter of the motorized spindle was shown in Equation (42), and its update process at each stress level was summarized as shown in

Figure 14.

As can be seen in

Figure 14, there is a large span between the posterior distribution probability density and the prior distribution probability density for each model parameter when the prior information is poor. There is also a large span between the posterior distribution probability density for the first stress level (

l = 7) and the posterior distribution probability density for the seventh stress level (

l = 1). This span illustrates that there is a large deviation between the prior parameter values and the true values in the presence of poor prior information, which in turn justifies the need for the research conducted in this article.

It can also be seen from

Figure 14 that compared with the span of the prior distribution and the posterior distribution, the span of the posterior distribution and the posterior distribution after the first stress in the test is significantly reduced, which proves the necessity of dynamic adjustment of the test plan in the test when the prior information is poor. In addition, the probability density of the posterior distribution of the model parameters at the first few stress levels (

l 4) is dominated by the shift of the mean, i.e., towards the true value of the model. The probability densities of the posterior distributions of the model parameters at the latter stress levels are dominated by the variance shifts, i.e., the distributions are adjusted according to the differences in the samples. In addition, the posterior probability densities of most of the model parameters have leveled off after the fifth stress level (

l = 3). Especially after the seventh stress level has been carried out for a period of time, the posterior distribution probability densities of each model parameter almost do not change anymore, indicating that the parameters have reached the true values of the samples, which in turn proves the availability of the method in optimizing the test plan.