Online Monitoring and Control of Butt-Welded Joint Penetration during GMAW

Abstract

1. Introduction

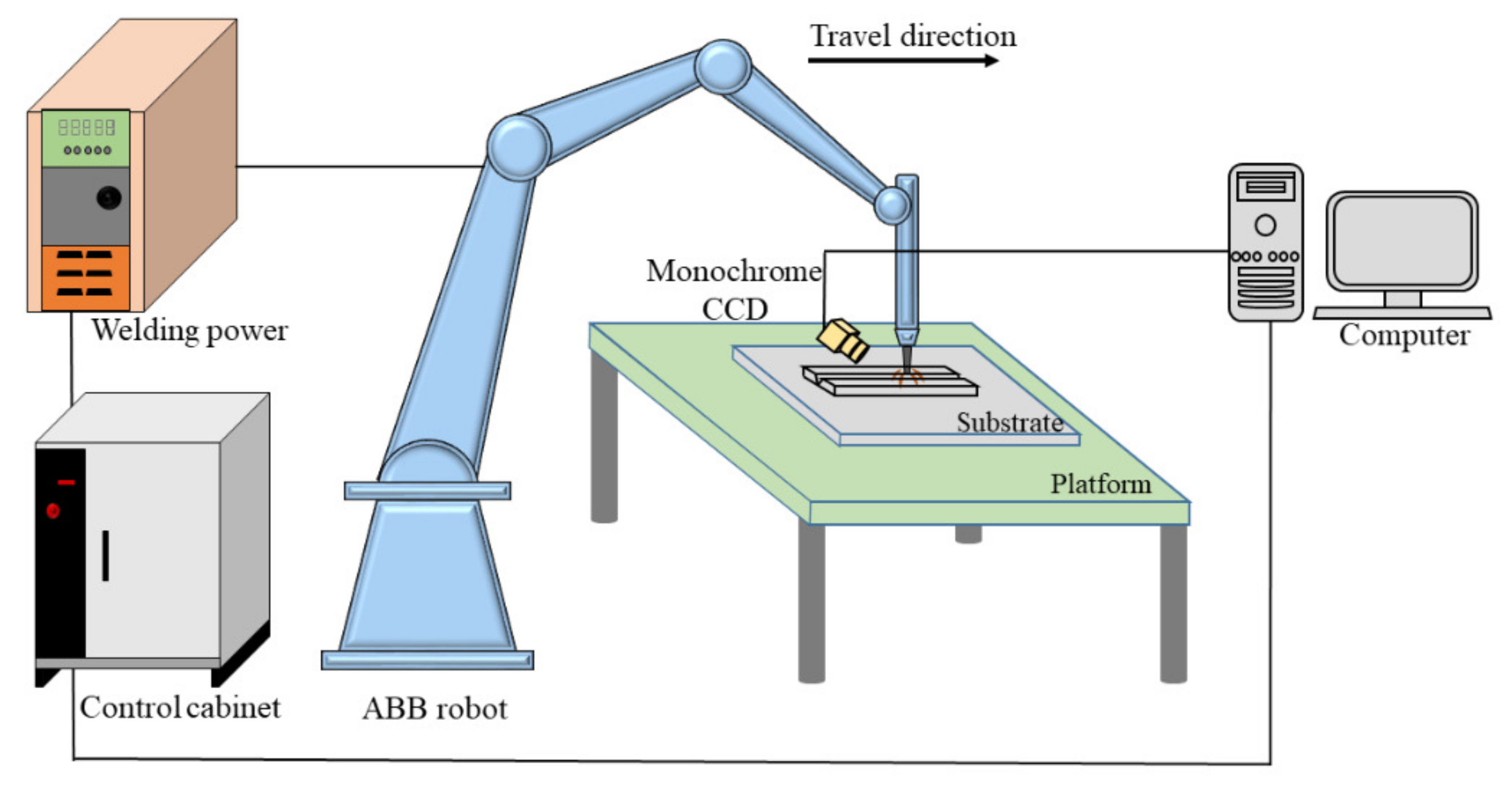

2. Experimental System and Data Acquisition

2.1. Setup Overview

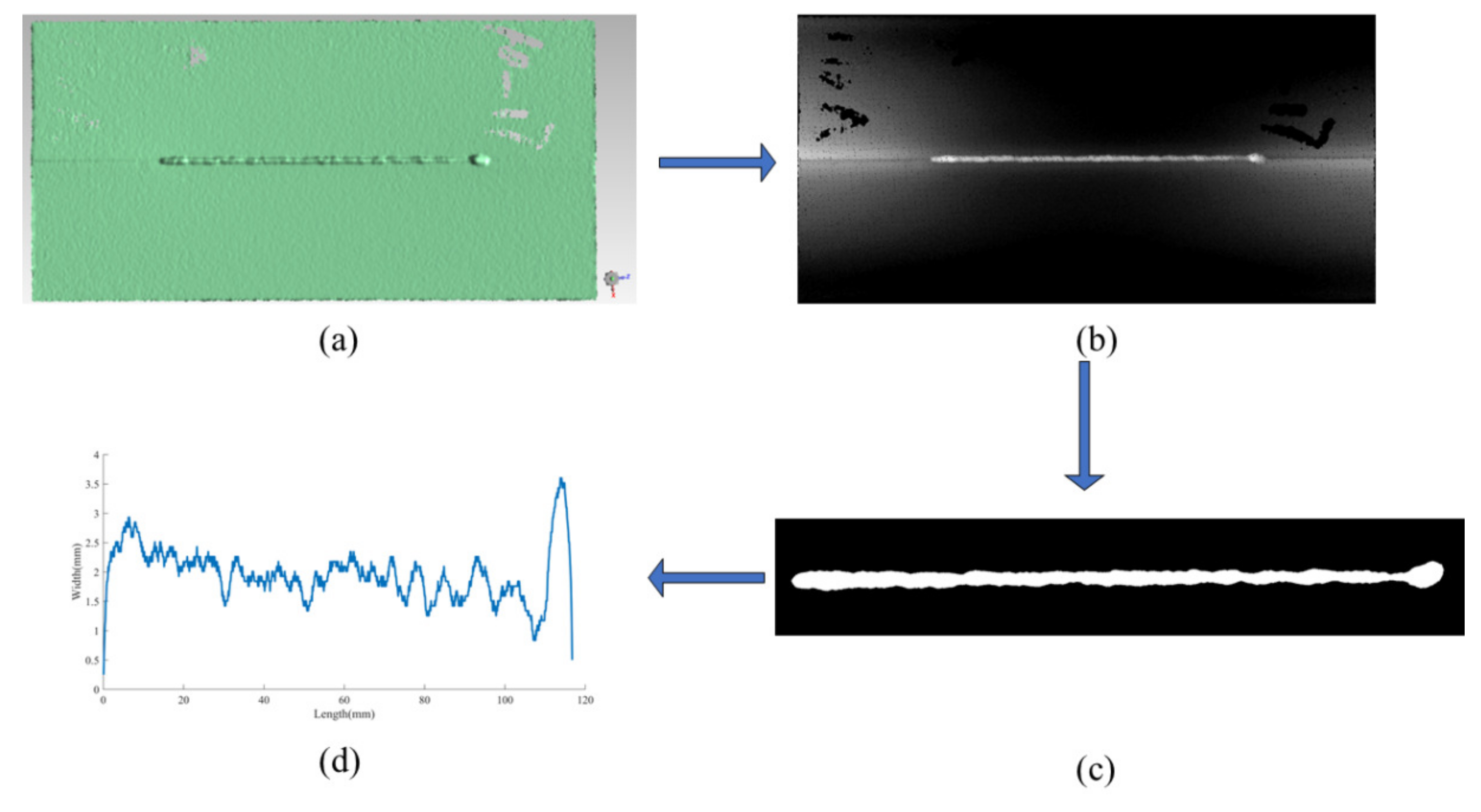

2.2. Measured Data

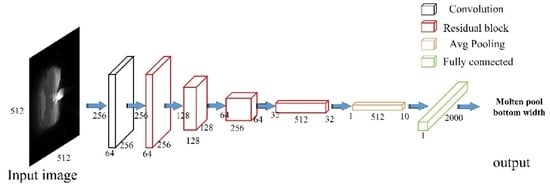

3. Network Structure

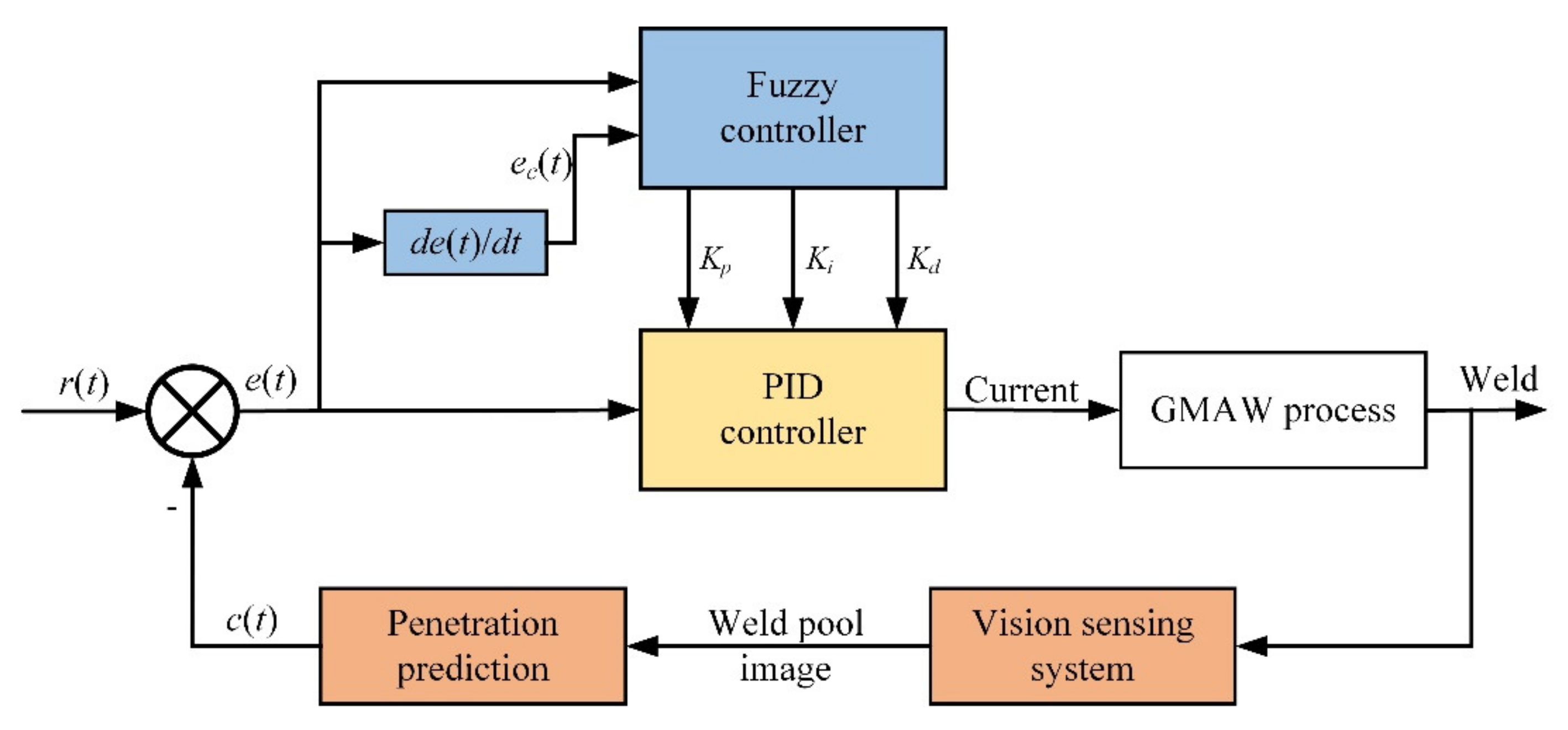

4. Control Strategy

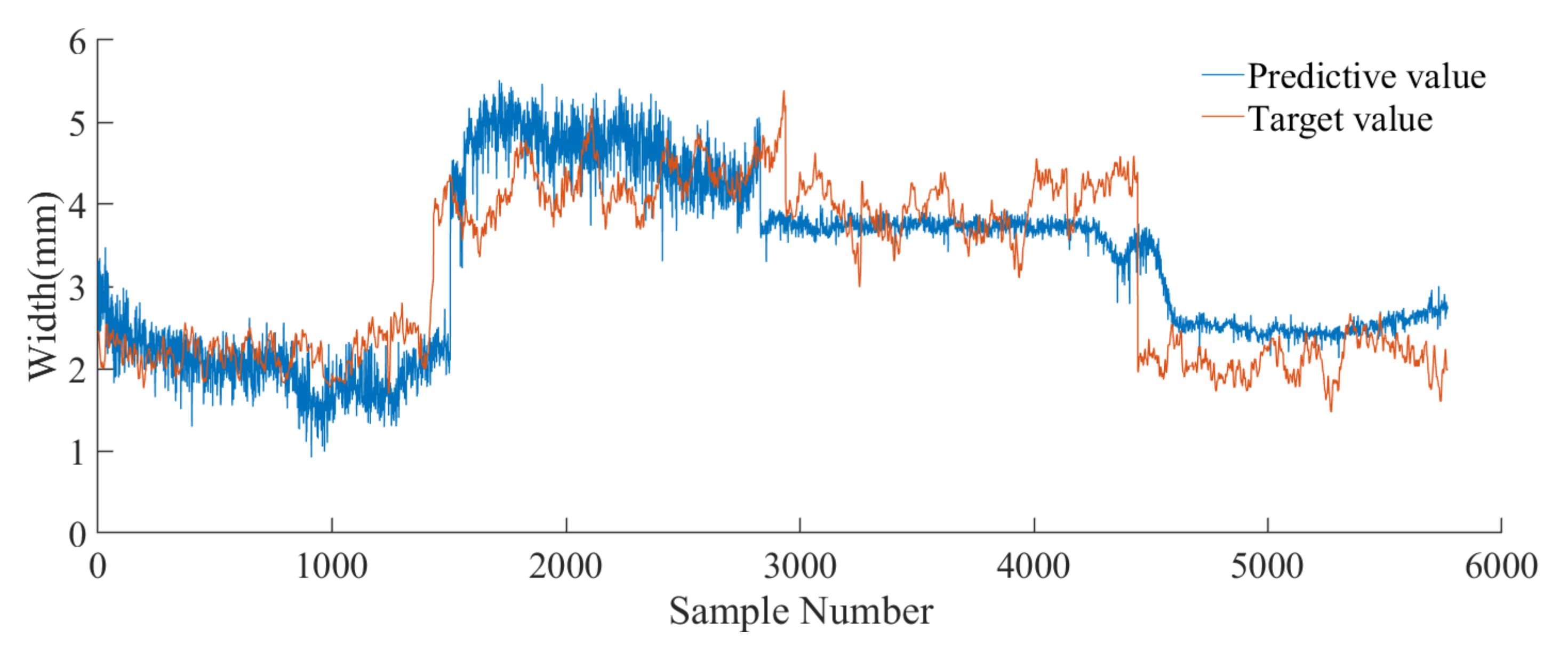

5. Experimental Results and Analysis

6. Conclusions

- The molten pool was monitored by visual sensing, and the width of the bottom molten pool was predicted by a constructed width-regression model.

- A fuzzy PID control system was established to control the welding current, so as to achieve real-time control of penetration.

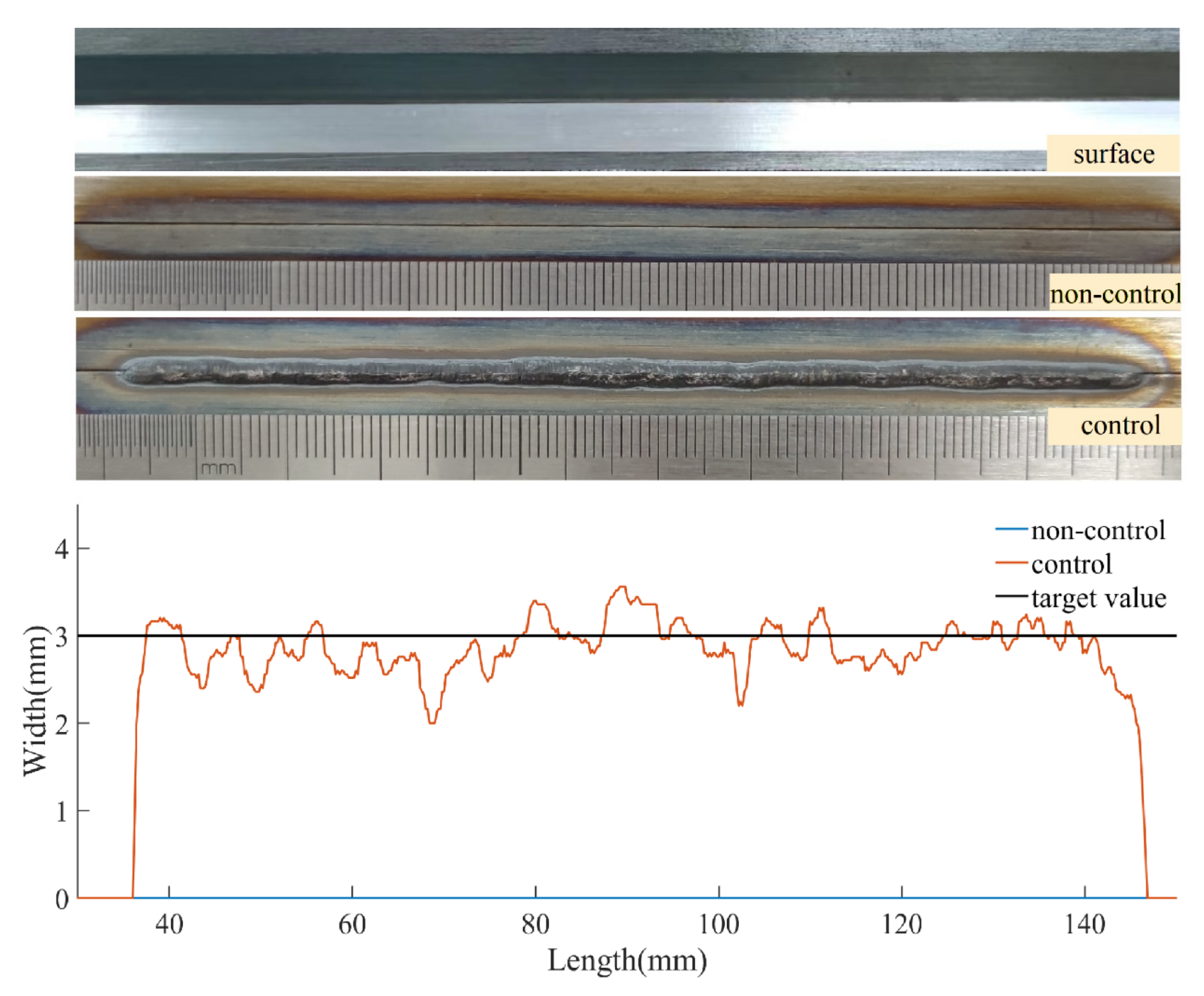

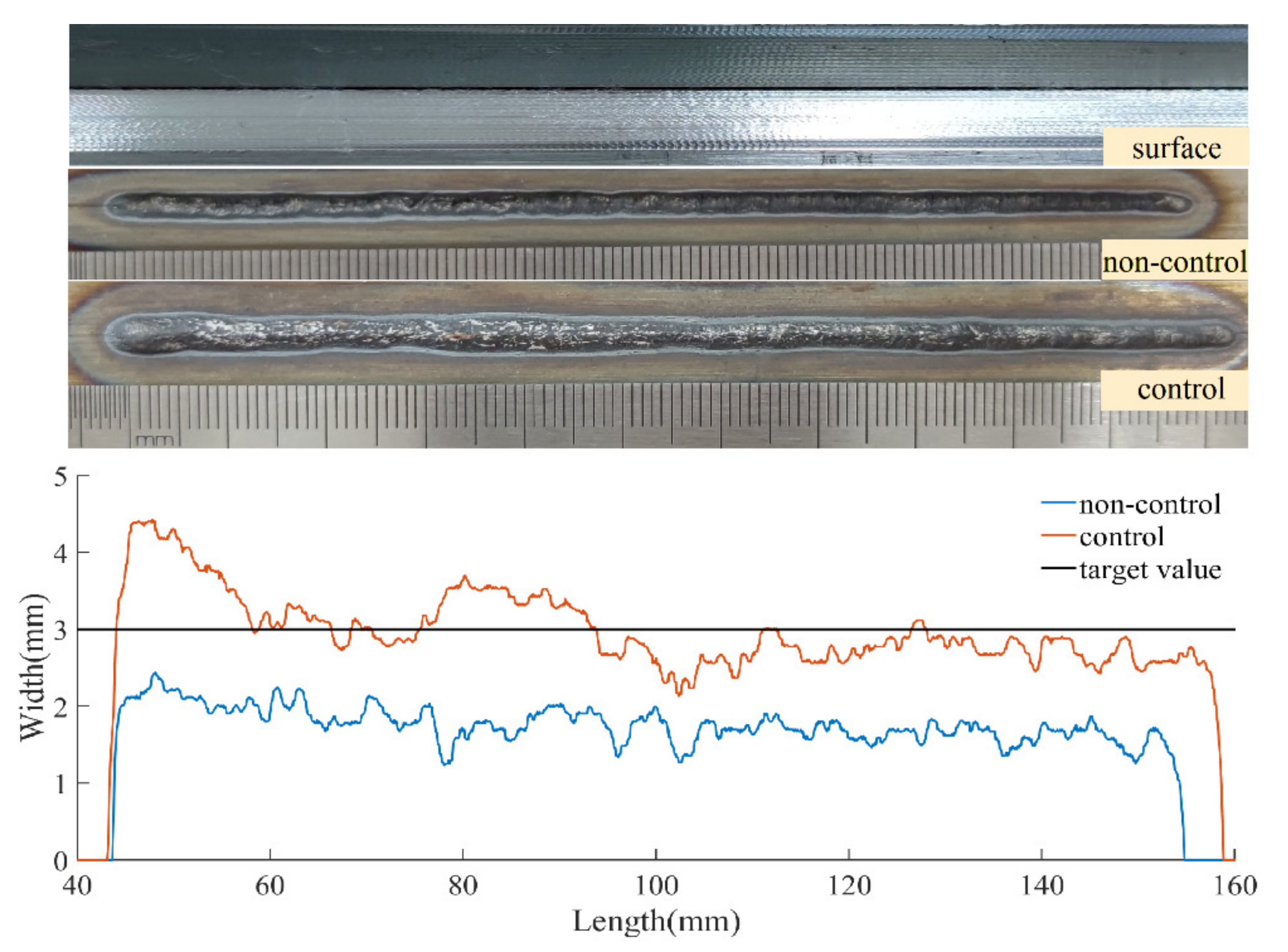

- Experiments with different groove angles showed that the designed closed-loop control system has a good adjustment effect on butt-welding penetration, and a satisfactory bottom weld width can be obtained.

- For a constant groove angle, the bottom weld width was initially established at the target value. For abruptly varying groove angles, the bottom weld width was first abruptly changed once and then adjusted by the control strategy to eventually approach the target value. For a gradual change in groove angle, the bottom weld width was gradually stabilized at the target value after several fluctuations under the control strategy.

- The designed closed-loop control system can be extended in the case of more butt-welding process parameters and more groove angles. For WAAM additive manufacturing technology, other geometrical parameters of the weld seam, such as width and height, can also be controlled using this system.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Y.; Wang, Q.; Liu, Y. Adaptive Intelligent Welding Manufacturing. Weld. J. 2021, 100, 63–83. [Google Scholar] [CrossRef]

- Zhang, Z.; Wen, G.; Chen, S. Audible Sound-based Intelligent Evaluation for Aluminum Alloy in Robotic Pulsed GTAW: Mechanism, feature selection and defect detection. IEEE Trans. Ind. Inform. 2018, 14, 2973–2983. [Google Scholar] [CrossRef]

- Yu, R.; Han, J.; Bai, L.; Zhao, Z. Identification of butt welded joint penetration based on infrared thermal imaging. J. Mater. Res. Technol. 2021, 12, 1486–1495. [Google Scholar] [CrossRef]

- Aendenroomer, A.; Ouden, G. Weld pool oscillation as a tool for penetration sensing during pulsed GTA welding. Weld. J. 1998, 77, 181–187. [Google Scholar]

- Wang, X.; Liu, Y.; Zhang, W.; Zhang, Y. Estimation of weld penetration using parameterized three-dimensional weld pool surface in gas tungsten arc welding. In Proceedings of the IEEE International Symposium on Industrial Electronics, Hangzhou, China, 28–31 May 2012; pp. 835–840. [Google Scholar]

- Chen, Z.; Chen, J.; Feng, Z. Welding penetration prediction with passive vision system. J. Manuf. Process. 2018, 36, 224–230. [Google Scholar] [CrossRef]

- Yang, J.; Wang, K.; Wu, T.; Zhou, X. Welding penetration recognition in aluminum alloy tandem arc welding based on visual characters of weld pool. Trans. China Weld. Inst. 2017, 38, 49–52. [Google Scholar]

- Wu, D.; Chen, H.; Huang, Y.; Chen, S. Online monitoring and model-free adaptive control of weld penetration in VPPAW based on extreme learning machine. IEEE Trans. Ind. Inform. 2019, 15, 2732–2741. [Google Scholar] [CrossRef]

- Veiga, F.; Suarez, A.; Aldalur, E.; Artaza, T. Wire arc additive manufacturing of invar parts: Bead geometry and melt pool monitoring. Measurement 2022, 189, 110452. [Google Scholar] [CrossRef]

- Pinto-Lopera, J.E.; ST Motta, J.M.; Absi Alfaro, S.C. Real-Time Measurement of Width and Height of Weld Beads in GMAW Processes. Sensors 2016, 16, 1500. [Google Scholar] [CrossRef]

- Dong, X.; Taylor, C.; Cootes, T. Automatic aerospace weld inspection using unsupervised local deep feature learning. Knowl.-Based Syst. 2021, 221, 106892. [Google Scholar] [CrossRef]

- Liu, L.; Wu, F.; Wang, Y.; Wang, J. Multi-Receptive-Field CNN for Semantic Segmentation of Medical Images. IEEE J. Biomed. Health Inform. 2020, 24, 3215–3225. [Google Scholar] [CrossRef]

- Nex, F.; Duarte, D.; Tonolo, F.; Kerle, N. Structural Building Damage Detection with Deep Learning: Assessment of a State-of-the-Art CNN in Operational Conditions. Remote Sens. 2019, 11, 2765. [Google Scholar] [CrossRef]

- Benjdira, B.; Khursheed, T.; Koubaa, A.; Ammar, A.; Kais, O. Car Detection using Unmanned Aerial Vehicles: Comparison between Faster R-CNN and YOLOv3. In Proceedings of the International Conference on Unmanned Vehicle Systems (UVS), Muscat, Oman, 5–7 February 2019; pp. 1–6. [Google Scholar]

- Zhang, Y.; Kovacevic, R. Neurofuzzy model-based predictive control of weld fusion zone geometry. IEEE Trans. Fuzzy Syst. 1998, 6, 389–401. [Google Scholar] [CrossRef]

- Chen, S.; Lou, Y.; Wu, L.; Zhao, D. Intelligent Methodology for Sensing, Modeling and Control of Pulsed GTAW: Part I Bead-on-Plate Welding. Weld. J. 2000, 79, 151–163. [Google Scholar]

- Nomura, K.; Fukushima, K.; Matsumura, T.; Asai, S. Burn-through prediction and weld depth estimation by deep learning model monitoring the molten pool in gas metal arc welding with gap fluctuation. J. Manuf. Process. 2020, 61, 590–600. [Google Scholar] [CrossRef]

- Martínez, A.; Bestard, G.; Silva, A.; Alfaro, S. Analysis of GMAW process with deep learning and machine learning techniques. J. Manuf. Process. 2021, 62, 695–703. [Google Scholar] [CrossRef]

- Bacioiu, D.; Melton, G.; Papaelias, M.; Shaw, R. Automated defect classification of Aluminium 5083 TIG welding using HDR camera and neural networks. J. Manuf. Process. 2019, 45, 603–613. [Google Scholar] [CrossRef]

- Huang, Y.; Yuan, Y.; Yang, L.; Wu, D.; Chen, S. Real-time Monitoring and Control of Porosity Defects during Arc Welding of Aluminum Alloys. J. Mater. Process. Technol. 2020, 286, 116832. [Google Scholar] [CrossRef]

- Lee, K.; Hwang, I.; Kim, Y.; Lee, H.; Kang, M.; Yu, J. Real-Time Weld Quality Prediction Using a Laser Vision Sensor in a Lap Fillet Joint during Gas Metal Arc Welding. Sensors 2020, 20, 1625. [Google Scholar] [CrossRef]

- Hou, W.; Wei, Y.; Guo, J.; Jin, Y.; Zhu, C. Automatic Detection of Welding Defects using Deep Neural Network. J. Phys. Conf. Ser. 2018, 933, 1–10. [Google Scholar] [CrossRef]

- Lecun, Y.; Bottou, L.; Bengio, Y.; Haffner, P. Gradient-based learning applied to document recognition. Proc. IEEE 1998, 86, 2278–2324. [Google Scholar] [CrossRef]

- Krizhevsky, A.; Sutskever, I.; Hinton, G. ImageNet Classification with Deep Convolutional Neural Networks. Adv. Neural Inf. Process. Syst. 2012, 25, 1–7. [Google Scholar] [CrossRef]

- Simonyan, K.; Zisserman, A. Very Deep Convolutional Networks for Large-Scale Image Recognition. Comput. Sci. 2014, 6, 1409–1556. [Google Scholar]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep Residual Learning for Image Recognition. In Proceedings of the 2016 IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 27–30 June 2016; Volume 1, pp. 770–778. [Google Scholar]

| Group | Groove Angle (°) | Current (A) | Length (mm) | Welding Speed (mm/s) | Penetration State |

|---|---|---|---|---|---|

| 1 | 45 | 200 | 120 | 7 | Full-penetration |

| 2 | 45 | 170 | 120 | 7 | Non-penetration |

| 3 | 30 | 184 | 120 | 7 | Full-penetration |

| 4 | 30 | 160 | 120 | 7 | Non-penetration |

| Network Layers | Output Size | Parameters |

|---|---|---|

| Input (512 × 512 × 1) | ||

| Convolution | 256 × 256 × 64 | 5 × 5, 64, stride = 2 |

| Residual Block 1 | 256 × 256 × 64 | basicblock × 3 |

| Residual Block 2 | 128 × 128 × 128 | basicblock × 4 |

| Residual Block 3 | 64 × 64 × 256 | basicblock × 6 |

| Residual Block 4 | 32 × 32 × 512 | basicblock × 3 |

| Pool | 10 × 1 × 512 | 4 × 3, avg_pool |

| Linear1 (feature) | 1000 | |

| Linear2 (feature) | 1 | |

| Parameters | Value |

|---|---|

| Wire diameter (mm) | 1.2 |

| Ar (98.5%) and O2 (1.5%) (L/min) | 25 |

| Welding length (mm) | 120 |

| Welding speed (mm/s) | 7 |

| Exposure time (μs) | 200 |

| Acquisition frequency (Hz) | 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Wang, Y.; Han, J.; Lu, J.; Zhao, Z. Online Monitoring and Control of Butt-Welded Joint Penetration during GMAW. Metals 2022, 12, 2009. https://doi.org/10.3390/met12122009

Xu X, Wang Y, Han J, Lu J, Zhao Z. Online Monitoring and Control of Butt-Welded Joint Penetration during GMAW. Metals. 2022; 12(12):2009. https://doi.org/10.3390/met12122009

Chicago/Turabian StyleXu, Xingwang, Yiming Wang, Jing Han, Jun Lu, and Zhuang Zhao. 2022. "Online Monitoring and Control of Butt-Welded Joint Penetration during GMAW" Metals 12, no. 12: 2009. https://doi.org/10.3390/met12122009

APA StyleXu, X., Wang, Y., Han, J., Lu, J., & Zhao, Z. (2022). Online Monitoring and Control of Butt-Welded Joint Penetration during GMAW. Metals, 12(12), 2009. https://doi.org/10.3390/met12122009