The Effect of Hot Oscillatory Pressing Temperature on Microstructure and Tensile Behavior of Powder Metallurgy Superalloy

Abstract

:1. Introduction

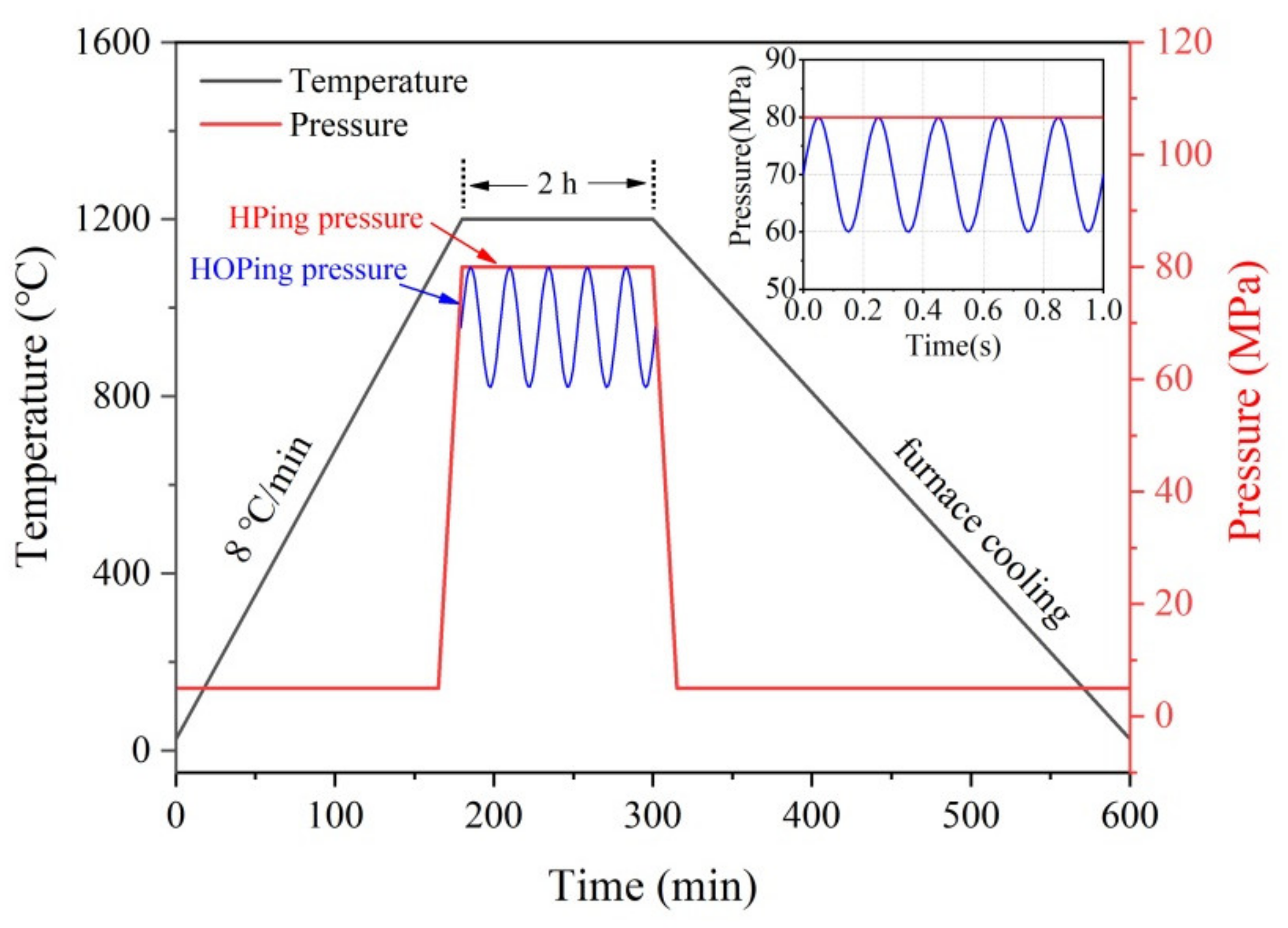

2. Materials and Methods

3. Results

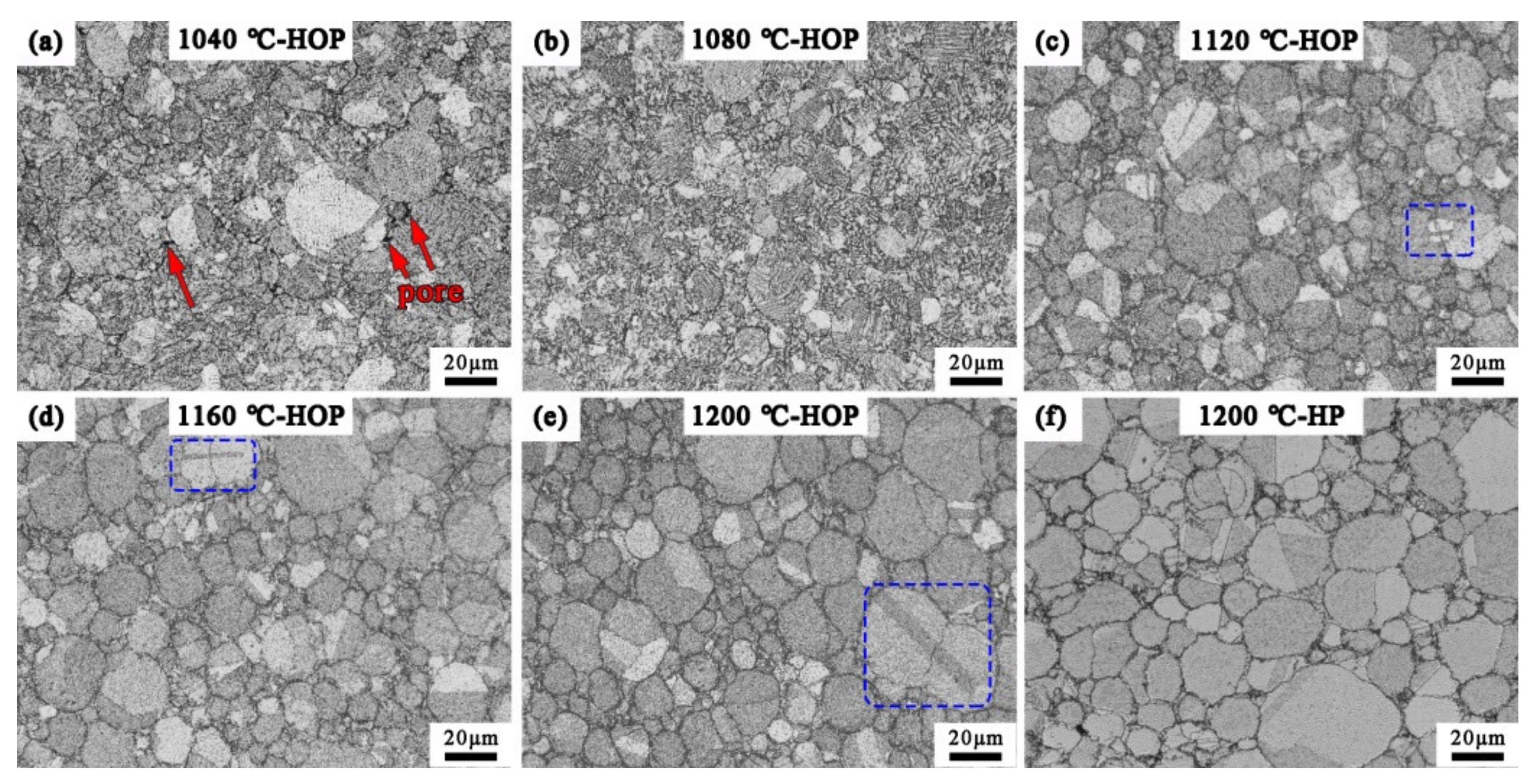

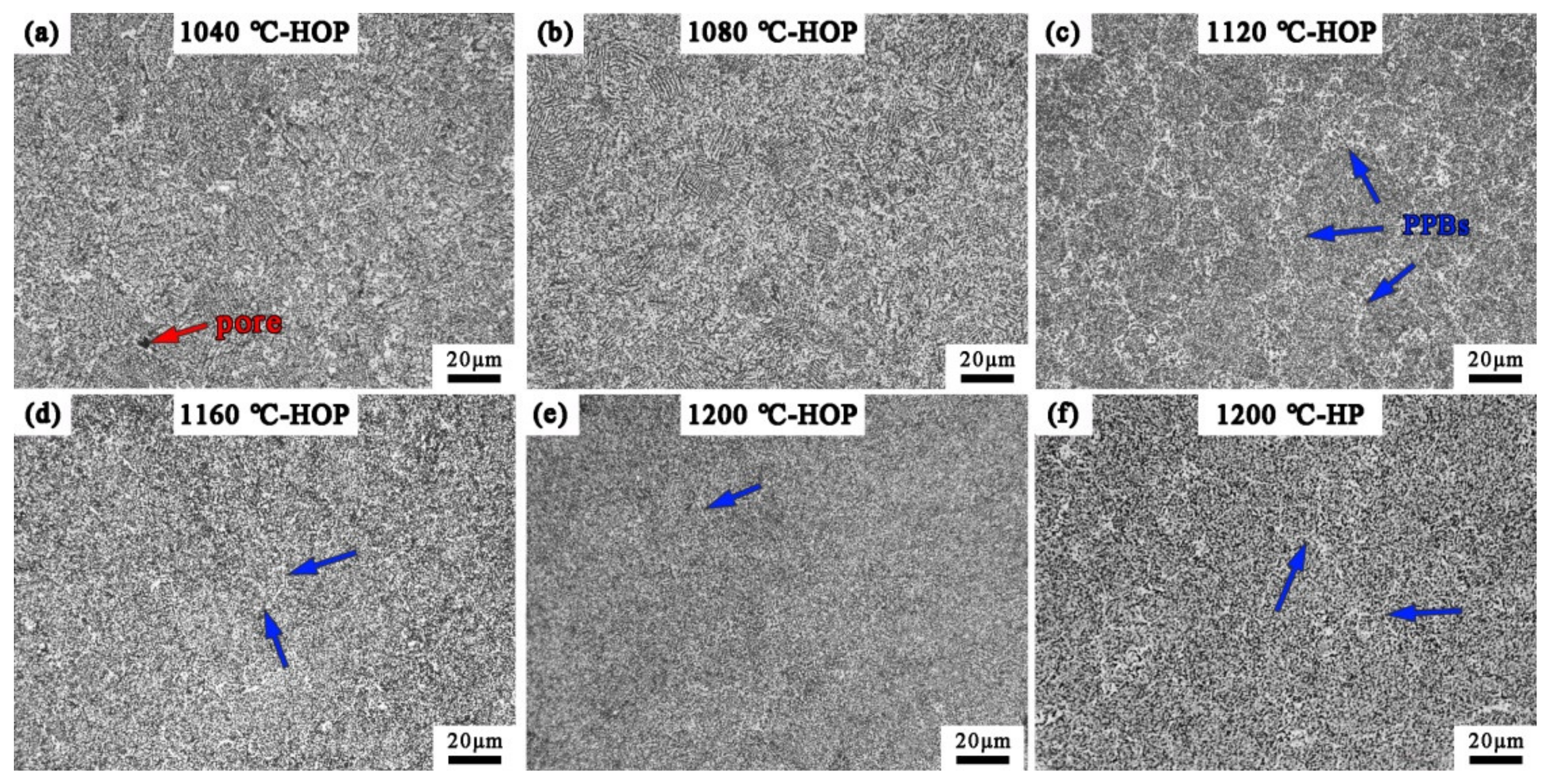

3.1. Microstructure Evolution

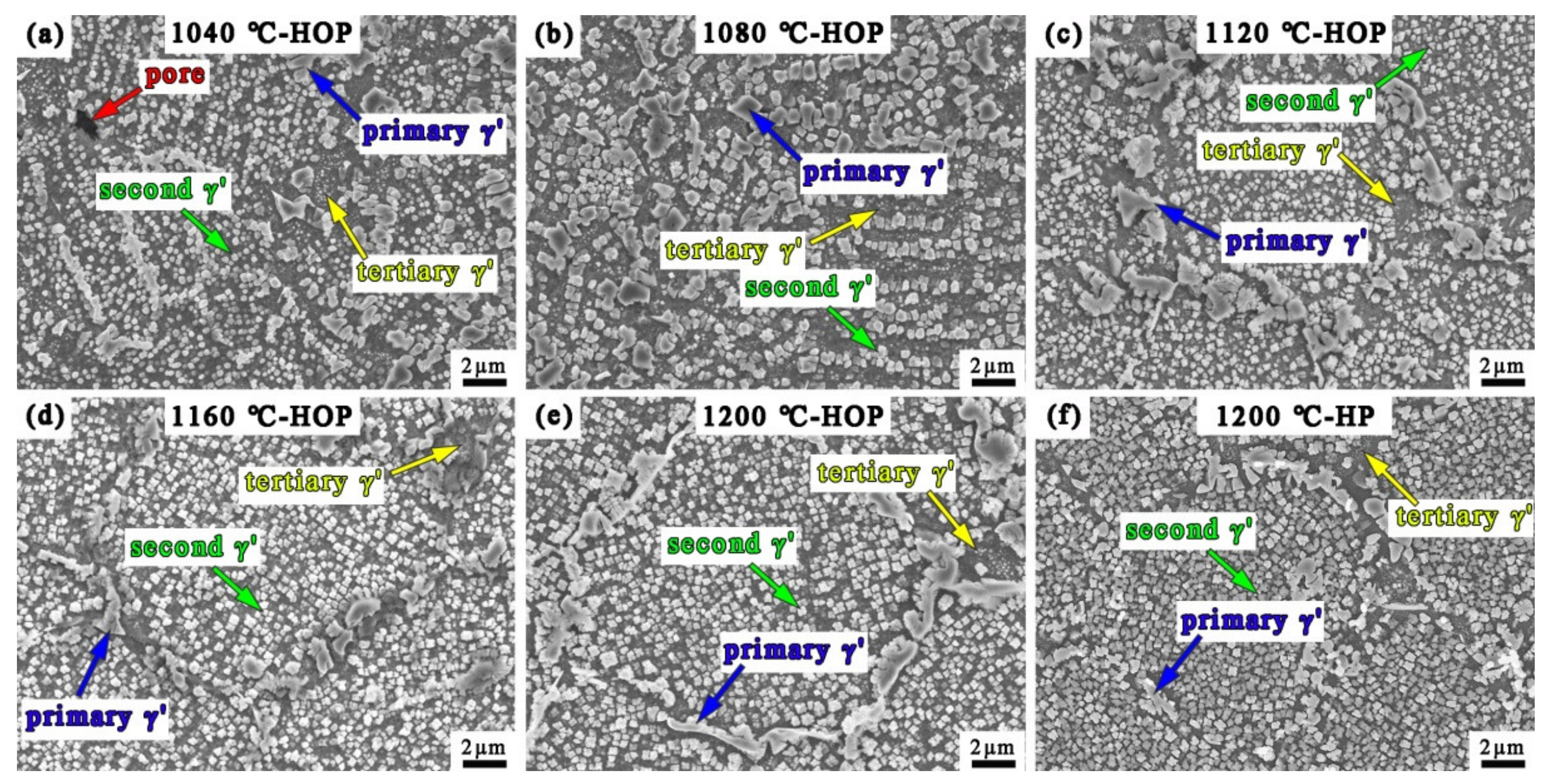

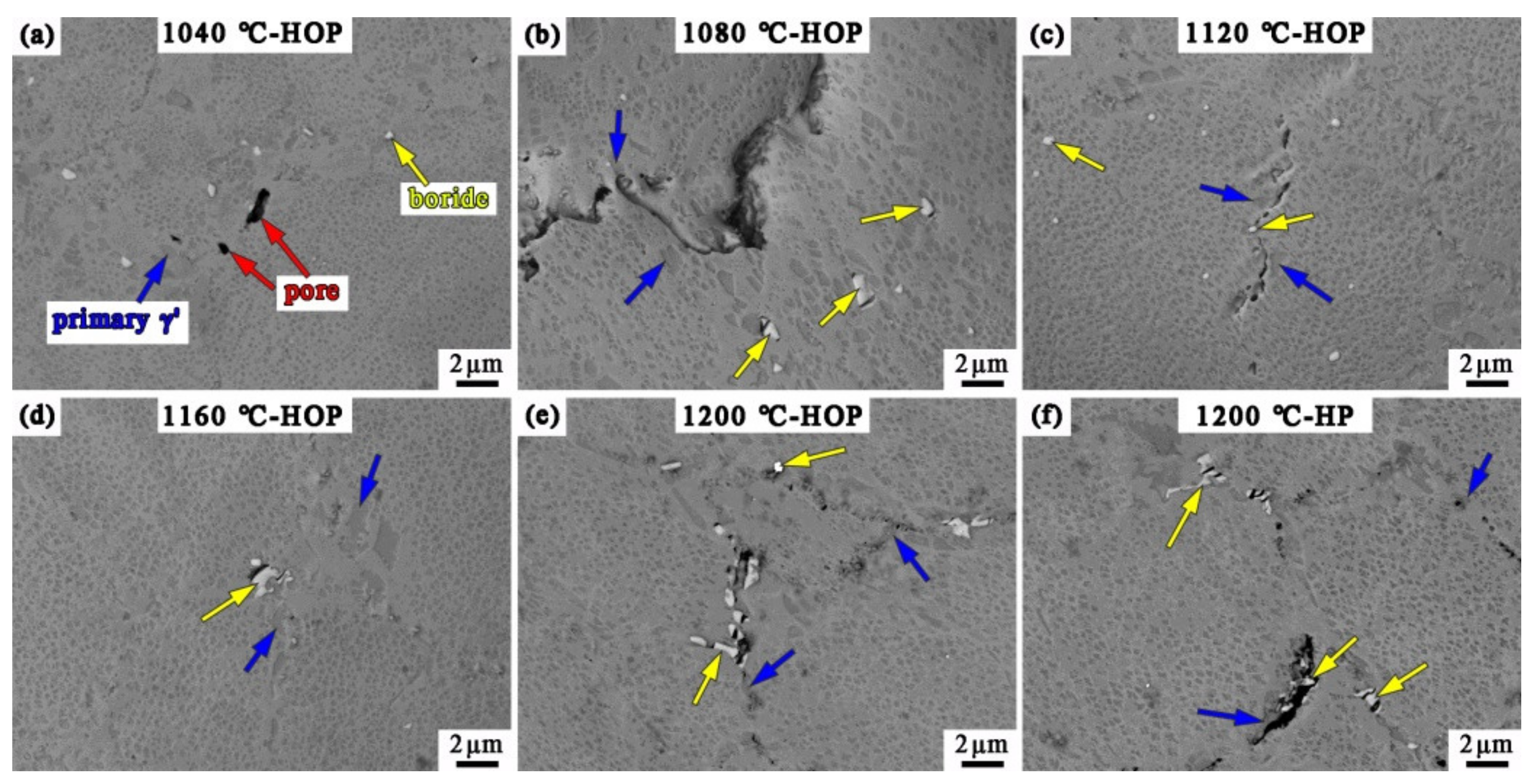

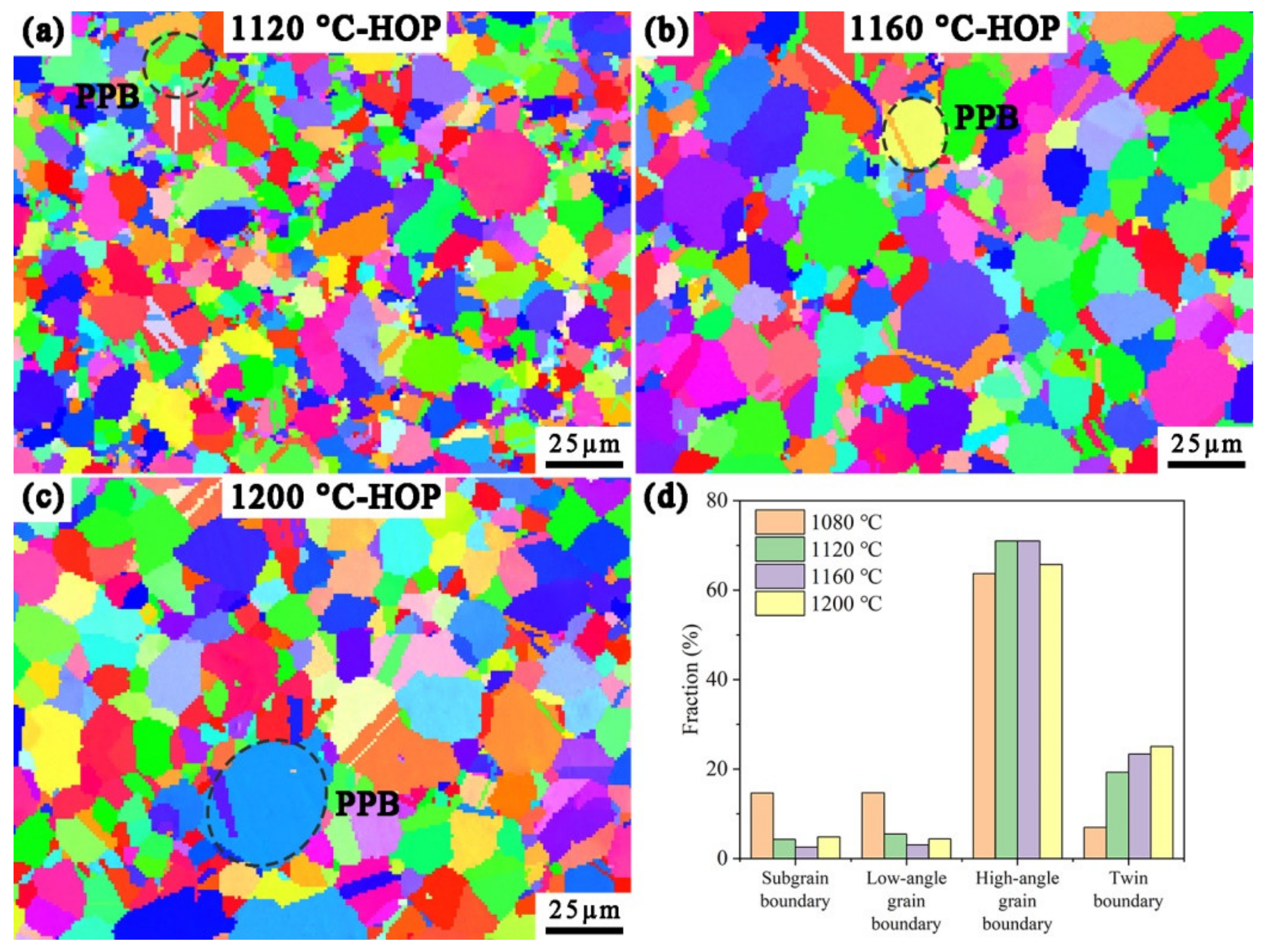

- Primary γ′ phases (shown by the blue arrow in Figure 7) are located on PPBs with a size of about 2 μm. With the increasing HOPing temperature, their morphology changes from bulk to chain-like;

- Secondary γ′ phases (shown by the green arrow in Figure 7) are located within the particles, with a size of about 500 nm. Their morphologies change from spherical to cubic or butterfly-like with the increase in HOPing temperature;

- Tertiary γ′ phases (shown by the yellow arrow in Figure 7) are located between primary γ′ phases and secondary γ′ phases and are less than 100 nm.

3.2. Tensile Properties and Fracture Behavior

4. Discussion

4.1. Microstructure Evolution of the HOP Samples

4.2. Relationship between Microstructure and Tensile Property

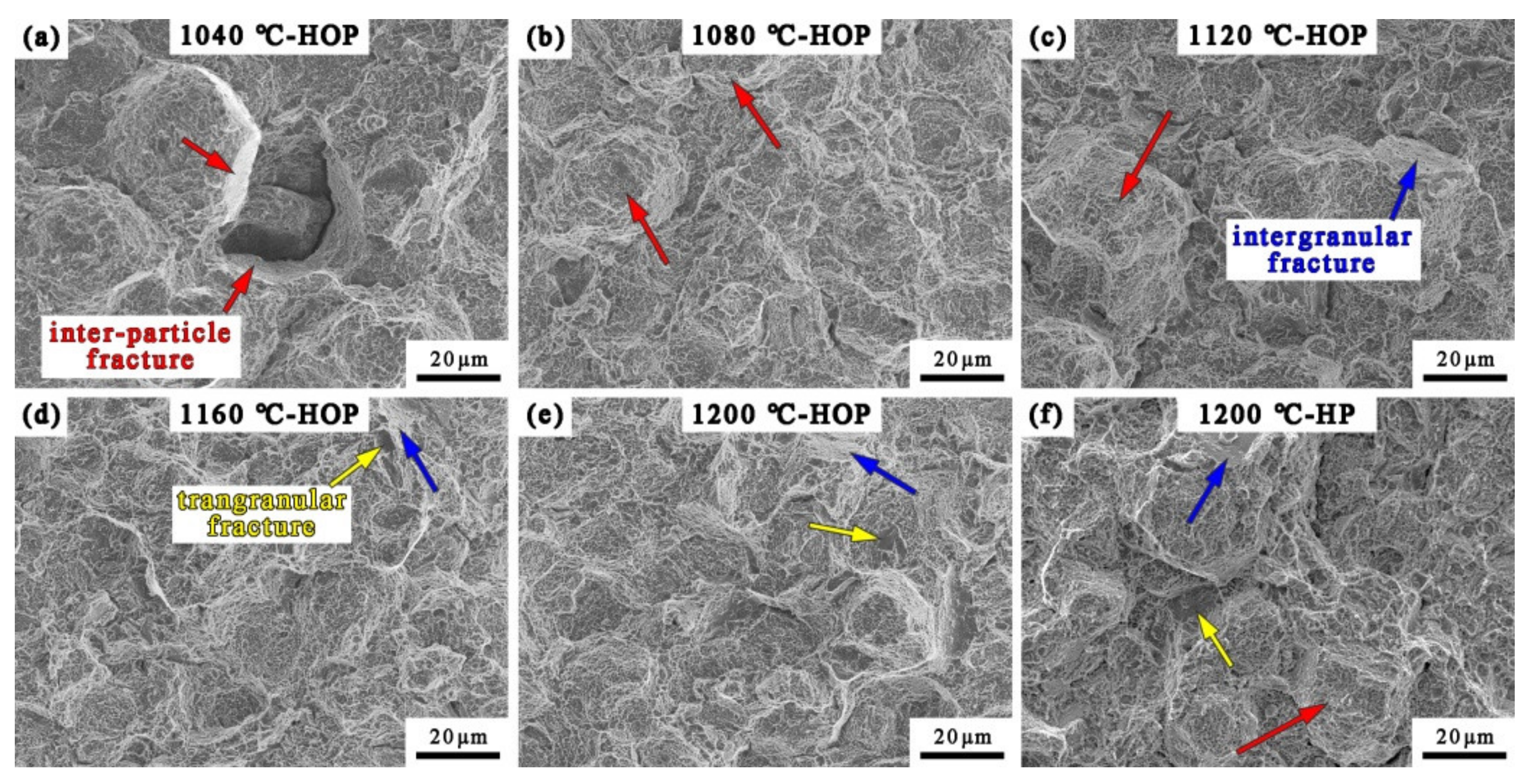

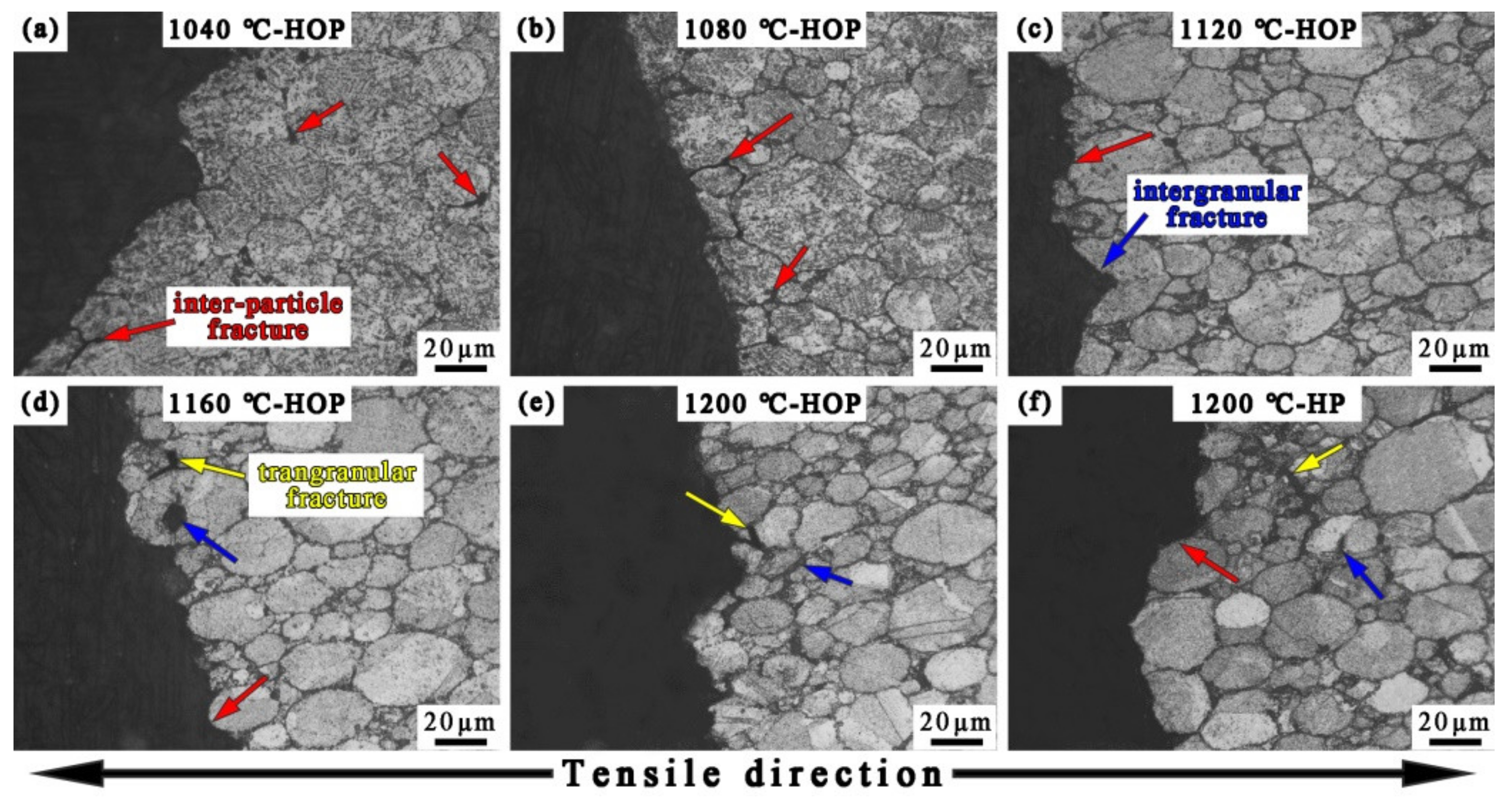

- The coarsened PPBs precipitates lead to a decrease in fracture toughness at the interface between the PPBs precipitates and the γ matrix, and the cracks are more likely to initiate and propagate at this interface. The research results of Zhang Y. et al. [41] show that precipitations on particle boundaries hinder dislocation movement and lead to dislocation pileup. The larger the precipitate size is, the more likely it is to produce the stress concentration at the precipitates and lead to accelerating crack propagation in the area of weak fracture toughness, presenting inter-particle fracture in the sample. The PPBs precipitate size in the 1200 °C-HOP is significantly larger than that in the 1160 °C-HOP, thus the severe stress concentration and dislocation pileup lead to a decrease in the plasticity of the 1200 °C-HOP sample (Figure 8).

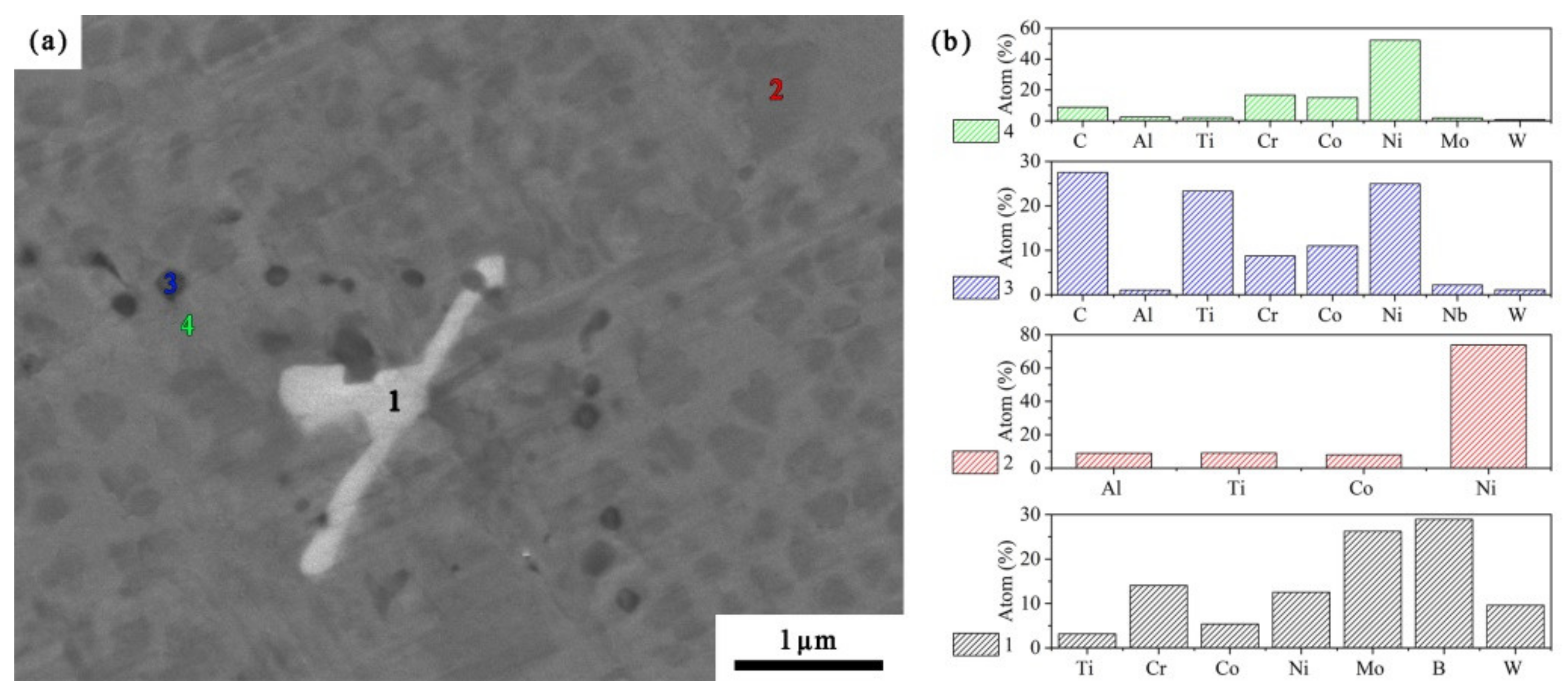

- The intensive dispersion of borides at PPBs is also the reason for the reduction of the tensile properties of materials. As a grain boundary strengthening element, B is added to superalloy powder. But according to the study of Witt M. et al. [42], when the materials HIPed at a high temperature, the B element was more likely to segregate at PPBs and form large borides. It is also presented in this work, as shown in Figure 6. The borides in the 1160 °C-HOP sample are small in size and mainly distributed inside the particles, while the borides in the 1200 °C-HOP sample are large and mainly distributed at PPBs. On the one hand, the intensive dispersion of borides at PPBs leads to the strengthening effect of B on grain boundaries being weakened, which significantly decreases the strength and plasticity of the material, presenting the intergranular fracture in the material. On the other hand, the large borides are more prone to initiating cracks. The segregation of borides at PPBs promotes the initiation and propagation of microcracks, which damages the tensile properties of the material.

4.3. The Effect of Oscillatory Pressure on Microstructure and Tensile Properties

- The PPBs scale is higher in the 1200 °C-HP (Figure 3). The size and volume fraction of the borides and carbides in the 1200 °C-HP are larger than those in the 1200 °C-HOP. The size and volume fraction of the primary γ′ phases are similar in these two samples. More PPBs precipitates damage the tensile properties of the 1200 °C-HP sample;

5. Conclusions

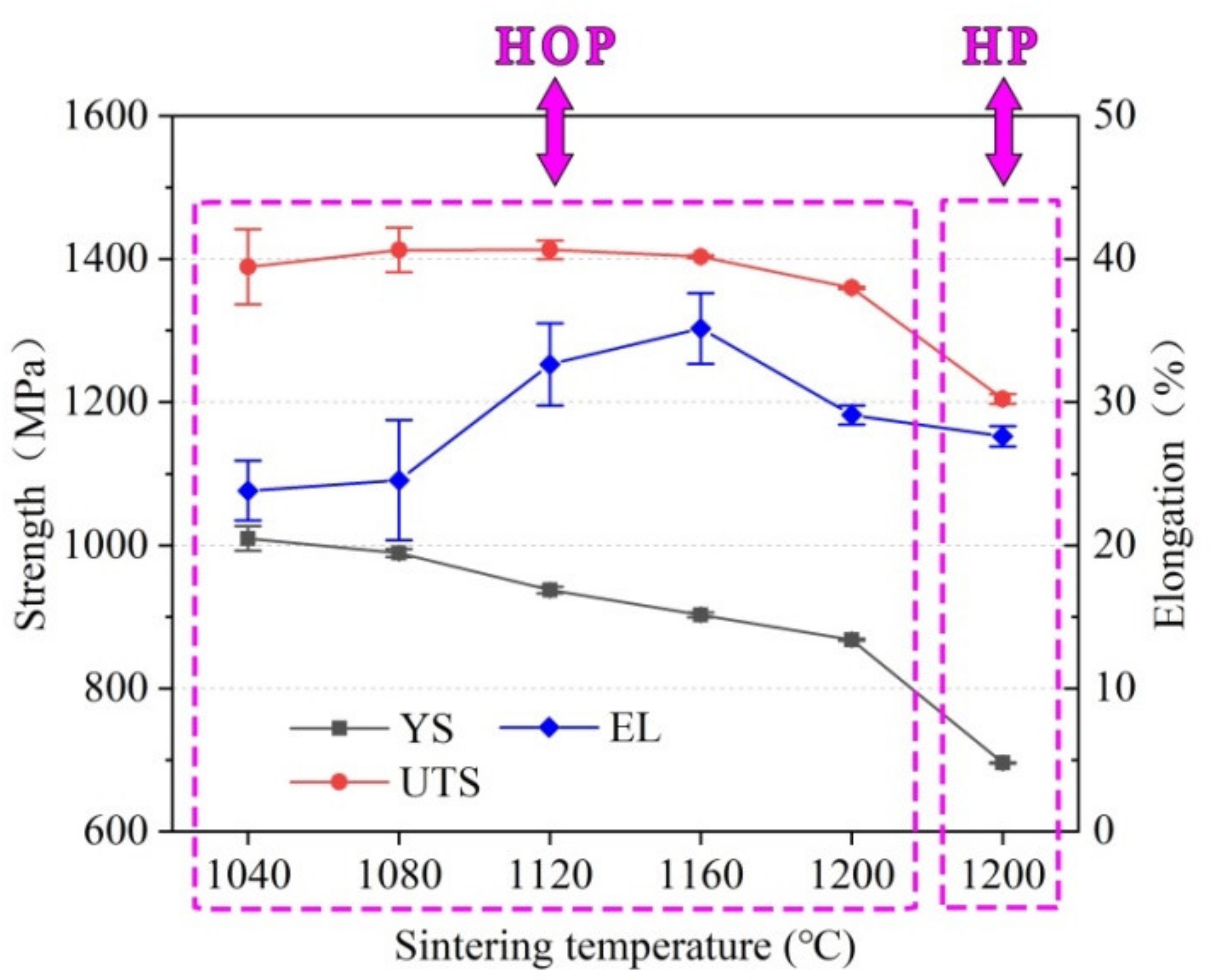

- Stress concentration is prone to be generated at the pores, which provides the path for crack initiation and propagation. It is the reason that poor tensile properties are presented in the samples HOPed at a low temperature (1040 °C-HOP);

- With the increase in HOPing temperature, grain coarsens, the PPBs scale decreases and the PPBs precipitates change from primary γ′ phases dominated to mainly borides and carbides, thus the yield strength decreases and the ultimate tensile strength and elongation increase first and then decrease;

- The highest ultimate tensile strength and elongation of 1403 MPa and 35 %, respectively, are reached when the HOPing temperature is 1160 °C;

- Compared with the HP process, the HOP could decrease the size and density of the PPBs precipitates and significantly enhance their room temperature tensile properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gloria, A.; Montanari, R.; Richetta, M.; Varone, A. Alloys for Aeronautic Applications: State of the Art and Perspectives. Metals 2019, 9, 662. [Google Scholar] [CrossRef]

- Fecht, H.; Furrer, D. Processing of Nickel-Base Superalloys for Turbine Engine Disc Applications. Adv. Eng. Mater. 2000, 2, 777–787. [Google Scholar] [CrossRef]

- Zhu, G.; Li, S.; Wang, R.; Wang, D.; Dong, A.; Shu, D.; Zhang, L.; Sun, B. In-situ SEM investigation on fracture behavior of GTD222 superalloy during tensile process at 760 °C. J. Mater. Res. 2020, 9, 15185–15190. [Google Scholar] [CrossRef]

- Guo, X.; Zheng, W.; An, W.; Antonov, S.; Li, L.; Cormier, J.; Feng, Q. High temperature creep behavior of a cast polycrystalline nickel-based superalloy K465 under thermal cycling conditions. Materialia 2020, 14, 100913. [Google Scholar] [CrossRef]

- Shang, Z.; Niu, H.; Wei, X.; Song, D.; Zou, J.; Liu, G.; Liang, S.; Nie, L.; Gong, X. Microstructure and tensile behavior of nickel-based single crystal superalloys with different Re contents. J. Mater. Res. Technol. 2022, 12, 2458–2469. [Google Scholar] [CrossRef]

- Orozco-Caballero, A.; Gutierrez, C.; Gan, B.; Jon, M.M. High-throughput nanoindentation mapping of cast IN718 nickel-based superalloys: Influence of the Nb concentration. J. Mater. Res. 2021, 36, 2213–2222. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, C.; Wu, Y.; Zhou, L.; Tian, Q. Microstructural stability and mechanical properties of GH742 Ni-based wrought superalloy for turbine disk applications. Mater. Sci. Eng. A 2022, 832, 142488. [Google Scholar] [CrossRef]

- Kumar Godasu, A.; Prakash, U.; Mula, S. Flow stress characteristics and microstructural evolution of cast superalloy 625 during hot deformation. J. Alloys Compd. 2020, 844, 156200. [Google Scholar] [CrossRef]

- Sahithya, K.; Balasundar IPant, P.; Raghu, T. Comparative study on the high temperature deformation behaviour of an as-cast Ni base superalloy subjected to different cooling rates after homogenization. J. Alloys Compd. 2020, 849, 156626. [Google Scholar] [CrossRef]

- Hu, B.; Liu, G.; Jia, C.; Tian, G. Development in new type high performance P/M superalloys. J. Mater. Eng. 2007, 2, 49–53. [Google Scholar]

- Zhang, G.; Zhang, Y.; Zheng, L.; Peng, Z. Research Progress in Powder Metallurgy Superalloys and Manufacturing Technologies for Aero-Engine Application. Acta Metall. Sin. 2019, 55, 1133–1144. [Google Scholar]

- Helle, A.; Easterling, K.; Ashby, M. Hot-isostatic pressing diagrams: New developments. Acta Metall. 1985, 33, 2163–2174. [Google Scholar] [CrossRef]

- Qin, Z.; Liu, C.; Wang, Z.; He, G.; Liu, F.; Huang, L.; Jiang, L. Formation and microstructure evolution of precipitation on prior particle boundaries in P/M nickel-base superalloys. Chin. J. Nonferrous Met. 2016, 1, 50–59. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, C.; Zhao, W.; Zheng, Z.; Zhong, Y. Prior Particle Boundary of PM FGH96 Superalloy and Its In-situ High-cycle Fatigue at Elevated Temperature. J. Aeronaut. Mater. 2017, 37, 83–89. [Google Scholar] [CrossRef]

- Lee, J.; Kim, Y.; Seo, S.; Lee, K. Effects of hot isostatic pressing treatment on the microstructure and tensile properties of Ni-based superalloy CM247LC manufactured by selective laser melting. Mater. Sci. Eng. A 2022, 841, 143083. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, Y.; Liu, P.; Zhang, Y. Study on the PPB defect of P/M superalloy FGH95. Powder Metall. Ind. 2006, 3, 1–5. [Google Scholar] [CrossRef]

- Qiu, C.L.; Attallah, M.M.; Wu, X.H.; Andrews, P. Influence of hot isostatic pressing temperature on microstructure and tensile properties of a nickel-based superalloy powder. Mater. Sci. Eng. A 2013, 564, 176–185. [Google Scholar] [CrossRef]

- Chang, L.; Sun, W.; Cai, Y.; Yang, R. Microstructure, Tensile Properties, and Hot-Working Characteristics of a Hot Isostatic-Pressed Powder Metallurgy Superalloy. Metall. Mater. Trans. A 2017, 48, 1273–1287. [Google Scholar] [CrossRef]

- Bai, Q.; Lin, J.; Tian, G.; Zou, J.; Dean, T. Review and Analysis of Powder Prior Boundary (PPB) Formation in Powder Metallurgy Processes for Nickel-based Super Alloys. J. Powder Metall. Min. 2015, 4, 1000127. [Google Scholar]

- Ning, Y.; Yao, Z.; Li, H.; Guo, H.; Tao, Y.; Zhang, Y. High temperature deformation behavior of hot isostatically pressed P/M FGH4096 superalloy. Mater. Sci. Eng. A 2010, 527, 961–966. [Google Scholar] [CrossRef]

- Wen, H.; Tang, X.; Jin, J.; Cai, C.; Yang, H.; Teng, Q.; Wei, Q.; Wang, X.; Zheng, C.; He, Y.; et al. Effect of extrusion ratios on microstructure evolution and strengthening mechanisms of a novel P/M nickel-based superalloy. Mater. Sci. Eng. A 2022, 847, 143356. [Google Scholar] [CrossRef]

- Lizzi, F.; Pradeep, K.; Stanojevic, A.; Sommadossi, S.; Poletti, M.C. Hot Deformation Behavior of a Ni-Based Superalloy with Suppressed Precipitation. Metals 2021, 11, 605. [Google Scholar] [CrossRef]

- Rao, G.; Srinvias, M.; Sarma, D. Effect of thermomechanical working on the microstructure and mechanical properties of hot isostatically pressed superalloy Inconel 718. Mater. Sci. Eng. A 2004, 383, 201–212. [Google Scholar] [CrossRef]

- Tan, G.; Li, H.; Wang, Y.; Yang, L.; Qiao, S.; Huang, Z.; Liu, M. Hot working characteristics of HEXed PM nickel-based superalloy during hot compression. Trans. Nonferrous Metal. Soc. China 2020, 30, 2709–2723. [Google Scholar] [CrossRef]

- Xie, Z.; Li, S.; An, L. A novel oscillatory pressure-assisted hot pressing for preparation of high performance ceramics. J. Am. Ceram. Soc. 2014, 97, 1012–1015. [Google Scholar] [CrossRef]

- Yuan, Y.; Fan, J.; Li, J.; Liu, J.; Zhao, K.; Liu, D.; An, L. Oscillatory pressure sintering of Al2O3 ceramics. Ceram. Int. 2020, 46, 15670–15673. [Google Scholar] [CrossRef]

- Gao, K.; Xu, Y.; Tang, G.; Fan, L.; Zhang, R.; An, L. Oscillating pressure sintering of W–Ni–Fe refractory alloy. J. Alloys Compd. 2019, 805, 789–793. [Google Scholar] [CrossRef]

- Gao, Y.; Gao, K.; Fan, L.; Yang, F.; Guo, X.; Zhang, R.; An, L. Oscillatory pressure sintering of WC-Fe-Ni cemented carbides. Ceram. Int. 2020, 46, 12727–12731. [Google Scholar] [CrossRef]

- Fan, J.; Yuan, Y.; Li, J.; Liu, J.; Zhao, K.; Liu, D.; An, L. Densification and grain growth in oscillatory pressure sintering of alumina toughened zirconia ceramic composites. J. Alloys Compd. 2020, 845, 155644. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, X.; Fan, J.; Yuan, Y.; Zhao, K.; Liu, J.; An, L. Sintering behavior and mechanical properties of alumina ceramics exposed to oscillatory pressure at different sintering stages. Ceram. Int. 2021, 47, 23682–23685. [Google Scholar] [CrossRef]

- Sun, D.; Zhao, K.; Li, G.; Kang, J.; Gao, K.; Zhang, Z.; Gao, Y.; Fan, L.; An, L. Hot oscillating pressed FGH4096 nickel-based alloy with enhanced ductility and strength. J. Alloys Compd. 2022, 894, 162366. [Google Scholar] [CrossRef]

- Ingesten, N.; Warren, R.; Winberg, L. The Nature and Origin of Previous Particle Boundary Precipitates in P/M Superalloys; Springer: Dordrecht, The Netherlands, 1982; pp. 1013–1027. [Google Scholar]

- Tan, L.; He, G.; Liu, F.; Li, Y.; Jiang, L. Effects of Temperature and Pressure of Hot Isostatic Pressing on the Grain Structure of Powder Metallurgy Superalloy. Materials 2018, 11, 328. [Google Scholar] [CrossRef] [PubMed]

- Sreenu, B.; Sarkar, R.; Satheesh Kumar, S.S.; Chatterjee, S.; Appa Rao, G. Microstructure and mechanical behaviour of an advanced powder metallurgy nickel base superalloy processed through hot isostatic pressing route for aerospace applications. Mater. Sci. Eng. A 2020, 797, 140254. [Google Scholar] [CrossRef]

- Chang, L.; Sun, W.; Cui, Y.; Yang, R. Influences of hot-isostatic-pressing temperature on microstructure, tensile properties and tensile fracture mode of Inconel 718 powder compact. Mater. Sci. Eng. A 2014, 599, 186–195. [Google Scholar] [CrossRef]

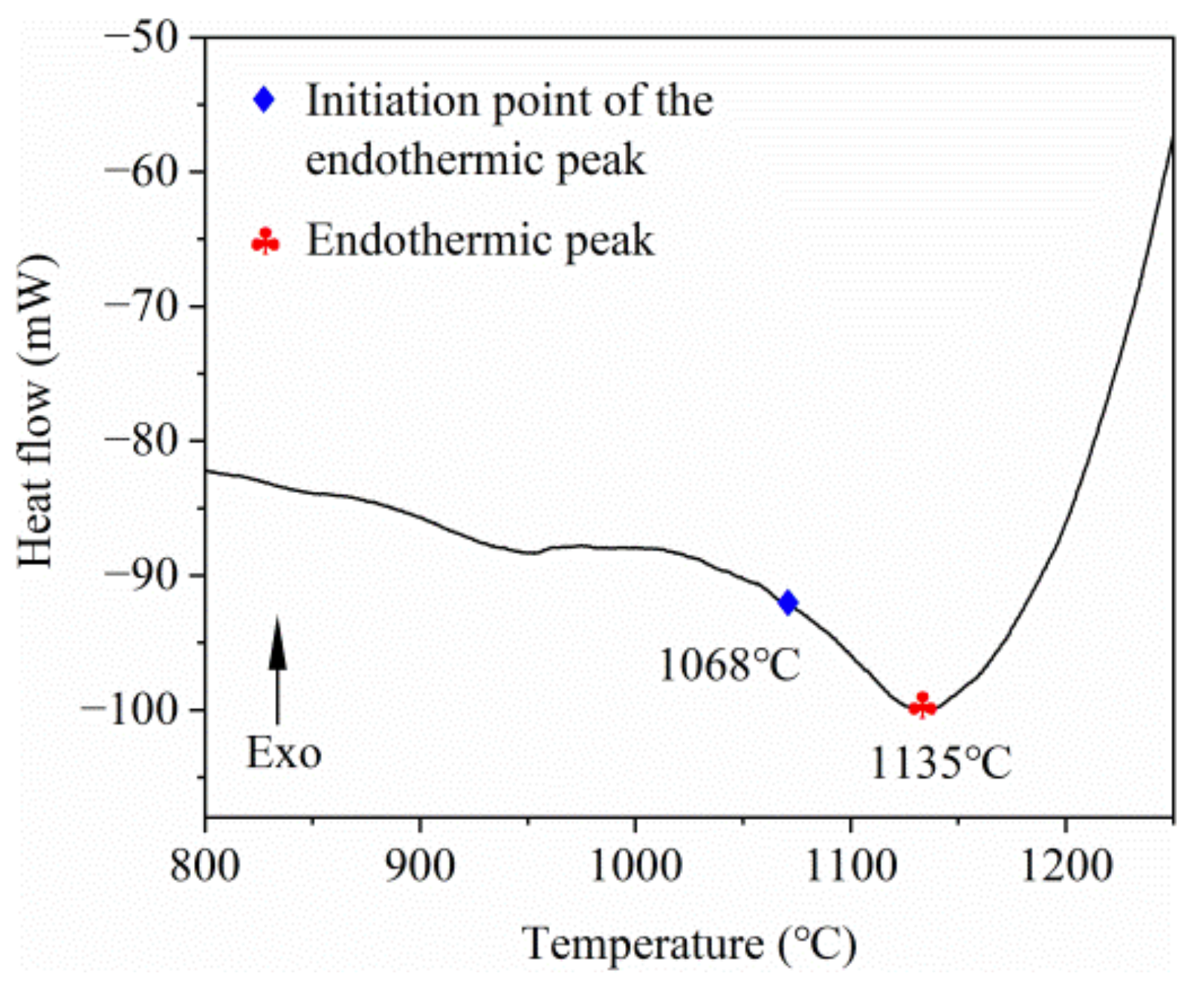

- Fang, B.; Ji, Z.; Tian, G.; Jia, C. Investigation on complete solution temperature of γ′ in the P /M superalloy of FGH96. Powder Metal. Technol. 2013, 31, 89–95. [Google Scholar] [CrossRef]

- Li, C.; Chen, L.; Qu, Z.; Lai, Y.; Liang, S. Measurement of complete dissolution temperature of γ′ phase in nickel-based P /M superalloy FGH4096. Heat Treat. Met. 2021, 46, 174–177. [Google Scholar] [CrossRef]

- Qiu, C.; Yang, D.; Wang, G.; Liu, Q. Microstructural development and tensile behavior of a hot isostatically pressed nickel-based superalloy. Mater. Sci. Eng. A 2020, 769, 138461. [Google Scholar] [CrossRef]

- Alvarado, K.; Janeiro, I.; Florez, S.; Flipon, B.; Franchet, J.-M.; Locq, D.; Dumont, C.; Bozzolo, N.; Bernacki, M. Dissolution of the Primary γ′ Precipitates and Grain Growth during Solution Treatment of Three Nickel Base Superalloys. Metals 2021, 11, 1921. [Google Scholar] [CrossRef]

- Cai, C.; Pan, K.; Teng, Q.; Gao, X.; Song, B.; Liu, J.; Wei, Q.; Zhou, K.; Shi, Y. Simultaneously enhanced strength and ductility of FGH4097 nickel-based alloy via a novel hot isostatic pressing strategy. Mater. Sci. Eng. A 2019, 760, 19–25. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Sun, Z.; Huang, H. Influence of PPB on Crack Growth Behavior of PM Ni-Based Superalloy. Rare Metal Mat. Eng. 2019, 48, 3282–3288. [Google Scholar]

- Witt, M.; Charles, J. Boride particles in a powder metallurgy superalloy. Mater. Sci. Technol. 1985, 1, 1063–1068. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, Y. AES analysis and pre-heat treatment of FGH96 superalloy powders. Chin. J. Nonferrous Met. 2012, 22, 2797–2803. [Google Scholar]

| Carbide | Boride | Primary γ′ | ||||

|---|---|---|---|---|---|---|

| Size/μm | Volume Fraction/% | Size/μm | Volume Fraction/% | Size/μm | Volume Fraction/% | |

| 1040 °C-HOP | 0.21 | 0.21 | 0.48 | 0.12 | 1.32 | 1.77 |

| 1080 °C-HOP | 0.23 | 0.25 | 0.60 | 0.16 | 1.51 | 2.14 |

| 1120 °C-HOP | 0.24 | 0.32 | 0.64 | 0.17 | 1.52 | 2.07 |

| 1160 °C HOP | 0.33 | 0.39 | 0.63 | 0.24 | 1.65 | 1.98 |

| 1200 °C HOP | 0.53 | 0.56 | 1.19 | 0.18 | 2.02 | 1.96 |

| 1200 °C-HP | 0.67 | 0.67 | 1.68 | 0.28 | 1.94 | 1.92 |

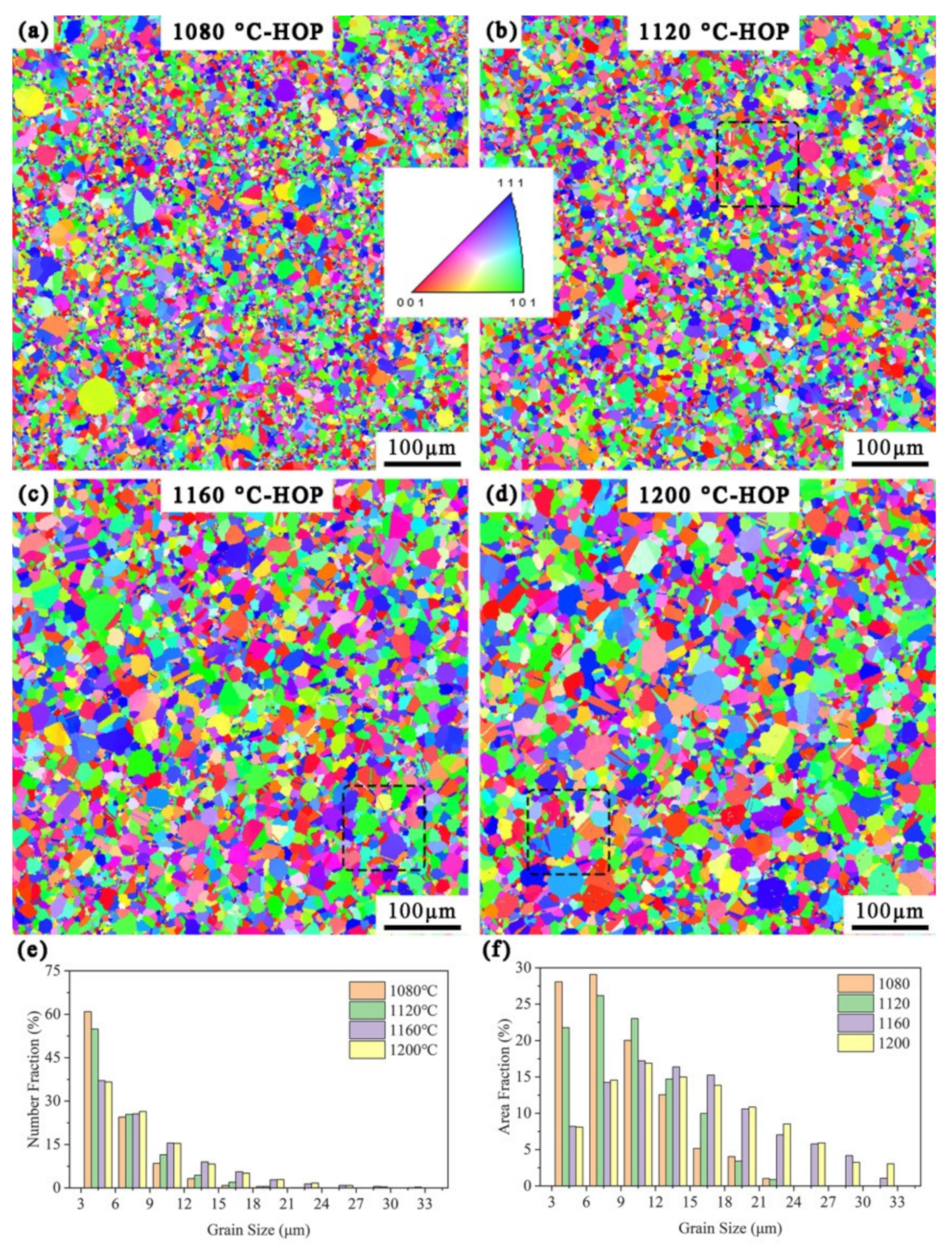

| HOPing Temperature/°C | Grain Size (Number Fraction)/μm | Grain Size (Area Fraction)/μm |

|---|---|---|

| 1080 | 6.08 | 9.09 |

| 1120 | 6.56 | 9.85 |

| 1160 | 8.58 | 14.28 |

| 1200 | 8.59 | 14.34 |

| HOPing Temperature/°C | The Volume Fraction of γ′/% |

|---|---|

| 1040 | 38.52 |

| 1080 | 39.66 |

| 1120 | 38.22 |

| 1160 | 37.84 |

| 1200 | 35.75 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Sun, D.; Kang, J.; Gao, Y.; Yan, X.; Gao, Q.; Gao, K. The Effect of Hot Oscillatory Pressing Temperature on Microstructure and Tensile Behavior of Powder Metallurgy Superalloy. Metals 2022, 12, 1652. https://doi.org/10.3390/met12101652

Li G, Sun D, Kang J, Gao Y, Yan X, Gao Q, Gao K. The Effect of Hot Oscillatory Pressing Temperature on Microstructure and Tensile Behavior of Powder Metallurgy Superalloy. Metals. 2022; 12(10):1652. https://doi.org/10.3390/met12101652

Chicago/Turabian StyleLi, Guizhong, Dejian Sun, Jiachen Kang, Yang Gao, Xuewei Yan, Qiancheng Gao, and Ka Gao. 2022. "The Effect of Hot Oscillatory Pressing Temperature on Microstructure and Tensile Behavior of Powder Metallurgy Superalloy" Metals 12, no. 10: 1652. https://doi.org/10.3390/met12101652

APA StyleLi, G., Sun, D., Kang, J., Gao, Y., Yan, X., Gao, Q., & Gao, K. (2022). The Effect of Hot Oscillatory Pressing Temperature on Microstructure and Tensile Behavior of Powder Metallurgy Superalloy. Metals, 12(10), 1652. https://doi.org/10.3390/met12101652