Effect of Tungsten Addition on Continuous Cooling Transformation and Precipitation Behavior of a High Titanium Microalloyed Steel

Abstract

1. Introduction

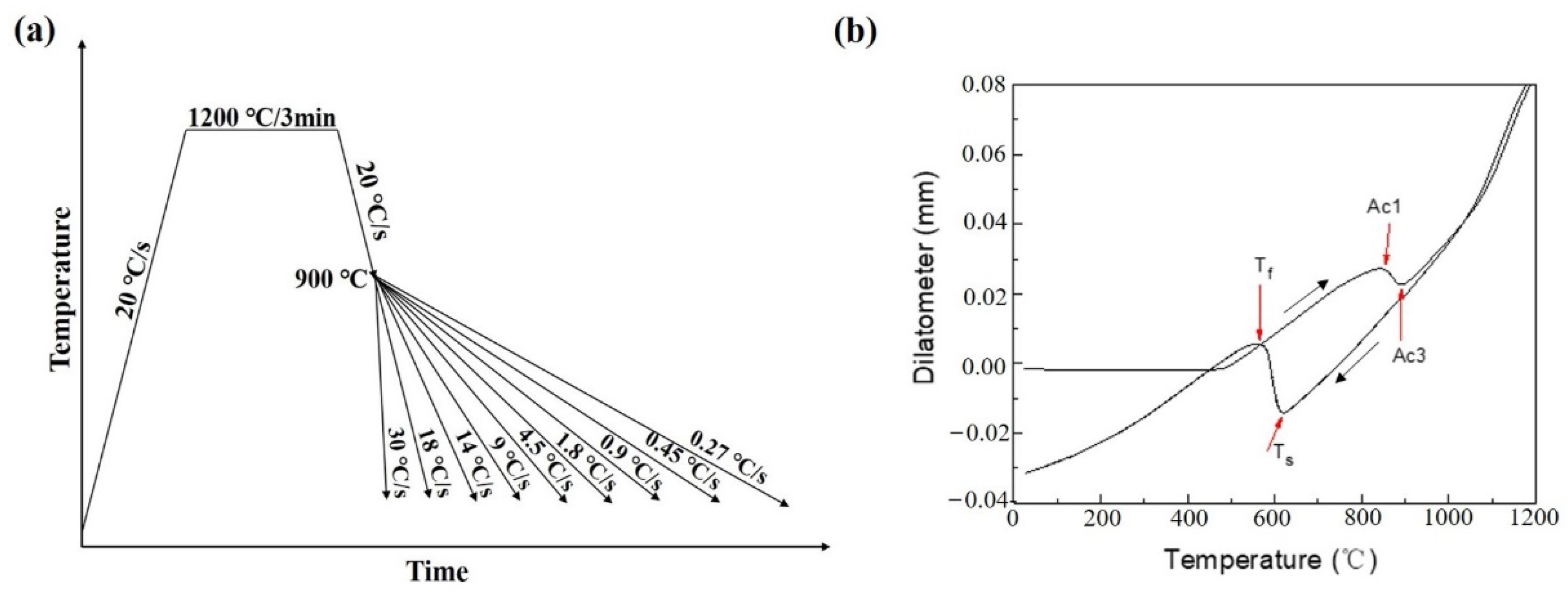

2. Materials and Methods

3. Results

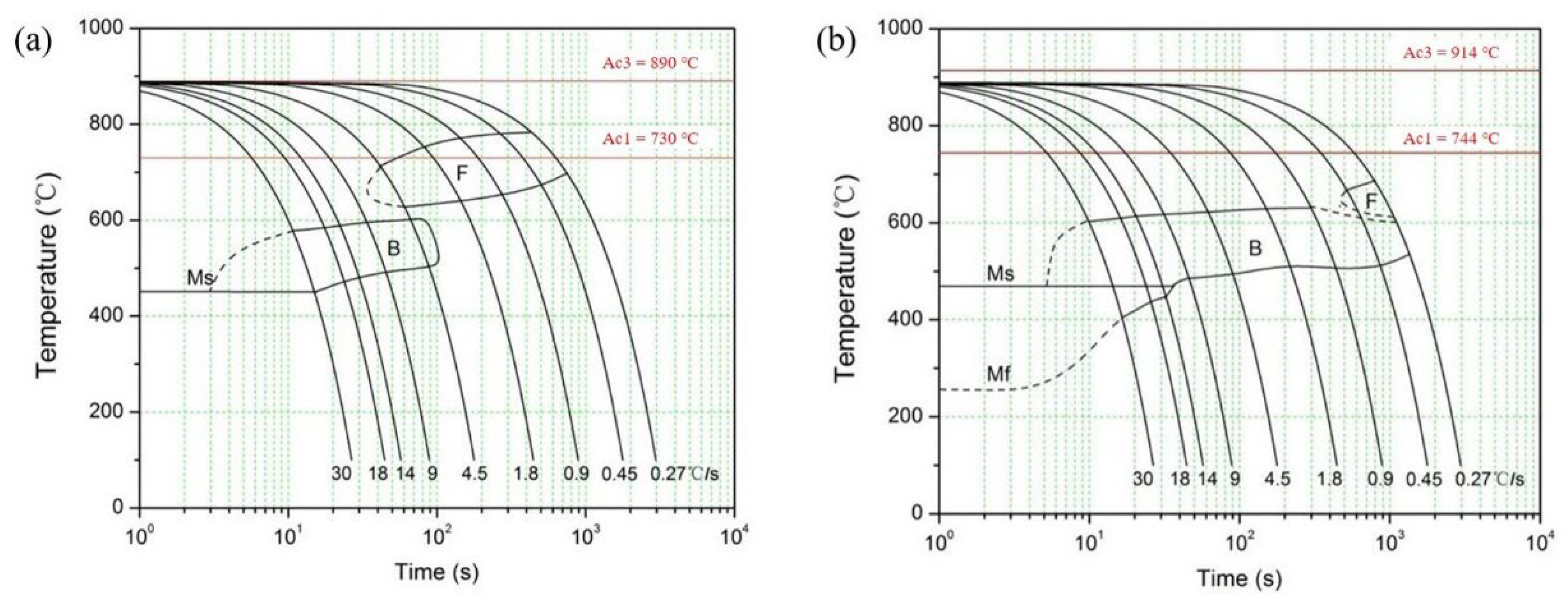

3.1. CCT Diagram

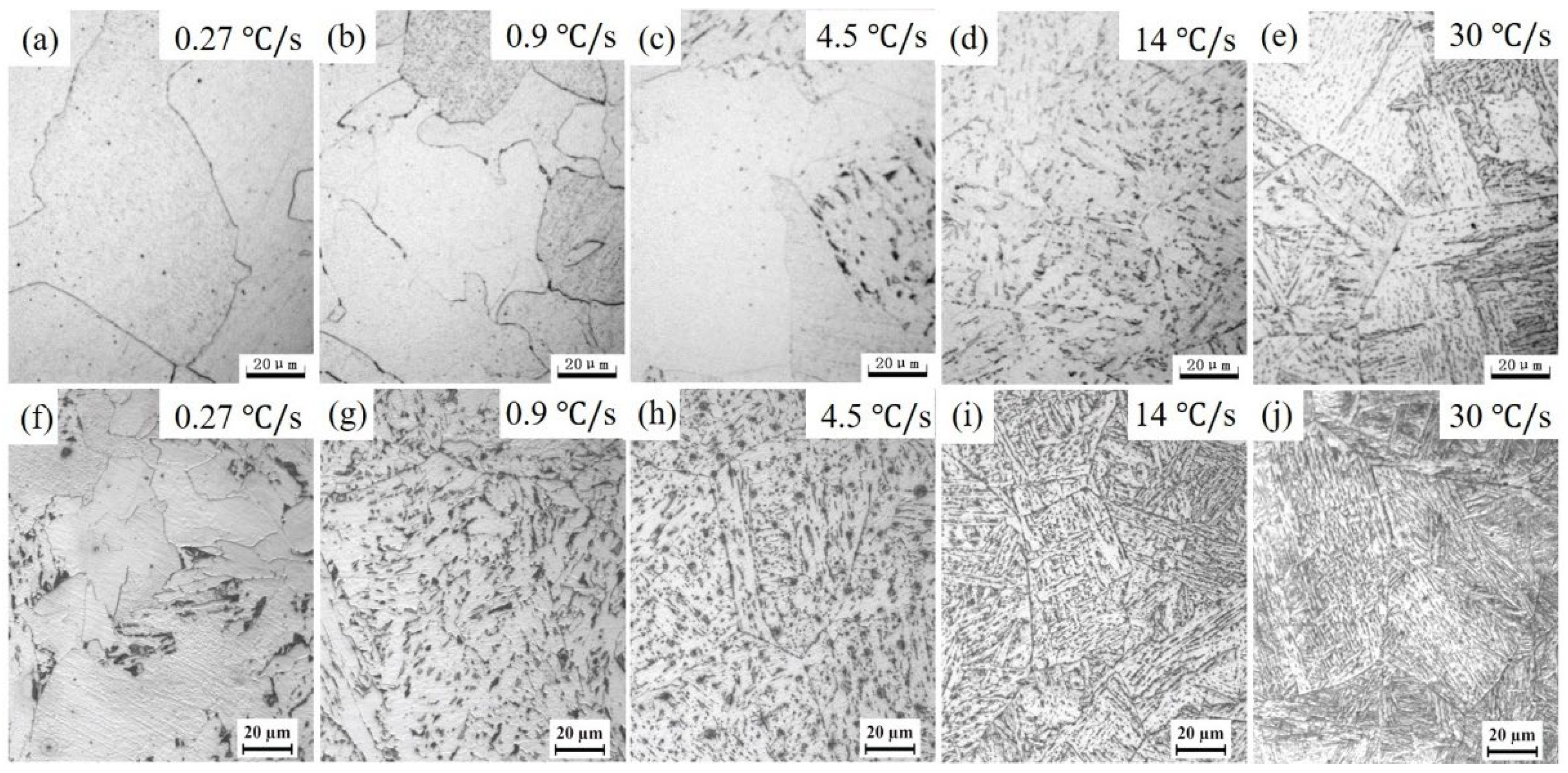

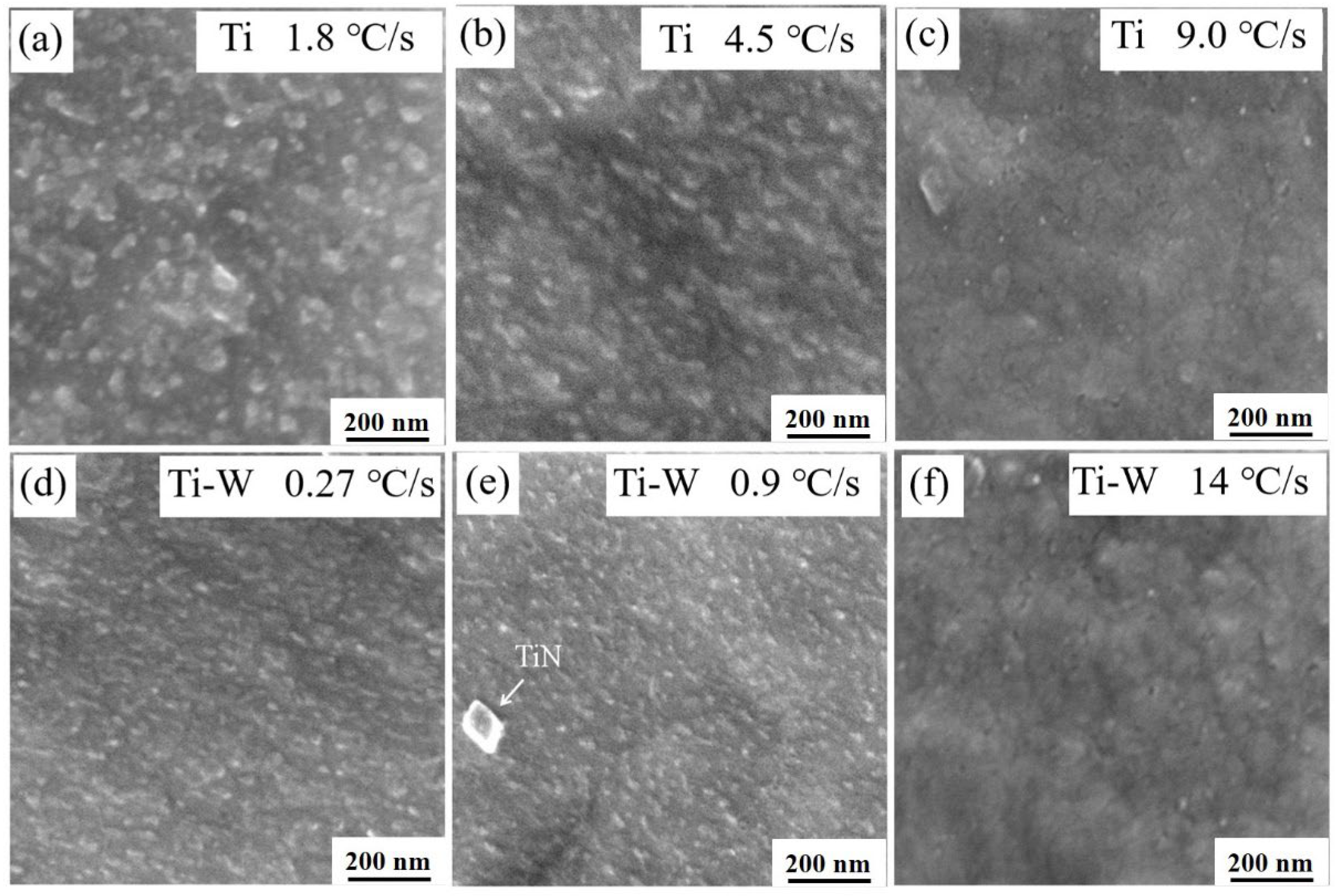

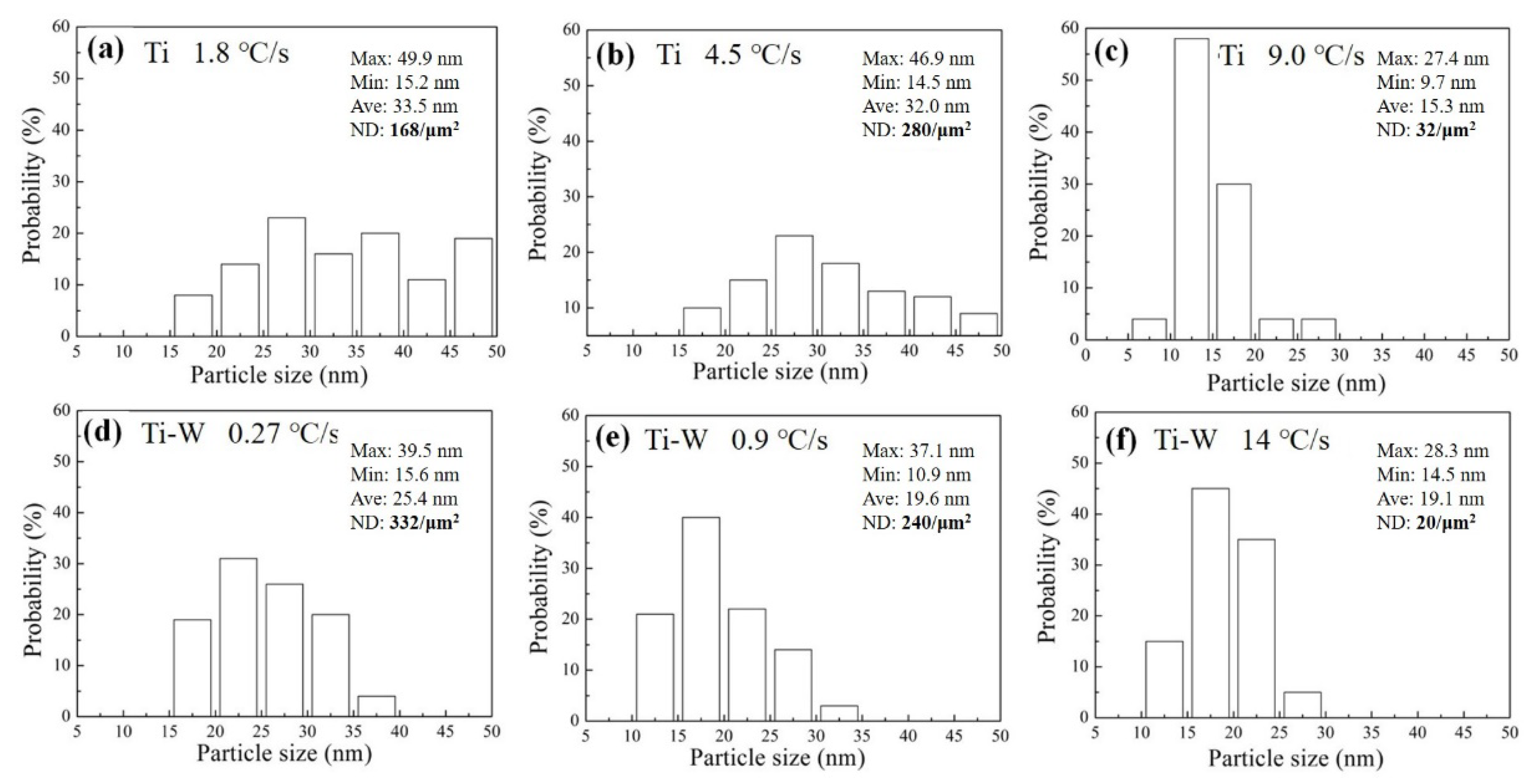

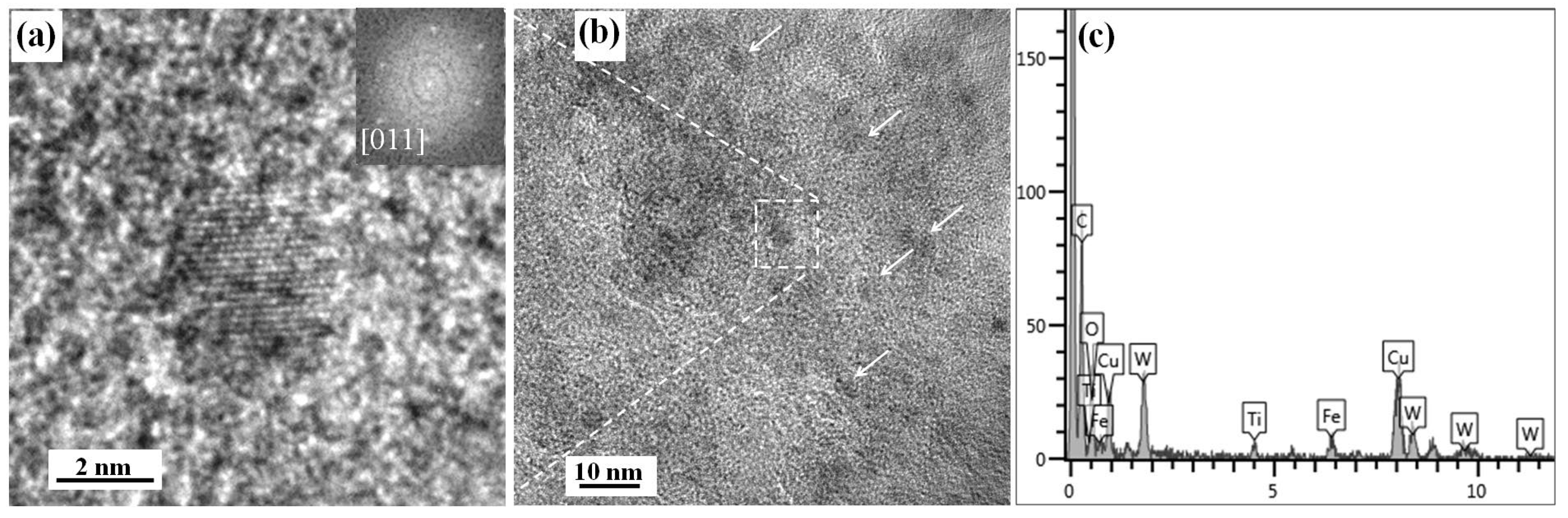

3.2. Microstructural Evolution

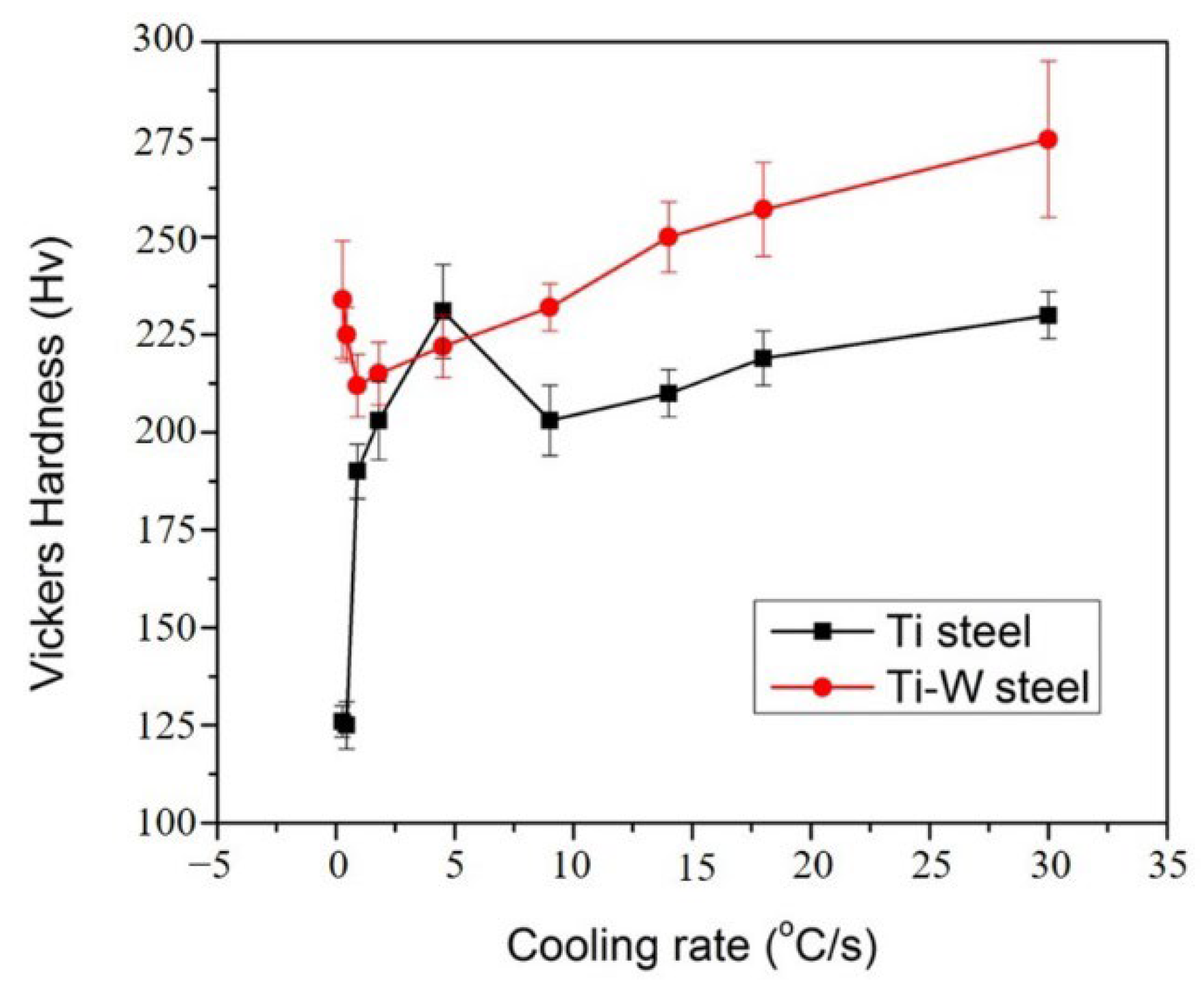

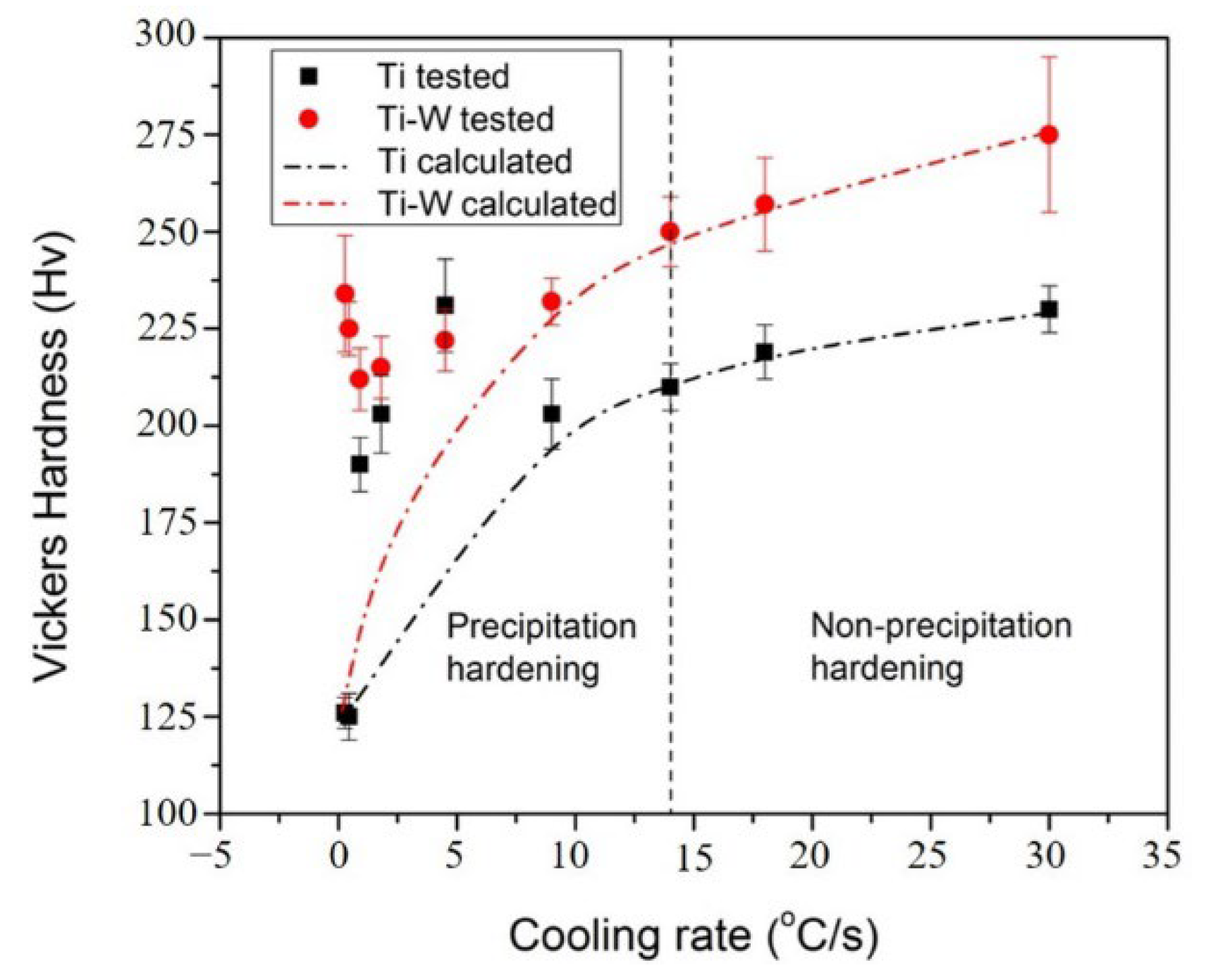

3.3. Hardness

4. Discussion

4.1. Effect of W Addition on the Microstructural Evolution

4.2. Relationships among Cooling Process, Transformation and Precipitation and the Effects of W Addition

5. Conclusions

- (1)

- W addition shifts the range of transformation products to the right side of the diagram. The ferrite transformation range moves to the side of lower cooling rates and reduced temperatures, and the bainite phase transformation range runs throughout the whole studied cooling rate range.

- (2)

- W addition increases the ferrite to austenite transformation temperatures. The measured Ac1 and Ac3 temperatures for Ti and Ti-W steels are Ac1 = 730 °C and Ac3 = 890 °C for Ti steel; and Ac1 = 744 °C and Ac3 = 914 °C for Ti-W steel.

- (3)

- W addition promotes the refinement of particle size and increases the number density of precipitates. The precipitates in Ti-W steel were identified as MC-type carbide with a high level of W and a small amount of Ti and Fe.

- (4)

- In the precipitation hardening region, W addition moves the precipitation hardening peak to lower cooling rates, which is attributed to the shift of ferrite phase transformation to low cooling rates and reduced temperatures after W addition. In the non-precipitation region, W addition exerts significant transformation strengthening effect with the increase in hardness of 40 HV.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yong, Q.L. Microalloyed Steels-Physical and Mechanical Metallurgy; Metallurgical Industry Press: Beijing, China, 1989. [Google Scholar]

- Mao, X.P.; Huo, X.D.; Sun, X.J. Strengthening mechanisms of a new 700 MPa hot rolled Ti-microalloyed steel produced by compact strip production. J. Mater. Proc. Technol. 2010, 210, 1660–1666. [Google Scholar] [CrossRef]

- Mao, X.P.; Sun, X.J.; Zhou, Y.L. Physical metallurgy for the titanium microalloyed strip produced by thin slab casting and rolling process. Acta Metall. Sin. 2006, 42, 1091–1095. [Google Scholar]

- Xu, G.; Gan, X.L.; Ma, G.J. The development of Ti-alloyed high strength microalloy steel. Mater. Des. 2010, 31, 2891–2896. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Mao, X.P.; Yang, Z.G. Strain-induced precipitation in a Ti micro-alloyed HSLA steel. Mater. Sci. Eng. A 2011, 529, 459–467. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Yong, Q.L.; Sun, X.J. An analytical model for the kinetics of strain-induced precipitation in titanium micro-alloyed steels. ISIJ Int. 2012, 52, 1661–1669. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Sun, X.J.; Yang, Z.G. Effect of Mn concentration on the kinetics of strain induced precipitation in Ti microalloyed steels. Mater. Sci. Eng. A 2013, 561, 212–219. [Google Scholar] [CrossRef]

- Tsai, S.P.; Su, T.C.; Yang, J.R. Effect of Cr and Al additions on the development of interphase-precipitated carbides strengthened dual-phase Ti-bearing steels. Mater. Des. 2017, 119, 319–325. [Google Scholar] [CrossRef]

- Wang, T.P.; Kao, F.H.; Wang, S.H. Isothermal treatment influence on nanometer-size carbide precipitation of titanium-bearing low carbon steel. Mater. Lett. 2011, 65, 396–399. [Google Scholar] [CrossRef]

- Huo, X.D.; Li, L.J.; Peng, Z.W. Effects of TMCP schedule on precipitation, microstructure and properties of Ti-Microalloyed high strength steel. J. Iron Steel Res. Int. 2016, 23, 593–601. [Google Scholar] [CrossRef]

- Funakawa, Y.; Shiozaki, T.; Tomita, K. Development of high strength hot-rolled sheet steel consisting of ferrite and nanometer-sized carbides. ISIJ Int. 2004, 44, 1945–1951. [Google Scholar] [CrossRef]

- Jang, J.H.; Lee, C.H.; Heo, Y.U. Stability of (Ti, M)C (M = Nb, V, Mo and W) carbide in steels using first-principles calculations. Acta Mater. 2012, 60, 208–217. [Google Scholar] [CrossRef]

- Park, D.B.; Huh, M.Y.; Shim, J.H. Strengthening mechanism of hot rolled Ti and Nb microalloyed HSLA steels containing Mo and W with various coiling temperature. Mater. Sci. Eng. A 2013, 560, 528–534. [Google Scholar] [CrossRef]

- Timokhina, I.; Miller, M.K.; Wang, J.T. On the Ti-Mo-Fe-C atomic clustering during interphase precipitation in the Ti-Mo steel studied by advanced microscopic techniques. Mater. Des. 2016, 111, 222–229. [Google Scholar] [CrossRef]

- Zhang, K.; Yong, Q.L.; Sun, X.J. Effect of tempering temperature on microstructure and mechanical properties of high Ti microalloyed directly quenched high strength steel. Acta Metall. Sin. 2014, 50, 913–920. [Google Scholar]

- Zhang, K.; Li, Z.D.; Wang, Z.Q. Precipitation behavior and mechanical properties of hot-rolled high strength Ti-Mo-bearing sheet steel: The great potential of nanometer-sized (Ti, Mo)C carbide. J. Mater. Res. 2016, 31, 1254–1263. [Google Scholar] [CrossRef]

- Kim, Y.W.; Song, S.W.; Seo, S.J. Development of Ti and Mo micro-alloyed hot-rolled high strength sheet steel by controlling thermomechanical controlled processing schedule. Mater. Sci. Eng. A 2013, 565, 430–438. [Google Scholar] [CrossRef]

- Seol, J.B.; Na, S.H.; Gault, B. Core-shell nanoparticles arrays double the strength of steel. Sci. Rep. 2017, 7, 42547. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Zhang, H.; Guo, C.H. Evolution of (Ti, Mo)C particles in austenite of a Ti-Mo-bearing steel. Mater. Des. 2016, 109, 361–366. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Zhang, H.; Guo, C.H. Effect of molybdenum addition on the precipitation of carbides in the austenite matrix of titanium micro-alloyed steels. J. Mater. Sci. 2016, 51, 4996–5007. [Google Scholar] [CrossRef]

- Peng, Z.W.; Li, L.J.; Chen, S.J. Isothermal precipitation kinetics of carbides in undercooled austenite and ferrite of a titanium microalloyed steel. Mater. Des. 2016, 108, 289–297. [Google Scholar] [CrossRef]

- Totten, G.E. Steel Heat Treatment: Metallurgy of Microalloyed Steels, 2nd ed.; CRC Press: Boca Raton, FL, USA, 1997. [Google Scholar]

- Zhao, J.W.; Jiang, Z.Y.; Kim, J.S. Effect of tungsten on continuous cooling transformation characteristics of microalloyed steel. Mater. Des. 2013, 49, 252–258. [Google Scholar] [CrossRef]

- Zhao, J.W.; Jiang, Z.Y.; Lee, C.S. Effect of tungsten addition and heat treatment conditions on microstructure and mechanical properties of microalloyed forging steels. Mater. Sci. Eng. A 2013, 562, 144–151. [Google Scholar] [CrossRef][Green Version]

- Zhao, J.W.; Lee, T.W.; Lee, J.H. Effects of tungsten addition on the microstructure and mechanical properties of microalloyed forging steels. Metall. Mater. Trans. A 2013, 44, 3511–3523. [Google Scholar] [CrossRef]

- Andrens, K.W. Empirical formula for calculation of some transformation temperatures. JISI 1965, 203, 721–727. [Google Scholar]

- Chen, J.; Tang, S.; Liu, Z. Influence of molybdenum content on transformation behavior of high performance bridge steel during continuous cooling. Mater. Des. 2013, 49, 465–470. [Google Scholar] [CrossRef]

- Kong, J.H.; Xie, C.S. Effect of molybdenum on continuous cooling bainite transformation of low-carbon microalloyed steel. Mater. Des. 2006, 27, 1169–1173. [Google Scholar] [CrossRef]

- Yong, Q.L. Secondary Phases in Steels; Metallurgical Industry Press: Beijing, China, 2006. [Google Scholar]

- Wang, B.; Fu, W.; Li, Y. Study of the phase diagram and continuous cooling transformation of 12%Cr ultra-super-critical rotor steel. Mater. Charact. 2008, 59, 1133–1136. [Google Scholar] [CrossRef]

| Steel | C | Mn | Si | Ti | W | S | P | N |

|---|---|---|---|---|---|---|---|---|

| Ti | 0.046 | 1.47 | 0.12 | 0.097 | - | 0.0060 | 0.0073 | 0.0024 |

| Ti-W | 0.041 | 1.50 | 0.20 | 0.095 | 0.39 | 0.0028 | 0.0060 | 0.0018 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Huo, D.; Zhou, Y.; Sui, G.; Jiang, F. Effect of Tungsten Addition on Continuous Cooling Transformation and Precipitation Behavior of a High Titanium Microalloyed Steel. Metals 2022, 12, 1649. https://doi.org/10.3390/met12101649

Wang Z, Huo D, Zhou Y, Sui G, Jiang F. Effect of Tungsten Addition on Continuous Cooling Transformation and Precipitation Behavior of a High Titanium Microalloyed Steel. Metals. 2022; 12(10):1649. https://doi.org/10.3390/met12101649

Chicago/Turabian StyleWang, Zhenqiang, Dongshen Huo, Yanyuan Zhou, Guoying Sui, and Fengchun Jiang. 2022. "Effect of Tungsten Addition on Continuous Cooling Transformation and Precipitation Behavior of a High Titanium Microalloyed Steel" Metals 12, no. 10: 1649. https://doi.org/10.3390/met12101649

APA StyleWang, Z., Huo, D., Zhou, Y., Sui, G., & Jiang, F. (2022). Effect of Tungsten Addition on Continuous Cooling Transformation and Precipitation Behavior of a High Titanium Microalloyed Steel. Metals, 12(10), 1649. https://doi.org/10.3390/met12101649