Investigation of Strength and Formability of 6016 Aluminum Tailor Welded Blanks

Abstract

:1. Introduction

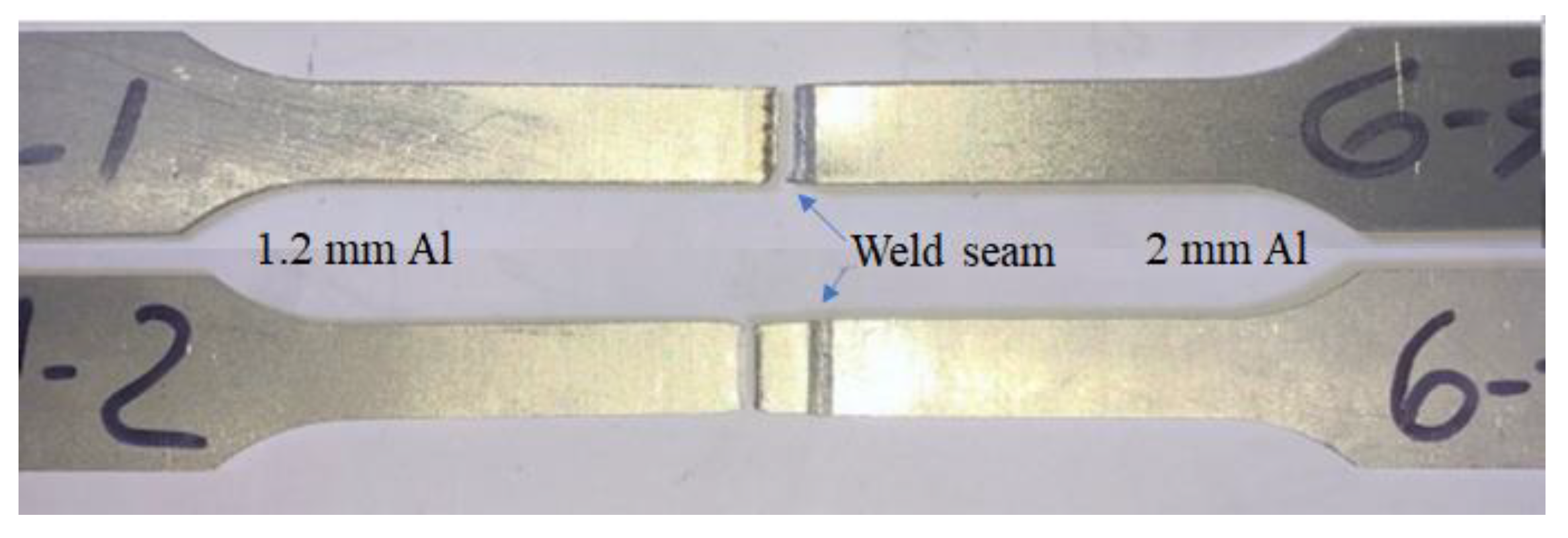

2. Materials and Methods

3. Results

3.1. Metallographic Examination

3.2. Tensile Test

3.3. Erichsen Test

4. Conclusions

- -

- The largest heat inputs (from 75 J/mm) generate welded joints with large porosity. The porosity has a clear effect on reducing the strength of the joints. Moreover, the largest root concavity and joint aspect ratio have been obtained at these heat input levels.

- -

- Under the tensile test, the joints fracture in the thinner base metals with the smallest cross-sectional area when they show a low amount of porosity.

- -

- The more resistant joints exhibit a tensile strength of around 190 MPa vs. 240 MPa of the base metals. The elongation at fracture of the welded joints is notably lower than the base metal (5% vs. 19%). This difference is mainly due to the dissimilar thickness of the welded samples, with the thinner sheet that elongates more than the thicker aluminum sheet.

- -

- The Erichsen index is about 3.5–3.7 mm for the more ductile welded joints vs. an index of 7 mm measured for the 2 mm thick aluminum sheet.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Peister, C.; George, L.; Omer, K.; Worswick, M.J.; Malcolm, S.; Dykeman, J.; Yau, C.; Soldaat, R.; Bernert, W. Forming of an axially tailored automotive channel section through hot stamping of tailor-welded blanks. J. Phys. Conf. Ser. 2017, 896, 012052. [Google Scholar] [CrossRef]

- Merklein, M.; Johannes, M.; Lechner, M.; Kuppert, A. A review on tailored blanks—Production, applications and evaluation. J. Mater. Proc. Technol. 2014, 214, 151–164. [Google Scholar] [CrossRef]

- Friedman, P.A.; Kridli, G.T. Microstructural and mechanical investigation of aluminum tailor-welded blanks. J. Mater. Eng. Perform. 2000, 9, 541–551. [Google Scholar] [CrossRef]

- Snopiński, P.; Tański, T.; Gołombek, K.; Rusz, S.; Hilser, O.; Donič, T.; Nuckowski, P.M.; Benedyk, M. Strengthening of AA5754 Aluminum Alloy by DRECE Process Followed by Annealing Response Investigation. Materials 2020, 13, 301. [Google Scholar] [CrossRef] [PubMed]

- Cao, X.; Wallace, W.; Poon, C.; Immarigeon, J.P. Research and progress in laser welding of wrought aluminum alloys. I. Laser welding processes. Mater. Manuf. Proc. 2003, 18, 1–22. [Google Scholar] [CrossRef]

- Liu, H.J.; Fujii, H.; Maeda, M.; Nogi, K. Tensile properties and fracture locations of friction-stir-welded joints of 2017-T351 aluminum alloy. J. Mater. Proc. Technol. 2003, 142, 692–696. [Google Scholar] [CrossRef]

- Aydın, H.; Bayram, A.; Uguz, A.; Akay, K.S. Tensile properties of friction stir welded joints of 2024 aluminum alloys in different heat-treated-state. Mater. Des. 2009, 30, 2211–2221. [Google Scholar] [CrossRef]

- Zadpoor, A.A.; Sinke, J.; Benedictus, R. Mechanics of tailor welded blanks: An overview. Key Eng. Mater. 2007, 344, 373–382. [Google Scholar] [CrossRef]

- Shakeri, H.R.; Buste, A.; Worswick, M.J.; Clarke, J.A.; Feng, F.; Jain, M.; Finn, M. Study of damage initiation and fracture in aluminum tailor welded blanks made via different welding techniques. J. Light Met. 2002, 2, 95–110. [Google Scholar] [CrossRef]

- Shibata, K.; Iwase, T.; Sakamoto, H.; Kasukawa, M.; Chiba, K.; Saeki, H. Welding of aluminium tailored blanks by Nd: YAG lasers. Weld. Int. 2003, 17, 282–286. [Google Scholar] [CrossRef]

- Wang, A.; Liu, J.; Gao, H.; Wang, L.; Masen, M. Hot stamping of AA6082 tailor welded blanks: Experiments and knowledge-based cloud—Finite element (KBC-FE) simulation. J. Mater. Proc. Technol. 2017, 250, 228–238. [Google Scholar] [CrossRef]

- Bagheri, B.; Abbasi, M.; Hamzeloo, R. Comparison of different welding methods on mechanical properties and formability behaviors of tailor welded blanks (TWB) made from AA6061 alloys. J. Mech. Eng. Sci. 2021, 235, 2225–2237. [Google Scholar] [CrossRef]

- Jie, M.; Cheng, C.; Chan, L.; Tang, C. Experimental and theoretical analysis on formability of aluminum tailor-welded blanks. J. Eng. Mater. Technol. 2006, 129, 151–158. [Google Scholar] [CrossRef]

- Liu, J.; Wang, L.L.; Lee, J.; Chen, R.; El Fakir, O.; Chen, L.; Lin, J.; Dean, T.A. Size-dependent mechanical properties in AA6082 tailor welded specimens. J. Mater. Proc. Technol. 2015, 224, 169–180. [Google Scholar] [CrossRef]

- Miles, M.P.; Decker, B.J.; Nelson, T.W. Formability and strength of friction-stir welded Aluminum sheets. Metall. Mater. Trans. A 2004, 35, 3461–3468. [Google Scholar] [CrossRef]

- Parente, M.; Safdarian, R.; Santos, A.D.; Lourerio, A.; Vilaca, P.; Natal Jorge, R.M. A study on the formability of aluminum tailor welded blanks produced by friction stir welding. Int. J. Adv. Manuf. Technol. 2016, 83, 2129–2141. [Google Scholar] [CrossRef]

- ISO 4136:2022; Destructive Tests on Welds in Metallic Materials—Transverse Tensile Test. International Standard of Organization (ISO): Geneva, Switzerland, 2022.

- ISO 20482:2013; Metallic Materials—Sheet and Strip Erichsen Cupping Test. International Standard of Organization (ISO): Geneva, Switzerland, 2013.

- ISO 13919-2; Electron and Laser-beam Welded Joints—Requirements and Recommendations on Quality Levels for Imperfections—Part 2: Aluminium, Magnesium and Their Alloys and Pure Copper. International Standard of Organization (ISO): Geneva, Switzerland, 2021.

- Story, J.M.; Heinemann, S.; Naefeler, S. Forming and joining issues and processes for aluminum tailor welded blank application. Light Metal Age 1998, 56, 40–47. [Google Scholar]

- Venkat, S.; Albrigth, C.E.; Ramasamy, S.; Hurley, J.P. CO2 laser beam welding of aluminum 5754-O and 6111-T4 alloys. Weld. J. 1997, 76, 275s–282s. [Google Scholar]

- Stasik, M.C.; Wagoner, R.H. Aluminum and Magnesium for Automotive Applications; Bryant, J.D., Ed.; TMS: Warrendale, PA, USA, 1996; pp. 69–83. [Google Scholar]

- Sun, T.; Franciosa, P.; Ceglarek, D. Effect of focal position offset on joint integrity of AA1050 battery busbar assembly during remote laser welding. J. Mater. Res. Technol. 2021, 14, 2715–2726. [Google Scholar] [CrossRef]

- Kim, J.S.; Watanabe, T.; Yoshida, Y. Effect of the beam-defocusing characteristics on porosity formation in laser welding. J. Mater. Sci. Lett. 1995, 14, 1624–1626. [Google Scholar] [CrossRef]

- Kutsuna, M.; Yan, Q. Study on porosity formation in laser welds of aluminium alloys. Weld. Int. 2010, 13, 597–611. [Google Scholar] [CrossRef]

- Suh, C.H.; Jung, Y.C.; Kim, Y.S. Effects of thickness and surface roughness on mechanical properties of aluminium sheets. J. Mech. Sci. Technol. 2010, 24, 2091–2098. [Google Scholar] [CrossRef]

- Deepika, D.; Lakshmi, A.A.; Rao, C.S.; Sateesh, N.; Nookaraju, B.C.; Subbiah, R. Formability of tailor welded blanks of aluminium alloy and steel—A review. Mater. Today 2021, 46, 722–728. [Google Scholar] [CrossRef]

| Al Alloy | Al | Mg | Si | Mn | Fe | Cr | Cu | Zn | Ti |

|---|---|---|---|---|---|---|---|---|---|

| 6016 | bal. | 0.3–0.6 | 1.0–1.5 | ≤0.2 | ≤0.5 | - | ≤0.2 | - | - |

| No. Run | Laser Power (%) | Welding Speed (-) | Focus Position (mm) | Heat Input (J/mm) |

|---|---|---|---|---|

| 1 | 62.5 | 1.25 | 1.5 | 60 |

| 2 | 62.5 | 1 | 1 | 75 |

| 3 | 62.5 | 1.5 | 2 | 50 |

| 4 | 67.5 | 1.25 | 2 | 64 |

| 5 | 67.5 | 1 | 1.5 | 81 |

| 6 | 67.5 | 1.5 | 1 | 54 |

| No. Run | Sheet Misalignment (mm) | Excess Root Penetration (mm) | Root Concavity (mm) | Aspect Ratio, Wt/Df (-) |

|---|---|---|---|---|

| 1 | 0.29 | 0.40 | 0 | 1.66 |

| 2 | 0.46 | 0.39 | 0.27 | 2.26 |

| 3 | 0.13 | 0.35 | 0 | 1.67 |

| 4 | 0.42 | 0.44 | 0.12 | 1.72 |

| 5 | 0.16 | 0.47 | 0.13 | 1.92 |

| 6 | 0.40 | 0.51 | 0 | 1.71 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Basile, D.; Sesana, R.; De Maddis, M.; Borella, L.; Russo Spena, P. Investigation of Strength and Formability of 6016 Aluminum Tailor Welded Blanks. Metals 2022, 12, 1593. https://doi.org/10.3390/met12101593

Basile D, Sesana R, De Maddis M, Borella L, Russo Spena P. Investigation of Strength and Formability of 6016 Aluminum Tailor Welded Blanks. Metals. 2022; 12(10):1593. https://doi.org/10.3390/met12101593

Chicago/Turabian StyleBasile, Dario, Raffaella Sesana, Manuela De Maddis, Luca Borella, and Pasquale Russo Spena. 2022. "Investigation of Strength and Formability of 6016 Aluminum Tailor Welded Blanks" Metals 12, no. 10: 1593. https://doi.org/10.3390/met12101593

APA StyleBasile, D., Sesana, R., De Maddis, M., Borella, L., & Russo Spena, P. (2022). Investigation of Strength and Formability of 6016 Aluminum Tailor Welded Blanks. Metals, 12(10), 1593. https://doi.org/10.3390/met12101593