Effect of Hybrid Laser Arc Welding on the Microstructure and Mechanical and Fracture Properties of 316L Sheet Welded Joints

Abstract

:1. Introduction

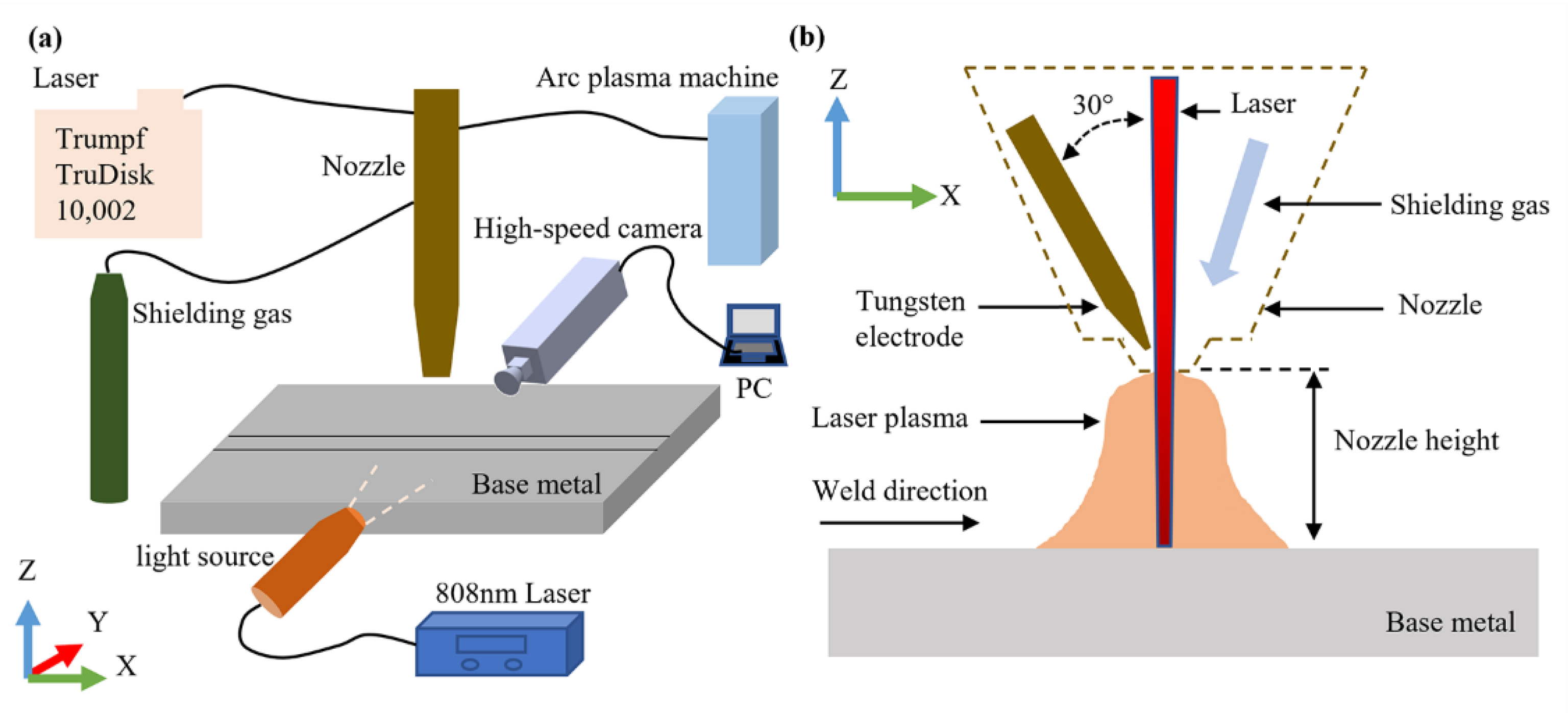

2. Experimental Method

3. Results and Discussion

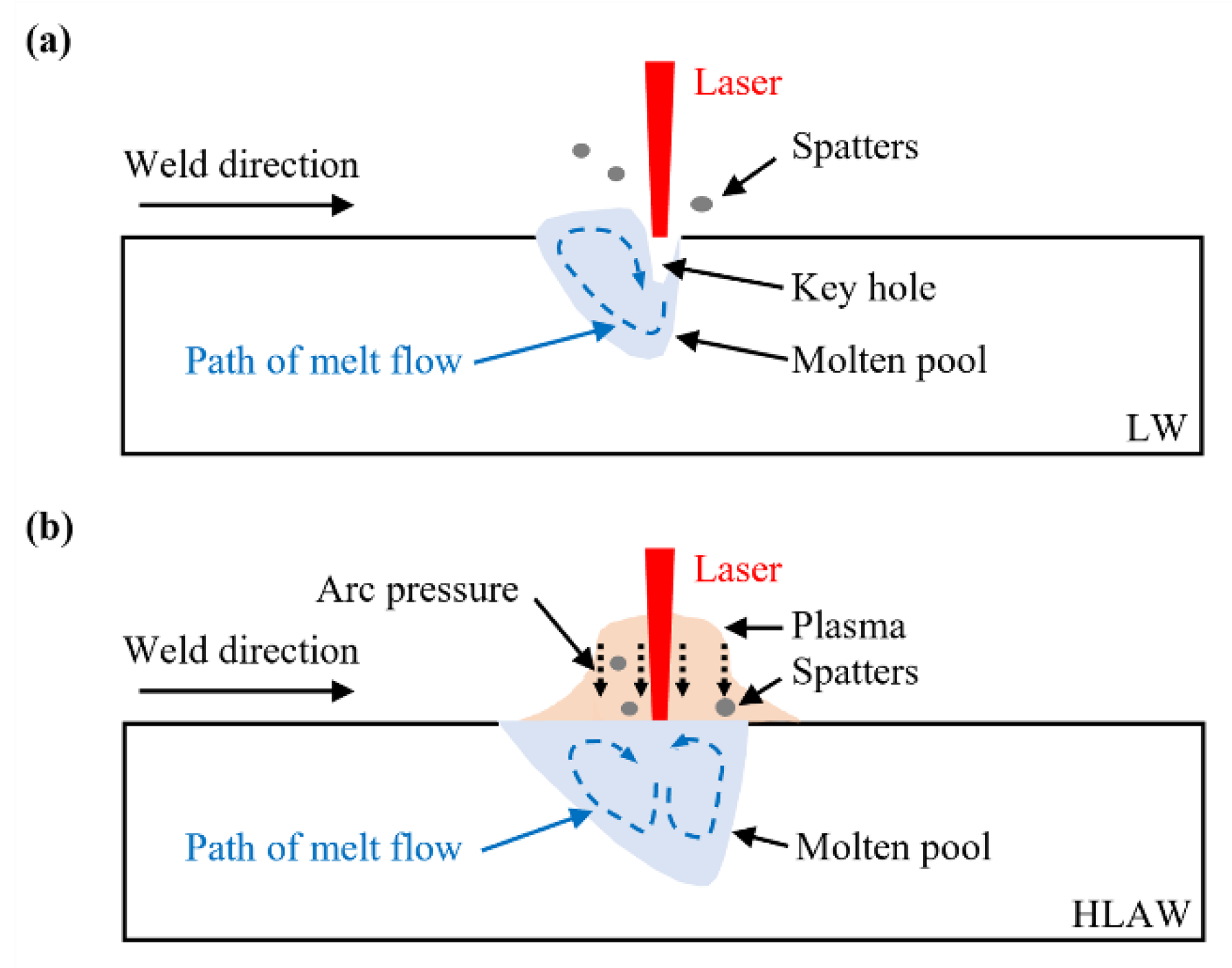

3.1. High-Speed Camera Images

3.2. Microstructure

3.3. Microhardness

3.4. Tensile Strength

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhuang, D.D.; Du, B.; Zhang, S.H.; Tao, W.W.; Wang, Q.; Shen, H.B. Effect and action mechanism of ultrasonic assistance on microstructure and mechanical performance of laser cladding 316L stainless steel coating. Surf. Coat. Technol. 2022, 433, 128122. [Google Scholar] [CrossRef]

- Varmaziar, S.; Atapour, M.; Hedberg, Y.S. Corrosion and metal release characterization of stainless steel 316L weld zones in whey protein solution. npj Mater. Degrad. 2022, 6, 1–9. [Google Scholar] [CrossRef]

- Wang, R.; Ji, X.; Qian, B.; Zhao, Z.; Huang, J.; Su, C.; Zhang, Q. Residual Stress Distribution Characteristics and Influencing Factors of 316L/Q235 Composite Plate during Heat Treatment. J. Mater. Eng. Perform. 2022, 31, 6933–6942. [Google Scholar] [CrossRef]

- Hedhibi, A.C.; Touileb, K.; Djoudjou, R.; Ouis, A.; Alrobei, H.; Ahmed, M.M.Z. Mechanical Properties and Microstructure of TIG and ATIG Welded 316L Austenitic Stainless Steel with Multi-Components Flux Optimization Using Mixing Design Method and Particle Swarm Optimization (PSO). Materials 2021, 14, 7139. [Google Scholar] [CrossRef]

- Xue, B.; Chang, B.; Wang, S.; Hou, R.; Wen, P.; Du, D. Humping Formation and Suppression in High-Speed Laser Welding. Materials 2022, 15, 2420. [Google Scholar] [CrossRef]

- Hou, J.; Li, R.; Xu, C.; Li, T.; Shi, Z. A comparative study on microstructure and properties of pulsed laser welding and continuous laser welding of Al-25Si-4Cu-Mg high silicon aluminum alloy. J. Manuf. Processes 2021, 68, 657–667. [Google Scholar] [CrossRef]

- Wang, B.; Hu, S.J.; Sun, L.; Freiheit, T. Intelligent welding system technologies: State-of-the-art review and perspectives. J. Manuf. Syst. 2020, 56, 373–391. [Google Scholar] [CrossRef]

- Lu, F.; Li, X.; Li, Z.; Tang, X.; Cui, H. Formation and influence mechanism of keyhole-induced porosity in deep-penetration laser welding based on 3D transient modeling. Int. J. Heat Mass Tran. 2015, 90, 1143–1152. [Google Scholar] [CrossRef]

- Yan, S.; Meng, Z.; Chen, B.; Tan, C.; Song, X.; Wang, G. Combined effect and mechanism of thermal behaviour and flow characteristic on microstructure and mechanical property of oscillation laser-welded of IN718. Sci. Technol. Weld. Joi. 2022, 1–9. [Google Scholar] [CrossRef]

- Wang, J.Y.; Qi, T.; Zhong, C.L.; Zhang, H.; Li, X.R.; Liu, F.D. Study on seam nitrogen behavior of high nitrogen steel hybrid welding. Optik 2021, 242, 167026. [Google Scholar] [CrossRef]

- Liu, H.; Du, X.; Guo, H.; Liu, J.; Chen, P.; Yang, H.; Hao, J. Finite element analysis of effects of dynamic preheating on thermal behavior of multi-track and multi-layer laser cladding. Optik 2021, 228, 166194. [Google Scholar] [CrossRef]

- Bai, X.; Zhang, H.; Wang, G. Modeling of the moving induction heating used as secondary heat source in weld-based additive manufacturing. Int. J. Adv. Manuf. Technol. 2015, 77, 717–727. [Google Scholar] [CrossRef]

- Hao, K.; Zhang, C.; Zeng, X.; Gao, M. Effect of heat input on weld microstructure and toughness of laser-arc hybrid welding of martensitic stainless steel. J. Mater. Process. Technol. 2017, 245, 7–14. [Google Scholar] [CrossRef]

- Chen, M.; Xin, L.; Zhou, Q.; He, L.; Wu, F. Effect of laser pulse on alternative current arc discharge during laser-arc hybrid welding of magnesium alloy. Opt. Laser. Eng. 2018, 100, 208–215. [Google Scholar] [CrossRef]

- Bang, H.S.; Bang, H.S.; Kim, Y.C.; Joo, S.M. Analysis of residual stress on AH32 butt joint by hybrid CO2 laser-GMA welding. Comp. Mater. Sci. 2010, 49, 217–221. [Google Scholar] [CrossRef]

- Piekarska, W.; Kubiak, M. Modeling of thermal phenomena in single laser beam and laser-arc hybrid welding processes using projection method. Appl. Math. Model. 2013, 37, 2051–2062. [Google Scholar] [CrossRef]

- Wang, L.; Zhao, Y.; Li, Y.; Zhan, X. Droplet Transfer Induced Keyhole Fluctuation and Its Influence Regulation on Porosity Rate during Hybrid Laser Arc Welding of Aluminum Alloys. Metals 2021, 11, 1510. [Google Scholar] [CrossRef]

- Acherjee, B. Hybrid laser arc welding: State-of-art review. Opt. Laser Technol. 2018, 99, 60–71. [Google Scholar] [CrossRef]

- Zhu, Y.; Cai, Y.; Dong, H.; Wang, M. Tailoring droplet transfer and molten pool flow during hybrid laser arc welding of nickel base alloy. Opt. Laser Technol. 2022, 147, 107620. [Google Scholar] [CrossRef]

- Li, C.; Fan, D.; Yu, X.; Huang, J. Residual stress and welding distortion of Al/steel butt joint by arc-assisted laser welding-brazing. T. Nonferr. Metal. Soc. 2019, 29, 692–700. [Google Scholar] [CrossRef]

- Chen, L.; Mi, G.; Zhang, X.; Wang, C. Numerical and experimental investigation on microstructure and residual stress of multi-pass hybrid laser-arc welded 316L steel. Mater. Des. 2019, 168, 107653. [Google Scholar] [CrossRef]

- Derakhshan, E.D.; Yazdian, N.; Craft, B.; Smith, S.; Kovacevic, R. Numerical simulation and experimental validation of residual stress and welding distortion induced by laser-based welding processes of thin structural steel plates in butt joint configuration. Opt. Laser Technol. 2018, 104, 170–182. [Google Scholar] [CrossRef]

- Mu, Z.; Chen, X.; Zheng, Z.; Huang, A.; Pang, S. Laser cooling arc plasma effect in laser-arc hybrid welding of 316L stainless steel. Int. J. Heat Mass Tran. 2019, 132, 861–870. [Google Scholar] [CrossRef]

- Lei, Z.; Zhu, Z.; Chen, H.; Li, Y. Fusion enhancement of hollow tungsten arc coaxially assisted by fiber laser. Opt. Laser Technol. 2022, 150, 107905. [Google Scholar] [CrossRef]

- Wu, Z.; Xu, Z.; Fan, W. Online detection of powder spatters in the additive manufacturing process. Measurement 2022, 194, 111040. [Google Scholar] [CrossRef]

- Kuryntsev, S.; Kolesnikov, D.; Vulpe, M. Investigation of the Effect of Welding Heat Input and Focal Distance of Laser Beam on Penetration Depth and Dynamics of Welding Pool Using a High-Speed Video Camera. Mater. Sci. Forum 2020, 989, 721–732. [Google Scholar] [CrossRef]

- Xie, L.; Shi, W.; Wu, T.; Gong, M.; Cai, D.; Han, S.; He, K. Effect of Dynamic Preheating on the Thermal Behavior and Mechanical Properties of Laser-Welded Joints. Materials 2022, 15, 6159. [Google Scholar] [CrossRef]

- Zong, R.; Chen, J.; Wu, C.S.; Chen, M.A. Undercutting Formation Mechanism in Gas Metal Arc Welding. Weld. J. 2016, 95, 174–184. [Google Scholar]

- Qi, Y.; Chen, G.; Liu, D. Droplet spatter suppression in laser lap welding of galvanized sheets using additional coaxial annular laser source. Opt. Laser Technol. 2022, 149, 107902. [Google Scholar] [CrossRef]

- Zhang, C.; Gao, M.; Zeng, X. Influences of synergy effect between laser and arc on laser-arc hybrid welding of aluminum alloys. Opt. Laser Technol. 2019, 120, 105766. [Google Scholar] [CrossRef]

- Shen, L.; Chen, Y.; Zhu, H.; Lei, Y.; Qiu, C. Ti6Al4V Alloy Remelting by Modulation Laser: Deep Penetration, High Compactness and Metallurgical Bonding with Matrix. Micromachines 2022, 13, 1107. [Google Scholar] [CrossRef]

- Li, K.; Liang, J.; Zhou, J. Preparation and characterization of laser cladded FeCrMoBSi amorphous composite coatings. Surf. Coat. Technol. 2021, 423, 127520. [Google Scholar] [CrossRef]

- Qin, R. Critical Assessment of the Electric Effect in Electric Arc Welding. Metals 2021, 11, 1917. [Google Scholar] [CrossRef]

- Sabzi, M.; Dezfuli, S.M. Drastic improvement in mechanical properties and weldability of 316L stainless steel weld joints by using electromagnetic vibration during GTAW process. J. Manuf. Processes 2018, 33, 74–85. [Google Scholar] [CrossRef]

- Sabzi, M.; Mousavi Anijdan, S.H.; Chalandar, A.R.B.; Park, N.; Jafarian, H.R.; Eivani, A.R. An experimental investigation on the effect of gas tungsten arc welding current modes upon the microstructure, mechanical, and fractography properties of welded joints of two grades of AISI 316L and AISI310S alloy metal sheets. Mater. Sci. Eng. A 2022, 840, 142877. [Google Scholar] [CrossRef]

- Ragavendran, M.; Vasudevan, M. Laser and hybrid laser welding of type 316L(N) austenitic stainless steel plates. Mater. Manuf. Process. 2020, 35, 922–934. [Google Scholar] [CrossRef]

| Type | Fe | C/% | Si/% | Mn/% | P/% | S/% | Mo/% | Cr/% | Ni/% |

|---|---|---|---|---|---|---|---|---|---|

| 316L | Balance | 0.027 | 0.62 | 1.06 | 0.042 | 0.004 | 2.14 | 16.12 | 10.02 |

| NO. | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Laser power (W) | 600 | 800 | 1000 | 600 | 800 | 1000 |

| Current (A) | 0 | 0 | 0 | 20 | 20 | 20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, L.; Shi, W.; Wu, T.; Gong, M.; Cai, D.; Han, S.; He, K. Effect of Hybrid Laser Arc Welding on the Microstructure and Mechanical and Fracture Properties of 316L Sheet Welded Joints. Metals 2022, 12, 2181. https://doi.org/10.3390/met12122181

Xie L, Shi W, Wu T, Gong M, Cai D, Han S, He K. Effect of Hybrid Laser Arc Welding on the Microstructure and Mechanical and Fracture Properties of 316L Sheet Welded Joints. Metals. 2022; 12(12):2181. https://doi.org/10.3390/met12122181

Chicago/Turabian StyleXie, Linyi, Wenqing Shi, Teng Wu, Meimei Gong, Detao Cai, Shanguo Han, and Kuanfang He. 2022. "Effect of Hybrid Laser Arc Welding on the Microstructure and Mechanical and Fracture Properties of 316L Sheet Welded Joints" Metals 12, no. 12: 2181. https://doi.org/10.3390/met12122181

APA StyleXie, L., Shi, W., Wu, T., Gong, M., Cai, D., Han, S., & He, K. (2022). Effect of Hybrid Laser Arc Welding on the Microstructure and Mechanical and Fracture Properties of 316L Sheet Welded Joints. Metals, 12(12), 2181. https://doi.org/10.3390/met12122181