A Comparison of the Effects of Ultrasonic Cavitation on the Surfaces of 45 and 40Kh Steels

Abstract

:1. Introduction

- -

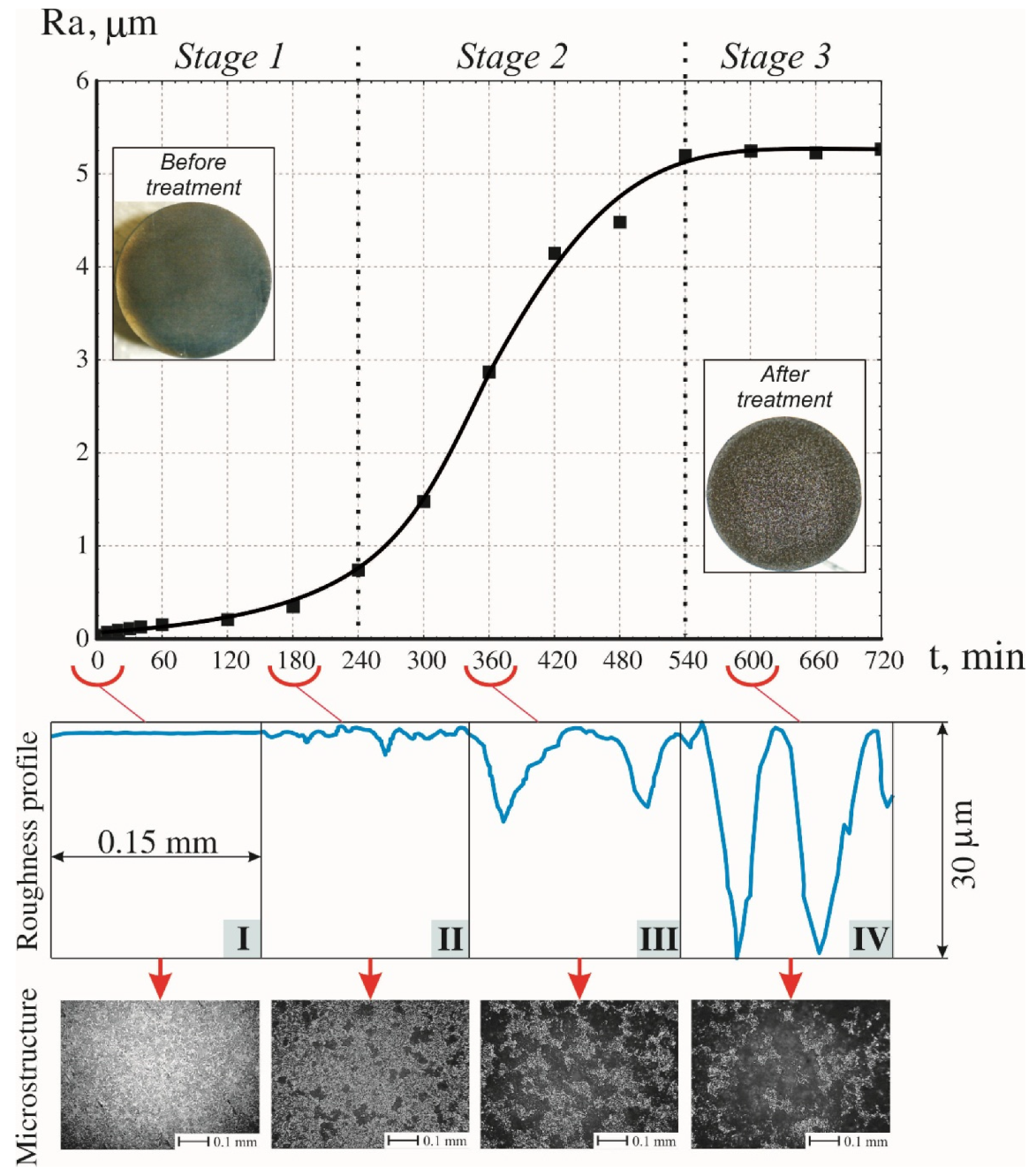

- The first stage is an incubation period, whereby the cavitation energy is spent on plastic deformation, structural transformations, and other changes in the surface layer that do not cause mass loss. This period characterizes the resistance of the material to cavitation;

- -

- The second stage involves a cavitation erosion treatment, leading to geometric surface changes due to the formation of erosion pits and accompanied by an increase in mass loss;

- -

- The third stage involves the destruction of the surface when brought to the critical state. This is expressed as a significant area of erosion damage, which practically does not change during further treatment.

2. Materials and Methods

2.1. Materials

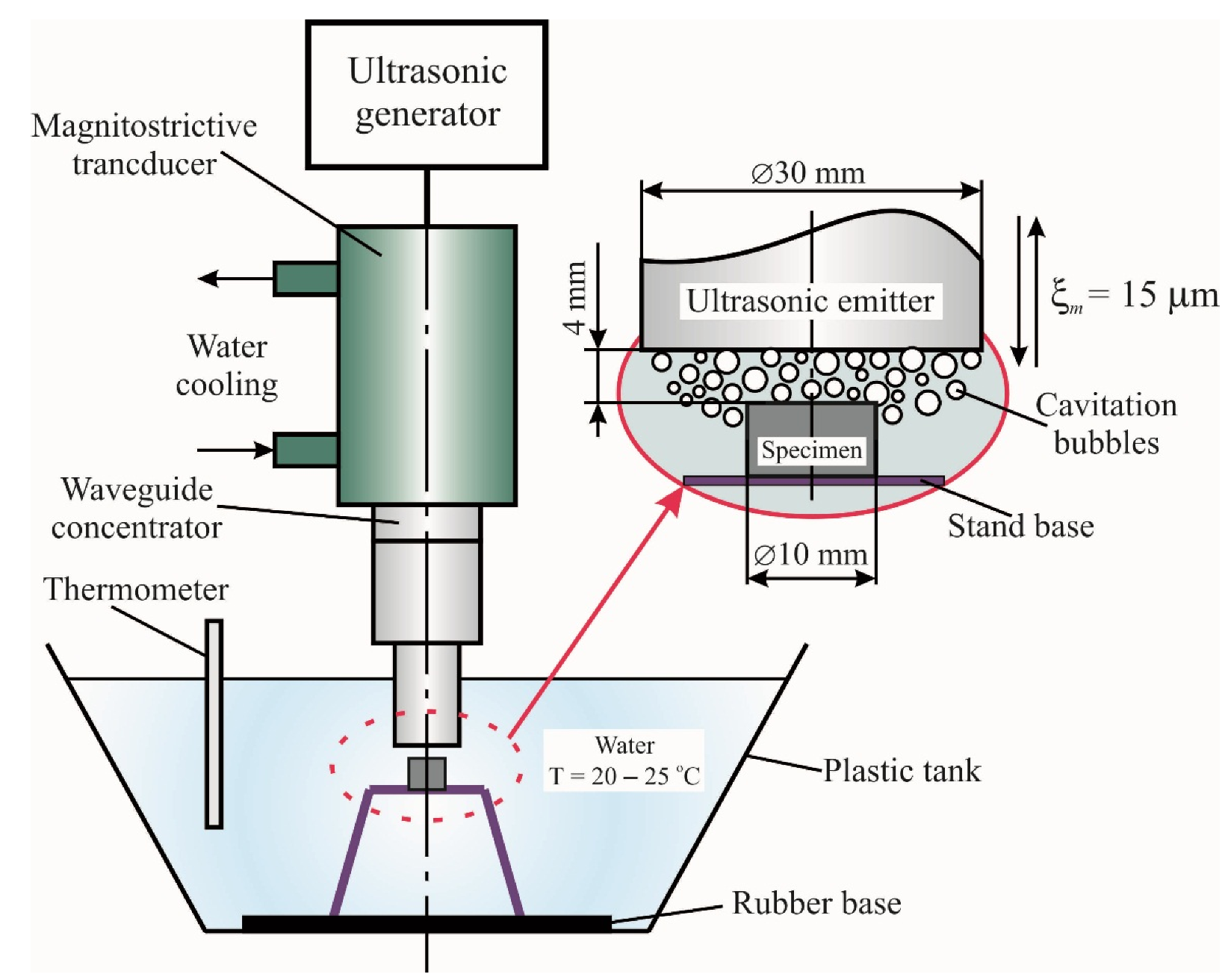

2.2. Experiment Scheme and Equipment

- -

- The first zone coincides with the cavitation area, which joins directly to the surface of the emitter and geometrically fits into a cylinder with a diameter corresponding to the diameter of the emitter and a height of 3–10 mm;

- -

- The second zone is behind the first and has a truncated cone shape, the height of which is determined by the depth of penetration of the acoustic stream (up to 100 mm);

- -

- The third zone contains the rest of the treated medium, which is outside the first and second zones and shows practically no erosion activity.

2.3. Estimation of Structure and Surface Properties

3. Results and Discussion

3.1. Microstructure Changes

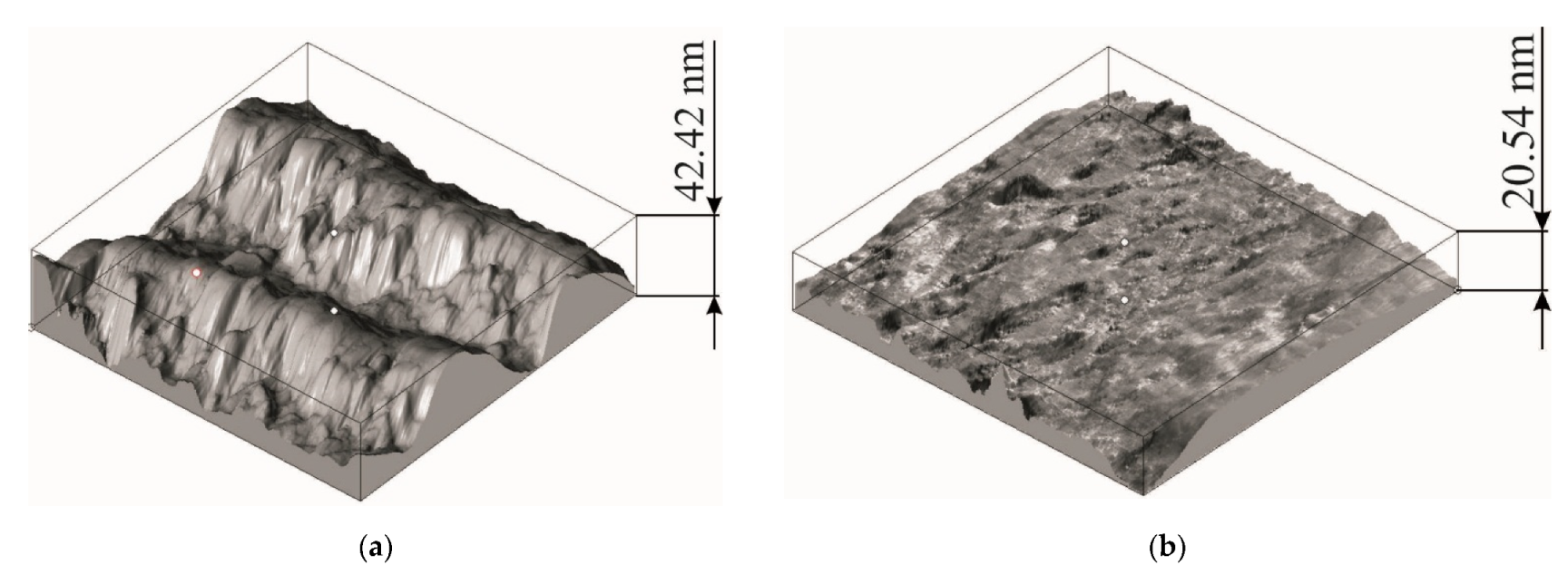

3.2. Influence of Ultrasonic Treatment on Roughness Parameters

- -

- The growth in roughness occurs during processing before the start of the erosion. This can be explained by the fact that at the initial moments of treatment under the action of cavitation, oxide sheets are removed (as considered in [62]), the surface is cleaned from residual grinding products (as considered in [63]), and individual surface elements are deformed (as considered in [64]);

- -

- A significant increase in roughness can be observed starting from 240 min of treatment, while an active increase in the area of erosion damage occurs starting from 60 min of treatment. This is due to the start of the erosion processes deep inside the specimen, i.e., when cavitation acts inside an already formed large cavity (up to an area of several grains). As a result, damage of the next lower layer of grains begins to occur. The abrupt rise in the graph is probably related to the size of the cavity area, which creates optimal conditions for the occurrence of “slot” cavitation, the erosion activity of which is extremely high;

- -

- The stabilization of the Ra (t) graph after 540 min of treatment coincides with the end of the growth of the erosion area.

3.3. Study of Sub-Microstructure

4. Conclusions

- The growth of cavitation erosion along the treated surfaces for the materials under consideration showed significant differences, which were mainly pronounced during the hardening period in 45 steel. The main factors influencing the research results were the ability of chromium to segregate impurities to grain boundaries, the large proportion of ferrite in the 40Kh steel, and the reduction in impact strength with the addition of chromium. As a result, 40Kh steel showed a “weak” boundary inclined to accelerated destruction;

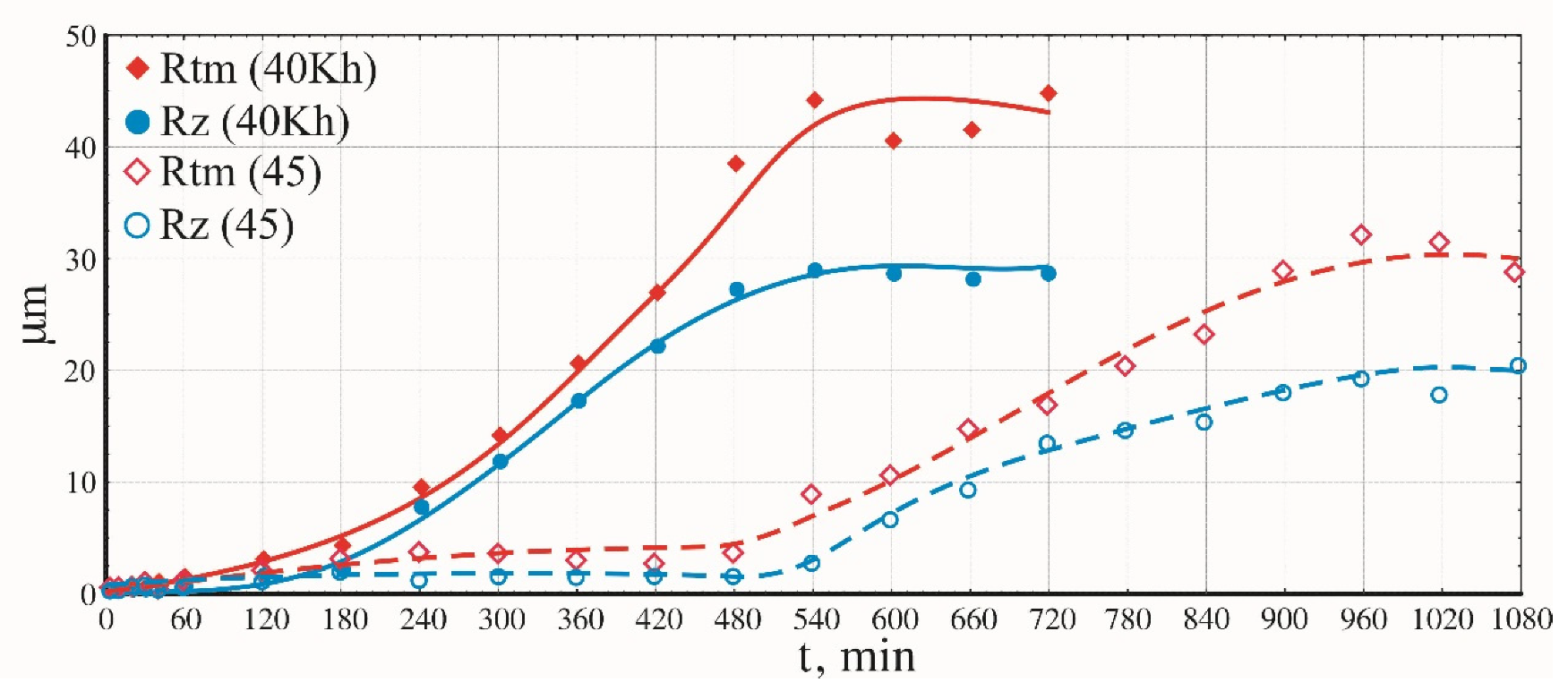

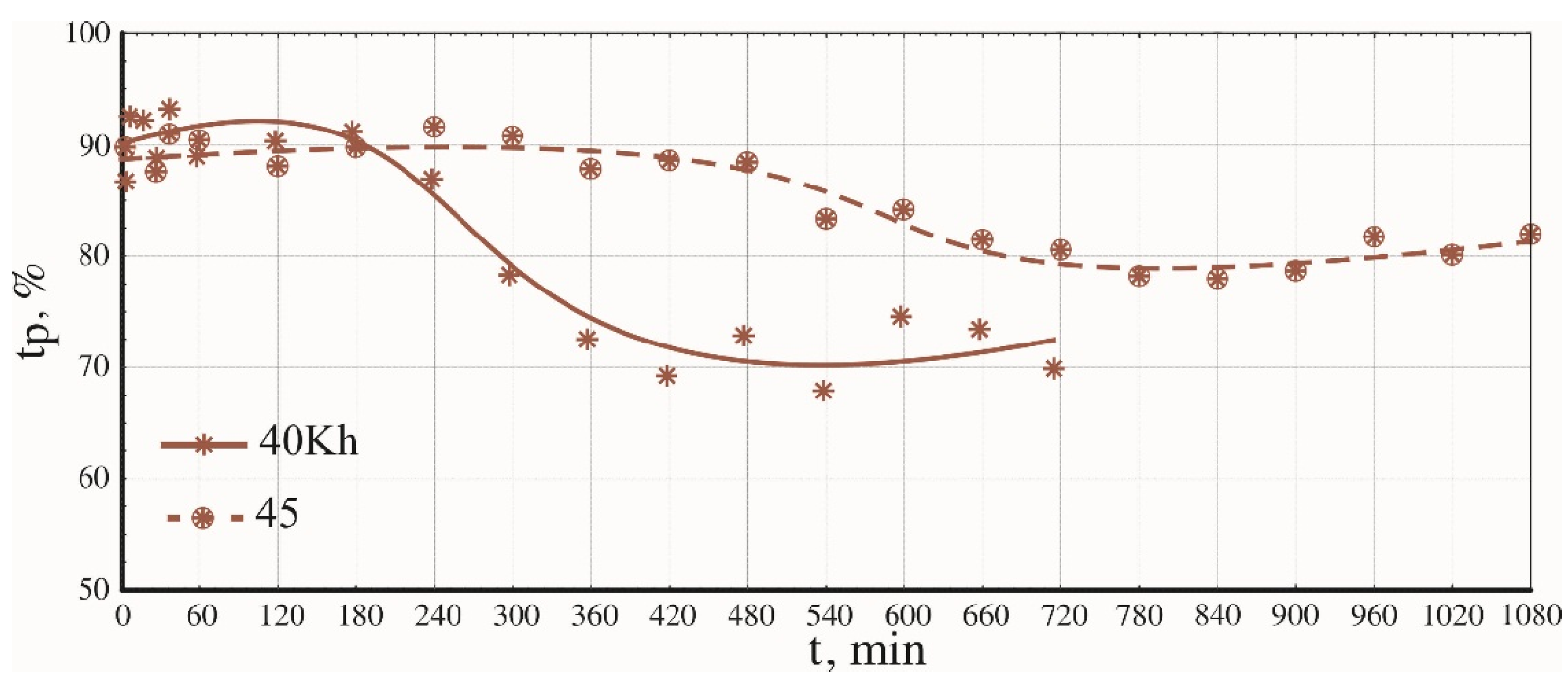

- A comparative analysis of the dynamics of the development of erosional damages in the steels and the resulting roughness profiles made it possible to consider in more detail the development of cavitation erosion and to clarify the stages of initiation and evolution of erosion damage. For 40Kh steel, the treatment can be divided into 3 stages, while for 45 steel it can be divided into 4 stages;

- The dynamics of the changes in the roughness profile for 40Kh steel were established, whereby the area of damage first increases, then the depth increases. For 45 steel, on the contrary, the maximum depth is first reached, then the area increases;

- With an increase in the area of erosional damage, the step parameters of roughness mostly increase, while with an increase in the depth of damage, the height parameters increase;

- From the point of view of ensuring the surface roughness of the materials under consideration, the most effective stage is the abrupt increase in the height of roughness. Thus, it is possible to change the Ra parameter from 0.04 microns to 5.2 microns for 40Kh steel, and from 0.02 microns to 1.3 microns for 45 steel;

- These results can be used in the treatment of complex-shaped products to obtain a specific roughness, as well as in the development of ultrasonic cleaning processes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bartashevich, S.A.; Rusak, E.V. Use of ultrasonic influence and chemically active substances for cleaning anilox shaft. Proc. BSTU 2015, 9, 29–33. [Google Scholar]

- Sirotyuk, M.G. Acoustic Cavitation; Science: Moscow, Russia, 2008. [Google Scholar]

- Kazantsev, V.F.; Prikhodko, V.M.; Fatyukhin, D.S. Physical Phenomena in the Powerful Ultrasound Field; LAP Lambert Academic Publishing: Saarbrucken, Germany, 2014; p. 80. ISBN 978-3-659-19555-6. [Google Scholar]

- Ebeling, K.G. Application of High Speed Holocinematographical Methods in Cavitation Research. In Cavitation and Inhomogeneities in Underwater Acoustics; Lauterborn, W., Ed.; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 1980; pp. 35–41. [Google Scholar]

- Nikitenko, I.; Pflieger, R. Toward a new paradigm for sonochemistry: Short review on nonequilibrium plasma observations by means of MBSL spectroscopy in aqueous solutions Sergey. Ultrason. Sonochem. Part B 2017, 35, 623–630. [Google Scholar] [CrossRef]

- Ji, R.; Virot, M.; Pflieger, R.; Sergey, I. Nikitenko Sonochemical decontamination of magnesium and magnesium-zirconium alloys in mild conditions. J. Hazard. Mater. 2021, 406, 124734. [Google Scholar] [CrossRef]

- Morosini, V.; Chave, T.; Virot, M.; Moisy, P.; Sergey, I. Nikitenko. Sonochemical water splitting in the presence of powdered metal oxides. Ultrason. Sonochem. 2016, 29, 512–516. [Google Scholar] [CrossRef] [PubMed]

- Panov, A.P.; Prikhodko, V.M. On cavitation destruction in the area of a rod emitter. Use of ultrasound in metallurgy: Scientific. Tr. MISiS Moscow. 1977, 90, 30–35. [Google Scholar]

- Prikhodko, V.M. Improving the Efficiency of the Ultrasonic Cleaning Process of Fuel Equipment Parts of Automotive Engines during Repair: Dissertation Cand; Tech. Science: Moscow, Russia, 1975. [Google Scholar]

- Vaidya, S.; Preece, C.M. Cavitation erosion of age-hardenable aluminum alloys. Metall. Trans. A 1978, 9, 299–307. [Google Scholar] [CrossRef]

- Rosenberg, L.D. Physics and Technology of Powerful Ultrasound. In Physical Foundations of Ultrasonic Technology; Rosenberg, L.D., Ed.; Science: Moscow, Russia, 1970; Volume 3, p. 689. [Google Scholar]

- Spencer, L.E. Efficient Cleaninig Methods. Met. Ind. 1957, 29, 91. [Google Scholar]

- Rozenberg, L.D. On the physics of ultrasonic cleaning. Ultrason. News 1960, 16, 4. [Google Scholar]

- Kikuchi, Y.; Shimizu, H. On the variation of acoustic radiation resistance in water under ultrasonic cavitation. J. Acoust. Soc. Am. 1959, 31, 1385–1386. [Google Scholar] [CrossRef]

- Agranat, A.B.; Bashkirov, I.V.; Kitaigorodsky, Y.I. A method of increasing the efficiency of ultrasound impact on processes occurring in liquids. Ultrason. Technol. 1964, 3, 38. [Google Scholar]

- Sirotyuk, M.G. On the behavior of cavitation bubbles at high intensities of ultrasound. Acoust. J. 1961, 7, 499. [Google Scholar]

- Fuchs, F.J. Power Ultrasonics. In Applications of High-Intensity Ultrasound; Elsevier: Amsterdam, The Netherlands, 2015; pp. 577–609. [Google Scholar]

- Panov, A.P. Ultrasonic Cleaning of Precision Parts; Mechanical Engineering: Moscow, Russia, 1984; p. 88. [Google Scholar]

- Timothy, J.M. Ultrasonic cleaning: An historical perspective. Ultrason. Sonochem. 2016, 29, 519–523. [Google Scholar]

- Prikhodko, V.M.; Buslaev, A.P.; Norkin, S.B.; Yashina, M.V. Modelling of cavitational erosion in the area of surfaces of smooth contact. Ultrason. Sonochem. 2001, 8, 59–67. [Google Scholar] [CrossRef]

- Habiba, L.; Premesh, S.L.; Tat-Hean, G.; Luiz, C.W. Numerical modelling of acoustic pressure fields to optimize the ultrasonic cleaning technique for cylinders. Ultrason. Sonochem. 2018, 45, 7–16. [Google Scholar]

- Tangsopha, W.; Thongsri, J.; Busayaporn, W. Simulation of ultrasonic cleaning and ways to improve the efficiency. In Proceedings of the International Electrical Engineering Congress (iEECON), Pattaya, Thailand, 8–10 March 2017; pp. 1–4. [Google Scholar]

- Kazantsev, V.F.; Kalachev, Y.N.; Nigmetzyanov, R.I.; Prikhodko, V.M.; Sundukov, S.K.; Fatyukhin, D.S. Instruments for Ultrasonic Cleaning: Monograph; Techpolygraphcentre: Moscow, Russia, 2017. [Google Scholar]

- Niemczewski, B. Observations of water cavitation intensity under practical ultrasonic cleaning conditions. Ultrason. Sonochem. 2007, 14, 13–18. [Google Scholar] [CrossRef] [PubMed]

- Niemczewski, B. Cavitation intensity of water under practical ultrasonic cleaning conditions. Ultrason. Sonochem. 2014, 21, 354–359. [Google Scholar] [CrossRef]

- Fatyukhin, D.S. Experimental Researches of the Influence of Ultrasonic Cleaning Parameters on the Value of Cavitation Erosion; Bulletin of Automob. Road Constr. State Tech. Univ. (MADI): Moscow, Russia, 2011. [Google Scholar]

- Li, P.; Wang, J.; Liao, Z.; Ueda, Y.; Yoshikawa, K.; Zhang, G. Microbubbles for Effective Cleaning of Metal Surfaces without Chemical Agents. 2021. Available online: https://ssrn.com/abstract=3914052 (accessed on 1 December 2021).

- Sarasua Miranda, J.A.; Ruiz-Rubio, L.; Aranzabe Basterrechea, E.; Vilas-Vilela, J.L. Non-Immersion Ultrasonic Cleaning: An Efficient Green Process for Large Surfaces with Low Water Consumption. Processes 2021, 9, 585. [Google Scholar] [CrossRef]

- Kazantsev, V.F.; Kuznetsov, S.Y.; Sundukov, S.K.; Fatyukhin, D.S.; Britvin, L.N. Ultrasound Treatment of Curved Contours and Complex Surfaces. Russ. Eng. Res. 2017, 37, 1074–1076. [Google Scholar] [CrossRef]

- Nigmetzyanov, R.I.; Kazantsev, V.F.; Prikhod’ko, V.M.; Sundukov, S.K.; Fatyukhin, D.S. Improvement in Ultrasound Liquid Machining by Activating Cavitational Clusters. Russ. Eng. Res. 2019, 39, 699–702. [Google Scholar] [CrossRef]

- Ryeol, P.; Minsu, C.; Eun Hyun, P.; Won-Jun, S.; Ho-Young, K.; Wonjung, K. Comparing cleaning effects of gas and vapor bubbles in ultrasonic fields. Ultrason. Sonochem. 2021, 76, 105618. [Google Scholar]

- Verhaagen, B.; Zanderink, T.; Fernandez Rivas, D. Ultrasonic cleaning of 3D printed objects and Cleaning Challenge Devices. Appl. Acoust. Part B 2016, 103, 172–181. [Google Scholar] [CrossRef]

- Lamminen, M.O.; Walke, H.W.; Weavers, L.K. Mechanisms and factors influencing the ultrasonic cleaning of particle-fouled ceramic membranes. J. Membr. Sci. 2004, 237, 213–223. [Google Scholar] [CrossRef]

- Hattori, S.; Itoh, T. Cavitation erosion resistance of plastics. Wear 2011, 271, 1103–1108. [Google Scholar] [CrossRef]

- Hattori, S.; Kitagawa, T. Analysis of cavitation erosion resistance of cast iron and nonferrous metals based on database and comparison with carbon steel data. Wear 2010, 269, 443–448. [Google Scholar] [CrossRef]

- Ding, H.; Tang, Q.; Zhu, Y.; Zhang, C.; Yang, H. Cavitation erosion resistance of 316L stainless steel fabricated using selective laser melting. Friction 2021, 9, 1580–1598. [Google Scholar] [CrossRef]

- Shchukin, D.; Skorb, E.; Belova, V.; Möhwald, H. Ultrasonic Cavitation at Solid Surfaces. Adv. Mater. 2011, 23, 1922–1934. [Google Scholar] [CrossRef] [PubMed]

- Hong, S.; Wu, Y.; Wu, J.; Zhang, Y.; Zheng, Y.; Li, J.; Lin, J. Microstructure and cavitation erosion behavior of HVOF sprayed ceramic-metal composite coatings for application in hydro-turbines. Renew. Energy 2021, 164, 1089–1099. [Google Scholar] [CrossRef]

- Cui, Z.D.; Man, H.C.; Cheng, F.T.; Yue, T.M. Cavitation erosion–corrosion characteristics of laser surface modified NiTi shape memory alloy. Surf. Coat. Technol. 2003, 162, 147–153. [Google Scholar] [CrossRef]

- Pola, A.; Montesano, L.; Tocci, M.; La Vecchia, G.M. Influence of Ultrasound Treatment on Cavitation Erosion Resistance of AlSi7 Alloy. Materials 2017, 10, 256. [Google Scholar] [CrossRef]

- Girelli, L.; Tocci, M.; Montesano, L.; Gelfi, M.; Pola, A. Investigation of cavitation erosion resistance of AlSi10Mg alloy for additive manufacturing. Wear 2018, 402, 124–136. [Google Scholar] [CrossRef]

- Szala, M.; Łatka, L.; Walczak, M.; Winnicki, M. Comparative Study on the Cavitation Erosion and Sliding Wear of Cold-Sprayed Al/Al2O3 and Cu/Al2O3 Coatings, and Stainless Steel, Aluminium Alloy, Copper and Brass. Metals 2020, 10, 856. [Google Scholar] [CrossRef]

- Dojcinovic, M.; Eric, O.; Rajnovic, D.; Sidjanin, L.; Balos, S. Effect of austempering temperature on cavitation behaviour of unalloyed ADI material. Mater. Charact. 2013, 82, 66–72. [Google Scholar] [CrossRef]

- Wade, E.H.R.; Preece, C.M. Cavitation erosion of iron and steel. Metall. Trans. A 1978, 9, 1299–1310. [Google Scholar] [CrossRef]

- Heathcock, C.J.; Protheroe, B.E.; Ball, A. Cavitation erosion of stainless steels. Wear 1982, 81, 311–327. [Google Scholar] [CrossRef]

- Munsterer, S.; Kohlhof, K. Cavitation protection by low temperature TiCN coatings. Surf. Coat. Technol. 1995, 74–75, 642–647. [Google Scholar] [CrossRef]

- Kowk, C.T.; Cheng, F.T.; Man, H.C. Laser surface modification of UNS S31603 stainless steel. Mater. Sci. Technol. A 2000, 290, 74–88. [Google Scholar] [CrossRef]

- Hammit, F.G. Cavitation and Multiphase Flow Phenomena; McGraw-Hill: New York, NY, USA, 1980; p. 222. [Google Scholar]

- Wang, J.; Gao, Y.; You, Z.; Fan, J.; Zhang, J.; Wang, S.; Xu, Z. The Effect of Ultrasonic Cleaning on the Secondary Electron Yield, Surface Topography, and Surface Chemistry of Laser Treated Aluminum Alloy. Materials 2020, 13, 296. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Verdan, S.; Burato, G.; Comet, M.; Reinert, L.; Fuzellier, H. Structural changes of metallic surfaces induced by ultrasound. Ultrason. Sonochem. 2003, 10, 291–295. [Google Scholar] [CrossRef]

- Szala, M.; Chocyk, D.; Skic, A.; Kamiński, M.; Macek, W.; Turek, M. Effect of Nitrogen Ion Implantation on the Cavitation Erosion Resistance and Cobalt-Based Solid Solution Phase Transformations of HIPed Stellite 6. Materials 2021, 14, 2324. [Google Scholar] [CrossRef]

- Zhukova, Y.; Ulasevich, S.A.; Dunlop, J.W.C.; Fratzl, P.; Möhwald, H.; Skorb, E.V. Ultrasound-driven titanium modification with formation of titania based nanofoam surfaces. Ultrason. Sonochem. 2017, 36, 146–154. [Google Scholar] [CrossRef] [Green Version]

- Jiao, Q.; Tan, X.; Zhu, J.; Feng, S.; Gao, J. Effects of ultrasonic agitation and surfactant additive on surface roughness of Si (111) crystal plane in alkaline KOH solution. Ultrason. Sonochem. 2016, 31, 222–226. [Google Scholar] [CrossRef]

- Jiao, Q.; Tan, X.; Zhu, C.; Hu, H. The effects of TMDD-PA concentration on roughness of Si and etching rate ratio of Si/in alkaline KOH solution. Chem. Phys. 2019, 529, 110397. [Google Scholar]

- Zhao, Y.; Bao, C.; Feng, R.; Mason, T.J. New etching method of PVC plastic for plating by ultrasound. J. Appl. Polym. Sci. 1998, 68, 1411–1416. [Google Scholar] [CrossRef]

- Aleksandrov, V.A.; Sundukov, S.K.; Fatyukhin, D.S.; Filatova, A.A. Ultrasonic Methods for Improving Object Surface Quality Prepared by Corrosion-Resistant Steel Powder Selective Laser Melting. Met. Sci. Heat Treat. 2018, 60, 381–386. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Metel, A.S.; Tarasova, T.V.; Filatova, A.A.; Sundukov, S.K.; Volosova, M.A.; Okunkova, A.A.; Melnik, Y.A.; Podrabinnik, P.A. Effect of Cavitation Erosion Wear, Vibration Tumbling, and Heat Treatment on Additively Manufactured Surface Quality and Properties. Metals 2020, 10, 1540. [Google Scholar] [CrossRef]

- Fatyukhin, D.S. Changes in the Surface Roughness of Machine Parts under the Action of Ultrasonic Liquid Treatment; Bulletin of Automob. Road Constr. State Tech. Univ. (MADI): Moscow, Russia, 2010. [Google Scholar]

- Chudina, O.V.; Alexandrov, V.A.; Fatyukhin, D.S. Influence of ultrasonic cavitation on the surface condition of structural steels. Strength. Technol. Coat. 2011, 74, 3–6. [Google Scholar]

- Sedlaczek, J.; Lohmann, C.H.; Lotz, E.M.; Hyzy, S.L.; Boyan, B.D.; Schwartz, Z. Effects of low-frequency ultrasound treatment of titanium surface roughness on osteoblast phenotype and maturation. Clin. Oral Implant. Res. 2017, 28, e151–e158. [Google Scholar] [CrossRef]

- Altay, R.; Sadaghiani, A.K.; Sevgen, M.I.; Şişman, A.; Koşar, A. Numerical and Experimental Studies on the Effect of Surface Roughness and Ultrasonic Frequency on Bubble Dynamics in Acoustic Cavitation. Energies 2020, 13, 1126. [Google Scholar] [CrossRef] [Green Version]

- Long, Y.; Bai, F.; Zhang, Y.; Saalbach, K.-A.; Twiefel, J. Impacts of ultrasound on oxide removal—An attempt towards acid-free cleaning. Ultrason. Sonochem. 2019, 57, 1–11. [Google Scholar] [CrossRef]

- Hauptmann, M.; Frederickx, F.; Struyf, H.; Mertens, P.; Heyns, M.; de Gendt, S.; Glorieux, C.; Brems, S. Enhancement of cavitation activity and particle removal with pulsed high frequency ultrasound and supersaturation. Ultrason. Sonochem. 2013, 20, 69–76. [Google Scholar] [CrossRef] [PubMed]

- Szala, M.; Awtoniuk, M. Neural modelling of cavitation erosion process of 34CrNiMo6 steel. IOP Conf. Ser. Mater. Sci. Eng. 2019, 710, 012016. [Google Scholar] [CrossRef]

| Material | C | Cr | Mn | Ni | Cu | W | Si | Fe |

|---|---|---|---|---|---|---|---|---|

| 40Kh | 0.39 | 0.95 | 0.57 | 0.26 | 0.09 | 0.01 | 0.2 | 97.53 |

| 45 | 0.46 | 0.09 | 0.55 | 0.27 | 0.1 | 0.01 | 0.21 | 98.31 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fatyukhin, D.S.; Nigmetzyanov, R.I.; Prikhodko, V.M.; Sukhov, A.V.; Sundukov, S.K. A Comparison of the Effects of Ultrasonic Cavitation on the Surfaces of 45 and 40Kh Steels. Metals 2022, 12, 138. https://doi.org/10.3390/met12010138

Fatyukhin DS, Nigmetzyanov RI, Prikhodko VM, Sukhov AV, Sundukov SK. A Comparison of the Effects of Ultrasonic Cavitation on the Surfaces of 45 and 40Kh Steels. Metals. 2022; 12(1):138. https://doi.org/10.3390/met12010138

Chicago/Turabian StyleFatyukhin, Dmitriy S., Ravil I. Nigmetzyanov, Vyacheslav M. Prikhodko, Aleksandr V. Sukhov, and Sergey K. Sundukov. 2022. "A Comparison of the Effects of Ultrasonic Cavitation on the Surfaces of 45 and 40Kh Steels" Metals 12, no. 1: 138. https://doi.org/10.3390/met12010138

APA StyleFatyukhin, D. S., Nigmetzyanov, R. I., Prikhodko, V. M., Sukhov, A. V., & Sundukov, S. K. (2022). A Comparison of the Effects of Ultrasonic Cavitation on the Surfaces of 45 and 40Kh Steels. Metals, 12(1), 138. https://doi.org/10.3390/met12010138