Analysis of Microstructure and Mechanical Properties of Bismuth-Doped SAC305 Lead-Free Solder Alloy at High Temperature

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

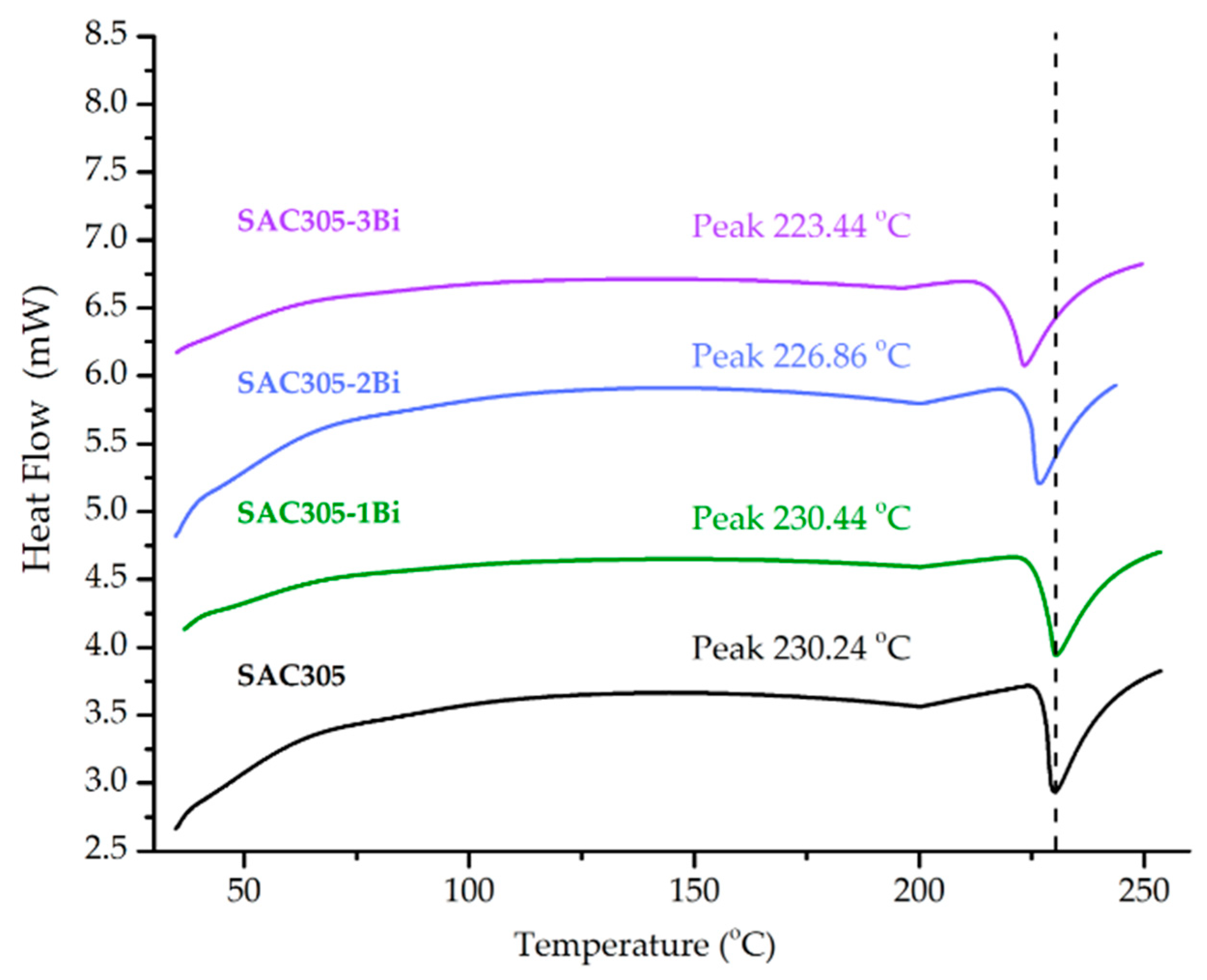

3.1. Differential Scanning Calorimetry

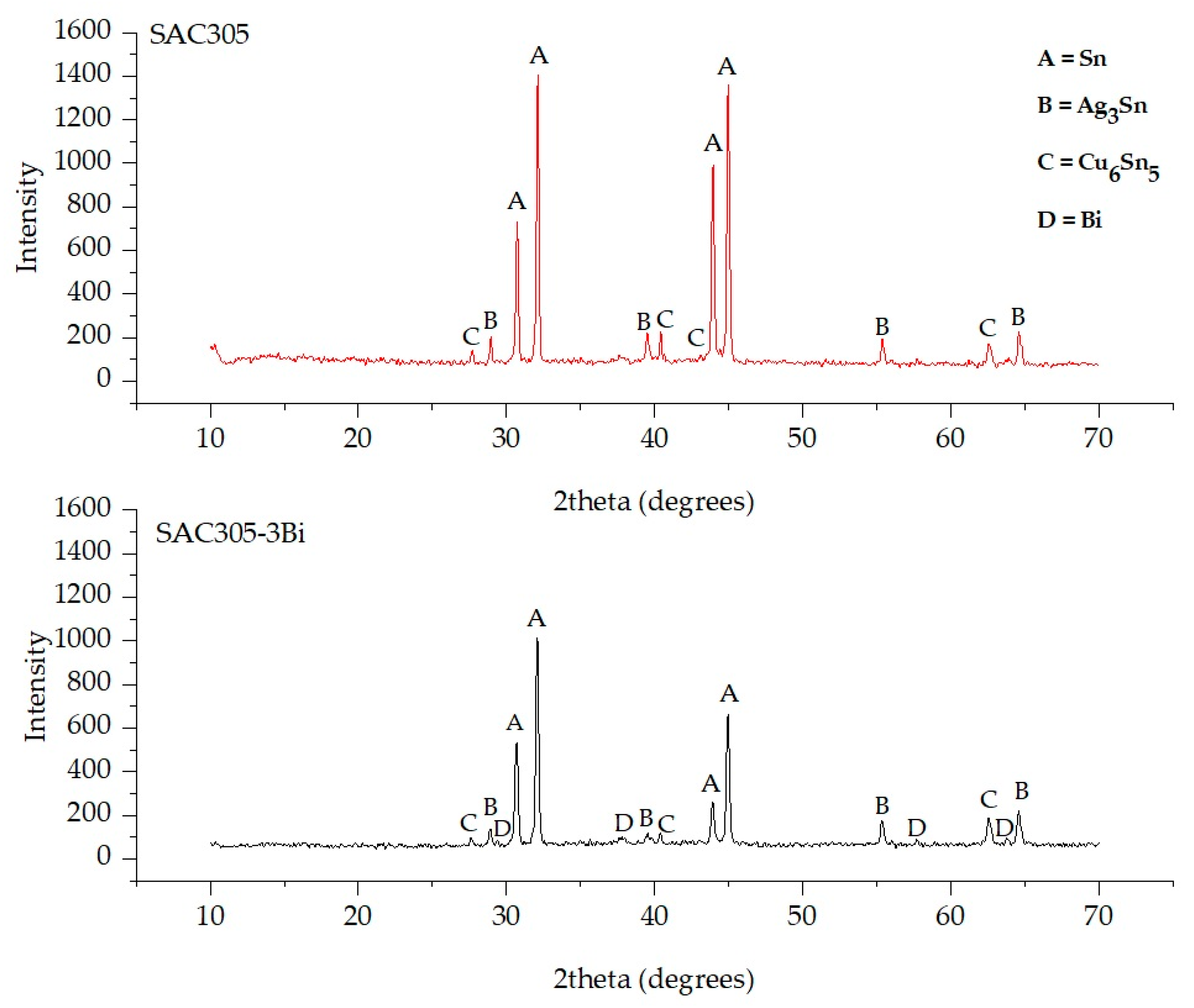

3.2. X-ray Diffractions Analysis

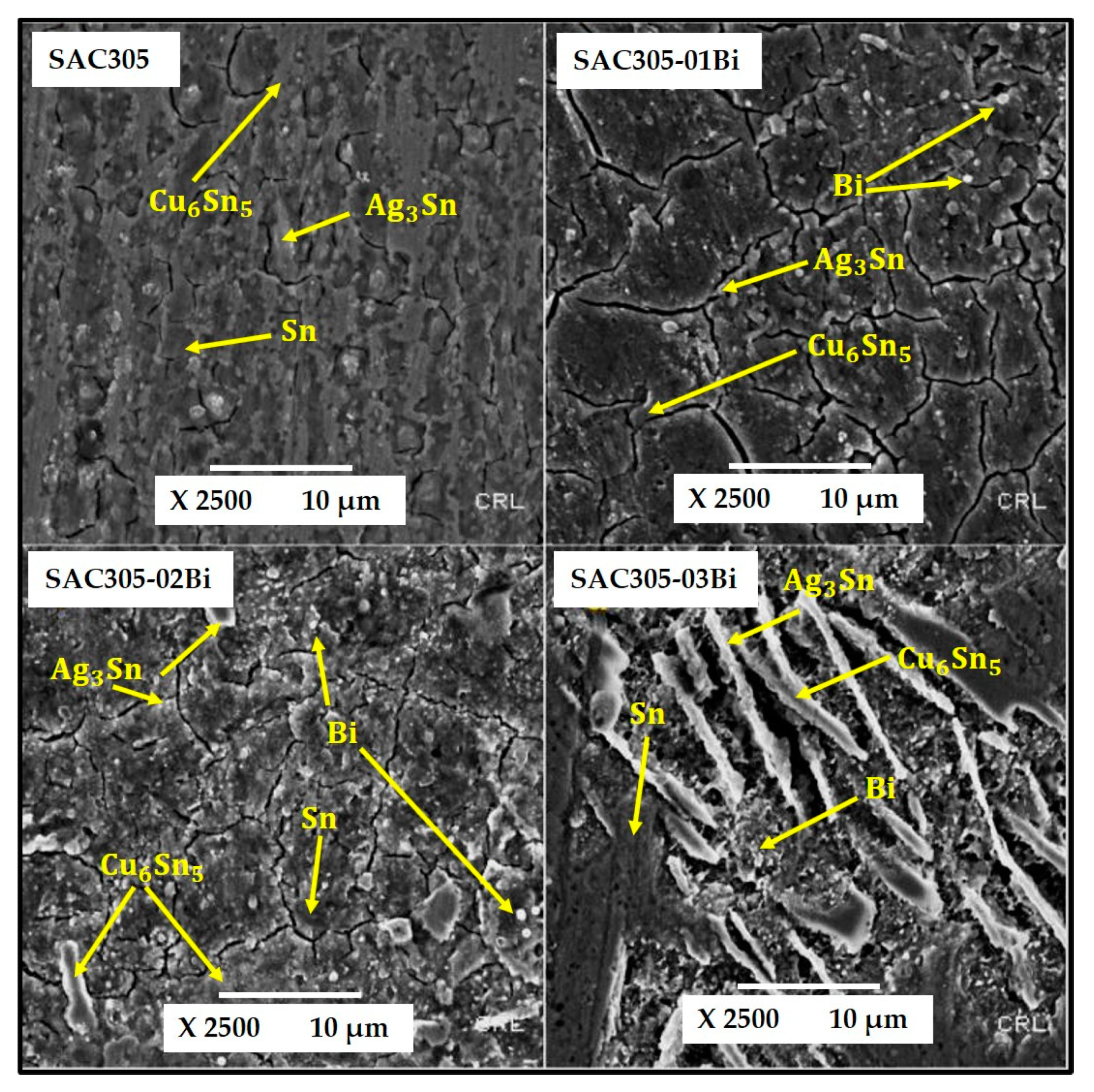

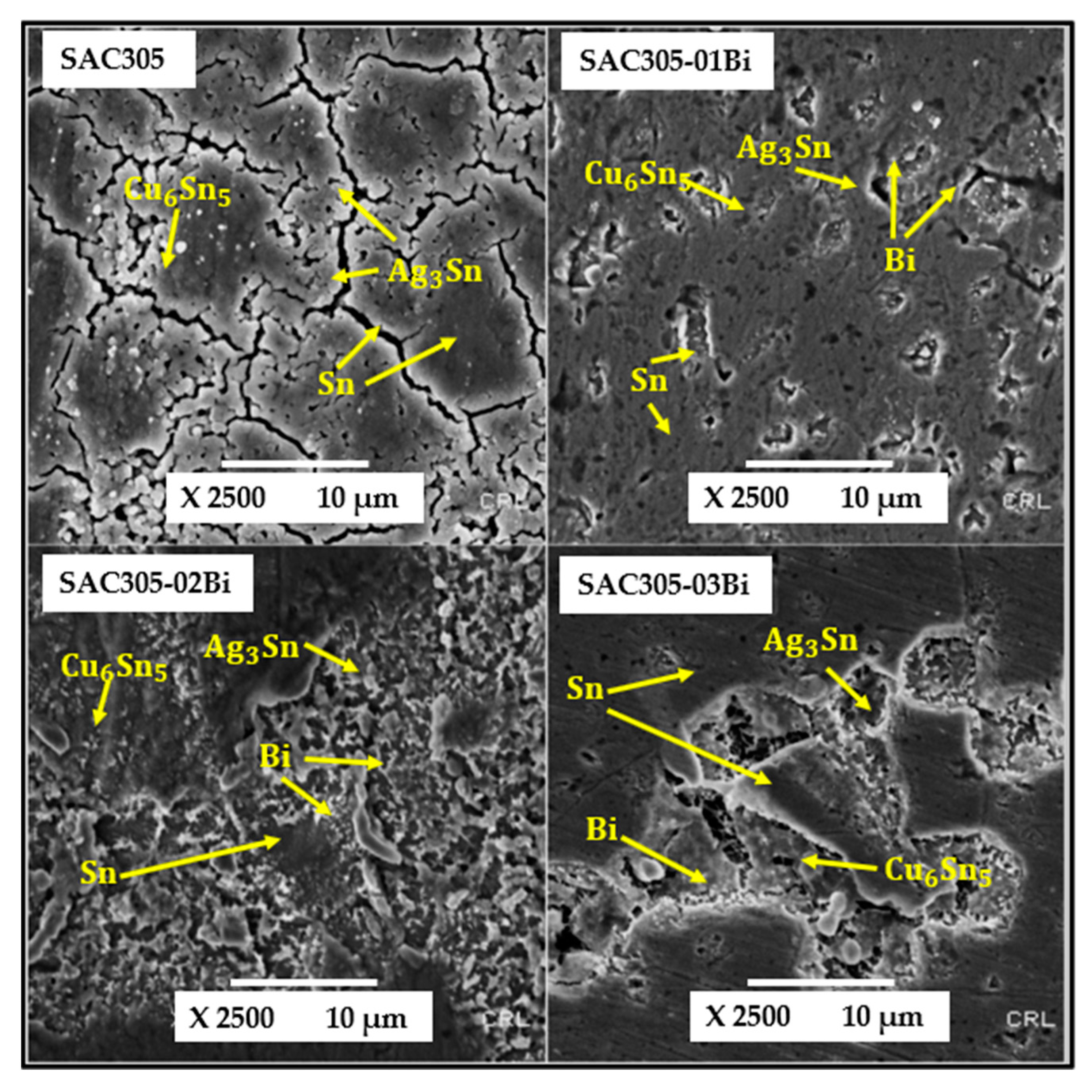

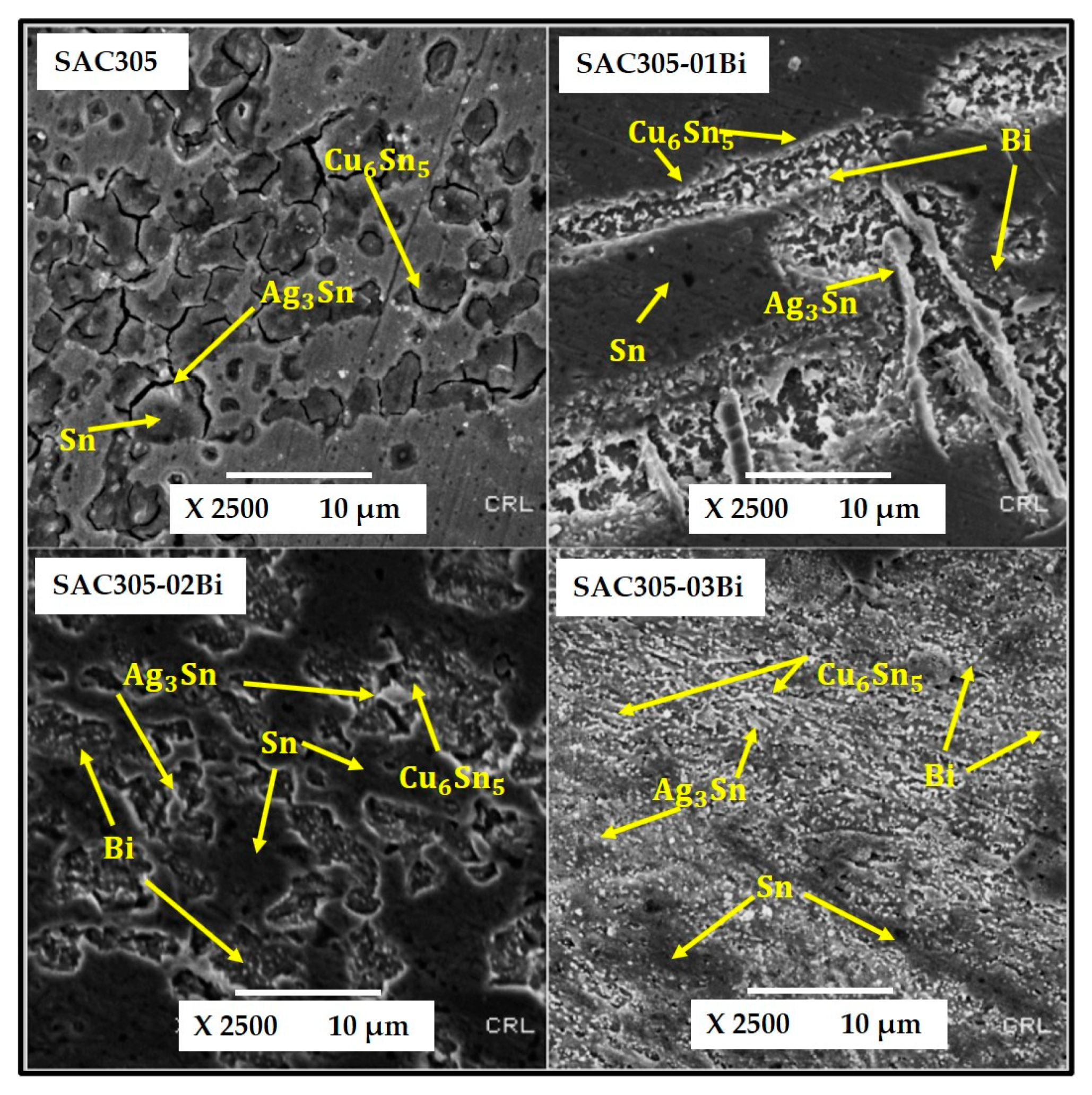

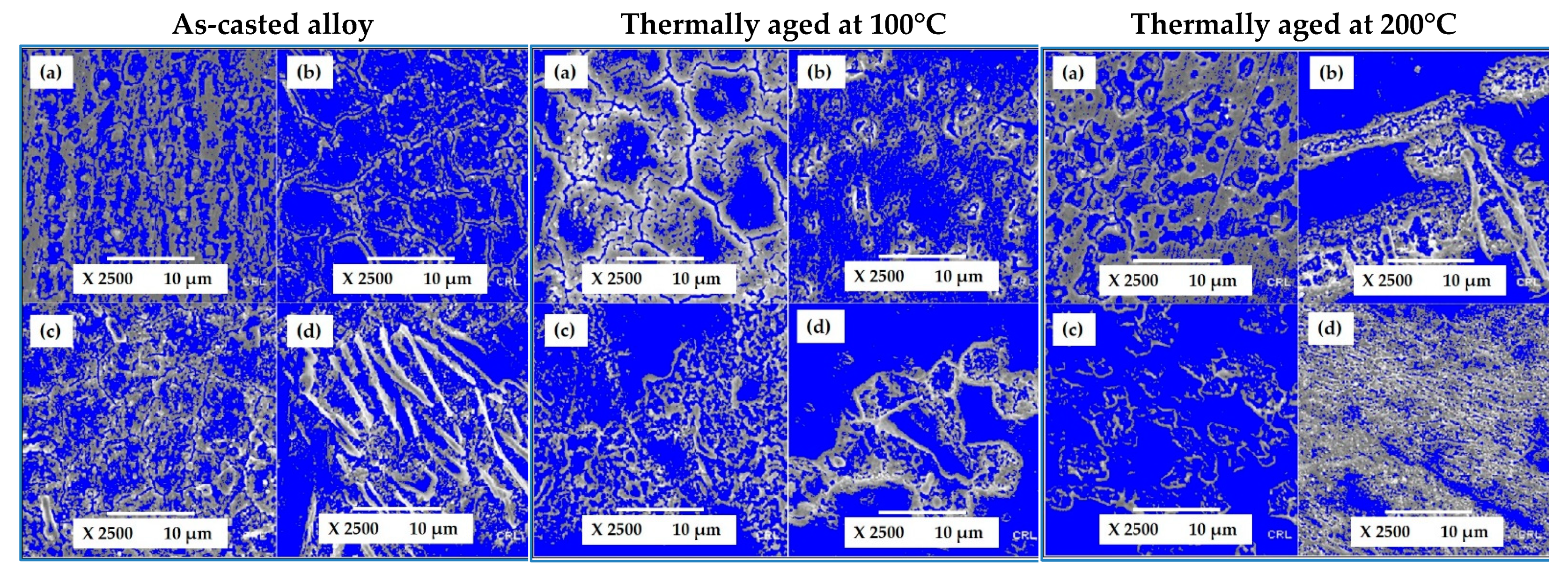

3.3. Microstructure Examination and Analysis of Intermetallic Compound Particle Size

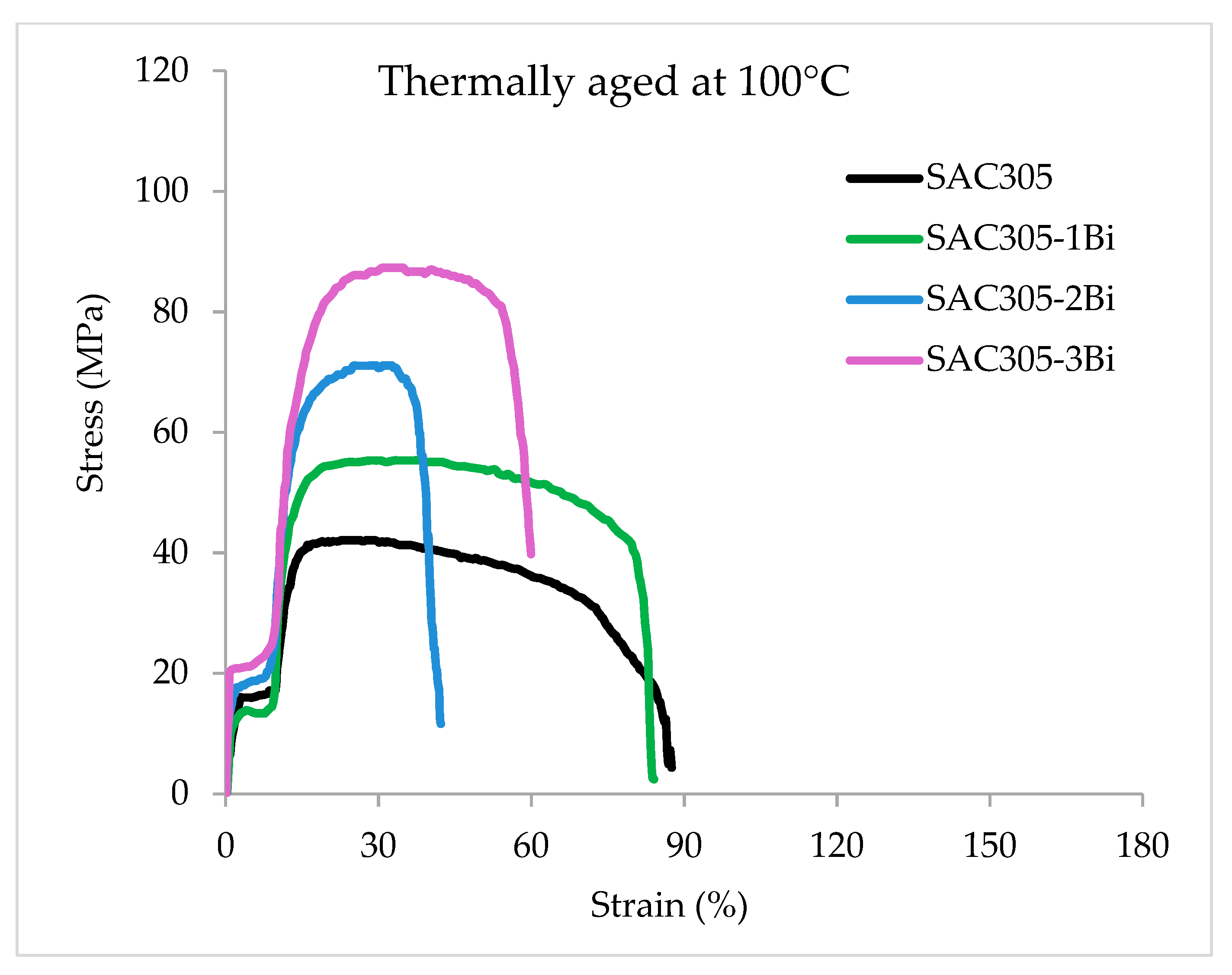

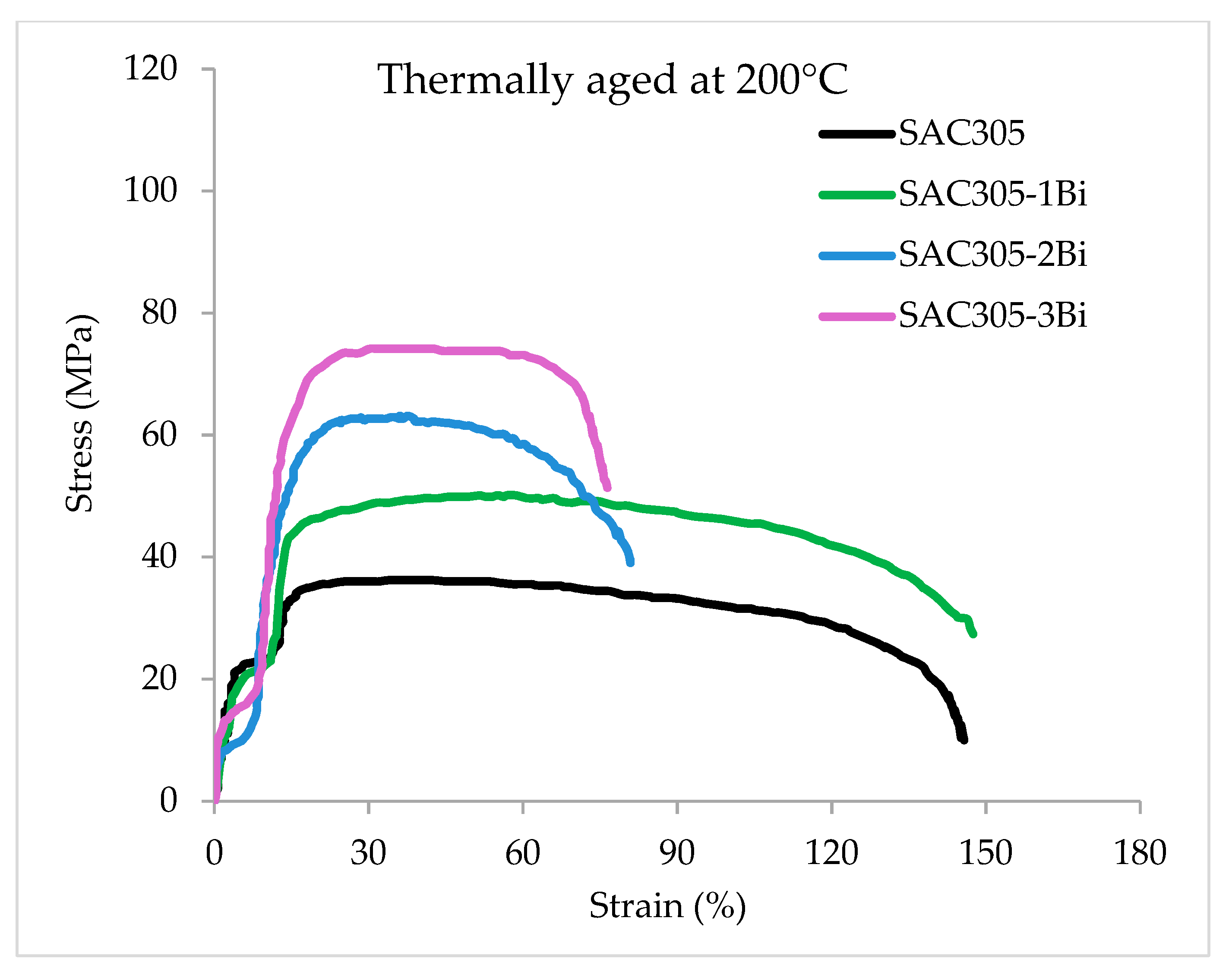

3.4. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Bismuth | Bi |

| Copper | Cu |

| Cerium | Ce |

| Energy Dispersive X-Ray Spectroscopy | EDS |

| Differential scanning calorimetry | DSC |

| Intermetallic compounds | IMCs |

| Lead | Pb |

| Lead-free solder | LFS |

| Scanning electron microscopy | SEM |

| Silver | Ag |

| Tin | Sn |

| Tin-Silver-Copper | SAC |

| Ultimate tensile strength | UTS |

| Universal testing machine | UTM |

| X-ray diffraction | XRD |

| Yield strength | YS |

| SAC105 | Sn-1.0 wt.%Ag-0.5 wt.%Cu |

| SAC305 | Sn-3.0 wt.%Ag-0.5wt.%Cu |

References

- Li, R.; Cong, S.; Mei, J.; Zhang, L.; Chen, Z.; Li, T.; Yuan, X. Interface evolution and mechanical properties of Sn–36Pb–2Ag solder joints under different aging conditions. J. Mater. Res. Technol. 2021, 10, 868–881. [Google Scholar] [CrossRef]

- Aamir, M.; Tolouei-Rad, M.; Din Israr, U.; Giasin, K.; Vafadar, A. Performance of SAC305 and SAC305-0.4La lead free electronic solders at high temperature. Solder. Surf. Mt. Technol. 2019, 31, 250–260. [Google Scholar] [CrossRef]

- Yasmin, T.; Sadiq, M.; Khan, M. Effect of Lanthanum Doping on the Microstructure Evolution and Intermetallic Compound (IMC) Growth during Thermal Aging of SAC305 Solder Alloy. J. Mater. Sci. Eng. 2014, 3, 1000141. [Google Scholar] [CrossRef]

- Aamir, M.; Muhammad, R.; Ahmed, N.; Sadiq, M.; Waqas, M. Mechanical properties of lead free solder alloy for green electronics under high strain rate and thermal aging. J. Eng. Appl. Sci. 2017, 36, 115–124. [Google Scholar]

- Depiver, J.a.; Mallik, S.; Harmanto, D. Solder joint failures under thermo-mechanical loading conditions—A review. Adv. Mater. Process. Technol. 2021, 7, 1–26. [Google Scholar] [CrossRef]

- Abdul Ameer Shnawah, D.; Faizul Bin Mohd Sabri, M.; Anjum Badruddin, I.; Said, S. A review on effect of minor alloying elements on thermal cycling and drop impact reliability of low-Ag Sn-Ag-Cu solder joints. Microelectron. Int. 2012, 29, 47–57. [Google Scholar] [CrossRef]

- Zhao, M.; Zhang, L.; Liu, Z.-Q.; Xiong, M.-Y.; Sun, L. Structure and properties of Sn-Cu lead-free solders in electronics packaging. Sci. Technol. Adv. Mater. 2019, 20, 421–444. [Google Scholar] [CrossRef] [PubMed]

- Aamir, M.; Muhammad, R.; Tolouei-Rad, M.; Giasin, K.; Silberschmidt Vadim, V. A review: Microstructure and properties of tin-silver-copper lead-free solder series for the applications of electronics. Solder. Surf. Mt. Technol. 2019, 32, 115–126. [Google Scholar] [CrossRef]

- Aamir, M.; Muhammad, R.; Hanif, M.; Ahmed, N. Relationships between Microstructure and Mechanical Properties in High Sn Content Pb-based and Pb-Free Solder Alloy after Thermal Aging. Int. J. Adv. Mater. Manuf. 2016, 1, 33–41. [Google Scholar]

- Aamir, M.; Muhammad, R.; Ahmed, N.; Alam, K. Impact of Thermal Aging on Microstructure and Mechanical Properties of high Sn Content, Sn-Pb Solders. In Proceedings of the Fourth International Conference on Aerospace Science & Engineering, Islamabad, Pakistan, 2–4 September 2015; pp. 187–191. [Google Scholar]

- Hashim, A.N.; Salleh, M.A.A.M.; Sandu, A.V.; Ramli, M.M.; Yee, K.C.; Mohd Mokhtar, N.Z.; Chaiprapa, J. Effect of Ni on the Suppression of Sn Whisker Formation in Sn-0.7Cu Solder Joint. Materials 2021, 14, 738. [Google Scholar] [CrossRef] [PubMed]

- Aamir, M.; Muhammad, R.; Ahmed, N.; Waqas, M. Impact of thermal aging on the intermetallic compound particle size and mechanical properties of lead free solder for green electronics. Microelectron. Reliab. 2017, 78, 311–318. [Google Scholar] [CrossRef]

- Sabri, M.F.M.; Shnawah, D.A.; Badruddin, I.A.; Said, S.B.M.; Che, F.X.; Ariga, T. Microstructural stability of Sn–1Ag–0.5 Cu–xAl (x = 1, 1.5, and 2 wt.%) solder alloys and the effects of high-temperature aging on their mechanical properties. J Mater. Charact. 2013, 78, 129–143. [Google Scholar] [CrossRef]

- Sadiq, M.; Pesci, R.; Cherkaoui, M. Impact of thermal aging on the microstructure evolution and mechanical properties of lanthanum-doped tin-silver-copper lead-free solders. J. Electron. Mater. 2013, 42, 492–501. [Google Scholar] [CrossRef][Green Version]

- Chuang, C.; Tsao, L.; Lin, H.; Feng, L. Effects of small amount of active Ti element additions on microstructure and property of Sn3. 5Ag0. 5Cu solder. Mater. Sci. Eng. A 2012, 558, 478–484. [Google Scholar] [CrossRef]

- Ali, B.; Sabri, M.F.M.; Jauhari, I.; Sukiman, N.L. Impact toughness, hardness and shear strength of Fe and Bi added Sn-1Ag-0.5Cu lead-free solders. Microelectron. Reliab 2016, 63, 224–230. [Google Scholar] [CrossRef]

- Erer, A.M.; Oguz, S.; Türen, Y. Influence of bismuth (Bi) addition on wetting characteristics of Sn-3Ag-0.5Cu solder alloy on Cu substrate. Eng. Sci. Technol. Int. J. 2018, 21, 1159–1163. [Google Scholar] [CrossRef]

- Matahir, M.; Chin, L.; Tan, K.; Olofinjana, A. Mechanical strength and its variability in Bi-modified Sn-Ag-Cu solder alloy. J. Achiev. Mater. Manuf. Eng. 2011, 46, 50–56. [Google Scholar]

- Hirai, Y.; Oomori, K.; Morofushi, H.; Shohji, I. Effect of Bi Addition on Tensile Properties of Sn–Ag–Cu Solder at Low Temperature. Mater. Trans. 2019, 60, 909–914. [Google Scholar] [CrossRef]

- Olofinjana, A.; Haque, R.; Mathir, M.; Voo, N.Y. Studies of the solidification characteristics in Sn-Ag-Cu-Bi solder alloys. Procedia Manuf. 2019, 30, 596–603. [Google Scholar] [CrossRef]

- El-Daly, A.; El-Taher, A.; Gouda, S. Development of new multicomponent Sn–Ag–Cu–Bi lead-free solders for low-cost commercial electronic assembly. J. Alloys Compd. 2015, 627, 268–275. [Google Scholar] [CrossRef]

- Fawzy, A.; Fayek, S.; Sobhy, M.; Nassr, E.; Mousa, M.; Saad, G. Tensile creep characteristics of Sn–3.5 Ag–0.5 Cu (SAC355) solder reinforced with nano-metric ZnO particles. Mater. Sci. Eng. A 2014, 603, 1–10. [Google Scholar] [CrossRef]

- Subri, N.W.B.; Sarraf, M.; Nasiri-Tabrizi, B.; Ali, B.; Mohd Sabri, M.F.; Basirun, W.J.; Sukiman, N.L. Corrosion insight of iron and bismuth added Sn–1Ag–0.5 Cu lead-free solder alloy. Corros. Eng. Sci. Technol. 2020, 55, 35–47. [Google Scholar] [CrossRef]

- Mahdavifard, M.H.; Sabri, M.F.M.; Shnawah, D.A.; Said, S.M.; Badruddin, I.A.; Rozali, S. The effect of iron and bismuth addition on the microstructural, mechanical, and thermal properties of Sn–1Ag–0.5 Cu solder alloy. Microelectron. Reliab. 2015, 55, 1886–1890. [Google Scholar] [CrossRef]

- Muhammad, R.; Ali, U. Optimized cerium addition for microstructure and mechanical properties of SAC305. Solder. Surf. Mt. Technol. 2020. ahead-of-print. [Google Scholar] [CrossRef]

- Aamir, M.; Waqas, M.; Iqbal, M.; Hanif, M.I.; Muhammad, R. Fuzzy logic approach for investigation of microstructure and mechanical properties of Sn96.5-Ag3.0-Cu0.5 lead free solder alloy. Solder. Surf. Mt. Technol. 2017, 29, 191–198. [Google Scholar] [CrossRef]

- Witkin, D.B. Influence of microstructure on quasi-static and dynamic mechanical properties of bismuth-containing lead-free solder alloys. Mater. Sci. Eng. A 2012, 532, 212–220. [Google Scholar] [CrossRef]

- Ali, B. Advancement in microstructure and mechanical properties of lanthanum-doped tin-silver-copper lead free solders by optimizing the lanthanum doping concentration. Solder. Surf. Mt. Technol. 2015, 27, 69–75. [Google Scholar] [CrossRef]

| S. No. | Alloy Names | Wt.% | |||

|---|---|---|---|---|---|

| Sn | Ag | Cu | Bi | ||

| 1 | SAC305 | 96.5 | 3.0 | 0.5 | 0 |

| 2 | SAC305-1Bi | 95.5 | 3.0 | 0.5 | 1 |

| 3 | SAC305-2Bi | 94.5 | 3.0 | 0.5 | 2 |

| 4 | SAC305-3Bi | 93.5 | 3.0 | 0.5 | 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, U.; Khan, H.; Aamir, M.; Giasin, K.; Habib, N.; Owais Awan, M. Analysis of Microstructure and Mechanical Properties of Bismuth-Doped SAC305 Lead-Free Solder Alloy at High Temperature. Metals 2021, 11, 1077. https://doi.org/10.3390/met11071077

Ali U, Khan H, Aamir M, Giasin K, Habib N, Owais Awan M. Analysis of Microstructure and Mechanical Properties of Bismuth-Doped SAC305 Lead-Free Solder Alloy at High Temperature. Metals. 2021; 11(7):1077. https://doi.org/10.3390/met11071077

Chicago/Turabian StyleAli, Umair, Hamza Khan, Muhammad Aamir, Khaled Giasin, Numan Habib, and Muhammad Owais Awan. 2021. "Analysis of Microstructure and Mechanical Properties of Bismuth-Doped SAC305 Lead-Free Solder Alloy at High Temperature" Metals 11, no. 7: 1077. https://doi.org/10.3390/met11071077

APA StyleAli, U., Khan, H., Aamir, M., Giasin, K., Habib, N., & Owais Awan, M. (2021). Analysis of Microstructure and Mechanical Properties of Bismuth-Doped SAC305 Lead-Free Solder Alloy at High Temperature. Metals, 11(7), 1077. https://doi.org/10.3390/met11071077