A Decision Support System for Changes in Operation Modes of the Copper Heap Leaching Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Overview

- Ore feed analysis: The data corresponding to the mineral feed includes the parameters of the raw feed, among which are: percentage of leachable oxides and sulfides, particle size, leaching flow rate, and level of chlorides added to the acid solution.

- Domain ontology development: Representation of knowledge about the dynamics of the leaching process, mainly indicating the configurations of the assets typical of a certain mode of operation.

- Rules, facts, and knowledge base: Generation of operation rules based on a specific subset of configurations in the mineral’s feed parameters that enter the process.

- Operational parameters and expected recovery levels: Identification of the operational parameters that significantly impact the response and determination of expected recovery levels is determining or estimating a tipping point where mineral recovery is negligible or becomes asymptotic.

- Knowledge of domain experts: Experts in the domain have the functions of generating the operating rules based on their knowledge of the dynamics of the process and the validation of the sequence of operating modes recommended by the algorithm or designed system.

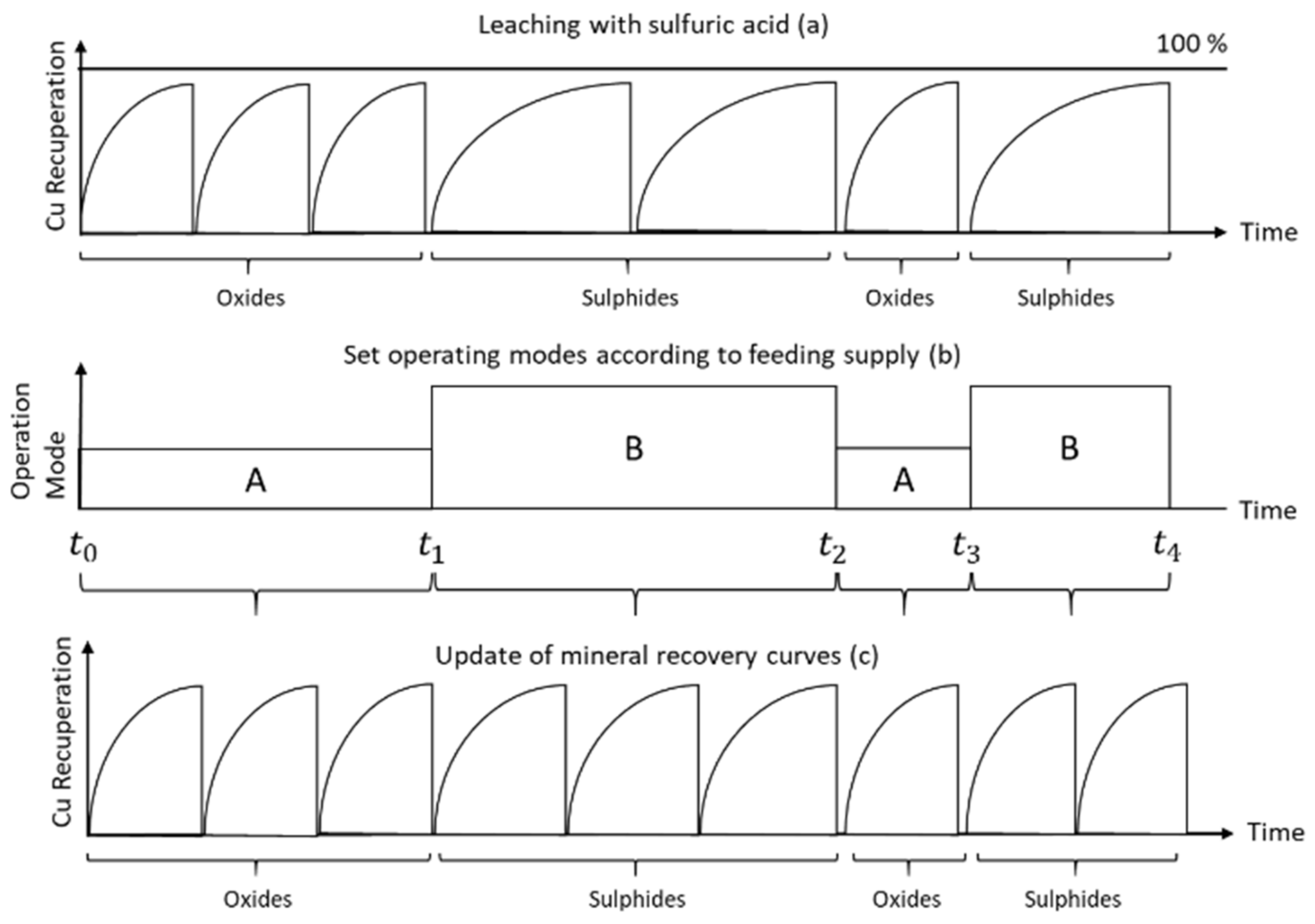

2.2. LX Process Modeling

2.3. Rules-Based System

2.4. Knowledge Representation

2.5. Planning of Operating Modes

- Mode A: Leaching of oxidized copper ores in acidic media.

- Mode B: Leaching of sulfide copper ores using H2SO4, and chlorides as a catalyst agent.

- Mode X: Mixed leaching of oxidized and sulfurized minerals in acidic media at low chloride concentrations (This mode of operation corresponds to a transition mode, between the leaching of oxides with H2SO4 and chloride-adhering sulfides).

2.6. Validation Using Performance Measures

- Accuracy (Acc): Corresponds to the proportion of correctly classified cases from all the examples in the dataset. This indicator can be calculated with the data from the confusion matrix (see Equation (1)).Accuracy = (TP + TN)/(TP + TN + FP + FN)

- Precision (p): The proportion of true positives (TP) among the elements is predicted as positive (see Equation (2)). Precision refers to the spread of the set of values obtained from repeated measurements of a quantity.Precision = TP/(TP + FP)

- Recall (r): The proportion of predicted true positives among all items classified as positive (see Equation (3)).Recall = TP (TP + FN)

- Specificity: (True Negative Rate) measures the proportion of negatives that are correctly identified (that is, the proportion of those who do not have the condition (not affected) who correctly identify as people who do not have the condition).Specificity = TN/(TN + FP)

- F1 score: The F1 value is used to combine the precision and recall measurements into a single value. This is practical because it makes it easier to compare the combined performance of precision and recall between various solutions. F1 score is calculated by taking the harmonic mean between precision and recall, as shown in Equation (5).F1 score = Precision × Recall/(Precision + Recall)

- Matthew’s correlation coefficient (MCC): An indicator that relates what is predicted with what is real, creating a balance between the classes, considering the instances correctly and incorrectly classified in classes that are pretty different in size and with a significant number of observations (see Equation (6)).MCC = (TN × TP − FP × FN)/([(TN + FN) × (FP + TP) × (TN + FP) × (FN + TP)]0.5)

- Kappa index: An indicator that represents the proportion of agreements observed beyond random with respect to the maximum possible agreement. It is used to evaluate the concordance or reproducibility of categorical measurement instruments and is defined as shown in Equation (7).ĸ = (Po − Pe)/(1 − Pe) | Pe = [(TP + FP) × (TP + FN) + (TN + FN) × (TN + FP)]/N2

3. Implementation

- 3.1. Implementation of knowledge representation

- 3.2. Expert module

- 3.3. Recommendation module

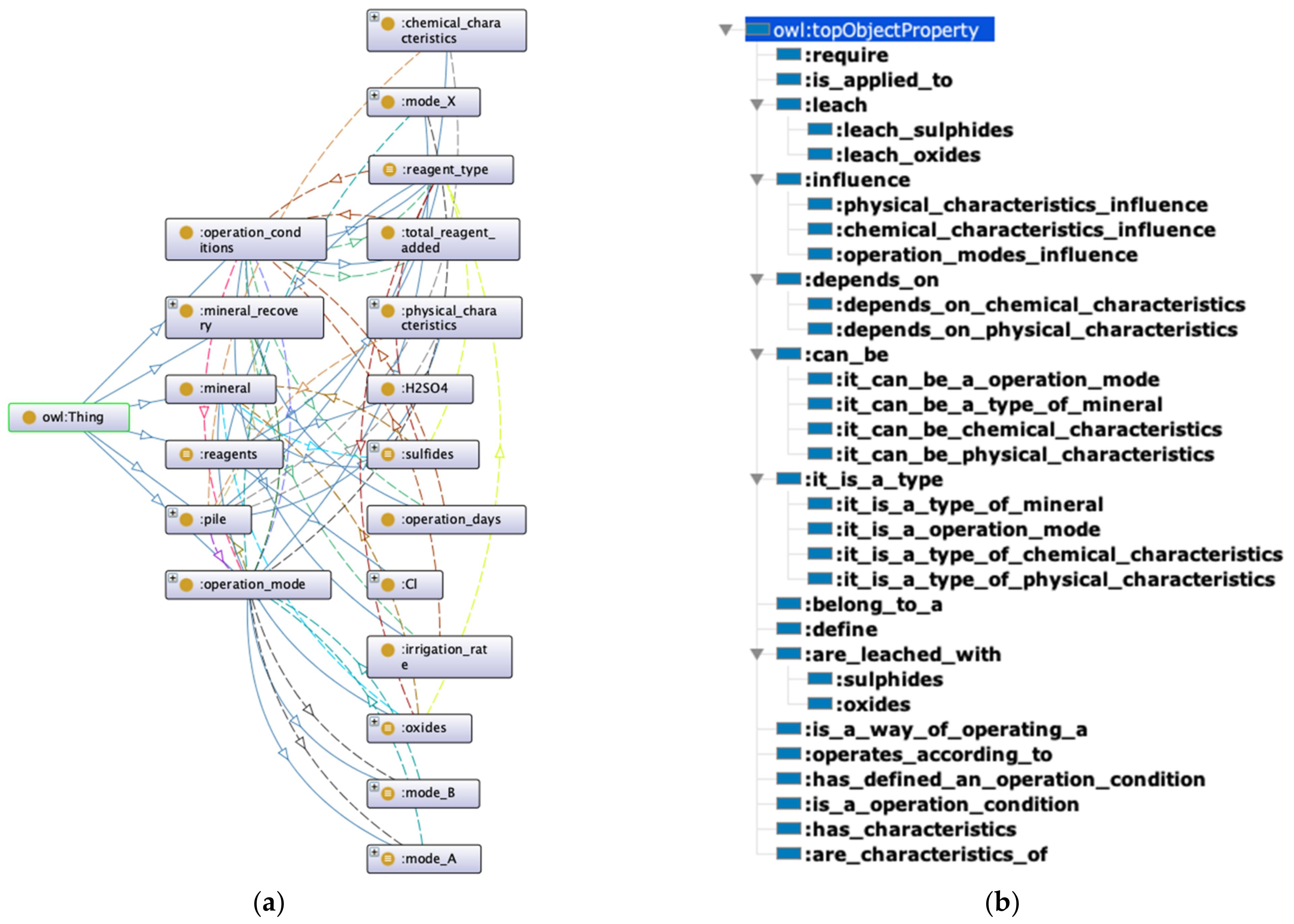

3.1. Implementation of Knowledge Representation

- Heap/Pile: Accumulations of mineralized material carried out in a mechanized way, forming a kind of continuous cake or embankment of varying height. The piles are slightly inclined to allow the drainage and capture of the solutions and are watered with a reagent solution to extract the mineral.

- Operation mode: Configuration of productive resources in order to adapt to the characteristics of the feed. For this knowledge model, three modes have been considered: MODEA, MODEB, and MODEX. The detail of each operation mode and conditions of changes are not of interest in this phase of the work.

- Mineral: Inorganic solid substance, formed by one or more defined chemical elements that are organized in an internal structure.

- Reagent: A chemical element that establishes an interaction with other substances in the framework of a chemical reaction, generating a substance with different properties called a product.

- Operating conditions: State of the variables of interest in a given mode of operation. Some variables are days of operation, irrigation ratios, type of reagent, total reagent added, mineral recovery, and update of the amount of mineral extracted from the heap.

- Mineral recovery: Output variable or ore recovery function.

- it_is_a_type: is the relationship between concepts that belong to the same hierarchy.

- depends_on: is the relationship established between the concepts involved or influence in copper recovery.

- leach: is the relationship between leaching agents and the type of material.

- operates_according_to: is the relationship between the heap and the operation mode. Sets the operating mode to be applied to a stack according to its characteristics.

- Axiom 1: if P1, P2 are heaps and OM1, OM2 are operating modes (the operating modes can exist independently of batteries and correspond to ways in which batteries have been operated previously), and if OM1 corresponds to P1, and OM2 corresponds to P2, then: P1 ∩ P2 = ∅.

- Axiom 2: if P1 is a leaching heap and OM1, OM2 are modes of operation, and P <oper> OM1 and P <oper> OM2, then: OM1 ≠ OM2 where <oper> represents the univocal correspondence of the operation of a stack according to an operation mode.

- Axiom 3: if P1, P2 are leaching heaps, M1, M2, and C1, C2 are the type of mineral and the operating conditions of the pile, respectively, and it is known that C1 <corresp> P1, C2 <corresp> P2 and M1 ≠ M2, then C1 ∩ C2 = ∅. <corresp> represents the relationship between a Stack where a specific material and operating conditions are established in a heap.

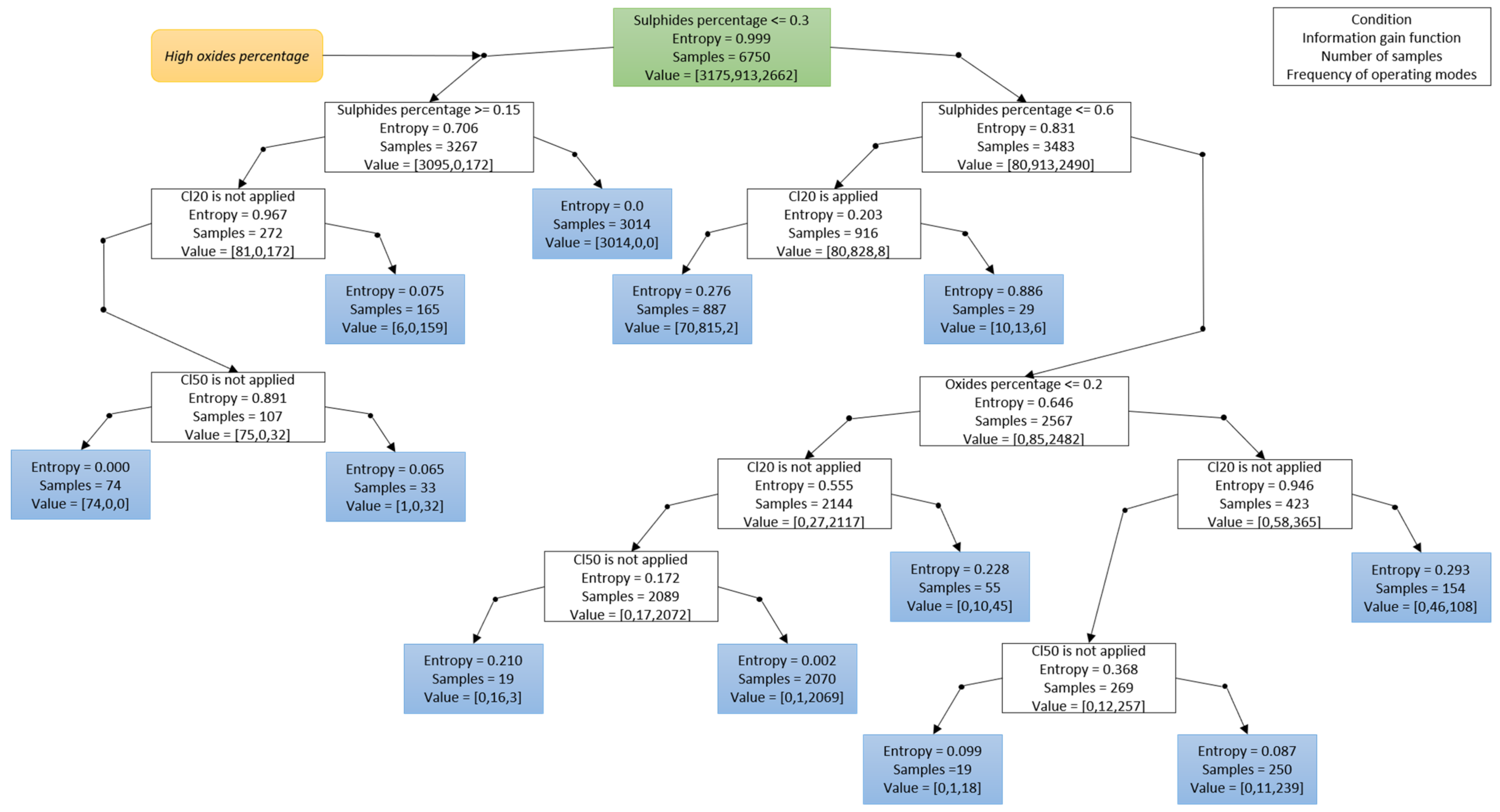

- Percentage of oxides in the feed (%O);

- Percentage of sulfides (secondary) in the feed (%S);

- Granulometry (d);

- Surface velocity of the leaching flow (μs); and

- Chloride at concentrations of 20 g/L (Cl20) and 50 g/L (Cl50) (see Table 1).

- Operation mode; and

- Copper recovery.

3.2. Expert Module

3.3. Recommendation Module

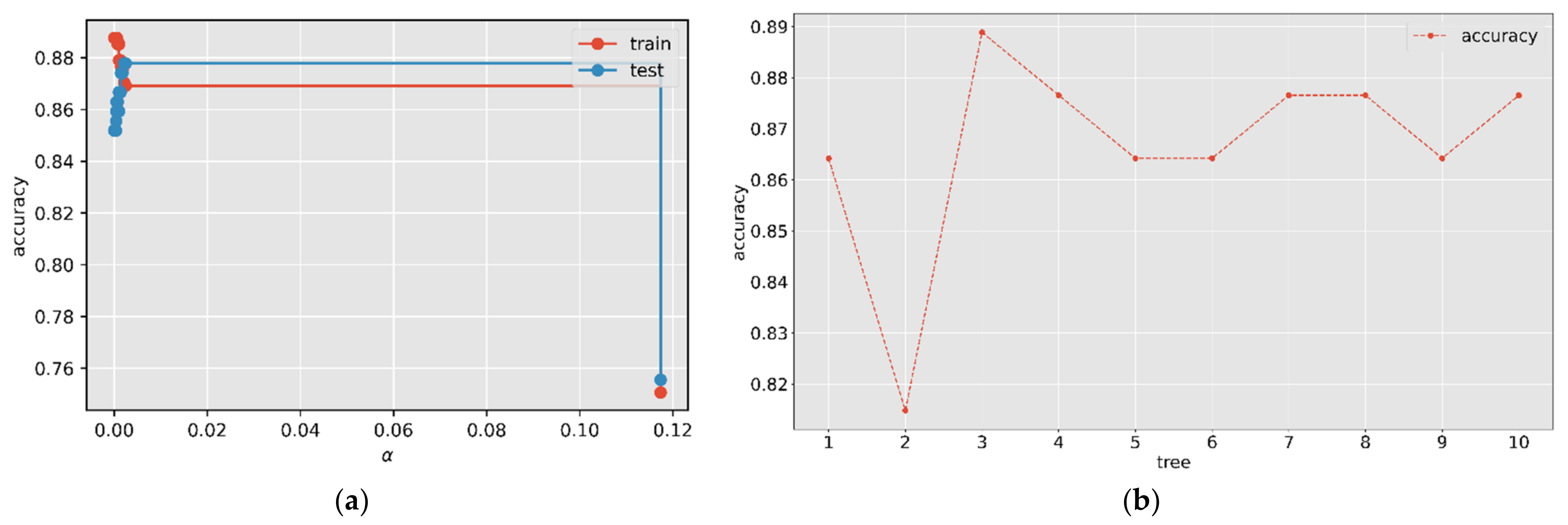

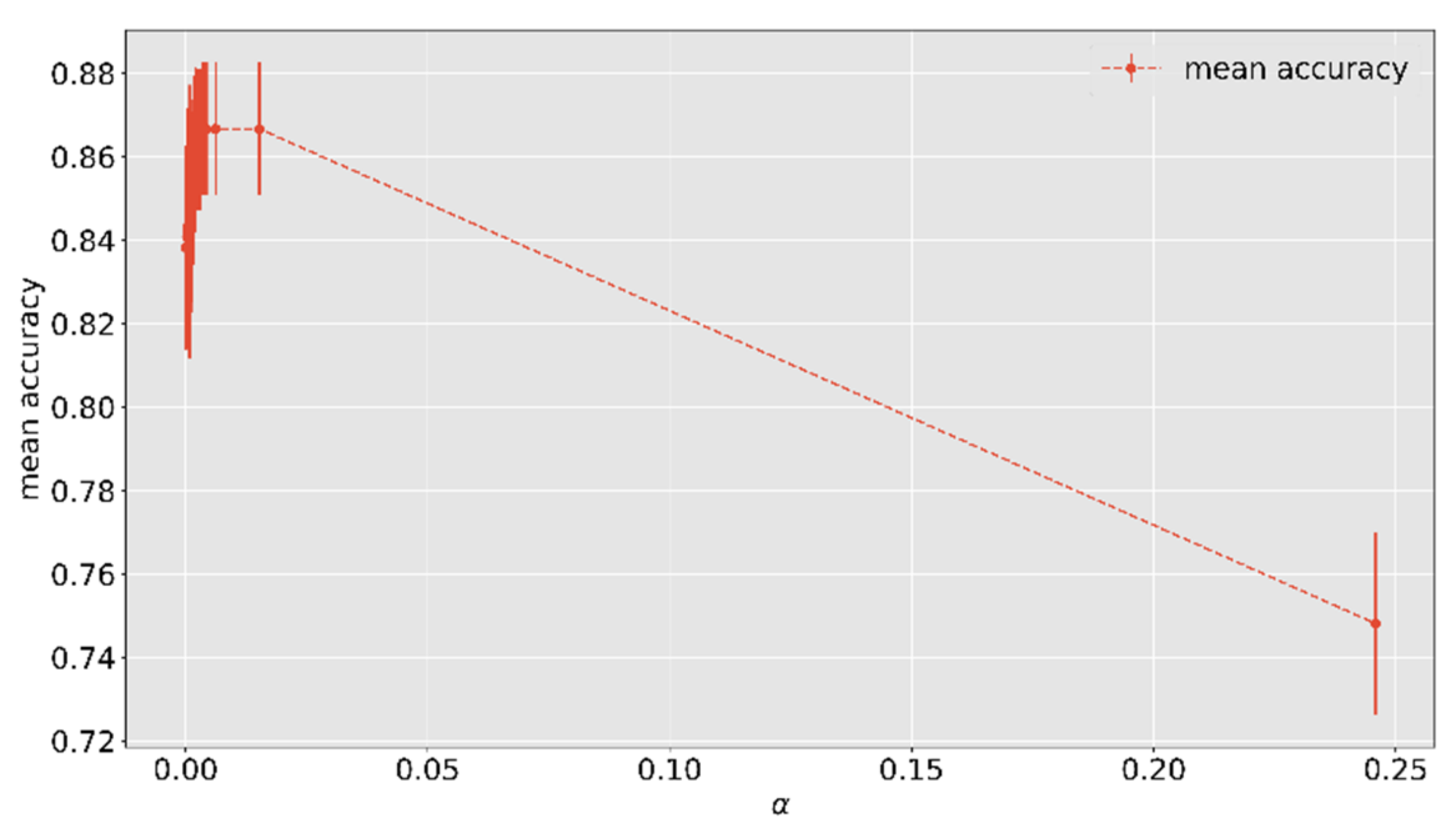

4. Results and Discussion

4.1. Implementation of the Recommendation System

Ontology Modeling

- Operating conditions

- ◦

- Days of operation

- ◦

- Irrigation ratios

- ◦

- Types of reagents

- ◦

- Total reagent added

- Modes of operation

- ◦

- Mode A

- ◦

- Mode B

- ◦

- Mode X

- Heap

- ◦

- Physical characteristics

- ⬝

- Heap height

- ⬝

- Granulometry

- ◦

- Chemical characteristics

- ⬝

- Grade of oxides

- ⬝

- Grade of primary sulfides

- ⬝

- Grade of secondary sulfides

- Types of reagents

- ◦

- H2SO4

- ◦

- Cl

- Mineral recovery

- Type of mineral in the feed (Mineral)

- ◦

- Oxides

- ◦

- Sulfides

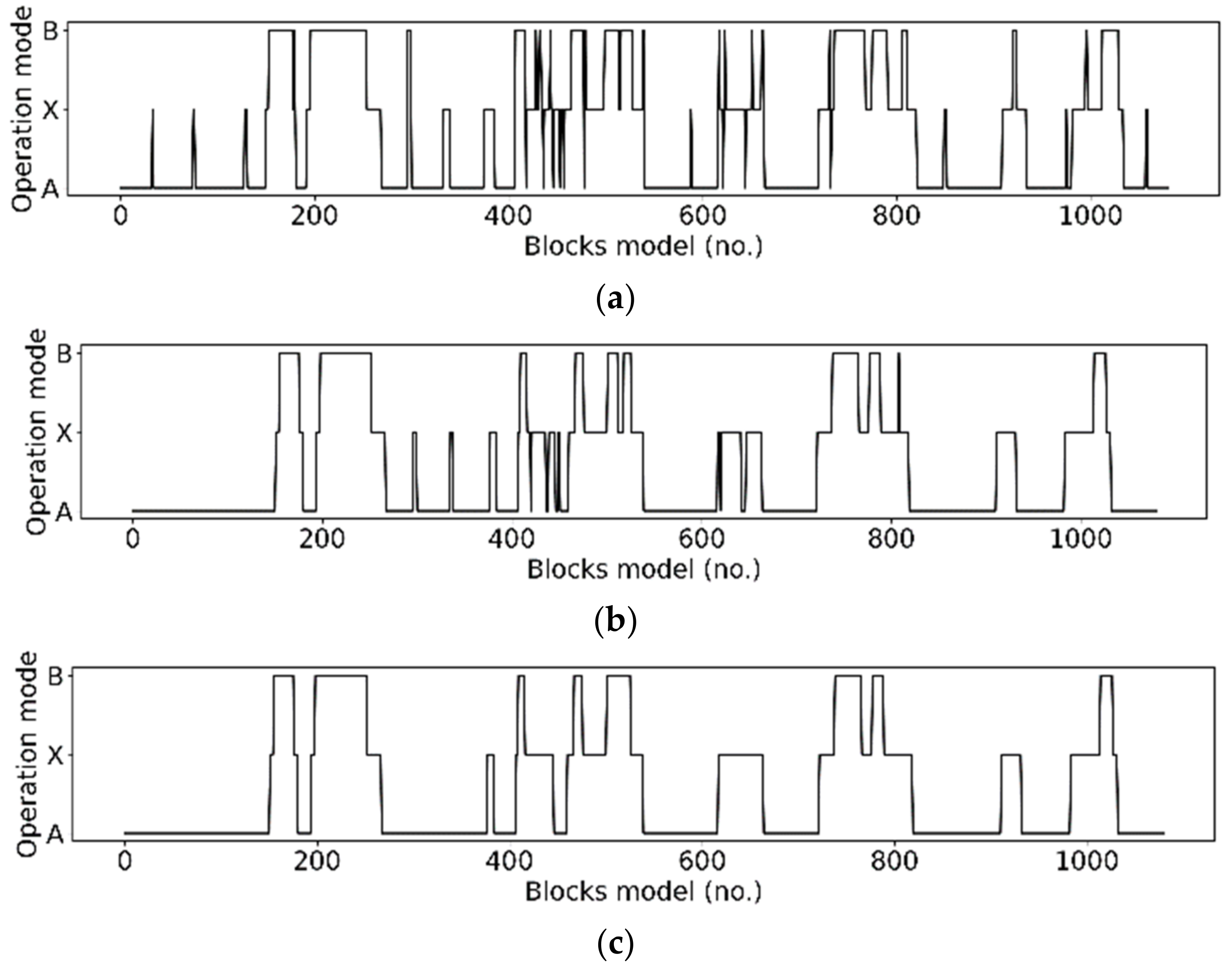

4.2. Evaluation of Recommendations

4.3. Discussion

5. Conclusions and Future Works

- The first decision support system was presented that allows decision support to the hydrometallurgical phase of heap leaching.

- An inference system was formalized and developed to recommend a mode of operation based on variations in feeding.

- This inference engine was integrated into a recommendation system that generates predictions of the responses.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schwab, K. The Fourth Industrial Revolution, 1st ed.; World Economic Forum: Cologny, Switzerland, 2016; Volume 1, ISBN 9781524758868. [Google Scholar]

- Lee, J.; Davari, H.; Singh, J.; Pandhare, V. Industrial artificial intelligence for industry 4.0-based manufacturing systems. Manuf. Lett. 2018, 18, 20–23. [Google Scholar] [CrossRef]

- Li, J.; Zhan, K. Intelligent mining technology for an underground metal mine based on unmanned equipment. Engineering 2018, 4, 381–391. [Google Scholar] [CrossRef]

- Li, L.; Pan, D.; Li, B.; Wu, Y.; Wang, H.; Gu, Y.; Zuo, T. Patterns and challenges in the copper industry in China. Resour. Conserv. Recycl. 2017, 127, 1–7. [Google Scholar] [CrossRef]

- Free, M. Hydrometallurgy: Fundamentals and Applications, 1st ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013; ISBN 9781118230770. [Google Scholar]

- Solomon, F.; Katz, E.; Lovel, R. Social dimensions of mining: Research, policy and practice challenges for the minerals industry in Australia. Resour. Policy 2008, 33, 142–149. [Google Scholar] [CrossRef]

- Ghassim, B.; Foss, L. Understanding the micro-foundations of internal capabilities for open innovation in the minerals industry: A holistic sustainability perspective. Resour. Policy 2018. [Google Scholar] [CrossRef]

- Domic, E. Hidrometalurgia: Fundamentos, Procesos y Aplicaciones, 1st ed.; Santiago De Chile: Santiago, Chile, 2001; ISBN 978-956-291-083-5. [Google Scholar]

- Cui, C.; Hu, M.; Weir, J.D.; Wu, T. A recommendation system for meta-modeling: A meta-learning based approach. Expert Syst. Appl. 2016, 46, 33–44. [Google Scholar] [CrossRef] [Green Version]

- Saldaña, M.; Toro, N.; Castillo, J.; Hernández, P.; Navarra, A. Optimization of the heap leaching process through changes in modes of operation and discrete event simulation. Minerals 2019, 9, 421. [Google Scholar] [CrossRef] [Green Version]

- Flanagan, D.M. Copper. In Mineral Commodity Summaries 2021; U.S. Geological Survey: Reston, VA, USA, 2021; pp. 52–53. ISBN 9781411343986. [Google Scholar]

- Torres, D.; Trigueros, E.; Robles, P.; Leiva, W.H.; Jeldres, R.I.; Toledo, P.G.; Toro, N. Leaching of pure chalcocite with reject brine and mno2 from manganese nodules. Metals 2020, 10, 1426. [Google Scholar] [CrossRef]

- Navarra, A.; Marambio, H.; Oyarzún, F.; Parra, R.; Mucciardi, F. System dynamics and discrete event simulation of copper smelters. Miner. Metall. Process. 2017, 34, 96–106. [Google Scholar] [CrossRef]

- Servicio Nacional de Geología y Minería. Anuario de la Mineria de Chile 2017; Servicio Nacional de Geología y Minería: Santiago, Chile, 2017.

- Consejo Minero. Cifras Actualizadas de la Minería; Consejo Minero: Santiago, Chile, 2021.

- Comisión Chilena del Cobre. Sulfuros Primarios: Desafíos y Oportunidades; Comisión Chilena del Cobre: Santiago, Chile, 2017.

- Morales, C. La Apuesta por la Reutilización de Escorias. Available online: http://www.nuevamineria.com/revista/la-apuesta-por-la-reutilizacion-de-escorias/ (accessed on 25 October 2020).

- Ibañez, T. Disolución de Calcopirita en Medios Clorurados. M.S. Thesis, Facultad de Ingeniería y Ciencias Geológicas, Universidad Católica del Norte, Antofagasta, Chile, 2011. [Google Scholar]

- Comisión Chilena del Cobre. Minería en Chile: Impacto en Regiones y Desafíos Para Su Desarrollo, 1st ed.; Betancour, M.C., Maldonado, P., Eds.; Salesianos: Santiago, Chile, 2013; ISBN 978-956-8242-20-6.

- Schlesinger, M.; King, M.; Sole, K.; Davenport, W. Extractive Metallurgy of Copper, 5th ed.; Elsevier: Amsterdam, The Netherlands, 2011; ISBN 9780080967899. [Google Scholar]

- Mellado, M.E.; Cisternas, L.A.; Gálvez, E.D. An analytical model approach to heap leaching. Hydrometallurgy 2009, 95, 33–38. [Google Scholar] [CrossRef]

- Mellado, M.; Cisternas, L.; Lucay, F.; Gálvez, E.; Sepúlveda, F. A posteriori analysis of analytical models for heap leaching using uncertainty and global sensitivity analyses. Minerals 2018, 8, 44. [Google Scholar] [CrossRef] [Green Version]

- Velásquez-Yévenes, L.; Nicol, M.; Miki, H. The dissolution of chalcopyrite in chloride solutions Part The effect of solution potential. Hydrometallurgy 2010, 103, 108–113. [Google Scholar] [CrossRef]

- Marsden, J.O.; Botz, M.M. Heap leach modeling. A review of approaches to metal production forecasting. Miner. Metall. Process. 2017, 34, 53–64. [Google Scholar] [CrossRef]

- Chetty, D. Acid-gangue interactions in heap leach operations: A review of the role of mineralogy for predicting ore behaviour. Minerals 2018, 8, 47. [Google Scholar] [CrossRef] [Green Version]

- Yévenes, L.V.; Miki, H.; Nicol, M. The dissolution of chalcopyrite in chloride solutions: Part 2: Effect of various parameters on the rate. Hydrometallurgy 2010, 103, 80–85. [Google Scholar] [CrossRef]

- Nicol, M.; Miki, H.; Velásquez-Yévenes, L. The dissolution of chalcopyrite in chloride solutions: Part 3: Mechanisms. Hydrometallurgy 2010, 103, 86–95. [Google Scholar] [CrossRef]

- Russell, S.; Norvig, P. Artificial Intelligence. A Modern Approach, 3th ed.; Prentice Hall: Englewood Cliffs, NJ, USA, 2016; Volume 3, ISBN 9781292153964. [Google Scholar]

- Kelleher, J.; Namee, B.M.; D’Arcy, A. Fundamentals of Machine Learning for Predictive Data Analytics, 1st ed.; The MIT Press: London, UK, 2015; ISBN 9780262029445. [Google Scholar]

- Jannach, D.; Zanker, M.; Felfernig, A.; Friedrich, G. Recommender Systems: An Introduction, 1st ed.; Cambridge University Press: New York, NY, USA, 2011; ISBN 9780521493369. [Google Scholar]

- Pérez, K.; Toro, N.; Saldaña, M.; Salinas-Rodríguez, E.; Robles, P.; Torres, D.; Jeldres, R.I. Statistical study for leaching of covellite in a chloride media. Metals 2020, 10, 477. [Google Scholar] [CrossRef] [Green Version]

- Toro, N.; Briceño, W.; Pérez, K.; Cánovas, M.; Trigueros, E.; Sepúlveda, R.; Hernández, P. Leaching of pure chalcocite in a chloride media using sea water and waste water. Metals 2019, 9, 780. [Google Scholar] [CrossRef] [Green Version]

- Mellado, M.E.; Casanova, M.P.; Cisternas, L.A.; Gálvez, E.D. On scalable analytical models for heap leaching. Comput. Chem. Eng. 2011, 35, 220–225. [Google Scholar] [CrossRef]

- Mellado, M.E.; Gálvez, E.D.; Cisternas, L.A. On the optimization of flow rates on copper heap leaching operations. Int. J. Miner. Process. 2011, 101, 75–80. [Google Scholar] [CrossRef]

- Dixon, D.G.; Hendrix, J.L. A general model for leaching of one or more solid reactants from porous ore particles. Metall. Trans. B 1993, 24, 157–169. [Google Scholar] [CrossRef]

- Dixon, D.G.; Hendrix, J.L. A mathematical model for heap leaching of one or more solid reactants from porous ore pellets. Metall. Trans. B 1993, 24, 1087–1102. [Google Scholar] [CrossRef]

- McCoy, J.T.; Auret, L. Machine learning applications in minerals processing: A review. Miner. Eng. 2019, 132, 95–109. [Google Scholar] [CrossRef]

- Saldaña, M.; González, J.; Jeldres, R.; Villegas, Á.; Castillo, J.; Quezada, G.; Toro, N. A stochastic model approach for copper heap leaching through Bayesian networks. Metals 2019, 9, 1198. [Google Scholar] [CrossRef] [Green Version]

- Milivojevic, M.; Stopic, S.; Friedrich, B.; Stojanovic, B.; Drndarevic, D. Computer modeling of high-pressure leaching process of nickel laterite by design of experiments and neural networks. Int. J. Miner. Metall. Mater. 2012, 19, 584–594. [Google Scholar] [CrossRef]

- Leiva, C.; Flores, V.; Salgado, F.; Poblete, D.; Acuña, C. Applying softcomputing for copper recovery in leaching process. Sci. Program. 2017, 2017. [Google Scholar] [CrossRef] [Green Version]

- Montgomery, D.C.; Runger, G.C. Applied Statistics and Probalisty for Engineers, 6th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2014; ISBN 9781118539712. [Google Scholar]

- Bezerra, M.A.; Santelli, R.E.; Oliveira, E.P.; Villar, L.S.; Escaleira, L.A. Response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta 2008, 76, 965–977. [Google Scholar] [CrossRef]

- Aguirre, C.L.; Toro, N.; Carvajal, N.; Watling, H.; Aguirre, C. Leaching of chalcopyrite (CuFeS2) with an imidazolium-based ionic liquid in the presence of chloride. Miner. Eng. 2016, 99, 60–66. [Google Scholar] [CrossRef]

- Dean, A.; Voss, D.; Draguljić, D. Design and Analysis of Experiments; Springer Texts in Statistics; Springer International Publishing: Cham, Switzerland, 2017; ISBN 978-3-319-52248-7. [Google Scholar]

- Pérez, K.; Villegas, Á.; Saldaña, M.; Jeldres, R.I.; González, J.; Toro, N. Initial investigation into the leaching of manganese from nodules at room temperature with the use of sulfuric acid and the addition of foundry slag—Part II. Sep. Sci. Technol. 2021, 56, 389–394. [Google Scholar] [CrossRef]

- Saldaña, M.; Gálvez, E.; Jeldres, R.I.; Díaz, C.; Robles, P.; Sinha, M.K.; Toro, N. Optimization of Cu and Mn dissolution from black coppers by means of an agglomerate and curing pretreatment. Metals 2020, 10, 657. [Google Scholar] [CrossRef]

- Chelgani, S.C.; Jorjani, E. Artificial neural network prediction of Al2O3 leaching recovery in the Bayer process–Jajarm alumina plant (Iran). Hydrometallurgy 2009, 97, 105–110. [Google Scholar] [CrossRef]

- Vyas, S.; Das, S.; Ting, Y.P. Predictive modeling and response analysis of spent catalyst bioleaching using artificial neural network. Bioresour. Technol. Rep. 2020, 9, 100389. [Google Scholar] [CrossRef]

- Hoseinian, F.S.; Abdollahzade, A.; Mohamadi, S.S.; Hashemzadeh, M. Recovery prediction of copper oxide ore column leaching by hybrid neural genetic algorithm. Trans. Nonferrous Met. Soc. China 2017, 27, 686–693. [Google Scholar] [CrossRef]

- Abdollahi, H.; Noaparast, M.; Shafaei, S.Z.; Akcil, A.; Panda, S.; Kashi, M.H.; Karimi, P. Prediction and optimization studies for bioleaching of molybdenite concentrate using artificial neural networks and genetic algorithm. Miner. Eng. 2019, 130, 24–35. [Google Scholar] [CrossRef]

- Flasiński, M. Rule-Based Systems, 1st ed.; Springer International Publishing: Cham, Switzerland, 2016; ISBN 978-3-319-40020-4. [Google Scholar]

- Grosan, C.; Abraham, A. Intelligent Systems, 1st ed.; Intelligent Systems Reference Library; Grosan, C., Abraham, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; Volume 17, ISBN 978-3-642-21003-7. [Google Scholar]

- Rattanasawad, T.; Buranarach, M.; Saikaew, K.R.; Supnithi, T. A comparative study of rule-based inference engines for the semantic web. IEICE Trans. Inf. Syst. 2018, 101, 82–89. [Google Scholar] [CrossRef] [Green Version]

- Brachman, R.J.; Levesque, H.J. Knowledge Representation and Reasoning; Elsevier Inc.: San Francisco, CA, USA, 2004; ISBN 9781558609327. [Google Scholar]

- Yun, W.; Zhang, X.; Li, Z.; Liu, H.; Han, M. Knowledge modeling: A survey of processes and techniques. Int. J. Intell. Syst. 2021. [Google Scholar] [CrossRef]

- Gruber, T.R. A translation approach to portable ontology specifications. Knowl. Acquis. 1993, 5, 199–220. [Google Scholar] [CrossRef]

- Studer, R.; Benjamins, V.; Fensel, D. Knowledge engineering: Principles and methods. IEEE Trans. Data Knowl. Eng. 1998, 25, 161–197. [Google Scholar] [CrossRef] [Green Version]

- Staab, S.; Studer, R. Handbook on Ontologies; Staab, S., Studer, R., Eds.; Springer: Berlin/Heidelberg, Germany, 2009; ISBN 978-3-540-70999-2. [Google Scholar]

- Toro, N.; Saldaña, M.; Gálvez, E.; Cánovas, M.; Trigueros, E.; Castillo, J.; Hernández, P.C. Optimization of parameters for the dissolution of Mn from manganese nodules with the use of tailings in an acid medium. Minerals 2019, 9, 387. [Google Scholar] [CrossRef] [Green Version]

- Demergasso, C.; Galleguillos, F.; Soto, P.; Serón, M.; Iturriaga, V. Microbial succession during a heap bioleaching cycle of low grade copper sulfides: Does this knowledge mean a real input for industrial process design and control? Hydrometallurgy 2010, 104, 382–390. [Google Scholar] [CrossRef]

- Hastie, T.; Tibshirani, R.; Friedman, J. The Elements of Statistical Learning: Data Mining, Inference and Prediction, 2nd ed.; Springer: Berlin, Germany, 2017; ISBN 9780387848570. [Google Scholar]

- Saldaña, M.; Rodríguez, F.; Rojas, A.; Pérez, K.; Angulo, P. Development of an empirical model for copper extraction from chalcocite in chloride media. Hem. Ind. 2020, 74, 285–292. [Google Scholar] [CrossRef]

- Saldaña, M.; Flores, V.; Toro, N.; Leiva, C. Representation for a Prototype of Recommendation System of Operation Mode in Copper Mining. In Proceedings of the 2019 14th Iberian Conference on Information Systems and Technologies (CISTI) IEEE, Coimbra, Portugal, 19–22 June 2019; pp. 1–4. [Google Scholar]

- Mellado, M.E.; Gálvez, E.D.; Cisternas, L.A. Stochastic analysis of heap leaching process via analytical models. Miner. Eng. 2012, 33, 93–98. [Google Scholar] [CrossRef]

- Flores, V.; Keith, B.; Leiva, C. Using artificial intelligence techniques to improve the prediction of copper recovery by leaching. J. Sens. 2020, 2020. [Google Scholar] [CrossRef] [Green Version]

- Kitamura, Y.; Ikeda, M.; Mizoguchi, R. A Model-Based Expert System Based on a Domain Ontology. In Expert Systems. The Technology of Knowledge Management and Decision Making for the 21st Century; Academic Press Inc.: Cambridge, MA, USA, 2002; pp. 171–196. ISBN 978-0-12-443880-4. [Google Scholar]

- Musen, M.A. The Protégé project: A look back and a look forward. AI Matters 2015, 1. [Google Scholar] [CrossRef] [PubMed]

| Cl/Sulfides | Non-Existent | Medium | High |

|---|---|---|---|

| Cl20 | 0 | 1 | 0 |

| Cl50 | 0 | 0 | 1 |

| System | Historical | ||

|---|---|---|---|

| Real/Predicted | A | B | X |

| A | 2982 | 47 | 146 |

| B | 17 | 769 | 127 |

| X | 94 | 81 | 2487 |

| Statistical/Mode | A | B | X |

|---|---|---|---|

| Accuracy | 0.9550 | 0.9597 | 0.9336 |

| Precision | 0.9392 | 0.8423 | 0.9343 |

| Recall | 0.9641 | 0.8573 | 0.9011 |

| Specificity | 0.9472 | 0.9754 | 0.9561 |

| Accuracy | 0.9550 | 0.9597 | 0.9336 |

| System | Historical | Expert | ||||

|---|---|---|---|---|---|---|

| Real/Predicted | A | B | X | A | B | X |

| A | 592 | 7 | 17 | 587 | 13 | 22 |

| B | 8 | 198 | 21 | 12 | 188 | 21 |

| X | 12 | 13 | 212 | 16 | 19 | 202 |

| Indicator | Modo | Proposal/Historical | Proposal/Expert |

|---|---|---|---|

| Accuracy | A | 0.95926 | 0.94167 |

| B | 0.95463 | 0.93981 | |

| X | 0.94167 | 0.92778 | |

| Precision | A | 0.96104 | 0.94373 |

| B | 0.87225 | 0.85068 | |

| X | 0.89451 | 0.85232 | |

| Recall | A | 0.96732 | 0.95447 |

| B | 0.90826 | 0.85455 | |

| X | 0.84800 | 0.82449 | |

| Specificity | A | 0.94872 | 0.92473 |

| B | 0.96636 | 0.96163 | |

| X | 0.96988 | 0.95808 | |

| F1 score | A | 0.96417 | 0.94907 |

| B | 0.88989 | 0.85261 | |

| X | 0.87064 | 0.83817 | |

| MCC | A | 0.91699 | 0.88090 |

| B | 0.86161 | 0.81480 | |

| X | 0.83351 | 0.79189 | |

| Kappa index | A | 0.91696 | 0.88082 |

| B | 0.86133 | 0.81480 | |

| X | 0.83301 | 0.79171 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saldaña, M.; Neira, P.; Flores, V.; Robles, P.; Moraga, C. A Decision Support System for Changes in Operation Modes of the Copper Heap Leaching Process. Metals 2021, 11, 1025. https://doi.org/10.3390/met11071025

Saldaña M, Neira P, Flores V, Robles P, Moraga C. A Decision Support System for Changes in Operation Modes of the Copper Heap Leaching Process. Metals. 2021; 11(7):1025. https://doi.org/10.3390/met11071025

Chicago/Turabian StyleSaldaña, Manuel, Purísima Neira, Víctor Flores, Pedro Robles, and Carlos Moraga. 2021. "A Decision Support System for Changes in Operation Modes of the Copper Heap Leaching Process" Metals 11, no. 7: 1025. https://doi.org/10.3390/met11071025

APA StyleSaldaña, M., Neira, P., Flores, V., Robles, P., & Moraga, C. (2021). A Decision Support System for Changes in Operation Modes of the Copper Heap Leaching Process. Metals, 11(7), 1025. https://doi.org/10.3390/met11071025