Fatigue and Crack Growth under Constant- and Variable-Amplitude Loading in 9310 Steel Using “Rainflow-on-the-Fly” Methodology

Abstract

1. Introduction

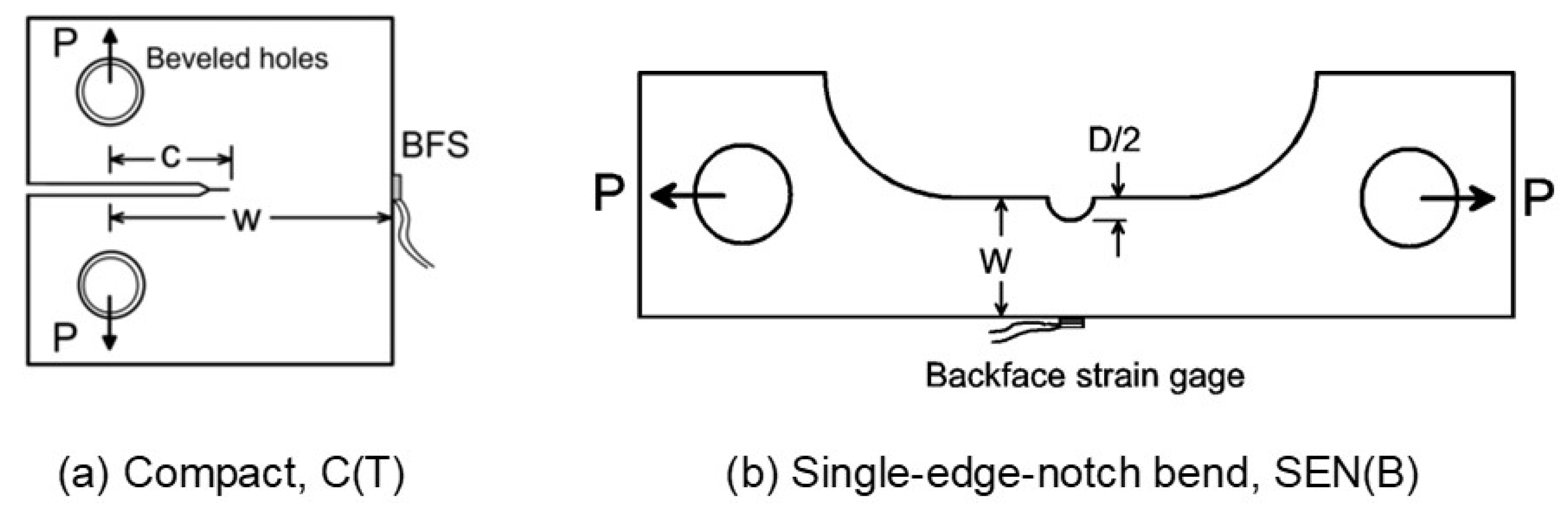

2. Material and Specimen Configurations

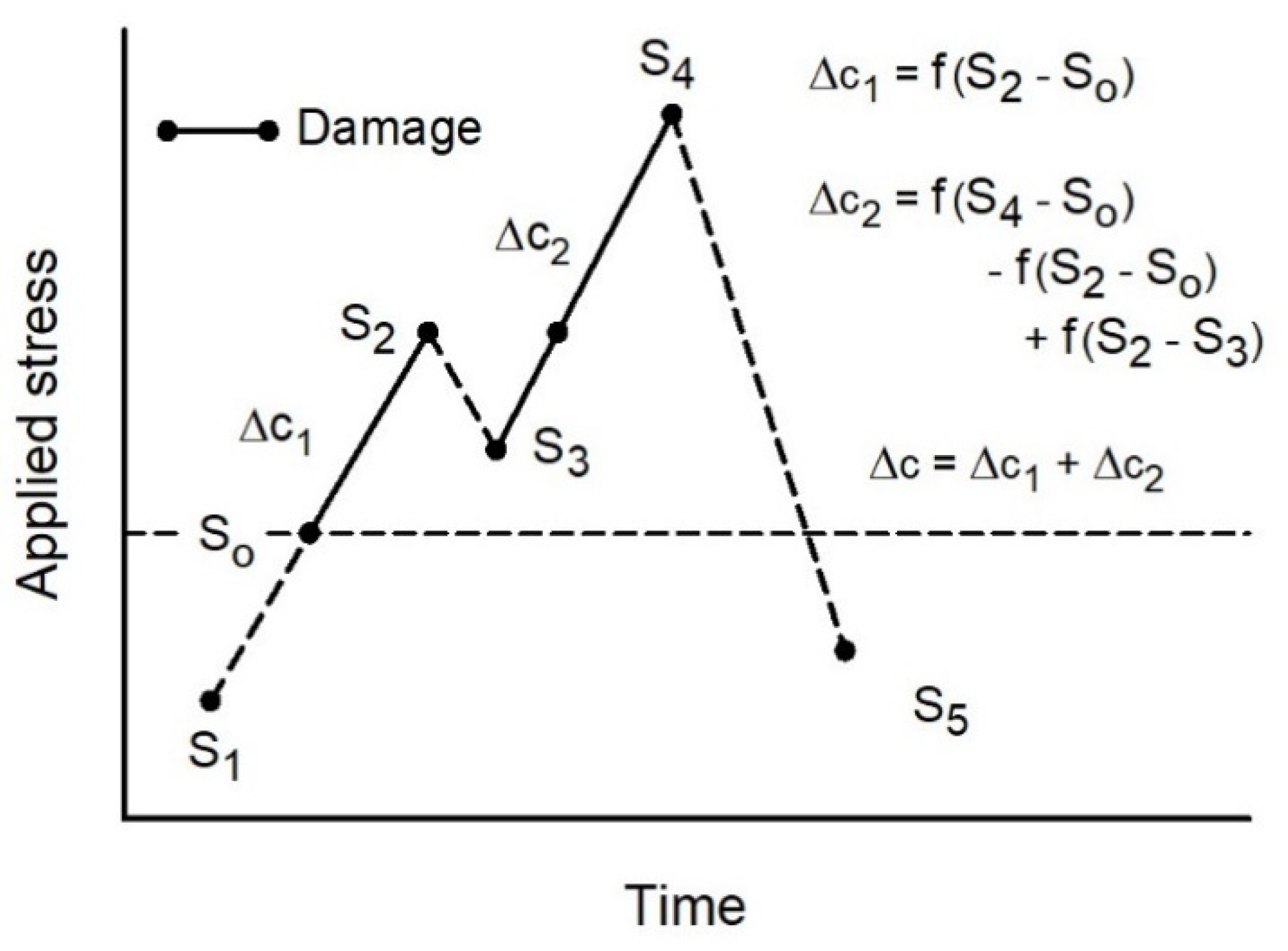

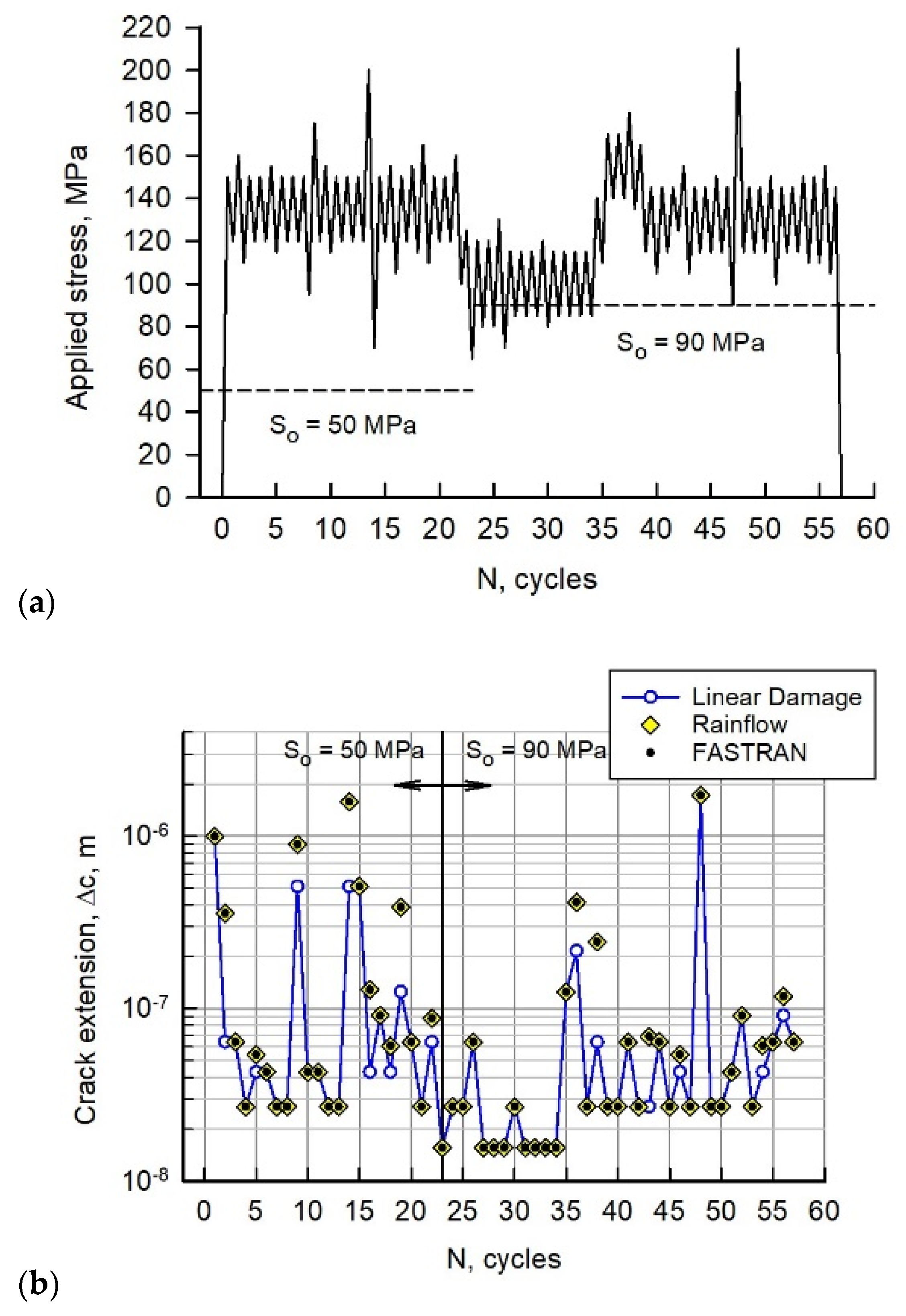

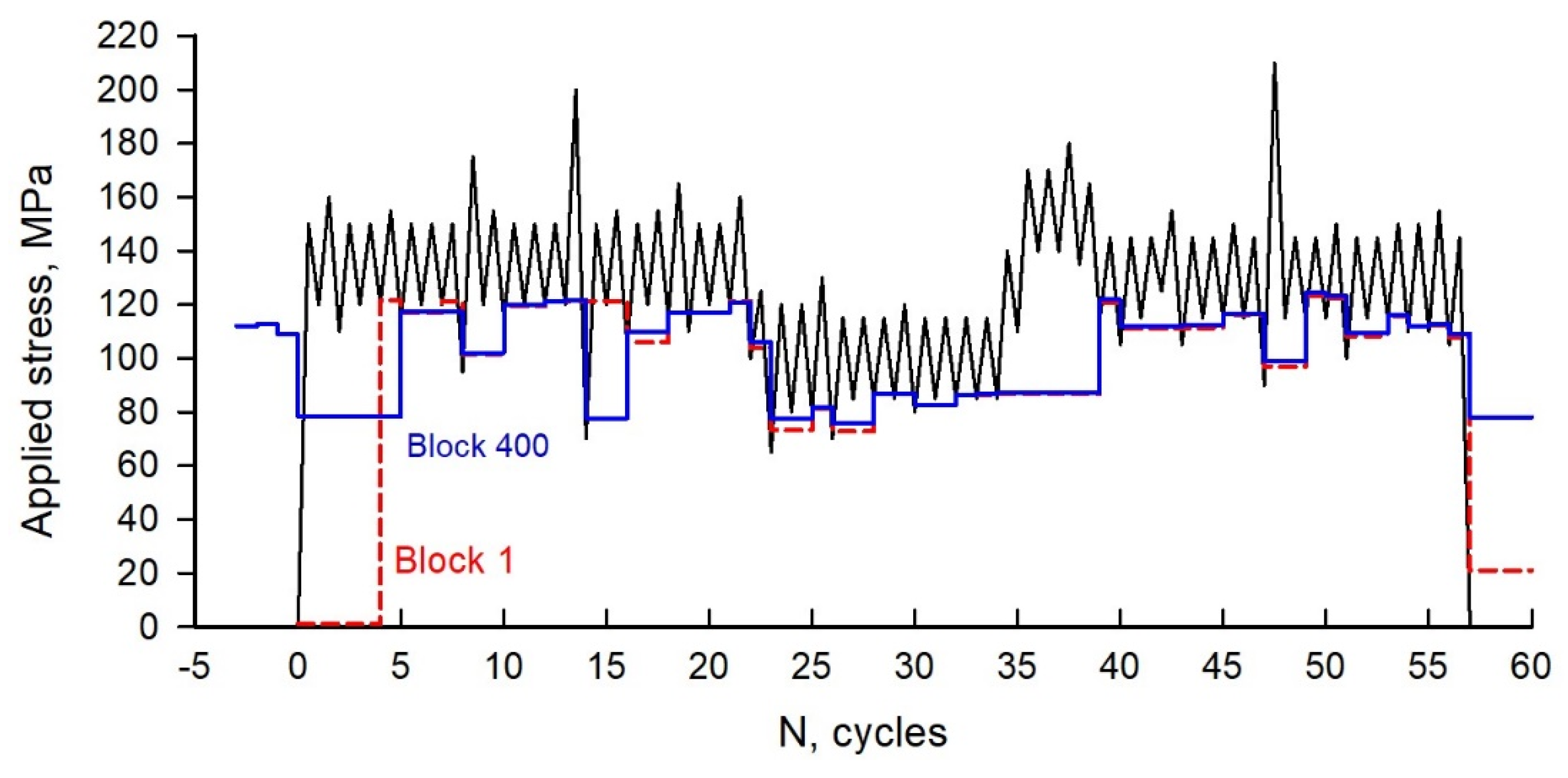

3. “Rainflow-on-the-Fly” Methodology

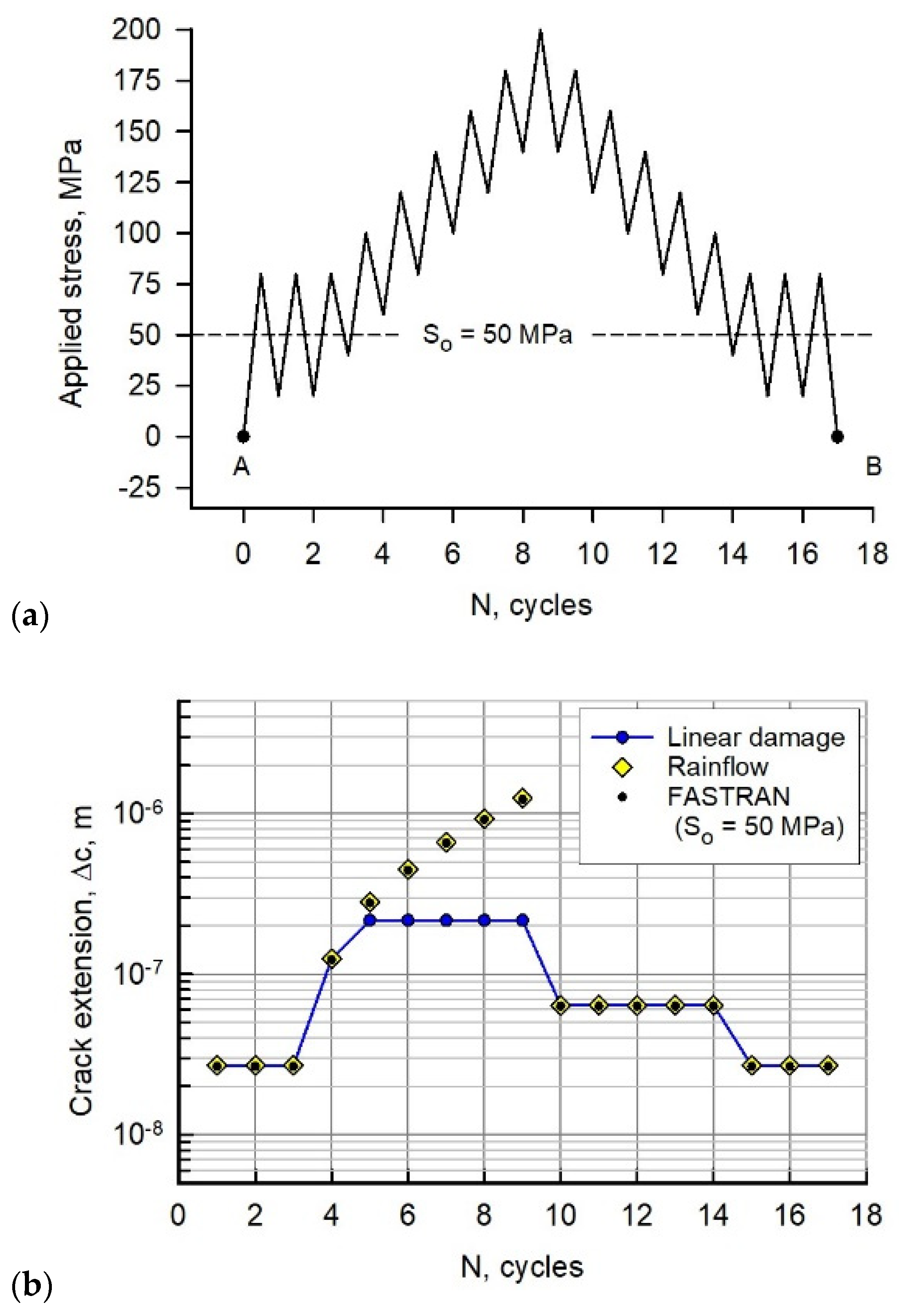

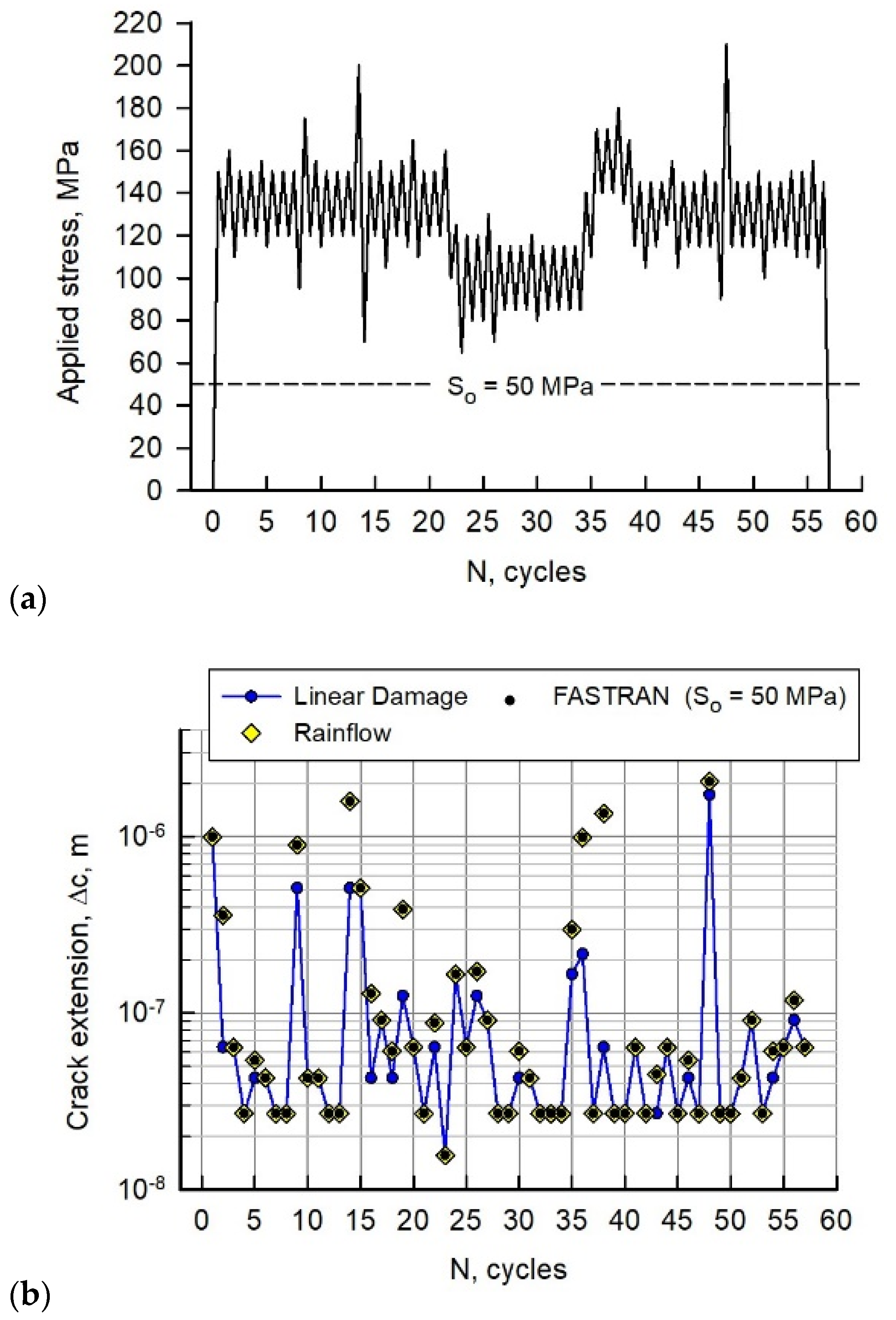

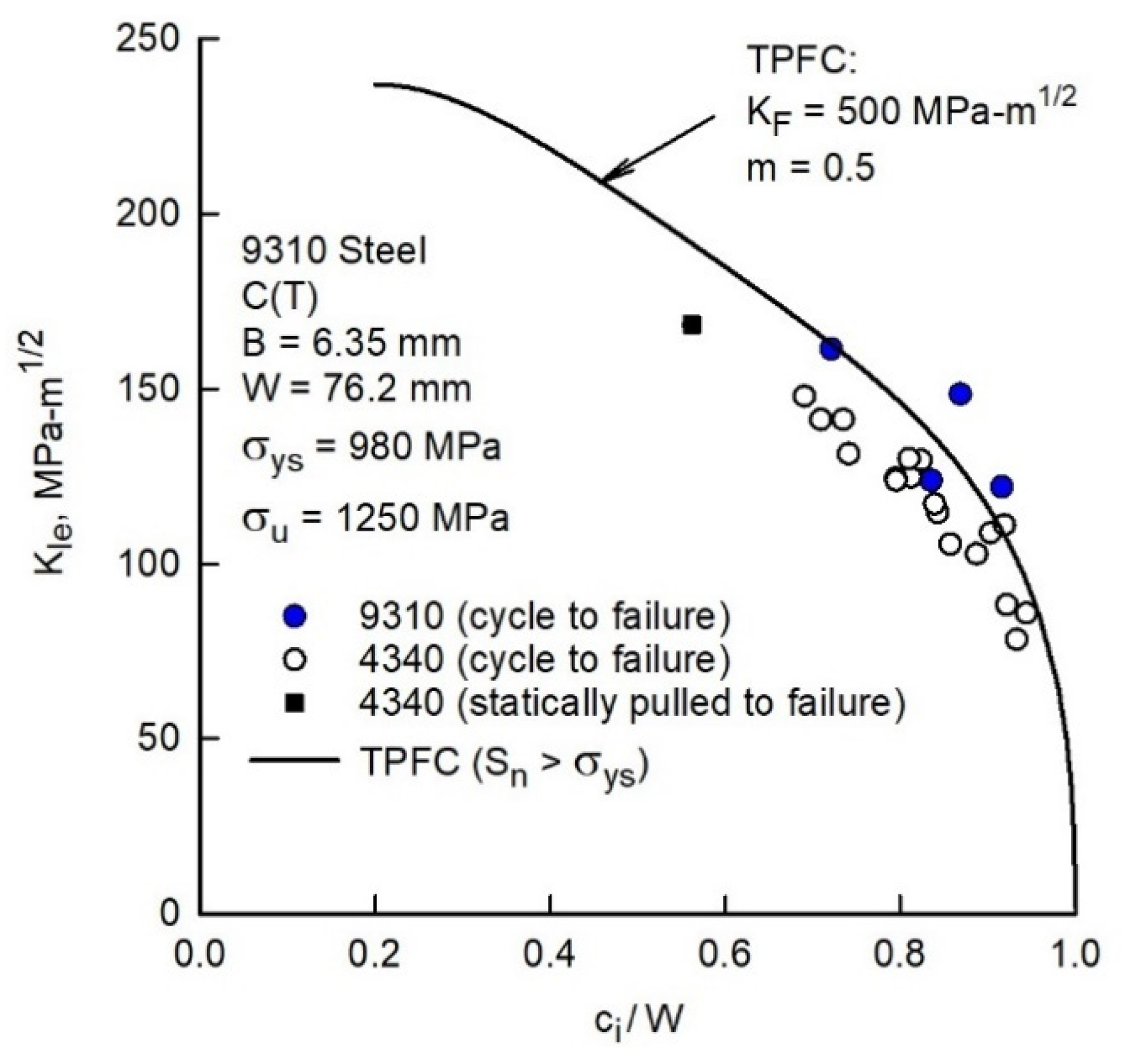

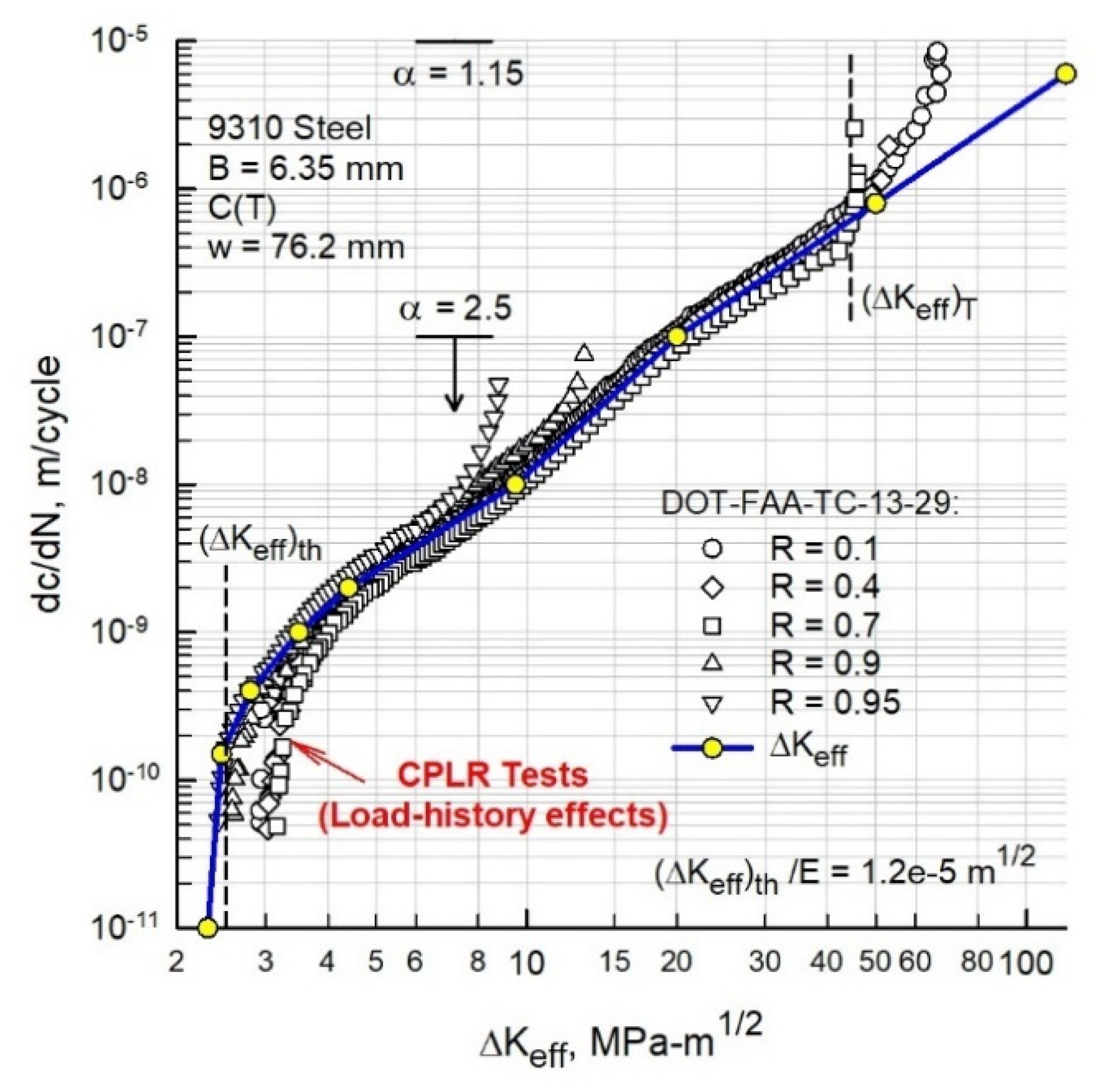

4. Fatigue-Crack-Growth and Fracture Tests on 9310 Steel

5. Fatigue-Crack-Growth and Crack-Closure Analyses

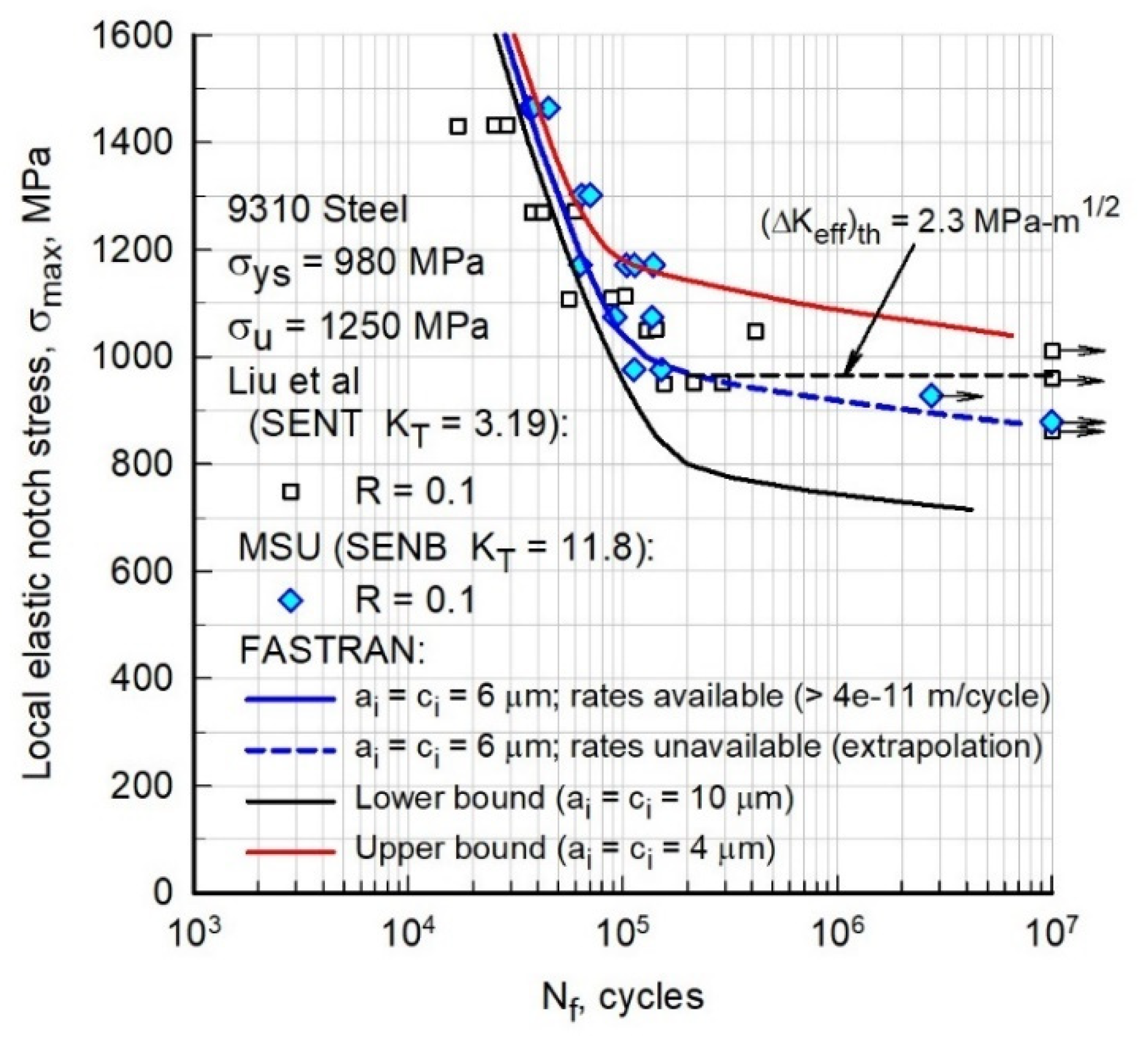

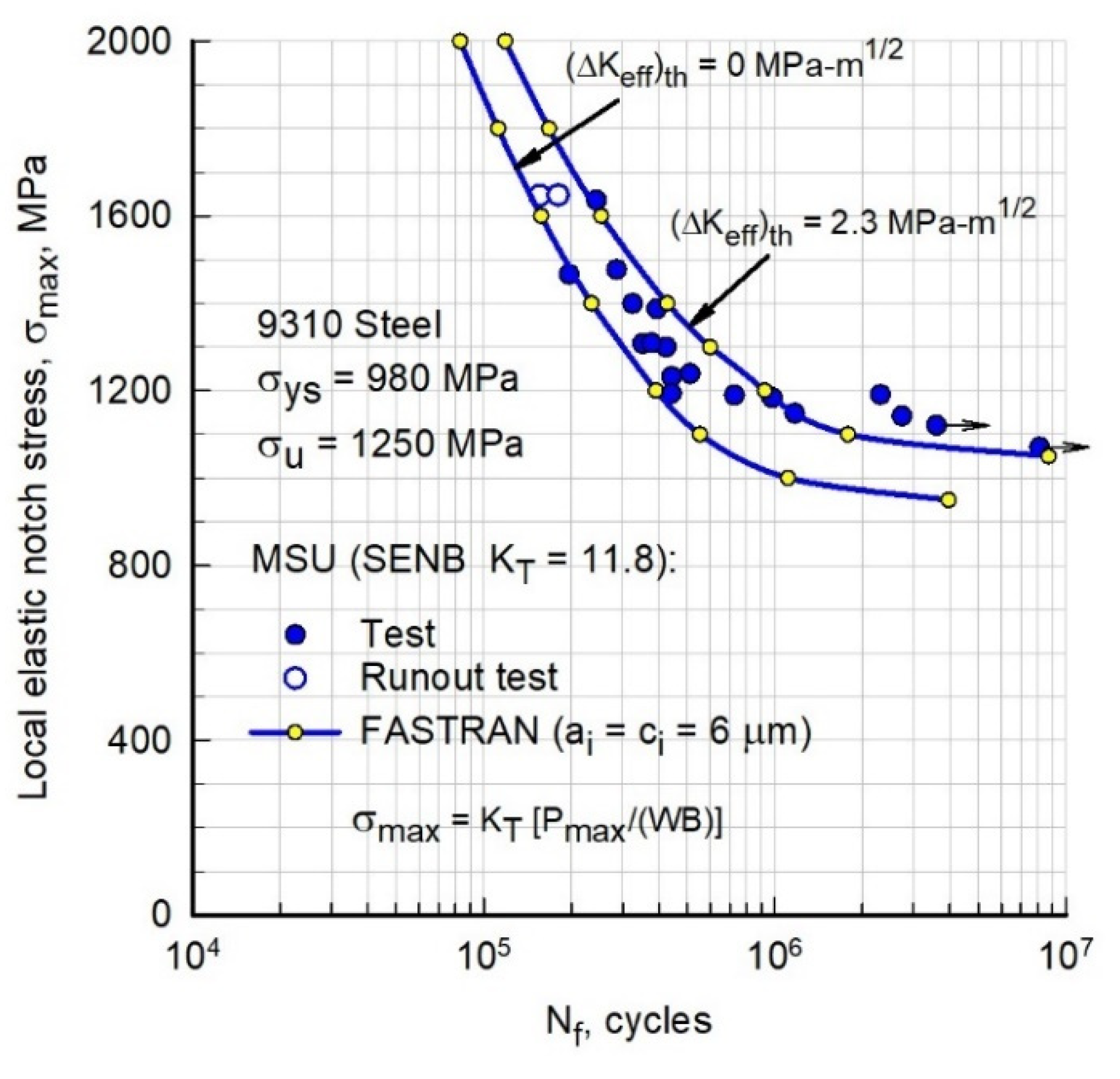

6. Fatigue Behavior of Notched Specimens

7. Concluding Remarks

Funding

Conflicts of Interest

Nomenclature

| a | crack depth in thickness direction, mm |

| ai | initial crack depth in thickness direction, mm |

| B | specimen thickness, mm |

| c | crack length in width direction, mm |

| ci | initial crack length in width direction, mm |

| D | single-edge-notch diameter, mm |

| da/dN | crack-growth rate in depth direction, m/cycle |

| dc/dN | crack-growth rate in width direction, m/cycle |

| E | modulus of elasticity, GPa |

| F | boundary-correction factor |

| Fn | boundary-correction factor based on net-section stress |

| K | stress-intensity factor, MPa√m |

| KF | elastic-plastic fracture toughness, MPa√m |

| KIe | elastic fracture toughness, MPa√m |

| Kmax | maximum stress-intensity factor, MPa√m |

| KT | elastic stress-concentration factor |

| m | fracture toughness parameter |

| N | number of cycles |

| Nf | number of cycles to failure |

| P | applied load, kN |

| Pf | failure load, kN |

| Pmax | maximum applied load, kN |

| Pmin | minimum applied load, kN |

| R | load ratio (Pmin/Pmax) |

| S | applied remote stress, MPa |

| Smax | maximum applied stress, MPa |

| Smin | minimum applied stress, MPa |

| So | crack-opening stress, MPa |

| w | specimen width, mm |

| α | tensile constraint factor |

| ΔK | stress-intensity factor range, MPa√m |

| ΔKc | stress-intensity-factor range at failure, MPa√m |

| ΔKeff | effective stress-intensity factor range, MPa√m |

| (ΔKeff)th | effective stress-intensity factor range threshold, MPa√m |

| (ΔKeff)T | effective stress-intensity factor range transition, MPa√m |

| ΔKo | effective threshold as a function of R, MPa√m |

| ρ | plastic-zone size, mm |

| σo | flow stress (average of σys and σu), MPa |

| σys | yield stress (0.2 percent offset), MPa |

| σu | ultimate tensile strength, MPa |

| ω | cyclic plastic-zone size, mm |

Abbreviations

| BFS | back-face strain |

| CPCA | compression pre-cracking constant amplitude |

| CPLR | compression pre-cracking load reduction |

| C(T) | compact (tension) specimen |

| SEN(B) | single-edge-notch (bend) specimen |

| SEN(T) | single-edge-notch (tension) specimen |

References

- Elber, W. Some Effects of Crack Closure on the Mechanism of Fatigue Crack Propagation under Cyclic Tension Loading. Ph.D. Thesis, University of New South Wales, Sydney, Australia, 1968. [Google Scholar]

- Elber, W. The significance of fatigue crack closure. In Damage Tolerance in Aircraft Structures; ASTM STP 486; American Society of Testing Materials: Philadelphia, PA, USA, 1971; pp. 230–242. [Google Scholar]

- Schijve, J. Significance of Fatigue Cracks in Micro-Range and Macro-Range; ASTM STP 415; American Society of Testing Materials: Philadelphia, PA, USA, 1967; pp. 415–459. [Google Scholar]

- Suresh, S. Fatigue of Materials; Cambridge University Press: Cambridge, UK, 1991. [Google Scholar]

- Stephens, R.I.; Fatemi, A.; Stephens, R.; Fuchs, H.O. Metal Fatigue in Engineering; John Wiley & Sons: New York, NY, USA, 2000. [Google Scholar]

- Newman, J.C., Jr. The merging of fatigue and fracture mechanics concepts—A historical perspective. Prog. Aerosp. Sci. 1998, 34, 345–388. [Google Scholar] [CrossRef]

- Schijve, J. Four lectures on fatigue crack growth. Eng. Fract. Mech. 1979, 11, 167–221. [Google Scholar] [CrossRef]

- Bowles, C.Q.; Schijve, J. The role of inclusions in fatigue crack initiation in an aluminum alloy. Int. J. Fract. 1973, 9, 171–179. [Google Scholar] [CrossRef]

- Morris, W.; Buck, O.; Marcus, H. Fatigue crack initiation and early propagation in Al 2219-T851. Metall. Trans. 1976, 7, 1161–1165. [Google Scholar] [CrossRef]

- Kung, C.Y.; Fine, M.E. Fatigue crack initiation and microcrack growth in 2024-T4 and 2124-T4 aluminum alloys. Metall. Trans. 1979, 10, 603–610. [Google Scholar] [CrossRef]

- Newman, J.C., Jr.; Edwards, P.R. Short-Crack Growth Behaviour in an Aluminum Alloy—An AGARD Cooperative Test Programme; AGARD Report No. 732; North Atlantic Treaty Organization: Neuilly Sur Seine, France, 1988. [Google Scholar]

- Mom, A.J.A.; Raizenne, M.D. (Eds.) AGARD Engine Disc Cooperative Test Programme; AGARD Report No. 766; North Atlantic Treaty Organization: Neuilly Sur Seine, France, 1988. [Google Scholar]

- Edwards, P.R.; Newman, J.C., Jr. (Eds.) Short-Crack Growth Behaviour in Various Aircraft Materials; AGARD Report No. 767; North Atlantic Treaty Organization: Neuilly Sur Seine, France, 1990. [Google Scholar]

- Newman, J.C., Jr.; Wu, X.R.; Venneri, S.L.; Li, C.G. Small-Crack Effects in High-Strength Aluminum Alloys—A NASA/CAE Cooperative Program; NASA RP-1309; National Aeronautics and Space Administration: Washington, WA, USA, 1994.

- Newman, J.C., Jr. Application of a closure model to predict crack growth in three engine disc materials. Int. J. Fract. 1996, 80, 193–218. [Google Scholar] [CrossRef]

- Newman, J.C., Jr.; Phillips, E.P.; Everett, R.A., Jr. Fatigue Analyses Under Constant- and Variable-Amplitude Loading Using Small-Crack Theory; NASA TM-209329; National Aeronautics and Space Administration: Washington, WA, USA, 1999.

- Murakami, Y. The rainflow method in fatigue. In Proceedings of the International Symposium Fatigue Damage Measurement and Evaluation under Complex Loadings, Fukuoka, Japan, 25–26 July 1991. [Google Scholar]

- Newman, J.C., Jr. FASTRAN—A Fatigue Crack Growth Life Prediction Code Based on the Crack-Closure Concept, Version 5.4 User Guide; Fatigue and Fracture Associates LLC: Eupora, MS, USA, 2013. [Google Scholar]

- Newman, J.C., Jr. Rainflow-on-the-fly methodology: Fatigue-crack growth under aircraft spectrum loading. Adv. Mater. Res. 2014, 891, 771–776. [Google Scholar] [CrossRef]

- Newman, J.C., Jr.; Yamada, Y.; Ziegler, B.M.; Shaw, J.W. Small- and Large-Crack Databases for Rotorcraft Materials; DOT/FAA/ TC-13/29; Department of Transportation: Washington, DC, USA, 2014.

- Topper, T.H.; Au, P.; El Haddad, M.L. The effects of compressive overloads on the threshold stress intensity for short cracks. In Proceedings of the AGARD Conference Proceedings No. 328, Toronto, ON, Canada, 19–24 September 1982; pp. 11.1–11.7. [Google Scholar]

- Suresh, S. Crack initiation in cyclic compression and its application. Eng. Fract. Mech. 1985, 21, 453–463. [Google Scholar] [CrossRef]

- Pippan, R. The growth of short cracks under cyclic compression. Fatigue Fract. Eng. Mater. Struct. 1987, 9, 319–328. [Google Scholar] [CrossRef]

- Pippan, R.; Plöchl, L.; Klanner, F.; Stüwe, H.P. The use of fatigue specimens pre-cracked in compression for measuring threshold values and crack growth. ASTM J. Test. Eval. 1994, 22, 98–106. [Google Scholar]

- Newman, J.C., Jr.; Schneider, J.; Daniel, A.; McKnight, D. Compression pre-cracking to generate near threshold fatigue-crack-growth rates in two aluminum alloys. Int. J. Fatigue 2005, 27, 1432–1440. [Google Scholar] [CrossRef]

- Newman, J.C., Jr.; Ruschau, J.J.; Hill, M.R. Improved test method for very low fatigue-crack-growth-rate data. Fatigue Fract. Eng. Mater. Struct. 2011, 34, 270–279. [Google Scholar] [CrossRef]

- Hudak, S., Jr.; Saxena, S.; Bucci, R.; Malcolm, R. Development of Standard Methods of Testing and Analyzing Fatigue Crack Growth Rate Data; AFML TR 78-40; Materials Laboratory: WPAFB, OH, USA, 1978. [Google Scholar]

- ASTM. Standard Test Method for Measurement of Fatigue Crack Growth Rates; E-647; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Swain, M.H.; Everett, R.A.; Newman, J.C., Jr.; Phillips, E.P. The growth of short cracks in 4340 steel and aluminum-lithium 2090. In AGARD Report No. 767; Edwards, P.R., Newman, J.C., Jr., Eds.; North Atlantic Treaty Organization: Neuilly Sur Seine, France, 1990; pp. 7.1–7.30. [Google Scholar]

- Herman, W.; Hertzberg, R.; Jaccard, R. A simplified laboratory approach for the prediction of short crack behavior in engineering structures. Fatigue Fract. Eng. Mater. Struct. 1988, 11, 303–320. [Google Scholar] [CrossRef]

- Newman, J.C., Jr. Fracture analysis of various cracked configurations in sheet and plate materials. In Properties Related to Fracture Toughness; ASTM STP 605; American Society of Testing Materials: Philadelphia, PA, USA, 1976; pp. 104–123. [Google Scholar]

- Ziegler, B.M. Fatigue and Fracture Testing and Analysis on Four Materials. Ph.D. Thesis, Mississippi State University, Mississippi State, MS, USA, April 2011. [Google Scholar]

- ten Have, A.A. Cold Turbistan—Final Definition of a Standardized Fatigue Test Loading Sequence for Tactical Aircraft Cold Section Engine Disc; NLR TR 87054 L; Nationaal Lucht-en Ruimtevaartlaboratorium: Delft, The Netherlands, 1987. [Google Scholar]

- Yamada, Y.; Newman, J.C., Jr. Crack closure under high load-ratio conditions for Inconel 718 near threshold behavior. Eng. Fract. Mech. 2009, 76, 209–220. [Google Scholar] [CrossRef]

- Yamada, Y.; Newman, J.C., Jr. Crack closure behavior of 2324-T39 aluminum alloy near threshold conditions for high load ratio and constant Kmax tests. Int. J. Fatigue 2009, 31, 1780–1787. [Google Scholar] [CrossRef]

- Newman, J.C., Jr.; Vizzini, A.; Yamada, Y. Fatigue Crack Growth Databases and Analyses for Threshold Behavior in Rotorcraft Materials; DOT/FAA/AR-10/3; Department of Transportation: Washington, DC, USA, 2010.

- Newman, J.C., Jr. Fracture analysis of surface- and through-cracked sheets and plates. Eng. Fract. Mech. 1973, 5, 667–689. [Google Scholar] [CrossRef]

- Newman, J.C., Jr. A crack-opening stress equation for fatigue crack growth. Int. J. Fract. 1984, 24, R131–R135. [Google Scholar] [CrossRef]

- Newman, J.C., Jr.; Kota, K.; Lacy, T.E. Fatigue and crack-growth behavior in a titanium alloy under constant-amplitude and spectrum loading. Eng. Fract. Mech. 2018, 187, 211–224. [Google Scholar] [CrossRef]

- Newman, J.C.; Beukers, A. Effects of constraint on crack growth under aircraft spectrum loading. In Fatigue of Aircraft Materials; Beukers, A., deJong, T., Sinke, J., Vlot, A., Vogelesang, L.B., Eds.; Langley Research Center: Delft, The Netherlands, 1992; pp. 83–109. [Google Scholar]

- Dugdale, D.S. Yielding of steel sheets containing slits. J. Mech. Phys. Solids 1960, 8, 100–104. [Google Scholar] [CrossRef]

- Newman, J.C., Jr. Fracture Mechanics Parameters for Small Fatigue Cracks; ASTM STP 1149; American Society of Testing Materials: West Conshohocken, PA, USA, 1992; pp. 6–33. [Google Scholar]

- Newman, J.C., Jr.; Swain, M.H.; Phillips, E.P. An assessment of the small-crack effect for 2024-T3. In Small Fatigue Cracks; Ritchie, R.O., Lankford, J., Eds.; The Metallurgical Society, Inc.: Warrendale, PA, USA, 1986; pp. 427–452. [Google Scholar]

- Liu, J.Z.; Wu, X.R.; Ding, C.F.; Hu, B.R.; Wang, L.F.; Annigeri, B.; Vestergaard, L.H.; Romanowski, A.; Schneider, G.J.; Forth, S.C. Crack growth behavior and fatigue-life prediction based on worst-case near-threshold data of a large crack for 9310 steel. Fatigue Fract. Eng. Mater. Struct. 2002, 25, 467–480. [Google Scholar] [CrossRef]

| ΔKeff, (MPa-m1/2) | da/dN and dc/dN (m/cycle) | Crack-Growth, Fracture and Tensile Properties |

|---|---|---|

| 2.30 | 1.0 × 10−11 | ΔKo = 0 q = 6 |

| 2.45 | 1.5 × 10−10 | α1 = 2.5 at 1.0 × 10−7 m/cycle |

| 2.80 | 4.0 × 10−10 | α2 = 1.15 at 1.0 × 10−5 m/cycle |

| 3.50 | 1.0 × 10−9 | KF = 500 MPa-m1/2 |

| 4.40 | 2.0 × 10−9 | m = 0.5 |

| 9.50 | 1.0 × 10−8 | σys = 980 MPa |

| 20.0 | 1.0 × 10−7 | σu = 1250 MPa |

| 50.0 | 8.0 × 10−7 | σo = 1115 MPa |

| 120.0 | 6.0 × 10−6 | E = 208.6 GPa |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Newman, J.C., Jr. Fatigue and Crack Growth under Constant- and Variable-Amplitude Loading in 9310 Steel Using “Rainflow-on-the-Fly” Methodology. Metals 2021, 11, 807. https://doi.org/10.3390/met11050807

Newman JC Jr. Fatigue and Crack Growth under Constant- and Variable-Amplitude Loading in 9310 Steel Using “Rainflow-on-the-Fly” Methodology. Metals. 2021; 11(5):807. https://doi.org/10.3390/met11050807

Chicago/Turabian StyleNewman, James C., Jr. 2021. "Fatigue and Crack Growth under Constant- and Variable-Amplitude Loading in 9310 Steel Using “Rainflow-on-the-Fly” Methodology" Metals 11, no. 5: 807. https://doi.org/10.3390/met11050807

APA StyleNewman, J. C., Jr. (2021). Fatigue and Crack Growth under Constant- and Variable-Amplitude Loading in 9310 Steel Using “Rainflow-on-the-Fly” Methodology. Metals, 11(5), 807. https://doi.org/10.3390/met11050807