Microstructure Refinement by Low-Temperature Ausforming in an Fe-Based Metastable High-Entropy Alloy

Abstract

1. Introduction

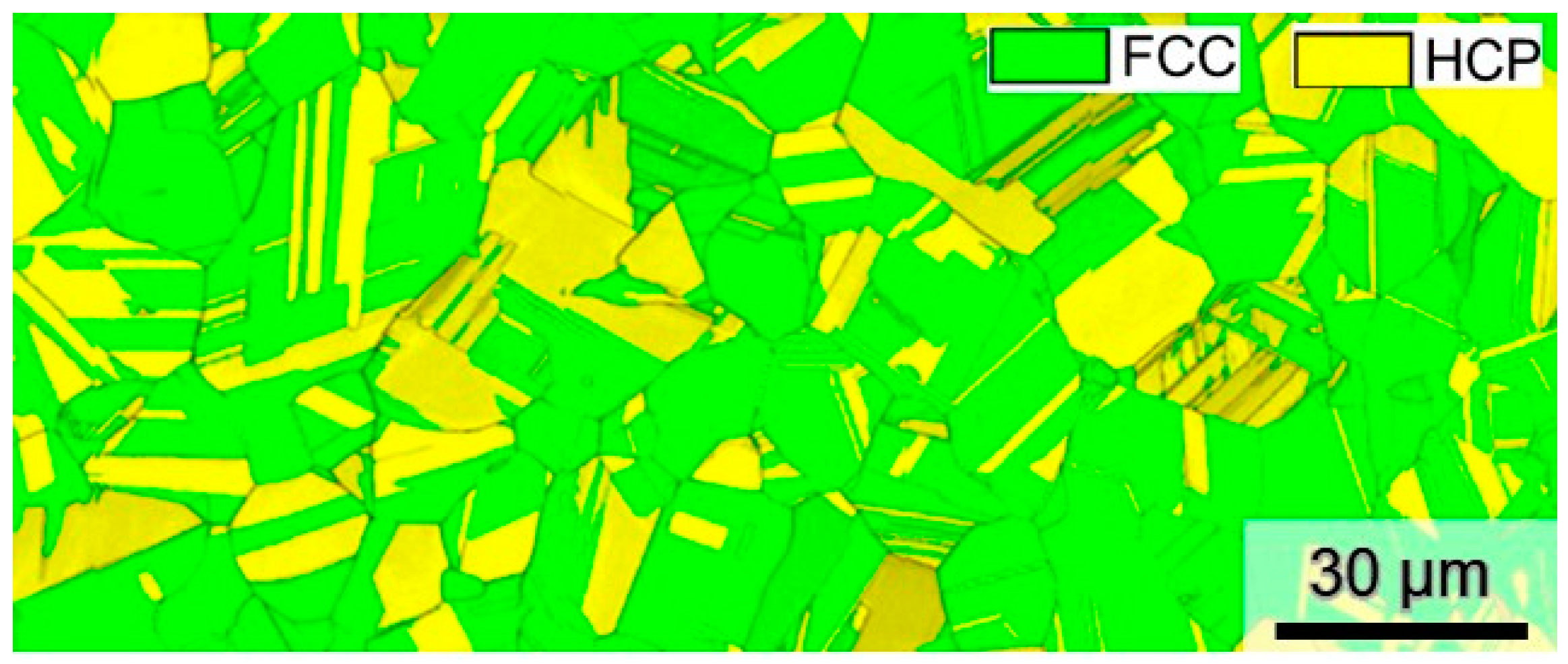

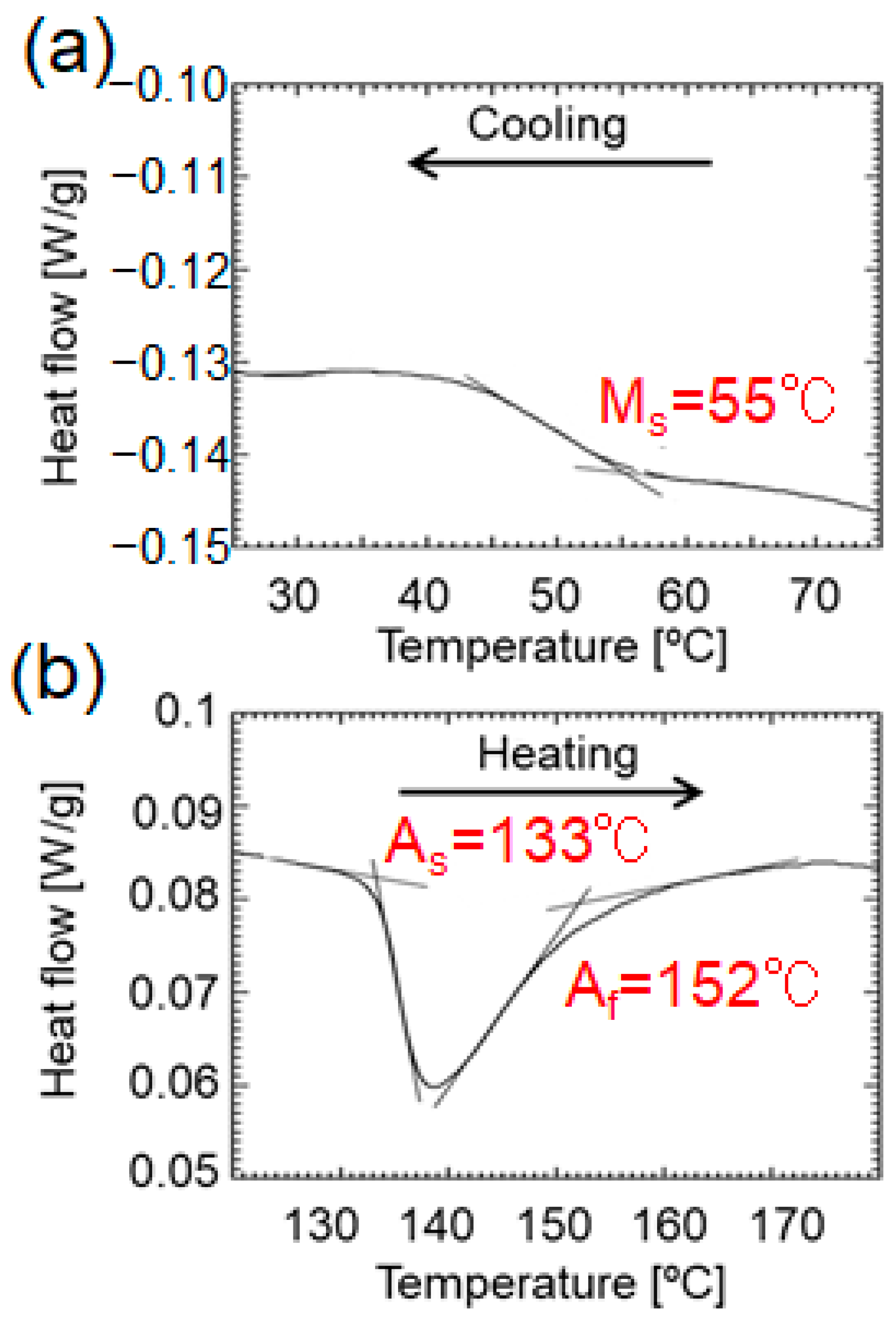

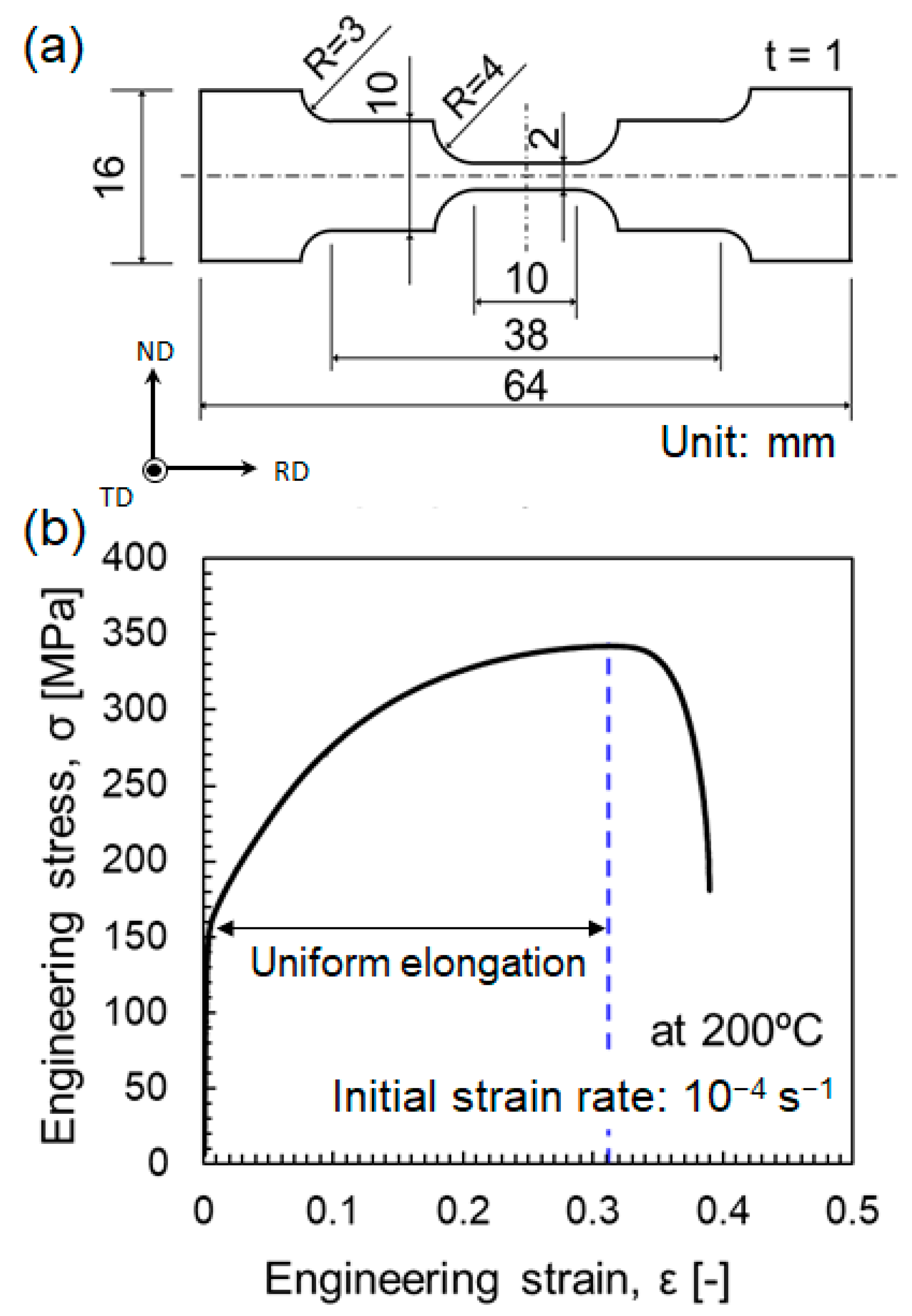

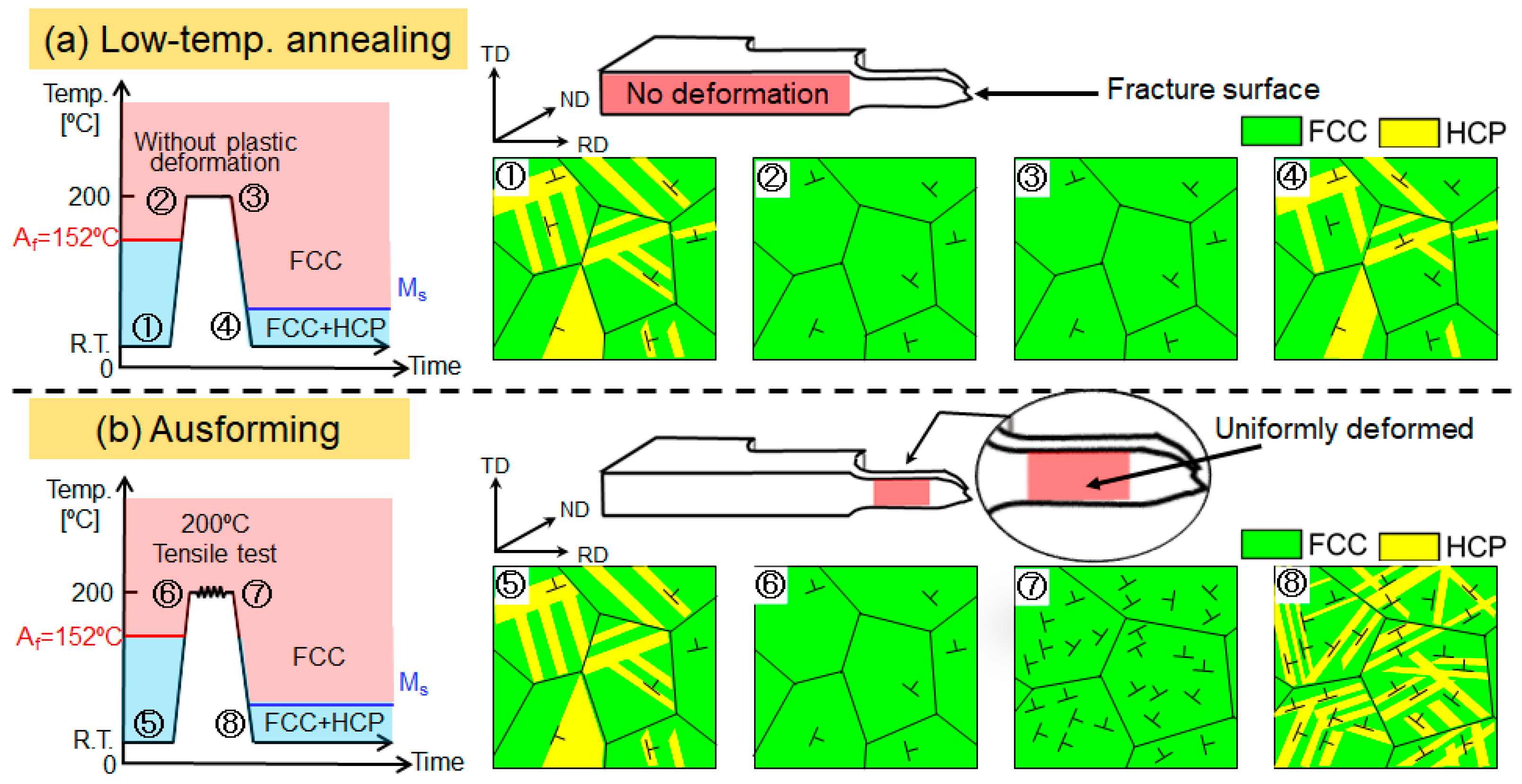

2. Materials and Methods

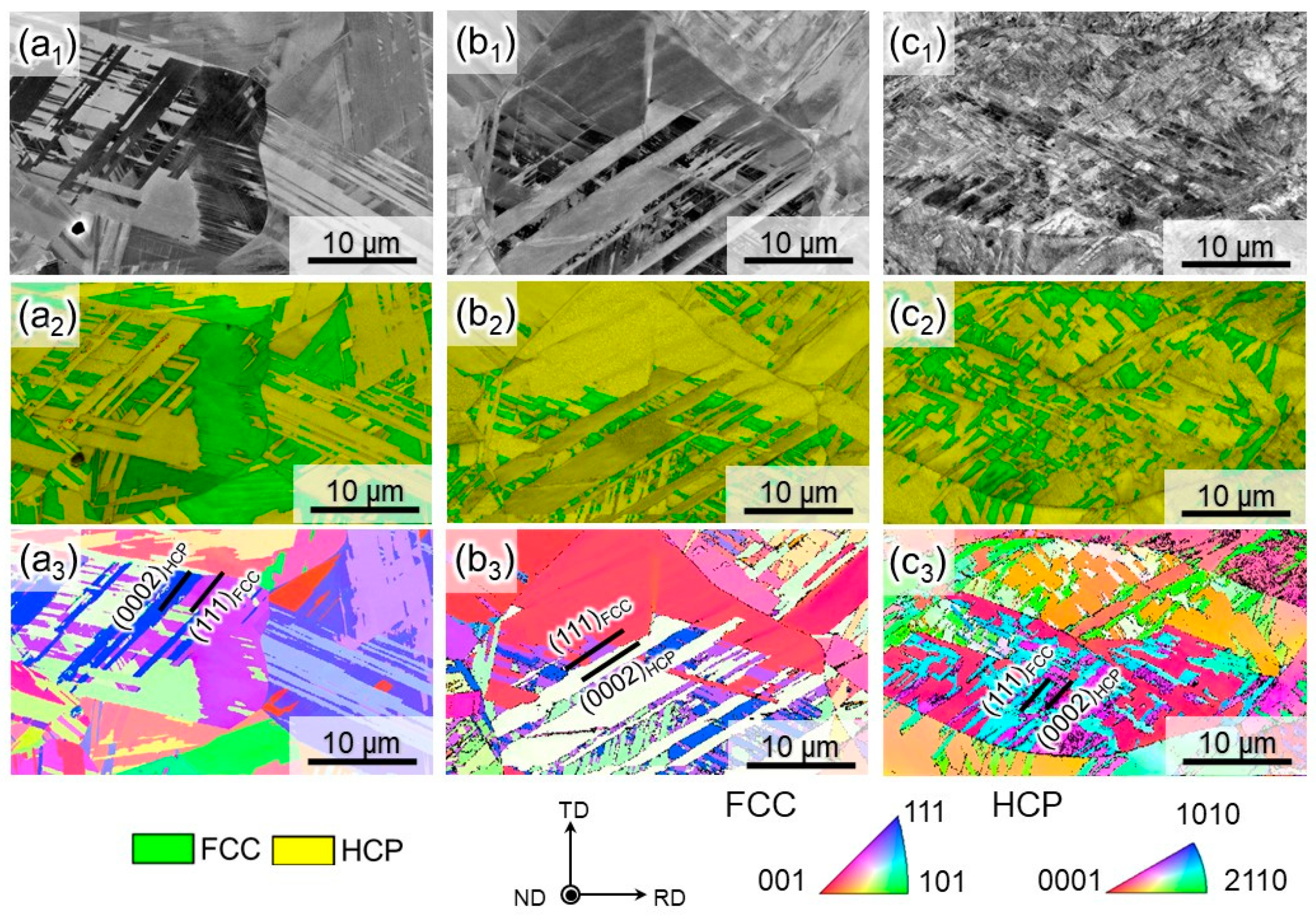

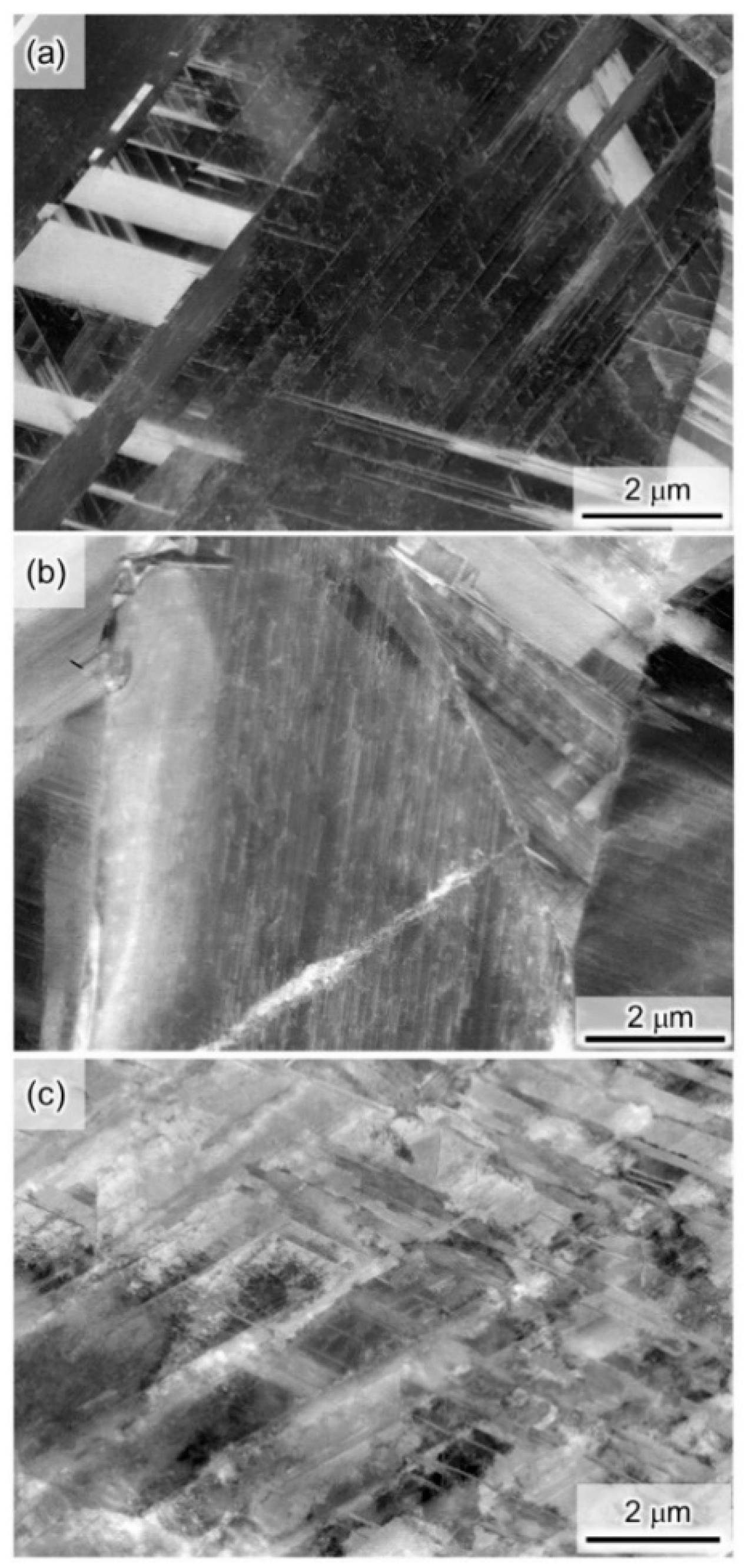

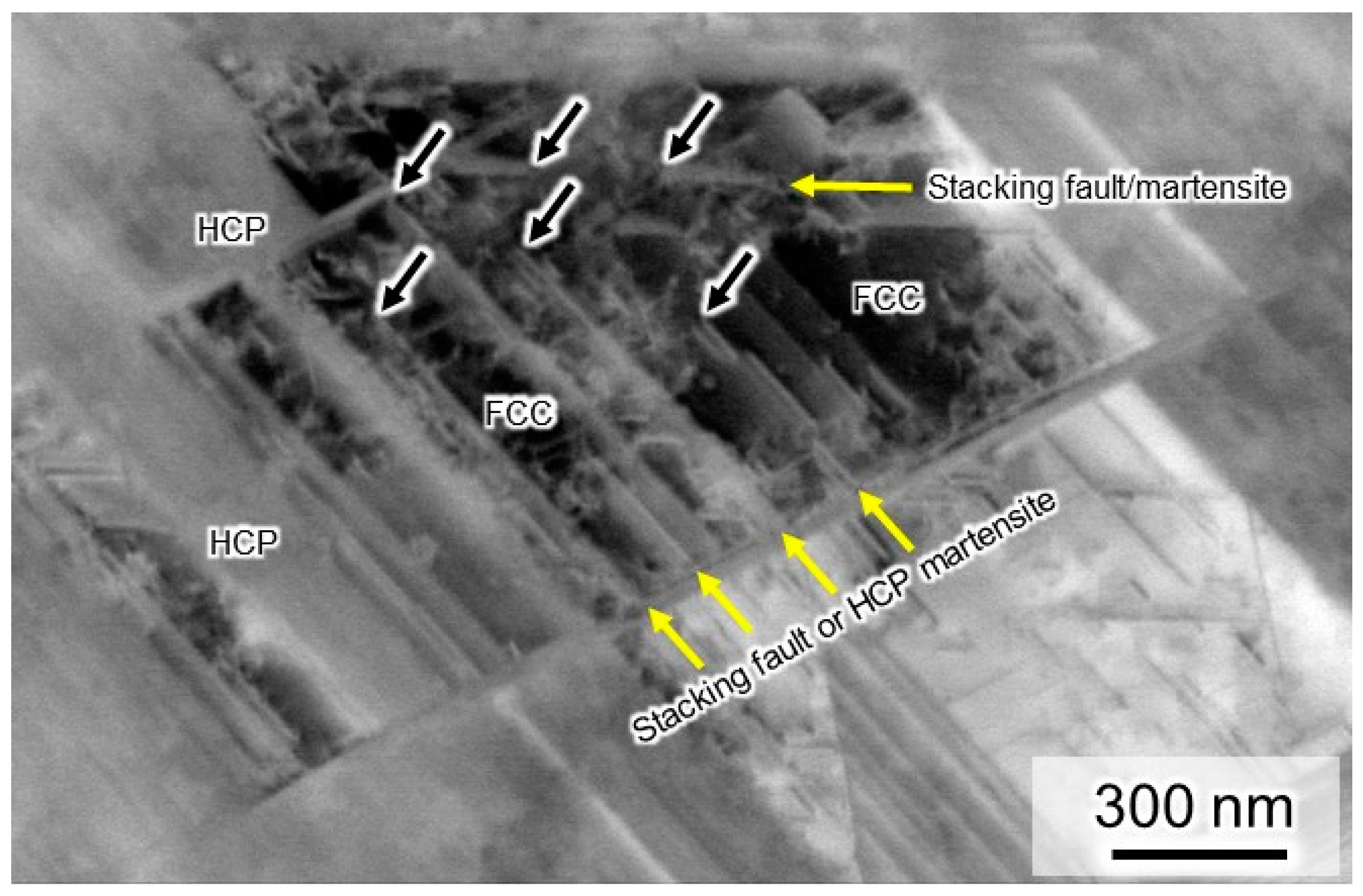

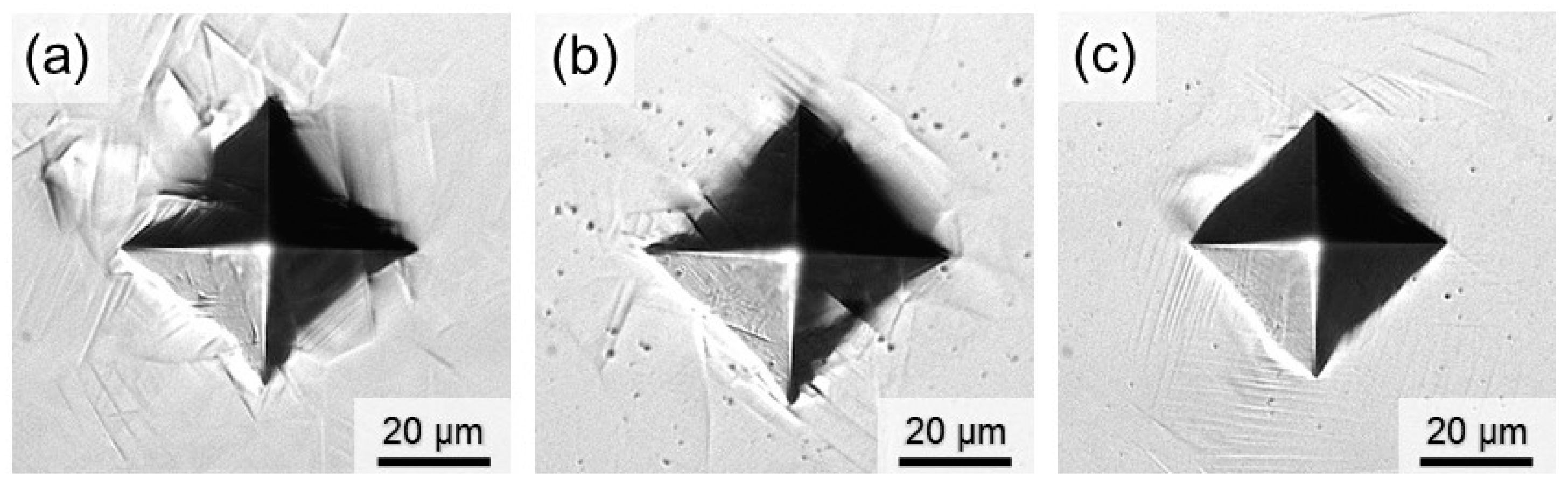

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tasan, C.C.; Diehl, M.; Yan, D.; Bechotold, M.; Roters, M.; Schemmann, L.; Zheng, C.; Peranio, N.; Ponge, D.; Koyama, M.; et al. An Overview of Dual-Phase Steels: Advances in Microstructure-Orientated Processing and Micromechanically Guided Design. Ann. Rev. Mater. Res. 2015, 45, 391–431. [Google Scholar] [CrossRef]

- Tamura, I. Some Fundamental Steps in Thermomechanical Processing of Steels. ISIJ Int. 1987, 27, 763–779. [Google Scholar] [CrossRef]

- Tsuzaki, K.; Fukasaku, S.-I.; Tomota, Y.; Maki, T. Effect of Prior Deformation of Austenite on the γ → ε Martensitic Transformation in Fe-Mn Alloys. Mater. Trans. JIM 1991, 32, 222–228. [Google Scholar] [CrossRef]

- Wang, D.; Liu, D.; Dong, Z.; Liu, W.; Chen, J. Improvement of Shape Memory Effect by Ausforming in Fe-28Mn-6Si-5Cr Alloy. Mater. Sci. Eng. A 2001, 315, 174–179. [Google Scholar] [CrossRef]

- Li, Z.; Pradeep, K.G.; Deng, Y.; Raabe, D.; Tasan, C.C. Metastable High-Entropy Dual-Phase Alloys Overcome the Strength-Ductility Trade-Off. Nature 2016, 534, 227–230. [Google Scholar] [CrossRef]

- Niendorf, T.; Wegener, T.; Li, Z.; Raabe, D. Unexpected Cyclic Stress-Strain Response of Dual-Phase High-Entropy Alloys Induced by Partial Reversibility of Deformation. Scr. Mater. 2018, 143, 63–67. [Google Scholar] [CrossRef]

- Koyama, M.; Tasan, C.C.; Tsuzaki, K. Overview of Metastability and Compositional Complexity Effects for Hydrogen-Resistant Iron Alloys: Inverse Austenite Stability Effects. Eng. Fract. Mech. 2019, 214, 123–133. [Google Scholar] [CrossRef]

- Li, Z.; Tasan, C.C.; Pradeep, K.G.; Raabe, D. A TRIP-Assisted Dual-Phase High-Entropy Alloy: Grain Size and Phase Fraction Effects on Deformation Behavior. Acta Mater. 2017, 131, 323–335. [Google Scholar] [CrossRef]

- Takaki, S.; Furuya, T.; Tokunaga, Y. Effect of Si and Al Additions on the Low Temperature Toughness and Fracture Mode of Fe-27Mn Alloys. ISIJ Int. 1990, 30, 632–638. [Google Scholar] [CrossRef]

- Koyama, M.; Kaneko, T.; Sawaguchi, T.; Tsuzaki, K. Microstructural Damage Evolution and Arrest in Binary Fe-High-Mn Alloys with Different Deformation Temperatures. Int. J. Fract. 2018, 213, 193–206. [Google Scholar] [CrossRef]

- Eguchi, T.; Koyama, M.; Fukushima, Y.; Tasan, C.C.; Tsuzaki, K. Fatigue Crack Growth Behavior and Associated Microstructure in a Metastable High-Entropy Alloy. Procedia Struct. Integr. 2018, 13, 831–836. [Google Scholar] [CrossRef]

- Bu, Y.; Li, Z.; Liu, J.; Wang, H.; Raabe, D.; Yang, W. Nonbasal Slip Systems Enable a Strong and Ductile Hexagonal-Close-Packed High-Entropy Phase. Phys. Rev. Lett. 2019, 122, 075502. [Google Scholar] [CrossRef] [PubMed]

- Otto, F.; Hanold, N.L.; George, E.P. Microstructural Evolution after Thermomechanical Processing in an Equiatomic, Single-Phase CoCrFeMnNi High-Entropy Alloy with Special Focus on Twin Boundaries. Intermetallics 2014, 54, 39–48. [Google Scholar] [CrossRef]

- Bhattacharjee, P.P.; Sathiaraj, G.D.; Zaid, M.; Gatti, J.R.; Lee, C.; Tsai, C.-W. Microstructure and Texture Evolution during Annealing of Equiatomic CoCrFeMnNi High-Entropy Alloy. J. Alloys Compd. 2014, 587, 544–552. [Google Scholar] [CrossRef]

- Zambaldi, C.; Raabe, D. Plastic Anisotropy of γ-TiAl revealed by axisymmetric indentation. Acta Mater. 2010, 58, 3516–3530. [Google Scholar] [CrossRef]

- Hua, D.; Xia, Q.; Wang, W.; Zhou, Q.; Li, S.; Qian, D.; Shi, J.; Wang, H. CoCrNi medium entropy alloy under nanoindentation. Int. J. Plast. 2021, 142, 102997. [Google Scholar] [CrossRef]

| C | Mn | P | S | N | O | Al | Cr | Co | Ni | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.009 | 29.84 | 0.004 | 0.007 | 0.010 | 0.013 | 0.002 | 9.55 | 10.69 | <0.01 | Bal. |

| As-Solution-Treated | Low-Temp. Annealed | Ausformed | |

|---|---|---|---|

| Hardness | 191 ± 12 HV | 173 ± 11 HV | 252 ± 5 HV |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koyama, M.; Gondo, T.; Tsuzaki, K. Microstructure Refinement by Low-Temperature Ausforming in an Fe-Based Metastable High-Entropy Alloy. Metals 2021, 11, 742. https://doi.org/10.3390/met11050742

Koyama M, Gondo T, Tsuzaki K. Microstructure Refinement by Low-Temperature Ausforming in an Fe-Based Metastable High-Entropy Alloy. Metals. 2021; 11(5):742. https://doi.org/10.3390/met11050742

Chicago/Turabian StyleKoyama, Motomichi, Takeaki Gondo, and Kaneaki Tsuzaki. 2021. "Microstructure Refinement by Low-Temperature Ausforming in an Fe-Based Metastable High-Entropy Alloy" Metals 11, no. 5: 742. https://doi.org/10.3390/met11050742

APA StyleKoyama, M., Gondo, T., & Tsuzaki, K. (2021). Microstructure Refinement by Low-Temperature Ausforming in an Fe-Based Metastable High-Entropy Alloy. Metals, 11(5), 742. https://doi.org/10.3390/met11050742