Analysis of As-Built Microstructures and Recrystallization Phenomena on Inconel 625 Alloy Obtained via Laser Powder Bed Fusion (L-PBF)

Abstract

1. Introduction

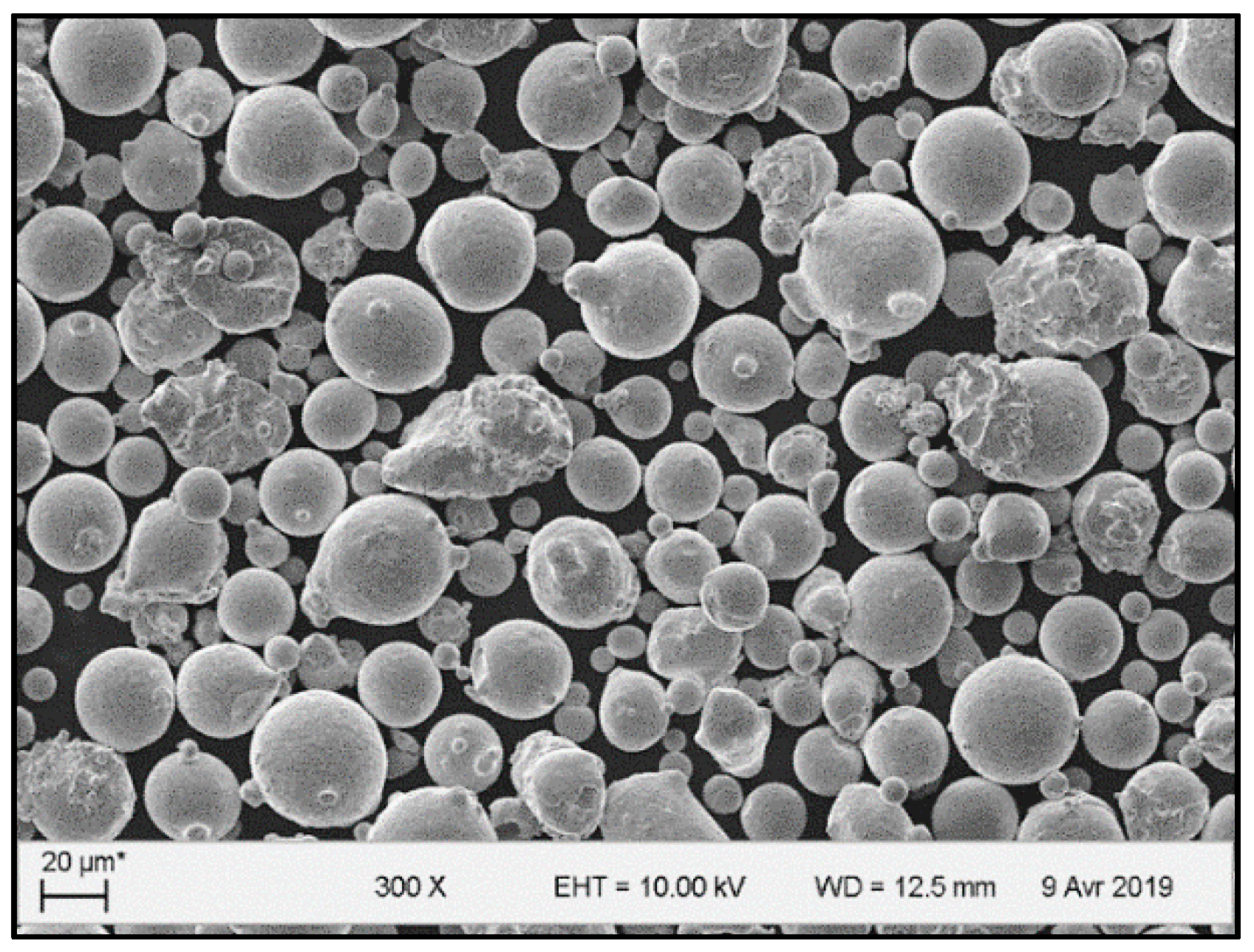

2. Materials and Methods

3. Results and Discussion

3.1. Analysis of As-Built Samples

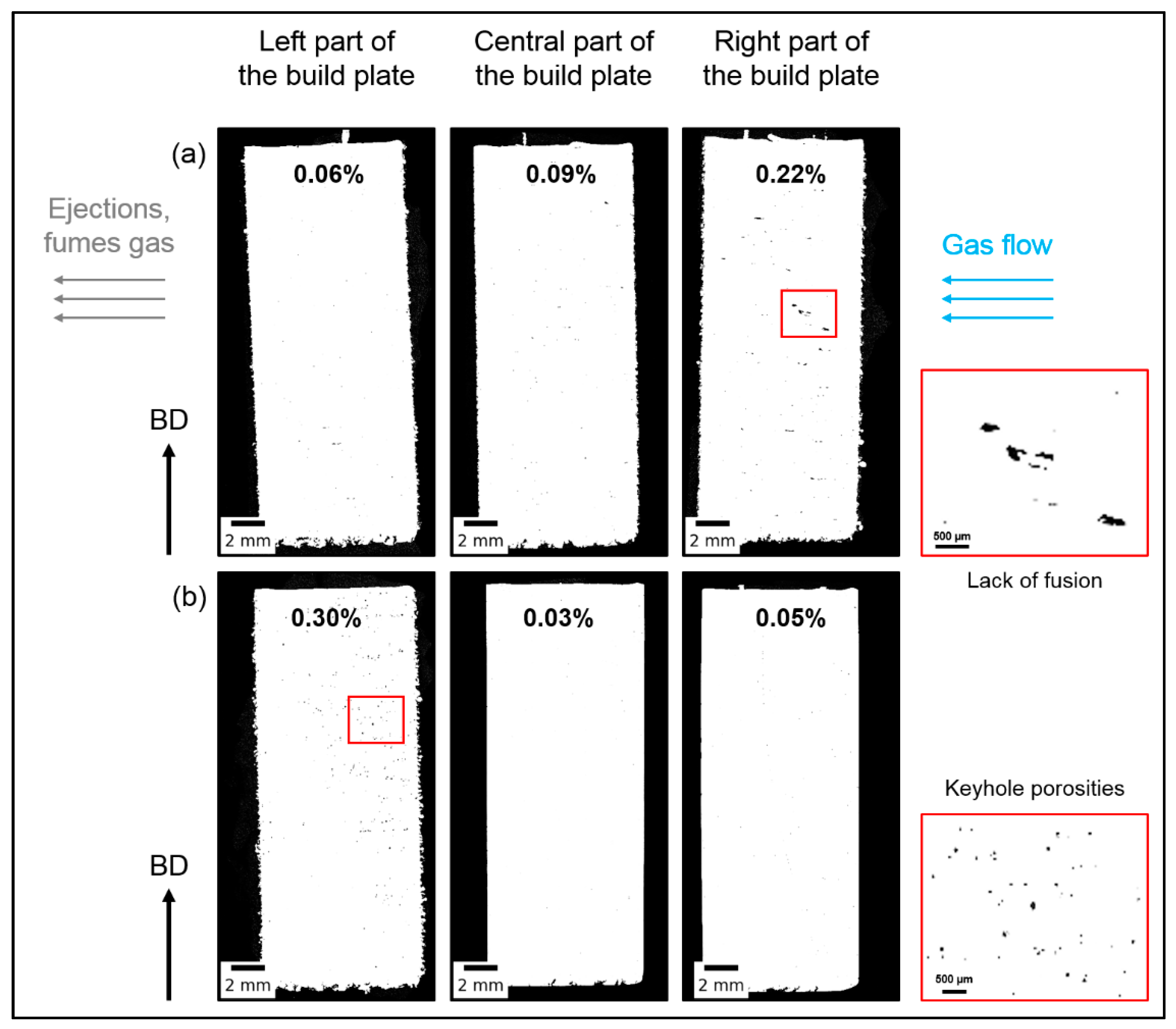

3.1.1. Samples Porosity

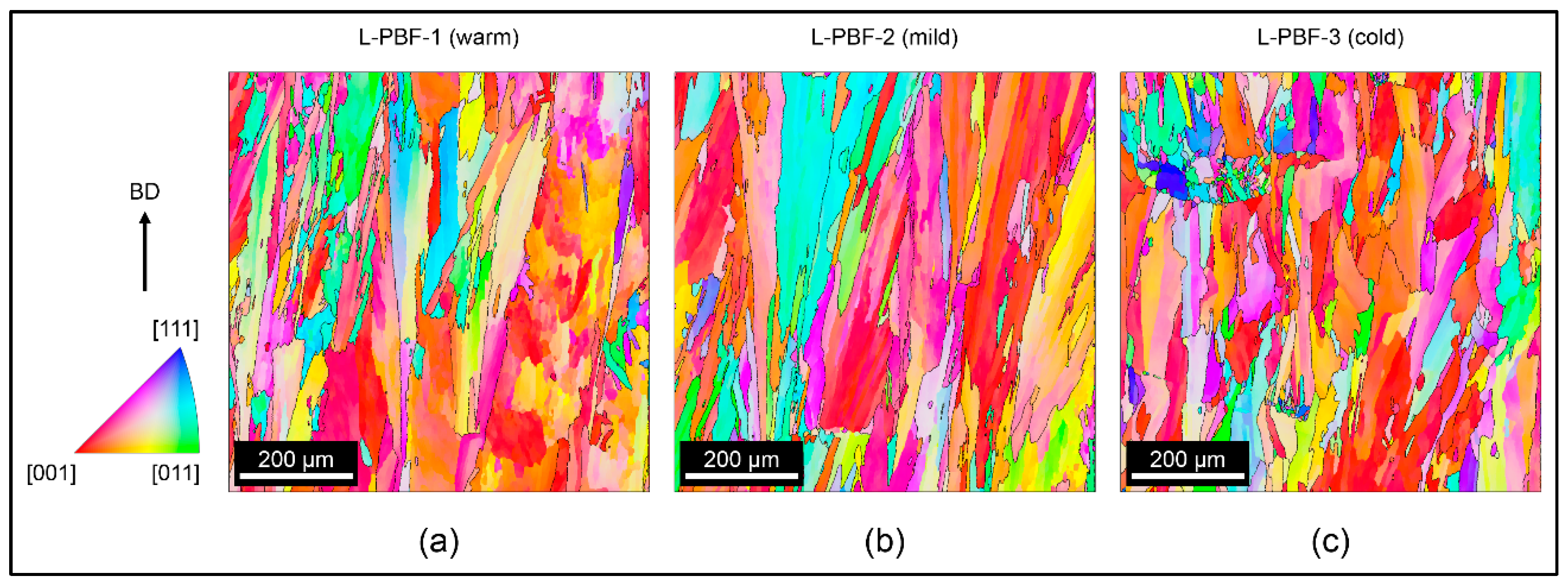

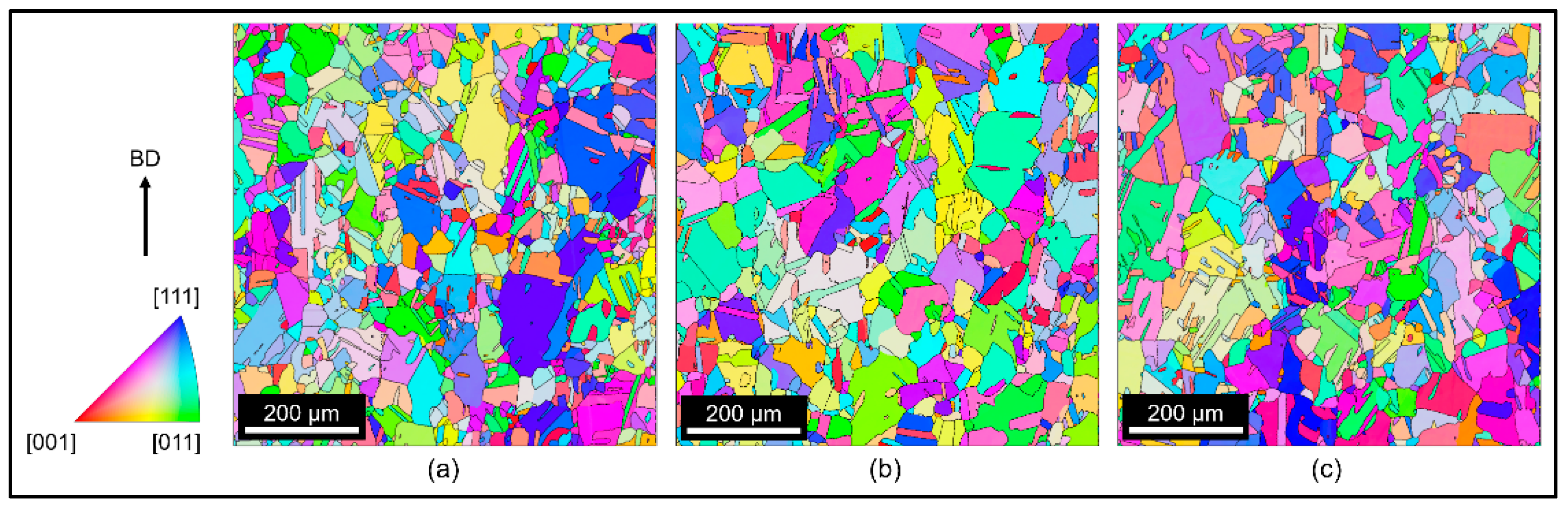

3.1.2. EBSD Analysis

3.1.3. Analysis of Dislocation Density

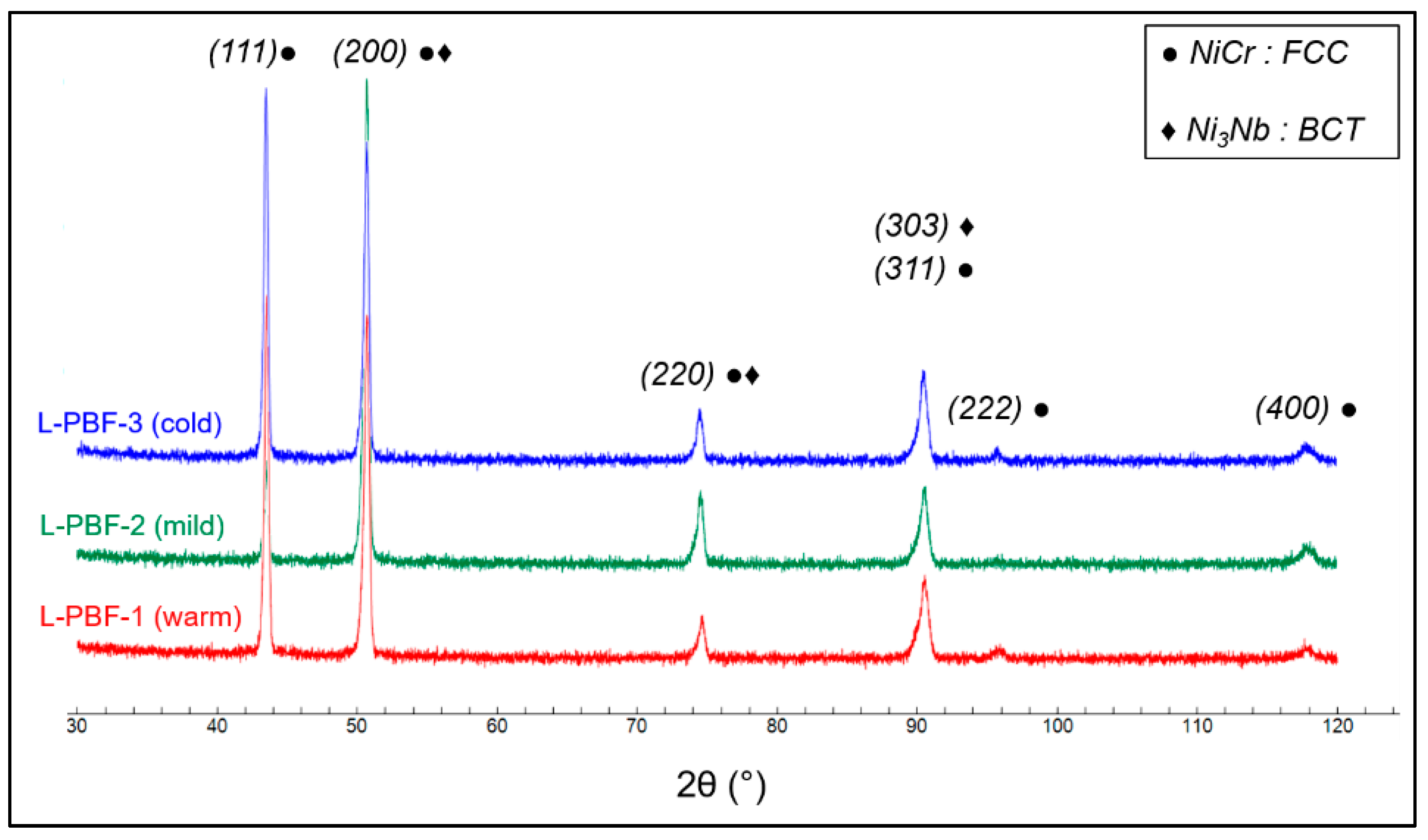

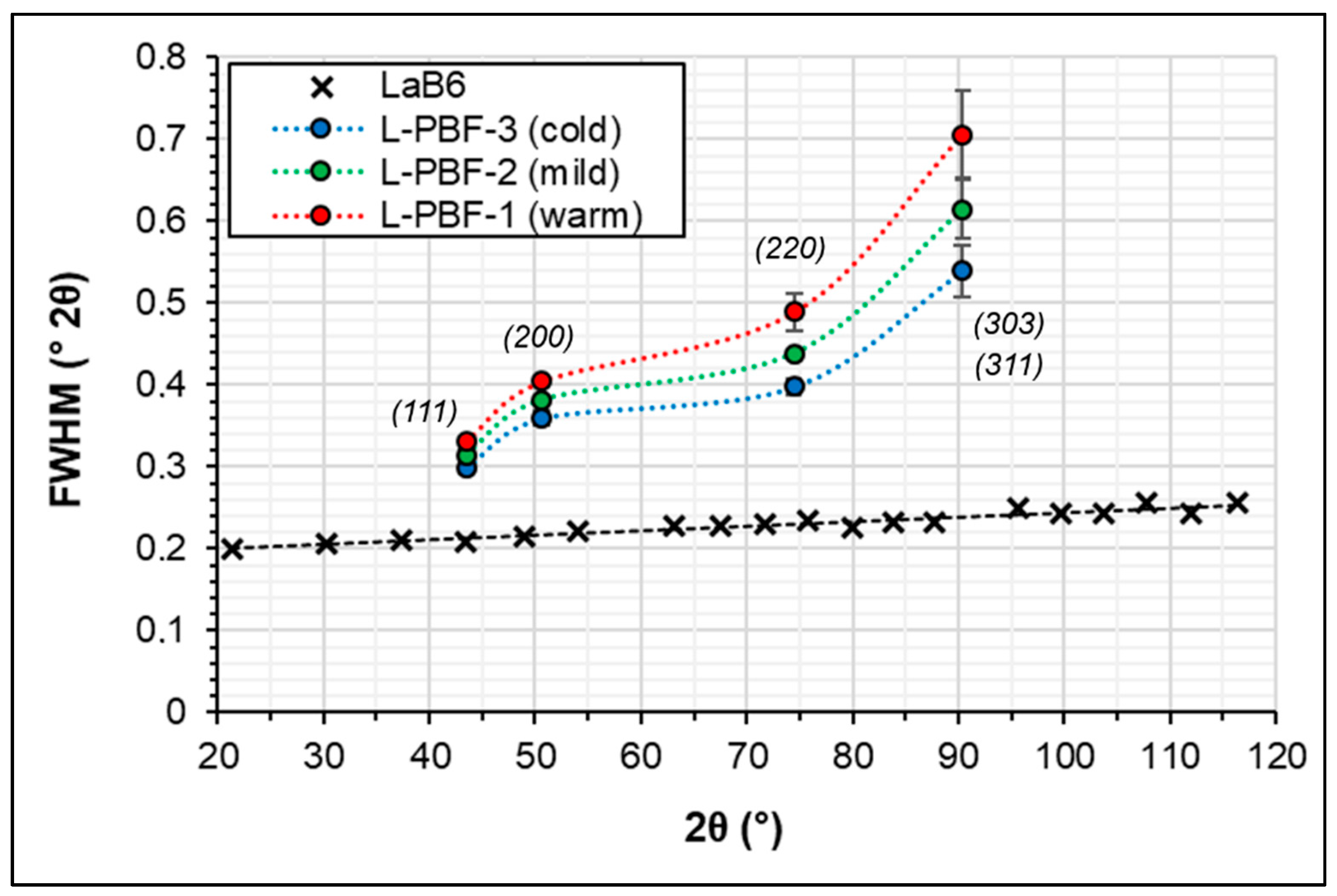

X-ray Diffraction Measurements

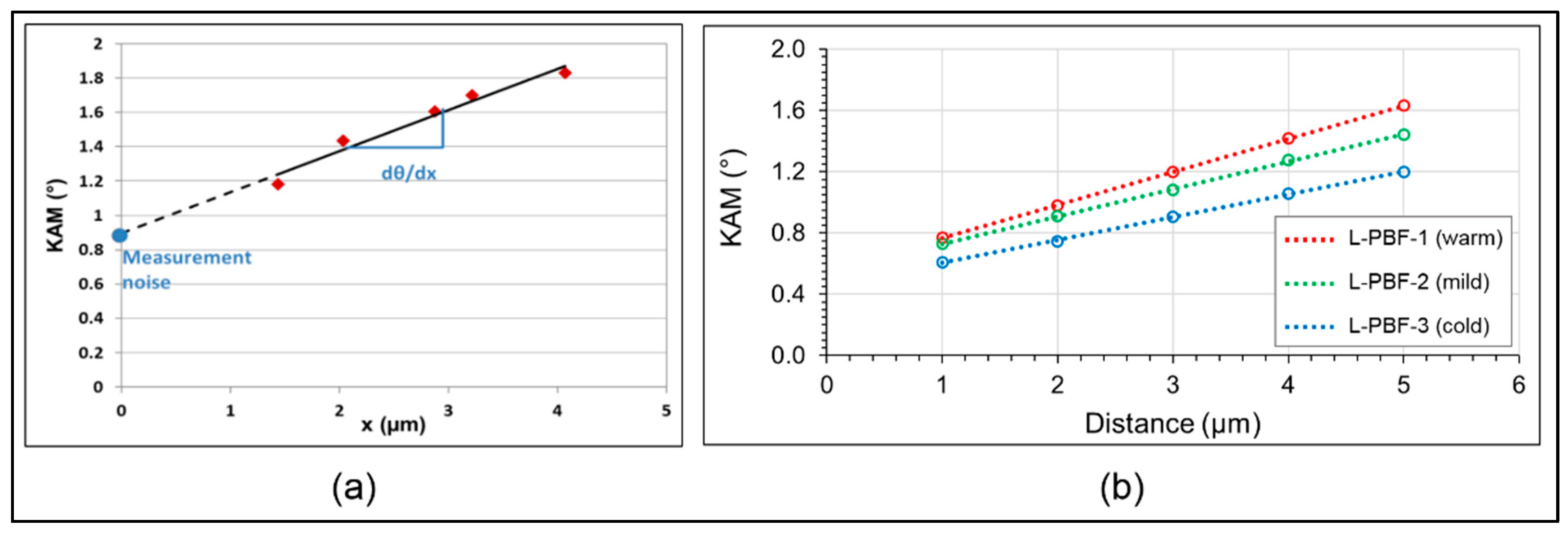

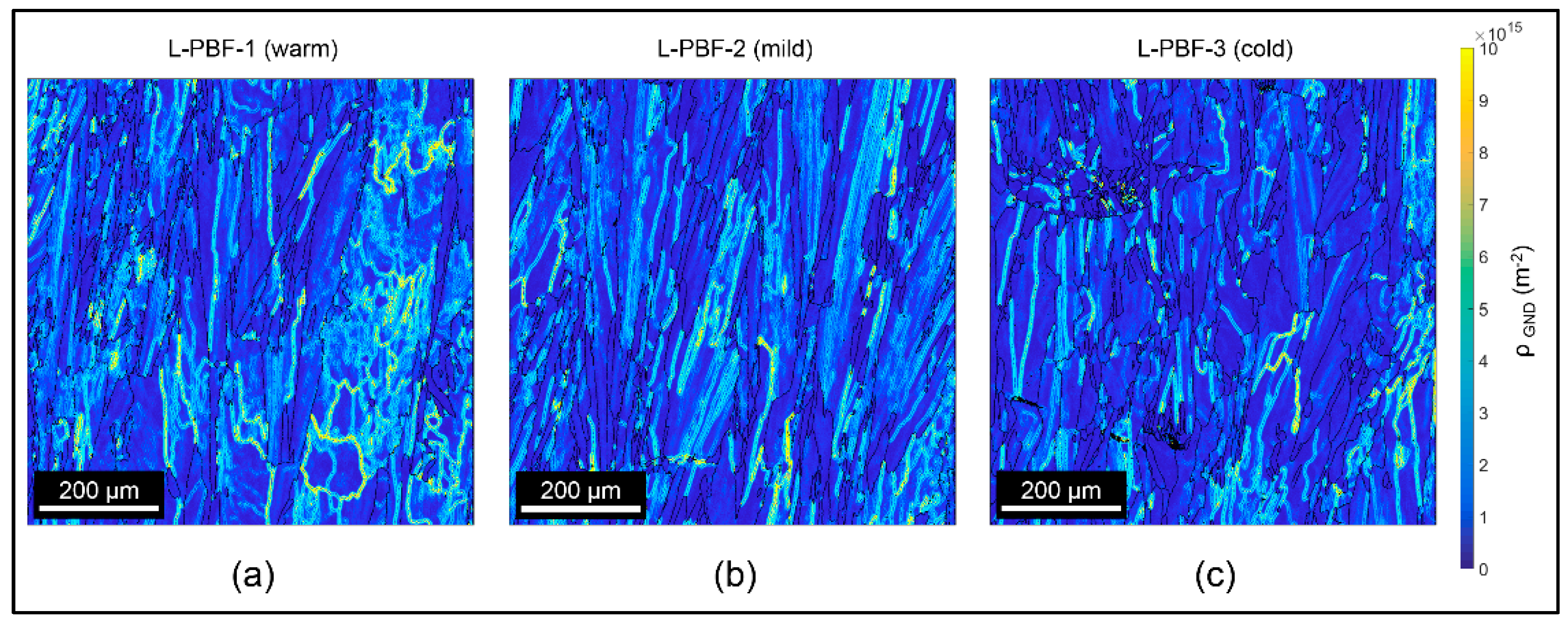

Estimation of GND Density from EBSD Data

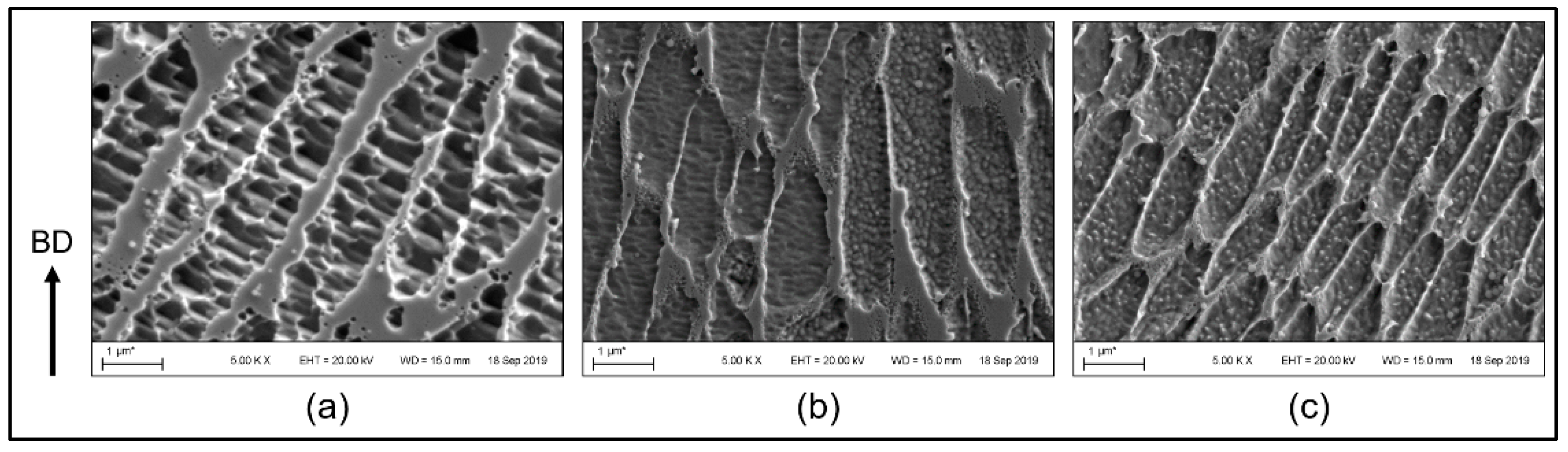

3.1.4. Analysis of Solidification Cells

3.1.5. Vickers Microhardness

3.2. Influence of Heat Treatments on Resulting Microstructures

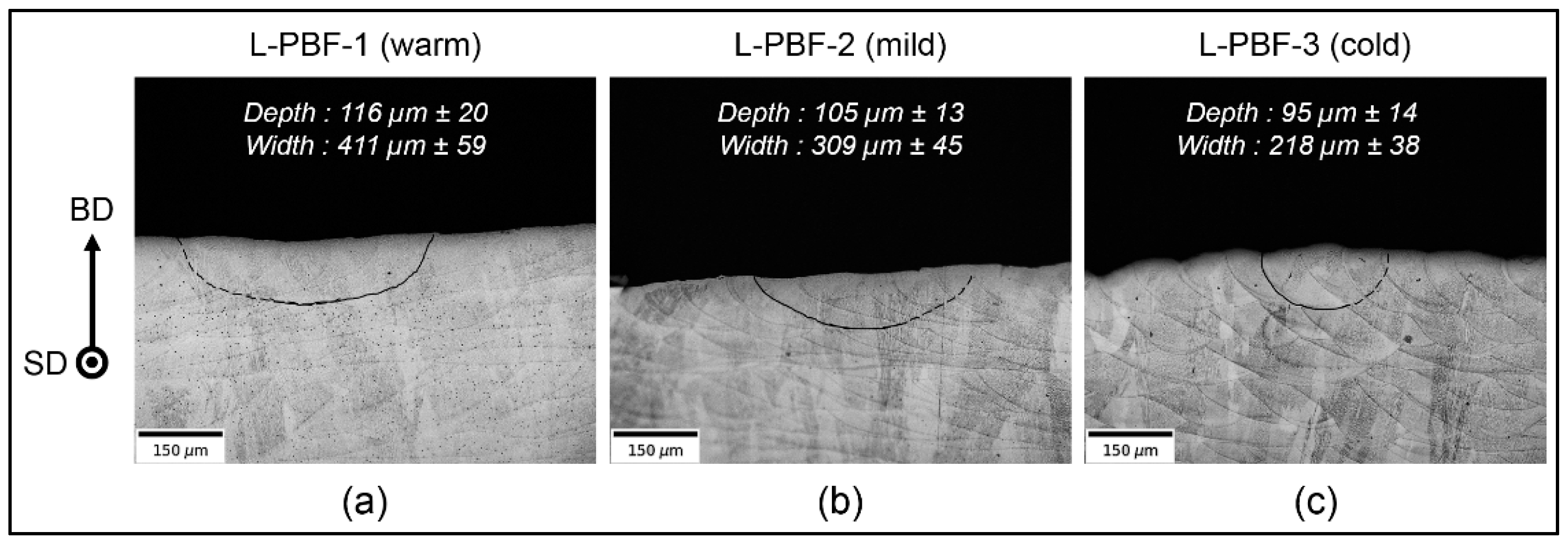

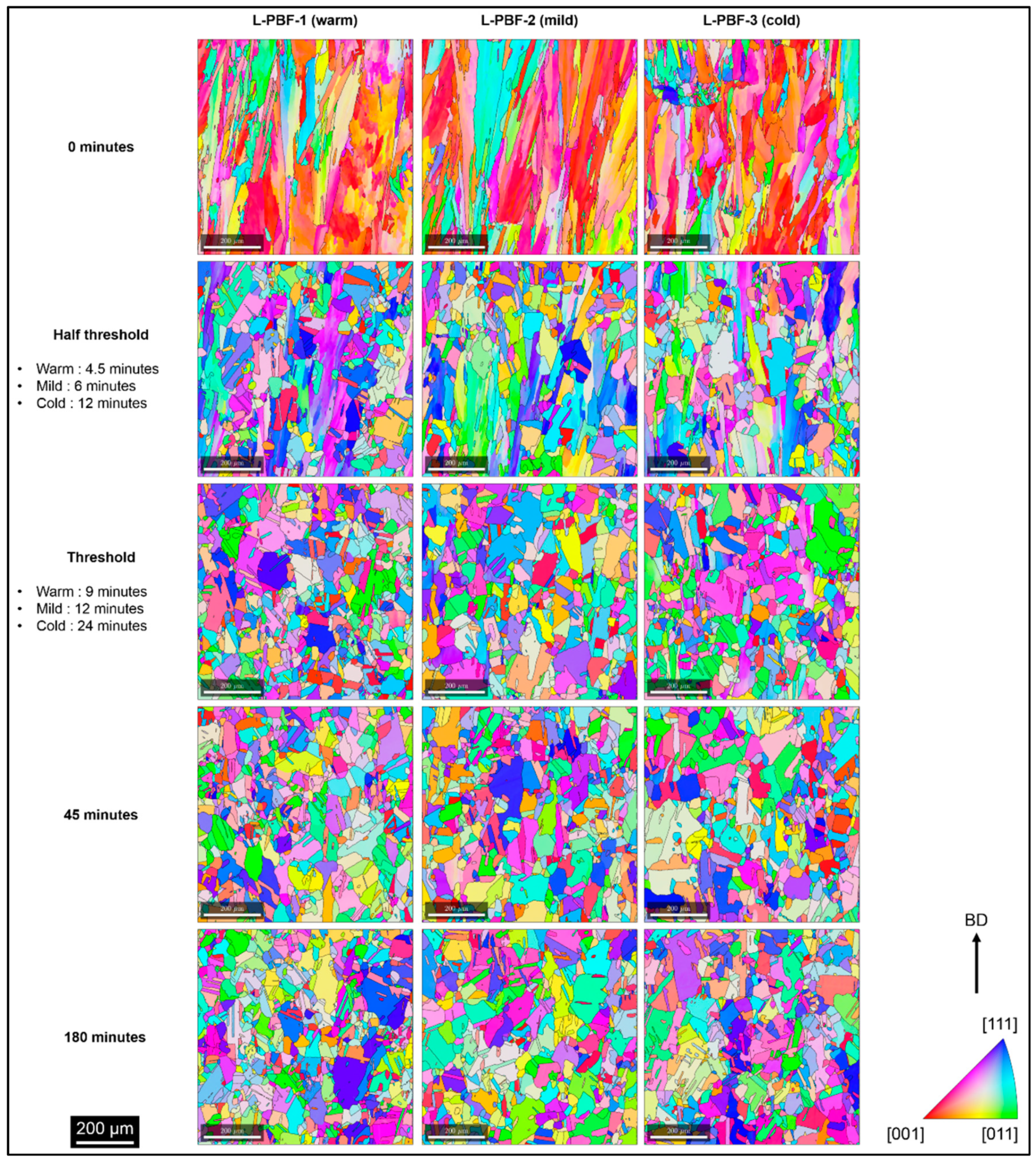

3.2.1. Microstructures after Heat Treatment

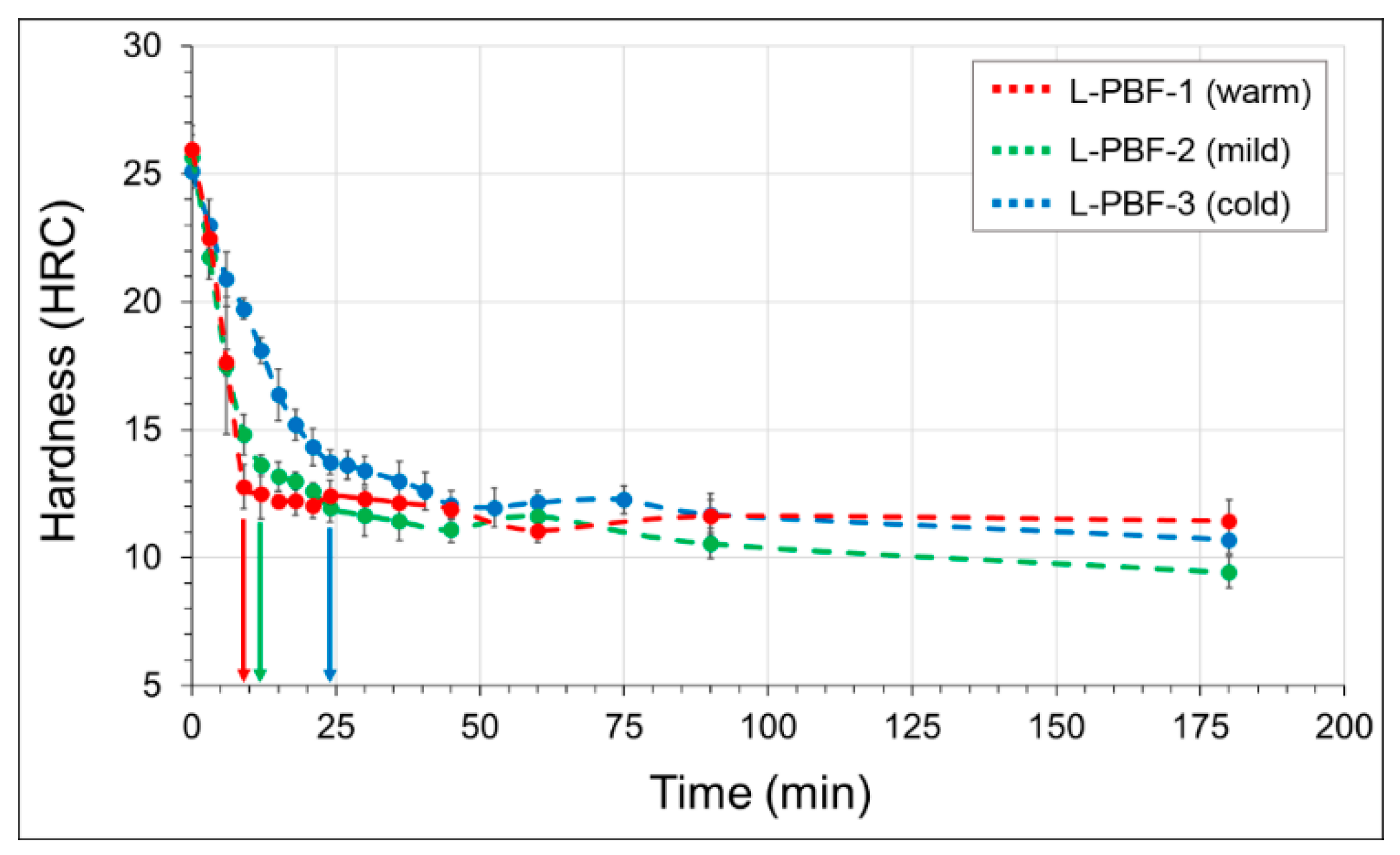

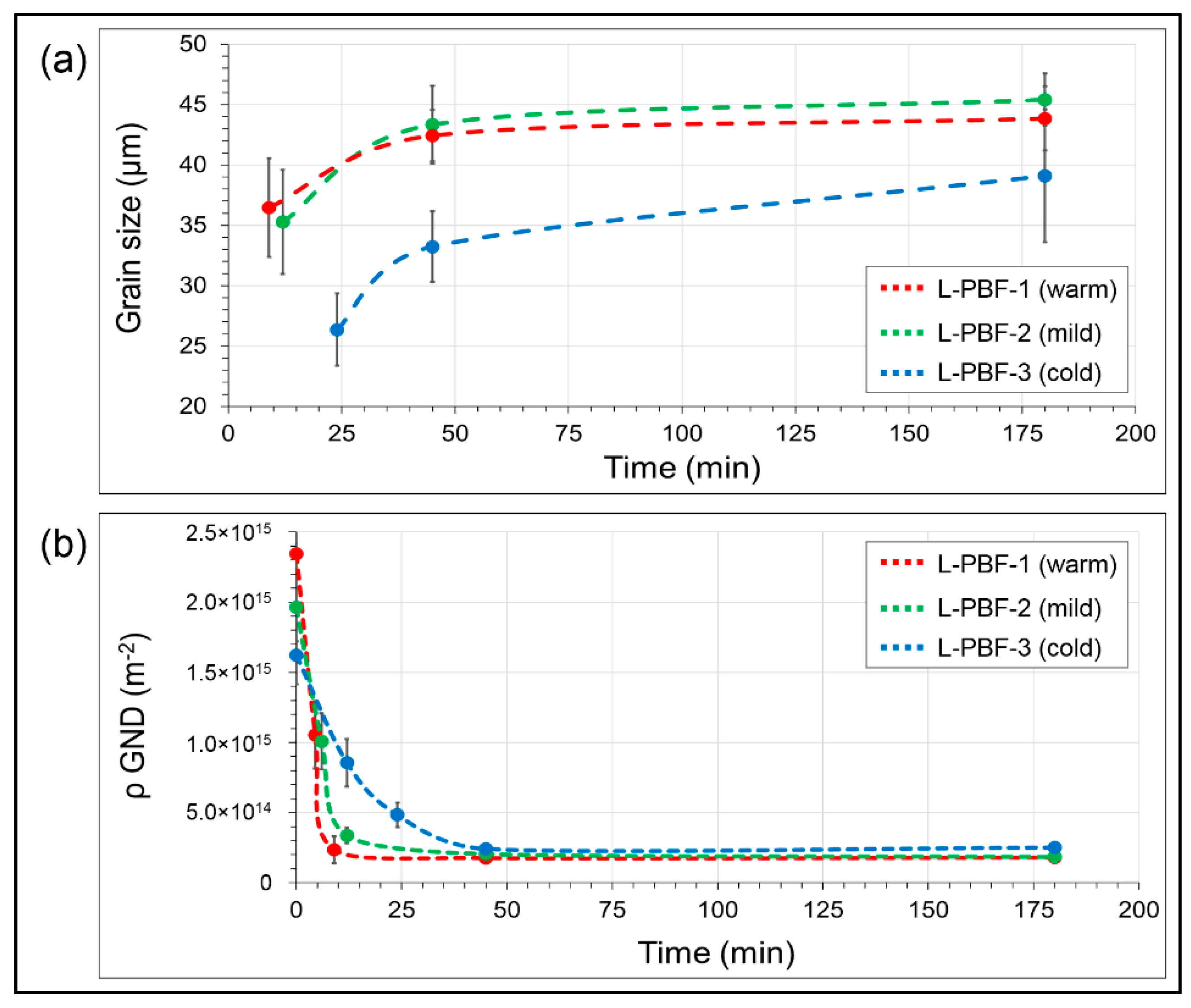

3.2.2. Analysis of Recrystallization Kinetics

3.3. Tensile Tests on As-Built and Heat-Treated L-PBF Samples

- The influence of grain boundaries on mechanical resistance (Hall-Petch-like effect). This would explain why horizontally oriented samples (i.e., the samples with columnar grains perpendicular to the loading axis) exhibited higher σY and UTS values. In this configuration, there is a higher density of grain boundaries perpendicular to the axis of the load to oppose the movement of the dislocations;

- The effect of the crystallographic texture, as (100)-oriented grains exhibited lower yield stress than other ones [55];

- A possible influence of nano-precipitates, explaining why the warmer L-PBF samples, having the higher ρGND, exhibited the lower resistance to tensile loading. In comparison with Kreitcberg et al. [11,56], the elongation lengths to failure of as-built L-PBF samples were two times lower in the present work, maybe due to larger amounts of porosities (0.03% to 0.26%).

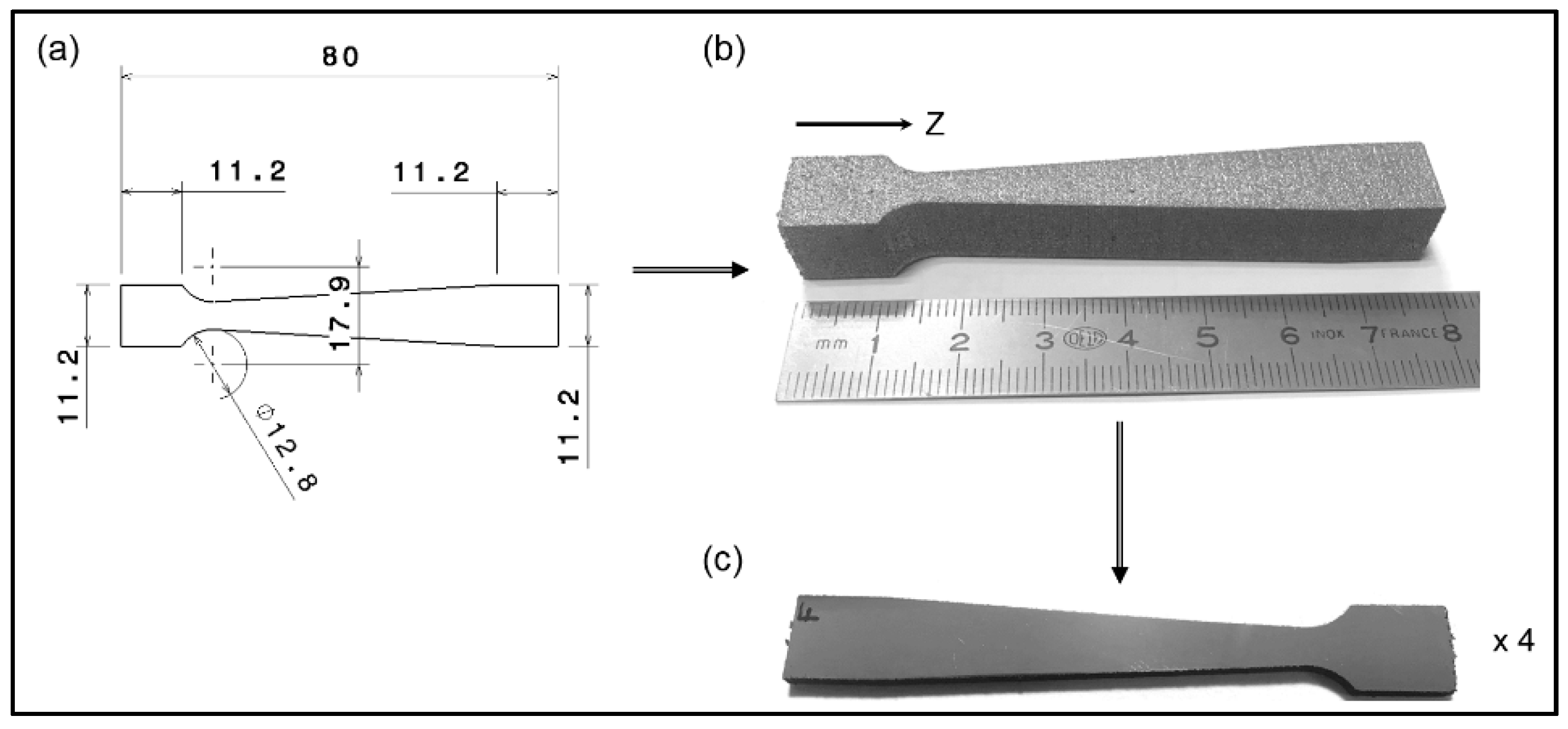

3.4. Comparison of As-Built and Work-Hardened Recrystallized L-PBF Samples

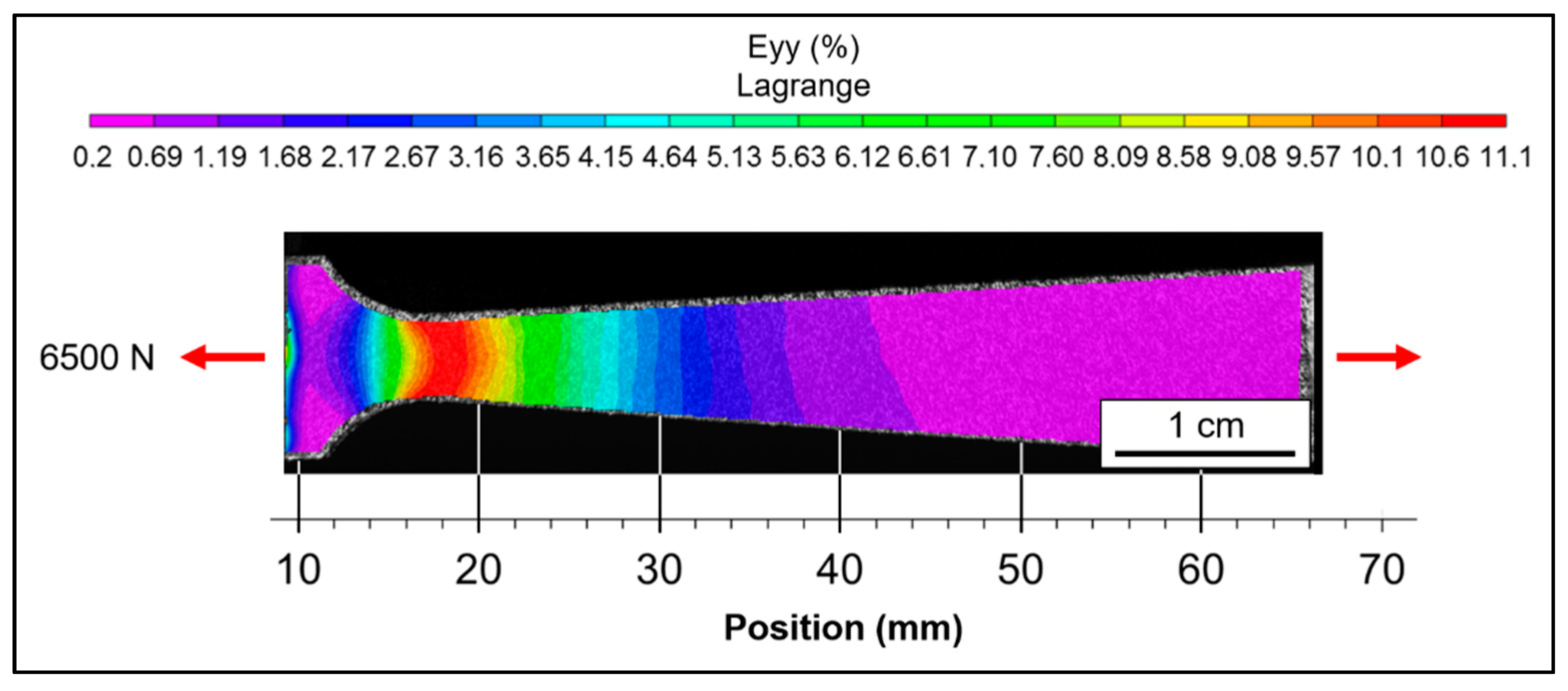

- During tensile tests, digital image correlation (DIC) was used to measure the 2D full-field strains (i.e., elastic and plastic strains) on the specimens’ flat surfaces. The software used was VIC 2D® (version 6, Correlated Solutions, University of South Carolina, Columbia, CA, USA) with a B/W Vieworks® 29 MPixel camera (Vieworks, Anyang, Korea). For instance, in Figure 17, a 10.69% plastic deformation was measured in the highly deformed part of the trapezoidal sample;

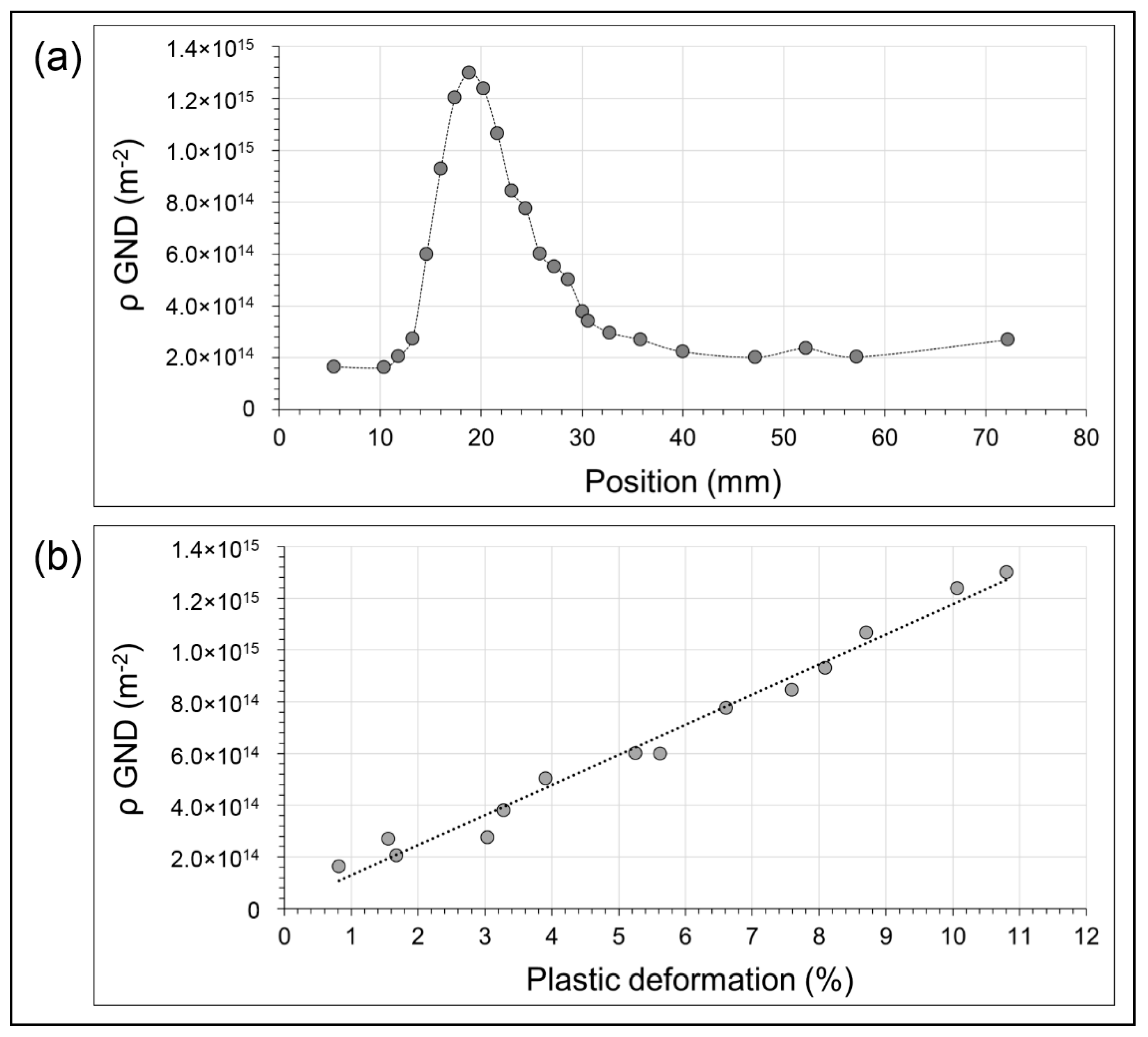

- After tensile tests, EBSD maps coupled with an analysis of GND density and hardness filiations were carried out to estimate dependencies between local deformation, hardness, and GND density values (Figure 18). It can clearly be seen that the GND density changed with the deformation; the more this increased, the more the GND density increased too. This observation has already been made by different authors [39,41,42,43] for different materials (IF steel or OFHC copper) deformed under tension or for aluminum deformed under compression. As shown in Figure 18b, in this study a linear dependency is shown between the ρGND and local deformation;

- Assuming the same linear εp/ρGND dependence at higher strain values and knowing the GND densities of as-built L-PBF samples, an estimation of the equivalent plastic deformation for each L-PBF condition could be attempted, giving values of 20.1% for L-PBF-1 (warm), 16.8% for L-PBF-2 (mild), and 13.9% for L-PBF-3 (cold).

4. Conclusions

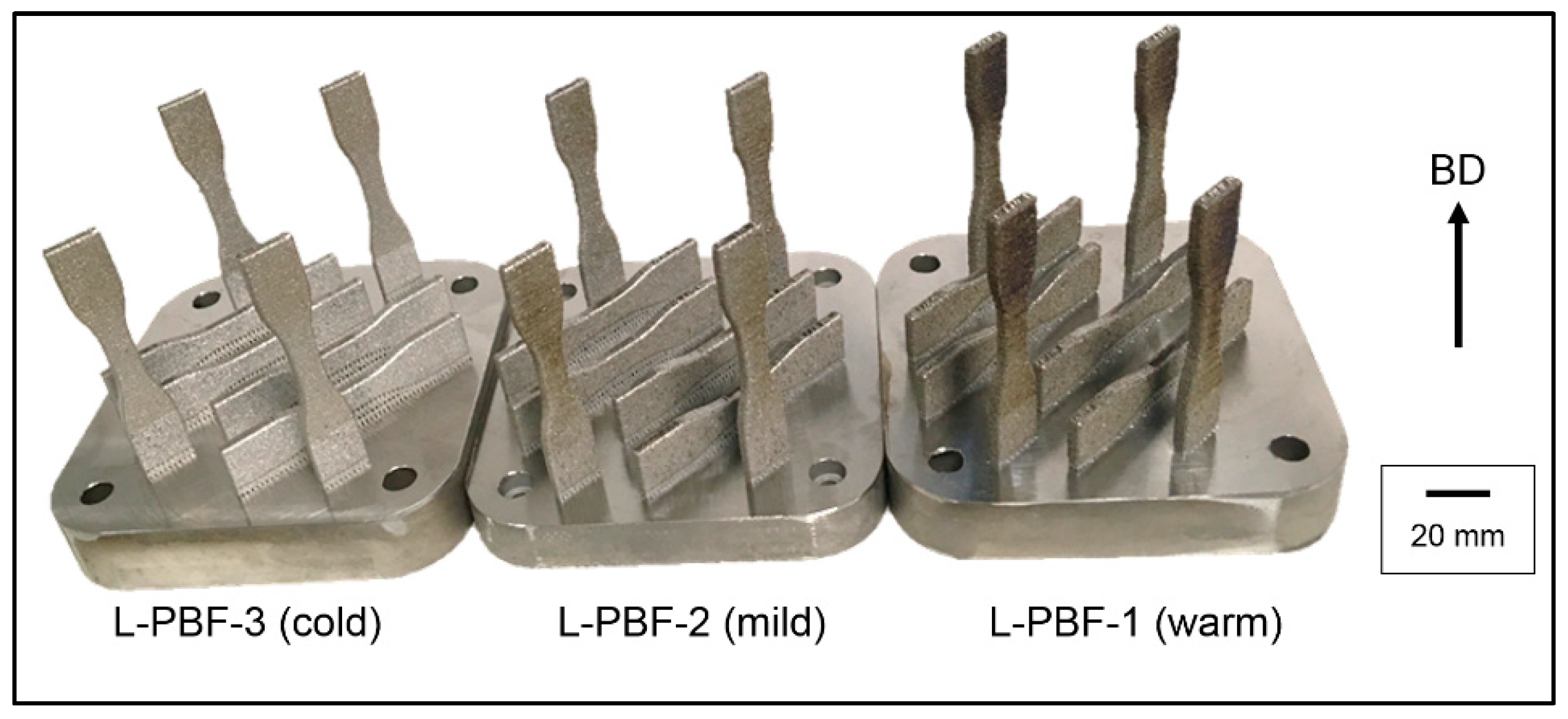

- Inconel 625 samples were produced with three different laser--powder bed fusion process conditions (respectively named “warm”, “mild”, and “cold”). As-built microstructures analyzed with EBSD in both cases exhibited columnar grains along the building direction but indicated higher densities of geometrically necessary dislocations (GND), ranging from 1.62 × 1015 m−2 to 2.34 × 1015 m−2 as the VED increased;

- The same dependence of the dislocation density with the VED was also found by the analysis of XRD Bragg peak broadening, which was consistent with microhardness data;

- All of the manufacturing conditions resulted in fine cellular microstructures, ranging from 0.6 to 1.1 µm;

- After being subjected to a 3 h, 1100 °C heat treatment, L-PBF samples were shown to fully recrystallize. Moreover, the recrystallization occurred earlier for high-energy (warm) L-PBF conditions (9 min), generating higher amounts of dislocations compared to the low-energy (cold) L-PBF conditions (24 min). These microstructural particularities induced a specific mechanical behavior for each condition;

- The raw L-PBF test samples with the columnar grain axis parallel to the load direction presented the lowest yield stress σY and UTS values (444 MPa and 718 MPa, respectively) but the highest elongation to failure A% (21%) compared to the test samples with columnar grains perpendicular to the load direction (633 MPa and 933 MPa and 12%, respectively). In addition, it was observed that L-PBF process parameters inducing higher dislocation densities produce samples with lower mechanical resistance;

- Fortunately, the recrystallization heat treatment made it possible to cancel these effects of manufacturing orientation and manufacturing parameters on the mechanical properties;

- By imposing a controlled tensile deformation on trapezoidal L-PBF samples combined with digital image correlation and EBSD analysis, equivalent plastic deformation values ranging between 13% (cold) and 20% (warm) could be estimated, providing new insight into the recrystallization driving force of as-built L-PBF samples and its dependence on process conditions;

- In view of this work, it would be interesting to compare the recrystallization behavior of L-PBF samples with wrought and work-hardened samples. In addition, Transmission Electron Microscopy (TEM) analyses should be carried out on the as-built samples to give better insight into the dislocation distributions or precipitation kinetics of the as-built microstructures. Finally, an in-depth characterization of any precipitates and their roles and impacts on recrystallization in the analysis of GNDs would be an interesting prospect for future studies.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Bai, Y.; Wang, D.; Yang, Y.; Wang, H. Effect of heat treatment on the microstructure and mechanical properties of maraging steel by selective laser melting. Mater. Sci. Eng. A 2019, 760, 105–117. [Google Scholar] [CrossRef]

- Liverani, E.; Toschi, S.; Ceschini, L.; Fortunato, A. Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L austenitic stainless steel. J. Mater. Process. Technol. 2017, 249, 255–263. [Google Scholar] [CrossRef]

- Pleass, C.; Jothi, S. Influence of powder characteristics and additive manufacturing process parameters on the microstructure and mechanical behaviour of Inconel 625 fabricated by Selective Laser Melting. Addit. Manuf. 2018, 24, 419–431. [Google Scholar] [CrossRef]

- Moussaoui, K.; Rubio, W.; Mousseigne, M.; Sultan, T.; Rezai, F. Effects of Selective Laser Melting additive manufacturing parameters of Inconel 718 on porosity, microstructure and mechanical properties. Mater. Sci. Eng. A 2018, 735, 182–190. [Google Scholar] [CrossRef]

- Zhang, J.; Song, B.; Wei, Q.; Bourell, D.; Shi, Y. A review of selective laser melting of aluminum alloys: Processing, microstructure, property and developing trends. J. Mater. Sci. Technol. 2019, 35, 270–284. [Google Scholar] [CrossRef]

- Wang, Z.; Xiao, Z.; Tse, Y.; Huang, C.; Zhang, W. Optimization of processing parameters and establishment of a relationship between microstructure and mechanical properties of SLM titanium alloy. Opt. Laser Technol. 2019, 112, 159–167. [Google Scholar] [CrossRef]

- Guo, M.; Gu, D.; Xi, L.; Zhang, H.; Zhang, J.; Yang, J.; Wang, R. Selective laser melting additive manufacturing of pure tungsten: Role of volumetric energy density on densification, microstructure and mechanical properties. Int. J. Refract. Met. Hard Mater. 2019, 84. [Google Scholar] [CrossRef]

- Yan, X.; Chang, C.; Dong, D.; Gao, S.; Ma, W.; Liu, M.; Liao, H.; Yin, S. Microstructure and mechanical properties of pure copper manufactured by selective laser melting. Mater. Sci. Eng. A 2020, 789, 139615. [Google Scholar] [CrossRef]

- Robinson, J.; Stanford, M.; Arjunan, A. Correlation between selective laser melting parameters, pore defects and tensile properties of 99.9% silver. Mater. Today Commun. 2020, 25, 101550. [Google Scholar] [CrossRef]

- Wang, X.; Muñiz-Lerma, J.A.; Shandiz, M.A.; Sanchez-Mata, O.; Brochu, M. Crystallographic-orientation-dependent tensile behaviours of stainless steel 316L fabricated by laser powder bed fusion. Mater. Sci. Eng. A 2019, 766, 138395. [Google Scholar] [CrossRef]

- Kreitcberg, A.; Brailovski, V.; Turenne, S. Effect of heat treatment and hot isostatic pressing on the microstructure and mechanical properties of Inconel 625 alloy processed by laser powder bed fusion. Mater. Sci. Eng. A 2017, 689, 1–10. [Google Scholar] [CrossRef]

- Wierzbanowski, K.; Tarasiuk, J.; Bacroix, B.; Miroux, A.; Castelnau, O. Deformation characteristics important for nucleation process. Case of low-carbon steel. Arch. Metall. 1999, 44, 183–201. [Google Scholar]

- Zhang, F.; Levine, L.E.; Allen, A.J.; Campbell, C.E.; Lass, E.A.; Cheruvathur, S.; Stoudt, M.R.; Williams, M.E.; Idell, Y. Homogenization kinetics of a nickel-based superalloy produced by powder bed fusion laser sintering. Scr. Mater. 2017, 131, 98–102. [Google Scholar] [CrossRef]

- Yan, F.; Xiong, W.; Faierson, E.J. Grain Structure Control of Additively Manufactured Metallic Materials. Materials 2017, 10, 1260. [Google Scholar] [CrossRef]

- Li, C.-L.; Won, J.W.; Choi, S.-W.; Choe, J.-H.; Lee, S.; Park, C.H.; Yeom, J.-T.; Hong, J.K. Simultaneous achievement of equiaxed grain structure and weak texture in pure titanium via selective laser melting and subsequent heat treatment. J. Alloy Compd. 2019, 803, 407–412. [Google Scholar] [CrossRef]

- Amato, K.; Hernandez, J.; Murr, L.E.; Martinez, E.; Gaytan, S.M.; Shindo, P.W.; Collins, S. Comparison of Microstructures and Properties for a Ni-Base Superalloy (Alloy 625) Fabricated by Electron Beam Melting. J. Mater. Sci. Res. 2012, 1, 3. [Google Scholar] [CrossRef]

- Li, C.; White, R.; Fang, X.; Weaver, M.; Guo, Y. Microstructure evolution characteristics of Inconel 625 alloy from selective laser melting to heat treatment. Mater. Sci. Eng. A 2017, 705, 20–31. [Google Scholar] [CrossRef]

- Marchese, G.; Colera, X.G.; Calignano, F.; Lorusso, M.; Biamino, S.; Minetola, P.; Manfredi, D. Characterization and Comparison of Inconel 625 Processed by Selective Laser Melting and Laser Metal Deposition. Adv. Eng. Mater. 2017, 19. [Google Scholar] [CrossRef]

- Lass, E.A.; Stoudt, M.R.; Williams, M.E.; Katz, M.B.; Levine, L.E.; Phan, T.Q.; Gnaeupel-Herold, T.H.; Ng, D.S. Formation of the Ni3Nb δ-Phase in Stress-Relieved Inconel 625 Produced via Laser Powder-Bed Fusion Additive Manufacturing. Met. Mater. Trans. A 2017, 48, 5547–5558. [Google Scholar] [CrossRef]

- De Terris, T.; Andreau, O.; Peyre, P.; Adamski, F.; Koutiri, I.; Gorny, C.; Dupuy, C. Optimization and comparison of porosity rate measurement methods of Selective Laser Melted metallic parts. Addit. Manuf. 2019, 28, 802–813. [Google Scholar] [CrossRef]

- Calandri, M.; Yin, S.; Aldwell, B.; Calignano, F.; Lupoi, R.; Ugues, D. Texture and Microstructural Features at Different Length Scales in Inconel 718 Produced by Selective Laser Melting. Materials 2019, 12, 1293. [Google Scholar] [CrossRef] [PubMed]

- Nye, J.F. Some geometrical relations in dislocated crystals. Acta Metall. 1953, 1, 153–162. [Google Scholar] [CrossRef]

- Cottrell, A.H. The Mechanical Properties of Matter; Wiley: New York, NY, USA, 1964. [Google Scholar]

- Ashby, M.F. The deformation of plastically non-homogeneous materials. Philos. Mag. 1970, 21, 399–424. [Google Scholar] [CrossRef]

- Birosca, S.; Liu, G.; Ding, R.; Jiang, J.; Simm, T.; Deen, C.; Whittaker, M. The dislocation behaviour and GND development in a nickel based superalloy during creep. Int. J. Plast. 2019, 118, 252–268. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, B.; Wang, H. Geometrically necessary dislocations distribution in face-centred cubic alloy with varied grain size. Mater. Charact. 2020, 162, 110205. [Google Scholar] [CrossRef]

- Williamson, G.; Hall, W. X-ray line broadening from filed aluminium and wolfram. Acta Met. 1953, 1, 22–31. [Google Scholar] [CrossRef]

- Williamson, G.K.; Smallman, R.E., III. Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray debye-scherrer spectrum. Philos. Mag. 1956, 1, 34–46. [Google Scholar] [CrossRef]

- Li, S.; Wei, Q.; Shi, Y.; Zhu, Z.; Zhang, D. Microstructure Characteristics of Inconel 625 Superalloy Manufactured by Selective Laser Melting. J. Mater. Sci. Technol. 2015, 31, 946–952. [Google Scholar] [CrossRef]

- Wauthier-Monnin, A.; Chauveau, T.; Castelnau, O.; Réglé, H.; Bacroix, B. The evolution with strain of the stored energy in different texture components of cold-rolled IF steel revealed by high resolution X-ray diffraction. Mater. Charact. 2015, 104, 31–41. [Google Scholar] [CrossRef]

- Murugesan, S.; Kuppusami, P.; Mohandas, E.; Vijayalakshmi, M. X-ray diffraction Rietveld analysis of cold worked austenitic stainless steel. Mater. Lett. 2012, 67, 173–176. [Google Scholar] [CrossRef]

- Hielscher, R. MTEX Toolbox. 2015. Available online: https://mtex-toolbox.github.io/ (accessed on 23 June 2019).

- Moussa, C.; Bernacki, M.; Besnard, R.; Bozzolo, N. About quantitative EBSD analysis of deformation and recovery substructures in pure Tantalum. IOP Conf. Ser. Mater. Sci. Eng. 2015, 89, 7. [Google Scholar] [CrossRef]

- Moussa, C.; Bernacki, M.; Besnard, R.; Bozzolo, N. Statistical analysis of dislocations and dislocation boundaries from EBSD data. Ultramicroscopy 2017, 179, 63–72. [Google Scholar] [CrossRef]

- Sow, M.; De Terris, T.; Castelnau, O.; Hamouche, Z.; Coste, F.; Fabbro, R.; Peyre, P. Influence of beam diameter on Laser Powder Bed Fusion (L-PBF) process. Addit. Manuf. 2020, 36, 101532. [Google Scholar] [CrossRef]

- Gao, Y.; Ding, Y.; Chen, J.; Xu, J.; Ma, Y.; Wang, X. Effect of twin boundaries on the microstructure and mechanical properties of Inconel 625 alloy. Mater. Sci. Eng. A 2019, 767, 138361. [Google Scholar] [CrossRef]

- Salman, O.; Gammer, C.; Chaubey, A.; Eckert, J.; Scudino, S. Effect of heat treatment on microstructure and mechanical properties of 316L steel synthesized by selective laser melting. Mater. Sci. Eng. A 2019, 748, 205–212. [Google Scholar] [CrossRef]

- Calcagnotto, M.; Ponge, D.; Demir, E.; Raabe, D. Orientation gradients and geometrically necessary dislocations in ultrafine grained dual-phase steels studied by 2D and 3D EBSD. Mater. Sci. Eng. A 2010, 527, 2738–2746. [Google Scholar] [CrossRef]

- Field, D.P.; Merriman, C.C.; Allainbonasso, N.; Wagner, F. Quantification of dislocation structure heterogeneity in deformed polycrystals by EBSD. Model. Simul. Mater. Sci. Eng. 2012, 20. [Google Scholar] [CrossRef]

- Plancher, E.; Tajdary, P.; Auger, T.; Castelnau, O.; Favier, V.; Loisnard, D.; Marijon, J.-B.; Maurice, C.; Michel, V.; Robach, O.; et al. Validity of Crystal Plasticity Models Near Grain Boundaries: Contribution of Elastic Strain Measurements at Micron Scale. JOM 2019, 71, 3543–3551. [Google Scholar] [CrossRef]

- Jiang, J.; Ben Britton, T.; Wilkinson, A.J. The orientation and strain dependence of dislocation structure evolution in monotonically deformed polycrystalline copper. Int. J. Plast. 2015, 69, 102–117. [Google Scholar] [CrossRef]

- Kundu, A.; Field, D.P. Geometrically Necessary Dislocation Density Evolution in Interstitial Free Steel at Small Plastic Strains. Met. Mater. Trans. A 2018, 49, 3274–3282. [Google Scholar] [CrossRef]

- Nowakowski, P.; Wiezorek, J.; Bathula, V.; Mielo, S.; Khanal, S.; Bonifacio, C.; Fischione, P. SEM and TEM characterization of plastic deformation structures in Aluminum by EBSD, TKD, and PED-based orientation imaging techniques. Microsc. Microanal. 2018, 24, 2182–2183. [Google Scholar] [CrossRef]

- Marchese, G.; Lorusso, M.; Parizia, S.; Bassini, E.; Lee, J.-W.; Calignano, F.; Manfredi, D.; Terner, M.; Hong, H.-U.; Ugues, D.; et al. Influence of heat treatments on microstructure evolution and mechanical properties of Inconel 625 processed by laser powder bed fusion. Mater. Sci. Eng. A 2018, 729, 64–75. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.M.; Ramirez, D.A.; Martinez, E.; Hernandez, J.; Amato, K.N.; Shindo, P.W.; Medina, F.R.; Wicker, R.B. Metal Fabrication by Additive Manufacturing Using Laser and Electron Beam Melting Technologies. J. Mater. Sci. Technol. 2012, 28, 1–14. [Google Scholar] [CrossRef]

- Mathers, G. Welding metallurgy. In The Welding of Aluminium and Its Alloys; Woodhead Publishing: Cambridge, UK, 2002; pp. 10–34. [Google Scholar] [CrossRef]

- Stefanescu, D.M. Science and Engineering of Casting Solidification, 3rd ed.; Springer International Publishing: Cham, Switzerland, 2015. [Google Scholar]

- Rafi, H.K.; Karthik, N.V.; Gong, H.; Starr, T.L.; Stucker, B.E. Microstructures and Mechanical Properties of Ti6Al4V Parts Fabricated by Selective Laser Melting and Electron Beam Melting. J. Mater. Eng. Perform. 2013, 22, 3872–3883. [Google Scholar] [CrossRef]

- Bertoli, U.S.; Guss, G.; Wu, S.; Matthews, M.J.; Schoenung, J.M. In-situ characterization of laser-powder interaction and cooling rates through high-speed imaging of powder bed fusion additive manufacturing. Mater. Des. 2017, 135, 385–396. [Google Scholar] [CrossRef]

- Vilaro, T.; Colin, C.; Bartout, J.; Nazé, L.; Sennour, M. Microstructural and mechanical approaches of the selective laser melting process applied to a nickel-base superalloy. Mater. Sci. Eng. A 2012, 534, 446–451. [Google Scholar] [CrossRef]

- Srinivasan, R.; Chen-Nan, S.; Baicheng, Z.; Jack, S.W.; Pei, W.; Sharon, N.M.L.; Tao, L.; Jun, W. Mechanical Properties and Microstructures of As Printed and Heat Treated Samples of Selective Laser Melted IN625 Alloy Powder. MATEC Web Conf. 2015, 30, 2002. [Google Scholar] [CrossRef]

- Nguejio, J.; Szmytka, F.; Hallais, S.; Tanguy, A.; Nardone, S.; Martinez, M.G. Comparison of microstructure features and mechanical properties for additive manufactured and wrought nickel alloys 625. Mater. Sci. Eng. A 2019, 764, e138214. [Google Scholar] [CrossRef]

- Floreen, S.; Fuchs, G.; Yang, W. The Metallurgy of Alloy 625. Superalloys 1994, 718, 13–37. [Google Scholar]

- Gerber, P.; Tarasiuk, J.; Chauveau, T.; Bacroix, B. A quantitative analysis of the evolution of texture and stored energy during annealing of cold rolled copper. Acta Mater. 2003, 51, 6359–6371. [Google Scholar] [CrossRef]

- Gu, T.; Medy, J.-R.; Klosek, V.; Castelnau, O.; Forest, S.; Hervé-Luanco, E.; Lecouturier-Dupouy, F.; Proudhon, H.; Renault, P.-O.; Thilly, L.; et al. Multiscale modeling of the elasto-plastic behavior of architectured and nanostructured Cu-Nb composite wires and comparison with neutron diffraction experiments. Int. J. Plast. 2019, 122, 1–30. [Google Scholar] [CrossRef]

- Kreitcberg, A.; Brailovski, V.; Turenne, S. Elevated temperature mechanical behavior of IN625 alloy processed by laser powder-bed fusion. Mater. Sci. Eng. A 2017, 700, 540–553. [Google Scholar] [CrossRef]

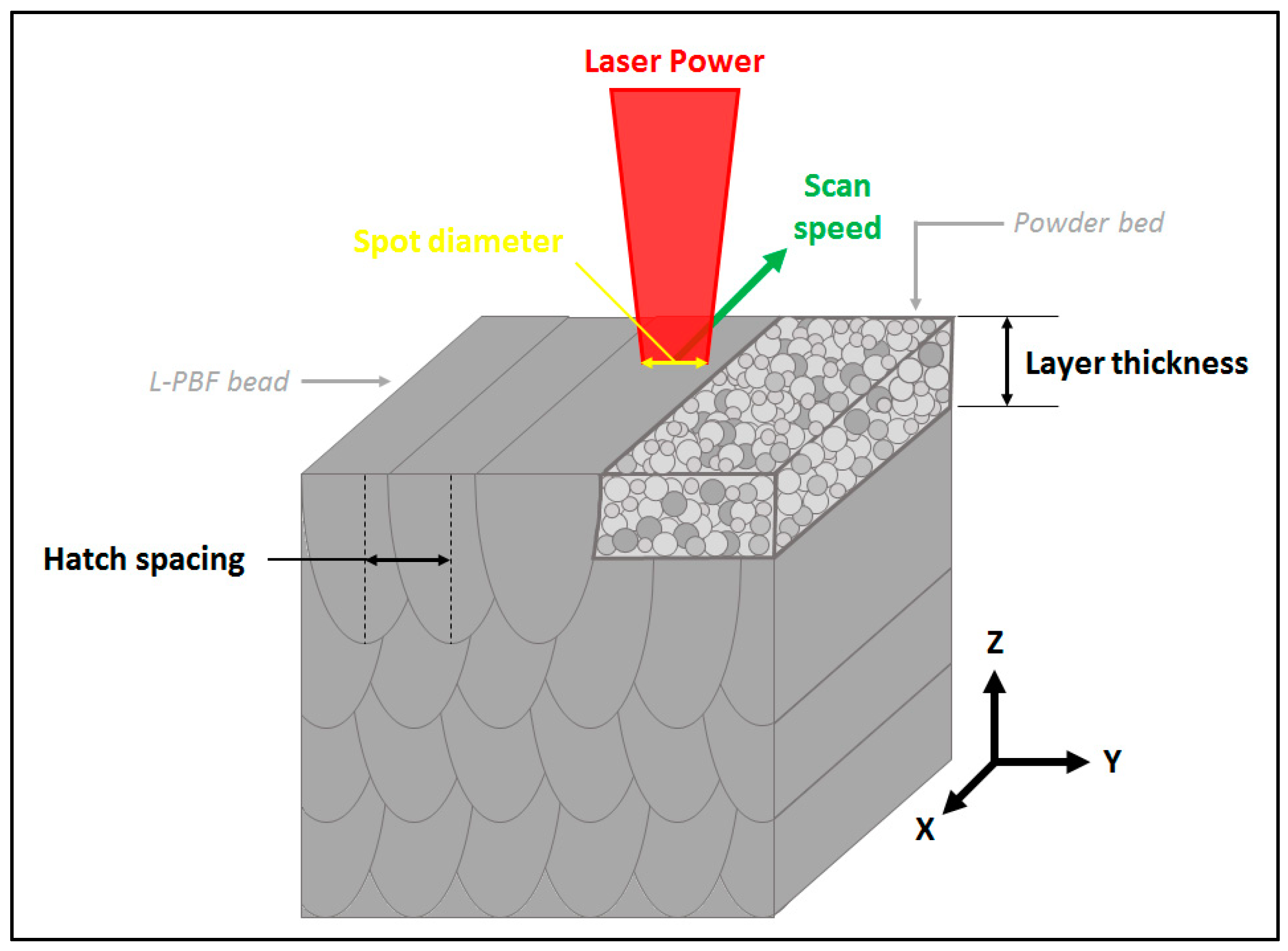

| Parameters | L-PBF-1 | L-PBF-2 | L-PBF-3 |

|---|---|---|---|

| Laser Power P (W) | 275 | 275 | 275 |

| Scan speed V (mm/s) | 224 | 449 | 897 |

| Hatch H (µm) | 75 | 75 | 75 |

| Spot Diameter D (µm) | 95 | 95 | 95 |

| Layer thickness t (µm) | 50 | 50 | 50 |

| VED (J/mm3) | 176 | 88 | 44 |

| Elements | Ni | Cr | Mo | Nb | Fe | Al | Ti |

|---|---|---|---|---|---|---|---|

| % (weight) | Balance | 22.07 | 9.32 | 3.67 | 0.33 | 0.17 | 0.15 |

| Manufacturing Conditions | L-PBF-1 | L-PBF-2 | L-PBF-3 |

|---|---|---|---|

| HV0.2 | 320 ± 10 | 318 ± 12 | 314 ± 11 |

| Parameters | σY (MPa) | UTS (MPa) | A% | |

|---|---|---|---|---|

| L-PBF-1 | H | 601 ± 15 | 908 ± 5 | 14 ± 1 |

| V | 444 ± 15 | 718 ± 9 | 18 ± 2 | |

| L-PBF-2 | H | 610 ± 6 | 907 ± 16 | 12 ± 2 |

| V | 500 ± 24 | 762 ± 24 | 16 ± 2 | |

| L-PBF-3 | H | 633 ± 2 | 933 ± 2 | 12 ± 2 |

| V | 592 ± 4 | 837 ± 4 | 21 ± 2 | |

| L-PBF-1 + HT | H | 368 ± 2 | 828 ± 3 | 25 ± 3 |

| V | 341 ± 7 | 746 ± 26 | 24 ± 2 | |

| L-PBF-2 + HT | H | 357 ± 4 | 814 ± 4 | 22 ± 1 |

| V | 346 ± 9 | 769 ± 1 | 24 ± 1 | |

| L-PBF-3 + HT | H | 379 ± 2 | 835 ± 14 | 23 ± 0 |

| V | 407 ± 7 | 849 ± 2 | 28 ± 0 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Terris, T.; Castelnau, O.; Hadjem-Hamouche, Z.; Haddadi, H.; Michel, V.; Peyre, P. Analysis of As-Built Microstructures and Recrystallization Phenomena on Inconel 625 Alloy Obtained via Laser Powder Bed Fusion (L-PBF). Metals 2021, 11, 619. https://doi.org/10.3390/met11040619

De Terris T, Castelnau O, Hadjem-Hamouche Z, Haddadi H, Michel V, Peyre P. Analysis of As-Built Microstructures and Recrystallization Phenomena on Inconel 625 Alloy Obtained via Laser Powder Bed Fusion (L-PBF). Metals. 2021; 11(4):619. https://doi.org/10.3390/met11040619

Chicago/Turabian StyleDe Terris, Thibaut, Olivier Castelnau, Zehoua Hadjem-Hamouche, Halim Haddadi, Vincent Michel, and Patrice Peyre. 2021. "Analysis of As-Built Microstructures and Recrystallization Phenomena on Inconel 625 Alloy Obtained via Laser Powder Bed Fusion (L-PBF)" Metals 11, no. 4: 619. https://doi.org/10.3390/met11040619

APA StyleDe Terris, T., Castelnau, O., Hadjem-Hamouche, Z., Haddadi, H., Michel, V., & Peyre, P. (2021). Analysis of As-Built Microstructures and Recrystallization Phenomena on Inconel 625 Alloy Obtained via Laser Powder Bed Fusion (L-PBF). Metals, 11(4), 619. https://doi.org/10.3390/met11040619