Influence of Pre-Aging on the Artificial Aging Behavior of a 6056 Aluminum Alloy after Conventional Extrusion

Abstract

1. Introduction

2. Materials and Methods

2.1. Material and Heat Treatment

2.2. Differential Scanning Calorimetry

2.3. Hardness Measurement

2.4. Tensile Testing

2.5. Microstructural Characterization

3. Results

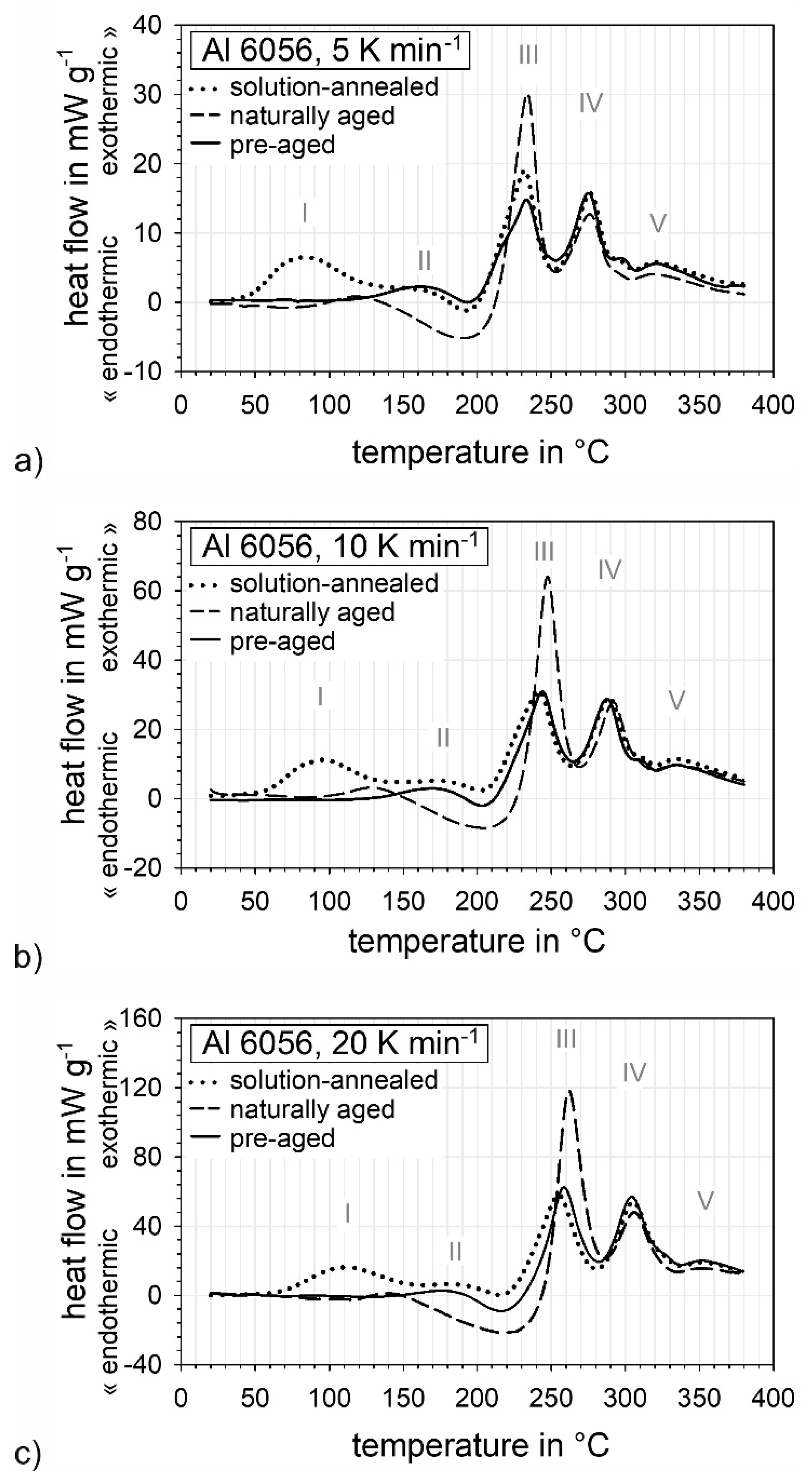

3.1. Precipitation Sequence

- peak I at 80 °C: separate Mg- and Si-clusters, as well as Mg-Si co-clusters;

- peak II at 160 °C: GP-zones;

- peak III at 230 °C: β”-precipitates;

- peak IV at 270 °C: β’-precipitates;

- peak V at 320 °C: Q-precipitates.

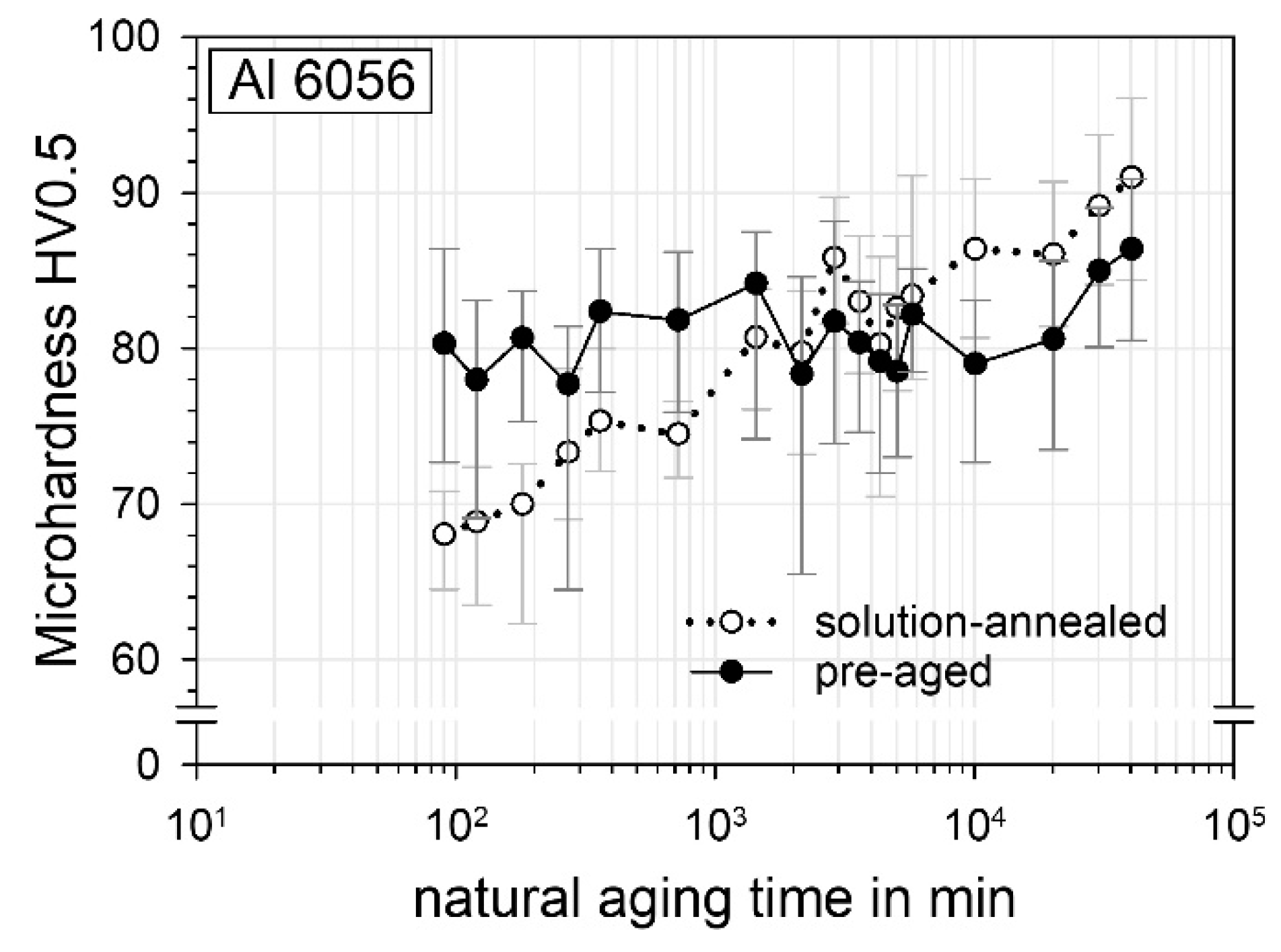

3.2. Aging Behavior

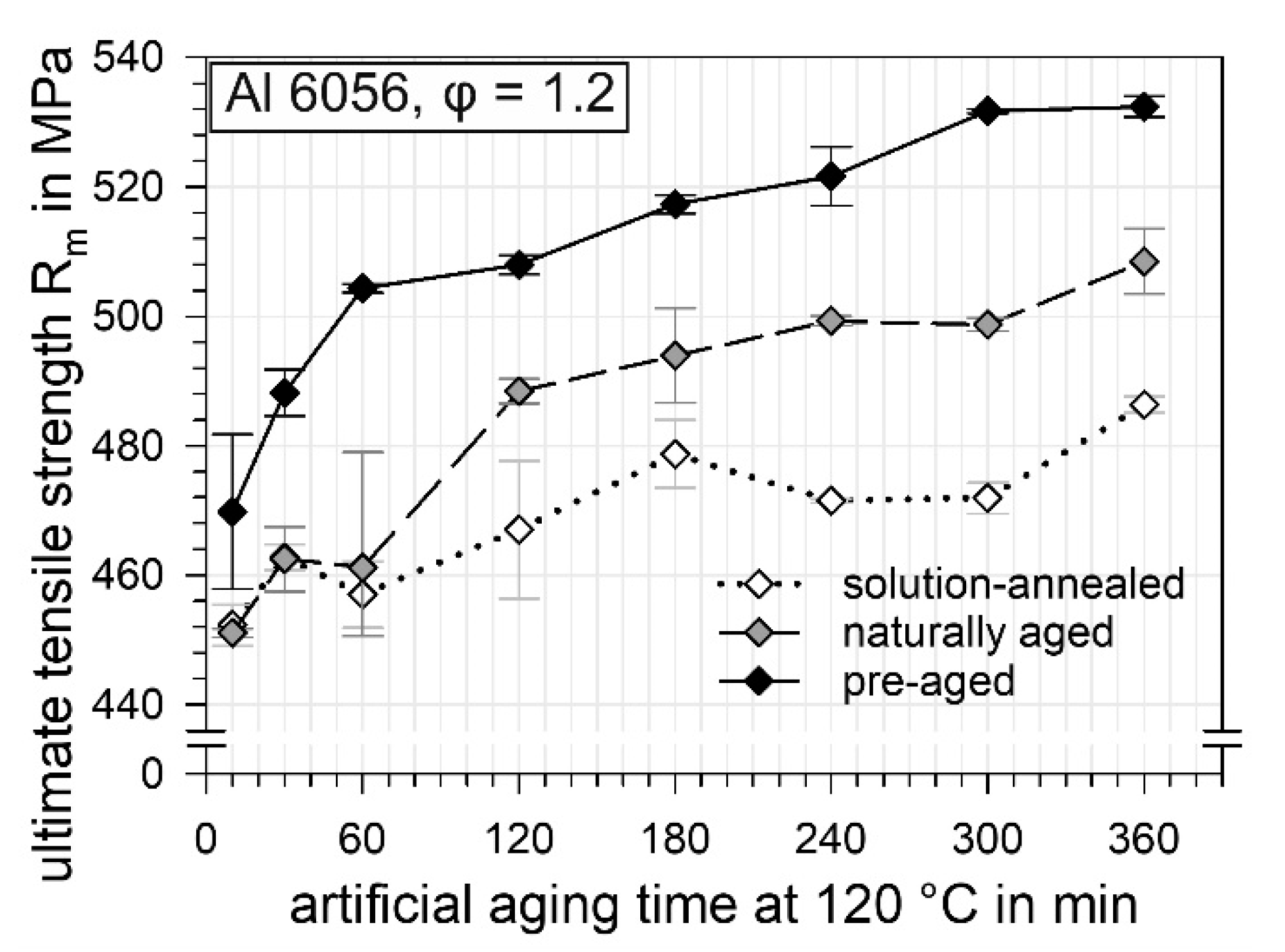

3.3. Tensile Properties

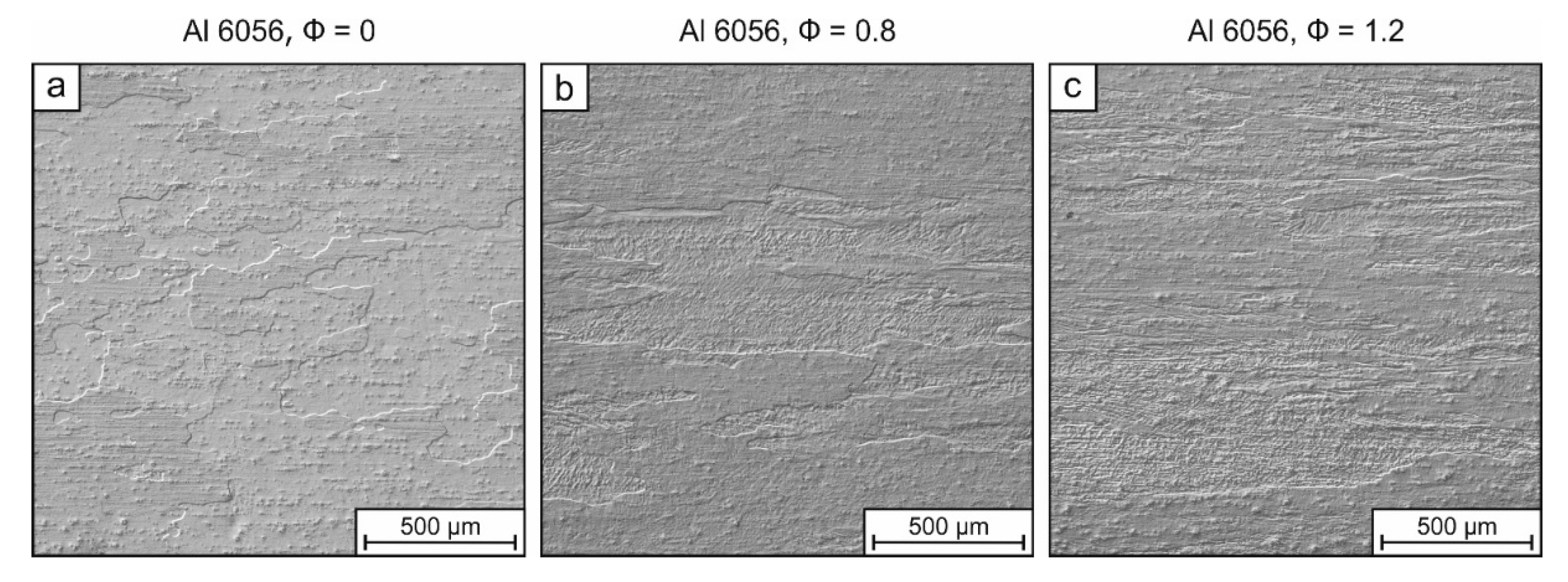

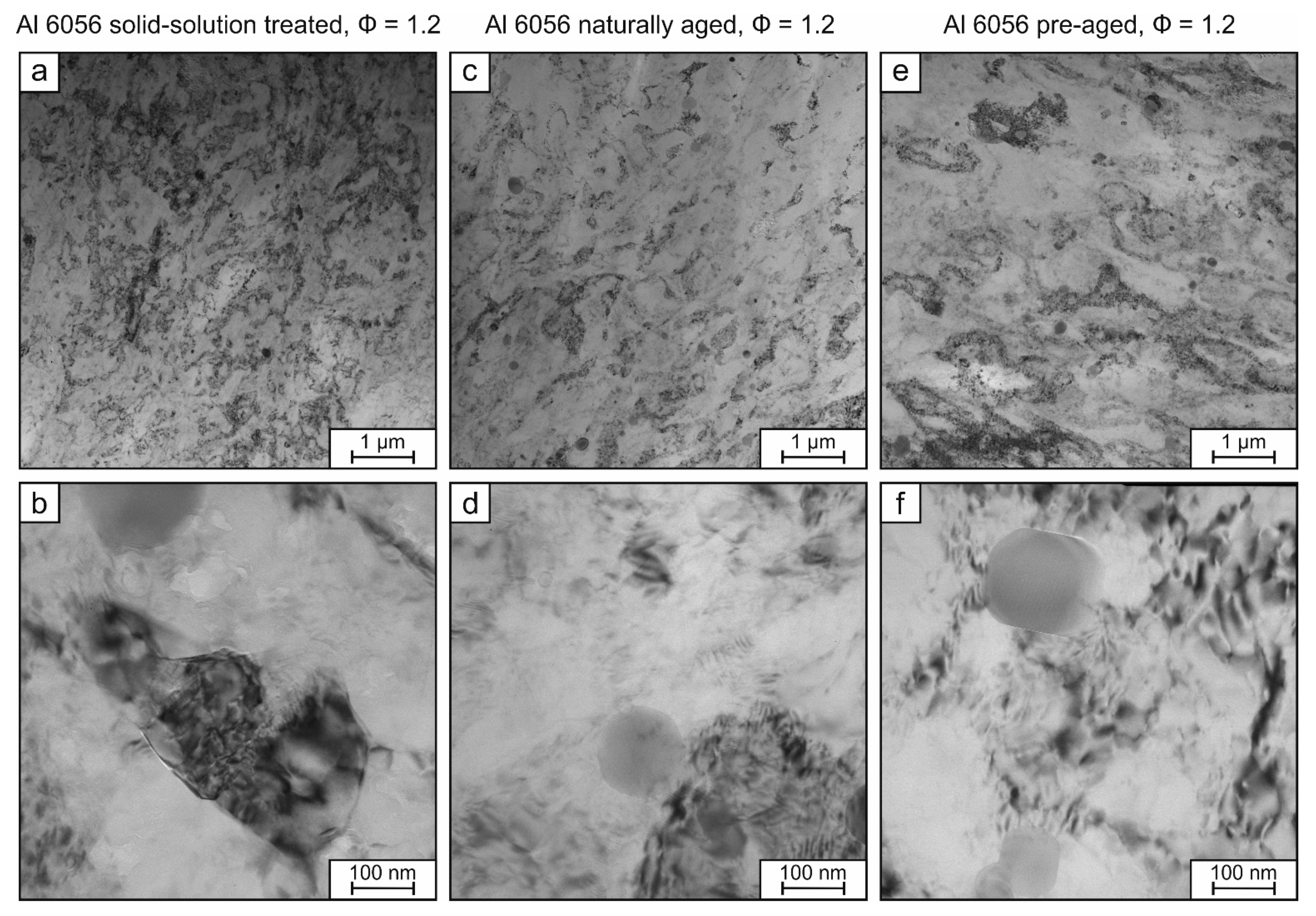

3.4. Microstructure

4. Discussion

4.1. Effect of Pre-Aging

4.2. Artificial Aging Behavior after Linear Extrusion

5. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Andersen, S.J.; Zandbergen, H.W.; Jansen, J.; Træholt, C.; Tundal, U.; Reiso, O. The crystal structure of the β″ phase in Al–Mg–Si alloys. Acta Mater. 1998, 46, 3283–3298. [Google Scholar] [CrossRef]

- Takeda, M.; Ohkubo, F.; Shirai, T.; Fukui, K. Stability of metastable phases and microstructures in the ageing process of Al–Mg–Si ternary alloys. J. Mater. Sci. 1998, 33, 2385–2390. [Google Scholar] [CrossRef]

- Delmas, F.; Casanove, M.J.; Lours, P.; Couret, A.; Coujou, A. Quantitative TEM study of the precipitation microstructure in aluminium alloy Al(MgSiCu) 6056 T6. Mater. Sci. Eng. A 2004, 373, 80–89. [Google Scholar] [CrossRef][Green Version]

- Chakrabarti, D.J.; Laughlin, D.E. Phase relations and precipitation in Al–Mg–Si alloys with Cu additions. Prog. Mater. Sci. 2004, 49, 389–410. [Google Scholar] [CrossRef]

- Miao, W.F.; Laughlin, D.E. Effects of Cu content and preaging on precipitation characteristics in aluminum alloy 6022. Metall. Mater. Trans. A 2000, 31, 361–371. [Google Scholar] [CrossRef]

- Pogatscher, S.; Antrekowitsch, H.; Leitner, H.; Ebner, T.; Uggowitzer, P.J. Mechanisms controlling the artificial aging of Al–Mg–Si Alloys. Acta Mater. 2011, 59, 3352–3363. [Google Scholar] [CrossRef]

- Hockauf, K.; Meyer, L.W.; Hockauf, M.; Halle, T. Improvement of strength and ductility for a 6056 aluminum alloy achieved by a combination of equal-channel angular pressing and aging treatment. J. Mater. Sci. 2010, 45, 4754–4760. [Google Scholar] [CrossRef]

- Zandbergen, M.W.; Cerezo, A.; Smith, G.D.W. Study of precipitation in Al-Mg-Si Alloys by atom probe tomography II. Influence of Cu additions. Acta Mater. 2015, 101, 149–158. [Google Scholar] [CrossRef]

- Liu, S.; Li, K.; Lu, J.; Sha, G.; Wang, J.; Yang, M.; Ji, G.; Song, M.; Wang, J.; Du, Y. On the atomic model of Guinier-Preston zones in Al-Mg-Si-Cu alloys. J. Alloys Compd. 2018, 745, 644–650. [Google Scholar] [CrossRef]

- Marioara, C.D.; Andersen, S.J.; Jansen, J.; Zandbergen, H.W. The influence of temperature and storage time at RT on nucleation of the β″ phase in a 6082 Al-Mg-Si alloy. Acta Mater. 2003, 51, 789–796. [Google Scholar] [CrossRef]

- Saga, M.; Sasaki, Y.; Kikuchi, M.; Yan, Z.; Matsuo, M. Effect of Pre-Aging Temperature on the Behavior in the Early Stage of Aging at High Temperature for Al-Mg-Si Alloy. Mater. Sci. Forum 1996, 217–222, 821–826. [Google Scholar] [CrossRef]

- Takaki, Y.; Aruga, Y.; Kozuka, M.; Sato, T. Effects of pre-aging and natural aging on bake hardening behavior in Al-Mg-Si alloys. Mater. Sci. Forum 2014, 794–796, 1026–1031. [Google Scholar] [CrossRef]

- Serizawa, A.; Hirosawa, S.; Sato, T. Three-Dimensional Atom Probe Characterization of Nanoclusters Responsible for Multistep Aging Behavior of an Al-Mg-Si Alloy. Metall. Mater. Trans. A 2008, 39, 243–251. [Google Scholar] [CrossRef]

- Matsuda, K.; Kawabata, T.; Uetani, Y.; Sato, T.; Kamio, A.; Ikeno, S. HRTEM observation of G.P. Zones and metastable phase in Al-Mg-Si alloys. Mater. Sci. Forum 2000, 331–337, 989–994. [Google Scholar] [CrossRef]

- Kim, J.K.; Jeong, H.G.; Hong, S.I.; Kim, Y.S.; Kim, W.J. Effect of aging treatment on heavily deformed microstructure of a 6061 aluminum alloy after equal channel angular pressing. Scr. Mater. 2001, 45, 901–907. [Google Scholar] [CrossRef]

- Hockauf, M.; Meyer, L.W.; Zillmann, B.; Hietschold, M.; Schulze, S.; Krüger, L. Simultaneous improvement of strength and ductility of Al-Mg-Si alloys by combining equal-channel angular extrusion with subsequent high-temperature short-time aging. Mater. Sci. Eng. A 2009, 503, 167–171. [Google Scholar] [CrossRef]

- Kim, W.J.; Kim, J.K.; Park, T.Y.; Hong, S.I.; Kim, D.I.; Kim, Y.S.; Lee, J.D. Enhancement of strength and superplasticity in a 6061 Al alloy processed by equal-channel-angular-pressing. Metall. Mater. Trans. A 2002, 33, 3155–3164. [Google Scholar] [CrossRef]

- Rezaei, M.R.; Toroghinejad, M.R.; Ashrafizadeh, F. Effects of ARB and ageing processes on mechanical properties and microstructure of 6061 aluminum alloy. J. Mater. Process. Technol. 2011, 211, 1184–1190. [Google Scholar] [CrossRef]

- Milkereit, B.; Kessler, O.; Schick, C. Recording of continuous cooling precipitation diagrams of aluminium alloys. Thermochim. Acta 2009, 492, 73–78. [Google Scholar] [CrossRef]

- Gallais, C.; Denquin, A.; Bréchet, Y.; Lapasset, G. Precipitation microstructures in an AA6056 aluminium alloy after friction stir welding: Characterisation and modelling. Mater. Sci. Eng. A 2008, 496, 77–89. [Google Scholar] [CrossRef]

- Edwards, G.A.; Stiller, K.; Dunlop, G.L.; Couper, M.J. The precipitation sequence in Al–Mg–Si alloys. Acta Mater. 1998, 46, 3893–3904. [Google Scholar] [CrossRef]

- Lloyd, D.J.; Evans, D.R.; Gupta, A.K. Precipitation reactions and the Differential Scanning Calorimetry response of AA6111 alloy. Can. Metall. Q. 2000, 39, 475–482. [Google Scholar] [CrossRef]

- Buha, J.; Lumley, R.N.; Crosky, A.G.; Hono, K. Secondary precipitation in an Al-Mg-Si-Cu alloy. Acta Mater. 2007, 55, 3015–3024. [Google Scholar] [CrossRef]

- Esmaeili, S.; Wang, X.; Lloyd, D.J.; Poole, W.J. On the precipitation-hardening behavior of the Al-Mg-Si-Cu alloy AA6111. Metall. Mater. Trans. A 2003, 34, 751–763. [Google Scholar]

- Frint, P.; Wagner, M.F.-X. Strain partitioning by recurrent shear localization during equal-channel angular pressing of an AA6060 aluminum alloy. Acta Mater. 2019, 176, 306–317. [Google Scholar] [CrossRef]

- Dutta, I.; Allen, S.M. A calorimetric study of precipitation in commercial aluminium alloy 6061. J. Mater. Sci. Lett. 1991, 10, 323–326. [Google Scholar] [CrossRef]

- Murayama, M.; Hono, K. Pre-precipitate clusters and precipitation processes in Al–Mg–Si alloys. Acta Mater. 1999, 47, 1537–1548. [Google Scholar] [CrossRef]

- Takata, K.; Takahashi, J.; Saga, M.; Ushioda, K.; Hibino, A.; Kikuchi, M. Effect of Two-Step Aging on Cluster Formation in Al-Mg-Si Alloys. Mater. Trans. 2014, 55, 885–891. [Google Scholar] [CrossRef]

- Kim, J.H.; Kobayashi, E.; Sato, T. Effects of Cu Addition on Behavior of Nanoclusters during Multi-Step Aging in Al-Mg-Si Alloys. Mater. Trans. 2011, 52, 906–913. [Google Scholar] [CrossRef]

- Pogatscher, S.; Antrekowitsch, H.; Leitner, H.; Pöschmann, D.; Zhang, Z.L.; Uggowitzer, P.J. Influence of interrupted quenching on artificial aging of Al–Mg–Si alloys. Acta Mater. 2012, 60, 4496–4505. [Google Scholar] [CrossRef]

- Pogatscher, S.; Werinos, M.; Antrekowitsch, H.; Uggowitzer, P.J. The Role of Vacancies in the Aging of Al-Mg-Si Alloys. Mater. Sci. Forum 2014, 794–796, 1008–1013. [Google Scholar] [CrossRef]

- Zi, Y.; Zeqin, L.; Leyvraz, D.; Banhart, J. Effect of pre-ageing on natural secondary ageing and paint bake hardening in Al–Mg–Si alloys. Materialia 2019, 7, 100413. [Google Scholar] [CrossRef]

- Yang, Z.; Liang, Z.; Leyvraz, D.; Banhart, J. Hardness data related to pre-ageing, natural secondary ageing, and paint bake hardening in Al-Mg-Si alloys. Data Br. 2019, 27, 104494. [Google Scholar] [CrossRef] [PubMed]

- Yamada, K.; Sato, T.; Kamio, A. Effects of quenching conditions on two-step aging behavior of Al-Mg-Si alloys. Mater. Sci. Forum 2000, 331, 669–674. [Google Scholar] [CrossRef]

- Engler, O.; Marioara, C.D.; Aruga, Y.; Kozuka, M.; Myhr, O.R. Effect of natural ageing or pre-ageing on the evolution of precipitate structure and strength during age hardening of Al–Mg–Si alloy AA 6016. Mater. Sci. Eng. A 2019, 759, 520–529. [Google Scholar] [CrossRef]

- Zandbergen, M.W.; Xu, Q.; Cerezo, A.; Smith, G.D.W. Study of precipitation in Al-Mg-Si alloys by Atom Probe Tomography I. Microstructural changes as a function of ageing temperature. Acta Mater. 2015, 101, 136–148. [Google Scholar] [CrossRef]

- Yu, W.; He, H.; Zhang, W.; Li, L.; Sun, C. Modulation of the natural aging effect on subsequent artificial aging in Al–Mg–Si aluminum alloys with alloying content ∼ 1 wt% through temperature tuning. J. Alloys Compd. 2020, 814, 152277. [Google Scholar] [CrossRef]

- Papazian, J.M. A calorimetric study of precipitation in aluminum alloy 2219. Metall. Trans. A 1981, 12, 269–280. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Liao, X.Z.; Jin, Z.; Valiev, R.Z.; Zhu, Y.T. Microstructures and mechanical properties of ultrafine grained 7075 Al alloy processed by ECAP and their evolutions during annealing. Acta Mater. 2004, 52, 4589–4599. [Google Scholar] [CrossRef]

- Zuiko, I.; Gazizov, M.; Kaibyshev, R. Effect of cold plastic deformation on mechanical properties of aluminum alloy 2519 after ageing. Mater. Sci. Forum 2014, 794–796, 888–893. [Google Scholar] [CrossRef]

- Ringer, S.P.; Muddle, B.C.; Polmear, I.J. Effects of cold work on precipitation in Al-Cu-Mg-(Ag) and Al-Cu-Li-(Mg-Ag) alloys. Metall. Mater. Trans. A 1995, 26, 1659–1671. [Google Scholar] [CrossRef]

- Suzuki, H.; Kanno, M.; Itoh, G. A consideration of the two-step aging process in an Al-Mg-Si alloy. Aluminium 1981, 57, 628–629. [Google Scholar]

- Liu, M.; Guo, Q.; Zhang, X.; Wüstenhagen, M.; Čížek, J.; Banhart, J. Clustering phenomena in quenched Al, Al–Mg, Al–Si and Al–Mg–Si alloys. Scr. Mater. 2020, 177, 203–207. [Google Scholar] [CrossRef]

- Horita, Z.; Ohashi, K.; Fujita, T.; Kaneko, K.; Langdon, T.G. Achieving High Strength and High Ductility in Precipitation-Hardened Alloys. Adv. Mater. 2005, 17, 1599–1602. [Google Scholar] [CrossRef]

| Element | Si | Mg | Cu | Mn | Zn | Fe | Zr | Ti | Cr | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| wt.% | 1.06 | 0.89 | 0.78 | 0.59 | 0.19 | 0.16 | 0.13 | 0.04 | 0.01 | balance |

| Wire Diameter d in mm | Yield Strength Rp0.2 in MPa | Ultimate Tensile Strength Rm in MPa | Elongation A100mm in % |

|---|---|---|---|

| 5.26 | 173 ± 1 | 188 ± 2 | 6.3 ± 1.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Winter, L.; Hockauf, K.; Scholze, M.; Hellmig, R.J.; Lampke, T. Influence of Pre-Aging on the Artificial Aging Behavior of a 6056 Aluminum Alloy after Conventional Extrusion. Metals 2021, 11, 385. https://doi.org/10.3390/met11030385

Winter L, Hockauf K, Scholze M, Hellmig RJ, Lampke T. Influence of Pre-Aging on the Artificial Aging Behavior of a 6056 Aluminum Alloy after Conventional Extrusion. Metals. 2021; 11(3):385. https://doi.org/10.3390/met11030385

Chicago/Turabian StyleWinter, Lisa, Kristin Hockauf, Mario Scholze, Ralph Jörg Hellmig, and Thomas Lampke. 2021. "Influence of Pre-Aging on the Artificial Aging Behavior of a 6056 Aluminum Alloy after Conventional Extrusion" Metals 11, no. 3: 385. https://doi.org/10.3390/met11030385

APA StyleWinter, L., Hockauf, K., Scholze, M., Hellmig, R. J., & Lampke, T. (2021). Influence of Pre-Aging on the Artificial Aging Behavior of a 6056 Aluminum Alloy after Conventional Extrusion. Metals, 11(3), 385. https://doi.org/10.3390/met11030385