Permeability Measurements of 3D Microstructures Generated by Phase Field Simulation of the Solidification of an Al-Si Alloy during Chill Casting

Abstract

:1. Introduction

Related Works

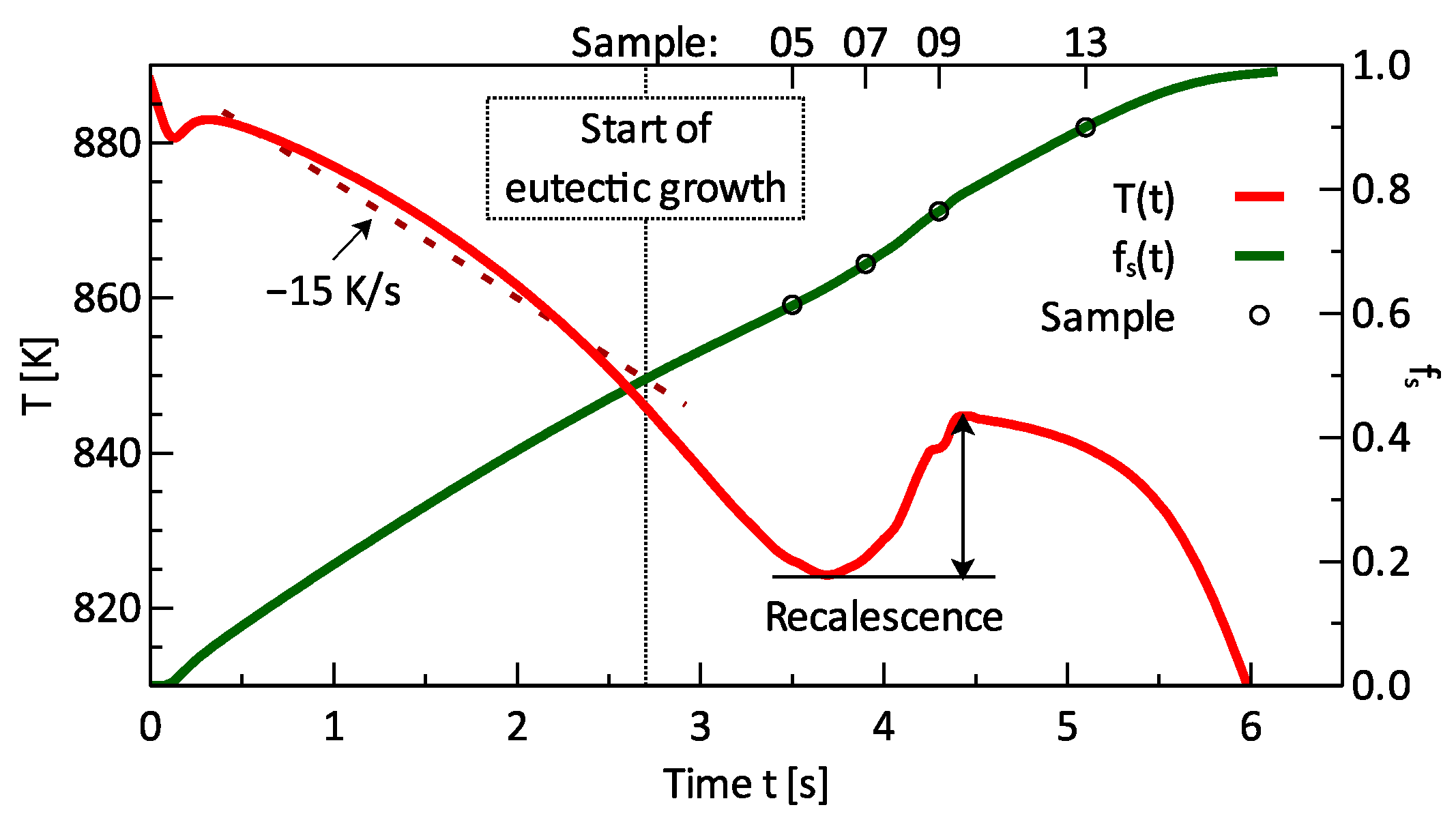

2. Materials and Methods

2.1. Phase Field Model

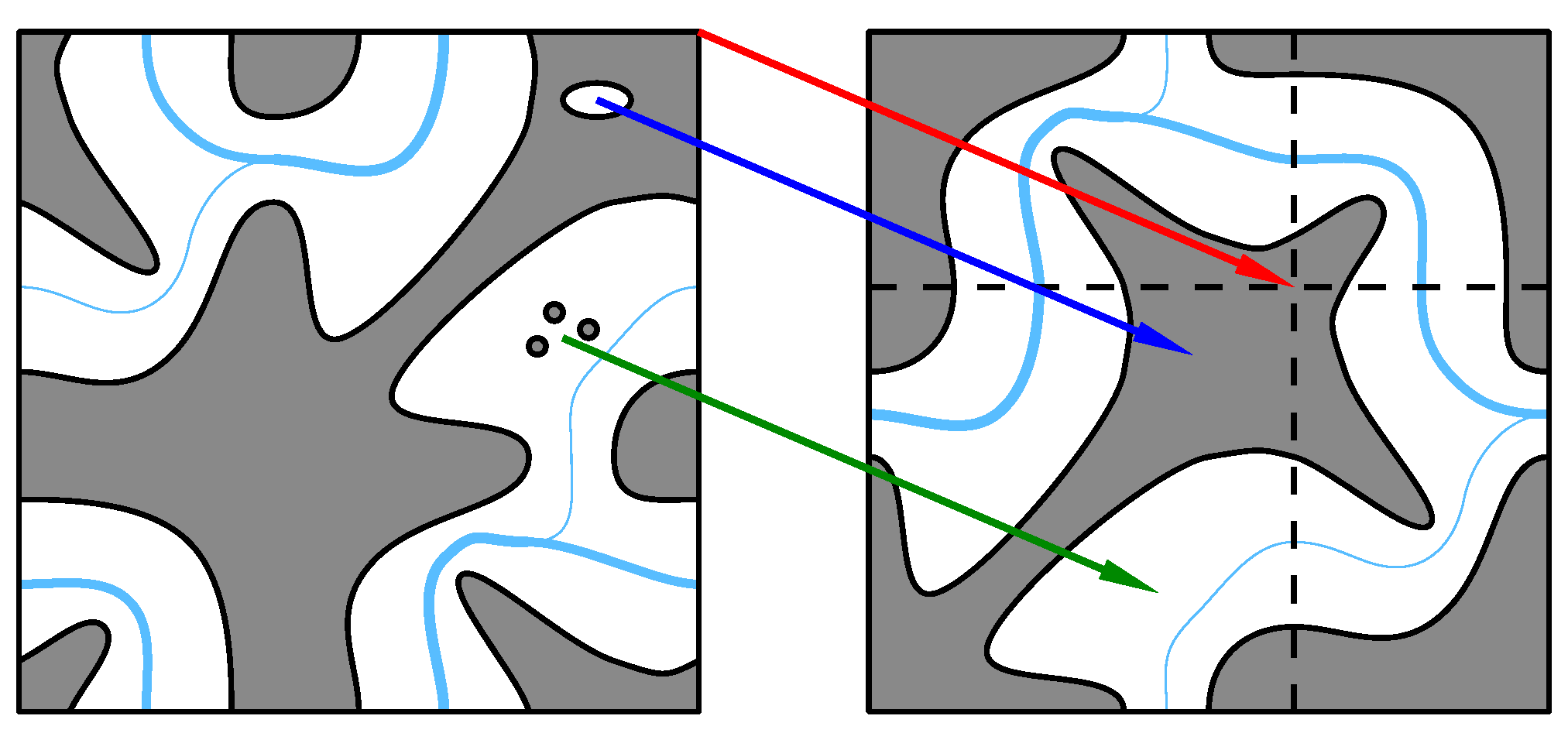

2.2. Digital Filtering

- (1)

- To minimize the effect due to blocked flow at the “sides”, an RVE of the periodic structure was chosen by a translation, such that the flow resulting from CFD simulations was minimal across the RVE boundaries parallel to the pressure gradient. As a criterion, the absolute flow across planes parallel to the boundaries was integrated and new boundary planes chosen, for which this quantity is small;

- (2)

- A supporting structure was added to keep grains in place. This structure consisted of 1.5 mm wide struts along the edges of the cubic RVE;

- (3)

- Completely encapsulated liquid, which does not contribute to the permeability, was removed (classified as solid region) to enhance structural stability of the models;

- (4)

- Isolated solid regions unconnected to the supported structure were removed.

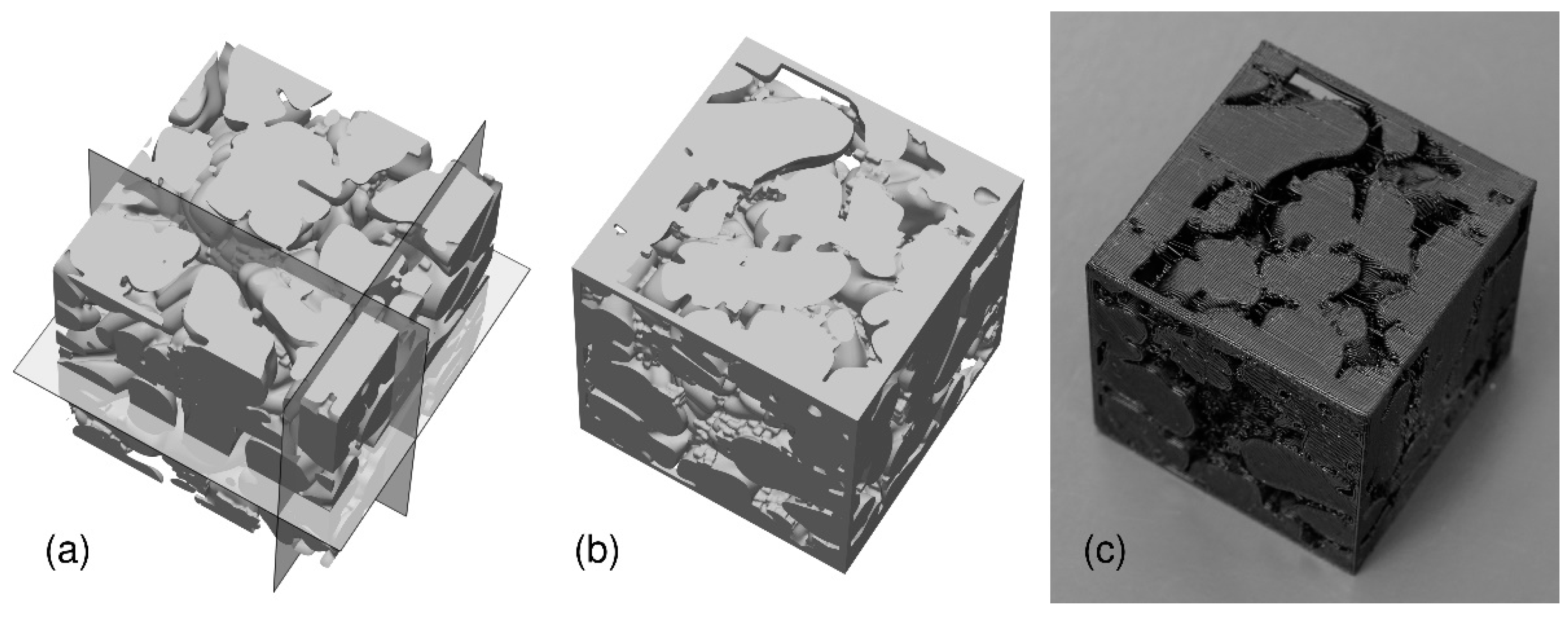

2.3. Additive Manufacturing

2.4. Permeability Measurements

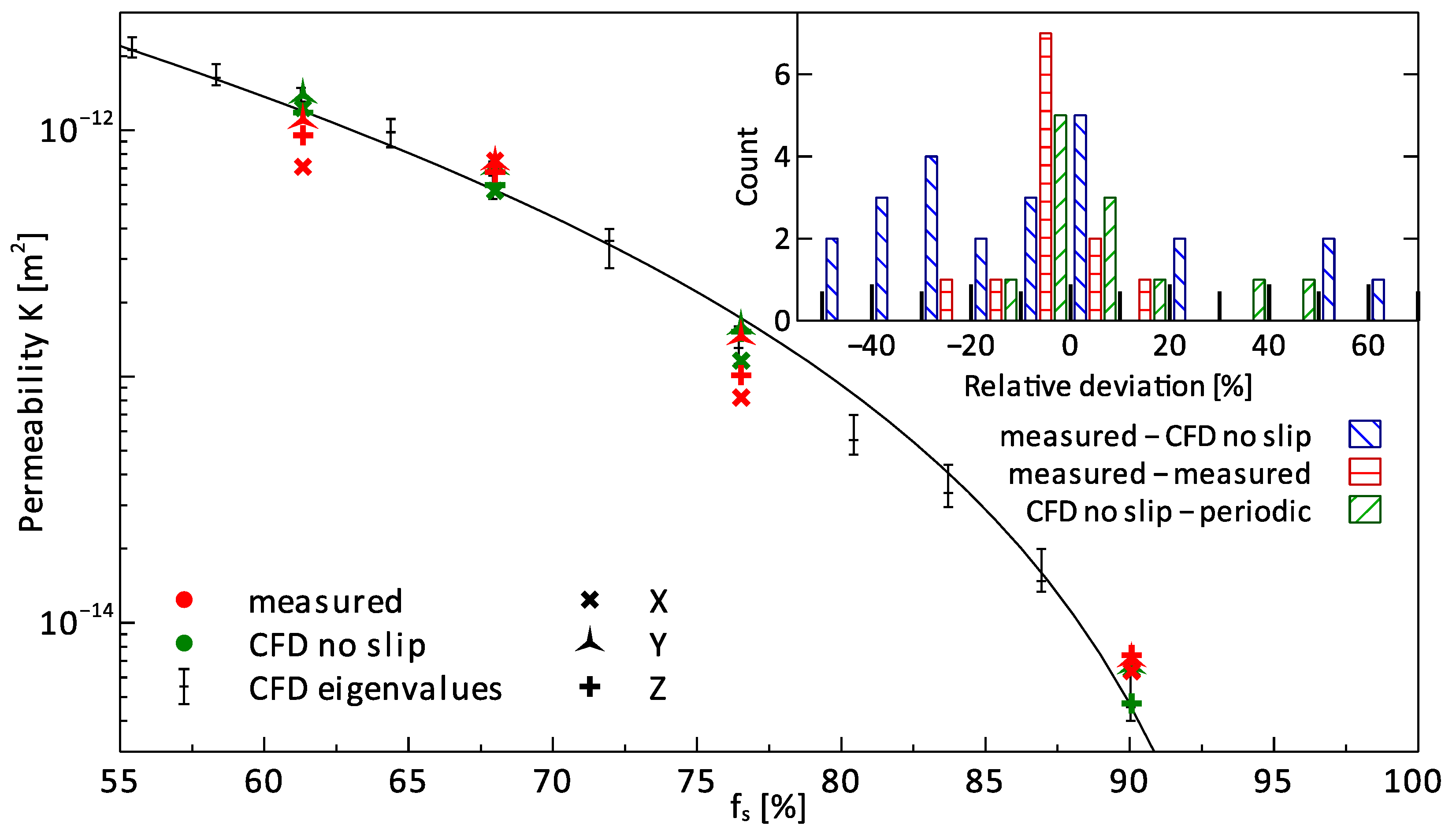

3. Results

4. Discussion

- Inaccurate CFD simulations;

- Structural differences between the physical models and the geometries used in CFD-simulations;

- Errors in the measurement process.

4.1. Accuracy of CFD Simulations

4.2. Accuracy of Physical Models

4.3. Accuracy of Measurements

5. Conclusions

Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Dantzig, J.A.; Rappaz, M. Solidification; EPFL Press: Lausanne, Switzerland, 2009. [Google Scholar]

- Rappaz, M.; Drezet, J.-M.; Gremaud, M. A new hot-tearing criterion. Metall. Mater. Trans. A 1999, 30, 449–455. [Google Scholar] [CrossRef]

- Böttger, B.; Apel, M.; Santillana, B.; Eskin, D.G. Relationship Between Solidification Microstructure and Hot Cracking Susceptibility for Continuous Casting of Low-Carbon and High-Strength Low-Alloyed Steels: A Phase-Field Study. Metall. Mater. Trans. A 2013, 44, 3765–3777. [Google Scholar] [CrossRef]

- Berger, R.; Apel, M.; Laschet, G. An analysis of the melt flow permeability for evolving hypoeutectic Al-Si mushy zone microstructures by phase field simulations. Materialia 2021, 15, 100966. [Google Scholar] [CrossRef]

- Khajeh, E.; Mirbagheri, S.M.H.; Davami, P. Modeling of permeability with the aid of 3D interdendritic flow simulation for equiaxed dendritic structures. Mater. Sci. Eng. A 2008, 475, 355–364. [Google Scholar] [CrossRef]

- Mirbagheri, S.M.H.; Khajeh, E. Modelling and simulation of equiaxed dendritic structures permeability for Pb–Sn alloys. Mater. Sci. Technol. 2008, 24, 1444–1451. [Google Scholar] [CrossRef]

- Madison, J.; Spowart, J.E.; Rowenhorst, D.J.; Aagesen, L.K.; Thornton, K.; Pollock, T.M. Fluid flow and defect formation in the three-dimensional dendritic structure of nickel-based single crystals. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2012, 43, 369–380. [Google Scholar] [CrossRef] [Green Version]

- Khajeh, E.; Maijer, D.M. Numerical determination of permeability of Al-Cu alloys using 3D geometry from X-ray microtomography. Mater. Sci. Technol. 2010, 26, 1469–1476. [Google Scholar] [CrossRef]

- Bhat, M.S.; Poirier, D.R.; Heinrich, J.C. Permeability for cross flow through columnar-dendritic alloys. Metall. Mater. Trans. B 1995, 26, 1049–1056. [Google Scholar] [CrossRef]

- Ludwig, A.; Kharicha, A.; Hölzl, C.; Domitner, J.; Wu, M.; Pusztai, T. 3D Lattice Boltzmann flow simulations through dendritic mushy zones. Eng. Anal. Bound. Elem. 2014, 45, 29–35. [Google Scholar] [CrossRef]

- Böttger, B.; Haberstroh, C.; Giesselmann, N. Cross-Permeability of the Semisolid Region in Directional Solidification: A Combined Phase-Field and Lattice-Boltzmann Simulation Approach. JOM 2016, 68, 27–36. [Google Scholar] [CrossRef]

- Mitsuyama, Y.; Takaki, T.; Sakane, S.; Shibuta, Y.; Ohno, M. Permeability tensor for columnar dendritic structures: Phase-field and lattice Boltzmann study. Acta Mater. 2020, 188, 282–287. [Google Scholar] [CrossRef]

- Takaki, T.; Sakane, S.; Ohno, M.; Shibuta, Y.; Aoki, T. Permeability prediction for flow normal to columnar solidification structures by large–scale simulations of phase–field and lattice Boltzmann methods. Acta Mater. 2019, 164, 237–249. [Google Scholar] [CrossRef]

- Li, L.; Zhang, R.; Hu, S.; Zhang, D.; Yang, S.; Wang, C.; Jiang, H. Prediction of mushy zone permeability of Al–4.5 wt% Cu alloy during solidification by phase field model and CFD simulation. China Foundry 2019, 16, 313–318. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Kang, J.; Guo, Z.; Han, Q. Effect of the forced flow on the permeability of dendritic networks: A study using phase-field-lattice Boltzmann method. Int. J. Heat Mass Transf. 2019, 131, 196–205. [Google Scholar] [CrossRef]

- Khajeh, E.; Maijer, D.M. Permeability evolution during equiaxed dendritic solidification of Al–4.5 wt%Cu. Model. Simul. Mater. Sci. Eng. 2012, 20, 035004. [Google Scholar] [CrossRef]

- James, J.D.; Brown, S.G.R.; Spittle, J.A.; Lavery, N.P. Experimental apparatus for validation of computer models of the permeability of metallic alloys in the mushy zone. In Proceedings of the Modeling of Casting, Welding and Advanced Solidification Processes—XI, Opio, France, 28 May–2 June 2006; pp. 1189–1196. [Google Scholar]

- Bodaghi, M.; Ban, D.; Mobin, M.; Park, C.H.; Lomov, S.V.; Nikzad, M. Additively manufactured three dimensional reference porous media for the calibration of permeability measurement set-ups. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106119. [Google Scholar] [CrossRef]

- MICRESS®, the Microstructure Evolution Simulation Software. Available online: www.micress.de (accessed on 1 August 2017).

- Torquato, S. Random Heterogeneous Materials; Interdisciplinary Applied Mathematics; Springer: New York, NY, USA, 2002; Volume 16. [Google Scholar]

- Eiken, J. A Phase-Field Model for Technical Alloy Solidification; Shaker Verlag: Herzogenrath, Germany, 2009. [Google Scholar]

- Aluminium-Based Alloys Databases. Available online: https://thermocalc.com/products/databases/aluminum-based-alloys/ (accessed on 23 November 2021).

- Thermocalc Software. Available online: www.thermocalc.com (accessed on 1 August 2017).

- Laschet, G.; Vossel, T.; Wolff, N.; Apel, M.; Bührig-Polaczek, A. Multiscale Solidification Simulation of an Axisymmetric A356 Component in Die Casting. In Proceedings of the 6th Decennial International Conference on Solidification Processing, Old Windsor, UK, 25–28 July 2017; pp. 576–580. [Google Scholar]

- Böttger, B.; Eiken, J.; Apel, M. Phase-field simulation of microstructure formation in technical castings—A self-consistent homoenthalpic approach to the micro–macro problem. J. Comput. Phys. 2009, 228, 6784–6795. [Google Scholar] [CrossRef]

- Zhou, B.; Laschet, G.; Eiken, J.; Behnken, H.; Apel, M. Multiscale solidification simulation of Sr-modified Al-Si-Mg alloy in die casting. IOP Conf. Ser. Mater. Sci. Eng. 2020, 861, 012034. [Google Scholar] [CrossRef]

- Osswald, T.A. Understanding Polymer Processing: Processes and Governing Equations, 2nd ed.; Carl Hanser Verlag GmbH & Co. KG: München, Germany, 2017. [Google Scholar]

- Dizon, J.R.C.; Espera, A.H.; Chen, Q.; Advincula, R.C. Mechanical characterization of 3D-printed polymers. Addit. Manuf. 2018, 20, 44–67. [Google Scholar] [CrossRef]

- Dey, A.; Yodo, N. A Systematic Survey of FDM Process Parameter Optimization and Their Influence on Part Characteristics. J. Manuf. Mater. Process. 2019, 3, 64. [Google Scholar] [CrossRef] [Green Version]

- Oliveira, J.P.; LaLonde, A.D.; Ma, J. Processing parameters in laser powder bed fusion metal additive manufacturing. Mater. Des. 2020, 193, 108762. [Google Scholar] [CrossRef]

- Gebhardt, A.; Kessler, J.; Thurn, L. 3D Printing: Understanding Additive Manufacturing; Carl Hanser Verlag GmbH & Co. KG: München, Germany, 2018. [Google Scholar]

- DIN EN ISO/ASTM 52900: Additive Fertigung—Grundlagen—Terminologie; Beuth Verlag GmbH: Berlin, Germany, 2018.

- Khajeh, E.; Maijer, D.M. Physical and numerical characterization of the near-eutectic permeability of aluminum–copper alloys. Acta Mater. 2010, 58, 6334–6344. [Google Scholar] [CrossRef]

- Bosart, L.W.; Snoddy, A.O. New Glycerol Tables. Ind. Eng. Chem. 1927, 19, 506–510. [Google Scholar] [CrossRef]

- Segur, J.B.; Oberstar, H.E. Viscosity of Glycerol and Its Aqueous Solutions. Ind. Eng. Chem. 1951, 43, 2117–2120. [Google Scholar] [CrossRef]

| Setting | PA6 | PVA |

|---|---|---|

| Nozzle temperature [°C] | 260 | 220 |

| Build plate temperature [°C] | 80 | |

| Nozzle diameter [mm] | 0.4 | 0.4 |

| Layer height [mm] | 0.2 | |

| Extrusion width [mm] | 0.5 | |

| Printing speed [mm/s] | 30 | |

| Infill density [%] | 100 | n/a |

| Sample | fS [%] | Permeability Measured, Scaled | BC | Permeability CFD | ||||

|---|---|---|---|---|---|---|---|---|

| KX | KY | KZ | KX | KY | KZ | |||

| 05 | 61.4 | 7.04 × 10−13 | 1.09 × 10−12 | 9.83 × 10−13 | ns | 1.23 × 10−12 | 1.39 × 10−12 | 1.18 × 10−12 |

| 7.16 × 10−13 | 1.11 × 10−12 | 9.23 × 10−13 | p | 1.28 × 10−12 | 1.44 × 10−12 | 1.27 × 10−12 | ||

| 07 | 68.1 | 7.13 × 10−13 | 7.31 × 10−13 | 7.27 × 10−13 | ns | 5.67 × 10−13 | 7.12 × 10−13 | 5.99 × 10−13 |

| 8.92 × 10−13 | 7.59 × 10−13 | 6.26 × 10−13 | p | 6.11 × 10−13 | 7.28 × 10−13 | 5.86 × 10−13 | ||

| 09 | 76.8 | 8.38 × 10−14 | 1.32 × 10−13 | 9.97 × 10−14 | ns | 1.16 × 10−13 | 1.60 × 10−13 | 1.52 × 10−13 |

| 8.06 × 10−14 | 1.58 × 10−13 | 1.03 × 10−13 | p | 1.30 × 10−13 | 1.56 × 10−13 | 1.16 × 10−13 | ||

| 13 | 90.7 | 6.35 × 10−15 | 7.14 × 10−15 | 7.12 × 10−15 | ns | 6.46 × 10−15 | 6.71 × 10−15 | 4.71 × 10−15 |

| 6.37 × 10−15 | 7.18 × 10−15 | 7.67 × 10−15 | p | 4.37 × 10−15 | 6.00 × 10−15 | 4.56 × 10−15 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Berger, R.; Apel, M.; Laschet, G.; Jessen, W.; Schröder, W.; Wipperfürth, J.; Austermann, J.; Hopmann, C. Permeability Measurements of 3D Microstructures Generated by Phase Field Simulation of the Solidification of an Al-Si Alloy during Chill Casting. Metals 2021, 11, 1895. https://doi.org/10.3390/met11121895

Berger R, Apel M, Laschet G, Jessen W, Schröder W, Wipperfürth J, Austermann J, Hopmann C. Permeability Measurements of 3D Microstructures Generated by Phase Field Simulation of the Solidification of an Al-Si Alloy during Chill Casting. Metals. 2021; 11(12):1895. https://doi.org/10.3390/met11121895

Chicago/Turabian StyleBerger, Ralf, Markus Apel, Gottfried Laschet, Wilhelm Jessen, Wolfgang Schröder, Jens Wipperfürth, Johannes Austermann, and Christian Hopmann. 2021. "Permeability Measurements of 3D Microstructures Generated by Phase Field Simulation of the Solidification of an Al-Si Alloy during Chill Casting" Metals 11, no. 12: 1895. https://doi.org/10.3390/met11121895

APA StyleBerger, R., Apel, M., Laschet, G., Jessen, W., Schröder, W., Wipperfürth, J., Austermann, J., & Hopmann, C. (2021). Permeability Measurements of 3D Microstructures Generated by Phase Field Simulation of the Solidification of an Al-Si Alloy during Chill Casting. Metals, 11(12), 1895. https://doi.org/10.3390/met11121895