3D Modeling of the Solidification Structure Evolution of Superalloys in Powder Bed Fusion Additive Manufacturing Processes

Abstract

:1. Introduction

2. The Modeling Approach

2.1. The Macro-Model Description

2.2. The Micromodel Description

2.2.1. Description of the Columnar Interface Tracking

2.2.2. Computational Aspects for 3D Modeling of AM Products

- The GPU (CUDA) and CPU (C++) were utilized to compile the 3D micromodel code;

- The CUDA 3D-Micro simulator is at least one order of magnitude faster than the CPU Micro-3D simulator using the Intel Skylake AL supercomputer;

- The CPU 3D-Micro simulator is fairly fast, typically taking about 8 h for a multilayer, multitrack simulation using a 2 μm mesh size (33 million cells, RAM 6 GB);

- The CPU 3D-Micro simulator can run 2.75 trillion cells on the Intel Skylake AL supercomputer (RAM 500 GB), which is equivalent of a 1.4 mm3 geometry using a 2 μm mesh size.

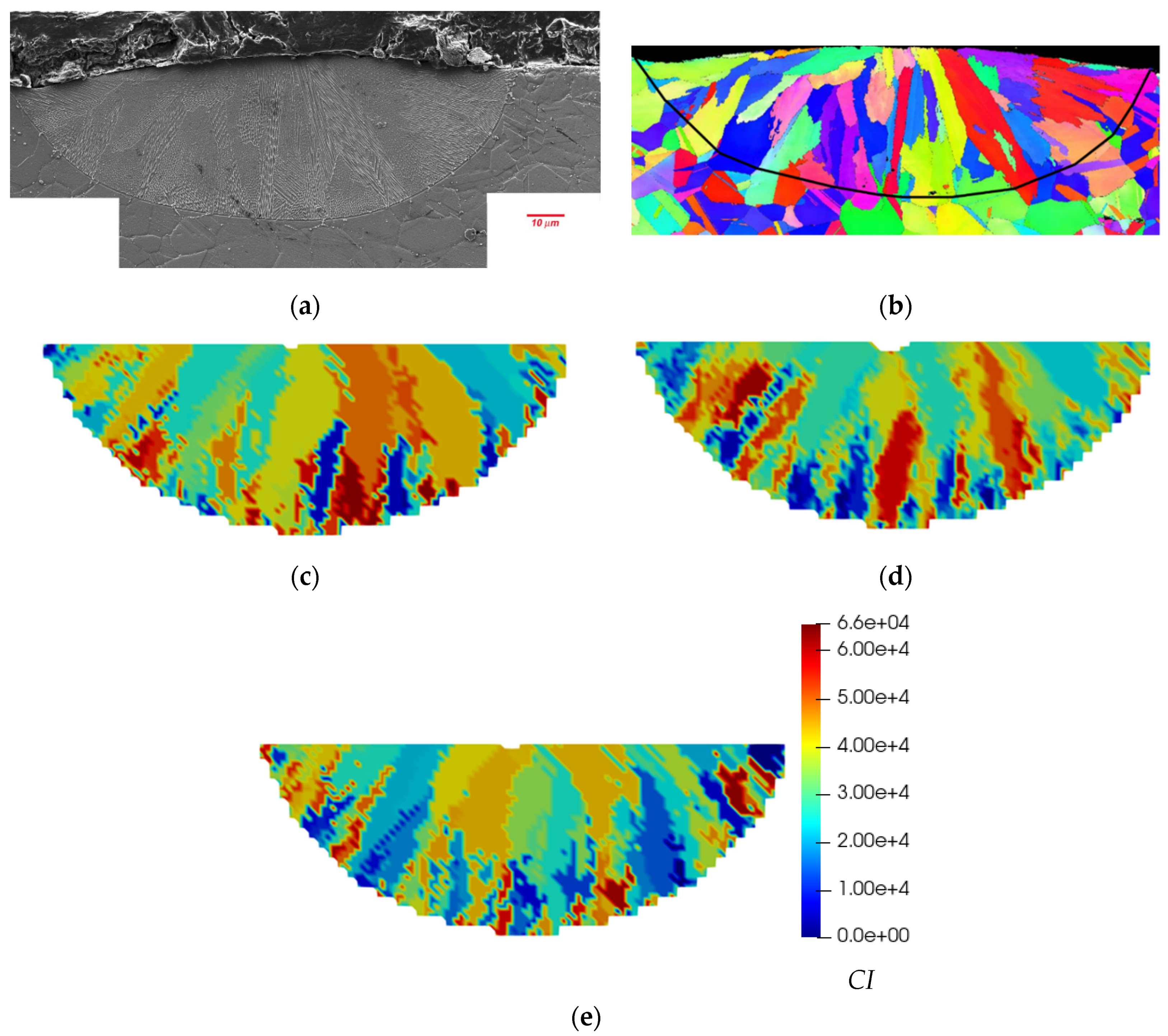

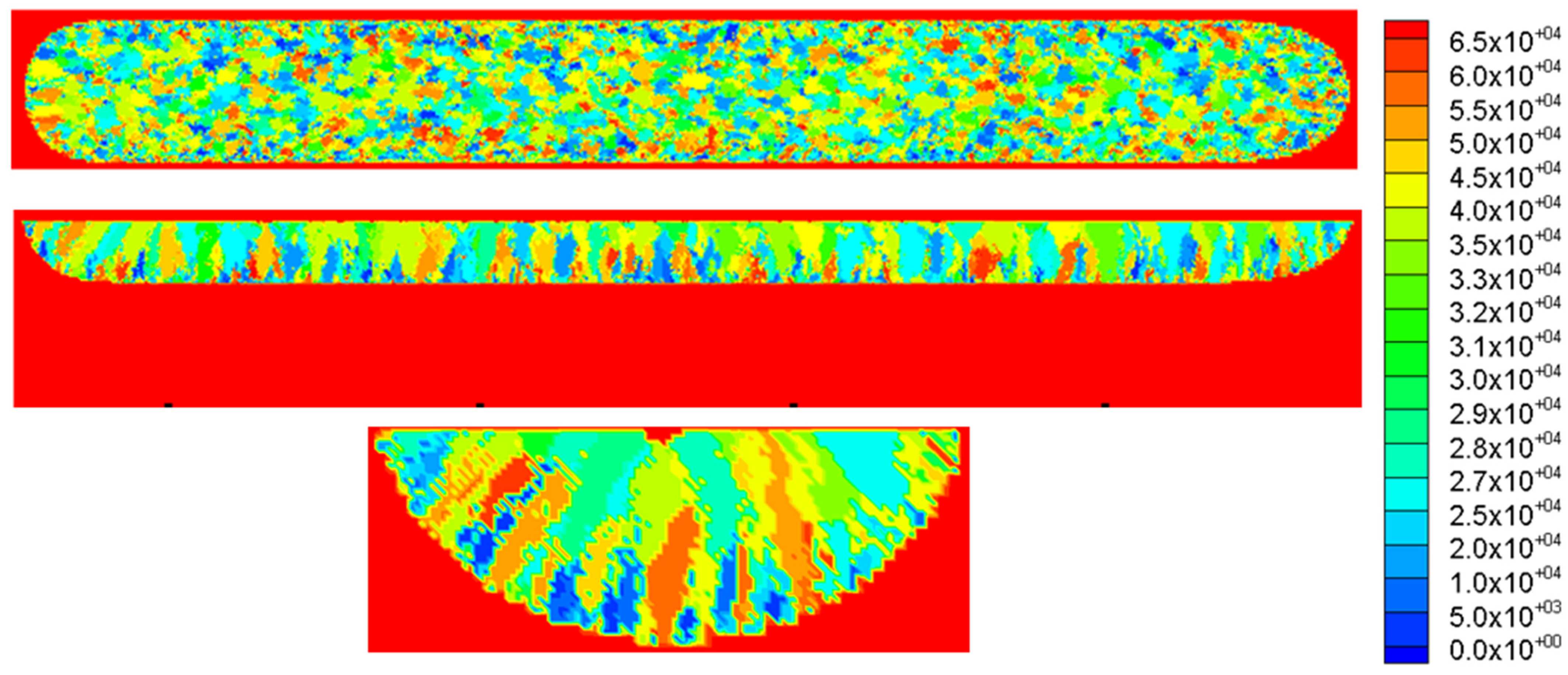

3. Results and Discussion

4. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Schwalbach, E.J.; Donegan, S.P.; Chapman, M.G.; Chaput, K.J.; Groeber, M.A. A discrete source model of powder bed fusion additive manufacturing thermal history. Addit. Manuf. 2019, 25, 485–498. [Google Scholar] [CrossRef]

- Oliveira, J.P.; LaLonde, A.; Ma, J. Processing parameters in laser powder bed fusion metal additive manufacturing. Mater. Des. 2020, 193, 108762. [Google Scholar] [CrossRef]

- Nastac, L. Modeling and Simulation of Microstructure Evolution in Solidifying Alloys, a Monograph; Springer: New York, NY, USA, 2004. [Google Scholar] [CrossRef]

- Nastac, L. A Multiscale Transient Modeling Approach for Predicting the Solidification Structure in VAR-Processed Alloy 718 Ingots. Met. Mater. Trans. A 2014, 45, 44–50. [Google Scholar] [CrossRef]

- Nastac, L.; Valencia, J.J.; Tims, M.L.; Dax, F.R. Advances in Solidification of IN718 and RS5 Alloys. In Proceedings of the Fifth International Special Emphasis Symposium on Superalloy 718, 625, 706, and Derivatives, Pittsburgh, PA, USA, 17–20 June 2001. [Google Scholar]

- Stefanescu, D.M. Science and Engineering of Casting Solidification; Springer: New York, NY, USA, 2009. [Google Scholar]

- Aziz, M.J. Model for solute redistribution during rapid solidification. J. Appl. Phys. 1982, 53, 1158–1168. [Google Scholar] [CrossRef] [Green Version]

- Baker, J.C.; Cahn, J.W. Thermodynamics of Solidification, Solidification; American Society of Metals: Metals Park, OH, USA, 1971; p. 23. [Google Scholar]

- 2018 AM-Bench Test Descriptions for AMB2018-02, NIST. Available online: https://www.nist.gov/ambench/amb2018-02-description (accessed on 30 November 2021).

- Rolchigo, M.; Stump, B.; Belak, J.F.; Plotkowski, A. Sparse thermal data for cellular automata modeling of grain structure in additive manufacturing. Model. Simul. Mater. Sci. Eng. 2020, 28, 065003. [Google Scholar] [CrossRef]

- Koepf, J.A.; Gotterbarm, M.R.; Markl, M.; Körner, C. 3D multi-layer grain structure simulation of powder bed fusion additive manufacturing. Acta Mater. 2018, 152, 119–126. [Google Scholar] [CrossRef]

- Rodgers, T.; Madison, J.D.; Tikare, V. Simulation of metal additive manufacturing microstructures using kinetic Monte Carlo. Comput. Mater. Sci. 2017, 135, 78–89. [Google Scholar] [CrossRef]

- Patankar, S.V. Numerical Heat Transfer and Fluid Flow; Hemisphere Publishing Corporation: New York, NY, USA, 1980. [Google Scholar]

- Nastac, L.; Sundarraj, S.; Yu, K.O.; Pang, Y. The Stochastic Modeling of Solidification Structures in Alloy 718 Remelt Ingots: Research Summary. J. Metals 1998, 50, 30–35. [Google Scholar]

- Wei, H.; Mazumder, J.; Debroy, T. Evolution of solidification texture during additive manufacturing. Sci. Rep. 2015, 5, 16446. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nastac, L. A 3D stochastic mesoscopic model for prediction of microstructure evolution during solidification of dendritic alloys. Met. Res. Technol. 2014, 111, 311–319. [Google Scholar] [CrossRef]

- Mohammadpour, P.; Phillion, A.B. Solidification microstructure selection maps for laser powder bed fusion of multicomponent alloys. IOP Conf. Ser. Mater. Sci. Eng. 2020, 861, 012005. [Google Scholar] [CrossRef]

- Khorasani, M.; Ghasemi, A.; Leary, M.; O’Neil, W.; Gibson, I.; Cordova, L.; Rolfe, B. Numerical and analytical investigation on meltpool temperature of laser-based powder bed fusion of IN718. Int. J. Heat Mass Transf. 2021, 177, 121477. [Google Scholar] [CrossRef]

| Property | Value | Unit |

|---|---|---|

| ρ | 7620 | kg/m3 |

| cp | 720 | J/kg/K |

| K | 30.1 | W/m/K |

| L | 2.95 × 105 | J/kg |

| mL | −12.0 | K/wt. % |

| Γ | 1.0 × 10−7 | K/m |

| DL | 3.0 × 10−9 | m2/s |

| ke | 0.5 | |

| 1622 | K | |

| 49.2 | K | |

| 1.0 × 1010 | m−2 | |

| a | 1.0 | μm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nastac, L. 3D Modeling of the Solidification Structure Evolution of Superalloys in Powder Bed Fusion Additive Manufacturing Processes. Metals 2021, 11, 1995. https://doi.org/10.3390/met11121995

Nastac L. 3D Modeling of the Solidification Structure Evolution of Superalloys in Powder Bed Fusion Additive Manufacturing Processes. Metals. 2021; 11(12):1995. https://doi.org/10.3390/met11121995

Chicago/Turabian StyleNastac, Laurentiu. 2021. "3D Modeling of the Solidification Structure Evolution of Superalloys in Powder Bed Fusion Additive Manufacturing Processes" Metals 11, no. 12: 1995. https://doi.org/10.3390/met11121995

APA StyleNastac, L. (2021). 3D Modeling of the Solidification Structure Evolution of Superalloys in Powder Bed Fusion Additive Manufacturing Processes. Metals, 11(12), 1995. https://doi.org/10.3390/met11121995