3. Results

The Ni

50.3Ti

32.2Hf

17.5 polycrystals were studied after aging at 873 K for 3 h (type (I) samples) in order to precipitate the dispersed H-phase particles of a certain size, in line with [

5,

7]. Precipitates in polycrystals were distributed all over the sample volume regardless of grain boundaries, as shown in previous works [

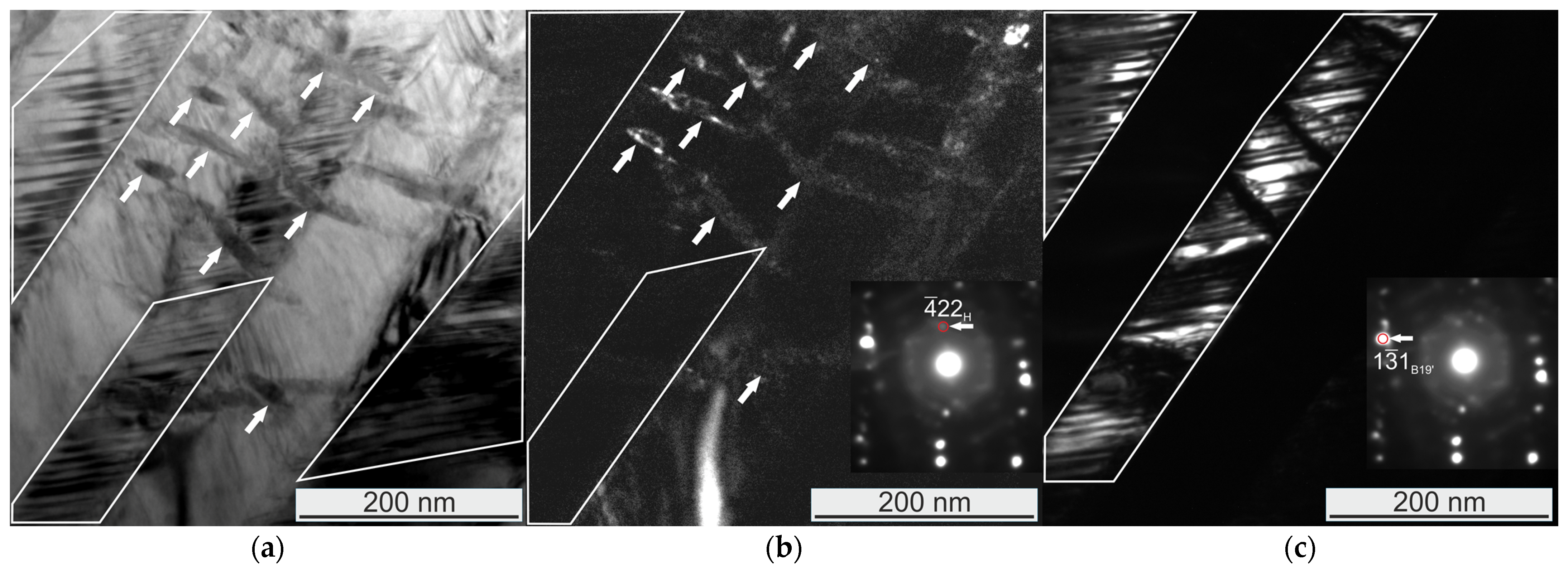

8]. The average grain size of the polycrystals was ~36 μm after aging. As shown in

Figure 1, the precipitated H-phase particles had sizes of up to 70 nm (marked by arrows). These particles are oblate spindle-shaped (the ratio of their length to width is 3:3.5) and merge with each other to form a new system of elongated particles. As reported by [

9], large particles with a spindle shape are elongated along the <011>

B2 direction and have typical reflexes of 1/2<111>

B2. These H-phase particles possess face-centered orthorhombic lattice with parameters a = 4a

0, b = 2√2a

0, and c = 6√2a

0 [

9,

10]. It should also be noted that the B19′-martensite variants possessed a high density of (001) compound nanotwins (marked by areas) and H-phase precipitates, which were completely embedded (

Figure 1).

The Ni

50.3Ti

32.2Hf

17.5 polycrystals aged at 873 K for 3 h (type (I) samples) underwent B2–B19′ MT at high temperatures of T > 373 K.

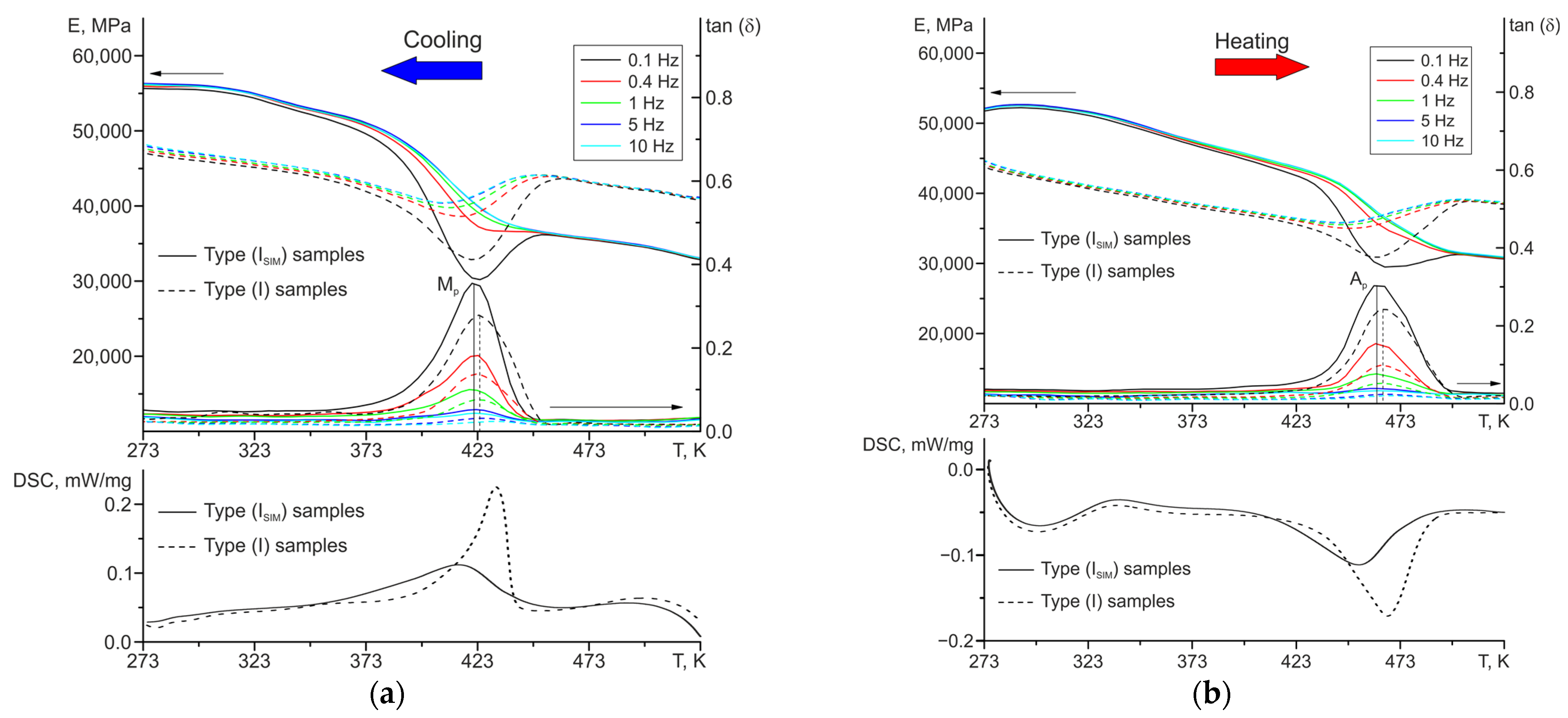

Figure 2 shows the dependence of the elastic modulus and tan (δ) (the characterization of internal friction) on the temperature in the studied type (I) and (I

SIM) samples upon cooling/heating at different frequencies. It was experimentally shown that, in the initial polycrystals (type (I) samples), the elastic moduli of both phases are high (44–46 GPa and 38–40 GPa for martensite at a temperature of 273 K and austenite at a temperature of 523 K, respectively). Moreover, a softening of the elastic modulus can be observed—its decrease as the starting temperature of MT approaches. Such behavior is one of the main features of thermoelastic MTs, characterized by the reconstruction of a crystal lattice that becomes soft, amenable, and easy to deform in order to create another phase due to the diffusionless process of atom displacement. The other feature of MT observed is a temperature peak of internal friction (

Mp and

Ap in

Table 1), which does not shift with a change in frequency (

Figure 2). The SIM-aging resulted in a change in elastic modulus (

EM increased by 8 GPa and

EA decreased by 8 GPa) and an increase in internal friction (by 25%) in the type (I

SIM) samples compared with the type (I) samples. The peak temperatures of heat emission (

Mp) and heat absorption (

Ap) obtained during the DSC studies are in accordance with the peak temperatures of internal friction obtained during the DMA studies and characterize the forward and reverse B2–B19′ MT (

Table 1,

Figure 2).

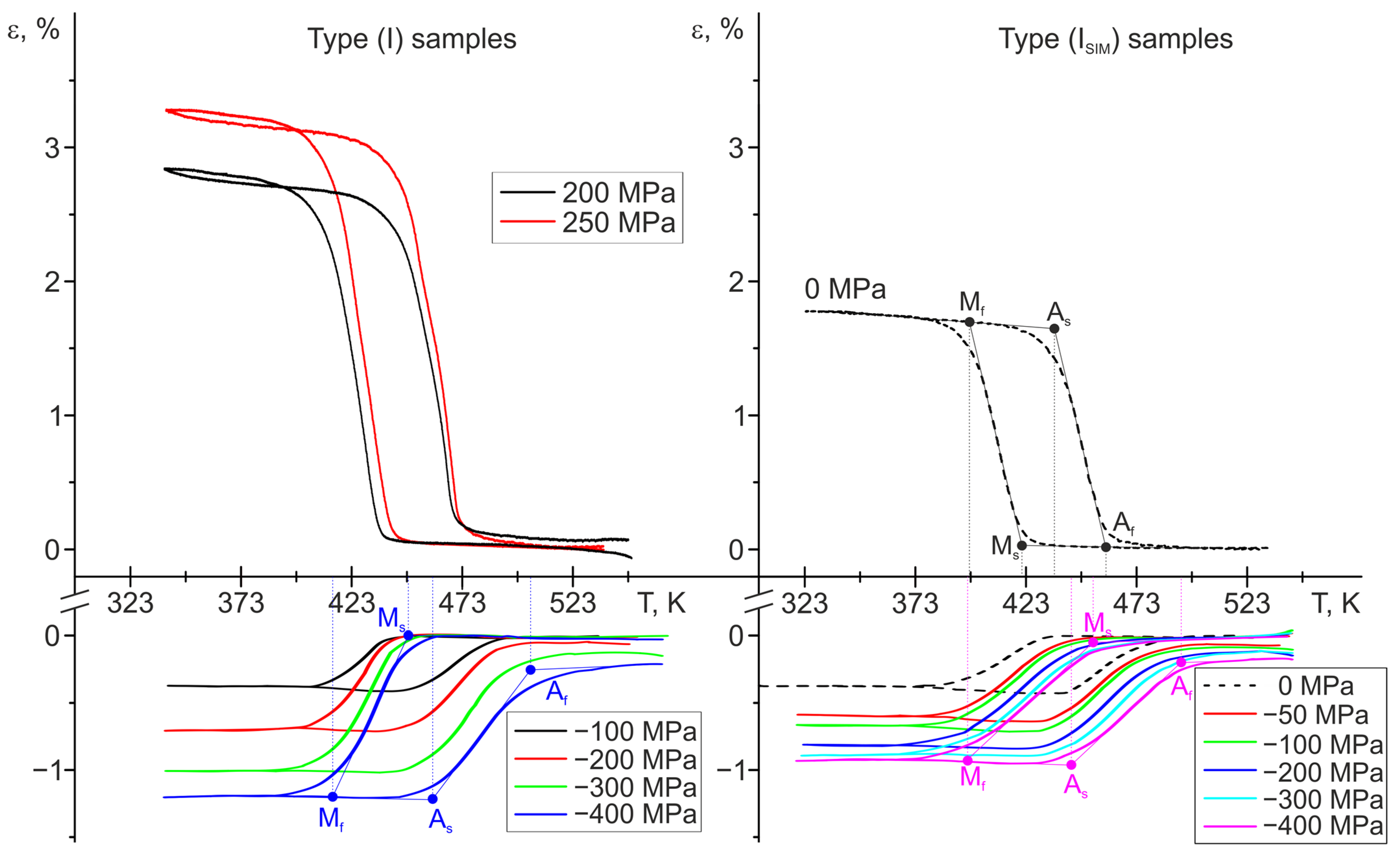

In

Figure 3, the ε(T) curves for NiTiHf polycrystals aged at 873 K for 3 h (type (I) samples) are shown. The value of maximum reversible strain for these crystals was found to be −1.0 ± 0.3% for an applied stress of 400 MPa in compression and +3.1 ± 0.3% for an applied stress of 250 MPa in tension. A further increase in stress level results in samples breaking in tension and the growth of irreversible strain in compression. The NiTiHf system possesses strong anisotropy in tension/compression in both the polycrystals and single crystals due to the anisotropy of the large maximum theoretical strain values at B2–B19′ MT (+16.8% in tension and −8.5% in compression) [

11]. As reported by [

12], the maximum theoretical strain in single crystals is characterized by crystal orientation and the stress way (tension or compression): 2.92%, 9.95%, and 8.1% were obtained for tensile samples along the [001], [011], and [111] directions, respectively. However, the maximum strain in compression was determined to be 0.97%, 8.0%, and 5.25% along the [001], [011], and [111] orientations, respectively. It is evident from the present work that NiTiHf polycrystals (type (I) samples) possess a low value of reversible strain in comparison with extruded polycrystals [

7], theoretical calculations [

13], and single crystals [

14]. The first reason for such behavior in the type (I) samples is the presence of H-phase particles, which do not undergo MT. The second reason is the large grain size (~36 μm) compared with extruded polycrystals that are characterized by the presence of polycrystal texture and, consequently, the primary martensite variant along the extruded direction [

15]. The last reason for low reversible strain is the high density of compound (001) twins [

16], which are not the solution of crystallographic theory of MT and appear as geometrically necessary twins in regions with high elastic stress and facilitate compatibility between matrix deformation and the elastic strain of nano-sized particles in NiTi-based alloys. The presence of such twinning results in the impossibility of reaching the maximum reversible strain—only local areas are known in which the theoretical values could be reached. Such behavior has previously been observed in both the polycrystals and the single crystals [

11]. In

Figure 3, the crystals after SIM-aging are presented; they are characterized by the presence of TWSME with a maximum strain of +1.8% and −0.5% in tension and compression, respectively, and the impossibility of obtaining ε(T) curves under applied stress in tension, due to the samples breaking down. The applied SIM-aging does not significantly result in the maximum reversible strain—its value decreases by 0.1%, while the value of irreversible strain decreases by 0.2%. The most evident difference after applying SIM-aging is the increase of reversible strain at minimum applied stress from −0.4% to −0.7% under the same stress level of −100 MPa.

4. Discussion

To perform the full analyses of obtained results, we must compare them with the data from our previous work [

6], where polycrystals with the same chemical composition—Ni

50.3Ti

32.2Hf

17.5 (at.%)—underwent SIM-aging following the same regime. However, these polycrystals were preliminarily aged in austenite at 773 K for 3 h, so they possessed a different microstructure compared to the polycrystals in the present work. The data from DMA (elastic modulus and tan (δ)), SME, and TWSME (maximum reversible strain and temperature hysteresis) experiments are presented for each crystal type in

Table 1.

The analyses of the obtained results and their comparison to the experimental data obtained for polycrystals with the same chemical composition—Ni

50.3Ti

32.2Hf

17.5 (at.%)—aged at 773 K for 3 h [

6] demonstrate that the effect of SIM-aging on viscoelastic and functional properties depends on the initial microstructure of heterophase alloys (

Table 1). The DMA properties of both polycrystal types (type (I) and type (I

SIM) samples) are presented as average values for both cooling and heating and are compared to the polycrystals aged at 773 K for 3 h with (type (II

SIM) samples) and without (type (II) samples) subsequent SIM-aging (

Table 1).

The increase of aging temperature from 773 K to 873 K for 3 h results in an increase in H-phase particle size from 10–15 nm [

6] to 70 nm. In addition, the particle shape changes from spherical to spindle with the increase in aging temperature. This change in microstructure leads to various changes in MTs and their parameters.

First, the increase in size along with the change in shape of the particles supposedly result in coherency loss. As reported by [

17], small particles possess the lowest free energy while they are coherent, unlike large particles, which must be semi- or noncoherent in order to have the minimal free energy. In this case, the critical size of particles (radius for spherical precipitates) is the main parameter to define the coherency of a “particle–matrix” boundary. According to [

17], this critical size can be presented as:

where

γst is the extra structural contribution to the interfacial energy,

μ is the shear modulus of the matrix, and

δ is the lattice misfit toward particles. If we assume that

δ is small, then the extra structural contribution can be defined as

γst ∝

δ.

The critical size of particles at which coherency loss occurs was estimated by using Equation (1). Using the average lattice parameters for the B2-austenite phase, B19′-martensite phase [

18], and H-phase particles [

9,

10], it was found that

rcrit is approximately 800 nm, which is in accordance with [

16]. Thus, the precipitates with sizes up to 70 nm, which formed at 873 K after 3 h, are fully coherent, as confirmed by [

16], where the coherency of elongated precipitates with the austenite matrix was affirmed by high-resolution transmission electron microscopy.

It should be noted that the H-phase elongated shape results in the appearance of stress on the edges of precipitates, caused by the misfit between the matrix and particles along the particle length axis [

9]. Therefore, the particles line up into elongated systems to partially relax such stress, thereby promoting the MT. It is also assumed that such stress on the edges of precipitates leads to dislocation formation and, consequently, partial coherency loss on the “precipitate–matrix” boundary upon MT.

Second, after austenite aging at 873 K for 3 h, the volume fraction of precipitates increases in comparison with aging at 773 K for 3 h, as evidenced by a decrease in SME strain by 0.3% in type (I) samples compared with type (II) samples. Hence, the volume fraction of a matrix, which could undergo MT, decreases, while the volume fraction of H-phase particles, which cannot undergo MT, increases. Additional proof of such behavior is an increase in TTs in the type (I) samples in comparison with the type (II) samples (

Table 1), which has also been observed for NiTiHf20 polycrystals in earlier research [

5].

The increase in H-phase particle volume fraction results in changes in materials’ viscoelastic properties. The values of the elastic modulus in the type (I) samples for both phases are 7–8 GPa greater than those of the type II samples, and the value of the internal friction peak is 25–50% greater. This can be explained by the following: a material with dispersed particles can be defined as a composite in which the different mechanical parameters are the parameters from both the matrix and the particles. As long as the particles are deformed only elastically, do not undergo MT, and greatly increase the strength properties of material, it can be assumed that the studied polycrystals can be considered a composite, where the main contribution into the elastic modulus is made by the H-phase particles. Thus, we can use the following equation to define the elastic modulus of the material [

19]:

where

δ is the volume fraction of particles. The elastic modulus of particles does not significantly differ with respect to the aging regime,

Eparticles >

Ematrix, and the H-phase has close parameters; these factors result in the elastic modulus of austenite (

EA) for type (I) samples being 8 GPa greater than that of the type (II) samples, as characterized by the smaller volume fraction of dispersed particles (

Table 1).

The change in microstructure after aging at 773 K and 873 K for 3 h, described above, results in a different effect of SIM-aging in type (I) and type (II) samples.

First, SIM-aging leads to the appearance of TWSME in both types of crystals (type (I

SIM) and type (II

SIM) samples). Type (I

SIM) polycrystals demonstrate TWSME with a maximum strain of − 0.5± 0.3% in compression and 1.8 ± 0.3% in tension, and its value is equal to ~50% of the maximum reversible strain upon cooling/heating under constant stress. The same behavior can be observed for crystals aged at 773 K for 3 h. It should be noted that the maximum reversible strain in type (II) and type (II

SIM) samples (−1.3% in compression and 5.0% in tension) is greater than that in type (I) and type (I

SIM) samples. Consequently, the TWSME in type (II) and type (II

SIM) samples shows a greater value of reversible strain in comparison with the type (I) and type (I

SIM) samples (

Table 1).

It should be noted that TWSME in NiTiHf polycrystals has previously been obtained after high-cycle trainings up to 1600 cycles [

20]. In this case, the physical reason for the appearance of TWSME is the internal stress field from both the dislocation clusters and the oriented B19′-martensite, resulting in a maximum reversible strain of 3% in torsion and 1.5% in tension. In the present work, we demonstrate the efficiency of SIM-aging for inducing TWSME in aged NiTiHf polycrystals; the maximum value of TWSME was 1.8–2.3% in tension, regardless of the initial microstructure. The physical reason for TWSME induction after SIM-aging is the change of the short-range order of point defects and atoms (atoms of different kinds in sublattices, vacancies, interstitial atoms, substitution, and introduction impurities) in accordance with martensite symmetry [

1]. Such rearrangement results in the stabilization and decrease of Gibbs free energy of oriented B19′-martensite formed under tensile/compressive stress upon SIM-aging. Thus, exactly one oriented B19′-martensite will be formed in the next stress-free thermocycle, inducing the TWSME. However, we cannot exclude the contribution of the dislocation formation and the residual B19′-martensite formation during SIM-aging (especially near the grain boundaries) to the TWSME induction.

Second, in NiTiHf polycrystals aged at 873 K for 3 h, SIM-aging partially increased the elastic modulus of martensite (

EM) (by 8 GPa) and the internal friction (by 25%); however, the elastic modulus of austenite decreased by the same value of 8 GPa (down to 31 GPa at a temperature of 250 °C) (

Table 1). As for the crystals aged at 773 K, SIM-aging increased the elastic modulus of both phases by 13 GPa and 5 GPa (for martensite and austenite, respectively), and the internal friction increased threefold (

Table 1). According to [

21], increased internal friction is evidence of increased mobility of twinning/interphase boundaries. It is assumed that such an effect is associated with increased compatibility between nano-sized H-phase particles and twinned B19′-martensite during SIM-aging. Thus, it is experimentally shown that the oriented growth of thermal-induced martensite (TWSME after SIM-aging) promotes an increase in internal friction upon MT in type (I

SIM) and (II

SIM) samples, regardless of the H-phase particle size.

SIM-aging results in a decrease in

Mf and

As TTs by 15–20 K. Thus, an increase in MT temperature interval Δ

1 (MT diffusion) is observed (

Figure 3). The same MT diffusion upon stress-assisted cooling/heating cycles was observed in type (II

SIM) samples, which were preliminarily aged at 773 K for 3 h [

6]. This increase in MT temperature interval is the result of an increase in stored elastic energy during direct MT due to a high density of compound twins and detwinning processes. Thus, the TTs can be expressed as follows, taking into account the effect of elastic and dissipative energy and the presence of external applied stresses [

4,

6,

22]:

where

T0(σ) is the chemical equilibrium temperature;

e and

d are the elastic and dissipative energy, respectively; ξ is the volume fraction of oriented martensite characterizing the overall process of MT; and Δ

S is the change of entropy during MT. From this, the MT diffusion (the difference between starting and finishing temperature of direct or reverse MT) can be expressed as follows:

Equations (3)–(7) show that an increase in stored elastic energy upon MT (at the maximum volume fraction of oriented martensite) results in a decrease in Mf(σ) and As(σ) TTs and a corresponding increase in MT diffusion (Δ1).

It should be noted that the relation of TTs defines the MT type. For example, in type (I) samples, the TTs at low applied stress (< 400 MPa) are related as

Ms <

As (

Figure 3). A further increase in stress leads to a change of MT type, and TTs are related as

As <

Ms. So long as SIM-aging provides the TTs shift, their relation to stress-assisted MTs is the same:

As <

Ms. This relation of TTs is defined by the contribution of elastic and dissipative energies. According to Equations (3) and (5), the difference between

As and

Ms temperatures can be written as follows:

Taking into account the fact that the value of dissipative energy during MT is almost constant and the value of elastic energy significantly increases with the volume fraction of oriented martensite (ξ), two assumptions can be made to simplify Equation (7):

,

. Thus, Equation (8) can be rewritten as:

It is obvious that if the stored energy during forward MT (

) becomes much greater than the dissipative energy, then the reverse MT can occur at temperatures lower than

Ms under the condition of counteracting chemical driving force:

Consequently, in order for As < Ms to be true, the following condition must be fulfilled: . Thus, during SIM-aging, one stress-induced martensite variant is formed, which is maintained for the entire duration of SIM-aging. This leads to a decrease in Gibbs free energy of such a martensite variant, causing it to form at lower stresses and/or higher temperatures. The additional internal stress fields near spindle-shaped H-phase dispersed particles combined with the oriented martensite variant growth result in TWSME induction. It should also be noted that MT occurs with the low elastic modulus softening in type (ISIM) samples, which can be explained by significant elastic distortions formed upon SIM-aging. It is assumed that such distortions are formed because of the presence of nonuniaxial precipitates and promote MT by decreasing the required softening of the austenite lattice to start the forward MT.