Tailoring the Austenite Fraction of a Cu and Ni Containing Medium-Mn Steel via Warm Rolling

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Description

2.2. Experimental Procedure

2.3. Materials Characterization

3. Results

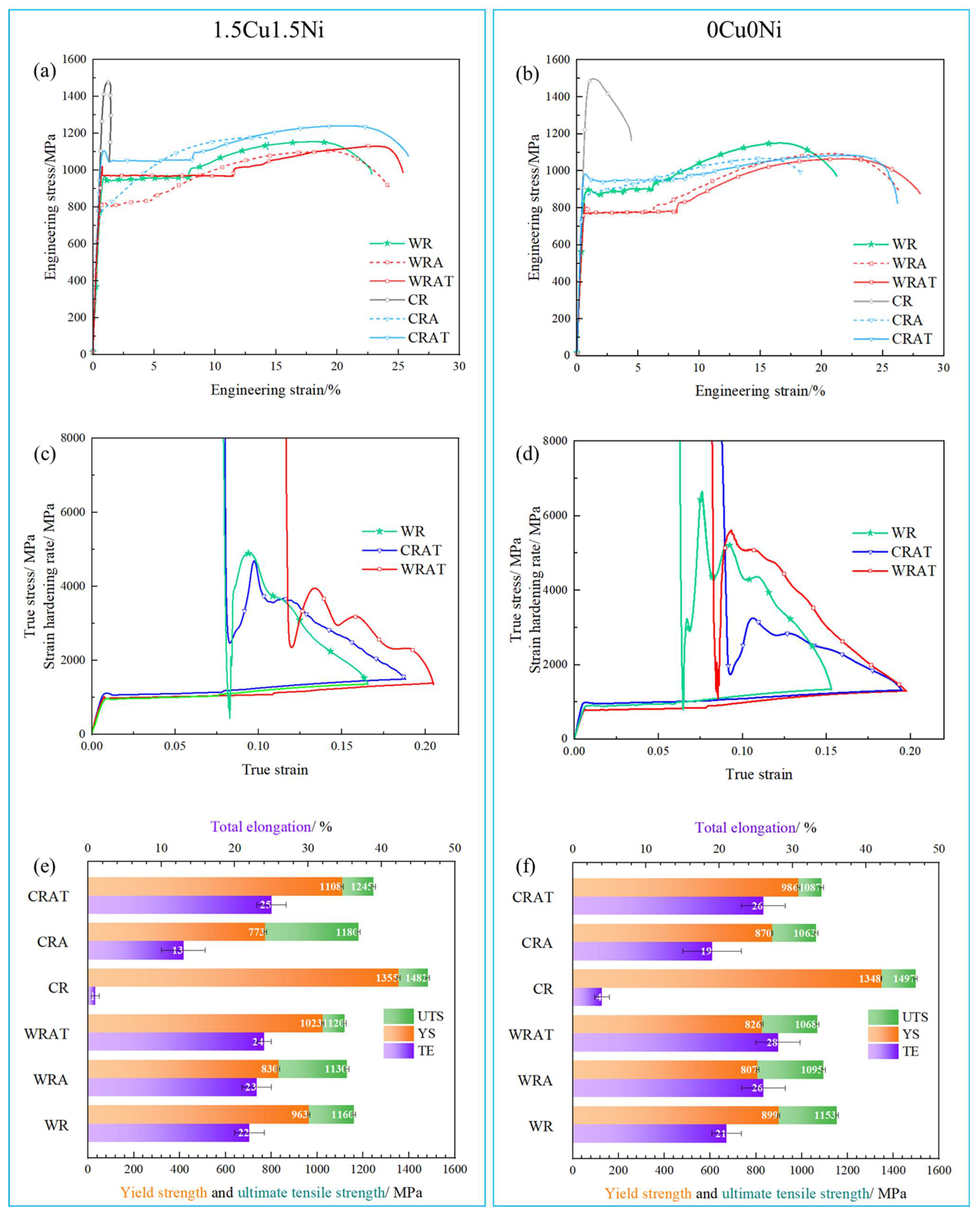

3.1. Tensile Properties

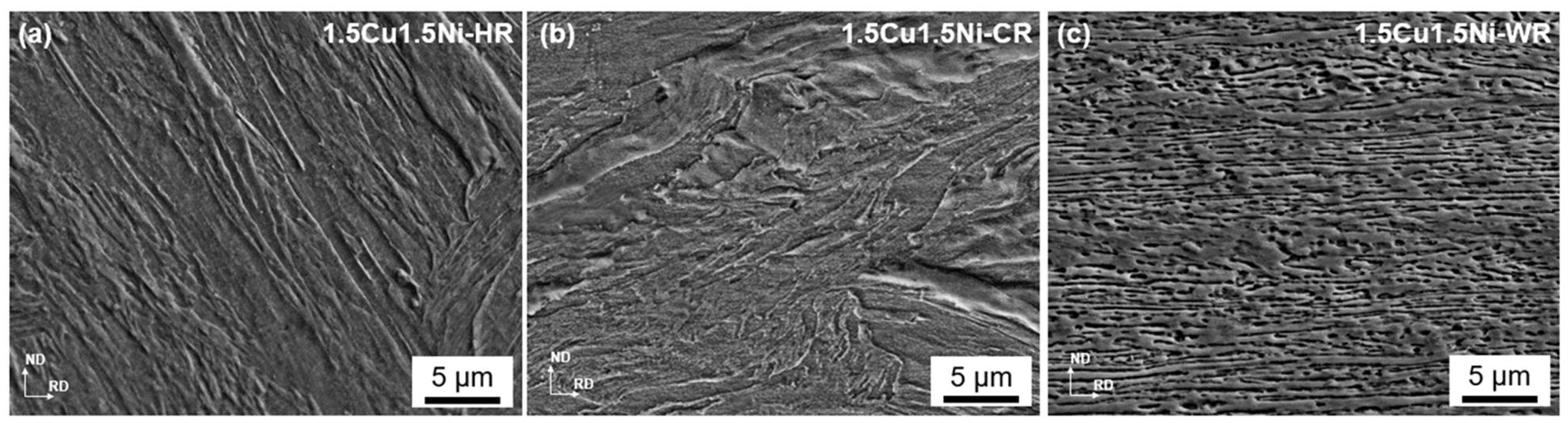

3.2. Microstructure Characteristics

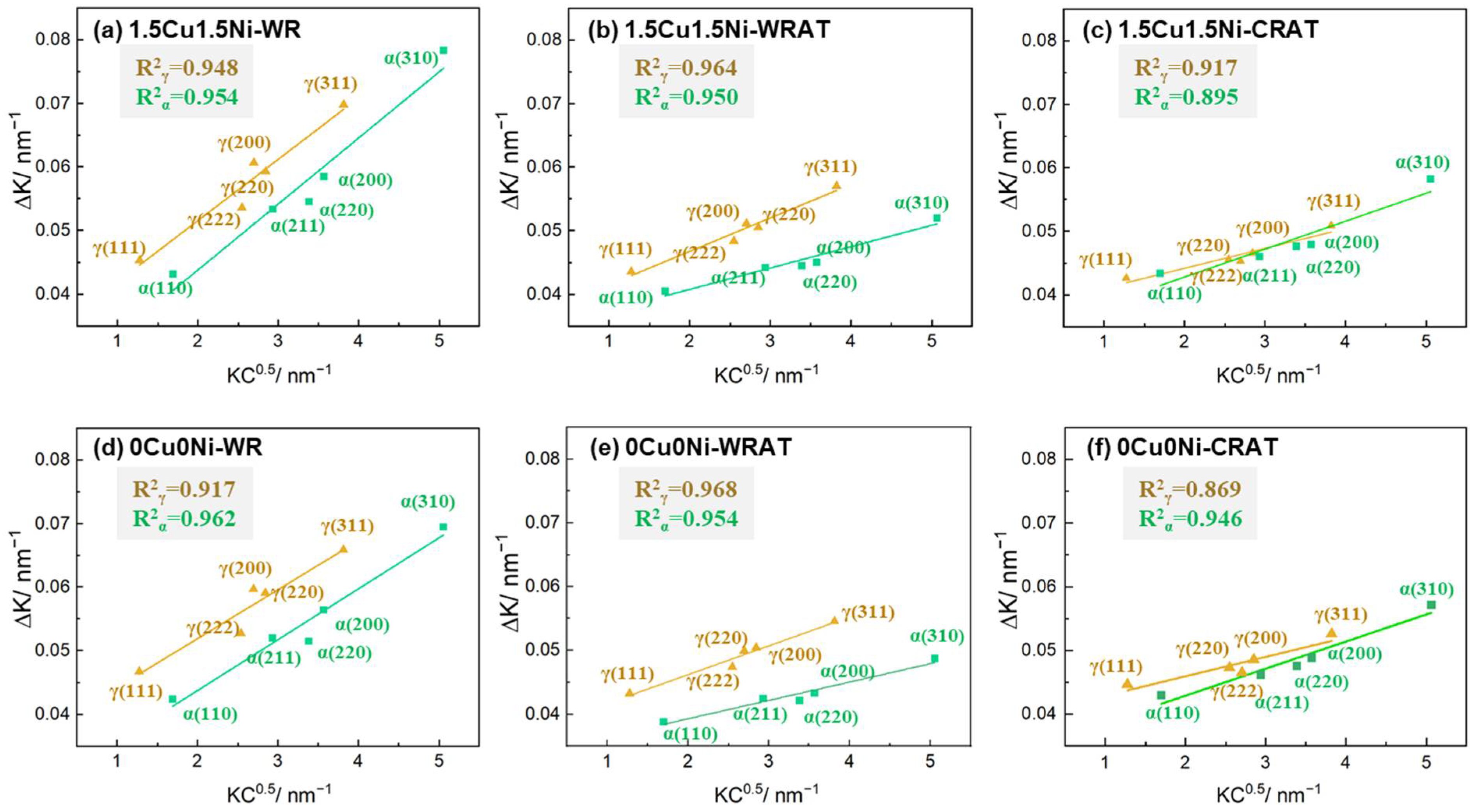

3.3. Dislocation Densities of the WR, WRAT, and CRAT Specimens

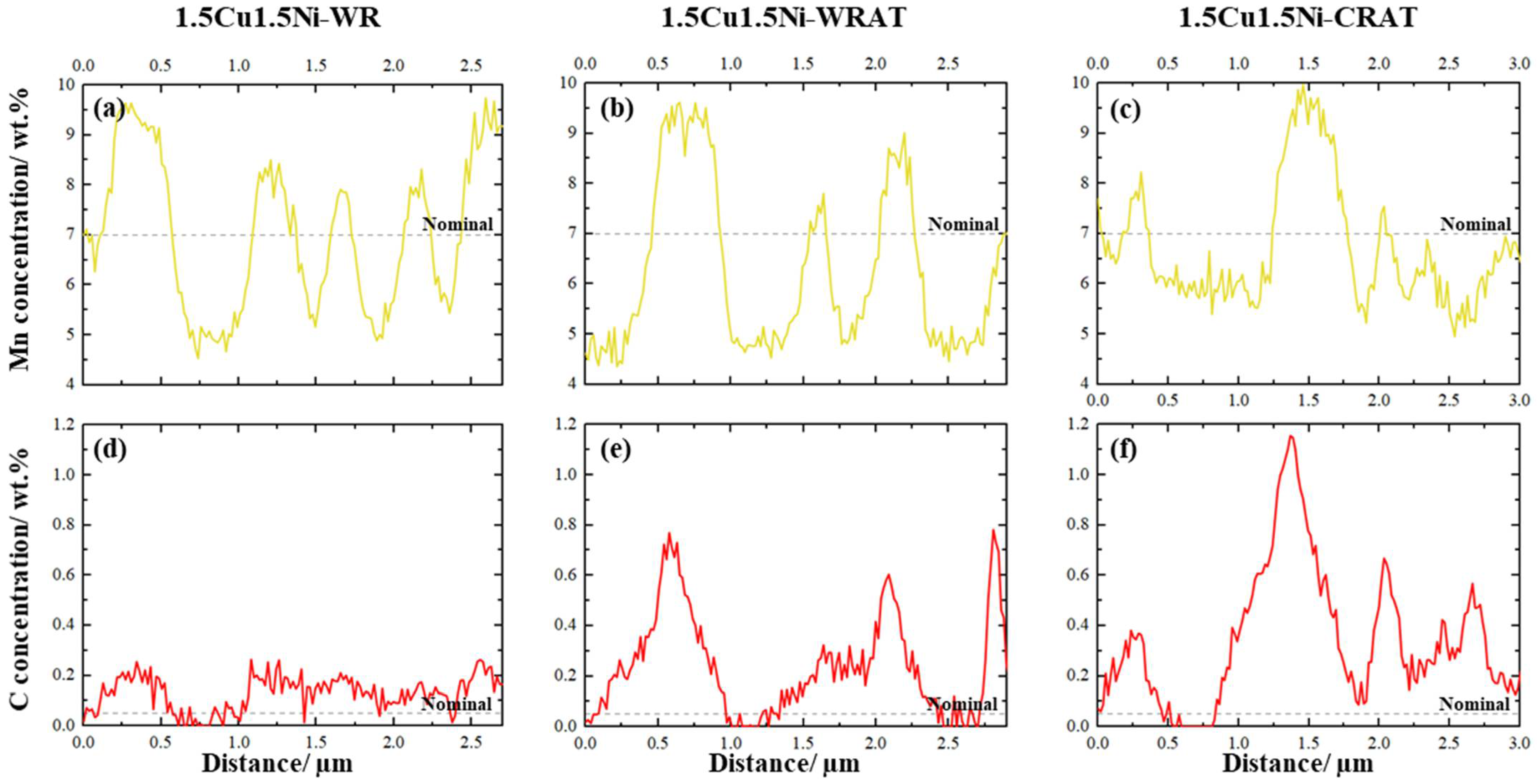

3.4. Elemental Partitioning of Different TMT Specimens

4. Discussion

4.1. Influencing Factors of Chemical Composition and Processing on the Austenite Reversion in MMnS

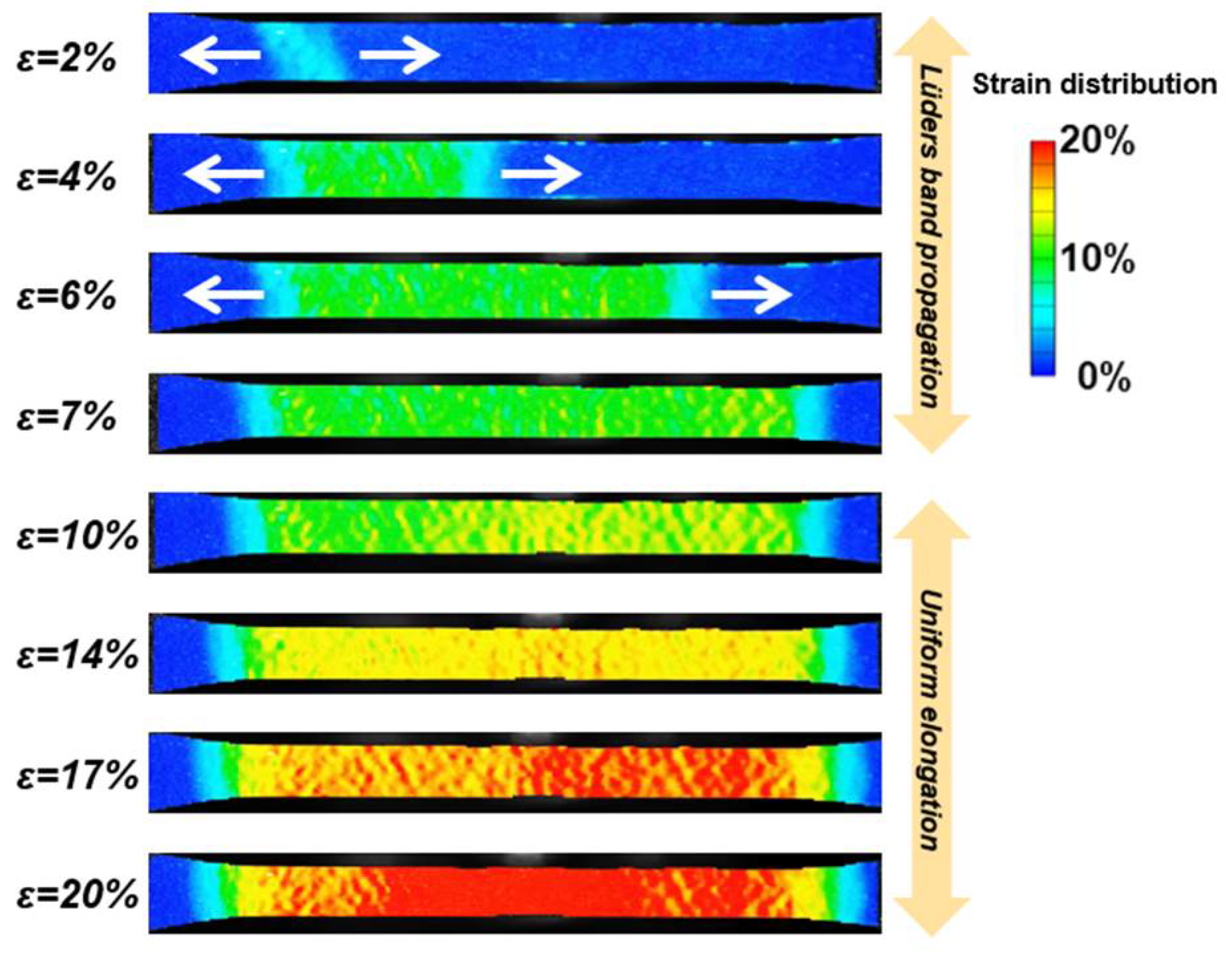

4.2. Mechanical Stability of RA

5. Conclusions

- (1)

- The investigated warm rolling processing route provided excellent tensile properties to the 1.5Cu1.5Ni-WR specimen, with a high yield strength of 967 MPa, a total strength of 1155 MPa, and total elongation of 23%;

- (2)

- The microstructure of the 1.5Cu1.5Ni-WR specimen contained 40.6 vol.% austenite. The warm rolling process preserved a large number of dislocations and provided a high fraction of retained austenite, owing to the lack of static recrystallization and the strong elemental partitioning;

- (3)

- The high strength of the 1.5Cu1.5Ni-WR specimen can be attributed to the deformed ferrite grains and the increased mechanical stability of the ultra-fine austenite grains with an inherent large dislocation density. The extraordinary ductility of the 1.5Cu1.5Ni-WR specimen was a consequence of the pronounced TRIP effect and the postponement of necking in the ultra-fine microstructure;

- (4)

- The proposed WR route delivers comparable tensile properties to the WRAT and CRAT routes, but the processing route is significantly shorter.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Raabe, D.; Sun, B.; Silva, A.d.; Gault, B.; Yen, H.-W.; Sedighiani, K.; Sukumar, P.T.; Filho, I.R.S.; Katnagallu, S.; Jägle, E.; et al. Current Challenges and Opportunities in Microstructure-Related Properties of Advanced High-Strength Steels. Metall. Mater. Trans. A 2020, 51, 5517–5586. [Google Scholar] [CrossRef]

- Lee, Y.-K.; Han, J. Current opinion in medium manganese steel. Mater. Sci. Technol. 2015, 31, 843–856. [Google Scholar] [CrossRef]

- Allam, T.; Bleck, W.; Klinkenberg, C.; Kintscher, B.; Krupp, U.; Rudnizki, J. The continuous casting behavior of medium manganese steels. J. Mater. Res. Technol. 2021, 15, 292–305. [Google Scholar] [CrossRef]

- Ma, Y. Medium-manganese steels processed by austenite-reverted-transformation annealing for automotive applications. Mater. Sci. Technol. 2017, 33, 1713–1727. [Google Scholar] [CrossRef]

- Hu, B.; Luo, H.; Yang, F.; Dong, H. Recent progress in medium-Mn steels made with new designing strategies, a review. J. Mater. Sci. Technol. 2017, 33, 1457–1464. [Google Scholar] [CrossRef]

- Speer, J.; Rana, R.; Matlock, D.; Glover, A.; Thomas, G.; De Moor, E. Processing Variants in Medium-Mn Steels. Metals 2019, 9, 771. [Google Scholar] [CrossRef] [Green Version]

- Suh, D.-W.; Kim, S.-J. Medium Mn transformation-induced plasticity steels: Recent progress and challenges. Scr. Mater. 2017, 126, 63–67. [Google Scholar] [CrossRef]

- Mishra, G.; Chandan, A.K.; Kundu, S. Hot rolled and cold rolled medium manganese steel: Mechanical properties and microstructure. Mater. Sci. Eng. A 2017, 701, 319–327. [Google Scholar] [CrossRef]

- Kozasu, I.; Shimizu, T.; Kubota, H. Recrystallization of Austenite of Si-Mn Steels with Minor Alloying Elements after Hot Rolling. ISIJ Int. 1971, 11, 367–375. [Google Scholar] [CrossRef] [Green Version]

- Tamura, I.; Ouchi, C.; Tanaka, T.; Sekine, H. Thermomechanical Processing of High-Strength Low-Alloy Steels; Butterworths: London, UK, 1988. [Google Scholar]

- Magalhães, A.S.; Moutinho, I.D.; Oliveira, I.R.; Ferreira, A.O.V.; Alves, D.S.; Santos, D.B. Ultrafinegrained Microstructure in a Medium Manganese Steel after Warm Rolling without Intercritical Annealing. ISIJ Int. 2017, 57, 1121–1128. [Google Scholar] [CrossRef] [Green Version]

- Magalhães, A.S.; Santos, C.E.d.; Ferreira, A.O.V.; Alves, D.S.; Santos, D.B. Analysis of medium manganese steel through cold-rolling and intercritical annealing or warm-rolling. Mater. Sci. Technol. 2018, 11, 1–14. [Google Scholar] [CrossRef]

- Zhao, X.; Shen, Y.; Qiu, L.; Liu, Y.; Sun, X.; Zuo, L. Effects of Intercritical Annealing Temperature on Mechanical Properties of Fe-7.9Mn-0.14Si-0.05Al-0.07C Steel. Materials 2014, 7, 7891–7906. [Google Scholar] [CrossRef] [Green Version]

- Hu, B.; Luo, H. A strong and ductile 7Mn steel manufactured by warm rolling and exhibiting both transformation and twinning induced plasticity. J. Alloys Compd. 2017, 725, 684–693. [Google Scholar] [CrossRef]

- Hodgson, P.; Cai, M.H.; Rolfe, B. Hot Forming of Medium Mn Steels with TRIP Effect. In Advanced High Strength Steel and Press Hardening; World Scientific: Singapore, 2016; pp. 27–34. [Google Scholar]

- Hawkins, D.N.; Shuttleworth, A.A. The effect of warm rolling on the structure and properties of a low-carbon steel. J. Mech. Work. Technol. 1979, 2, 333–345. [Google Scholar] [CrossRef]

- Allam, T.; Guo, X.; Sevsek, S.; Lipińska-Chwałek, M.; Hamada, A.; Ahmed, E.; Bleck, W. Development of a Cr-Ni-V-N Medium Manganese Steel with Balanced Mechanical and Corrosion Properties. Metals 2019, 9, 705. [Google Scholar] [CrossRef] [Green Version]

- Kong, H.; Liu, C. A Review on Nano-Scale Precipitation in Steels. Technologies 2018, 6, 36. [Google Scholar] [CrossRef] [Green Version]

- Allam, T.; Guo, X.; Lipińska-Chwałek, M.; Hamada, A.; Ahmed, E.; Bleck, W. Impact of precipitates on the hydrogen embrittlement behavior of a V-alloyed medium-manganese austenitic stainless steel. J. Mater. Res. Technol. 2020, 9, 13524–13538. [Google Scholar] [CrossRef]

- Shyamal, S.; Farahani, M.G.; Allam, T.; Hamada, A.S.; Haase, C.; Kömi, J.I.; Chakraborti, P.C.; Sahu, P. Activation of a hybrid twinning mechanism in a Cr-Ni-Si-V-N medium manganese austenitic steel containing precipitates. Scr. Mater. 2021, 192, 83–88. [Google Scholar] [CrossRef]

- Kapoor, M.; Isheim, D.; Ghosh, G.; Vaynman, S.; Fine, M.E.; Chung, Y.-W. Aging characteristics and mechanical properties of 1600MPa body-centered cubic Cu and B2-NiAl precipitation-strengthened ferritic steel. Acta Mater. 2014, 73, 56–74. [Google Scholar] [CrossRef]

- Zou, Y.; Xu, Y.B.; Han, D.T.; Hu, Z.P.; Misra, R.D.K.; Cao, L.F.; Song, H. Combined contribution of Cu-rich precipitates and retained austenite on mechanical properties of a novel low-carbon medium-Mn steel plate. J. Mater. Sci. 2019, 54, 3438–3454. [Google Scholar] [CrossRef]

- Yan, S.; Liang, T.; Chen, J.; Li, T.; Liu, X. A novel Cu-Ni added medium Mn steel: Precipitation of Cu-rich particles and austenite reversed transformation occurring simultaneously during ART annealing. Mater. Sci. Eng. A 2019, 746, 73–81. [Google Scholar] [CrossRef]

- Tsuchiyama, T.; Yamamoto, S.; Hata, S.; Murayama, M.; Morooka, S.; Akama, D.; Takaki, S. Plastic deformation and dissolution of ε-Cu particles by cold rolling in an over-aged particle dispersion strengthening Fe-2mass%Cu alloy. Acta Mater. 2016, 113, 48–55. [Google Scholar] [CrossRef] [Green Version]

- Gražulis, S.; Chateigner, D.; Downs, R.T.; Yokochi, A.F.T.; Quirós, M.; Lutterotti, L.; Manakova, E.; Butkus, J.; Moeck, P.; Le Bail, A. Crystallography Open Database—An open-access collection of crystal structures. J. Appl. Crystallogr. 2009, 42, 726–729. [Google Scholar] [CrossRef] [PubMed]

- Lutterotti, L. Maud: A Rietveld analysis program designed for the internet and experiment integration. Acta Crystallogr. A 2000, 56, s54. [Google Scholar] [CrossRef] [Green Version]

- Kong, H.J.; Yang, T.; Chen, R.; Yue, S.Q.; Zhang, T.L.; Cao, B.X.; Wang, C.; Liud, W.H.; Luance, J.H.; Jiao, Z.B.; et al. Breaking the strength-ductility paradox in advanced nanostructured Fe-based alloys through combined Cu and Mn additions. Scr. Mater. 2020, 186, 213–218. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, L.; Findley, K.O.; Speer, J.G. Influence of Temperature and Grain Size on Austenite Stability in Medium Manganese Steels. Metall. Mater. Trans. A 2017, 48, 2140–2149. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Ni | Mo | Cu | Al | N | Ac1 | Ac3 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0Cu0Ni | 0.05 | 1.5 | 7.0 | 0.005 | 0.004 | 0.01 | 0.51 | 0.01 | 1.5 | 0.006 | 600 | 1030 |

| 1.5Cu1.5Ni | 0.07 | 1.4 | 7.0 | 0.005 | 0.004 | 1.48 | 0.50 | 1.47 | 1.5 | 0.006 | 588 | 940 |

| Specimen | Thermo-Mechanical Treatment |

|---|---|

| WR | Warm rolling |

| WRA | Warm rolling + Annealing |

| WRAT | Warm rolling + Annealing + Tempering |

| CR | Hot rolling + Cold rolling |

| CRA | Hot rolling + Cold rolling + Annealing |

| CRAT | Hot rolling + Cold rolling + annealing + Tempering |

| 1.5Cu1.5Ni-WR | 1.5Cu1.5Ni-WRAT | 1.5Cu1.5Ni-CRAT | |

|---|---|---|---|

| Average austenite ECD/μm | 0.45 | 0.38 | 0.40 |

| Average austenite grain aspect ratio | 1.91 | 3.88 | 2.31 |

| 1.5Cu1.5Ni-CRAT | 1.5Cu1.5Ni-WR | 1.5Cu1.5Ni-WRAT | 0Cu0Ni-CRAT | 0Cu0Ni-WR | 0Cu0Ni-WRAT | |

|---|---|---|---|---|---|---|

| Austenite fraction before tensile test/% | 33.74 | 40.57 | 39.67 | 20.96 | 32.33 | 33.28 |

| Austenite fraction after fracture/% | 2.85 | 1.27 | 2.05 | 1.29 | 0.19 | 0.47 |

| True strain before necking | 0.19 | 0.17 | 0.20 | 0.20 | 0.15 | 0.20 |

| k | 13.15 | 20.99 | 14.52 | 14.02 | 33.51 | 21.71 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Z.; Li, J.; Shen, X.; Allam, T.; Richter, S.; Song, W.; Bleck, W. Tailoring the Austenite Fraction of a Cu and Ni Containing Medium-Mn Steel via Warm Rolling. Metals 2021, 11, 1888. https://doi.org/10.3390/met11121888

Xu Z, Li J, Shen X, Allam T, Richter S, Song W, Bleck W. Tailoring the Austenite Fraction of a Cu and Ni Containing Medium-Mn Steel via Warm Rolling. Metals. 2021; 11(12):1888. https://doi.org/10.3390/met11121888

Chicago/Turabian StyleXu, Zigan, Jiyao Li, Xiao Shen, Tarek Allam, Silvia Richter, Wenwen Song, and Wolfgang Bleck. 2021. "Tailoring the Austenite Fraction of a Cu and Ni Containing Medium-Mn Steel via Warm Rolling" Metals 11, no. 12: 1888. https://doi.org/10.3390/met11121888

APA StyleXu, Z., Li, J., Shen, X., Allam, T., Richter, S., Song, W., & Bleck, W. (2021). Tailoring the Austenite Fraction of a Cu and Ni Containing Medium-Mn Steel via Warm Rolling. Metals, 11(12), 1888. https://doi.org/10.3390/met11121888