Wear Behaviors of Stainless Steel and Lubrication Effect on Transitions in Lubrication Regimes in Sliding Contact

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Materials

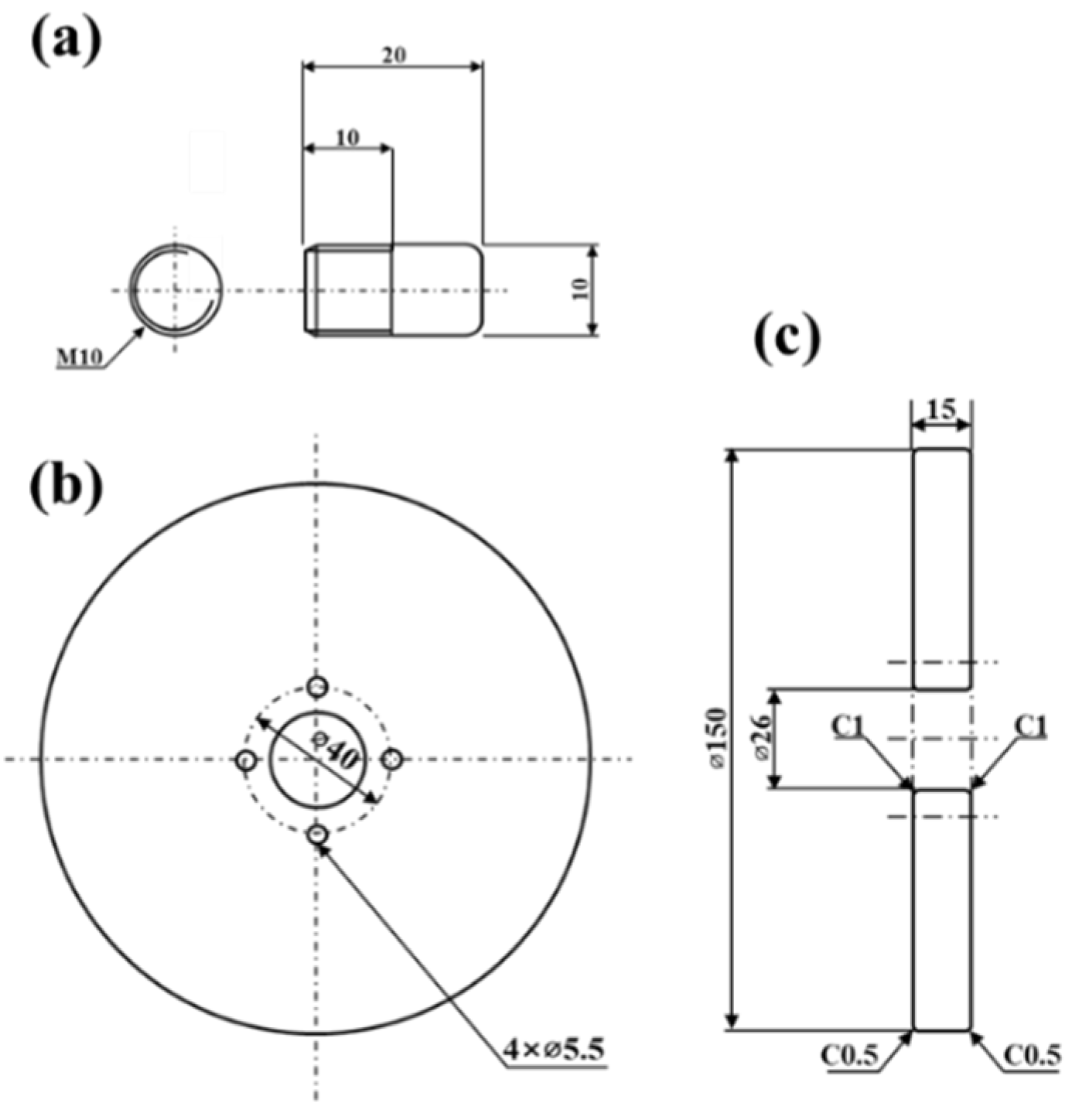

2.2. Block-on-Disk Sliding Wear Test

2.3. Analysis of Wear Characteristics

3. Results and Discussion

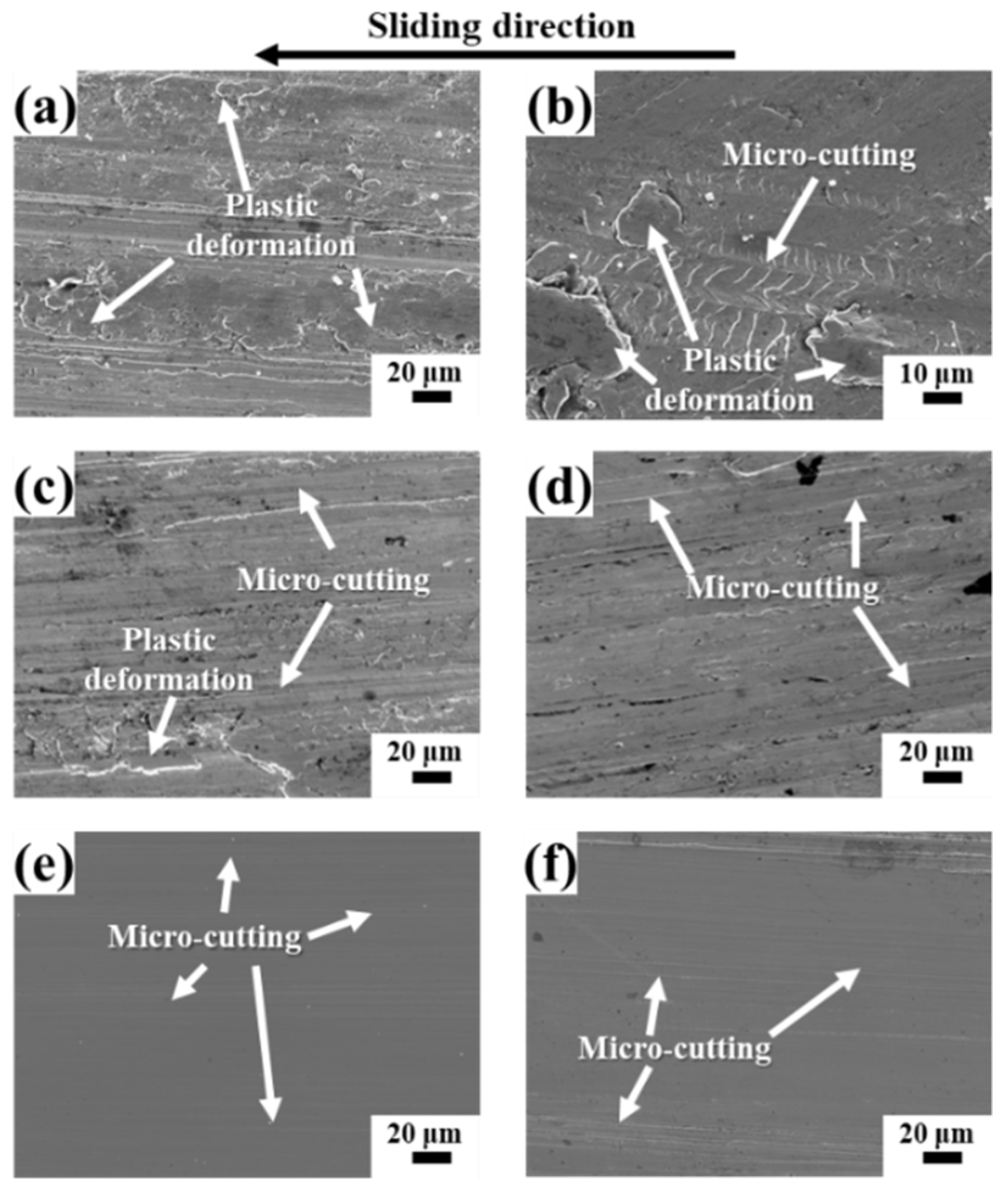

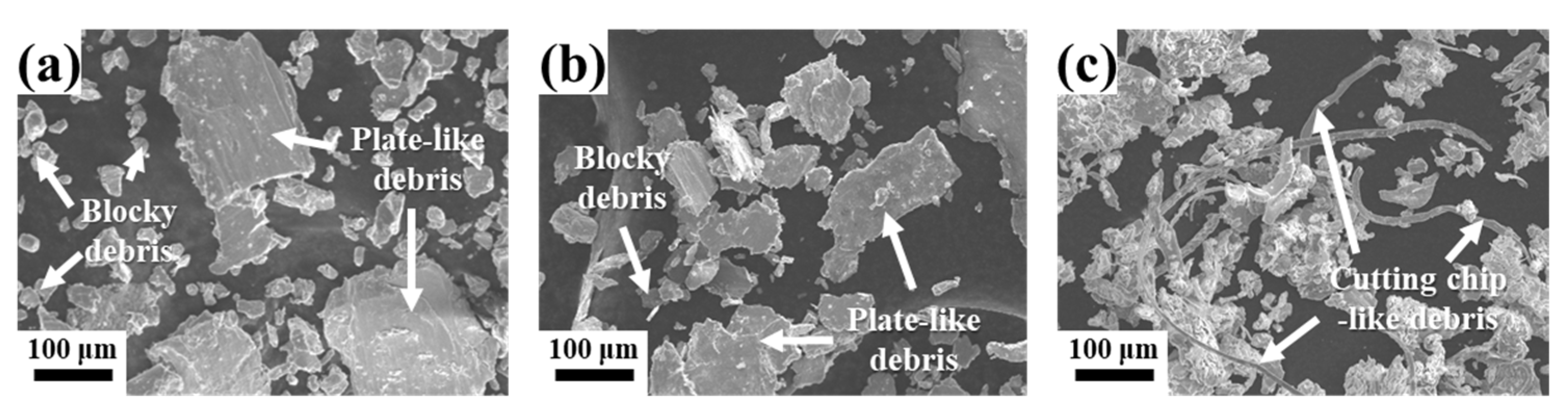

3.1. Wear Behaviors and Characteristics

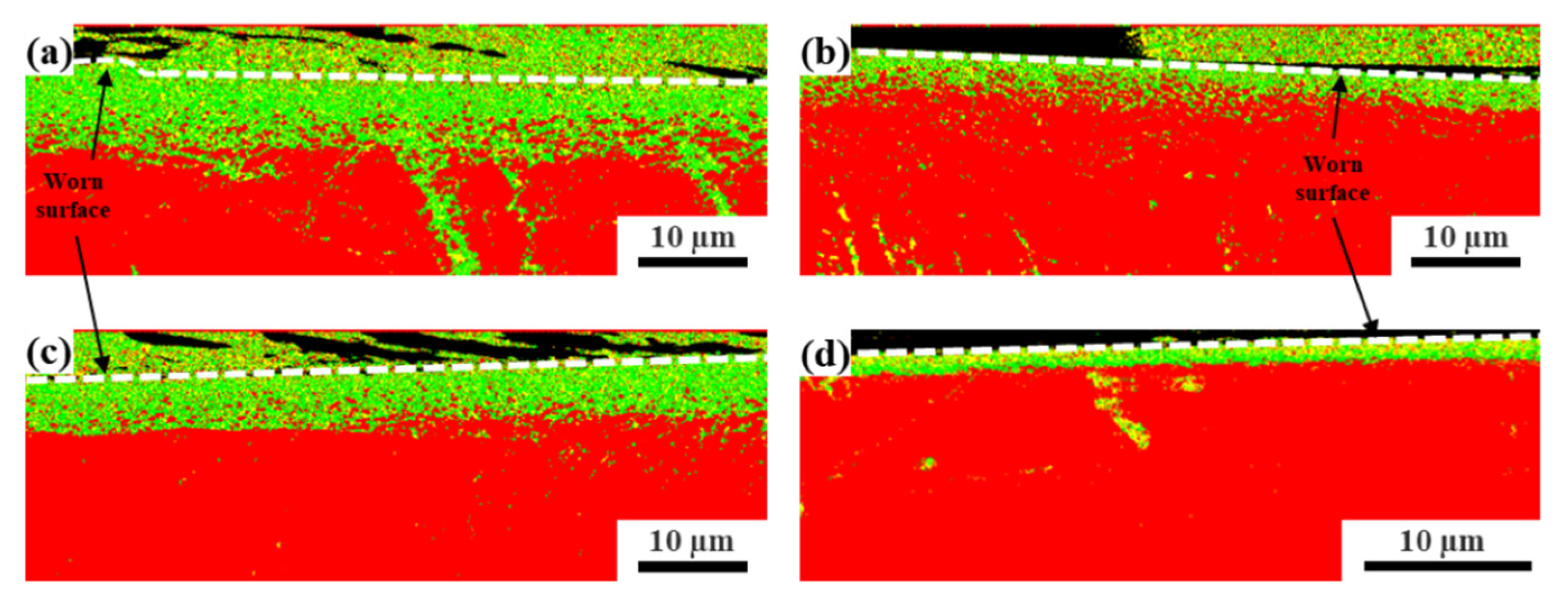

3.2. Phase Transformation Behavior

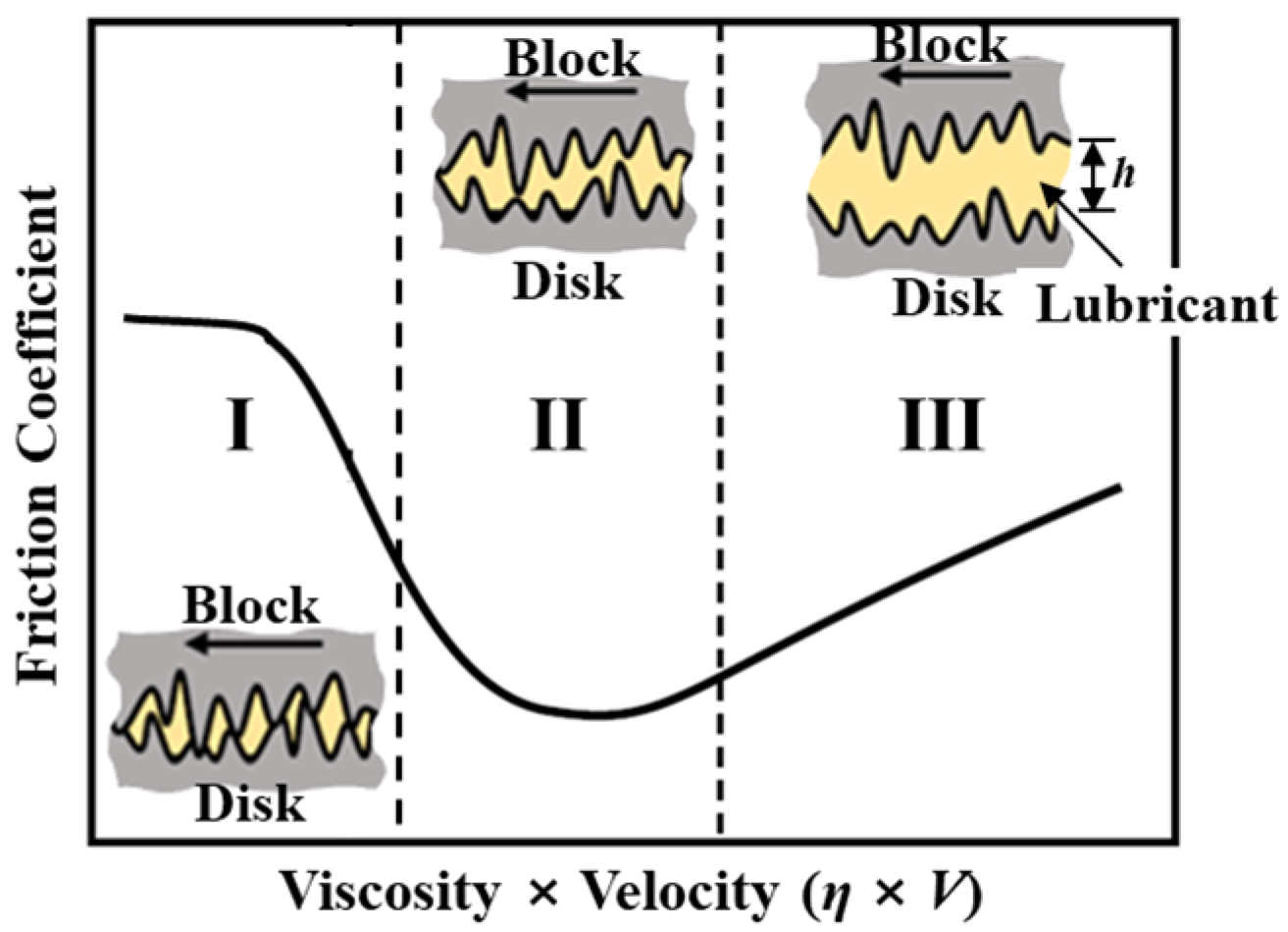

3.3. Stribeck Curve and Lubrication Region

4. Conclusions

- Owing to the high metallurgical compatibility between the disk and block, strong adhesion is prone to occur during wear. When water or oil is applied, a lubricating film is formed on the contact surface, decreasing Ar and adhesion.

- In the oil-lubricated contact, a significant amount of thin and elongated cutting chip-like debris was observed. This is attributed to the high lubricating effect of oil, which causes mild abrasive wear.

- In the water-lubricated contact at 300 rpm, the water film at the contact surface acted as a coolant, decreasing the temperature from the frictional heat, resulting in a thicker martensite layer compared to the dry contact at 300 rpm.

- At less than 200 rpm, the dry and water-lubricated conditions are both considered to be in the boundary lubrication regime, and no significant differences in both the friction coefficient and Ws were observed. However, above 200 rpm, under the water-lubricated condition, the lubrication regime shifts to the mixed lubrication region, resulting in a significant change in Ws.

- In comparison to the dry or water-lubricated conditions, which fall in the boundary lubrication regime at a low rotation speed (100 rpm), the high viscosity of the oil-based lubricant causes the lubrication condition to enter the mixed lubrication regime early at a lower speed, thus reducing Ws over the 100–300 rpm range.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wei, X.; Hua, M.; Xue, Z.; Gao, Z.; Li, J. Evolution of friction-induced microstructure of SUS 304 meta-stable austenitic stainless steel and its influence on wear behavior. Wear 2009, 267, 1386–1392. [Google Scholar] [CrossRef]

- Lamberson, L.; Mates, S.; Eliasson, V. Dynamic Behavior of Materials; Springer: Cham, Switzerland, 2020; Volume 1. [Google Scholar]

- McEvily, A.J.; Velazquez, J.L.G. Fatigue crack tip deformation. Metall. Trans. A 1992, 23, 2211–2221. [Google Scholar] [CrossRef]

- Rabinowicz, E. Friction and Wear of Materials, 2nd ed.; Wiley: New York, NY, USA, 1995. [Google Scholar]

- Junior, A.B.; Diniz, A.E.; Filho, F.T. Tool wear and tool life in end milling of 15–5 PH stainless steel under different cooling and lubrication conditions. Int. J. Adv. Manuf. Technol. 2009, 43, 756–764. [Google Scholar] [CrossRef]

- Xingzhong, Z.; Jiajun, L.; Baoliang, Z.; Hezhou, M.; Zhenbi, L. Wear behavior of Si3N4 ceramic cutting tool material against stainless steel in dry and water-lubricated conditions. Ceram. Int. 1999, 25, 309–315. [Google Scholar] [CrossRef]

- Salih, N.; Salimon, J.; Yousif, E. Synthetic biolubricant basestocks based on environmentally friendly raw materials. J. King Saud Univ. Sci. 2012, 24, 221–226. [Google Scholar] [CrossRef] [Green Version]

- Higdon, C.; Cook, B.; Harringa, J.; Russell, A.; Goldsmith, J.; Qu, J.; Blau, P. Friction and wear mechanisms in AlMgB14-TiB2 nanocoatings. Wear 2011, 271, 2111–2115. [Google Scholar] [CrossRef]

- Fiedler, H.C. The effect of deformation on the martensitic transformation in austenitic stainless steels. Trans. ASM 1955, 47, 267–290. [Google Scholar]

- Choi, J.-Y.; Jin, W. Strain induced martensite formation and its effect on strain hardening behavior in the cold drawn 304 austenitic stainless steels. Scr. Mater. 1997, 36, 99–104. [Google Scholar] [CrossRef]

- Hong, W.; Cai, W.; Wang, S.; Tomovic, M.M. Mechanical wear debris feature, detection, and diagnosis: A review. Chin. J. Aeronaut. 2018, 31, 867–882. [Google Scholar] [CrossRef]

- Seifert, W.W.; Westcott, V.C. A method for the study of wear particles in lubricating oil. Wear 1972, 21, 27–42. [Google Scholar] [CrossRef]

- Dowson, D.; Dalmaz, G.; Childs, T.; Taylor, C.; Godet, M. Wear Particles: From the Cradle to the Grave; Elsevier: Amsterdam, The Netherlands, 1992. [Google Scholar]

- Roylance, B.; Raadnui, S. The morphological attributes of wear particles—their role in identifying wear mechanisms. Wear 1994, 175, 115–121. [Google Scholar] [CrossRef]

- Eisentraut, K.J.; Newman, R.W.; Saba, C.S.; Kauffman, R.E.; Rhine, W.E. Spectrometric oil analysis. Detecting engine failures before they occur. Anal. Chem. 1984, 56, 1086A–1094A. [Google Scholar] [CrossRef]

- Bharath, V.; Auradi, V.; Nagaral, M.; Boppana, S.B.; Ramesh, S.; Palanikumar, K. Microstructural and Wear Behavior of Al2014-Alumina Composites with Varying Alumina Content. Trans. Indian Inst. Met. 2021, 56, 1–15. [Google Scholar] [CrossRef]

- Suh, N.P. An overview of the delamination theory of wear. Wear 1977, 44, 1–16. [Google Scholar] [CrossRef]

- Wilson, S.; Alpas, A.T. Thermal effects on mild wear transitions in dry sliding of an aluminum alloy. Wear 1999, 225, 440–449. [Google Scholar] [CrossRef]

- Zhang, J.; Alpas, A.T. Delamination wear in ductile materials containing second phase particles. Mater. Sci. Eng. A 1993, 160, 25–35. [Google Scholar] [CrossRef]

- Ashok Raj, J.; Kailas, S.V. Evolution of wear debris morphology during dry sliding of Ti–6Al–4V against SS316L under ambient and vacuum conditions. Wear 2020, 456, 203378. [Google Scholar]

- Talonen, J.; Hänninen, H. Formation of shear bands and strain-induced martensite during plastic deformation of metastable austenitic stainless steels. Acta Mater. 2007, 55, 6108–6118. [Google Scholar] [CrossRef]

- Schramm, R.E.; Reed, R.P. Stacking fault energies of seven commercial austenitic stainless steels. Metall. Trans. A 1975, 6, 1345. [Google Scholar] [CrossRef]

- Noh, J.H.; Lee, S.G.; Park, H.; Kang, N. Effect of Composition on Strain-Induced Martensite Transformation and Tensile Stress-Strain Curve for Austenitic Stainless Steels. J. Weld. Join. 2018, 36, 28–33. [Google Scholar] [CrossRef] [Green Version]

- Olson, G.B.; Cohen, M. A general mechanism of martensitic nucleation: Part I. General concepts and the FCC→HCP transformation. Metall. Trans. A 1976, 7, 1897–1904. [Google Scholar]

- Allain, S.; Chateau, J.P.; Bouaziz, O. A physical model of the twinning-induced plasticity effect in a high manganese austenitic steel. Mater. Sci. Eng. A 2004, 387, 143–147. [Google Scholar] [CrossRef]

- Curtze, S.; Kuokkala, V.T.; Oikari, A.; Talonen, J.; Hänninen, H. Thermodynamic modeling of the stacking fault energy of austenitic steels. Acta Mater. 2011, 59, 1068–1076. [Google Scholar] [CrossRef]

- Saeed-Akbari, A.; Mosecker, L.; Schwedt, A.; Bleck, W. Characterization and prediction of flow behavior in high-manganese twinning induced plasticity steels: Part I. Mechanism maps and work-hardening behavior. Metall. Mater. Trans. A 2012, 43, 1688–1704. [Google Scholar] [CrossRef]

- Walter, M.; Roncery, L.M.; Weber, S.; Leich, L.; Theisen, W. XRD measurement of stacking fault energy of Cr–Ni austenitic steels: Influence of temperature and alloying elements. J. Mater. Sci. 2020, 55, 13424–13437. [Google Scholar] [CrossRef]

- Mosecker, L.; Pierce, D.T.; Schwedt, A.; Beighmohamadi, M.; Mayer, J.; Bleck, W.; Wittig, J.E. Temperature effect on deformation mechanisms and mechanical properties of a high manganese C+ N alloyed austenitic stainless steel. Mater. Sci. Eng. A 2015, 642, 71–83. [Google Scholar] [CrossRef]

- Kadokawa, J. Ionic Liquids: New Aspects for the Future; InTech: Rijeka, Croatia, 2013. [Google Scholar]

- Williams, J.A. Engineering Tribology; Oxford University Press: Oxford, UK, 1994. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, Y.-S.; Yamagishi, S.; Tsuro, M.; Ji, C.; Cho, S.; Kim, Y.; Choi, M. Wear Behaviors of Stainless Steel and Lubrication Effect on Transitions in Lubrication Regimes in Sliding Contact. Metals 2021, 11, 1854. https://doi.org/10.3390/met11111854

Lee Y-S, Yamagishi S, Tsuro M, Ji C, Cho S, Kim Y, Choi M. Wear Behaviors of Stainless Steel and Lubrication Effect on Transitions in Lubrication Regimes in Sliding Contact. Metals. 2021; 11(11):1854. https://doi.org/10.3390/met11111854

Chicago/Turabian StyleLee, Yoon-Seok, Shunnosuke Yamagishi, Masataka Tsuro, Changwook Ji, Seungchan Cho, Yangdo Kim, and Moonhee Choi. 2021. "Wear Behaviors of Stainless Steel and Lubrication Effect on Transitions in Lubrication Regimes in Sliding Contact" Metals 11, no. 11: 1854. https://doi.org/10.3390/met11111854

APA StyleLee, Y.-S., Yamagishi, S., Tsuro, M., Ji, C., Cho, S., Kim, Y., & Choi, M. (2021). Wear Behaviors of Stainless Steel and Lubrication Effect on Transitions in Lubrication Regimes in Sliding Contact. Metals, 11(11), 1854. https://doi.org/10.3390/met11111854