Microstructure and Failure Processes of Reactor Pressure Vessel Austenitic Cladding

Abstract

:1. Introduction

2. Materials and Methods

3. Results

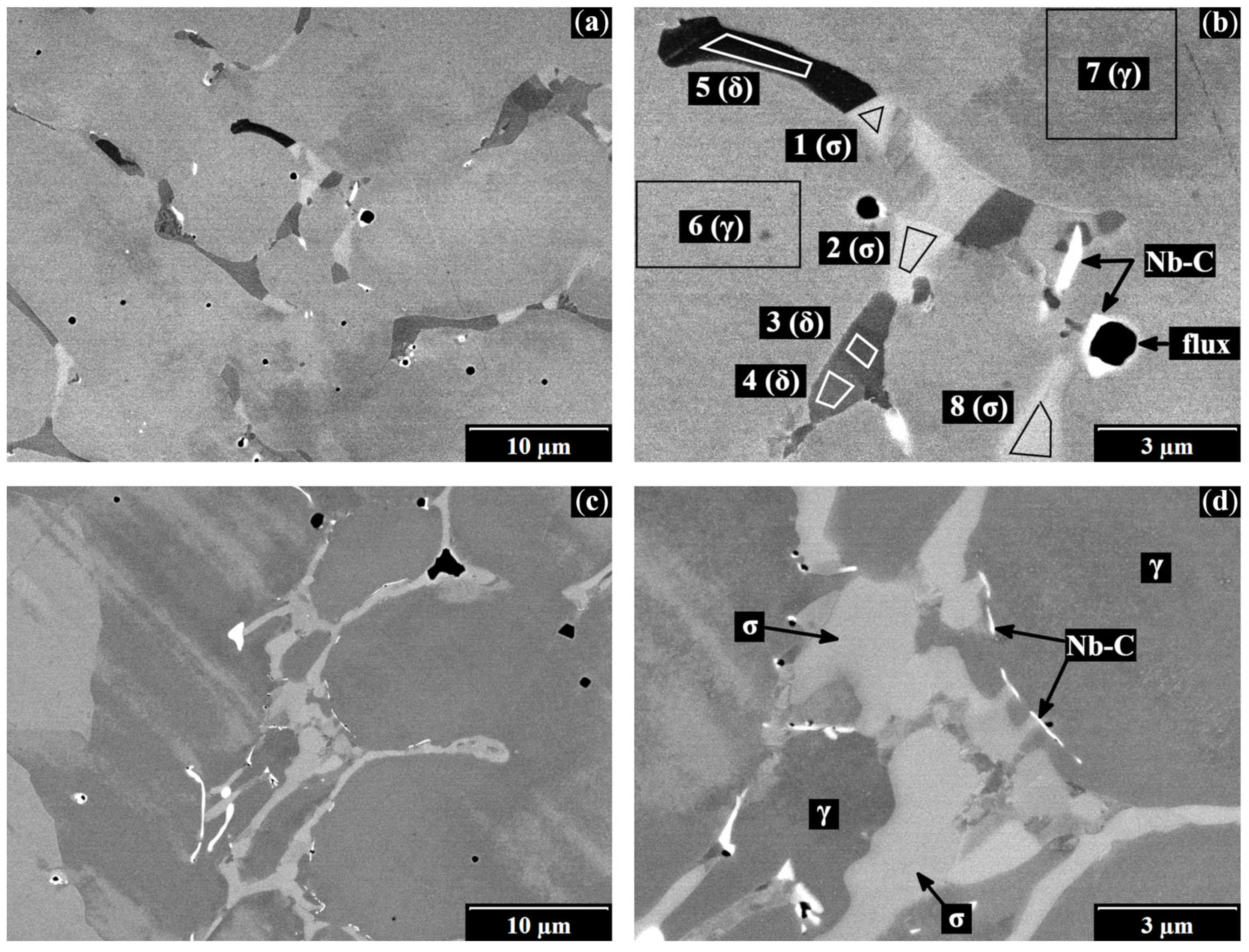

- Delta ferrite was characterized by slightly elevated amounts of chromium (26 ÷ 28 wt. %, as opposed to the ca 20 wt.% typical of austenite) and local depletion of nickel (less than 2 wt.% in comparison with bulk content of 10 wt.% in austenite). Ferritic areas could be identified by dark contrast in SEM backscattered electron COMPO micrographs (Figure 4).

- The sigma phase was highly enriched with chromium (36 ÷ 38 wt. %), as well as with silicon (up to 1.9 wt. %). The composition was consistent with CL1 and typical of this type of stainless steels [12].

- Niobium carbides could be easily recognized by the brightest contrast caused by the high relative atomic number of niobium (Figure 4b,d). The carbides were found to decorate solidification aggregates and flux particles. Practically no niobium content was detected within ferritic areas and sigma particles.

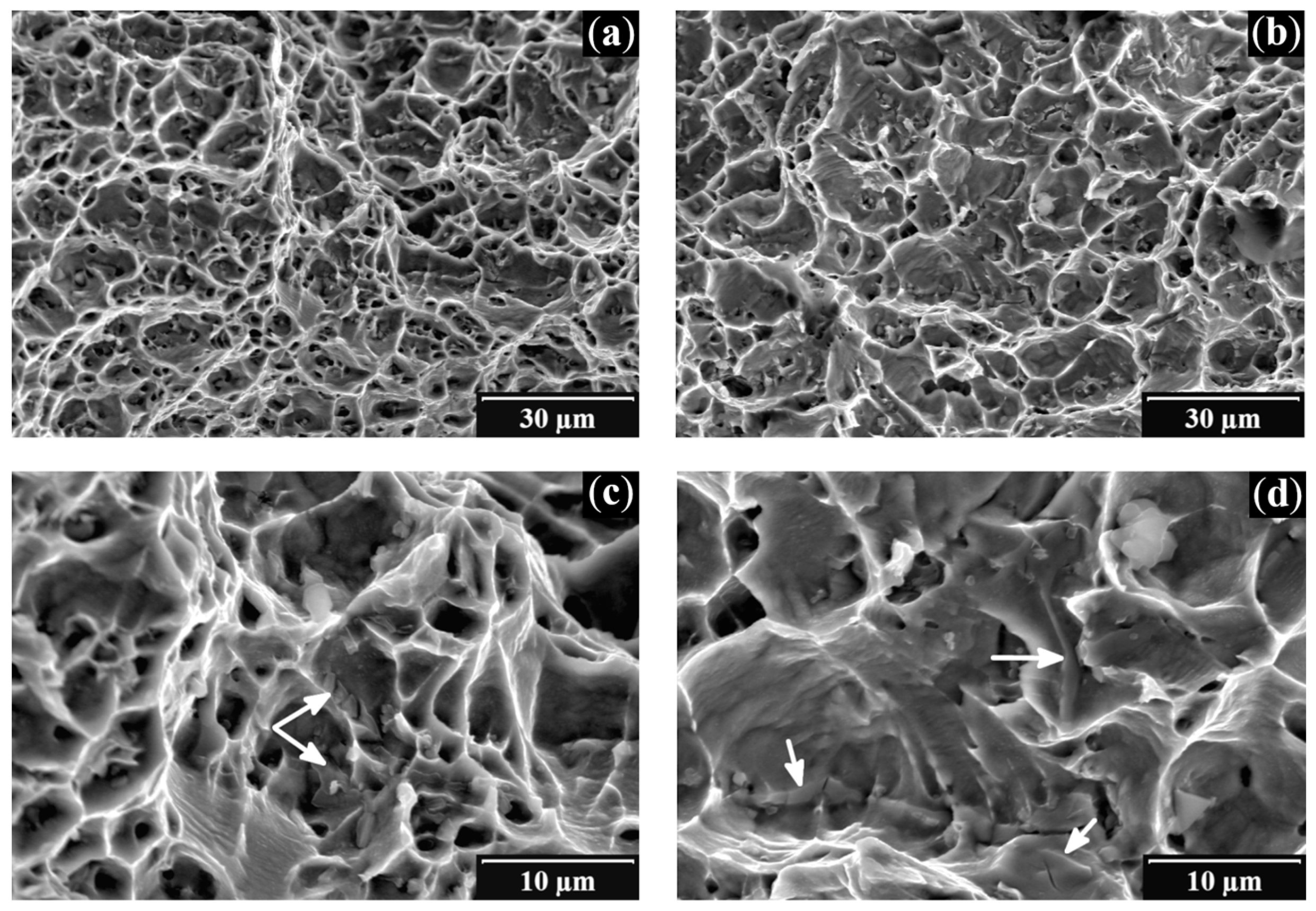

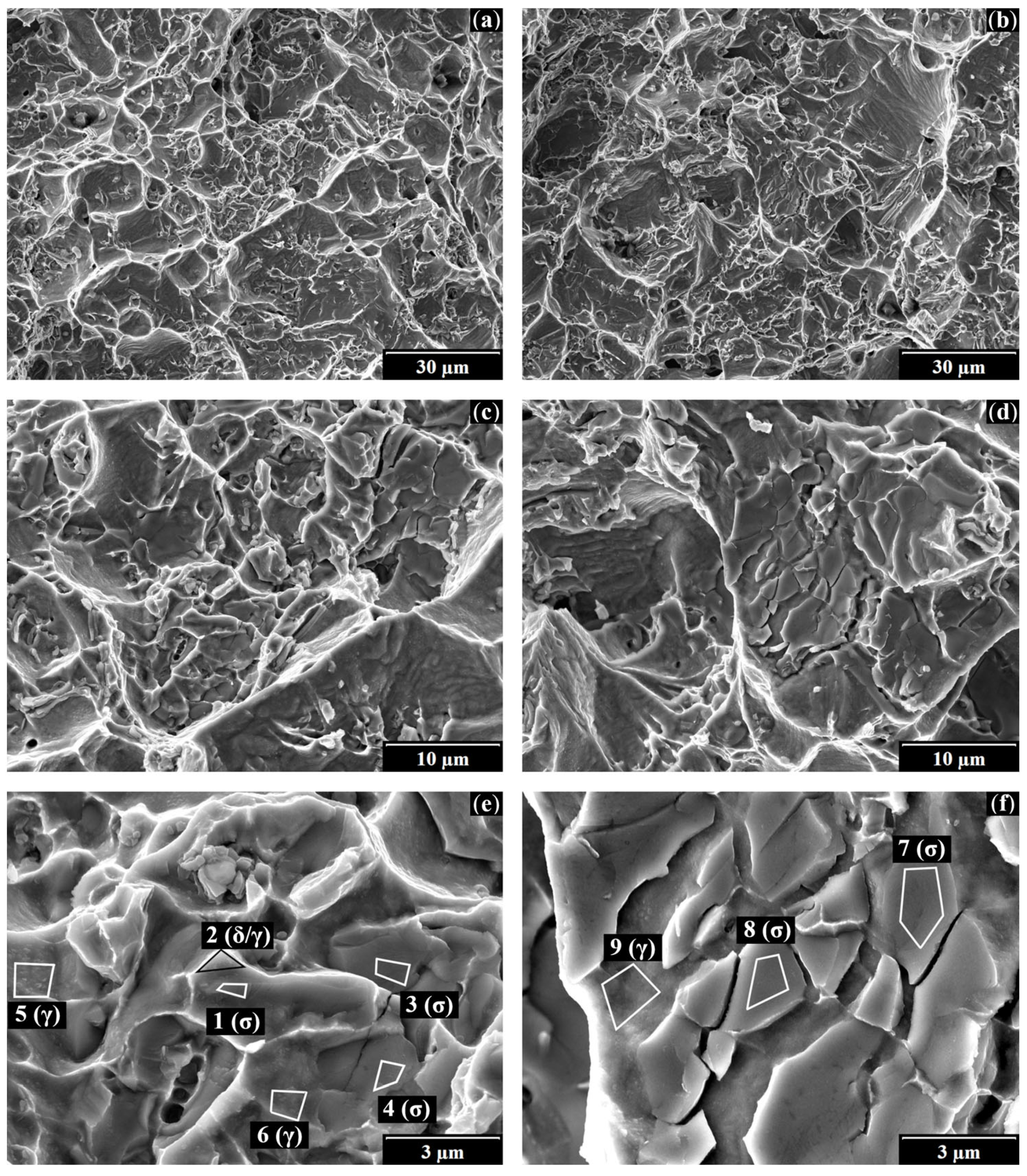

- Fracture surfaces of specimens with low ductile tearing resistance (T1, T2, T5) were characterized by much larger ductile dimples and cavities. Detailed fractographic analysis identified large secondary particles cracked in an evidently non-ductile (brittle) manner (see Figure 6). Contents of alloying elements within the particles were evaluated by means of EDX analysis. Table 3 shows that the particles were always particularly enriched with chromium, as well as with silicon in some cases. Hence, the particles were identified as sigma phase forming segments of solidification aggregates.

4. Discussion

5. Conclusions

- The second cladding was characterized as a duplex austenitic-ferritic stainless steel with a dominant portion of austenite and a specific solidification structure constituted by cells and dendrites. Individual segments of solidification aggregates were composed of residual delta-ferrite, sigma phase and other secondary phases.

- Extreme variations were indicated in the dimensions, distribution and phase composition of solidification aggregates at different distances from the welded substrate. Some areas were characterized by sparsely distributed aggregates having small dimensions and approximately balanced portions of ferrite and sigma phase, while others were characterized by large thick aggregates constituted almost exclusively by sigma phase.

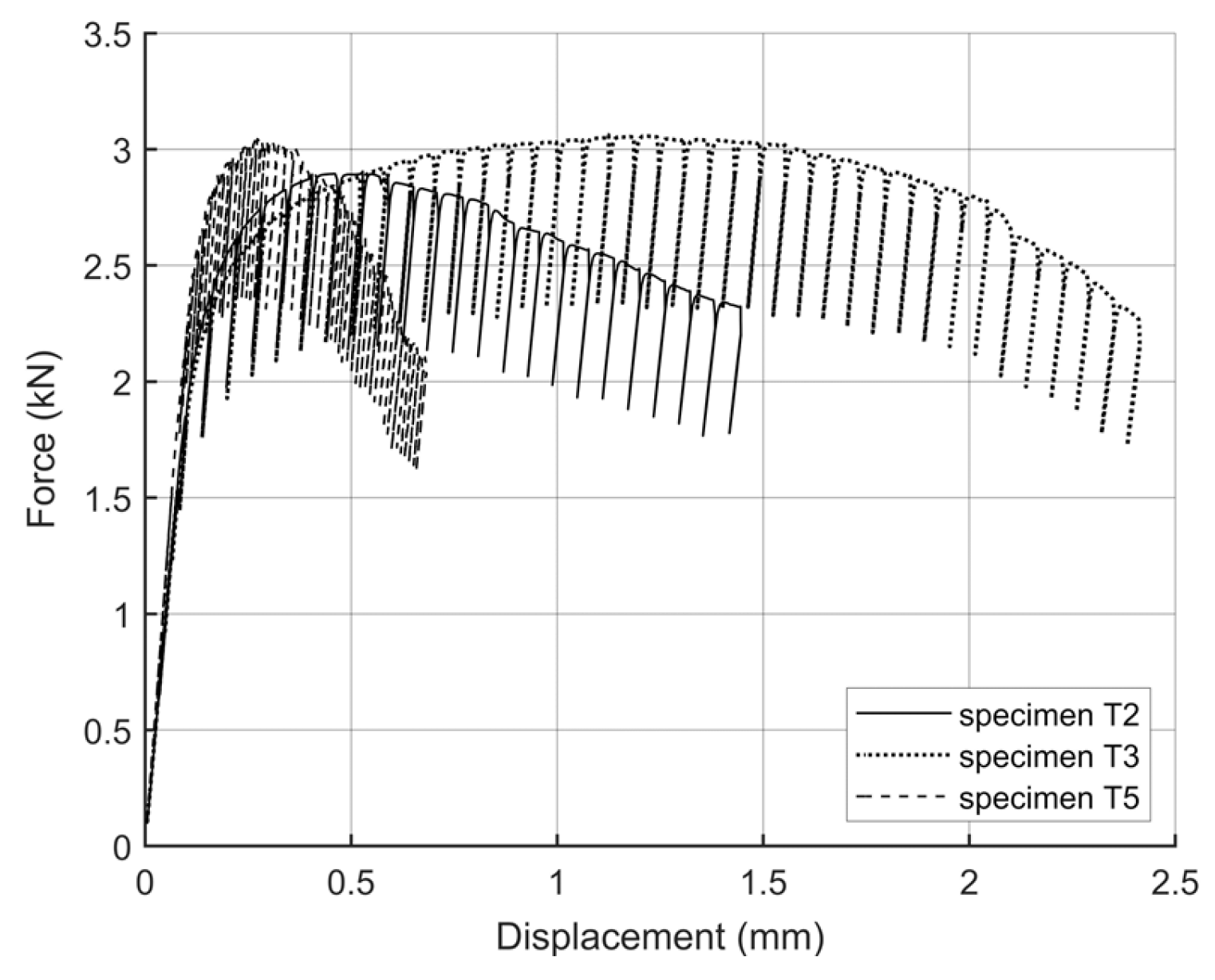

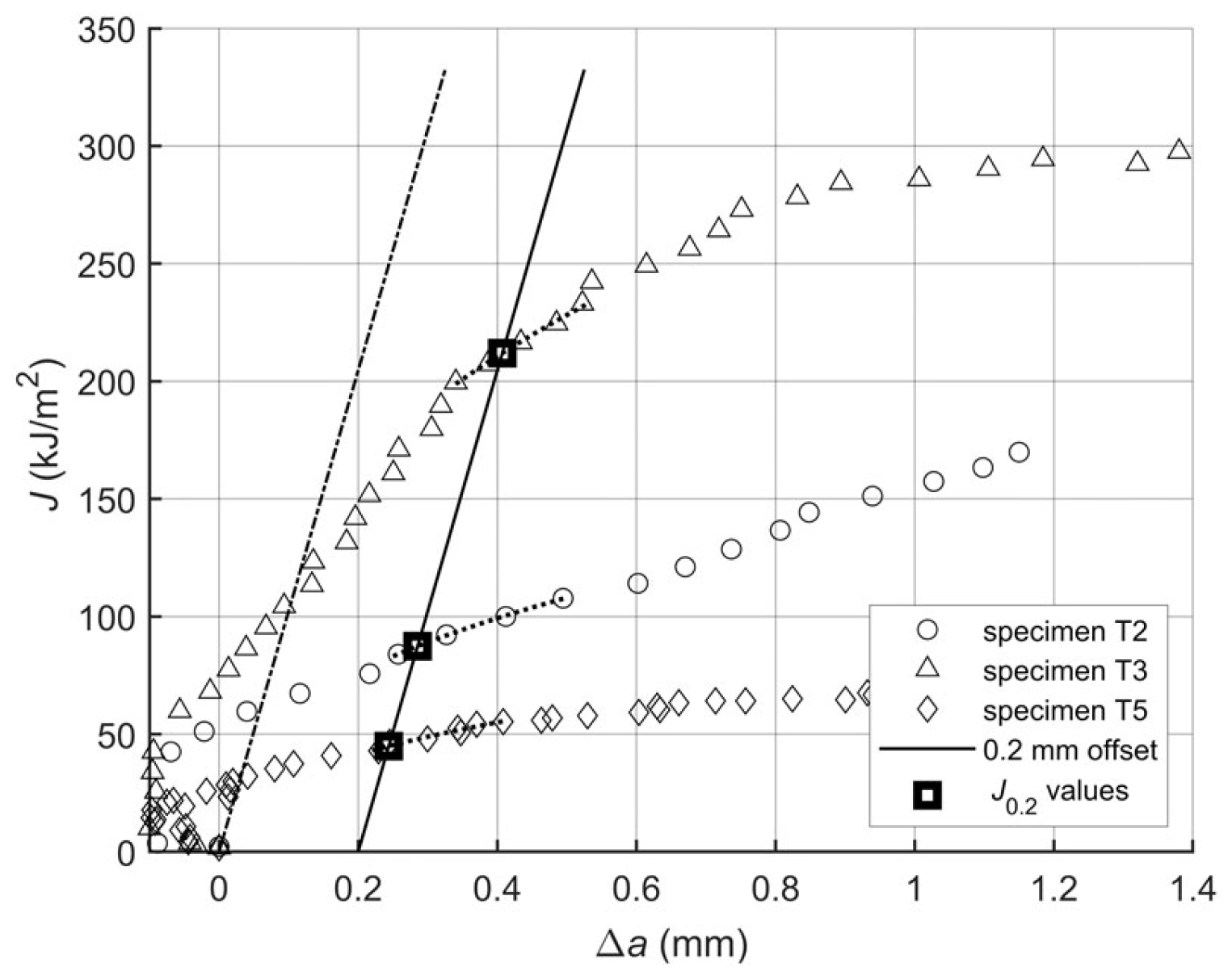

- Local ductile tearing resistance of cladding was always fully determined by local parameters of solidification cells and dendrites in the area of crack propagation: whenever a crack propagated through an area characterized by an elevated portion of brittle sigma phase, the sigma-enriched segment of cells and dendrites were given to premature brittle cracking, and thereby facilitated the formation of ductile dimples, which manifested itself in a considerable promotion of crack growth rate. A general conclusion could be drawn that the extreme scatter of fracture toughness values, J0.2, might be attributed to a combination of the extreme heterogeneity of the cladding and the fortuity of precrack positions and orientations within individual test specimens.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| BM | Base metal |

| CL1 | First cladding |

| CL2 | Second cladding |

| CELZ | Cellular zone |

| DENZ | Dendritic zone |

| RPV | Reactor pressure vessel |

| SEM | Scanning electron microscope |

| TRZ | Transition zone between CELZ and DENZ |

References

- Gillemot, F. Overview of Reactor Pressure Vessel Cladding. Int. J. Nucl. Knowl. Manag. 2010, 4, 265–278. [Google Scholar] [CrossRef]

- Gillemot, F.; Horváth, M.; Úri, G.; Fekete, T.; Houndeffo, E.; Acosta, B.; Debarberis, L.; Viehrig, H.W. Radiation Stability of WWER RPV Cladding Materials. Int. J. Press. Vessel. Pip. 2007, 84, 469–474. [Google Scholar] [CrossRef]

- Guidelines on Pressurized Thermal Shock Analysis for WWER Nuclear Power Plants; IAEA-EBP-WWER-08; IAEA: Vienna, Austria, 2006.

- Viehrig, H.W.; Altstadt, E.; Houska, M. Radiation Response of the Overlay Cladding from the Decommissioned WWER-440 Greifswald Unit 4 Reactor Pressure Vessel. Nucl. Eng. Des. 2015, 286, 227–236. [Google Scholar] [CrossRef]

- Zarazovskii, M.; Dubyk, Y. Open Issues in PTS Assessment of WWER RPVs. Procedia Struct. Integr. 2019, 22, 305–312. [Google Scholar] [CrossRef]

- Trampus, P. Pressurized Thermal Shock Analysis of the Reactor Pressure Vessel. Procedia Struct. Integr. 2018, 13, 2083–2088. [Google Scholar] [CrossRef]

- Chen, M.; Yu, W.; Qian, G.; Shi, J.; Cao, Y.; Yu, Y. Crack Initiation, Arrest and Tearing Assessments of a RPV Subjected to PTS Events. Ann. Nucl. Energy 2018, 116, 143–151. [Google Scholar] [CrossRef]

- Štefan, J.; Siegl, J.; Adámek, J.; Kopřiva, R.; Kytka, M. Failure Behaviour of Cladding Made from Sv 07Kh25N13 Austenitic Stainless Steel. Int. J. Press. Vessel. Pip. 2021, 189, 104275. [Google Scholar] [CrossRef]

- Guidelines for Prediction of Irradiation Embrittlement of Operating WWER-440 Reactor Pressure Vessels; IAEA: Vienna, Austria, 2005.

- Gosatomnadzor of Russia. Equipment and Piping of Nuclear Power Installations. Weld Joints and Weld Overlays. Rules of Inspection; PNAE G-7-010-89; Gosatomnadzor of Russia: Moscow, Russia, 2000.

- ASTM International. Standard Test Method for Measurement of Fracture Toughness; ASTM E 1820-99; ASTM: West Conshohocken, PA, USA, 1999. [Google Scholar]

- Vitek, J.M.; David, S.A. The Sigma Phase Transformation in Austenitic Stainless Steels. Weld. J. 1986, 65, 106–111. [Google Scholar]

- Hsieh, C.-C.; Wu, W. Overview of Intermetallic Sigma (σ) Phase Precipitation in Stainless Steels. ISRN Metall. 2012, 2012, 16. [Google Scholar] [CrossRef]

- Lee, J.S.; Kim, I.S.; Jang, C.H.; Kimura, A. Irradiation Embrittlement of Cladding and HAZ of RPV Steel. Nucl. Eng. Technol. 2005, 38, 405–410. [Google Scholar]

- Kim, I.S.; Lee, J.S.; Kimura, A. Embrittlement of ER309L Stainless Steel Clad by σ-Phase and Neutron Irradiation. J. Nucl. Mater. 2004, 329–333, 607–611. [Google Scholar] [CrossRef]

- Lee, J.S.; Kim, I.S.; Kasada, R.; Kimura, A. Microstructural Characteristics and Embrittlement Phenomena in Neutron Irradiated 309L Stainless Steel RPV Clad. J. Nucl. Mater. 2004, 326, 38–46. [Google Scholar] [CrossRef]

- Hsieh, C.C.; Lin, D.Y.; Chang, T.C. Microstructural Evolution during the δ/σ/γ Phase Transformation of the SUS 309LSi Stainless Steel after Aging under Various Nitrogen Atmospheric Ratios. Mater. Sci. Eng. A 2008, 475, 128–135. [Google Scholar] [CrossRef]

- Timofeev, B.T.; Karzov, G.P. Assessment of the WWER-440/V-213 Reactor Condition. Int. J. Press. Vessel. Pip. 2006, 83, 216–226. [Google Scholar] [CrossRef]

- Timofeev, B.T.; Karzov, G.P.; Blumin, A.A.; Anikovsky, V.V. Fracture Toughness of 15X2MFA Steel and Its Weldments. Int. J. Press. Vessel. Pip. 2000, 77, 41–52. [Google Scholar] [CrossRef]

- Timofeev, B.T.; Karzov, G.P. Assessment of the WWER-1000 Reactor Condition. Int. J. Press. Vessel. Pip. 2006, 83, 464–473. [Google Scholar] [CrossRef]

- Timofeev, B.T.; Blumin, A.A.; Anikovsky, V.V. Fracture Toughness of 15X2HMFA Steel and Its Welds. Int. J. Press. Vessel. Pip. 1997, 74, 165–172. [Google Scholar] [CrossRef]

| Material | C | Si | Mn | Cr | Ni | Nb | S | P |

|---|---|---|---|---|---|---|---|---|

| Sv 07Kh25N13 (first cladding) | max. 0.09 | 0.3 1.2 | 0.8 2.0 | 22.0 26.5 | 11.0 14.0 | - | max. 0.020 | max. 0.030 |

| Sv 08Kh19N10G2B (second cladding) | max. 0.10 | max. 1.0 | 1.3 2.2 | 17.5 20.5 | 8.0 11.0 | 0.7 1.2 | max. 0.020 | max. 0.030 |

| No | Fe | Cr | Ni | Mn | Si | Identification |

|---|---|---|---|---|---|---|

| 1 | 56.1 | 38.3 | 2.5 | 1.6 | 1.6 | Sigma phase |

| 2 | 55.7 | 36.5 | 4.8 | 1.2 | 1.8 | Sigma phase |

| 3 | 70.0 | 27.6 | 1.3 | 0.3 | 0.9 | Delta ferrite |

| 4 | 68.1 | 27.3 | 1.7 | 1.8 | 1.1 | Delta ferrite |

| 5 | 69.7 | 26.1 | 1.2 | 1.7 | 1.2 | Delta ferrite |

| 6 | 67.6 | 19.0 | 10.1 | 2.5 | 0.9 | Austenite |

| 7 | 68.5 | 20.2 | 8.6 | 1.9 | 0.9 | Austenite |

| 8 | 57.8 | 38.1 | 0.2 | 2.0 | 1.9 | Sigma phase |

| No | Fe | Cr | Ni | Mn | Si | Identification |

|---|---|---|---|---|---|---|

| 1 | 61.8 | 32.7 | 3.4 | 1.1 | 1.1 | Sigma phase |

| 2 | 69.9 | 21.9 | 5.6 | 1.6 | 1.1 | Ferrite/austenite (unclear) |

| 3 | 59.7 | 33.9 | 3.4 | 1.4 | 1.7 | Sigma phase |

| 4 | 59.7 | 34.4 | 2.5 | 1.6 | 1.8 | Sigma phase |

| 5 | 65.8 | 21.4 | 10.1 | 1.8 | 1.0 | Austenite |

| 6 | 64.5 | 25.0 | 8.3 | 1.2 | 1.0 | Austenite |

| 7 | 59.6 | 33.2 | 4.8 | 1.3 | 1.1 | Sigma phase |

| 8 | 60.1 | 32.8 | 4.4 | 1.4 | 1.4 | Sigma phase |

| 9 | 67.4 | 20.2 | 9.6 | 1.8 | 1.0 | Austenite |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Štefan, J.; Siegl, J.; Adámek, J.; Kopřiva, R.; Falcník, M. Microstructure and Failure Processes of Reactor Pressure Vessel Austenitic Cladding. Metals 2021, 11, 1676. https://doi.org/10.3390/met11111676

Štefan J, Siegl J, Adámek J, Kopřiva R, Falcník M. Microstructure and Failure Processes of Reactor Pressure Vessel Austenitic Cladding. Metals. 2021; 11(11):1676. https://doi.org/10.3390/met11111676

Chicago/Turabian StyleŠtefan, Jan, Jan Siegl, Jan Adámek, Radim Kopřiva, and Michal Falcník. 2021. "Microstructure and Failure Processes of Reactor Pressure Vessel Austenitic Cladding" Metals 11, no. 11: 1676. https://doi.org/10.3390/met11111676

APA StyleŠtefan, J., Siegl, J., Adámek, J., Kopřiva, R., & Falcník, M. (2021). Microstructure and Failure Processes of Reactor Pressure Vessel Austenitic Cladding. Metals, 11(11), 1676. https://doi.org/10.3390/met11111676