Abstract

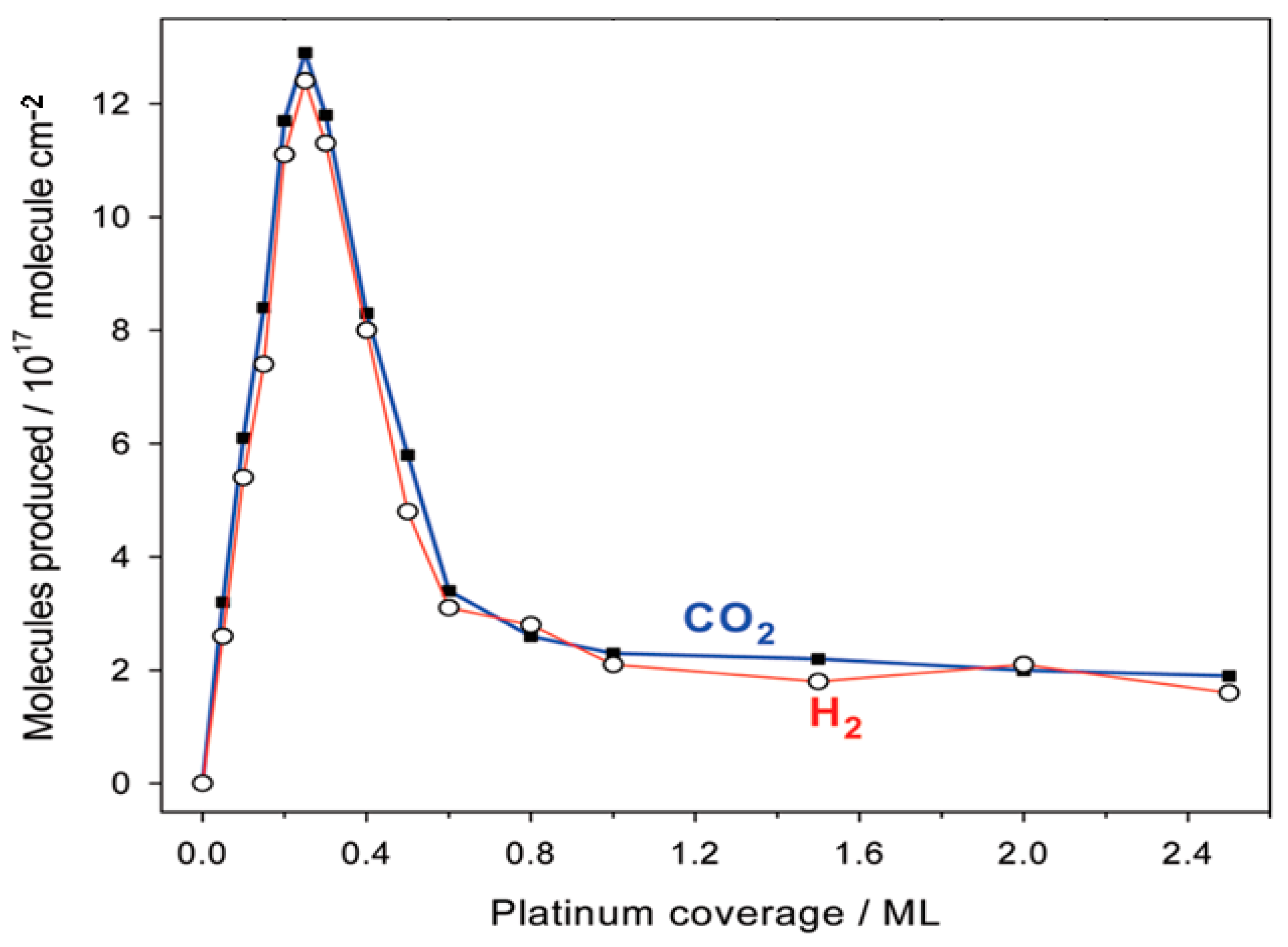

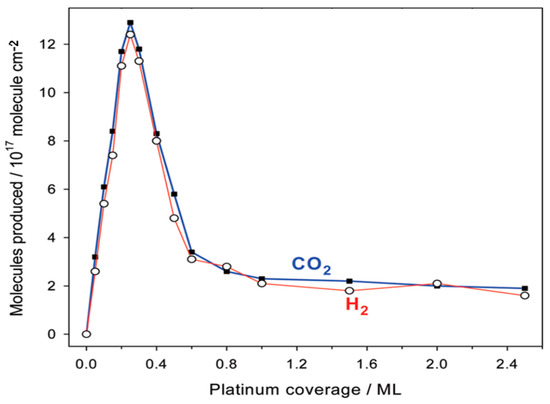

The water gas shift (WGS) is an equilibrium exothermic reaction, whose corresponding industrial process is normally carried out in two adiabatic stages, to overcome the thermodynamic and kinetic limitations. The high temperature stage makes use of iron/chromium-based catalysts, while the low temperature stage employs copper/zinc-based catalysts. Nevertheless, both these systems have several problems, mainly dealing with safety issues and process efficiency. Accordingly, in the last decade abundant researches have been focused on the study of alternative catalytic systems. The best performances have been obtained with noble metal-based catalysts, among which, platinum-based formulations showed a good compromise between performance and ease of preparation. These catalytic systems are extremely attractive, as they have numerous advantages, including the feasibility of intermediate temperature (250–400 °C) applications, the absence of pyrophoricity, and the high activity even at low loadings. The particle size plays a crucial role in determining their catalytic activity, enhancing the performance of the nanometric catalytic systems: the best activity and stability was reported for particle sizes < 1.7 nm. Moreover the optimal Pt loading seems to be located near 1 wt%, as well as the optimal Pt coverage was identified in 0.25 ML. Kinetics and mechanisms studies highlighted the low energy activation of Pt/Mo2C-based catalytic systems (Ea of 38 kJ·mol−1), the associative mechanism is the most encountered on the investigated studies. This review focuses on a selection of recent published articles, related to the preparation and use of unstructured platinum-based catalysts in water gas shift reaction, and is organized in five main sections: comparative studies, kinetics, reaction mechanisms, sour WGS and electrochemical promotion. Each section is divided in paragraphs, at the end of the section a summary and a summary table are provided.

1. Introduction

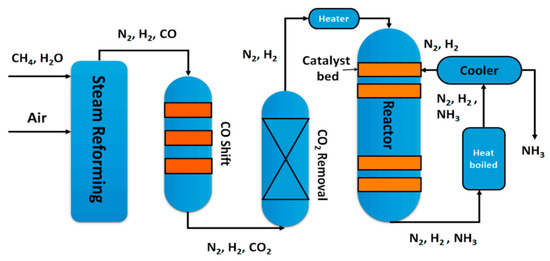

Water-gas shift (WGS) is a mildly exothermic equilibrium reaction (ΔH0298K = −41.2 kJ·mol−1), which can be conducted both heterogeneously and homogeneously, although the homogeneous process is not of commercial interest [1]. The WGS is involved in the production of important chemicals and in numerous chemical transformation processes, such as production of ammonia [2,3] (Figure 1) and methanol [4] as well as hydrogen, the likely energy carrier of the future [5]. The WGS reaction, besides taking part in the syngas production processes, is normally used to reduce the CO concentration, increasing the hydrogen content or to tune the H2/CO ratio in the gas stream [6]. The major issue of the WGS process is the exothermicity of the reaction: as the reaction proceeds the temperature increases due to the heat of the reaction, but, at the same time, the equilibrium conversion decreases and therefore a thermodynamic limitation occurs. On the other hand, too low temperatures slow down the reaction kinetics and, in any case, the threshold temperatures of the catalysts play a fundamental role in the process parameters choice. The exothermic reactions are normally carried out in multistage processes [7], to achieve a compromise between acceptable reaction rates and good conversion values. In the case of WGS, two shift processes are enough to reach a CO concentration, in the gas stream, less than 0.2% [8]: the high temperature shift (HTS) operates in the temperature range 300–450 °C to take advantage of the high reaction rate, while the low temperature shift (LTS) operates in the temperature range 200–250 °C to reach higher conversions [9]; moreover, an intermediate cooling stage is also operated. The conventionally used catalysts in HTS processes are iron–chromium oxide based; until the 1980s the original unsupported formulation remained almost unvaried [10], with the most efforts focused on improving the synthesis.

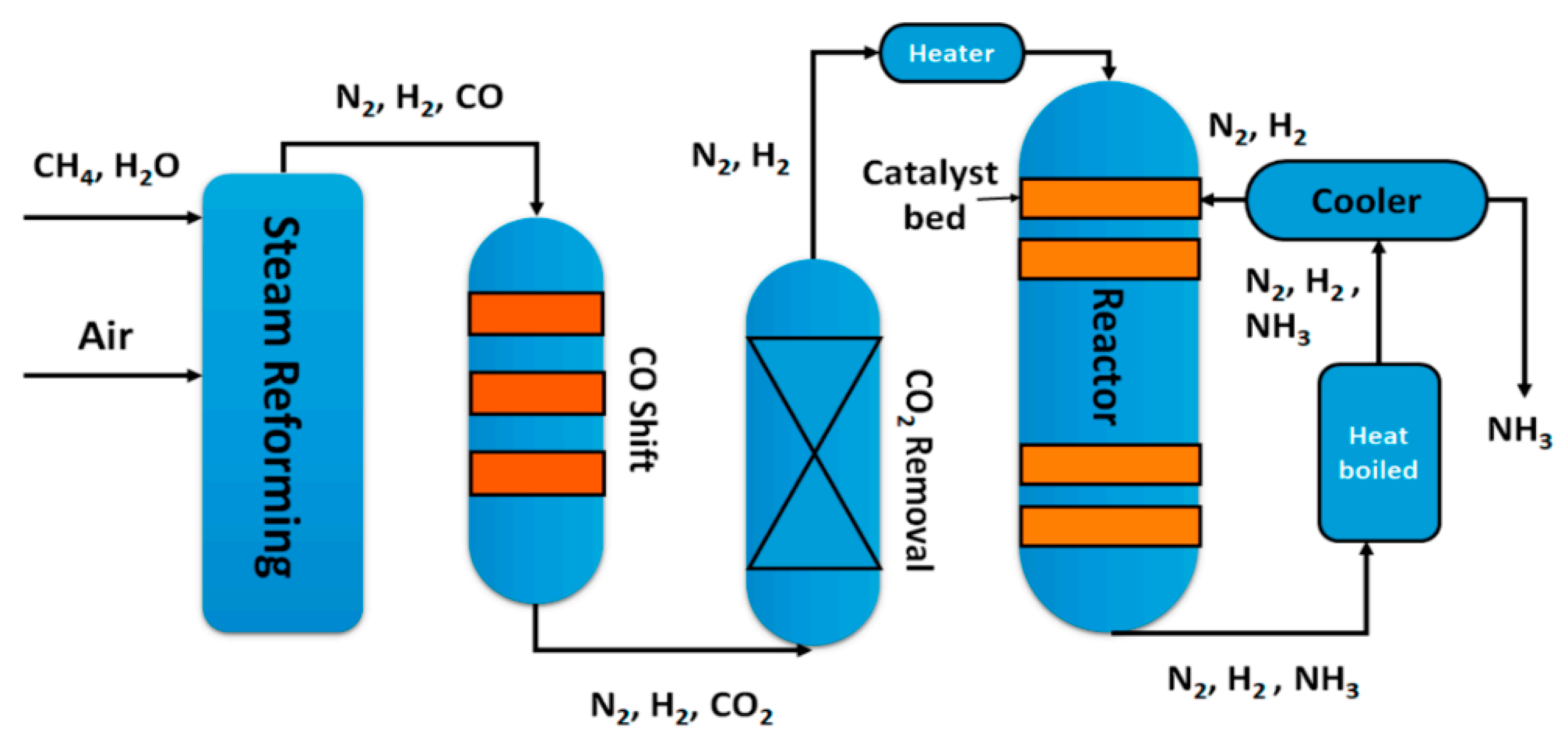

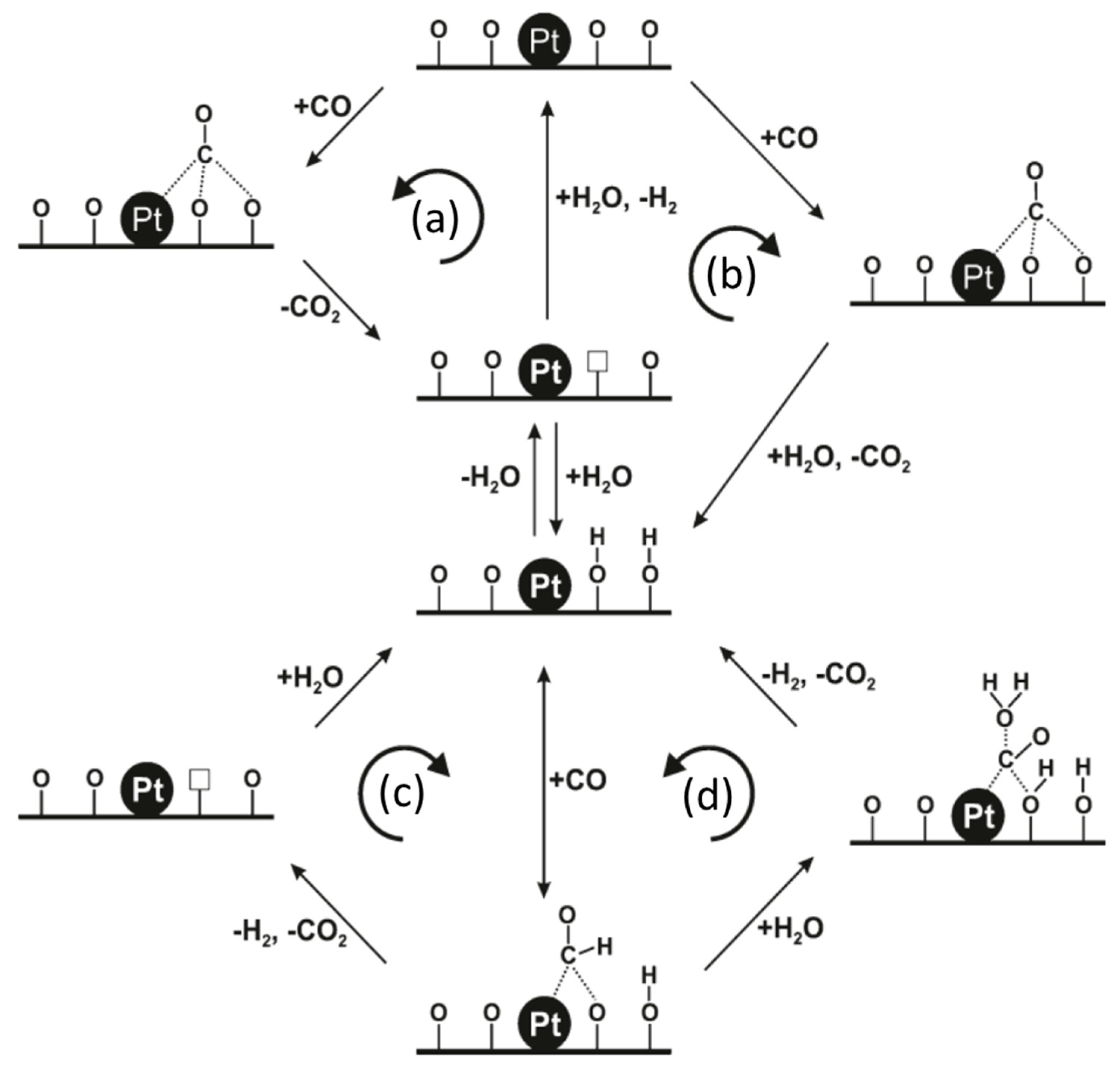

Figure 1.

A flow scheme of the Haber–Bosch process, reproduced from [3], with permission from MDPI, 2018.

Only later, the effect of promoters was investigated to increase the activity, and thermally stabilize the catalysts under WGS reaction conditions [11]. The conventionally used LTS catalysts are copper–zinc oxide based [12], usually Cu supported on alumina stabilized with zinc oxide promoter [13]. The use of these catalysts, despite the good performance in WGS reaction, presents a series of critical issues. In particular, HTS catalysts may suffer from overreduction [11], they are not active at low temperature and present toxicity problems due to the presence of Cr(VI) in the waste. On the other hand, LTS catalysts are pyrophoric and sensitive to the temperature, deactivating over 350 °C [14]; moreover, they are sulphur, halogen and unsaturated hydrocarbon intolerant [15]. In the last decades a growing interest has been focused on the use of noble metals-based catalysts, in particular to platinum supported on highly reducible oxides [16]. These catalysts are attractive for strategic reasons: the high activity in a wide range of temperature allows their use both in HTS and LTS processes; the non-pyrophoricity makes them suitable for oxidative start up and shut down cyclic operations; the high compatibility with conductive structures make them the ideal candidates for the design of structured reactors for a single-stage WGS process [17].

Several papers have been published on the use and the role of platinum as catalyst in the WGS reaction, focusing on the structural characteristics and morphology of the catalysts, on the chemical nature of the species and intermediates in the reaction mechanisms and on the effect of promoters in reaction conditions [18]. These works have involved both theoretical and experimental studies and have obtained a level of understanding that constitutes the basis for the design of highly selective catalysts and innovative reactor configurations. The studies on this kind of catalysts have highlighted the strong correlation between the reaction performances and the active metal particle size; the possibility of using increasingly powerful and faster computers, the recent advances in the sophisticated synthetic methodology and in atomic resolution microscopy, allowing the synthesis and study of nanoparticle and sub-nanoparticle catalytic based systems up to the single atom level [19]. Understanding the reaction mechanisms at the atomic level for sure provides fundamental information; however, most of the catalytic systems, in addition to the active metal, have a non-inert support; therefore the catalytic activity is strongly related to the metal/support interactions. For this reason, the design of innovative reactor configurations [20], as well as new catalytic formulations [21], cannot ignore the understanding of phenomena at the molecular level, as well as the roles that regulate the transition from microscopic to macroscopic phenomena.

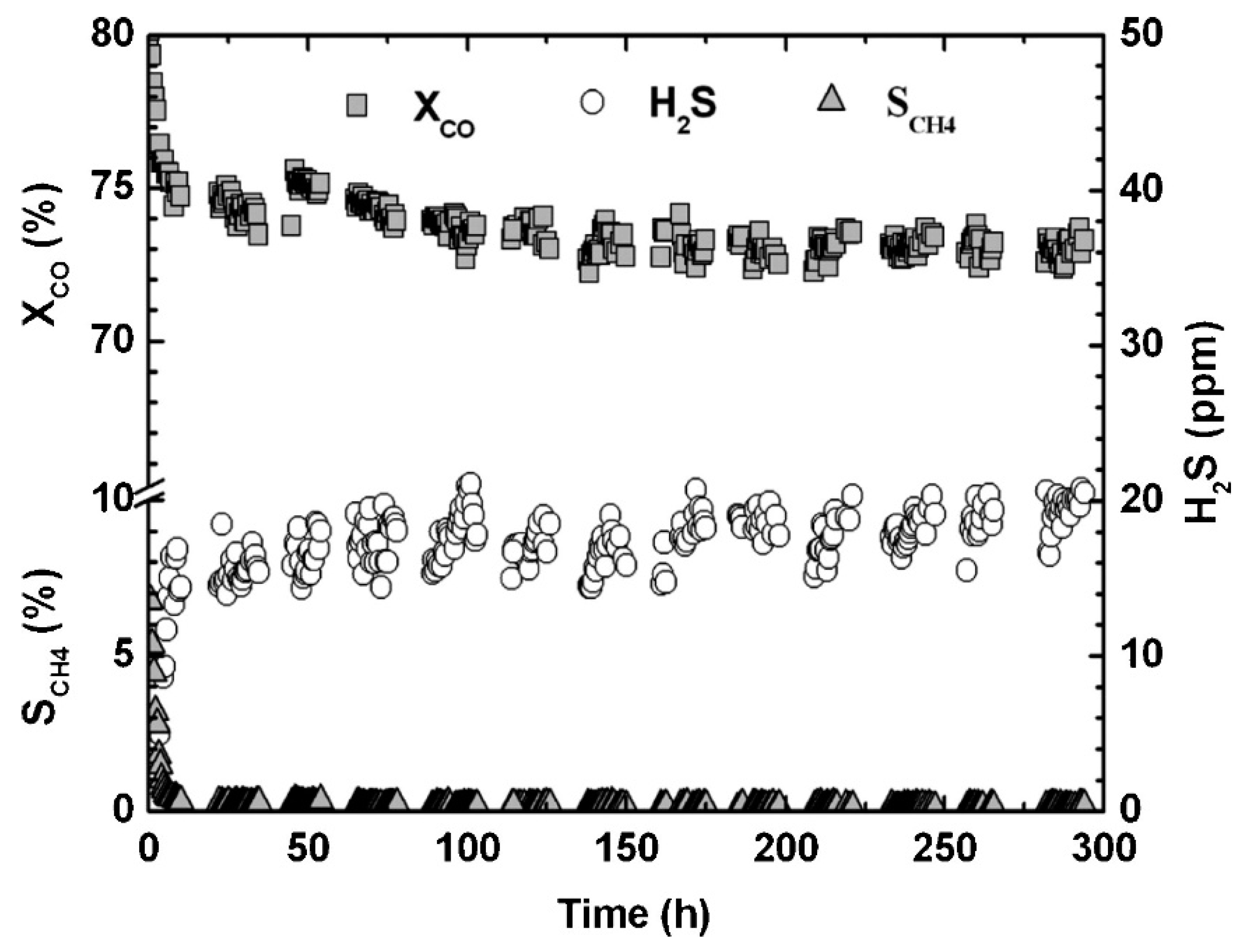

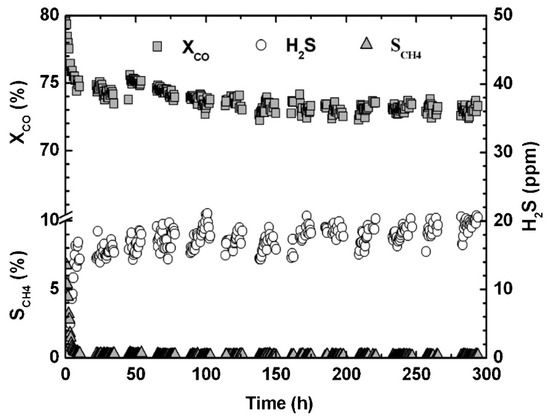

It is also worthy to highlight the particular issue of the catalyst stability, which is a determinant factor in the WGS process. Together with an eventual poisoning effect due to the presence of sour gasses, such as H2S, in the process stream, most of the deactivation problems are mainly related to the cycling operation which the process requires. For this reason, an interesting topic in the research of new catalytic formulations is the catalyst stability under different reaction conditions and operating cycles. This aspect is further detailed in Section 5.

In this short review, the main results published in recent selected articles (from 2011 up to now) on the Pt-based heterogeneous unstructured catalysts for WGS reaction will be summarized; Pt-based structured catalysts have recently been the objective of a comprehensive review on structured catalysts for WGS reaction [22]. The review article has been divided in five main sections, while the articles have been distributed, considering the closest correspondence to the topic: comparative studies (monometallic, polymetallic and promoted catalysts), kinetics studies, reaction mechanism studies, deactivation studies and electrochemical promotion.

2. Comparative Studies

2.1. Monometallic Catalysts: The Supports

This section is devoted to the Pt-based monometallic catalysts literature survey, focusing on the effect of the support preparation on the WGS reaction. The section is divided into four paragraphs, the first (Section 2.1.1) is devoted to the effect of ceria support, the second (Section 2.1.2) to the effect of ceria-based solid solutions and mixed oxide support, the third (Section 2.1.3) to the effect of supports different from ceria, finally the forth (Section 2.1.4) to commercial supports; moreover a brief conclusion is also provided. At the end of the section Table 1 reports the performance of one selected catalyst per article.

2.1.1. Effect of the Preparation Method of the Ceria Support

Pastor-Perez et al. [23] compared the catalytic activity of three platinum-based catalysts obtained by impregnation of ceria support with three different techniques: urea homogeneous precipitation (Pt/CeO2-U), microwave-assisted hydrothermal synthesis (Pt/CeO2-MW) and polymer-assisted hydrothermal synthesis (Pt/CeO2-T). The catalytic tests were carried out by using two different feeding conditions: an ideal gas stream and a real gas stream. The Pt/CeO2-T catalyst showed the worst catalytic activity, due to the poorest reducibility and lowest Pt dispersion. Under ideal stream conditions, Pt/CeO2-U and Pt/CeO2-MW catalysts showed similar trend, while under realistic stream conditions the Pt/CeO2-U catalyst showed the best catalytic activity. TPR (temperature programmed reduction) and XPS (X-ray photoelectron spectroscopy) analyses showed that the ceria surface reduction, on Pt/CeO2-U catalyst, took place at a lower temperature; the enhanced redox properties were related to the electronics perturbations resulting from the strong metal-support interaction, which could explain the excellent catalytic activity. In addition, the smallest band gap was observed for the CeO2-U support, due to a higher concentration of Ce3+ ions and oxygen vacancies in the sample. Such structural defects play an important role in the catalytic activity, acting as adsorption sites for water activation and assisting the noble metal to complete the catalytic cycle. Furthermore, Pt/CeO2-U had the higher Pt/Ce ratio, corresponding to the best metallic dispersion, which positively affected the catalytic activity. In further studies, the effect of a cold Ar radio frequency (RF) plasma treatment on the catalytic activity of a Pt/CeO2 catalyst was evaluated [24]. The results of the activity tests showed that the plasma treatment alone did not improve the CO conversion, compared to the conventional reduction treatment, while higher catalytic activity was observed when both treatments were combined, particularly in the calcined sample. This result was attributed to the high electron density of Pt particles on the support and to the strong interaction between the Pt particles and the support, which took place at a lower temperature than the conventional Pt/CeO2 catalyst, as well to the increased metal-support interaction obtained.

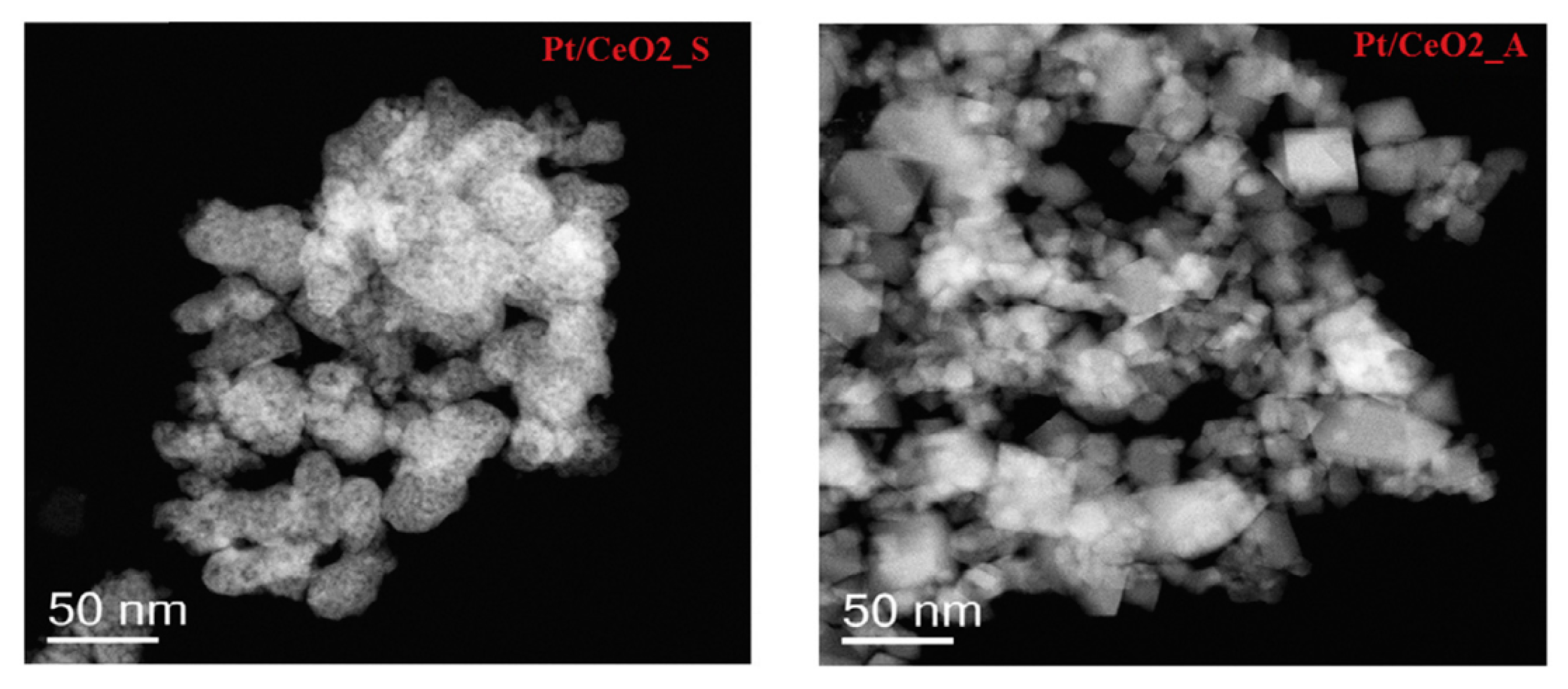

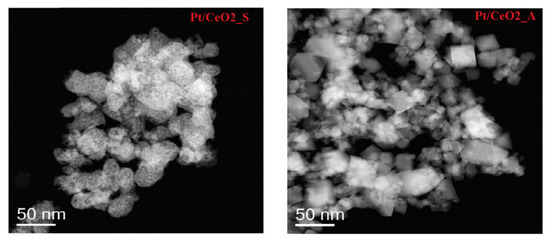

Palma et al. [25] investigated the WGS activity of a platinum-based catalyst supported on nanocrystalline ceria (PtCeSAS), prepared through the CO2 supercritical antisolvent process (SAS) using cerium acetylacetonate (Ce(acac)3) as precursor. The PtCeSAS catalyst showed higher CO conversion than the PtCeComm catalyst, prepared by impregnation of commercial ceria, in all the investigated temperature range. The better performance of PtCeSAS was ascribed to the higher specific surface area and to the smaller crystallite size, confirming the beneficial role of the SAS process. In further studies, the superior activity of platinum-based catalysts supported on nano-ceria prepared by the SAS process (Pt/CeO2_S), with respect the platinum-based catalysts supported on commercial nanoceria (Pt/CeO2_A), was attributed to the higher reducibility of the Pt/CeO2_S catalyst compared to Pt/CeO2_A [26]. The Raman spectra and TEM (transmission electron microscopy) images (Figure 2) demonstrated a much higher presence of the oxygen vacancies in the CeO2_S support, suggesting high distortions of the lattice and consequently, higher oxygen storage capacity, directly involved in the reaction mechanism.

Figure 2.

TEM images of Pt/CeO2_S and Pt/CeO2_A samples, reproduced from [26], with permission from Elsevier, 2018.

Potdar et al. [27] developed a nano-sized Pt/CeO2 catalyst, in which the support was obtained by a precipitation/digestion technique, using different digestion times (2, 4, 8 h). The 1wt%Pt/CeO2 catalyst, obtained by depositing Pt on the 4 h digested-ceria, approached CO equilibrium conversion at the reaction temperature of 320 °C and showed in general higher conversion values than the catalyst obtained with the ceria without the digestion phase in the whole temperature range. This result highlighted the beneficial effect of the digestion phase, controlling both the BET (Brunauer–Emmett–Teller) surface area of the pre-calcined CeO2 support and the activity of the same Pt/CeO2 catalyst. Roh et al. [28] studied, in time-on stream tests, the catalyst obtained with 4 h digested-ceria, showing a slightly decrease of the CO conversion during the reaction time. The deactivation was ascribed to the Pt sintering and to the carbonate species formation, which blocked the active sites. The high activity and stability of this catalyst was attributed to the weakening of the superficial Ce-O bond by the nano-sized Pt species, thus releasing reactive and available oxygen for the oxidation of CO to CO2, with a simultaneous creation of oxygen vacancies on CeO2 supports re-filled by H2O.

Im et al. [29] compared nanorod and particle shape CeO2 as a support of platinum-based catalysts. The supports were synthesized through hydrothermal process (for nanorod support) and through precipitation method (for particle shape support). Three different reaction times (12, 48, and 96 h) for hydrothermal preparation ceria nanorods were applied, obtaining some differences in physical characteristics, such as aspect ratio, BET surface area, pore diameter and pore volume. The Pt/CeO2 catalyst, obtained by loading the ceria, synthesized with 12 h of hydrothermal process time, showed the highest catalytic activity, due to the high concentration of Ce3+ and to the strong interaction between Pt and Ce. Furthermore, the reduced pores size hindered to internal diffusion, with a consequent negative effect on the catalytic activity.

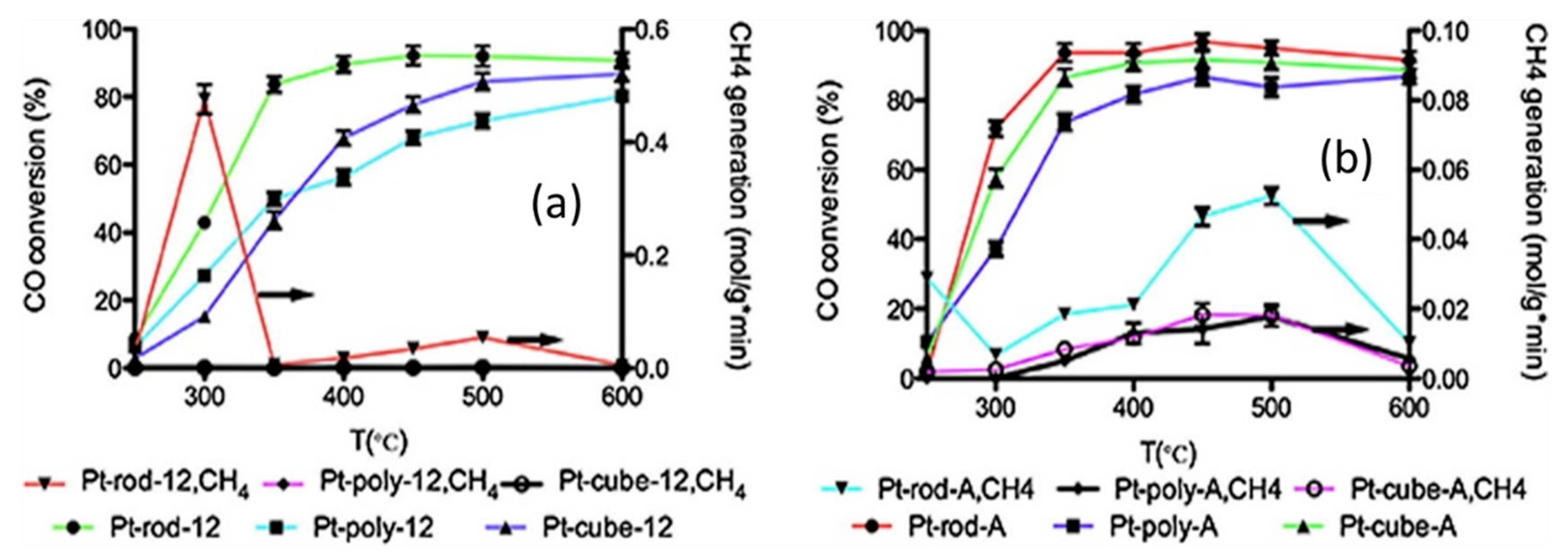

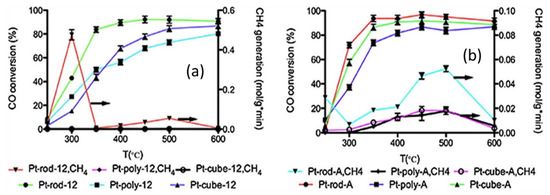

Mei et al. [30] investigated nanometric ceria with different shapes (rod, cube, polyhedron), to evaluate the effect of preparation method and a sodium cyanide (NaCN) leaching on the catalytic activity. Platinum loading was performed in three different ways: deposition/precipitation method with (NH4)2CO3, deposition/precipitation method with NH4OH and impregnation method. The results demonstrated that the catalyst obtained by loading the ceria nanorod had the highest CO conversion (Figure 3) when the preparation method was deposition/precipitation with NH4OH or impregnation, while in the case of the catalyst obtained by loading the polyhedron ceria, the highest CO conversion was obtained when the preparation method was deposition/precipitation with (NH4)2CO3. The characterization results suggested a higher Pt dispersion and stabilization on ceria nanorods than on the other kind of support, probably due to a better anchoring of the fine Pt clusters. The leaching with NaCN of the catalysts prepared by impregnation method resulted in the increase of the CO conversions at low temperature, due to the strengthening of the Pt-ceria interaction, with the rod- ceria based catalyst showing the highest catalytic activity.

Figure 3.

CO conversion of the catalysts prepared by (a) impregnation method and (b) (NH4)2CO3 deposition–precipitation (DP) method; reaction conditions: GHSV = 460,000 h−1; feeding = 24.7 vol.% CO, 15.91 vol.% N2, 59.37 vol.% H2O, adapted from [30], with permission from publisher Elsevier, 2015.

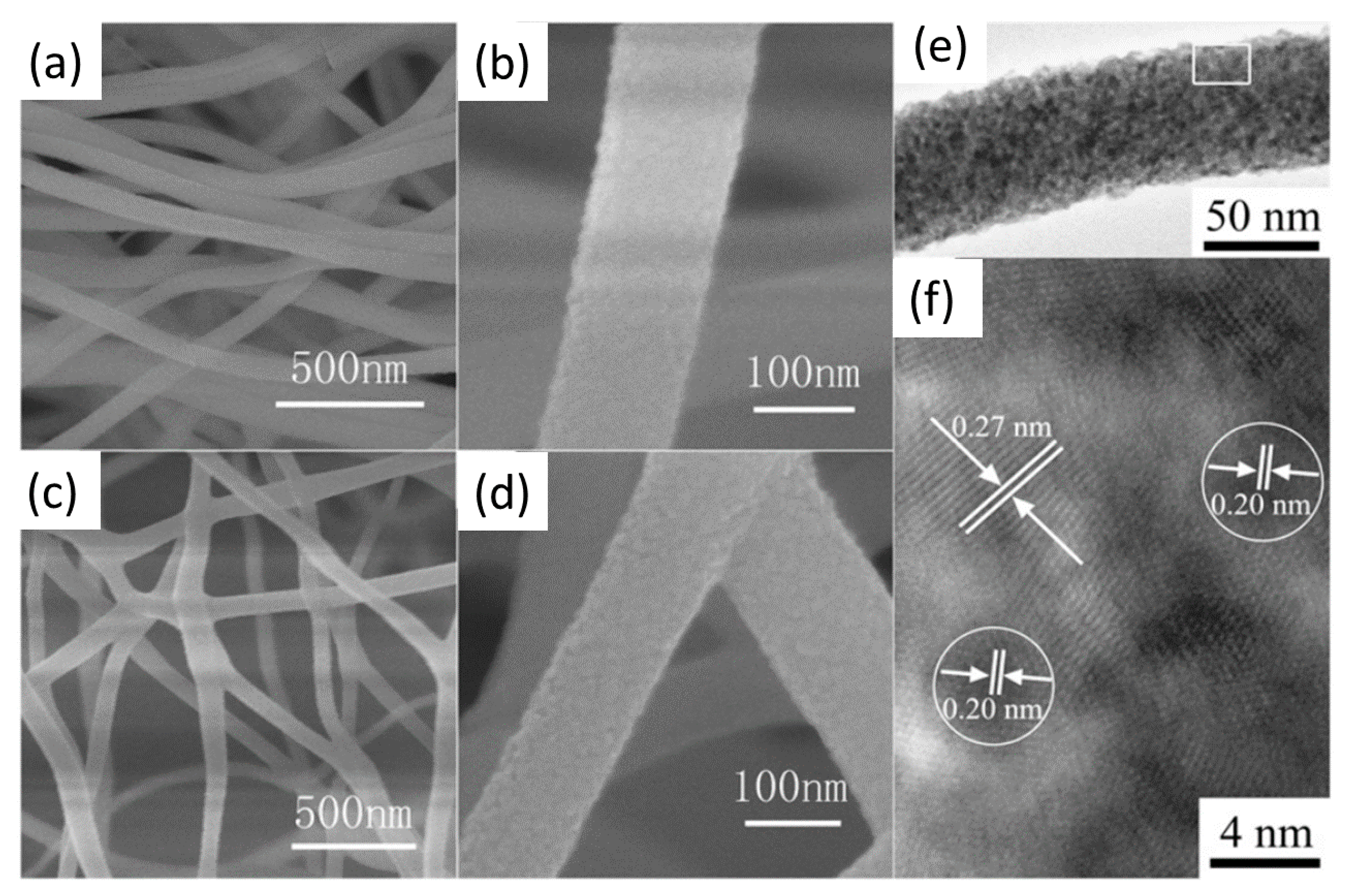

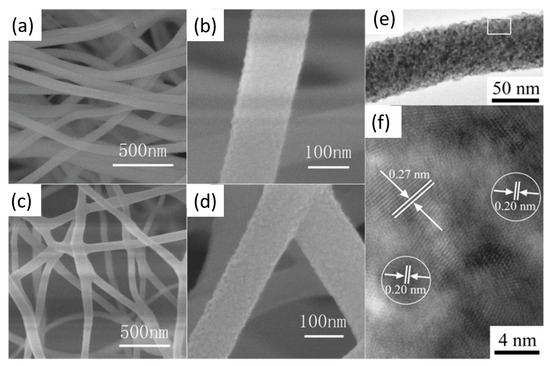

Tang et al. [31] investigated the use of Pt/CeO2 nanofibers, with a diameter of 80–120 nm, obtained by electrospinning method; after calcining the nanofibers at 400 °C, 5–10 nm particles were obtained (Figure 4). The activity of the Pt/CeO2 nanofiber catalyst was compared with that of CeO2 nanofibers, with that of Pt/CeO2 nanofiber prepared without the use of electrospinning and with that of Pt/CeO2 powder. The results showed superior catalytic activity of the Pt-CeO2 nanofiber at low temperatures.

Figure 4.

SEM (a–d) and HR-TEM images (e,f) of CeO2 (a,b) and Pt/CeO2 (c–f) nanofibers, adapted from [31], with permission from Elsevier, 2012.

2.1.2. Effect of the Preparation Method of the Ceria-Based Solid Solutions and Mixed Oxide Support

Jeong et al. [32] carried out a comparative study on nano-sized Pt/Ce0.8Zr0.2O2 and Pt/Ce0.2Zr0.8O2 catalysts to evaluate the effect of ceria cubic structure and zirconia tetragonal structure. The nano-sized supports were prepared by one-step co-precipitation/digestion method, while platinum was loaded by incipient wetness impregnation method. Higher CO conversion value was obtained with the Pt/Ce0.8Zr0.2O2 catalyst, due to higher Pt dispersion, easier reducibility and higher OSC (oxygen storage capacity) of the cubic Ce0.8Zr0.2O2 support. Palma et al. [33] compared the performance of platinum-based catalysts supported on commercial CeO2 and CeO2/ZrO2 and on a prepared CeO2/γ-Al2O3 oxide (14% w/w of Ce). The Pt/CeO2/ZrO2 catalyst showed better activity and selectivity than the other catalysts for all the investigated temperatures; the stability test showed a deactivation in the first 40 h of reaction, attributed to sintering phenomena, and a stable trend in the further 40 h of reaction.

Castano et al. [34] compared the catalytic behavior of gold and platinum-based catalysts supported on commercial γ-alumina, CeO2/Al2O3 and Ce0.8Fe0.2/Al2O3 prepared by incipient wetness impregnation. The results showed a stronger influence of the support nature in the Au-based catalysts than in the Pt ones; the authors ascribed this effect to the water dissociation, which might take place only on the support for Au catalysts, while it can occur both on the support and on the metal particle in the case of Pt catalysts.

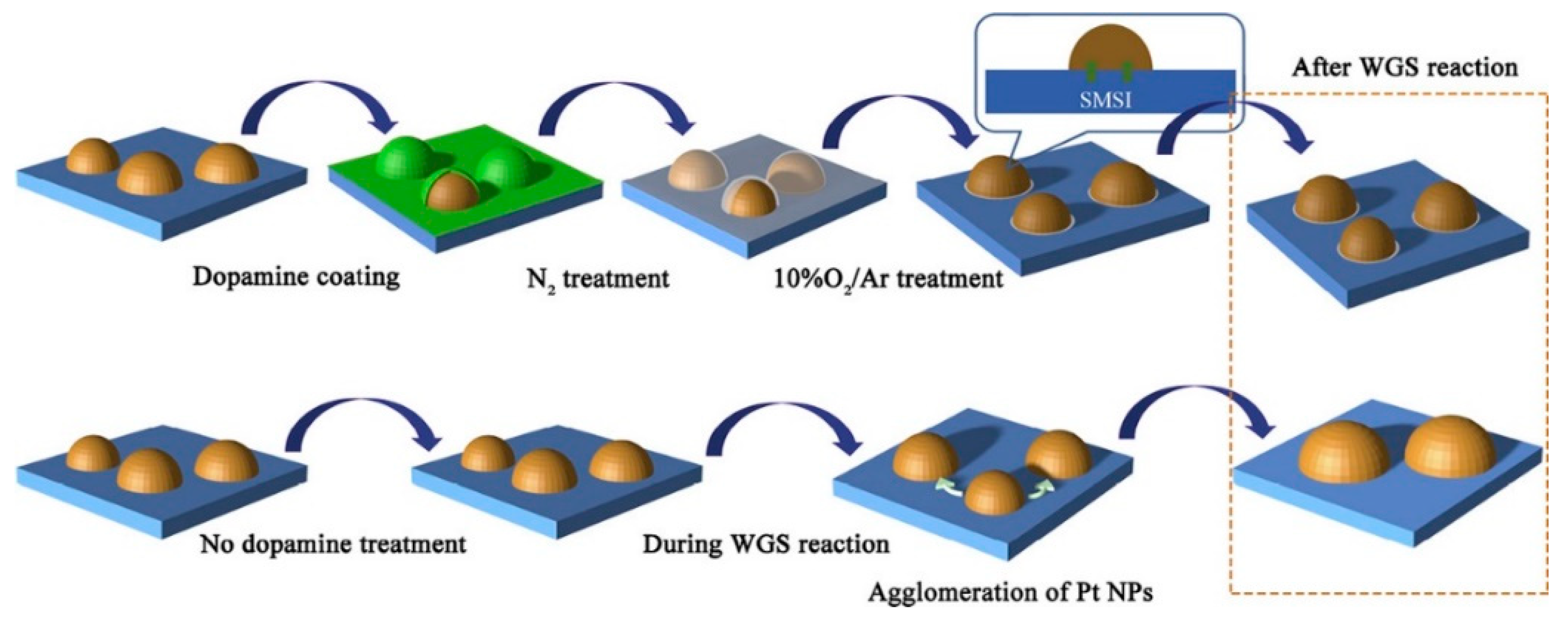

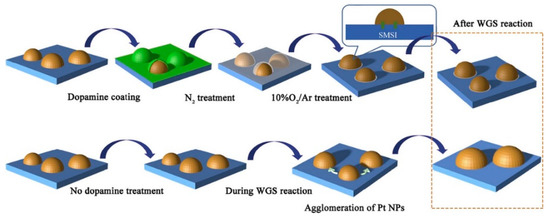

Zhang et al. [35] investigated the effect of a dopamine treatment on the catalyst preparation. The support was obtained by wet impregnation while the Pt/Ce0.4Ti0.6O2 catalyst was immersed in a dopamine solution, then heated at 700 °C in N2 for 2 h, and finally calcined at 500 °C for further 2 h (Figure 5). The activity tests were carried out on both the treated catalyst and the untreated one, showing that below 250 and above 350 °C the CO conversion values were almost similar, while in this temperature range, the treated catalyst showed better catalytic activity. The stability tests evidenced that the untreated catalyst deactivated during 12 h of reaction, while the treated catalyst did not show any deactivation, due to its strong resistance to Pt nanoparticles sintering, also due to the thermal treatment in N2 at 700 °C, which leaded to a Pt nanoparticles structure re-arrangement.

Figure 5.

Schematic representation for the synthesis of doped and undoped of platinum-based catalysts supported on ceria-titania, reproduced from [35], with permission from Elsevier, 2019.

Wan et al. [36] compared the activity of a core-shell Pt/CeO2 nanotube catalyst encapsulated in porous SiO2 (Pt/CeO2 nanotube@ SiO2), with a Pt/CeO2 catalyst, obtained by loading commercial ceria, in time on stream tests. The CeO2 nanotubes were synthesized by hydrothermal method, the platinum was loaded by deposition method, while the encapsulation was realized by using a modified Stöber method [37]. The Pt/CeO2 nanotube@ SiO2 catalyst showed higher activity than the other catalysts due to the high surface area, which increases the contact interface between the metal nanoparticles and transition-metal oxide supports, moreover after the aging time a serious deactivation of the not SiO2 encapsulated catalysts occurred. This result highlighted the ability of SiO2 encapsulation to prevent the Pt nanoparticle sintering. Roh et al. [38] compared the activity of Pt-based catalysts, prepared by incipient wetness impregnation of CeO2 and ZrO2 supports obtained by precipitation method, MgO prepared by calcination of magnesium nitrate at 500 °C, and commercial Al2O3 and MgO-Al2O3 (MgO = 30 wt%). The results evidenced the dependency of the catalytic activity from the catalyst reduction property and the platinum dispersion; the Pt/CeO2 catalyst showed the highest CO conversion and hydrogen selectivity in the whole investigated temperature range, due to the better reducibility of Pt/CeO2 and, above all, to the higher oxygen storage capacity of CeO2.

2.1.3. Effect of Preparation Method of Supports Different from Ceria

Yati et al. [39] compared the WGS activity of Pt@Al2O3 nanorod catalyst, obtained by NaBH4 reduction of trimethyl(tetra-decyl) ammonium bromide (TTAB)–stabilized Pt NPs precursor solution, on polymerized alumina, with that of Pt/Al2O3-A and Pt/Al2O3-S catalysts, obtained by impregnation aerogel alumina and sol-gel alumina respectively, with the TTAB-stabilized solution. The Pt@Al2O3 catalyst showed higher CO conversion than the other ones in all the studied conditions. The time on stream tests highlighted the higher stability of Pt@Al2O3 catalyst compared to the other catalysts, which showed a much faster deactivation due to the sintering phenomena. The TEM images of Pt@Al2O3 suggested a stabilizing effect of the tiny alumina nanorods which surrounded the Pt nanoparticles, producing an unusually larger metal-support interface compared to Pt supported on the bulk alumina surface.

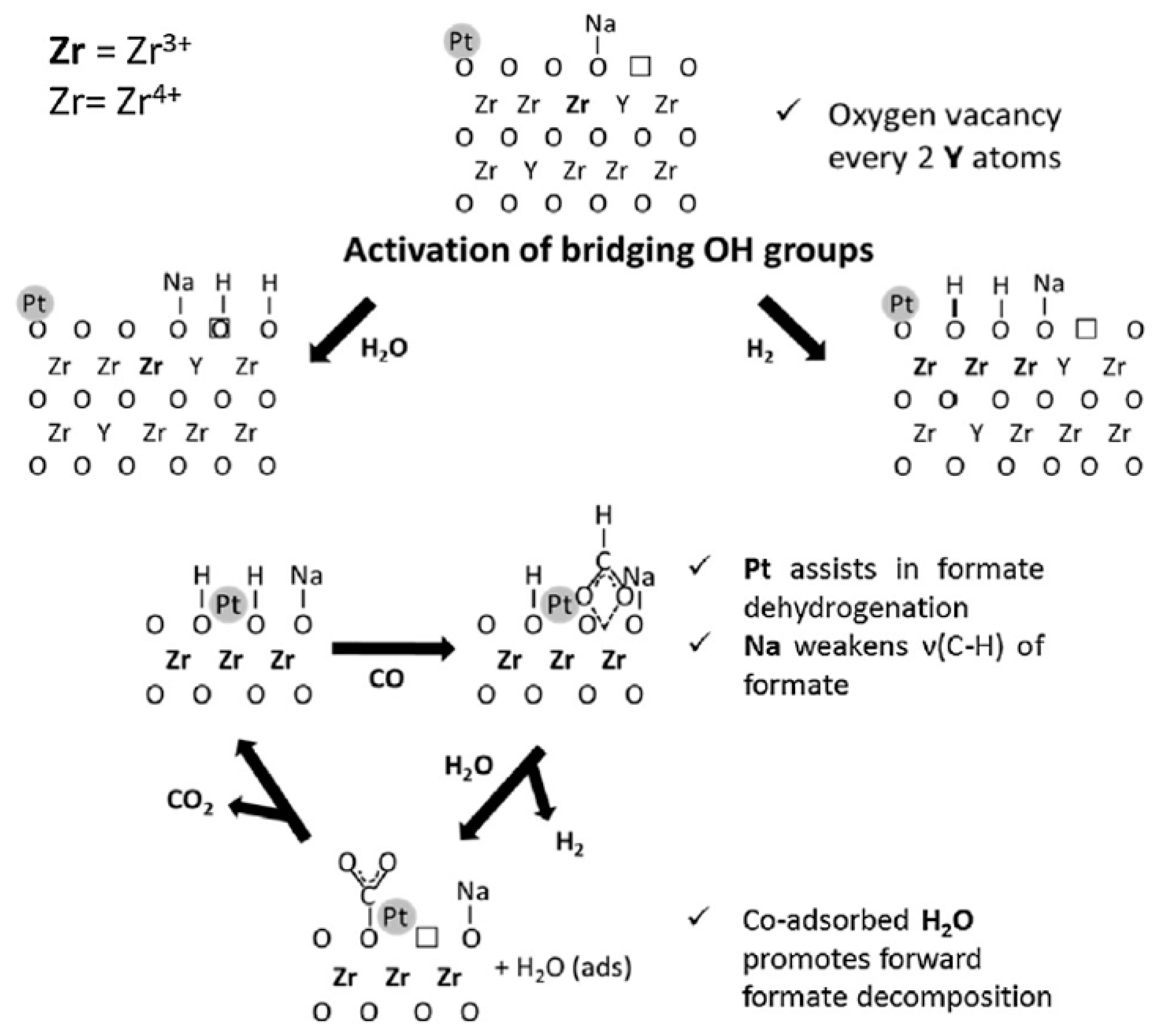

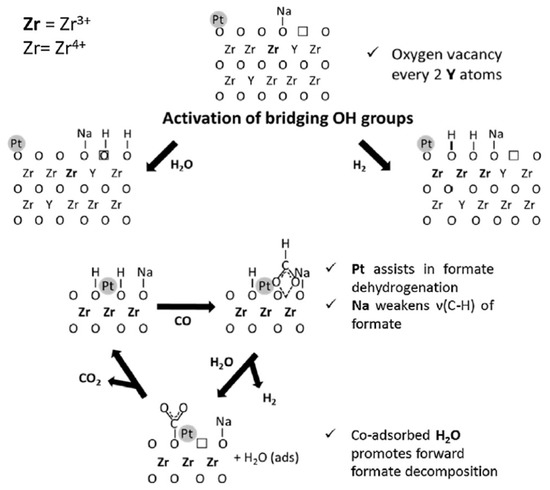

Subramanian et al. [40] investigated the use of nano-sized Pt/ZnO catalyst in the WGS reaction, by using of two different ZnO support, spherical (ZRT) and rod type (Z70), obtained by precipitation method at ambient temperature and 70 °C respectively. The ZRT type catalysts showed higher TOF and reaction rate; the best performance was attributed to a better interfacial contact between Pt and ZnO. Martinelli et al. [41] investigated the effect of yttrium in 0.5wt%Pt/Zr(1−x)Y(x)Oδ (x = 0.1, 0.25, 0.5, 0.75, 0.9) catalysts for the LTS. The supports were prepared by homogeneous precipitation of zirconia and yttrium nitrate using sodium hydroxide as the precipitating agent. The catalytic activity of the mixed oxide-based catalyst was compared to those of 0.5wt%Pt/ZrO2 and 0.5wt%Pt/Y2O3.

The yttria supported Pt catalyst showed the worst performance, while the best performance was obtained with 0.5%Pt/Zr0.9Y0.1O1.95 catalyst, which had the higher concentration of surface defects, as confirmed by DRIFT of adsorbed CO, and a higher surface formates mobility, as suggested by the formates decomposition experiments. The presence of yttrium deformed the zirconia lattice, improving the oxygen mobility, the high number of defects in the crystal structures of the mixed oxide system increased the amount of bridging OH groups or oxygen vacancy sites on the surface of the support, thus increasing the active sites for associative or redox reaction mechanisms.

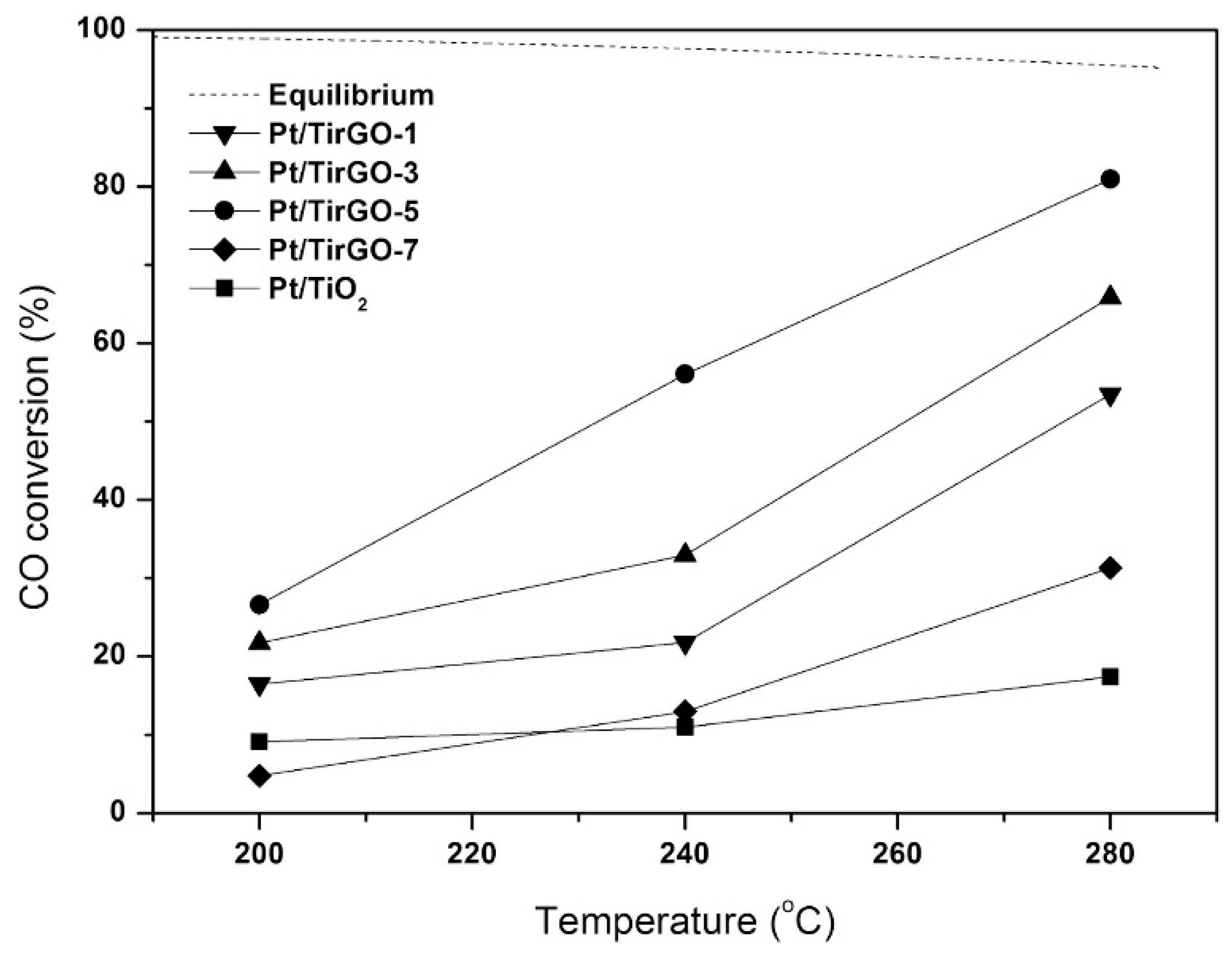

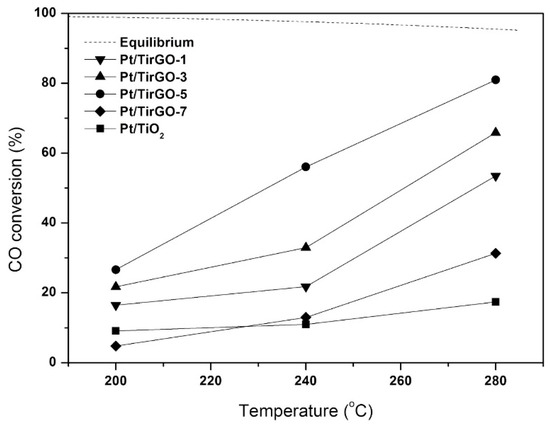

Kwon et al. [42] investigated the use of 1wt%Pt/TiO2/PRGO catalysts (PRGO = partially reduced graphite oxide), with different TiO2 content. The Pt/TirGO-n catalysts were prepared by adding the appropriate amount of Ti(OnBu)4 (n = 1, 3, 5, 7 mL) to PRGO followed by impregnation with the platinum precursor, moreover, for comparison, Pt/TiO2 was also prepared without adding PRGO. The activity tests results demonstrated that the incorporation of PRGO in the TiO2 support improved the catalytic activity; moreover, the best catalytic activity was provided by Pt/TirGO-5 (Figure 6). The functional groups on the PRGO surface behaved as anchors, strongly binding the titanium ions; an optimal TiO2/PRGO ratio induced a uniform dispersion of nanosized TiO2 on the PRGO surface, by balancing the number of functional groups, moreover, it modulated the number of surface PRGO defects, maximizing the reactivity of the functional groups with the interacting TiO2 precursor.

Figure 6.

CO conversions in water gas shift (WGS) reaction with Pt/TirGO catalysts and Pt/TiO2 (S/C ratio = 3.3, GHSV = 47,700 h−1), reproduced from [42], with permission from Elsevier, 2017.

2.1.4. Commercial Supports

Franchini et al. [43] studied the influence of zirconia polymorphism in Pt/ZrO2 catalyst for the WGS reaction, by using monoclinic zirconia (m-ZrO2) and tetragonal zirconia (t-ZrO2). The activity tests highlighted the higher performance, in terms of CO conversion, of the Pt/m-ZrO2 catalyst, due to the higher concentration of coordinatively unsaturated sites on the monoclinic structure which allowed a more extensive CO adsorption on the support surface. In addition, the catalysts deactivation was also investigated through the analysis of metal dispersion after the WGS reaction evaluating the cyclohexane dehydrogenation rate. The results showed a gradual drop in platinum dispersion for both catalysts, with a stronger reduction in the Pt/m-ZrO2 catalyst, due to sintering phenomena.

2.1.5. Conclusions

Summarizing, the supports play a crucial role in regulating the catalytic activity; the particle size and the porosimetric characteristics of the support can modulate the dispersion of the active phases, furthermore the interactions between active phases and support can modify the electronic characteristics of the catalytic systems, regulating both the activity and the selectivity. The platinum-based catalysts supported on reducible oxides, such as ceria and ceria/zirconia, certainly represent a significant example, where the redox properties of the supports can tune the catalytic activity and determining the reaction mechanism. The use of specific shapes such as nanorods and nanofibers can provide better performance, in preventing the particle sintering and enhancing the catalytic activity.

Table 1.

Selected catalysts per article reported in the Section 2.1: Monometallic Catalysts: the supports.

Table 1.

Selected catalysts per article reported in the Section 2.1: Monometallic Catalysts: the supports.

| Selected Catalyst (Particle/Crystallite Size) | Preparation Procedure | Operative Condition WGS | CO Conversion (XCO) (Temperature) | Ref. |

|---|---|---|---|---|

| 1wt%Pt/CeO2 (12 nm) | Pt loading by wet impregnation; CeO2 by microwave-assisted hydrothermal synthesis | WHSV = 40,000 mL·g−1·h−1; H2O/CO = 6 | XCO ≈ 97% (T = 360 °C) | [23] |

| 1wt%Pt/CeO2 (not specified) | Wet impregnation + Ar plasma treatment | WHSV = 40,000 mL·g−1·h−1; CO/H2O = 6 | XCO ≈ 97% (T = 280 °C) | [24] |

| 1wt%Pt/CeO2 (14.0 nm) | Pt loading by wet impregnation; CeO2 by supercritical antisolvent process | GHSV = 5000 h−1; H2O/CO = 3 | XCO ≈ 99% (T = 287 °C) | [25] |

| 1wt%Pt/CeO2 (5.8 nm) | Pt loading by wet impregnation; CeO2 by supercritical antisolvent process | WHSV = 1.13 gCO·gcat−1·h−1; H2O/CO = 3 | XCO ≈ 98% (T = 280 °C) | [26] |

| 1wt%Pt/CeO2 (7.9 nm) | Incipient wetness impregnation | GHSV = 45,625 h−1; H2O/(CH4 + CO + CO2) = 2 | XCO ≈ 87% (T = 320 °C) | [27] |

| 1wt%Pt/CeO2 (1.4 nm) | Incipient wetness impregnation | GHSV = 45,625 h−1; H2O/(CH4 + CO + CO2) = 2 | XCO ≈ 82% (T = 320 °C) | [28] |

| 1wt%Pt/CeO2 nanorods (1.6 nm) | Pt loading by incipient wetness impregnation; CeO2 by hydrothermal process for 12 h | GHSV = 95,541 h−1; H2O/(CH4 + CO + CO2) = 2 | XCO ≈ 77% (T = 360 °C) | [29] |

| 3wt%Pt/CeO2-nanorod (<2 nm) | Pt by impregnation method | GHSV = 4.6 × 105 h−1; H2O/CO = 2.4 | XCO ≈ 92% (T = 600 °C) | [30] |

| 1wt%Pt/CeO2 nanofibers (4.5 nm) (dnanofibers = 80–120 nm) | Electrospinning technology | WHSV = 60,000 mL·gcat−1·h−1; H2O/CO = 5.3 | XCO ≈ 98% (T = 350 °C) | [31] |

| 1wt% Pt/Ce0.8Zr0.2O2 (1.69 nm) | Incipient wetness impregnation | GHSV = 45,515 h−1; H2O/(CH4 + CO + CO2) = 2 | XCO ≈ 86% (T = 320 °C) | [32] |

| 1Wt%Pt/CeO2/ZrO2 (7.22 nm) | Wet impregnation | GHSV = 5000 h−1; H2O/CO = 5 | Equilibrium CO conversion at 200 °C | [33] |

| 2wt%Pt/Ce0.8Fe0.2/Al2O3 (2.2 nm) | Wet impregnation | GHSV = 4000 h−1; H2O/CO = 6.9 | Equilibrium CO conversion at 280 °C | [34] |

| 1.63wt%Pt/Ce0.4Ti0.6O2 (7.25 nm) | Wet impregnation | GHSV = 3600 h−1; H2O/(CO + CO2) = 4.8 | XCO ≈ 91% (T = 400 °C) | [35] |

| 0.9wt%Pt/CeO2@SiO2-nanotube (3.1 nm) | CeO2 by hydrothermal synthesis method SiO2 shell by modified Stober method | WHSV = 36,000 mL·gcat−1·h−1; H2O/CO = 3 | XCO ≈ 30% (T = 250 °C) | [36] |

| 1wt%Pt/CeO2 (3 nm) | Incipient wetness impregnation | GHSV = 45,515 h−1; H2O/(CH4 + CO + CO2) = 2 | XCO ≈ 88% (T = 320 °C) | [38] |

| 1wt%Pt@Al2O3-nanorods (10.4 nm) | Pt loading by NaBH4 reduction Al2O3 by polymerization | GHSV = 22,500 h−1; H2O/CO = 2 | XCO ≈ 96% (T = 450 °C) | [39] |

| 1Wt%Pt/sZnOspherical morphology (1.5 nm) | Incipient wetness impregnation | GHSV = 9583 h−1; H2O/(CH4 + CO + CO2) = 2 | XCO ≈ 92% (T = 240 °C) | [40] |

| 0.5wt%Pt/Zr0.9Y0.1O1.95 (0.5–2 nm) | Incipient wetness impregnation | GHSV = 120,220 h−1; H2O/CO = 8.7 | XCO ≈ 74% (T = 300 °C) | [41] |

| 1wt%Pt/TiO2/PRGO-5 (11.3 nm) | Incipient wetness impregnation | GHSV = 47,770 h−1; H2O/(CH4 + CO + CO2) = 3.3 | XCO ≈ 81% (T = 280 °C) | [42] |

| 1wt%Pt/ZrO2-monoclinic (10.1 nm) | Incipient wetness impregnation | WHSV = 43,200 mL·gcat−1·h−1; H2O/(CO + CO2) = 3.2 | XCO ≈ 65% (T = 300 °C) | [43] |

2.2. Monometallic Catalysts: The Active Phase

This section is devoted to the Pt-based monometallic catalysts for the WGS reaction, focusing on the effect of the active phase. The preparation method is reviewed in Section 2.2.1; the effect of the platinum loading is reviewed in Section 2.2.2; the comparative studies between platinum and rhodium are reviewed in Section 2.2.3; finally a brief conclusion is also provided. At the end of the section Table 2 reports the performance of one selected catalyst per article.

2.2.1. Effect of the Preparation Method

Jain et al. [44] investigated the use of reactive spray deposition technology (RSDT) in the preparation of nano Pt/CeO2 catalysts. The catalytic activity was compared to those reported in literature for Pt/CeO2 catalysts prepared with conventional processes (sol-gel, co-precipitation, and incipient wetness impregnation), under the same operating conditions. The results highlighted the superior activity of the catalyst prepared by RSDT, due to the uniform distribution of Pt nanoparticles on the ceria surface and to the non-agglomeration between the particles. Lu et al. [45] investigated the effect of using a photochemical method, through UV irradiation in the range 200–400 nm generated by a 500 W quartz mercury vapor arc lamp, in preparing three catalysts. The Pta/CeO2 catalyst was synthesized by irradiation of the precursor suspension, the Ptb/CeO2 was obtained by adding poly(vinylpyrrolidone) to the precursor suspension, while the Ptc/CeO2 was obtained by adding poly(vinylpyrrolidone) and 4-benzyolbenzoic to the precursor suspension. The latter catalyst showed both the best catalytic activity, attributable to the smaller particle Pt size (1.7 nm) and to the uniform distribution on the surface of the porous CeO2 nanofibers, and the best stability (no notable deactivation over 12 h of reaction).

Rajesh et al. [46] investigated the effect of the incorporation of platinum, in cationic form, into the stable perovskite lattice BaCeO3. Three types of catalysts were prepared, of general formula BaCe1−xPtxO3−δ, (x = 2, 4 and 6 mol%) by the citrate-gel method. The catalytic activity and the evolution of active species were studied in two reaction cycles, discovering that the catalytic activities in the second cycle were much higher than those in the first cycle; the authors attributed this behavior to the enrichment of the cationic platinum on the surface, since it was observed that the overall Pt surface concentration increased after the first cycle, with a prevalence of Pt(IV), and after the second cycle, the amount of Pt(II) species on the surface increases at the expense of Pt(IV).

2.2.2. Effect of the Platinum Loading

Tiwari et al. [47] studied the effect of loading and particles size in platinum-based catalysts supported on nanocrystalline ceria. Three catalysts, Xwt%Pt/CeO2 (X = 0.9, 1.9, 4.7), were prepared by hydrothermal method, with Pt particle sizes equal to 0.8, 3.7, 7.8 nm respectively. The stability of the catalyst was strongly dependent from the platinum loading and reaction temperature; the 0.9wt%Pt/CeO2 catalyst was stable during 30 h of reaction at 140 °C, on the contrary the CO conversion decreased with the time for 1.9wt%Pt-CeO2 and 4.7wt%Pt-CeO2 at the same reaction conditions. On the other hand, the 0.9wt%Pt-CeO2 catalyst showed a decrease in the CO conversion with time at 180 °C, that the authors related to the Pt2+ reduction to metallic Pt, which occurred at 151 °C. The XPS studies, in fact, revealed that the fresh catalyst contained Pt2+ as the active specie for the WGS reaction.

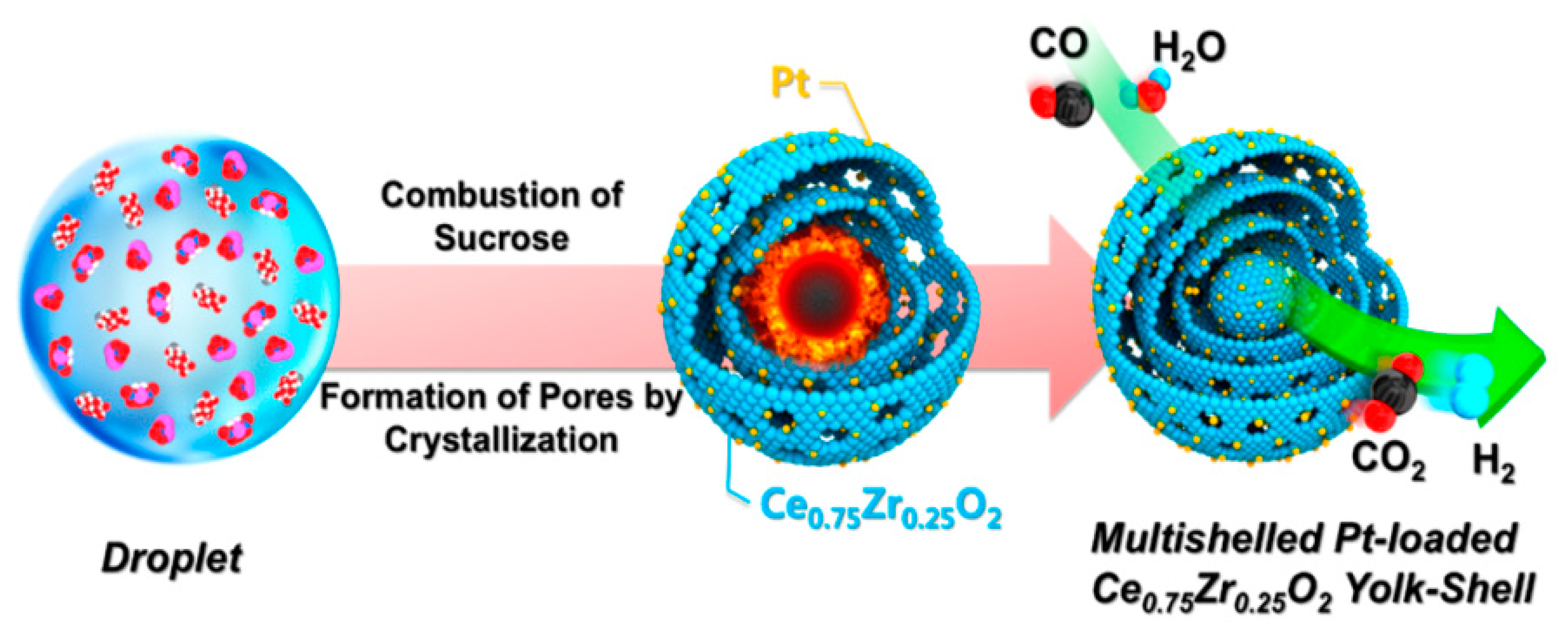

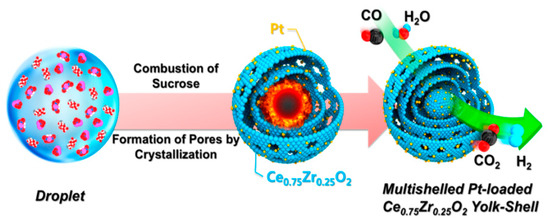

Shim et al. [48] investigated Pt-loaded Ce0.75Zr0.25O2 yolk−shell microspheres (Figure 7). The catalysts were prepared by a spray pyrolysis method with different platinum loadings (0.5 wt%, 2 wt% and 4 wt%). The 2wt%Pt/Ce0.75Zr0.25O2 catalyst was the most active in WGS reaction, a further increase of the Pt loading was detrimental. The time on stream tests, performed at 320 °C for in a 20 h of reaction, highlighted the excellent stability of all of the yolk-shell catalysts, demonstrating the ability of the Ce0.75Zr0.25O2 yolk-shell-structure to prevent the Pt sintering, thereby maintaining a high catalyst activity.

Figure 7.

Schematic diagram of the formation mechanism of Pt-doped Ce0.75Zr0.25O2 powders with yolk−shell structure, reproduced from [48], with permission from American Chemical Society, 2016.

Cornaglia et al. [49] studied the platinum loading on Xwt%Pt/La2O3·SiO2 (X = 0.02, 0.1, 0.2, 0.6, 1.2%). All the Pt catalysts showed good stability, but the 0.6 and 0.1 wt% Pt-based formulations showed superior stability even under severe conditions of start-up and shut-down cycles. The 1wt%Pt/La2O3·SiO2 catalyst showed the highest activity per gram of platinum, due to the complete reduction of surface metallic platinum; in fact, for higher loadings, the surface platinum was incompletely reduced at the same temperature, negatively effecting the catalytic activity. The 0.1wt%Pt/La2O3·SiO2 catalyst was also tested as a catalyst in a Pd-Ag membrane reactor (Pd/Ag ratio 77/23), obtaining a CO conversion higher than those of equilibrium obtainable in a conventional reactor. On the contrary, an increase in the GHSV significantly dropped the hydrogen recovery, as the reactants residence time in the reactor decreased.

The effect of the platinum loading on Pt(x)@TiO2 (x = 1.0, 1.2, 1.7, 2.2, 2.6, 2.6 nm) yolk/shell nanosphere was also investigated by Zhao et al. [50]. The yolk/shell nanostructure allowed sufficient exposure of the active sites to the reactants because of the presence of void spaces in the shell, maintaining at the same time the protective effect against the Pt nanoparticles sintering. Furthermore, the particle size had a significant influence on the catalytic activity; the Pt(1.0)@TiO2 catalyst showed the highest CO conversion values among the tested catalysts, reaching the thermodynamic equilibrium at a lower temperature than the other catalysts. The Pt(1.0)@TiO2 catalyst showed a much lower non-reactive metallic Pt fraction, confirming an increased average oxidation valence and hence more electron-deficient metal centers.

Galeano et al. [51] investigated the effect of the active metal loading in Pt encapsulated NaA zeolite. The catalysts were prepared by hydrothermal method, using two heating sources, conventional Pt(x)_NaA_CH (x = 2.2, 1.6, 0.6, 0.2 wt%) and microwave radiation (Pt(0.5)_NaA_MW). The microwave method allowed to significantly reduce the synthesis time. For comparison, a catalysts prepared by ionic exchange was also prepared (Pt(0.6)_NaA_IEx). The Pt(2.2)_NaA_CH catalyst showed the highest CO conversions at both the studied temperatures, moreover, the time on stream tests, carried out on the Pt(0.6)_NaA_CH and Pt(0.6)_NaA_MW catalysts, highlighted the excellent stability provided by the encapsulation method, which limited the sintering phenomena.

2.2.3. Comparative Studies between Pt and Rh

Roberts et al. [52] performed a study on the long-term stability tests (i.e., >600 h) on platinum and rhodium-based catalysts, supported both on titania and on ceria, using a typical reformate fuel processing stream. Both Pt-based and Rh-based catalysts were prepared by wet impregnation technique using the Chemspeed Isynth robot [53]. All the catalysts deactivated overtime, however Pt/CeO2 exhibited the best performance; the Rh/TiO2 catalyst showed a significant deactivation after 500 h of use, partially due to the increase in space velocity, the Pt/TiO2 catalyst showed very low catalytic activity, probably due to the support redox properties.

Cavusoglu et al. [54] compared the activity of Xwt%Pt/CeO2 and Ywt%Rh/CeO2 in HTS reaction, at different metal loading (Y = 3.1 and 1.9, X = 3.7 and 1.7). The catalysts were prepared by flames spray pyrolysis, for comparison a 0.74wt%Pt/CeO2 catalyst was prepared by incipient wetness impregnation method. The Pt-based catalysts showed higher activity than the Rh-based catalysts, moreover, the Pt-based flame made catalysts showed higher activity than the Pt/CeO2 catalyst prepared by impregnation. Summarizing Pt-based catalysts were more active than the Rh-based samples, moreover the latter showed methane formation starting from 300 °C.

The use of Rh/La2O3·SiO2 and Pt/La2O3·SiO2 catalysts in a membrane reactor for the WGS reaction, evaluating the influence of the main operating and design variables on the CO conversion and H2 recovery, was investigated by Cornaglia et al. [55]. The catalytic behavior was preliminary studied in a conventional fixed bed reactor, showing similar catalytic activity, however Pt/La2O3·SiO2 provided a higher hydrogen selectivity. Subsequently the activity tests were carried out at 400 °C, under atmospheric pressure, in a double tubular palladium membrane reactor. The time on stream tests highlighted the excellent stability of the catalysts, no significant deactivation occurred in 100 h of reaction. The effect of the H2O/CO ratio was also investigated employing a sweep gas flow rate, showing an increase in H2 recovery with the decrease of the H2O/CO ratio, due to the H2 partial pressure increase.

2.2.4. Conclusions

Summarizing, the catalytic activity is strongly related to the active phase loading, the best performance was reported for Pt loading ≈ 1 wt%, moreover an enhanced stability can be reached by incorporating the active phase, the best stability was reported for particle sizes < 1 nm. Finally, the comparative studies between Pt and Rh demonstrate a superior performance of the Pt-based catalysts, both in terms of CO conversion and hydrogen yield.

Table 2.

Selected catalysts per article reported in Section 2.2: Monometallic Catalysts: the Active Phase.

Table 2.

Selected catalysts per article reported in Section 2.2: Monometallic Catalysts: the Active Phase.

| Selected Catalyst (Particle/Crystallite Size) | Preparation Procedure | Operative Condition WGS | CO Conversion/Rate (XCO)/(rCO) (Temperature) | Ref. |

|---|---|---|---|---|

| 1wt%Pt/CeO2 (1.5–2 nm) | Reactive Spray Deposition Technology | GHSV = 8622 h−1; H2O/CO = 3 | Equilibrium CO (T = 350 °C) | [44] |

| 3wt%Pt/CeO2 (1.7 nm) | Pt loading by photochemical method adding PVP and 4-benzyolbenzoic acid; CeO2 by co-electrospinning | WHSV = 1.2 × 105 mL·g−1·h−1; H2O/CO = 5 | XCO ≈ 95% (T = 450 °C) | [45] |

| BaCe0.96Pt0.04O(3-δ) (<100 nm) | Citrate-gel method | GHSV = 5000 h−1; H2O/CO = 4.5 | XCO ≈ 86% (T = 400 °C) | [46] |

| 0.9wt%Pt/CeO2 (0.8 nm) | Hydrothermal method | GHSV = 5000 h−1; H2O/CO = 1 | XCO ≈ 97% (T = 140 °C) | [47] |

| 2wt%Pt/Ce0.75Zr0.25O2 (7.45 nm) | Yolk−shell microspheres formation by a spray pyrolysis process | GHSV = 18,193 h−1; H2O/(CH4 + CO + CO2) = 2 | XCO ≈ 89% (T = 320 °C) | [48] |

| 1.2wt%Pt/La2O3·SiO2 | Incipient wetness impregnation | GHSV = 2.8 × 106 h−1; H2O/CO = 3 | rCO = 350 mol·g−1·min−1 (T = 400 °C) | [49] |

| Pt@TiO2 (1.0 nm) | Yolk-shell nanospheres by a reverse micelle system | WHSV = 40,000 mL·gcat−1·h−1; H2O/CO = 5 | XCO ≈ 99%, T = 260 °C) | [50] |

| 2.2wt%Pt_NaA (not specified) | NaA zeolite by hydrothermal syntesis with conventional heating; Pt loading by encapsulation | GHSV = 6421 h−1; H2O/CO = 2 | XCO ≈ 96% (T = 400 °C) | [51] |

| 0.5wt%Pt/CeO2 (1.3 nm) | By wet impregnation | H2O/(CO + CO2) = 2.5 | XCO ≈ 45% (T = 275 °C) | [52] |

| 3.7wt% Pt/CeO2 (2.3 nm) | Flamespray pyrolisis method | WHSV = 5 × 104 mL·g−1·h−1; H2O/CO = 4 | XCO ≈ 97% (T = 250 °C) | [54] |

| 0.6wt%Pt/La2O3·SiO2 (not specified) | By Incipient wetness impregnation | WHSV = 6–24 × 103 mL·g−1·h−1; H2O/CO = 3 | XCO ≈ 95% (T = 400 °C) | [55] |

2.3. Polymetallic Catalysts and Addition of Promoters: The Active Phase

The addition of a second metal or a promoter is a widely used strategy to improve the performance of the catalysts, both in terms of catalytic activity and selectivity. In this section, the effect of the addition of promoters to the active species and to the support is reviewed, and the description is divided into three different paragraphs: Section 2.3.1 (the addition of Na, Re, Mo, V and Ni), Section 2.3.2 (comparative studies between multiple metals) and Section 2.3.3 (the addition of promoters to the support). Two tables are provided, Table 3 and Table 4, reporting the performance of one catalyst per reviewed article, moreover, at the end of the section a brief summary is also provided.

2.3.1. The Addition of Na, Re, Mo, V and Ni

Jeong et al. [56] investigated the addition of Na to Pt/CeO2 catalysts, by varying the Na amounts in the range 1–3 wt%. The best performance, in terms of catalytic activity and stability, at a temperature of 240 °C, were obtained with the 1wt%Pt-2wt%Na/CeO2 catalyst. The authors attributed this better behavior to the easier reducibility and higher oxygen storage capacity (OSC) of the catalyst.

Azzam et al. [57] investigated the influence of preparation strategies, the Pt/Re molar ratios, and the metals contents on the catalytic activity and stability of Pt–Re/TiO2 catalysts. The results indicated that the most significant effect of Re on the catalyst performance was obtained if the Re precursor was impregnated prior to the Pt precursor without intermediate drying and calcination, if a Pt/Re molar ratio of unity was used, and if a 0.5 wt% content of each metal was applied. The authors, by means of H2-TPR and in situ FTIR spectroscopy, deeply investigating the catalyst behavior, and they reported that Pt and Pt–Re catalysts exhibited identical CO vibration peaks, indicating that the Re did not interact with the Pt particles under WGS reaction conditions. However, similar experiments on reduced catalysts in the presence of CO showed that Re was partially reduced and interacted significantly with CO, thus enhancing the water activation, since the latter was able to oxidize metallic Re under WGS reaction conditions, resulting in new types of OH groups.

Ciftci et al. [58] studied the activity of Re addition to carbon-supported Pt catalysts in aqueous-phase reforming (APR) of glycerol and the WGS reaction, and the results were compared with the ones of carbon-supported alone Pt and Re. The experimental tests showed that the Re addition resulted in a higher conversion, due to the increase of the dehydration (C–O cleavage) reactions with respect to the decarbonylation (C–C cleavage) ones. This preference was attributed to the presence of acidic sites generated in the steam treated PtRe alloys.

Sener et al. [59] tested at 270 °C PtMo bimetallic catalysts supported on carbon and silica. The carbon supported catalysts, in which the Pt nanoparticles were saturated with Mo species at a Mo:Pt atomic ratio of 0.32, showed a strong promotional effect of Mo, which increased the TOF more than 2000 folds. On the contrary, the silica-supported catalysts, even if more active, showed a smaller promotional effect of Mo. This higher promoting effect in the carbon-supported catalysts was attributed to the formation of active sites for WGS at the interface between Pt atoms and Mo moieties that were possibly in an oxidized form.

The addition of Mo was also investigated by Osman et al. [60], in Pt and Cu supported on Mo2C/η-Al2O3, Mo2C/γ-Al2O3 or Mo2C catalysts. The activity tests results showed the superior activity of 4wt%Pt/Mo2C/η-Al2O3 catalyst, highlighting the synergistic effect between the two most active phases of Pt metal and Mo2C.

Kokumai et al. [61] studied the effect of vanadium addition to Pt/Al2O3 catalysts for the WGS reaction. The results showed an enhance catalyst activity, however, the increase of V content did not clearly affect the WGS activity, which might be related to the formation of polymeric VOx species interacting with alumina surface instead of new interfacial Pt-VOx sites that would favour the reaction. The in-situ characterization of the catalysts showed that metallic Pt and V3+/V4+ species were present during WGS reaction regardless of V loading.

Chein et al. [62] compared the performance of mono-(Pt) and bimetallic (Pt-Ni) catalysts supported by CeO2 and Al2O3. The results showed that the CeO2 addition to the support improved the activity of the Pt/Al2O3 catalyst only for the high S/C ratio cases and enhanced the activity of the bimetallic Pt-Ni catalyst in terms of CO conversion, H2 yield and stability.

Pt-Ni bimetallic catalysts, supported on γ-Al2O3, SiO2, TiO2, CeO2, HSA-ZrO2 and LSA-ZrO2, were investigated also by Wang et al. [63]. The results showed that the bimetallic catalyst had a higher activity than the monometallic one, due to the change in CO binding energy as result of the synergistic effect of the two metals. Moreover, the reducibility of the support had a positive effect on the catalytic activity, that was higher for the catalysts supported on reducible or partially reducible supports (CeO2, TiO2 and HSA-ZrO2) if compared with the one of the catalysts supported on non-reducible supports (γ-Al2O3, SiO2 and LSA-ZrO2). A deep investigation of the results indicated that the Pt-Ni bimetallic catalysts follow the activity trend of CeO2 > HSA-ZrO2 > TiO2∼ γ-Al2O3 > SiO2 > LSA-ZrO2, moreover, at similar CO conversion, the trend for the production of the undesirable CH4 was SiO2 > CeO2∼ γ-Al2O3 > TiO2∼ HSA-ZrO2.

2.3.2. Comparative Studies between Multiple Metals

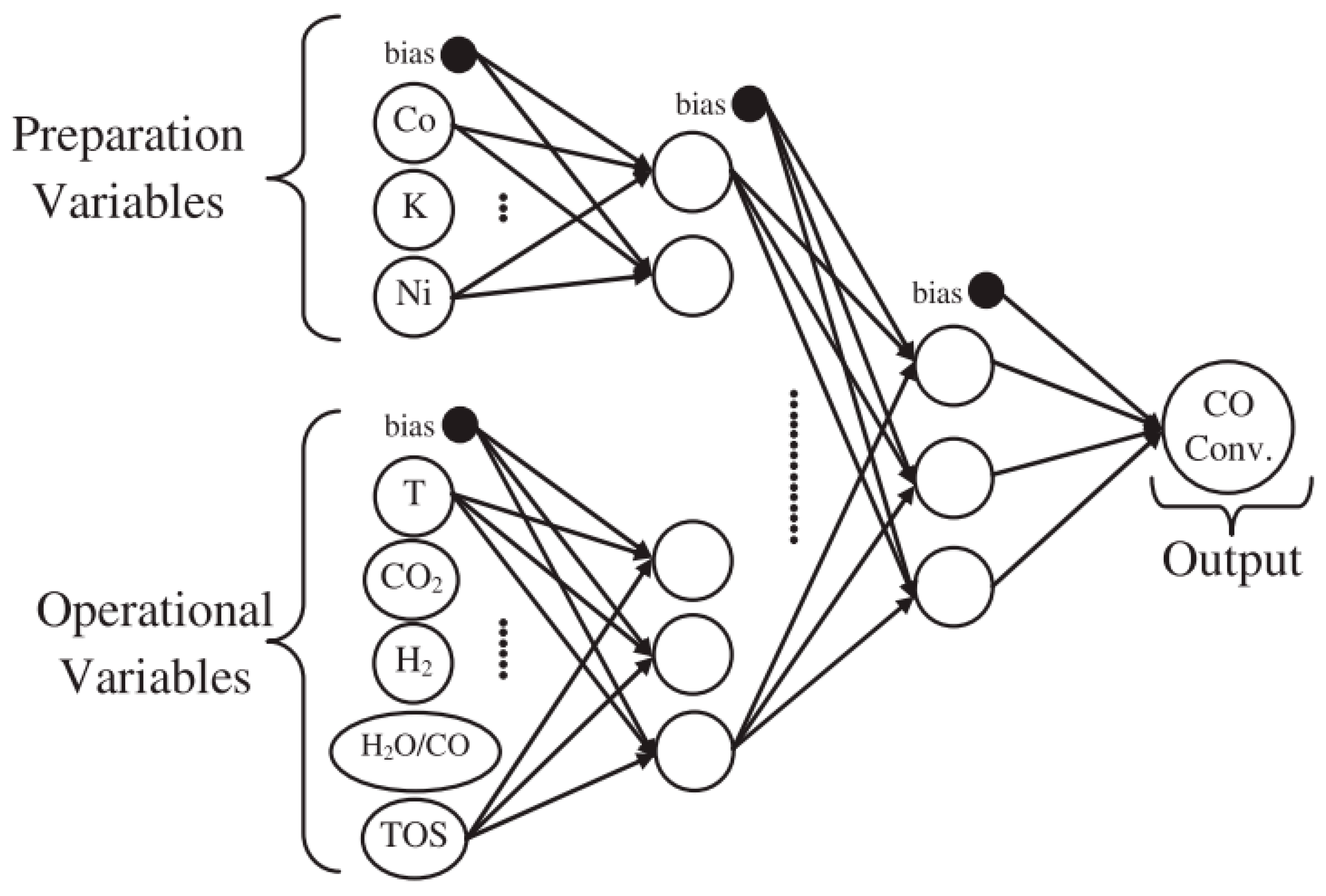

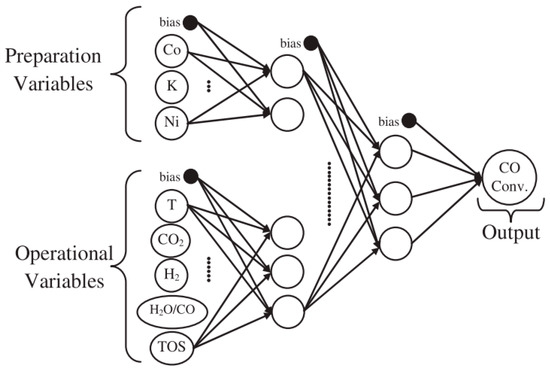

Gunay et al. [64] investigated the effects of adding a promoter (K, Co and Ni) to Pt-CeO2/Al2O3 catalyst by means of both experimental tests and computational analysis through modular neural networks (Figure 8). The catalyst without promoters (1wt%Pt-1.25wt%Ce/Al2O3) showed the best performance, when a mixture of 5% CO and 10% H2O was feed, so clearing that the promoters had no effect on the catalyst activity. On the contrary, when the feed composition was changed by adding CO2 and H2, K addition (1wt%Pt-1.25wt%K-1.25wt%Ce/Al2O3) had the effect to significantly increase the catalytic activity, if compared to the other modified catalysts and to the not modified Pt-Ce.

Figure 8.

Topology of the optimum neural network model, reproduced from [61], with permission from Elsevier, 2017.

Palma et al. [65] investigated the catalytic activity in low temperature WGS reaction of different bimetallic 1%Pt/1%M/CeZrO4 catalysts (M = Na, Mo, Sn, Cu, Zn). The results indicated that in the temperature range of 200–400 °C the 1Pt/1Sn/CeZrO4 catalyst showed the higher both CO conversion and H2-selectivity, while at lower temperatures the monometallic 1Pt/CeZrO4 catalyst showed the best performance. Further investigations were performed by studying the effect of the addition of Re, La and Rh) to PtM/CeZrO4 catalysts [66]. The results indicated that the 1Pt/1Re/CeZrO4 showed the best performance in terms of both CO conversion and H2 selectivity even at low temperatures and if compared to the 1Pt/CeZrO4 catalyst. Moreover, the effect of the sequence of impregnation of the two active metals was also evaluated, and the best performance was related to the catalyst in which was firstly loaded the rhenium.

Izquierdo et al. [67] prepared different Pt based mono and bimetallic catalysts, which were deposited into a microchannel reactor and tested in the temperature range of 300–450 °C. All the catalysts contained 25% of CeO2, the bimetallic ones contained 2.5% Pt and 2.5% of Me where Me = Ni, Co, Mo, Pd, Fe, Re, Y, Cu or Zn. The results showed that even if the tested catalysts, except the ones with Cu and Zn, reached the CO equilibrium conversion at 400 °C, all suffered of deactivation problems. Only the 2.1Pt–2.1Re catalyst showed stable activity for a duration of more than 100 h.

Rajesh et al. [68] prepared different Pt doped in the B site of LaBO3 (B = Mn, Fe, Co) perovskite catalysts, and this was found to be successful only in the case of Fe and Co and not in case of Mn, due to the sintering of Pt in the latter, so showing a distinct resistance to lattice incorporation and an intolerance to oxygen vacancies which would be created consequent to Pt substitution. Therefore, LaMn1−xPtxO3−d showed an extremely poor activity in WGS reaction. On the contrary, Pt doped Co and Fe perovskite catalysts showed a CO conversion of about 90% above 300 °C [69]. The authors attributed this enhanced catalytic activity to the multiple oxidation states (+4 and +2) of Pt in these compounds: in this way, a reduction of the B ions from the ideal state of +3 was observed for compensating the charge of Pt(IV), which was in turn found to enhance the oxygen vacancies on the surface. The ionic Pt species in tandem with oxygen vacancies capable of acting as water adsorption sites may be enhancing their WGS activity suppressing CO or CO2 hydrogenation.

Table 3.

Summary of the main catalytic results from the articles reported in Section 2.3.1 and Section 2.3.2.

Table 3.

Summary of the main catalytic results from the articles reported in Section 2.3.1 and Section 2.3.2.

| Selected Catalyst (Particle/Crystallite Size) | Preparation Procedure | Operative Condition WGS | CO Conversion/Rate (XCO)/(r) (Temperature) | Ref. |

|---|---|---|---|---|

| 1wt%Pt-2wt%Na/CeO2 (2.2 nm) | By incipient wetness impregnation | GHSV = 45,515 h−1; H2O/(CH4 +CO + CO2) = 2.0 | Equilibrium CO conversion (T = 310 °C) | [56] |

| 0.5wt%Pt–0.5wt%Re/TiO2 (not specified) | By co-impregnation | GHSV = 410,000 h−1; H2O/CO = 2.5 | XCO ≈ 90% (T = 300 °C) | [57] |

| Pt0.25-Mo0.75/C (1.27 nm) | By controlled surface reaction | WHSV = 240,000 mL·gcat−1·min−1; H2O/CO = 2 | r ≈ 10 μmol/gcat·s (T = 300 °C) | [58] |

| 4.3wt%Pt/64.6wt%Mo2C (not specified) | By wet impregnation | GHSV = 125,000 h−1 H2O/(CO + CO2) = 1.23 | XCO = 70% (T = 250 °C) | [60] |

| 4.79wt%VOx-0.49wt%Pt/Al2O3 (not specified) | By wet impregnation | WHSV = 80,000 mL·gcat−1·h−1; H2O/CO = 3 | XCO ≈ 60% (T = 450 °C) | [61] |

| 2.5wt%Pt-2.5wt%Ni/5wt%CeO2/Al2O3 (not specified) | By wetness incipient impregnation | W/FCOin = 20.37 gcat·h/molCO; H2O/CO = 5 | XCO ≈ 80% (T = 750 °C) | [62] |

| 1wt%Pt-1.25wt%K-1.25wt%CeO2/Al2O3 (not specified) | By incipient wetness co-impregnation | WHSV = 24,000 mL·gcat−1·h−1; H2O/(CO + CO2) = 0.67 | XCO ≈ 60% (T = 300 °C) | [64] |

| 1wt%Pt/1wt%Sn/CeZrO4 (9.3 nm) | By wet impregnation | GHSV = 10,000 h−1; H2O/CO = 3.75 | Equilibrium CO conversion (T = 230 °C) | [65] |

| 1wt%Pt-1wt%Re/CeZrO4 (9.4 nm) | By wet impregnation | GHSV = 10,000 h−1; H2O/CO = 3.75 | Equilibrium CO conversion (T = 200 °C) | [66] |

| 2.1wt%Pt–2.1wt%Re/25wt%CeO2/Al2O3 (1.4–5.0 nm) | By the incipient wetness impregnation | WHSV = 400,000 mL·gcat−1·h−1 H2O/(CO + CO2)= 2.2 | XCO ≈ 74% (T = 400 °C) | [67] |

| LaCo0.94Pt0.04O3-δ (75.5 nm) | By pyrolysis | GHSV = 5000 h−1; H2O/(CO + CO2) = 1.8 | XCO ≈ 90% (T = 325 °C) | [69] |

2.3.3. The Addition of Promoters to the Support

Mohamed et al. [70] investigated the effect of different loadings of Pt–Au/FSM-16 catalysts. The authors presented a non-conventional preparation technique, by synthesizing nanowire Pt–Au clusters introducing Au+ into in situ designed Pt carbonyl clusters. The Au addition provided positive effects in decreasing the platinum reduction temperatures as well as stabilizing the carbonyl clusters formed, moreover, the 2.5Au-2.5Pt/FSM16) catalyst showed higher activity than that of 2.5Pt/FSM-16.

Buitrago et al. [71] studied the performance of carbon-supported platinum catalysts promoted by ceria. The catalysts were prepared by first dispersing CeO2 over an activated carbon support at different loadings (20, 30 and 40 wt%), to obtain a high ceria surface area, and then by incorporating platinum by impregnation with three different solutions (acetonic, aqueous and ethanolic) of [Pt(NH3)4](NO3)2 to investigate the effect of the solvent in the final catalyst. The results of the activity tests were compared with the ones obtained by using Pt/CeO2 and Pt/C catalysts as references. The results showed that the best performance was obtained by the catalysts with 40 wt% CeO2 prepared by aqueous impregnation of the platinum precursor, that achieved conversions higher than 70% at 300 °C, and showed no deactivation under reaction at this temperature for 120 h.

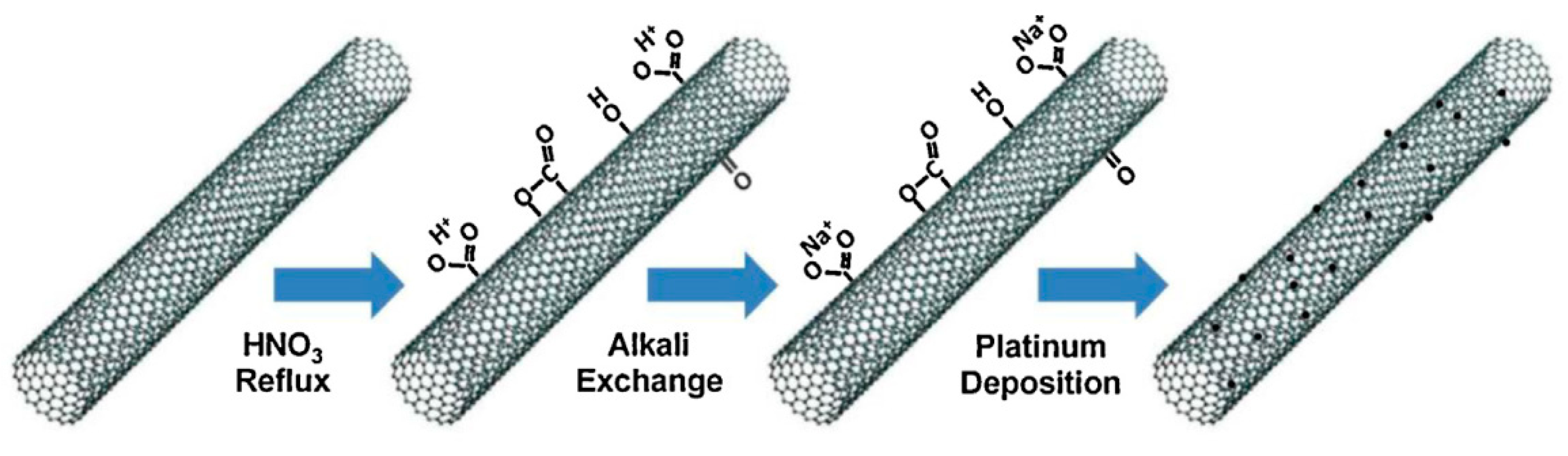

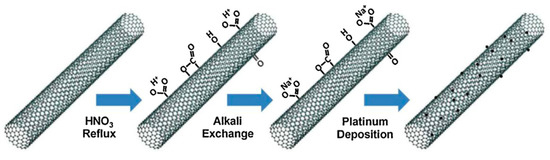

Zugic et al. [72] investigated the controlled addition of Na, through Na ion-exchange by means of nitric acid oxidation of the carbon nanotubes (so allowing the creation of anchoring sites for platinum) in the activation of multi-walled carbon nanotube-supported platinum catalysts (Pt/MWNT) for the WGS reaction (Figure 9).

Figure 9.

Schematic of the preparation of alkali-promoted Pt/MWNT catalysts, reproduced from [72], with permission from Elsevier, 2014.

The results showed that the Na addition increased the catalyst activity, by altering the surface oxygen distribution through the stabilization of an oxidized platinum state. Meira et al. [73] studied the effect of ceria addition (12 and 20 wt%) to Pt/Al2O3 catalysts. The supports were prepared by adding cerium precursor during the sol-gel synthesis of Al2O3 or by impregnation of Al2O3. The results showed that CeO2 addition increased the WGS specific reaction rates up to seven times, suggesting that the preparation method had a significant impact on the structural and surface properties of ceria, and that the participation of interfacial Pt-O-Ce sites gave a crucial contribution to the significant increases of specific reaction rate.

Mao et al. [74] prepared Pt based catalysts by using as supports LaCoO3 films deposited onto MgAl2O4 powders by atomic layer deposition (ALD). The prepared catalysts were characterized by a 0.5 nm thickness of films and exhibited a perovskite structure after redox cycling at 800 °C; in addition, the films covered the substrate uniformly, as well as the Pt on the support. The reduced forms of the LaCoO3-containing (with 3 wt% Pt), compared with conventional Pt on MgAl2O4, were highly active for the WGS reaction, while the oxidized catalysts showed much lower activities.

Brandt et al. [75] studied the activity of Pt-Re surfaces, prepared with different methods. In one case Pt and Re surfaces were prepared by annealing Re films on Pt (111) to form Pt-Re surface alloys, in another case Pt was deposited on Re/Pt (111), finally Pt was deposited on Re clusters supported on highly oriented pyrolytic graphite (HOPG) surfaces. In all cases, the turnover frequency (TOF) was higher for Pt on Re surface compared to pure Pt, while the lower TOFs for PtRe alloy surface and PtRe clusters on HOPG, compared to PtRe/TiO2 suggested a promotional effect of the support.

2.3.4. Conclusions

Summarizing, the results of the comparative studies highlighted the positive effect of rhenium and alkali metals addition, both in the CO conversion and on the stability of the catalysts. In the case of rhenium, the optimal loading was found to be 0.5 wt% Re with a Pt/Re ratio equal to 1 and an impregnation sequence in which rhenium was the first metal loaded. Sodium promotion has been successful used, through the surface modification of fascinating multi-walled carbon nanotube, which modify the surface oxygen distribution, thus stabilizing an oxidized platinum state.

Table 4.

Summary of the main catalytic results from the articles reported in Section 2.3.3 (the addition of promoters to the support).

Table 4.

Summary of the main catalytic results from the articles reported in Section 2.3.3 (the addition of promoters to the support).

| Selected Catalyst (Particle/Crystallite Size) | Preparation Procedure | Operative Condition WGS | CO Conversion/H2 Formation Rate (XCO)/(rH2) (Temperature) | Ref. |

|---|---|---|---|---|

| 2.5wt%Au-2.5wt%Pt/FSM16 (7 nm) | Pt and Au loading by co-impregnation; FSM by surfactant templation | H2O/CO = 0.08 | rH2 = 5 mmol·gcat−1 (T = 77 °C) | [70] |

| 1wt%Pt–40wt%CeO2/C (not specified) | Pt and Ce loading by impregnation under vacuum with acetone | WHSV = 60,000 mL·gcat−1·h−1 H2O/CO = 20.5 | XCO > 70% (T = 300 °C) | [72] |

| 20wt%CeO2/1wt%Pt/Al2O3 (5.7 nm) | By sol-gel synthesis | WHSV = 130,000 mL·gcat−1·h−1 H2O/CO = 10 | XCO ≈ 95% (T = 350 °C) | [73] |

3. Kinetics of Water-Gas Shift Reaction

The study and the evaluation of the kinetic parameters for water-gas shift reaction has been carried out over both monometallic as well as bimetallic and promoted platinum-based catalysts. In the following two paragraphs, a review of the approach followed by various authors regarding WGS kinetics is reported.

3.1. Monometallic Catalysts

In this section, the kinetic studies of Pt-based monometallic catalysts are reviewed. The section has been divided into three paragraphs based on the type of support: Section 3.1.1 reports the studies of the articles on Pt/Mo2C-based catalysts; Section 3.1.2 reports the studies of the article on Pt/CeO2-based catalysts; and Section 3.1.3 report the studies of the article on Pt/MnO2-based and Pt/strontium hydroxy and fluorapatite catalysts. A brief summary concludes the section.

3.1.1. Pt/Mo2C-Based Catalysts

Schweitzer et al. [76] employed monometallic Pt catalysts supported on nanostructured molybdenum carbide (Mo2C) for water gas shift reaction. They compared the activation energies of the 4wt%Pt/Mo2C catalysts with those reported for other catalytic systems finding slightly lessened values (53 kJ·mol−1 for 3.8wt%Pt/Mo2C, 80 kJ·mol−1 for 5wt%Pt/CeO2, 51 kJ·mol−1 for 2wt%Pt/TiO2 and 66 kJ·mol−1 for 0.5wt%Pt/TiO2), which demonstrate a higher activity of the sample supported on molybdenum carbide. The improved reaction rates for WGS recorded over the Pt/Mo2C catalyst were explained via TEM characterizations, which revealed a low contact angle between the active particles and the Mo2C and proved a strong interaction Pt-support. They also identified two different reaction rates for the active sites on the particles surface and on their perimeter, finding that those on the perimeter are the rate-determining steps for WGS. Highly dispersed raft-like Pt particles were identified on the Mo2C support and, by increasing the Pt loading, their diameter increased, without affecting the thickness. Such particles are characterized by high surface to volume and perimeter to volume ratios, which is a relevant benefit when the rate-determining step is linked to perimeter active centers.

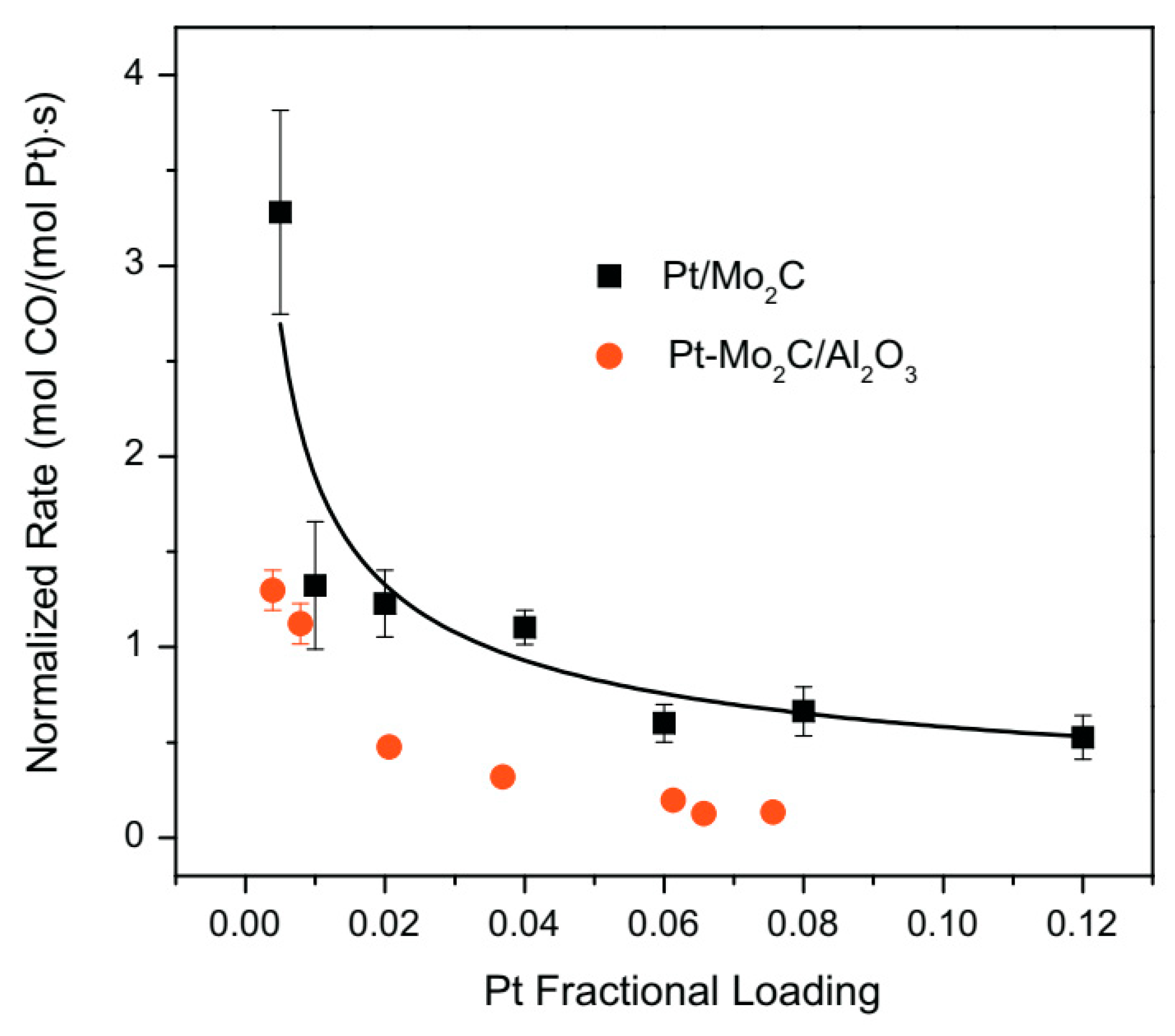

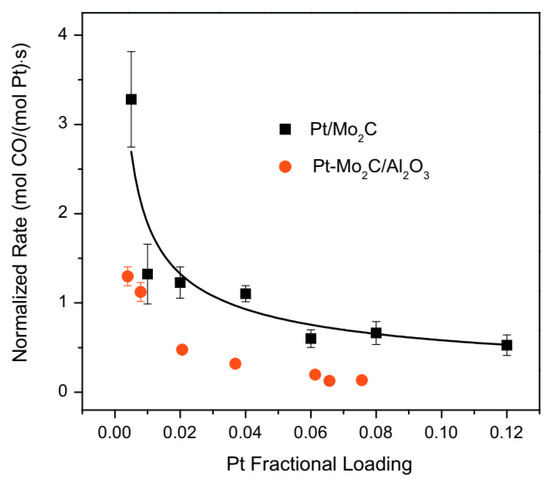

The effect of passivation on the activity of the Pt/ Mo2C catalyst was also investigated [77]. After support (Mo2C) synthesis via temperature programmed reaction, the reactor was removed from the furnace and cooled at room temperature; the unpassivated material was exposed to inert atmosphere while the passivated sample was treated in air (referred as p-Mo2C). Thereafter, Pt deposition was carried out via wet impregnation in both cases. The specific surface area of Mo2C and p-Mo2C were very similar; however, Pt particles were small and uniformly dispersed onto the unpassivated support while very large agglomerates of platinum were detected over the Pt/p-Mo2C sample. As a result, WGS rates and turnover frequencies (TOFs) were lower for the passivated catalyst, proving that the formation of the passivation layer had a negative impact on the metal-support interactions. The same authors also tested a 4wt%Pt-22wt%Mo2C/Al2O3 catalyst [78], which displayed similar activation energies compared to the Pt/Mo2C sample, lower than those observed for the Mo2C-free catalyst (Pt/Al2O3). The WGS rates were measured between 380 and 420 °C with a GHSV = 125,000 h−1 and the kinetic results obtained for the two catalysts containing Mo2C were compared in terms of normalized reaction rates (measured at 240 °C and evaluated by subtracting to the rate of the catalysts those measured for the supports Mo2C and Mo2C/Al2O3 and by dividing for the platinum loading). The profile obtained in the two cases (Figure 10) showed a very similar trend, demonstrating that the type of active sites as well as the interaction between Pt and molybdenum carbide are almost unaffected by Al2O3 deposition. Additionally in this case, atypical morphologies were observed for the Pt particles in the sample containing Mo2C, better dispersed than the cubo-octahedral particles of the Pt/Al2O3 sample.

Figure 10.

Dependence of platinum normalized water–gas shift rates on the Pt loading for Pt/Mo2C and Pt-Mo2C/Al2O3 adapted from [78], with permission from Elsevier, 2013; P = 1 atm, T = 240 °C, 11% CO, 43% H2, 6% CO2, 21% H2O, 19% N2, WHSV = 70 h−1.

The presence of small platinum coverage on the carbide surface was also identified as the ground for the excellent activity of Pt/MoC catalysts [79], tested for WGS reaction under CO/H2O ratio of 2:1 between 135 and 195 °C. Small particles of platinum, in fact, assured a better and close contact with the MoC support, with the synergistic interactions Pt-MoC favouring a quick water dissociation: the WGS reaction occurs at Pt-carbide interface with the dissociation of water on the carbide side while CO is bounded to the Pt particles. The resulting activation energy (38 kJ·mol−1) was very low compared to the values reported for Pt(111) single crystals; a similar result was also recorded over a Pt/TiC catalyst. For both the supports (MoC and TiC), the superior performance of the 1:1 carbide was observed. In fact, for these carbides, the number of Mo or Ti atoms exposed is lower while, due to the positive charge of the metals, the Mo2C and Ti2C supports are responsible for stronger interactions with OH and O, thus causing slower WGS reaction rates.

3.1.2. Pt/CeO2-Based Catalysts

Wen et al. [80] synthetized platinum nanoclusters encapsulated on the internal concave surface of mesoporous CeO2 (Pt@mp-CeO2) or impregnated on the external surface of ceria nanoroads (Pt/rod-CeO2). Despite the particle sizes of Pt nanoclusters are similar in the two cases (3–6 nm), the activation energy was 60 kJ·mol−1 for the Pt@mp-CeO2, lower than the value of 78 kJ·mol−1 recorded for the Pt/rod-CeO2 (150 °C < T < 240 °C, 5.6% CO, 22.44% H2O, 71.96% Ar, WHSV = 4.2 h−1). The interaction between Pt and the local interface for the two samples is similar; however, the density of oxygen vacancies on the internal concave surface is higher compared to those measured for the Pt/rod-CeO2, which is related to a reduced adsorption energy of the OH groups and an improved reaction rate.

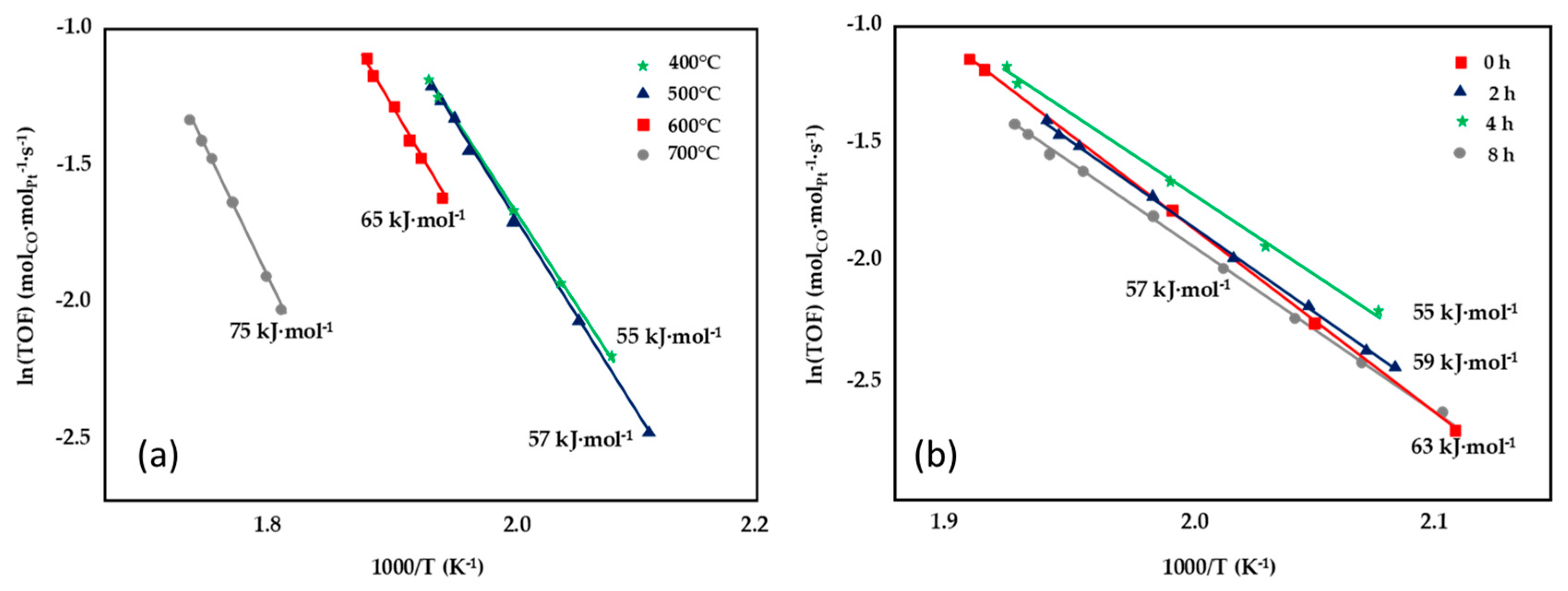

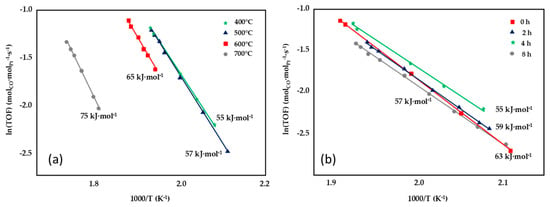

The synthesis of nano-sized CeO2 having high surface area and the strong interaction between Pt and CeO2 resulted in a highly active 1wt%Pt/CeO2 catalyst, as shown by Jeong et al. [81]. The support was synthetized through the thermal decomposition of crystalline cerium hydroxy carbonate, which was prepared via a novel precipitation/digestion method. The effect of pre-calcination temperature (400–700 °C) and aging time (0–8 h) on the kinetics was investigated (Figure 11) and the best results were recorded for the sample prepared at 400 °C and for an aging time of 4 h, which displayed the lowest activation energy (55 kJ·mol−1), ascribable to the relevant presence of stabilized Ce-PtOx species, which are highly active for the WGS reaction.

Figure 11.

Effect of pre-calcination temperature (a) and aging time (b) on the Arrhenius plots of the turnover frequency, adapted from [81], with permission from Elsevier, 2015; CO conversion obtained over Pt/CeO2 catalysts tested at P = 1 atm, 6.5% CO, 7.1% CO2, 0.7% CH4, 42.4% H2, 28.7% H2O, 14.5% N2, GHSV = 45,515 h−1.

The same authors [82] compared the performance of 1wt%Pt/CeO2, 1wt%Pt/ZrO2 and 1wt%Pt/Ce(1−x)ZrxO2 catalysts (x = 0.2, 0.8) and the different catalyst activity was correlated to their reduction profiles. The Pt/CeO2 catalyst, despite showing the worst Pt dispersion (37.6% compared to 66.9% of the Pt/Ce0.8Zr0.2O2, for example), displayed the lowest activation energy and the highest turnover frequency (Table 5). The Pt/CeO2 showed very high reducibility compared to the other samples, with the first peak of hydrogen consumption at 70 °C: due to the temporary reduction of Ce4+ to Ce3+, the support is able to supply active oxygen to oxidize CO in CO2; then is able to be re-oxidized by taking oxygen form water. Thus, beside dispersion, catalyst reducibility is another key factor affecting the activity for WGS reaction.

Table 5.

Turnover frequency (TOF) and activation energy (Ea) for WGS reaction over Pt/CeO2, PtZrO2 and Pt/Ce(1−x)ZrxO2 catalysts, date from [82]; at P = 1 atm, 6.5% CO, 7.1% CO2, 0.7% CH4, 42.4% H2, 28.7% H2O, 14.5% N2, GHSV = 45515 h−1.

Torrente-Murciano and Garcia-Garcia [83] synthetized two different nanostructured ceria supports (nanorods and nanocubes) by changing the operative conditions during hydrothermal treatment and compared their performance for WGS with a catalyst supported on ceria commercial nanoparticles; 1.5 wt% platinum was deposited by incipient wetness over the three supports. Despite the Pt particles size was slightly lower for the samples supported on CeO2 nanotubes and nanoparticles, the catalyst prepared from nanorods assured the best performance for WGS. In fact, catalyst activity and selectivity are mainly affected by platinum-ceria support interactions compared to the Pt crystallites dimension. The authors found that, for ceria nanorods, the selective exposure of the (100) and (110) crystal plane resulted in an optimum Pt-CeO2 interaction, thus strongly increasing WGS reaction rate and catalyst selectivity. In fact, methane formation was very low over the latter catalyst, proving that methanation is suppressed. Under a reacting stream of 5% CO, 5% H2O, 90% Ar and a GHSV = 4520 h−1, the 3 catalysts displayed similar activation energies (in the range 45–50 kJ·mol−1) while the reaction rates increased in the following order Pt/CeO2 cubes < Pt/CeO2 particles < Pt/CeO2 rods (43.1 < 49.9 < 189.8 molCO·kgcatalyst·h−1).

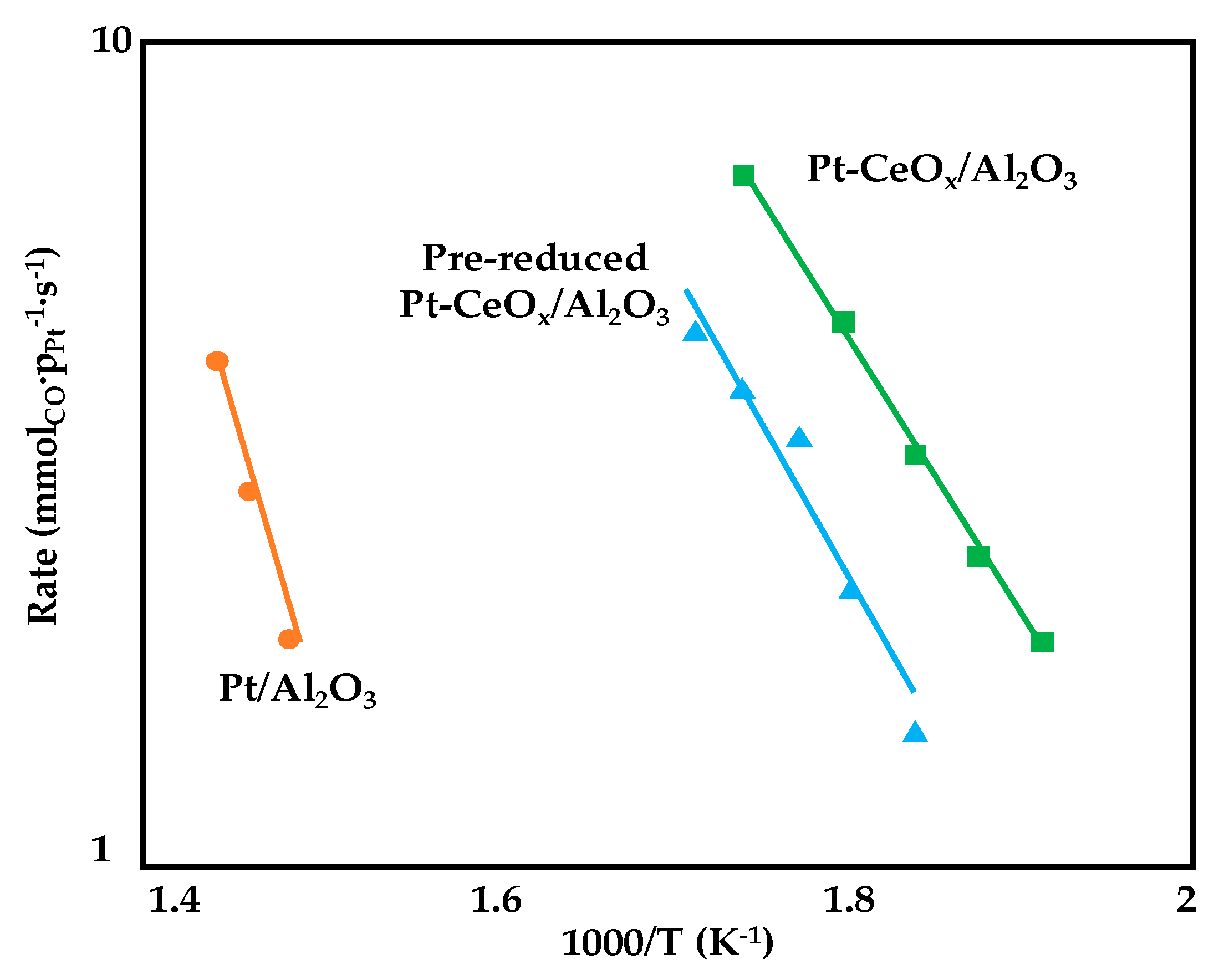

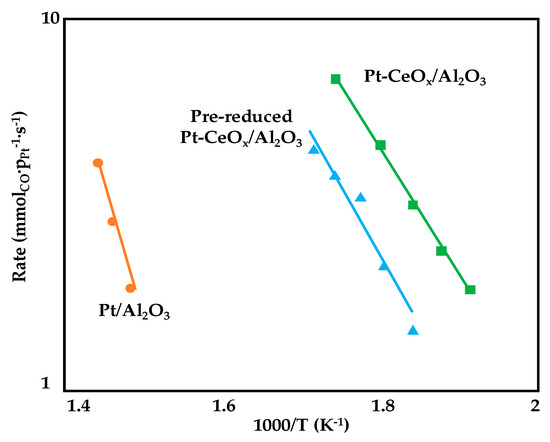

In the attempt of improving metal-support interaction, Deal et al. [84] prepared three alumina supported Pt catalysts by using the supercritical fluid deposition of an organometallic precursor (platinum acetylacetonate) for Pt deposition. Three samples were synthetized and tested for WGS reaction (1.25wt%Pt/Al2O3, 1.25wt%Pt-5wt%CeOx/Al2O3 and pre-treated Pt-CeOx/Al2O3, where the pre-treatment of the bare support was carried out in a H2/N2 stream at 300 °C for 4 h). As depicted in Figure 12, the addition of ceria to the Pt/Al2O3 catalyst significantly reduced (of almost 50%) the activation energy for the WGS reaction while similar values were recorded for the two Pt-CeOx/Al2O3 (71 kJ·mol−1); however, the pre-reduction did not allow a promotion of the reaction rate and this result is ascribable to the formation of both Pt cluster and crystalline nanoparticles upon the treatment. On the contrary, for the not pre-treated sample, a more uniform particle size was observed with a migration of ceria to form a crystalline shell around the Pt nanoparticles, thus increasing the number of interfacial sites which promotes CO oxidation.

Figure 12.

Arrhenius plots used to calculate apparent activation energies for WGS reaction on supported Pt catalysts, adapted from [84], with permission from Elsevier, 2017; P = 1 atm, 16% CO, 32% H2, 32% H2O, 20% N2, GHSV = 75,000 mL·gcat−1·h−1.

3.1.3. Pt/MnO2-Based and Pt/strontium Hydroxy and Fluorapatite Catalysts

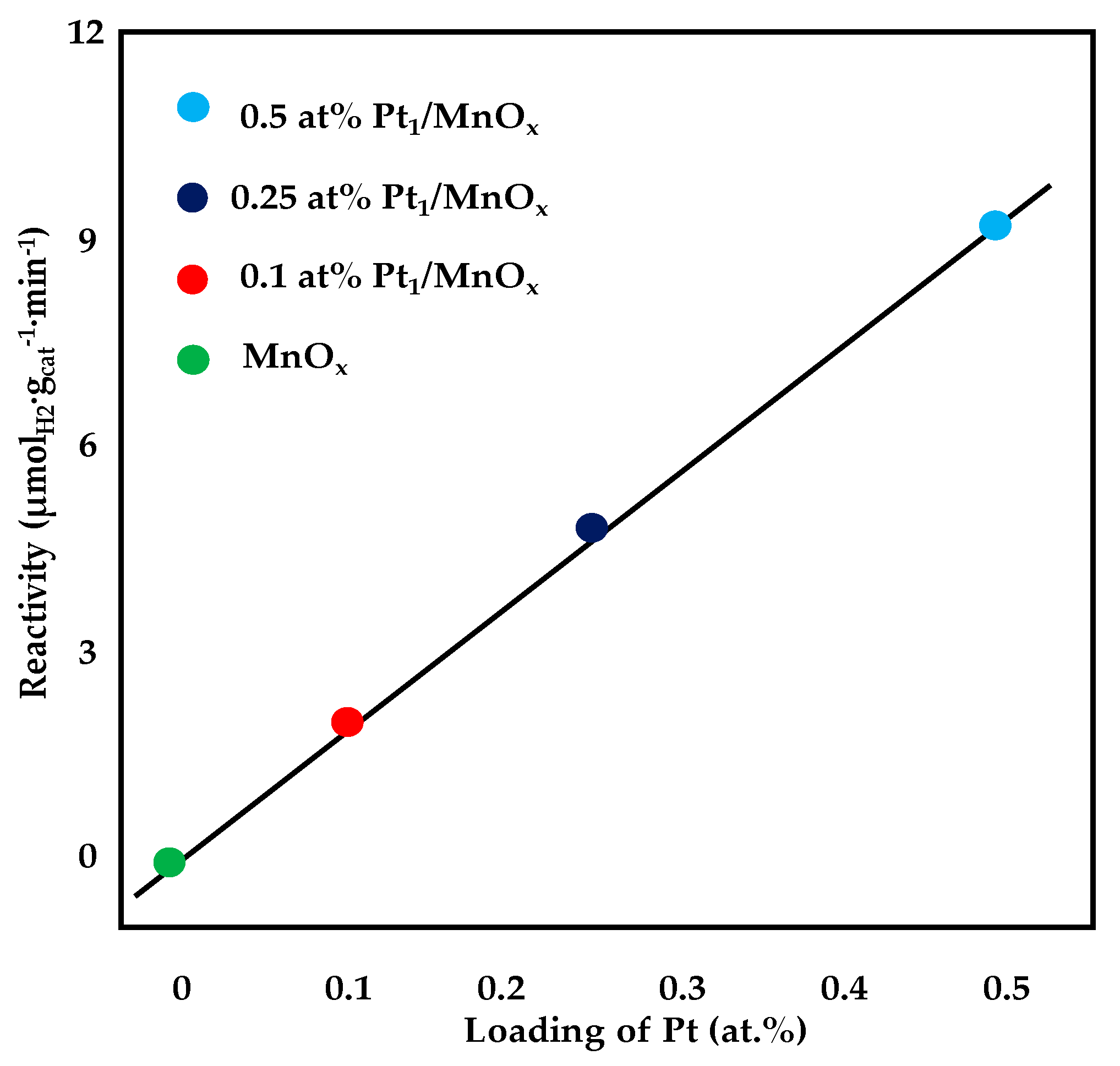

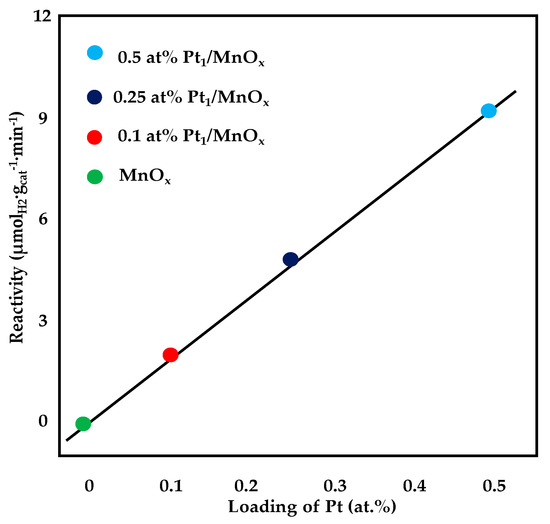

Shan et al. [85] investigated the performance of Pt-based catalysts supported on MnO2 nanoroads prepared via hydrothermal method (1wt%Pt/MnO2). Kinetic measurements were performed under an 8%CO, 24% H2O, 68% Ar stream and in a temperature range of 150–350 °C. The activation energy of WGS reaction calculated from the Arrhenius plot was 56 kJ·mol−1, which demonstrated the comparable activity of the MnO2 supported sample with Pt/CeO2 catalysts described in the literature. The authors, in fact, proved that, during WGS reaction, non-stoichiometric MnO1−x were formed and that, similarly to the results reported for ceria, oxygen vacancies participate into the reaction. Kuai et al. [86] applied a synchronous pyrolysis−deposition route for the addition of platinum to mesoporous MnOx. This technique allowed preparing atomically dispersed catalysts. By comparing the activity of as-prepared catalyst with a sample synthetized via conventional route (impregnation), the first one catalyst displayed a WGS activity more than two times higher and this result is ascribable to the lower number of single-atom active sites on the impregnated catalyst. The activation energy for the sample prepared by the pyrolysis-deposition route was 78 kJ·mol−1, which well agreed with the values reported for Pt single-atom catalysts with various supports. As depicted in Figure 13, by changing the platinum loading from 0.1 to 0.5 at%, the WGS activity displayed a linear increase, proving that the single Pt atom bounded to the support is active for the water gas shift reaction and that monodispersed single-atom active sites are present in the samples. Pt catalysts supported on a binary γ-Al2O3-α-Ga2O3 oxide, prepared via a simple-step precipitation and characterized by a good dispersion of the active phase, have also been tested for WGS reaction. Catalyst activity was investigated under a 2.5% CO, 10% H2O and 87.5% N2 mixture with a GHSV = 18,000 h−1. The 3wt%Pt/γ-Al2O3/25wt%α-Ga2O3 displayed a light-off reaction temperature of 280 °C with an apparent activation energy of 49.4 kJ·mol−1. For these catalysts, it was found that the presence of isolated basal or peripheral Pt atom species, rather than platinum dispersion, strongly contributed to the catalysts performance [87].

Figure 13.

Reactivity of WGS as a function of platinum loading, adapted from [86], with permission from American Chemical Society, 2018; T = 200 °C, 10% CO, 3% H2O, 87% He (linear fitting with R2 = 0.9988).

Miao et al. [88] deposited Pt nanoparticles (1 wt%) on strontium hydroxy and fluorapatite. WGS activity was investigated between 250 and 450 °C, with a reacting mixture of 5% CO, 20% H2O, 75% He under a GHSV = 150,000 mL·gcat−1·h−1. The prepared catalysts displayed high reducibility of the Pt oxidized species, comparable to the data reported for supports such as ceria: the interactions between the ionic support and the platinum particles allowed the formation of small Pt cluster on the apatite, characterized by improved reducibility and enhanced activity for WGS reaction. In particular, these supports are able to facilitate the activation of water: due to the presence of the apatite cations, the adsorption of water molecules in a strongly polarized fashion on the apatite surface assures an easier H2O dissociation. While CO is activated on the noble metal, water links to the ionic phosphates and the formate species are the main reaction intermediates. The comparison with other works found in the literature showed an increase of the reaction rate on the Pt/Sr apatite of almost 30% with respect to the previously described Pt/Sr apatite, with activation energies being slightly lower (70–72 kJ·mol−1). The reaction rate increased linearly with Pt loading up to 1 wt%, reaching the value of 0.68 molCO·molPt−1·s−1 at 300 °C.

3.1.4. Conclusions

Summarizing, in this section, among the described samples, the most advantageous catalyst, which displayed very low activation energy for the investigated reaction, was the Pt-MoC, with an Ea of 38 kJ·mol−1, while the activation energy of the much more used PtCeO2-based catalysts was in the range 55–80 kJ·mol−1.

3.2. Polymetallic and Promoted Catalysts

Various metals, including molybdenum and alkali, have been used as promoters for WGS reaction. In addition, the effect of support doping by the introduction of various metals has also been investigated. This section has been divided into three paragraphs based on the type of promoter: Section 3.2.1 reports the studies of the articles on Mo-promoted catalysts; Section 3.2.2 reports the studies of the article on alkali-promoted catalysts; and Section 3.2.3 reports the studies of the article on the rare earth and transition metals-promoted catalysts. A brief summary concludes the section.

3.2.1. Mo-Promoted Catalysts

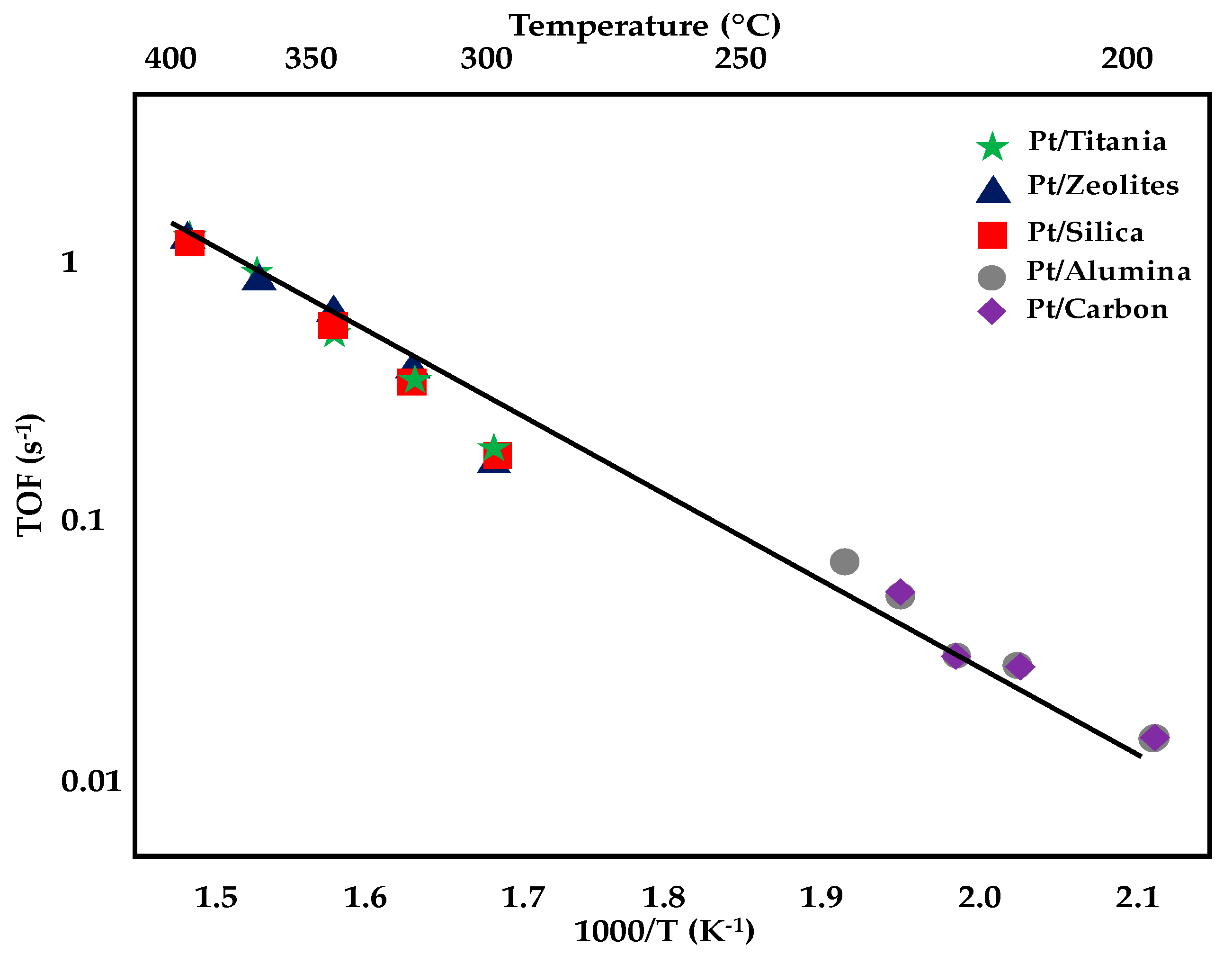

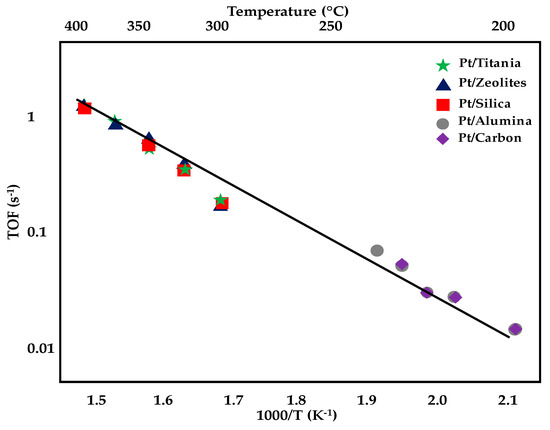

Williams et al. [89] reported an increase in WGS rate upon Mo promotion for Pt/SiO2 and Pt/Al2O3 catalysts. Characterization studies revealed that Mo was in close proximity to Pt: the formation of Pt-Mo bimetallic particles decreased the carbon monoxide coverage over platinum and increased the CO reaction order, which is normally close to zero for Mo-free catalysts. Moreover, molybdenum provided a support-type effect by increasing the ability of the support to dissociate water in a similar manner over both Al2O3 and SiO2. Thus, a reduction in apparent activation energies of 20–40 kJ·mol−1 was observed for the Mo-promoted catalysts. However, reaction rates increased up to a molybdenum content of 3.4 wt% over alumina and 4.2% on silica: the highest turnover frequency can be reached for Pt-Pt to Pt-Mo ratios ranging between 4 and 5, with the best results over 3.4wt%Mo/Al2O3 and 1.2wt%Mo/SiO2. The reaction orders, the activation energies the TOFs values obtained over the alumina and silica-based catalysts are summarized in Table 6.

Table 6.

Results of kinetic measurements over doped and un-doped Pt/SiO2 and Pt/Al2O3 catalysts; P = 1 atm, 4–21% CO, 5–25% CO2, 11–34% H2O, and 14–55% H2, data from [89].

Similarly, a loading of 1.7 wt% of Mo on a 3.5 wt% Pt/SiO2 catalysts assured a reduction in the activation energy from 67 to 44 kJ·mol−1 (kinetic measurements were performed between 150 and 300 °C under a CO/H2O ratio of 3:10 and a GHSV = 18,000 mL·gcat−1·h−1). The authors found that the active sites for WGS reaction lied on the interface between MoOx patches and the Pt particles and that the loading of 1.7% (Mo/Pt atomic ratio ) assured the optimal coverage of molybdenum oxides on platinum. In such conditions, a bifunctional reaction mechanism was identified: water can be activated on the interfacial sites and react with the carbon monoxide adsorbed on the nearby Pt nanoparticles [90].

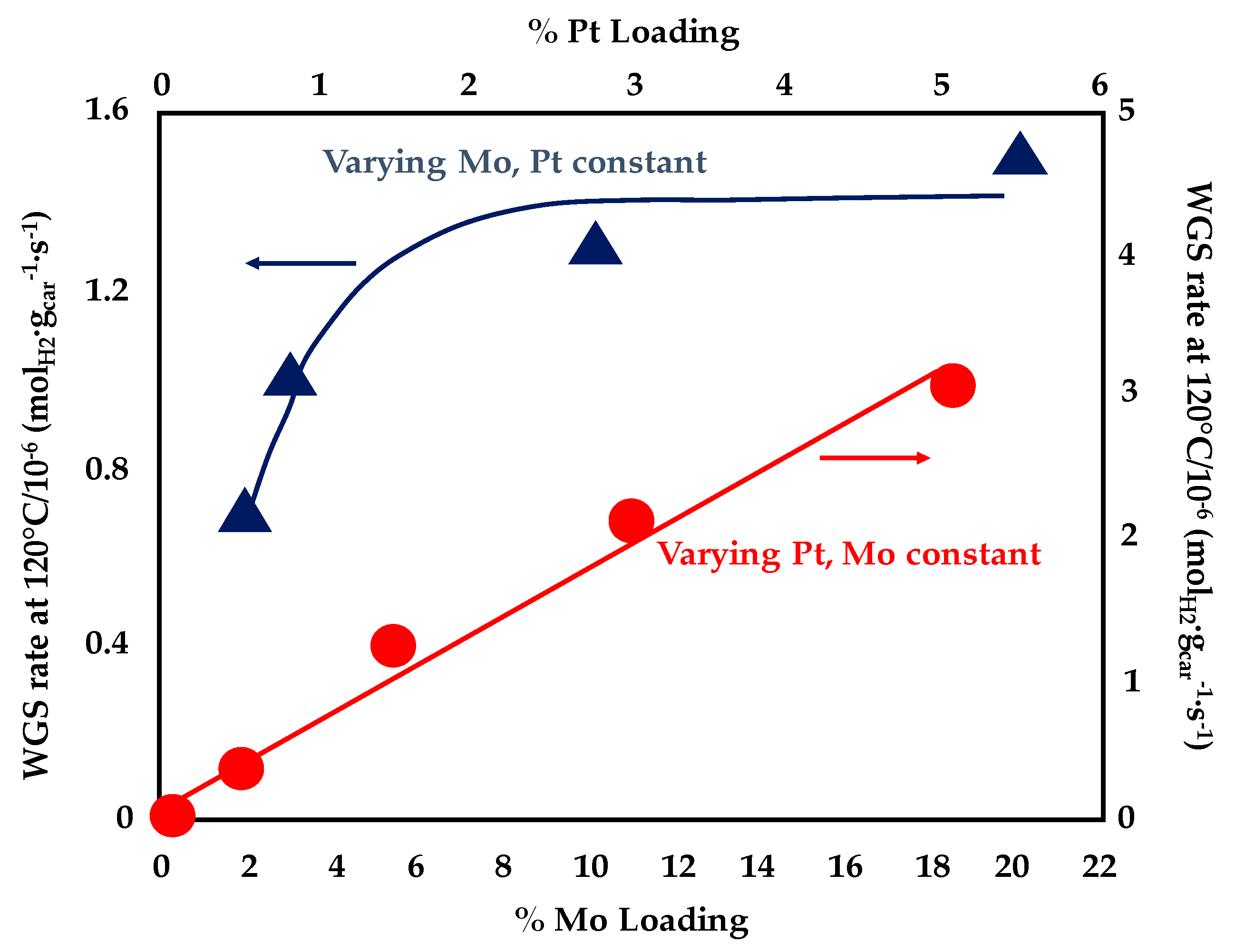

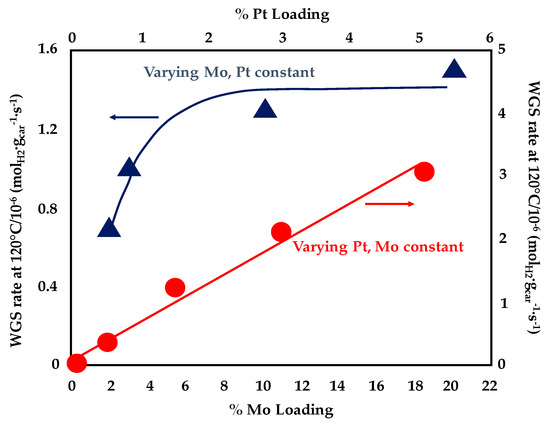

A bifunctional reaction mechanism with CO activated on Pt-Mo nanoparticles and water dissociating on the Mo2C support was also described by Sabnis et al [91]. They deposited platinum nanoparticles on multiwalled carbon nanotubes (MCNTs) and evaluated the effect of Mo addition by incipient wetness impregnation; during the reduction process of the dried material (carried out in the presence of pure H2 at 600 °C for 3 h), Mo reacted with the carbon of the support to form Mo2C domains. Additionally in this case, the addition of Mo to the Pt/MCNT catalysts resulted in a reduction of the apparent activation energy (from 83 kJ·mol−1 measured for the 4wt%Pt/MCNT to 48 kJ·mol−1 recorded over the 5wt%Pt-10wt%Mo/MCNT). Various Pt/Mo2C/MCNT samples were prepared changing the Mo lading at a fixed Pt content of 1.5 wt% and varying the Pt loading at a fixed Mo content of 10 wt%. Very close apparent activation energies, apparent reaction order and reaction rate per total mole of Pt were measured over the above samples, which demonstrates that the chemical nature of the active sites is similar, independently form Pt as well as Mo loadings. However, as depicted in Figure 14, higher Pt loadings result in a linear increase of the WGS rate per gram of catalyst while a stabilization in the curve obtained by increasing the Mo loading was observed above 10 wt%. These results suggest that higher Mo contents favour the formation of less active sites while the number of the most active (Pt-Mo) sites increase with Pt loading. In fact, by varying the platinum content, it is possible to enhance the number of Pt-Mo alloy bimetallic particles and the dominant active sites for WGS reaction are located both on the Pt-Mo bimetallic particles and on the interface between Pt-Mo particles and the Mo2C domain. Thus, a linear increase of WGS rate per gram of catalyst was observed with the increase of support surface area covered by the Pt-Mo nanoparticles.

Figure 14.

WGS rate per gram of catalyst at 120 °C as a function of Pt and Mo lading for Pt/Mo2C/MCNT adapted from [91], with permission from Elsevier, 2015; P = 1 atm, 7% CO, 22% H2O, 8.5%, CO2, 37.5% H2.

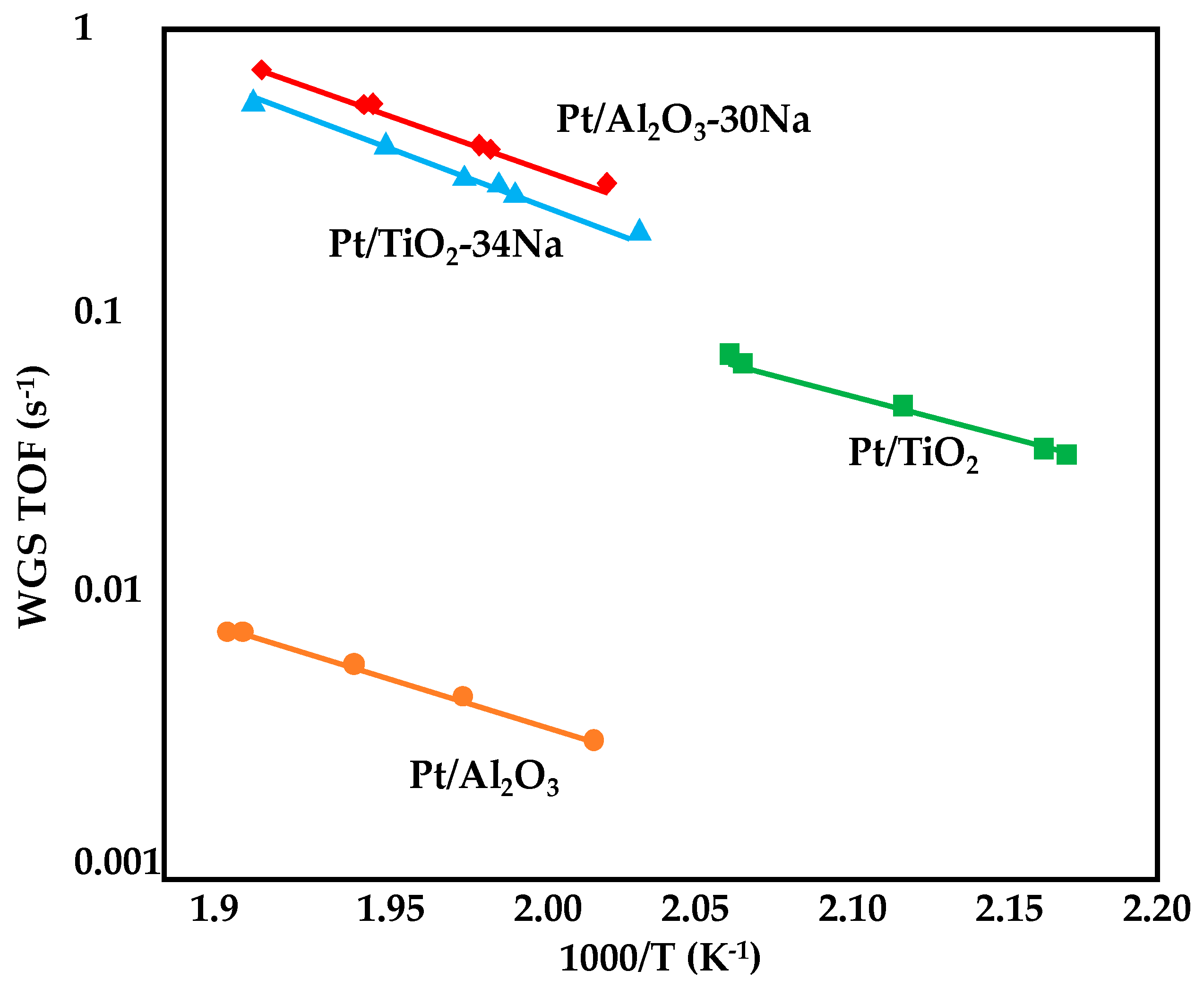

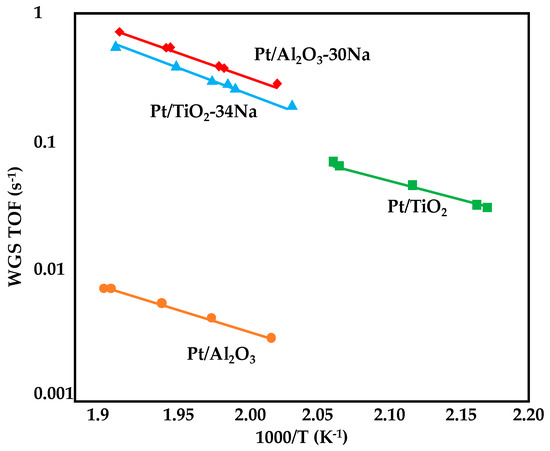

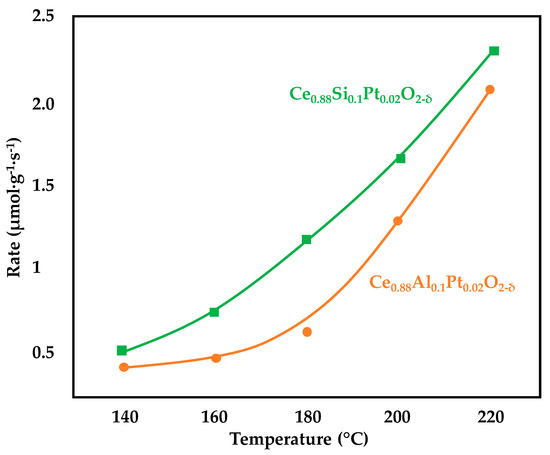

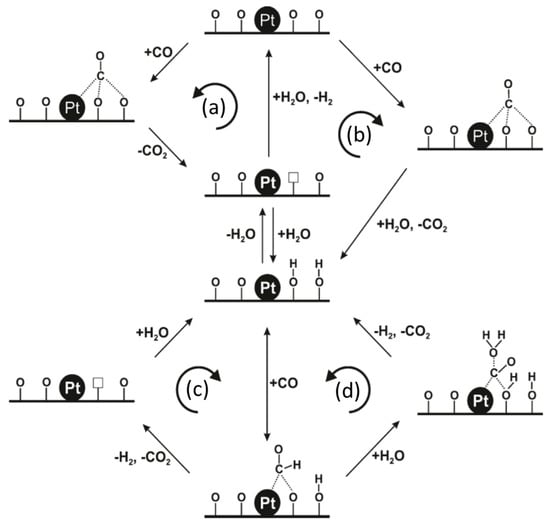

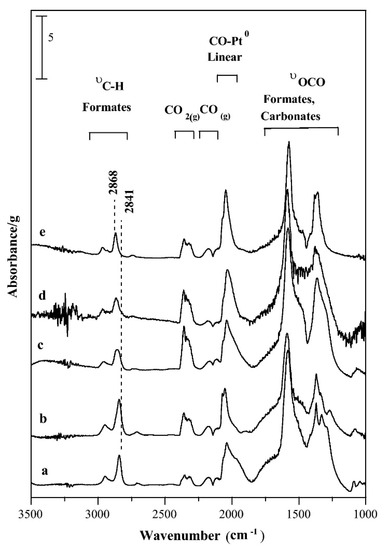

3.2.2. Alkali-Promoted Catalysts