Corrosion-Fatigue Analysis of High-Strength Steel Wire by Experiment and the Numerical Simulation

Abstract

1. Introduction

2. Experimental Analysis

2.1. Experimental Preparation

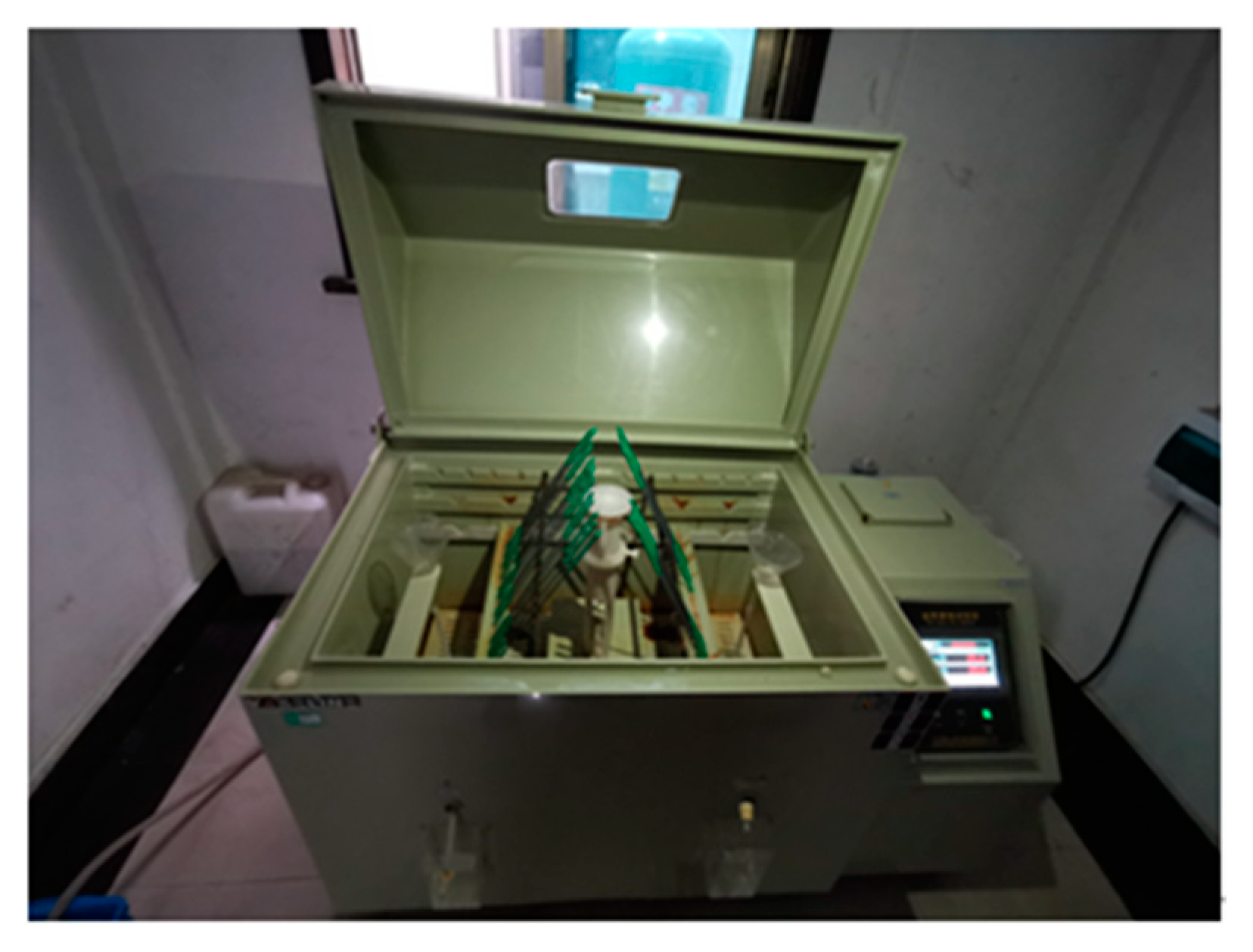

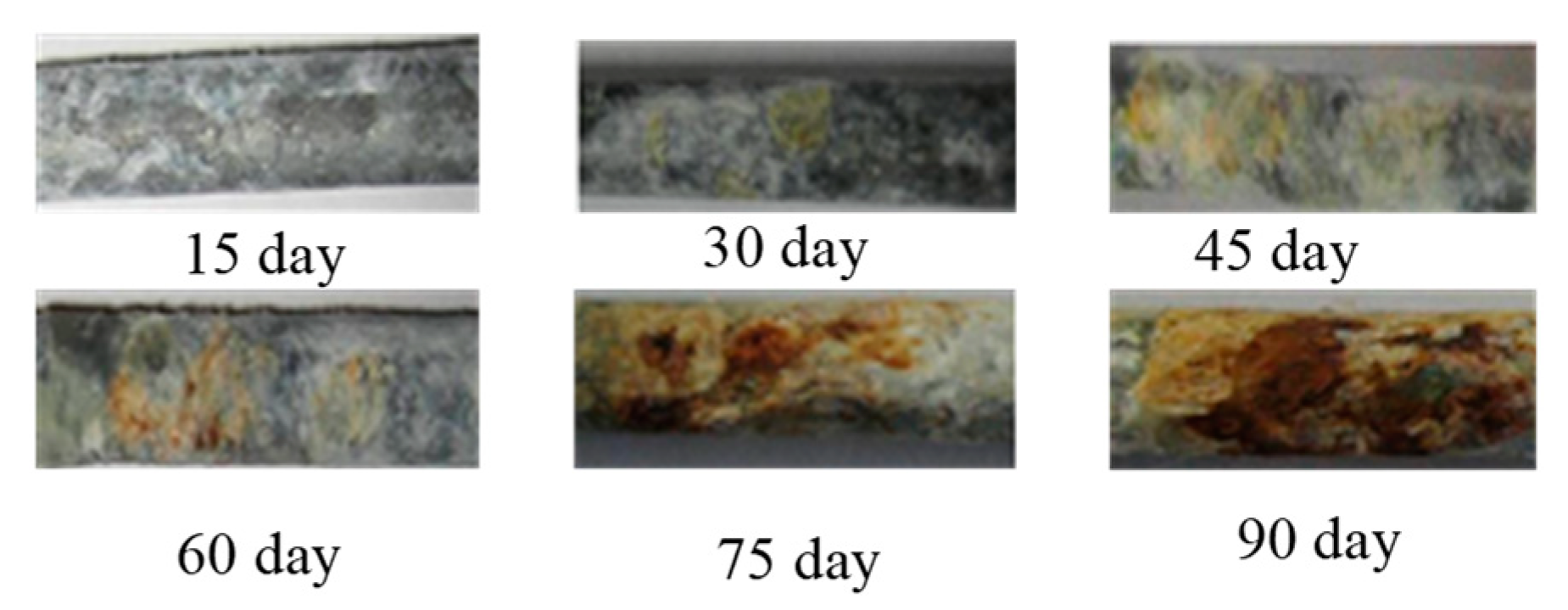

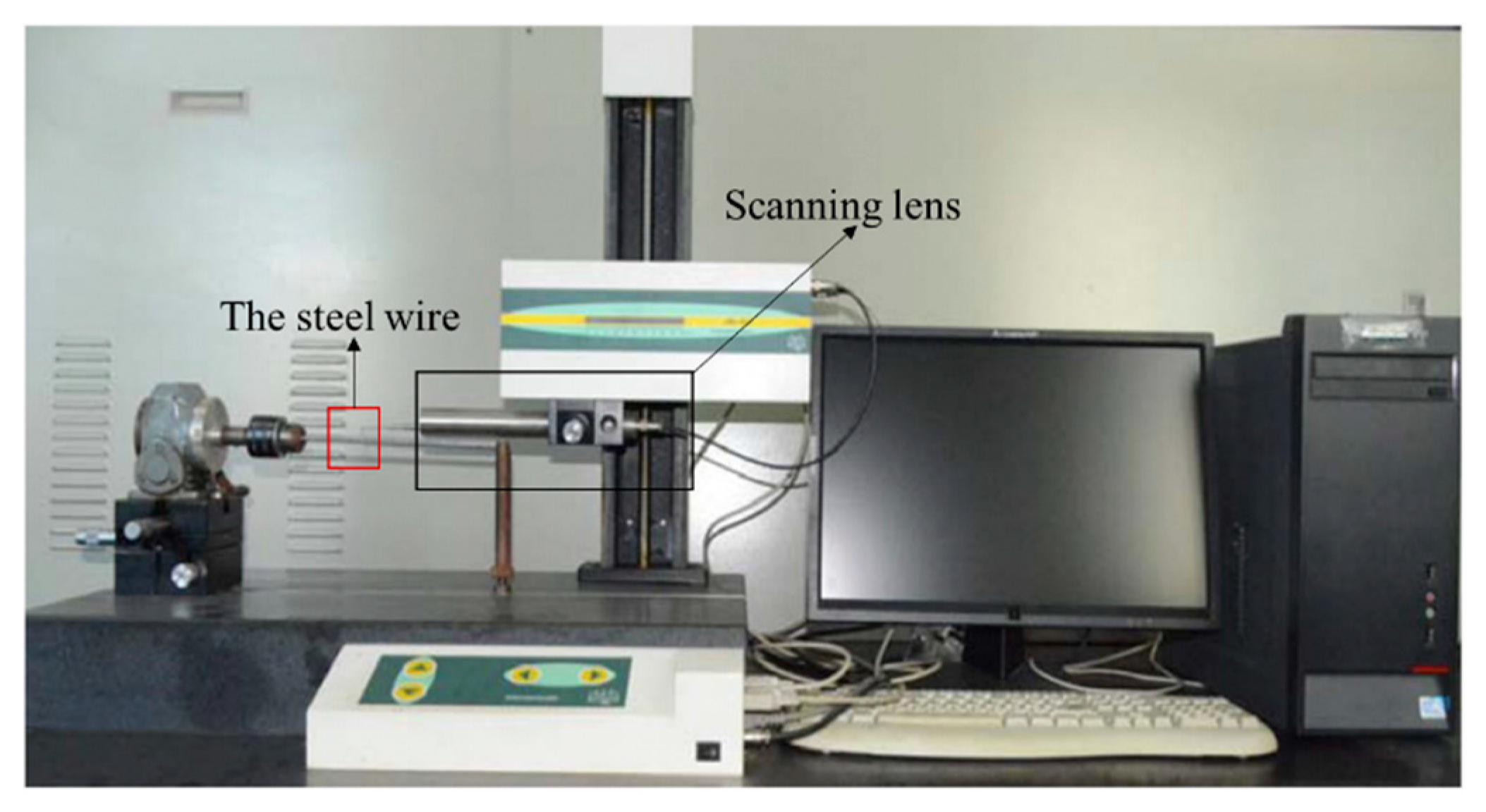

2.2. Corrosion Test

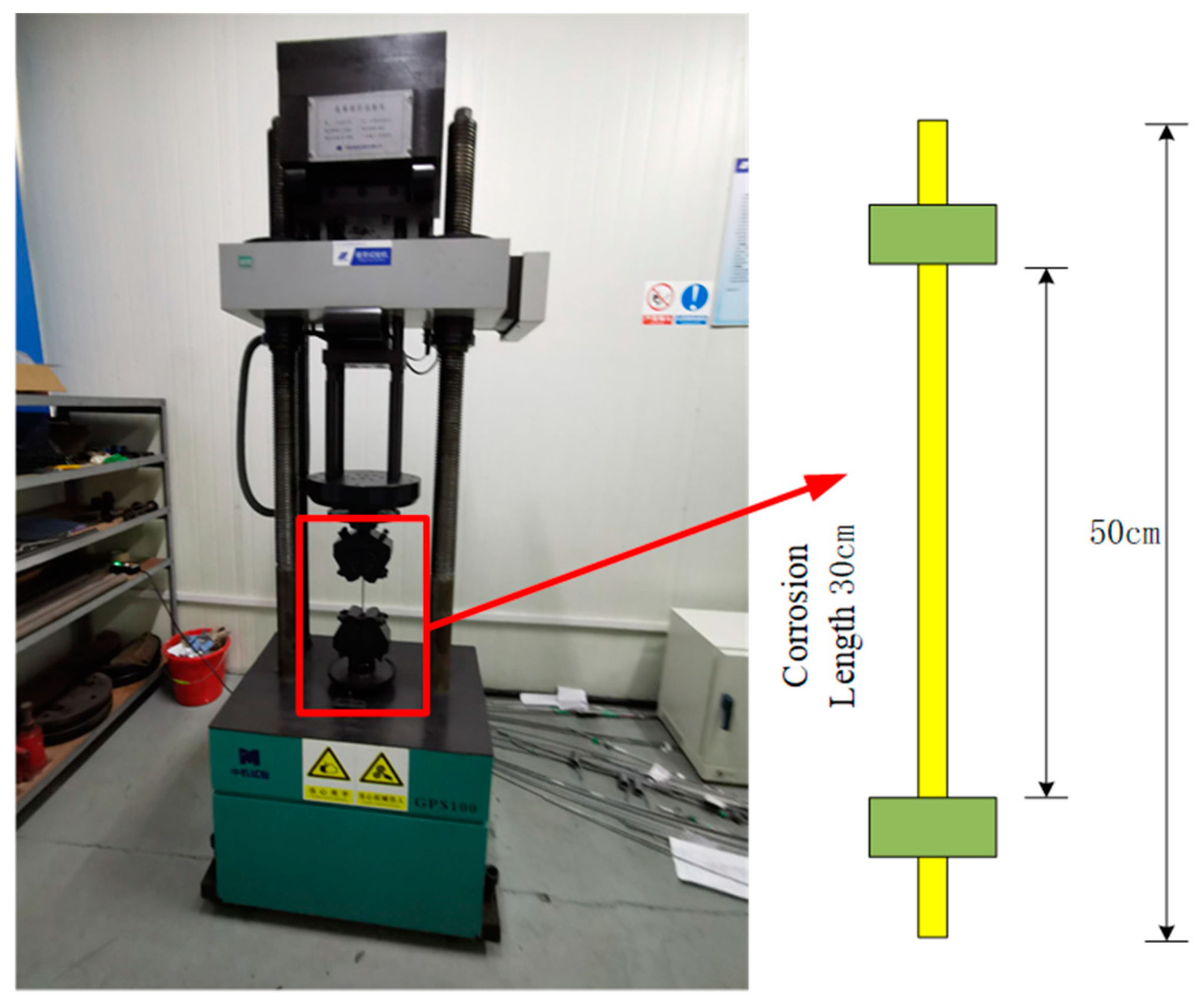

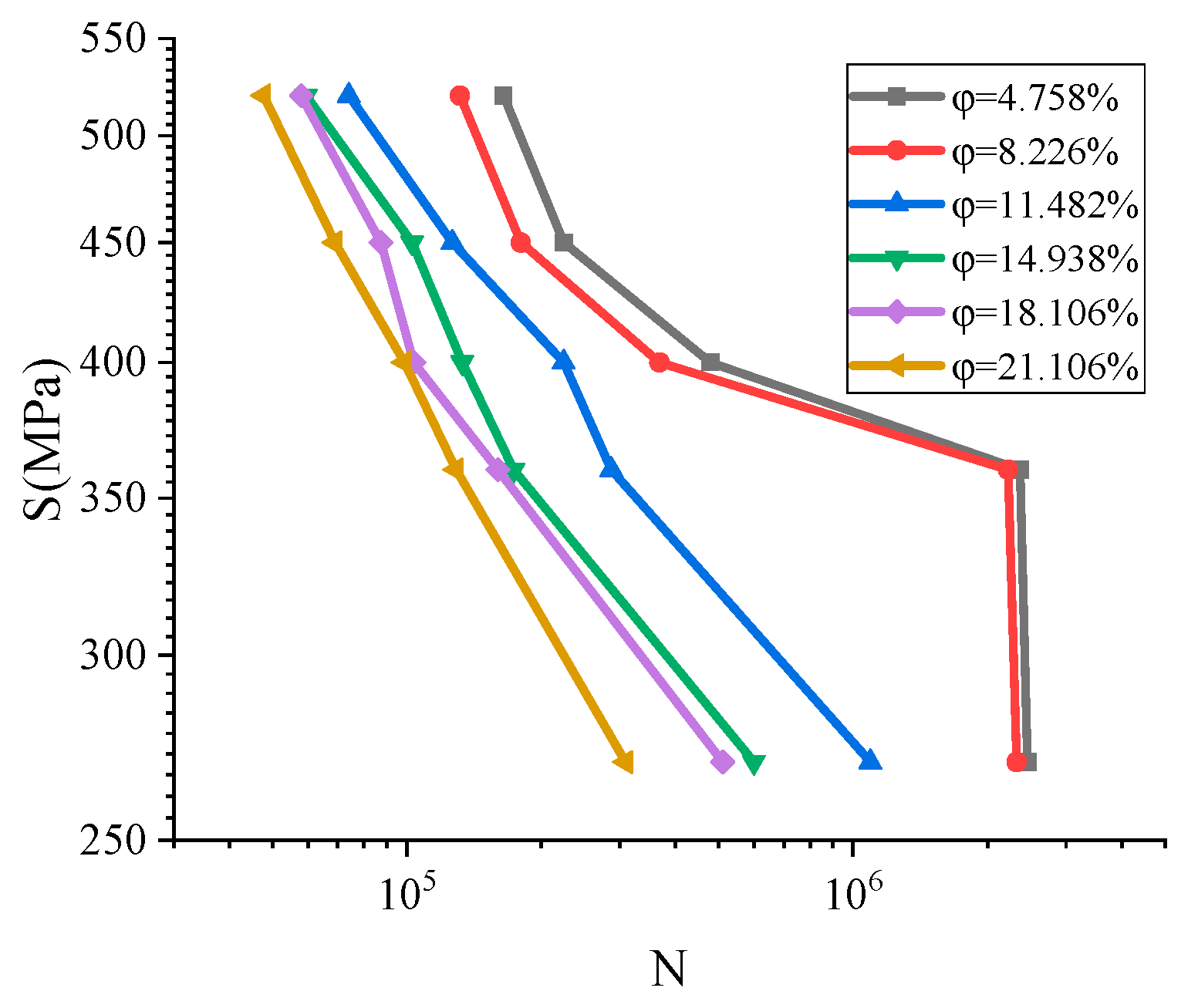

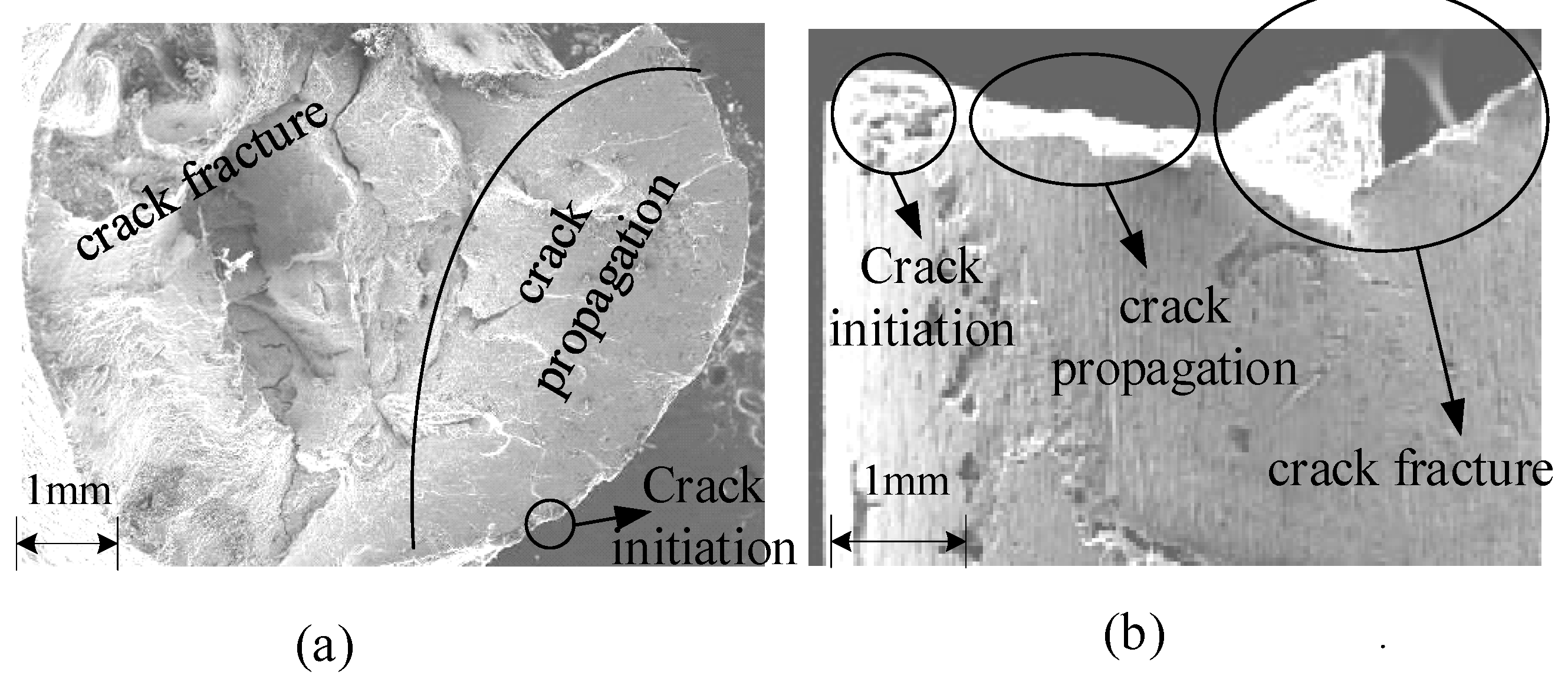

2.3. Fatigue Test

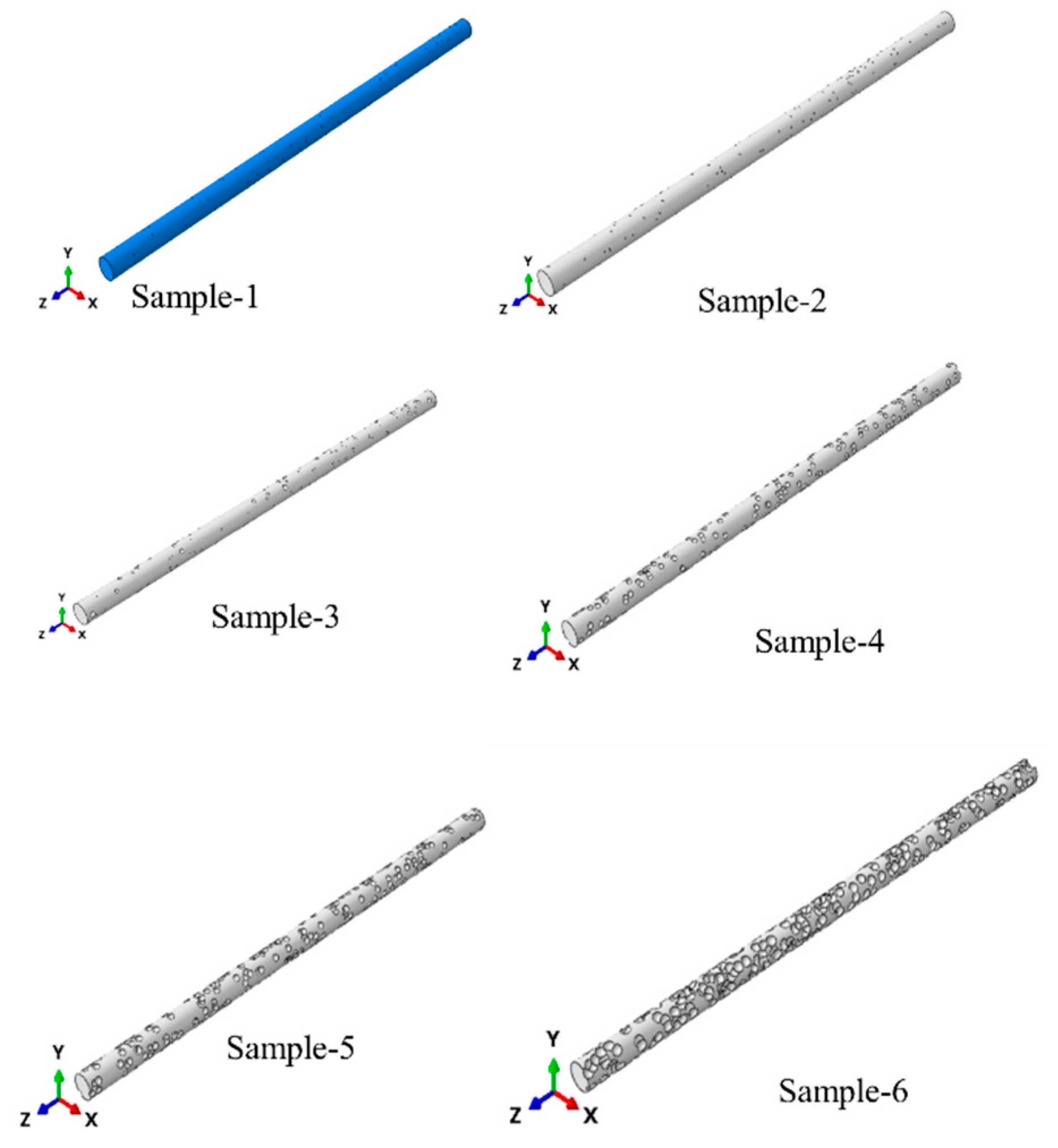

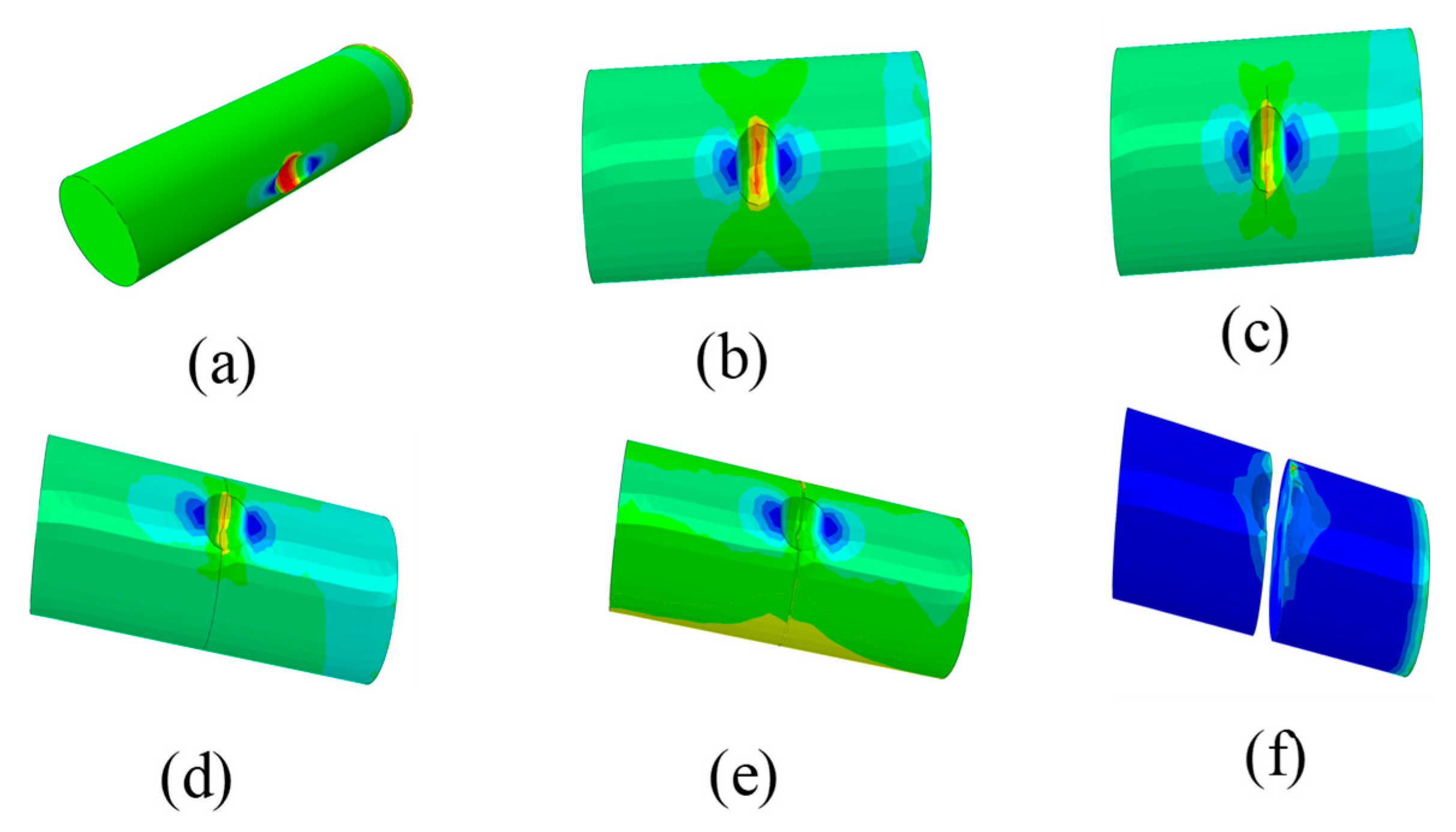

3. Numerical Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Xue, S.; Shen, R. Real time cable force identification by short time sparse time domain algorithm with half wave. Measurement 2020, 152, 107355. [Google Scholar] [CrossRef]

- Zhou, Y.; Chen, S. Investigation of the live-load effects on long-span bridges under traffic flows. J. Bridge Eng. 2018, 23, 04018021. [Google Scholar] [CrossRef]

- Guo, T.; Liu, Z.; Correia, J.; de Jesus, A.M. Experimental study on fretting-fatigue of bridge cable wires. Int. J. Fatigue 2020, 131, 105321. [Google Scholar] [CrossRef]

- Lesiuk, G.; Rymsza, B.; Rabiega, J.; Correia, J.A.; De Jesus, A.; Calcada, R. Influence of loading direction on the static and fatigue fracture properties of the long term operated metallic materials. Eng. Fail. Anal. 2019, 96, 409–425. [Google Scholar] [CrossRef]

- Chang, X.-D.; Peng, Y.-X.; Zhu, Z.-C.; Zou, S.-Y.; Gong, X.-S.; Xu, C.-M. Evolution Properties of Tribological Parameters for Steel Wire Rope under Sliding Contact Conditions. Metals 2018, 8, 743. [Google Scholar] [CrossRef]

- Xue, S.; Shen, R.; Chen, W.; Miao, R. Corrosion fatigue failure analysis and service life prediction of high strength steel wire. Eng. Fail. Anal. 2020, 110, 104440. [Google Scholar] [CrossRef]

- Wang, Y.; Zheng, Y.; Zhang, W.; Lu, Q. Analysis on Damage Evolution and Corrosion Fatigue Performance of High-strength Steel Wire for Bridge Cable: Experiments and Numerical Simulation. Theor. Appl. Fract. Mech. 2020, 102571. [Google Scholar] [CrossRef]

- Xue, S.; Shen, R.; Shao, M.; Chen, W.; Miao, R. Fatigue failure analysis of steel wire rope sling based on share-splitting slip theory. Eng. Fail. Anal. 2019, 105, 1189–1200. [Google Scholar] [CrossRef]

- Ni, Y.Q.; Ye, X.W.; Ko, J.M. Monitoring-Based Fatigue Reliability Assessment of Steel Bridges: Analytical Model and Application. J. Struct. Eng. 2010, 136, 1563–1573. [Google Scholar] [CrossRef]

- Zhao, Z.W.; Haldar, A.; Breen, F.L. Fatigue-Reliability Evaluation of Steel Bridges. J. Struct. Eng. 1994, 120, 1608–1623. [Google Scholar] [CrossRef]

- Adasooriya, N.D.; Siriwardane, S.C. Remaining fatigue life estimation of corroded bridge members. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 603–622. [Google Scholar] [CrossRef]

- Zampieri, P.; Curtarello, A.; Maiorana, E.; Pellegrino, C. A Review of the Fatigue Strength of Shear Bolted Connections. Int. J. Steel Struct. 2019, 19, 1084–1098. [Google Scholar] [CrossRef]

- Zampieri, P.; Curtarello, A.; Pellegrino, C.; Maiorana, E. Fatigue strength of corroded bolted connection. Frat. Integrità Strutt. 2018, 12, 90–96. [Google Scholar] [CrossRef]

- Zampieri, P.; Curtarello, A.; Maiorana, E.; Pellegrino, C. Numerical analyses of corroded bolted connections. Procedia Struct. Integr. 2017, 5, 592–599. [Google Scholar] [CrossRef]

- Zampieri, P.; Curtarello, A.; Maiorana, E.; Pellegrino, C.; De Rossi, N.; Savio, G.; Concheri, G. Influence of corrosion morphology on the Fatigue strength of Bolted joints. Procedia Struct. Integr. 2017, 5, 409–415. [Google Scholar] [CrossRef]

- Toribio, J.; Ovejero, E. Effect of cold drawing on microstructure and corrosion performance of high-strength steel. Mech. Time-Depend. Mater. 1997, 1, 307–319. [Google Scholar] [CrossRef]

- Aleksandrov Fabijanić, T.; Kurtela, M.; Škrinjarić, I.; Pötschke, J.; Mayer, M. Electrochemical Corrosion Resistance of Ni and Co Bonded Near-Nano and Nanostructured Cemented Carbides. Metals 2020, 10, 224. [Google Scholar] [CrossRef]

- Zhang, W.-P.; Li, C.-K.; Gu, X.-L.; Zeng, Y.-H. Variability in cross-sectional areas and tensile properties of corroded prestressing wires. Constr. Build. Mater. 2019, 228, 116830. [Google Scholar] [CrossRef]

- Marandi, L.; Sen, I. Effect of Saline Atmosphere on the Mechanical Properties of Commercial Steel Wire. Metall. Mater. Trans. A 2019, 50, 132–141. [Google Scholar] [CrossRef]

- Li, L.; Mahmoodian, M.; Li, C.-Q.; Robert, D. Effect of corrosion and hydrogen embrittlement on microstructure and mechanical properties of mild steel. Constr. Build. Mater. 2018, 170, 78–90. [Google Scholar] [CrossRef]

- Fang, K.; Li, S.; Chen, Z.; Li, H. Geometric characteristics of corrosion pits on high-strength steel wires in bridge cables under applied stress. Struct. Infrastruct. Eng. 2020, 1–15. [Google Scholar] [CrossRef]

- National Standard of the People’s Republic of China. GBT 10125-2012 Corrosion Tests in Artificial Atmospheres-Salt Spray Tests; Standards Press of China: Beijing, China, 2012. [Google Scholar]

| Sample Number | ||||

|---|---|---|---|---|

| 1 | 201.3 | 1675 | 1843 | 5.7 |

| 2 | 200.8 | 1656 | 1851 | 5.5 |

| 3 | 198.9 | 1657 | 1846 | 5.8 |

| 4 | 199.5 | 1668 | 1845 | 5.6 |

| 5 | 202.4 | 1671 | 1863 | 5.4 |

| Mean | 200.58 | 1665.4 | 1849.6 | 5.6 |

| Sample Number | Number of Corrosion Pits | Average Radius of Corrosion Pit (mm) |

|---|---|---|

| 1-1 | 117 | 0.07 |

| 1-2 | 115 | 0.09 |

| 1-3 | 119 | 0.08 |

| 1-4 | 111 | 0.08 |

| 1-5 | 114 | 0.07 |

| 2-1 | 212 | 0.13 |

| 2-2 | 214 | 0.15 |

| 2-3 | 209 | 0.16 |

| 2-4 | 205 | 0.14 |

| 2-5 | 217 | 0.13 |

| 3-1 | 227 | 0.19 |

| 3-2 | 238 | 0.33 |

| 3-3 | 269 | 0.34 |

| 3-4 | 289 | 0.36 |

| 3-5 | 245 | 0.34 |

| 4-1 | 316 | 0.47 |

| 4-2 | 318 | 0.49 |

| 4-3 | 319 | 0.48 |

| 4-4 | 319 | 0.35 |

| 4-5 | 318 | 0.49 |

| 5-1 | 398 | 0.56 |

| 5-2 | 379 | 0.52 |

| 5-3 | 356 | 0.54 |

| 5-4 | 378 | 0.57 |

| 5-5 | 389 | 0.56 |

| 6-1 | 435 | 0.76 |

| 6-2 | 456 | 0.72 |

| 6-3 | 423 | 0.74 |

| 6-4 | 425 | 0.72 |

| 6-5 | 418 | 0.76 |

| Corrosion Time (days) | Sample Number | φ (%) | Lfrac (cm) | S (MPa) | Experimental Number of Cycles |

|---|---|---|---|---|---|

| 15 | 1-1 | 4.72 | 21.2 | 520 | 164,567 |

| 1-2 | 4.83 | 22.4 | 450 | 224,653 | |

| 1-3 | 4.76 | 13.4 | 400 | 478,456 | |

| 1-4 | 4.52 | 20.2 | 360 | 2,456,345 | |

| 1-5 | 4.96 | 12.4 | 270 | 2467876 | |

| 30 | 2-1 | 8.23 | 29.2 | 520 | 131,345 |

| 2-2 | 8.45 | 28.4 | 450 | 179,876 | |

| 2-3 | 7.79 | 27.6 | 400 | 367,987 | |

| 2-4 | 8.32 | 30.1 | 360 | 2,324,567 | |

| 2-5 | 8.34 | 30.4 | 270 | 2,333,459 | |

| 45 | 3-1 | 11.12 | 30.5 | 520 | 74,123 |

| 3-2 | 11.23 | 21.2 | 450 | 126,387 | |

| 3-3 | 11.38 | 30.1 | 400 | 224,278 | |

| 3-4 | 11.56 | 25.6 | 360 | 287,089 | |

| 3-5 | 12.12 | 27.2 | 270 | 1,092,876 | |

| 60 | 4-1 | 14.37 | 29.7 | 520 | 59,346 |

| 4-2 | 15.12 | 31.2 | 450 | 102,583 | |

| 4-3 | 15.23 | 18.2 | 400 | 132,967 | |

| 4-4 | 14.98 | 20.3 | 360 | 173,261 | |

| 4-5 | 14.99 | 22.4 | 270 | 598,698 | |

| 75 | 5-1 | 18.12 | 23.4 | 520 | 57,896 |

| 5-2 | 17.97 | 22.6 | 450 | 87,289 | |

| 5-3 | 17.86 | 24.5 | 400 | 103,471 | |

| 5-4 | 18.56 | 27.8 | 360 | 159,826 | |

| 5-5 | 18.02 | 27.8 | 270 | 509,916 | |

| 90 | 6-1 | 19.34 | 29.2 | 520 | 47,647 |

| 6-2 | 20.12 | 24.6 | 450 | 68,912 | |

| 6-3 | 20.34 | 25.3 | 400 | 98,759 | |

| 6-4 | 20.36 | 31.1 | 360 | 128,798 | |

| 6-5 | 20.37 | 19.9 | 270 | 308,791 |

| Corrosion Time (days) | Sample Number | Calculated Number of Cycles | Error (%) |

|---|---|---|---|

| 15 | 1-1 | 134,789 | 18.09 |

| 1-2 | 193,498 | 13.87 | |

| 1-3 | 398,732 | 16.66 | |

| 1-4 | 2,154,346 | 12.29 | |

| 1-5 | 2,163,837 | 12.32 | |

| 30 | 2-1 | 117,964 | 10.19 |

| 2-2 | 169,987 | 5.50 | |

| 2-3 | 328,976 | 10.60 | |

| 2-4 | 2,129,876 | 8.38 | |

| 2-5 | 2,132,435 | 8.61 | |

| 45 | 3-1 | 61,987 | 16.37 |

| 3-2 | 105,132 | 16.82 | |

| 3-3 | 201,765 | 10.04 | |

| 3-4 | 265,410 | 7.55 | |

| 3-5 | 1,051,123 | 3.82 | |

| 60 | 4-1 | 51,987 | 12.40 |

| 4-2 | 103,263 | 0.66 | |

| 4-3 | 109,876 | 17.37 | |

| 4-4 | 148,654 | 14.20 | |

| 4-5 | 512,189 | 14.45 | |

| 75 | 5-1 | 52,678 | 9.01 |

| 5-2 | 79,777 | 8.61 | |

| 5-3 | 92,345 | 10.75 | |

| 5-4 | 134,234 | 16.01 | |

| 5-5 | 480,001 | 5.87 | |

| 90 | 6-1 | 39,213 | 17.70 |

| 6-2 | 60,021 | 12.90 | |

| 6-3 | 87,879 | 11.02 | |

| 6-4 | 107,123 | 16.83 | |

| 6-5 | 291,176 | 5.70 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, S.; Shen, R. Corrosion-Fatigue Analysis of High-Strength Steel Wire by Experiment and the Numerical Simulation. Metals 2020, 10, 734. https://doi.org/10.3390/met10060734

Xue S, Shen R. Corrosion-Fatigue Analysis of High-Strength Steel Wire by Experiment and the Numerical Simulation. Metals. 2020; 10(6):734. https://doi.org/10.3390/met10060734

Chicago/Turabian StyleXue, Songling, and Ruili Shen. 2020. "Corrosion-Fatigue Analysis of High-Strength Steel Wire by Experiment and the Numerical Simulation" Metals 10, no. 6: 734. https://doi.org/10.3390/met10060734

APA StyleXue, S., & Shen, R. (2020). Corrosion-Fatigue Analysis of High-Strength Steel Wire by Experiment and the Numerical Simulation. Metals, 10(6), 734. https://doi.org/10.3390/met10060734