Abstract

Currently, high-speed steel (HSS) powders are deposited locally on a metal surface through direct energy deposition (DED) onto hardface tool steel. Although the HSS powder enhances the hardness and the abrasion resistance of a metal surface, it makes the tool steel brittle because of its high carbon content. In addition, the steel is likely to break when subjected to a high load over time. This study focused on improving the steel toughness by applying a post-heat treatment. To fabricate a uniformly deposited layer through DED, M4 powder was deposited onto a pre-heated substrate (AISI D2). In addition, four post-heat-treated specimens were prepared, and their mechanical properties were compared. The Charpy impact and hardness tests were conducted to evaluate the durability required for the D2 die. The deposited M4 powder possessed a high hardness but a relatively low impact toughness. During laser melting, a stable bond formed between M4 and D2 without any cracks or delamination. The hardness of the initial M4 deposited layer was 63 HRC, which changed to 54–63 HRC depending on the effect of the post-heat treatment. Moreover, the post-heat-treatment process improves the impact toughness of the M4 deposited layer by changing its microstructure.

1. Introduction

Increasing the strength of an automobile frame enables a reduction in weight and an increase in passenger protection. Steels that produce the filler must have a high strength. Recently, additive manufacturing (AM) is gaining momentum in diverse industrial applications. Among AM technologies, directed energy deposition (DED) technology is capable of achieving 3-dimensional molding to obtain diverse shapes and local strengthening of metallic surfaces; hence, this technology is receiving significant attention. The DED technology can be used for hardfacing tool steel surfaces and to perform repairs because it exhibits a superior refined microstructure and strong fusion bonding between the substrate and the metal powder. Hashemi et al. [1] reported an improvement in the wear resistance and tool life by laser cladding a thin layer of high-speed steel (HSS) powder on the target materials. However, despite its superior performance, HSS is extremely susceptible to cracking during laser cladding when there is a high amount of carbon [2]. Fallah et al. [3] studied the effect of localized surface preheating on the microstructure of the laser-direct-deposited samples as well as crack formation in the samples. High-speed tool steel M4 was useful for effectively improving the wear resistance through preheating with no deposition defects such as cracks and pores [4]. Nevertheless, the M4 deposited layer showed poor mechanical properties such as low toughness and vulnerability to cracks despite its high hardness [5]. Furthermore, although the thermal stress was reduced, residual stress remains after cooling the metal to room temperature in the deposition process. Post-heat treatment is a conventional method of combining heating and cooling operations that is used to improve the mechanical properties, such as the hardness, wear resistance, and impact resistance, of metals or alloys. Sola et al. [6] assessed the influence of the heat treatment on the microstructural and mechanical properties of high-speed tool steel (AISI M2). Through post-heat treatment, recrystallization of metal structures, the diffusion of atoms and phase transformation can occur, and the residual stress is relieved. Post-heat treatment alters the microstructures of the deposited layer that are produced via the direct energy deposition (DED) process, and it changes its mechanical properties. However, most studies on post-heat-treatment processes have focused on bulk or welded materials. As the microstructures of the deposited layer produced via the DED process generally form fine dendritic tissues, differences in the properties of the metals that are used for welding with a bulk material are expected. Therefore, the effects of the post-heat-treatment process on the microstructure and the mechanical properties of an M4 deposited layer produced via the DED process should be studied.

Shim et al. [7] determined that the post-deposition heat treatment significantly influences the mechanical and metallurgical characteristics of M4. In the experiment, it shows post-deposition quenching and tempering, which led to a reduction in the hardness. This was attributed to the relieved residual stress, the tempered martensite, and the removal of carbon from the martensite during tempering. Wang et al. [8] compared the abrasive wear behavior of a variety of tool steel coatings (CPM 9V, CPM 10, and CPM 15V) in the laser cladding process. They reported that when large amounts of residual austenite exist in the deposited layer, the mechanical properties can be improved via transformation into martensite, which is promoted by the post-heat treatment. Telasang et al. [9] improved the mechanical properties of the H13 powders through laser cladding and the post-cladding heat treatment. In addition, Telasang et al. investigated the cause through the observation of changes in the microstructural properties and the residual stress. They reported that the mechanical properties changed according to the volume fraction of carbide as the martensite or the residual austenite phase-transformed to pearlite/bainite through the post-cladding heat treatment. Park et al. [10] examined the effect of the heat treatment on the properties of the tool steels (H13 and D2) that are deposited via the DED process. According to their study, the hardness of the deposited H13 decreased after the heat treatment, but the hardness of the deposited D2 increased after the heat treatment. Moreover, the microstructure of the deposited D2 steel after the heat treatment consisted of fine carbides of tempered martensite; the microstructures of the bulk material D2 and the deposited layer showed differences. Sun et al. [11] used laser cladding for repairing the damaged part in accordance with AISI 4340 and they applied the post-heat-treatment process to maintain or improve the fatigue characteristics, which improved the tensile property and the fatigue life. In addition, Lourenço et al. [12] deposited the AerMet® 100 powder on a substrate of the same material and observed the fatigue life after post-heat treatment, which was not effective for improving the fatigue life after deposition. Jo et al. [13] reported that this method, based on multi-layer cladding with a combination of functional metal powders, increased the tool steel life.

Most of the abovementioned studies used laser cladding and they aimed to improve the mechanical properties (e.g., hardness, wear resistance, fatigue life) through the post-heat-treatment process. Furthermore, by treating the laser melting state as hardened tissue, they focused on the changes in the microstructure of the tool steel that is post-treated with tempering only. Thus far, little research has been conducted on manufacturing M4 powder multi-layers via laser deposition and applying them to the post-heat-treatment process. Almost no studies have focused on the effect of quenching processes, including tempering the M4 tool steel that is deposited on a conventional die steel (D2). Moreover, tool steels that are used in high-hardness cold presses require a high toughness in addition to a high hardness and wear resistance, and the durability (i.e., hardness, wear behavior, and toughness) of the tool steels deposited through DED should be evaluated; however, no study in this regard has been conducted.

Therefore, our study focused on the mechanical properties of the tool steel required for the hardfacing of cold press dies (e.g., a press die of UHSS). This study also investigated the changes in the mechanical properties that are caused by different heat treatment conditions that are applied after depositing the M4 powders using DED technology. Hence, AISI M4 powders were deposited on an AISI D2 substrate through preheating, and a specimen for evaluating the impact toughness was fabricated through the post-heat treatment. The toughness changes that were incorporated via post-heat treatment were evaluated using the Charpy impact test, and the hardness and the microstructure of the deposited layer were also examined.

2. Materials and Methods

2.1. Materials

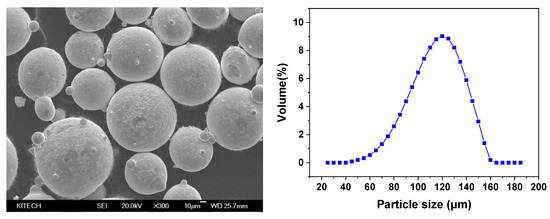

In this study, the AISI D2 material was used in the experiments as the substrate and the hardfaced surface was created with the AISI M4 powder by laser melting. D2 has a very high carbon and chrome content. After it is hardened through the appropriate heat treatment (quenching and tempering), it is suitable for a wide range of practical applications. M4 steel powder, which consists of spherical particles with an average particle size of approximately 110 μm (supplied by Carpenter Co., Philadelphia, PA, USA), was used as the powder for the DED process (Figure 1). M4 is a molybdenum-based high-speed tool steel; the hardness of the substrate is used for general cutting tools that must have a high degree of toughness, such as cold-forged tools, molds, and parts for the high-speed presses. Table 1 lists the chemical compositions of the two materials that are used in this study.

Figure 1.

M4 powder image and the particle size for the laser deposition.

Table 1.

Chemical composition of the materials. (unit: wt %).

2.2. Preparation of the Specimens

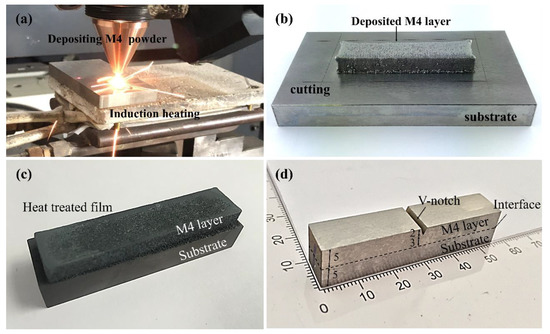

In this study, the DED process conditions listed in Table 2 were employed. Figure 2 shows the DED process with the pre/post-heat treatment. The DED process was followed by preheating and deposition, cutting and post-heat treatment, and specimen machining. Using the DED process, 12 specimens were prepared for the impact specimen. Three repetitive tests were conducted per condition. The preheating process was required to deposit the M4 powder without delamination [14]. To do this, a high-frequency induction heating device was used. For substrate preheating, the D2 substrate was placed on the induction coil, and it was heated until a temperature of 250 °C was reached. The DED equipment for these experiments consisted of a 5-axis, 4 kW CO2 laser and a coaxial powder nozzle. The coaxial powder nozzle has the advantage of being directionally independent owing to the symmetry between the powder and the laser. The process uses a high-power laser beam that is focused onto a substrate to melt the substrate, and it simultaneously melts the material that is being deposited onto the substrate melting pool. The metal powder was continuously injected into the molten pool with argon, and the coaxial gas was used to prevent oxidation that was created on the substrate by the laser. The beam diameter was 1.0 mm while the powder delivery nozzle diameter was 5.3 mm and it was located 9 mm from the substrate surface. The motion system consisted of five stages: X, Y, Z, tilt, and rotation. This was commanded by a digital computer numerical control machine that was manufactured by Siemens.

Table 2.

Parameters for direct energy deposition (DED) processing.

Figure 2.

Process of directed energy deposition: (a) the pre-heating and deposition of M4 powder; (b) deposited M4 layer on the D2 substrate; (c) post-heat-treated M4 layer; (d) fabrication of a Charpy impact specimen.

2.3. Post-Heat Treatment Conditions

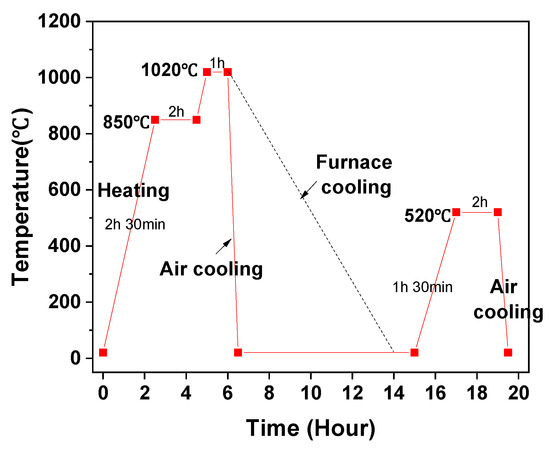

To examine how the post-heat treatment affects the mechanical properties of the sample that was produced by DED for the same pre-heating treatment condition of 250 °C, the M4 powders were deposited with a size of 57 mm × 12 mm × 5.75 mm. The deposited specimen was completely cooled to room temperature, and then, the post-heat-treatment process was applied. In general, the microstructure is stabilized, and the toughness is imparted to the tool steels by performing quenching, a tempering process, after hardening. In this heat treatment process, changes in the microstructure and the mechanical properties appear according to the heating temperature, speed, retention time, and the cooling rate. In this experiment, four post-heat-treatment conditions were established based on the heat-treatment conditions of the substrate (AISI D2). The heating rate was set as 5 °C /min. Heating for 2 h at 850 °C and for 1 h at 1020 °C was applied to all the experiments (Figure 3). Subsequently, as shown in Table 3, four heat-treatment conditions were compared by changing the cooling rate and the tempering process. Consequently, the post-heat-treatment conditions consisted of air cooling after heating to 1020 °C (A), furnace cooling after heating to 1020 °C (F), tempering of the specimen air-cooled after heating to 1020 °C (AT), and tempering of the specimen furnace-cooled after heating to 1020 °C (FT).

Figure 3.

Graph of post-heat treatment temperature.

Table 3.

Post-heat treatment conditions.

To observe the microstructure of the deposited layer, electrolytic polishing was performed using a Lectropol-5 (Struers Corp., Cleveland, UT, USA) for each of the deposited samples. Electrolytic polishing was performed with a voltage of 35 V, a time of 25 s, and a flow rate of 9 L/min using electrolytes (A3 solution, perchloric acid:butoxyethanol:methanol at a ratio of 1:6:4) at a current of 0.80 A. The microstructure was observed using a field-emission scanning electron microscope (JEOL Ltd., 7100 f, Tokyo, Japan). In addition, X-ray diffraction (XRD, KURARAY Ltd., Tokyo, Japan) was performed for the identification of the phase volume fractions. The quantitative XRD analysis was performed using the Cullity method (Equation (1)) [15]. XRD was performed using Cu Kα radiation, which was generated at 50 kV and 40 mA; the diffraction angle varied between 20° and 120° with a scanning rate of 5°/min. The mechanical properties after the heat treatment according to the conditions were evaluated in terms of the hardness and the impact toughness. The hardness was measured using a Rockwell hardness tester (HR-521, Akashi, Japan). A cone-shaped diamond tip with a diameter of 0.5 inch was used to indent the surface of the deposited layer using a load of 150 N. The penetration depth of the specimen was measured, and it was converted to the HRC unit. To evaluate the toughness, which is the resistance against fracture, the Charpy impact test was performed. The specimen for the impact test was prepared with a deposited layer that is 5 mm in height. A 2-mm-deep V-notch was formed in the specimen, which is consistent with the ASTM E23 standard. The impact test was performed at room temperature using a Charpy impact machine. The impact energy, impact velocity, and impact angle were set to 50 J, 3.8 m/s, and 150°, respectively.

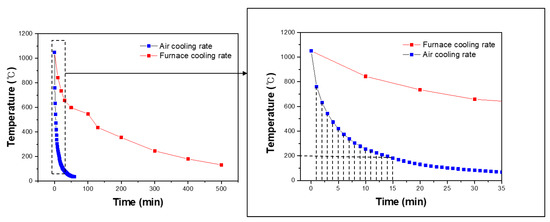

3. Microstructure Prediction by the Cooling Rate

During heating in the post-heat-treatment process, the microstructure of the deposited layer became austenitized, and phase transformation occurred, which depends on the cooling rate. This change is correlated with the chemical composition of the material and it affects the grain size and the precipitate formation [16]. Figure 4 shows the cooling rate that was measured in the post-heat-treatment experiment. As the air-cooled specimens had a small volume of deposition, they were cooled very quickly (within 800 s); hence, they were below 200 °C after being heated to 1020 °C. The formation of some carbides and martensite structures is expected when comparing it with the continuous cooling transformation (CCT) curve. In contrast, furnace-cooled specimens have a very slow cooling rate; thus, ferrite, pearlite, and bainite microstructures can be formed. Therefore, it was expected that the phase transformation of the microstructure would occur, and the mechanical properties would show differences depending on the post-heat-treatment conditions.

Figure 4.

Temperature during air cooling and furnace cooling.

4. Microstructure

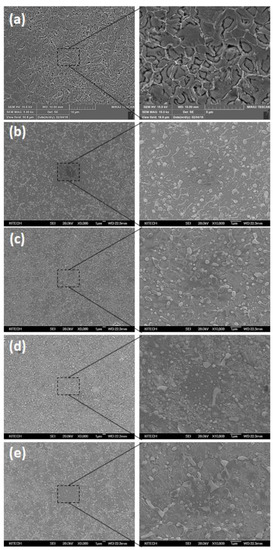

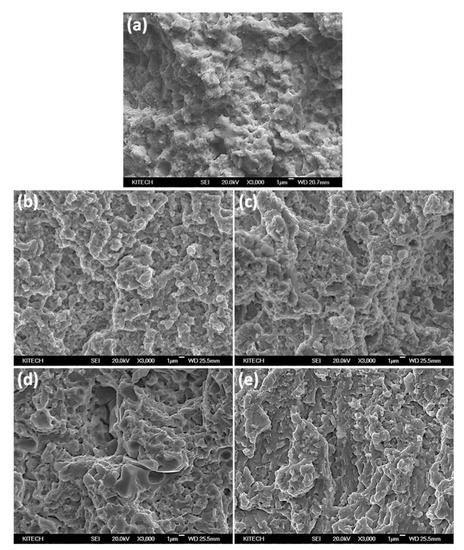

Figure 5 shows the microstructure according to the M4 deposited layer and the post-heat-treatment conditions. No defects, such as cracks or pores, were observed in all of the specimens. Figure 5a shows the cross-section of the M4 layer that was deposited through preheating. It can be observed that fine cellular dendrite microstructures were formed in the M4 deposited layer, and the MC-based carbides were thinly distributed according to the cell shape. In contrast, the post-heat-treated microstructure showed a different shape from the deposited M4 microstructure (Figure 5b–e). This phenomenon occurred because the microstructure was recrystallized, and phase transformation occurred. This is due to the microstructure being heated to a temperature that was above its transformation point in the post-heat-treatment process. The post-heat-treated microstructure in the M4 deposited layer did not show any cellular dendrite structures, and the thinly precipitated carbide aggregated spherically. According to the cooling curve and the CCT curve, the martensite structure was formed under air-cooled condition A. Under condition F, at a slow cooling rate, the carbon elements formed bainite or ferrite structures through diffusion and transformation. Nevertheless, no significant differences were observed in the SEM images of the microstructures according to the post-heat-treatment conditions (different cooling rates and tempering). Hence, the crystal structure and the phase in the microstructure were analyzed through XRD.

Figure 5.

Microstructures of the M4 deposited layer after the post-heat-treatment condition: (a) as-deposited; (b) A; (c) F; (d) AT; (e) FT.

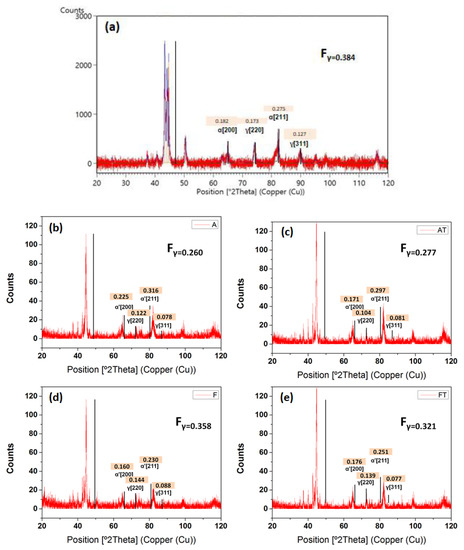

Figure 6 shows the unique spectra that appears under X-ray irradiation. When the peaks appear at the same locations on the spectra, they indicate the same crystal structure or phase. However, different peak intensities (peak heights) indicate differences in the content of the crystal structures. All spectra showed the highest peak at approximately 42°. At this location, a combination of crystal structures γ [111] and α’ [110] for the phases appeared. Here, gamma (γ) represents a face-centered-cubic (FCC) lattice, and alpha prime (α’) represents a body-centered-cubic (BCC) lattice. The FCC crystal structure was predicted to be an austenite structure, and the BCC structure was estimated to be a martensite structure. However, ferrite, pearlite, or bainite structures that show a BCC structure may be included. The peaks at approximately 51°, 65°, 74°, 82°, 90°, 95°, and 99° were γ [200], α’ [200], γ [220], α’ [211], γ [311], γ [222], and α’ [200], respectively [10]. In addition, fine carbides appeared in the microstructure images of SEM, but they appeared as very weak peaks, and it was difficult to detect them under the given XRD condition.

Figure 6.

XRD spectrum of the post-heat-treated condition: (a) non–heat-treated M4 deposits: (b) A; (c) F; (d) AT; (e) FT.

Table 4 shows the volume fractions in the microstructure that were calculated with the intensity value of each peak in the XRD spectrum. This was used to calculate the content of all the residual austenite through the four peak values (α’ [200], γ [220], α’ [211], and γ [311]) based on the Cullity equation (Equation (1)) [15].

Table 4.

Initial volume fraction of the retained austenite (integrated XRD peak intensity).

When the residual austenite value was calculated through the XRD analysis, the M4 microstructures before the post-heat treatment showed a residual austenite content of 38.4%. The microstructures after the post-heat treatment showed a different residual austenite content due to the phase transformation. The residual austenite had an FCC structure with a higher filling rate and ductility than the martensite BCC structure; however, its strength was lower. Among the post-heat-treatment conditions, the air-cooling condition (A), which has a faster cooling rate, showed the lowest residual austenite content. The high martensite content in the microstructures was inferred from the CCT curve. Under the furnace-cooling condition (F), the residual austenite was 27.7%, which is similar to the air-cooling condition. However, the other microstructures were estimated to be pearlite, ferrite, and bainite. When tempering work was additionally performed under AT and FT, the austenite content in the microstructures increased.

5. Mechanical Properties

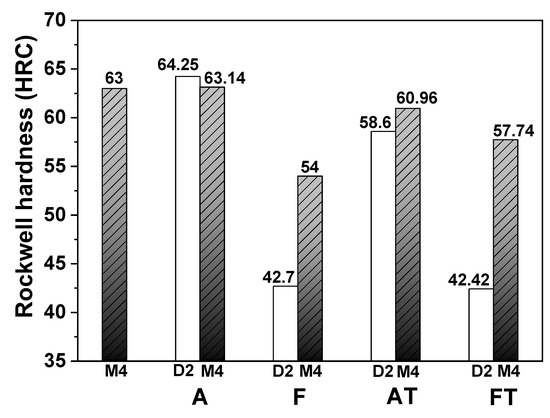

5.1. Hardness

To observe the effect of the heat-treatment on the changes in the hardness of the deposited layer, the hardness was measured at five points in the deposited layer and the substrate for each deposited sample for each heat-treatment condition. Figure 7 shows a comparison of the Rockwell hardness of the specimens according to the heat treatment condition, and the specimens display different hardness levels. The hardness is determined by a combination of various factors including the grain size, carbide content, size, and distribution; however, the hardness was observed to change based on the change in the crystal structure, which has the largest effect on the hardness. The hardness of the M4 that was deposited through preheating with no post-heat treatment was 63 HRC. Post-heat treatment condition A showed a deposited layer hardness of 63.14 HRC (Standard Deviation (SD): 0.26), and the hardness of the substrate was 64.25 HRC (SD: 1.37). It was expected that the hardness would increase because the martensite fraction increased owing to the fast cooling rate in the post-heat-treatment process; however, the hardness had a negligible change. In contrast, the hardness of the substrate was 64.25 HRC, which is higher than the hardness of the original material. Owing to the nature of the substrate, this is attributed to its high carbon content. A high carbon material can easily be transformed to the martensite form in the cooling process, thereby resulting in high hardness. Under condition F, when performing cooling in a heat-treatment furnace with a slow cooling rate, some microstructures of the residual austenite transformed into bainite, pearlite, or ferrite microstructures. These microstructures showed a low hardness with a slow cooling rate because they have a lower hardness than the martensite structures (deposited layer 54 HRC (SD: 0.68), substrate 42.7 HRC (SD: 0.31)). The hardness of the substrate was also low for the same reason; however, the extent of the hardness change was large. The hardness also changed when tempering was performed after air cooling or furnace cooling in the post-heat-treatment process. Condition AT’s hardness for the deposited layer was 60.96 HRC (SD: 0.44), and the substrate had a hardness of 58.6 HRC (SD: 0.49). Condition FT’s hardness for the deposited layer was 42.42 HRC (SD: 0.17), and the substrate had a hardness of 57.74 HRC (SD: 0.36). This phenomenon appears to have occurred because the martensite and the residual austenite structures transformed to bainite, pearlite, or ferrite in the tempering process.

Figure 7.

Rockwell hardness of the post-heat treated M4.

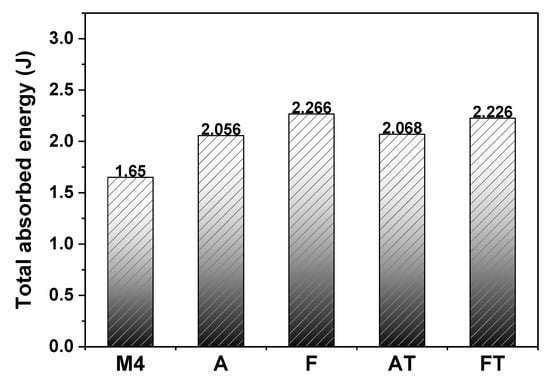

5.2. Impact Toughness

Impact toughness is an important factor that can evaluate the durability of the dies together with hardness. Hence, the Charpy impact test was performed under the same conditions to observe the changes in the impact toughness from the post-heat-treatment. Figure 8 shows the test results. The impact toughness of the M4-deposited specimen without a post-heat-treatment process was 1.65 J, which shows the lowest impact toughness for these tests. In contrast, the impact toughness improved under all the post-heat-treatment conditions. It was 2.056 J (SD: 0.35) under condition A, 2.266 J (SD: 0.39) under condition F, 2.068 J (SD: 0.02) under condition AT, and 2.226 J (SD: 0.47) under condition FT. As mentioned above in the observations of the microstructure and the hardness, the microstructures were recrystallized by the post-heat-treatment process, which has a higher toughness. Under condition A where the cooling rate was fast, the hardness was high due to the high martensite fraction; however, the specimen showed the lowest impact toughness among the post-heat-treated specimens. A martensite structure is characterized by the brittleness and has the lowest ductility among the metal crystal structures. However, the furnace-cooled specimen (condition F) showed a high toughness. As the austenite structures were slowly cooled at a high temperature, they phase-transformed the microstructures (pearlite or ferrite), which exhibited a high toughness as they contained relatively soft tissues. The tempering process was expected to improve the impact toughness because some martensite structures are transformed to soft tissues such as bainite or ferrite. However, the tempering process did not show a notable effect in this experiment.

Figure 8.

Total absorbed energy of the post-heat treated M4.

Figure 9 displays the fracture surfaces due to a crack that started from the V-notch during the Charpy impact test. Figure 9a shows the fracture surface of a non-post-treated specimen. During the microstructure observation, the specimen formed cellular dendrite tissues, and the fracture surface showed crack propagation along the grain boundaries of the cell shape that is similar to the microstructure shape. The microstructures illustrated in Figure 9b–e show the fracture surfaces of the post-heat-treated specimens. Since the microstructure observation did not reveal any significant changes in the microstructure due to the effect of the post-heat-treatment, we were not able to observe any significant changes under each condition along the fracture surface. However, the post-heat-treatment process caused microstructure phase transformation and it changed the impact toughness. Consequently, the fracture surface shows differences before and after the post-heat treatment. The fracture surface before the post-heat treatment showed a crack propagation phenomenon, but after the heat treatment process, a complex fracture surface of a more crystalline structure appeared. Some fracture surfaces with dimples were also observed. Consequently, the post-heat-treated specimen was expected to show high impact toughness in the impact test. Thus, the post-heat-treatment process was able to improve the toughness of the M4 deposited layer. In addition, the changes in the mechanical properties according to the cooling rate were greater after the heat treatment due to the tempering effect.

Figure 9.

Micro-images of the fracture surface: (a) as-deposited M4; (b) A; (c) F; (d) AT; (e) FT.

6. Conclusions

In this study, the post-heat-treatment process was examined in the M4 deposited layer to improve the mechanical properties. To this end, the M4 powders were deposited on the D2 substrate through preheating. In addition, an observation of the microstructures and an analysis of the mechanical properties were performed based on the changes from the four types of post-heat-treatment processes. The following conclusions were obtained.

(1) Microstructure observation and XRD analysis revealed a phase transformation for the microstructures in the M4 deposited layer during the post-heat-treatment process. The microstructures showed different transformations depending on the cooling rate that was applied after they were heated to 1020 °C. Under the air-cooling condition, the austenite structure transformed to a martensite structure at a fast cooling rate. Under the furnace-cooling condition, due to the slow cooling rate, it transformed to ferrite, pearlite, and bainite tissues. The tempering process tended to increase the amount of residual austenite.

(2) The phase transformation of the M4 deposited layer also occurred in the post-heat-treatment process, which resulted in different mechanical properties. The air-cooled specimen with a higher martensite fraction showed the highest hardness, and the furnace-cooled specimen showed the lowest hardness. In contrast, the air-cooled specimen displayed low impact toughness, but the furnace-cooled specimen that contained the soft ferrite tissues showed high impact toughness. The effect of tempering on the impact toughness was insignificant.

In conclusion, the post-heat-treatment process effectively improves the impact toughness of the M4 deposited layer by changing the microstructure. It is expected that the durability of the dies can be enhanced by the combination of air cooling, which can impart high toughness while satisfying the hardness required in the actual dies through a post-heat-treatment process. In addition, tempering can improve the durability since it contributes to the stabilization of the microstructure. Although we conducted this study for the M4 layer according to the substrate material condition, in the future, better heat treatment conditions are required to achieve high impact toughness while maintaining high hardness along the surface.

Author Contributions

This work was done with the cooperation and the joint efforts of all the authors. D.S.S., K.Y.L., and G.Y.B. designed the experiments; G.Y.B. and G.Y.S. performed the experiments; K.Y.L. and D.S.S. analyzed the experimental data; G.Y.B. wrote the paper; D.S.S. and K.Y.L. reviewed and edited the paper. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Korea Institute of Energy Technology Evaluation and Planning (KETEP) funded by the Korea government (MOTIE) (grant number 2018201010633B).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hashemi, N.; Martens, A.; Montrieux, H.M.; Tchuindjang, J.T.; Dedry, O.; Carrus, R.; Lecomte-Beckers, J. Oxidative wear behaviour of laser clad high speed steel thick deposits: Influence of sliding speed, carbide type and morphology. Surf. Coat. Technol. 2017, 315, 519–529. [Google Scholar] [CrossRef]

- Rahman, N.U.; Capuano, L.; van der Meer, A.; de Rooij, M.B.; Matthews, D.T.A.; Walmag, G.; Sinnaeve, M.; Garcia-Junceda, A.; Castillo, M.; Römer, G.R.B.E. Development and characterization of multilayer laser cladded high speed steels. Addit. Manuf. 2018, 24, 76–85. [Google Scholar] [CrossRef]

- Fallah, V.; Alimardani, M.; Corbin, S.F.; Khajepour, A. Impact of localized surface preheating on the mi-crostructure and crack formation in laser direct deposition of Satellite 1 on AISI 4340 steel. Appl. Surf. Sci. 2010, 257, 1716–1723. [Google Scholar] [CrossRef]

- Shim, D.S.; Baek, G.Y.; Lee, E.M. Effect of substrate preheating by induction heater on direct energy disposition of AISI M4 powder. Mater. Sci. Eng. A 2017, 682, 550–562. [Google Scholar] [CrossRef]

- Baek, G.Y.; Shin, G.Y.; Lee, K.Y.; Shim, D.S. Mechanical properties of tool steels with high wear resistance via directed energy deposition. Metals 2019, 9, 282. [Google Scholar] [CrossRef]

- Sola, R.; Veronesi, P.; Giovanardi, R.; Forti, A.; Parigi, G. Effect of heat treatment before cryogenic cooling on the properties of AISI M2 steel. La Metall. Ital. 2017, 10, 5–16. [Google Scholar]

- Shim, D.S.; Baek, G.Y.; Lee, S.B.; Yu, J.Y.; Choi, Y.S.; Park, S.H. Influence of heat treatment on wear behavior and impact toughness of AISI M4 coated by laser melting deposition. Surf. Coat. Technol. 2017, 328, 219–230. [Google Scholar] [CrossRef]

- Wang, F.; Mao, H.; Zhang, D.; Zhao, X.; Shen, Y. Online study of cracks during laser cladding process on acoustic emission technique and finite element analysis. Appl. Surf. Sci. 2008, 255, 3267–3275. [Google Scholar] [CrossRef]

- Telasang, G.; Dutta Majumdar, J.; Wasekar, N.; Padmanabham, G.; Manna, I. Microstructure and mechanical properties of laser clad and post-cladding tempered AISI H13 tool steel. Metall. Mater. Trans. A 2015, 46, 2309–2321. [Google Scholar] [CrossRef]

- Park, J.S.; Lee, M.-J.; Cho, Y.-J.; Sung, J.H.; Jeong, M.-S.; Lee, S.-K.; Choi, Y.-J.; Kim, D.H. Effect of heat treatment on the characteristics of tool steel deposited by the directed energy deposition process. Met. Mater. Int. 2016, 22, 143–147. [Google Scholar] [CrossRef]

- Sun, S.D.; Liu, Q.; Brandt, M.; Luzin, V.; Cottam, R.; Janardhana, M.; Clark, G. Effect of laser clad repair on the fatigue behaviour of ultra-high strength AISI 4340 steel. Mater. Sci. Eng. A 2014, 606, 46–57. [Google Scholar] [CrossRef]

- Lourenço, J.M.; Sun, S.D.; Sharp, K.; Luzin, V.; Klein, A.N.; Wang, C.H.; Brandt, M. Fatigue and fracture behavior of laser clad repair of AerMet® 100 ultra-high strength steel. Int. J. Fatigue 2016, 85, 18–30. [Google Scholar] [CrossRef]

- Jo, Y.K.; Yu, J.H.; Jeong, H.S.; Beak, G.Y.; Lee, G.Y.; Park, S.H. Experimental analysis on multilayer cladding using AISI-M4/H13 metal powders for enhancement of wear resistance and shockproof characteristics. J. Korean Soc. Precis. Eng. 2019, 36, 1059–1064. [Google Scholar] [CrossRef]

- Baek, G.Y.; Lee, K.Y.; Park, S.H.; Shim, D.S. Effects of substrate preheating during direct energy deposition on microstructure, hardness, tensile strength, and notch toughness. Met. Mater. Int. 2017, 23, 1204–1215. [Google Scholar] [CrossRef]

- Cullity, B.D. Elements of x-Ray Diffraction; Addison-Wesley Publishing Company, Inc.: Reading, MA, USA, 1978; pp. 1–509. [Google Scholar]

- Briki, J.; Slima, S.B. A new continuous cooling transformation diagram for AISI M4 high-speed tool steel. J. Mater. Eng. Perform. 2008, 17, 864–869. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).