Effect of Stress-Relieving Heat Treatment on the High Strain Rate Dynamic Compressive Properties of Additively Manufactured Ti6Al4V (ELI)

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

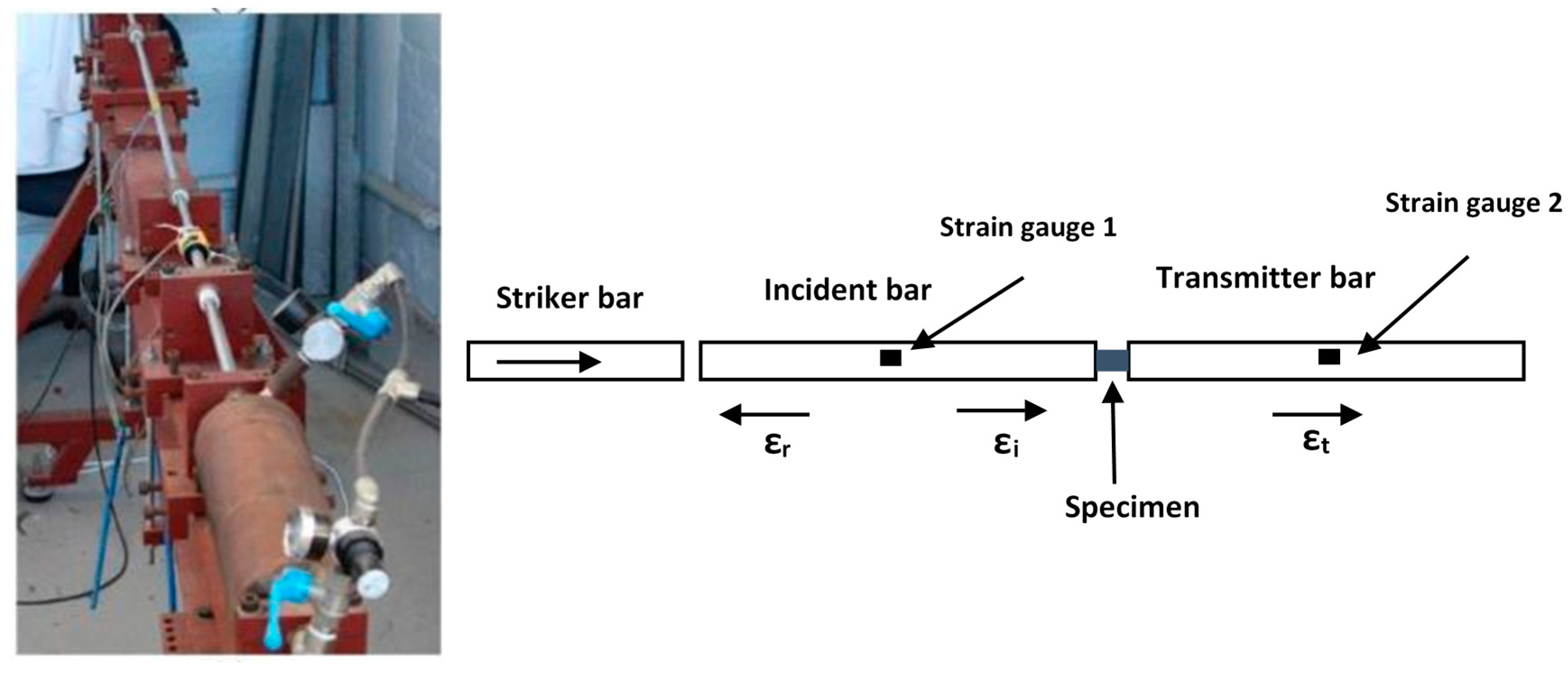

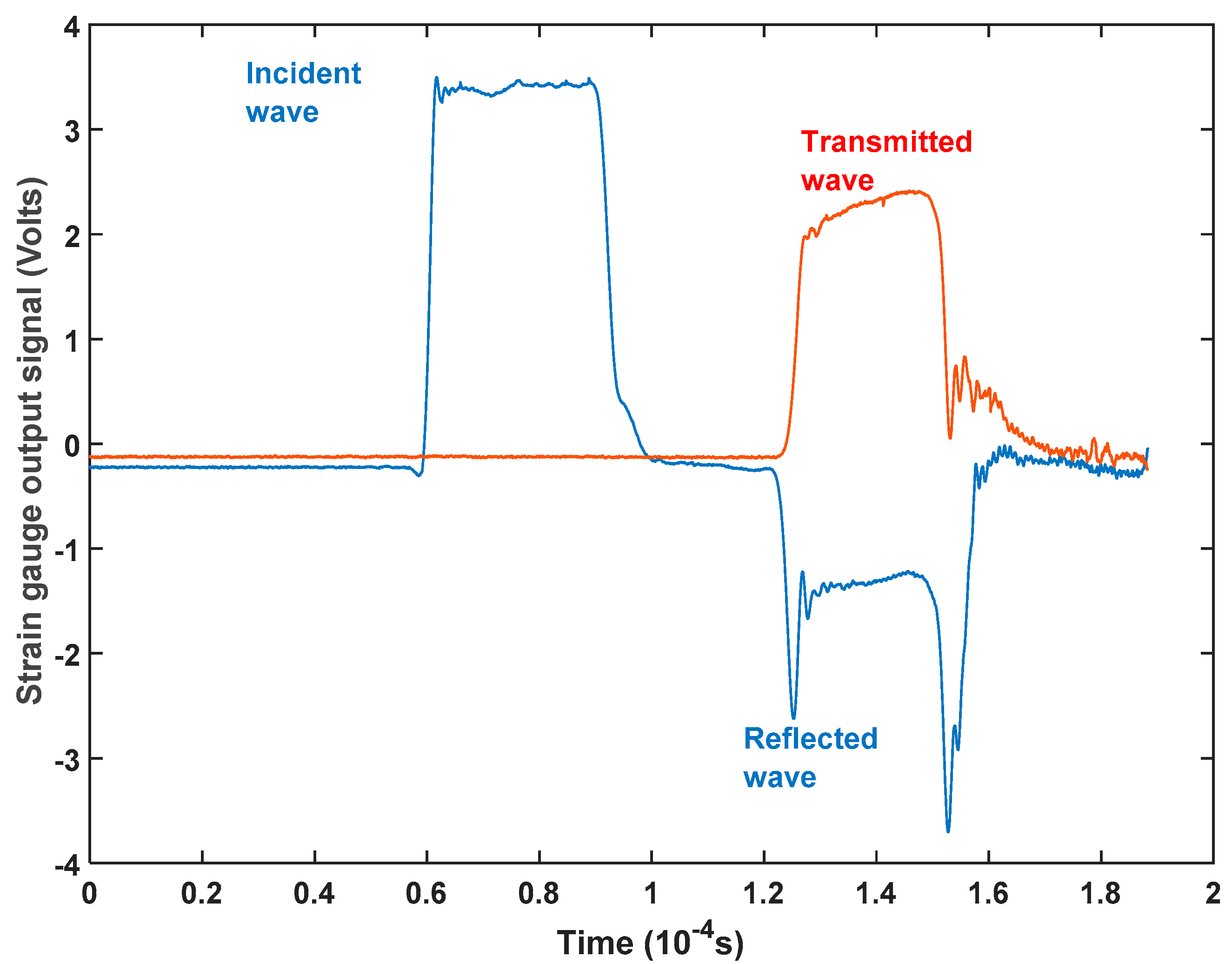

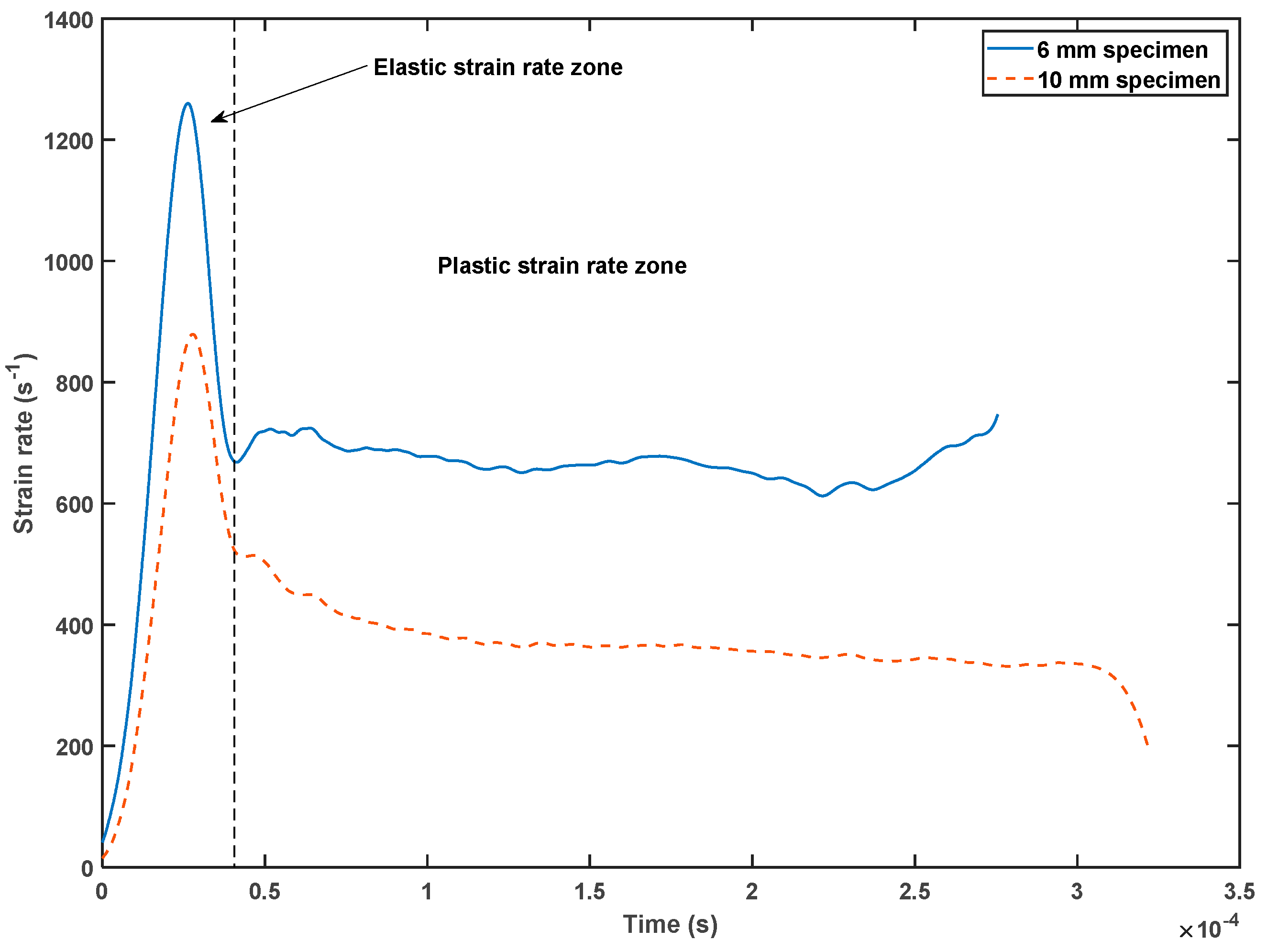

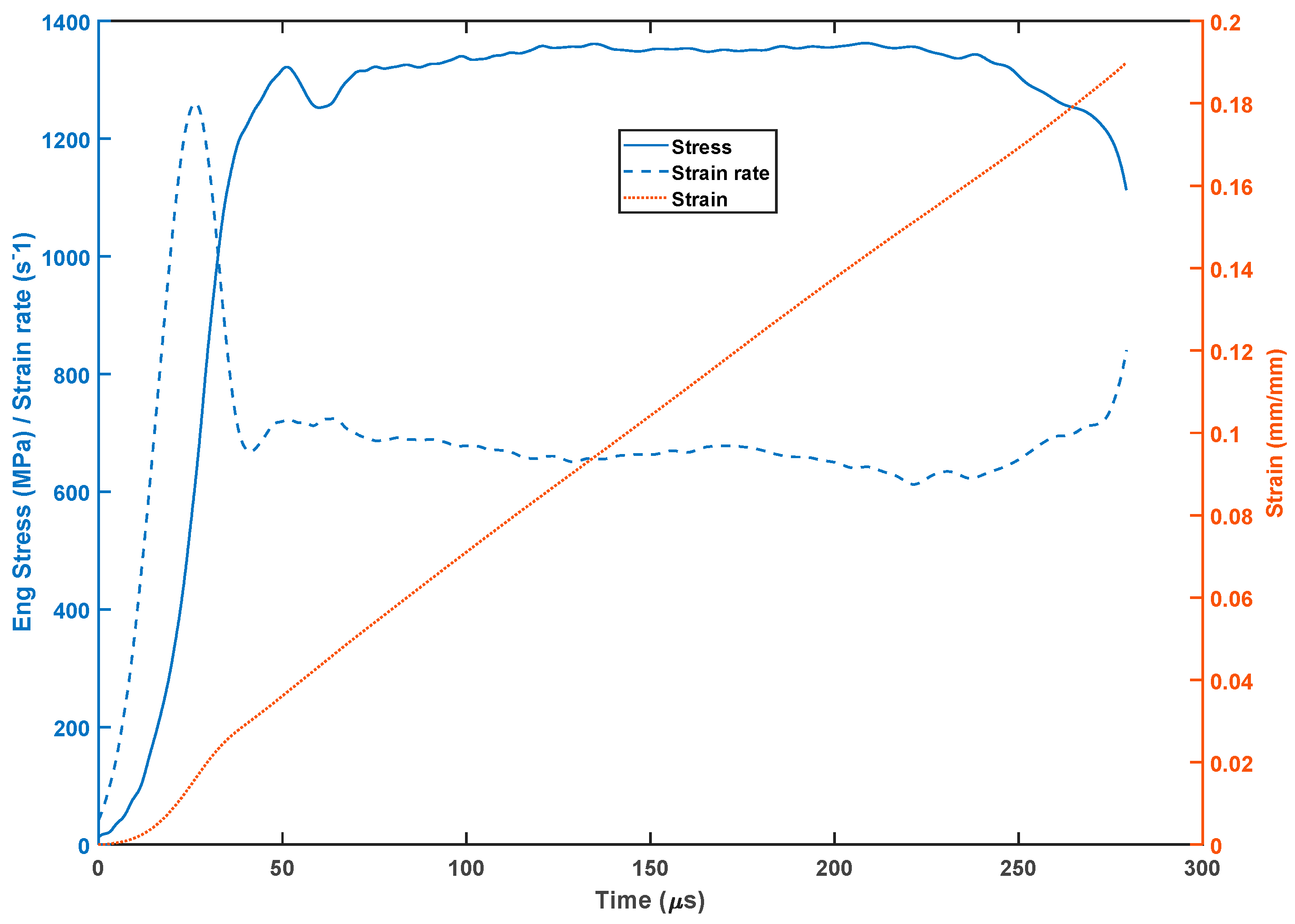

2.2. Dynamic Compression Test

2.3. Preparation of Fractured and Cut Surfaces (in the Unfractured Specimens)

3. Results and Discussion

3.1. Microstructure

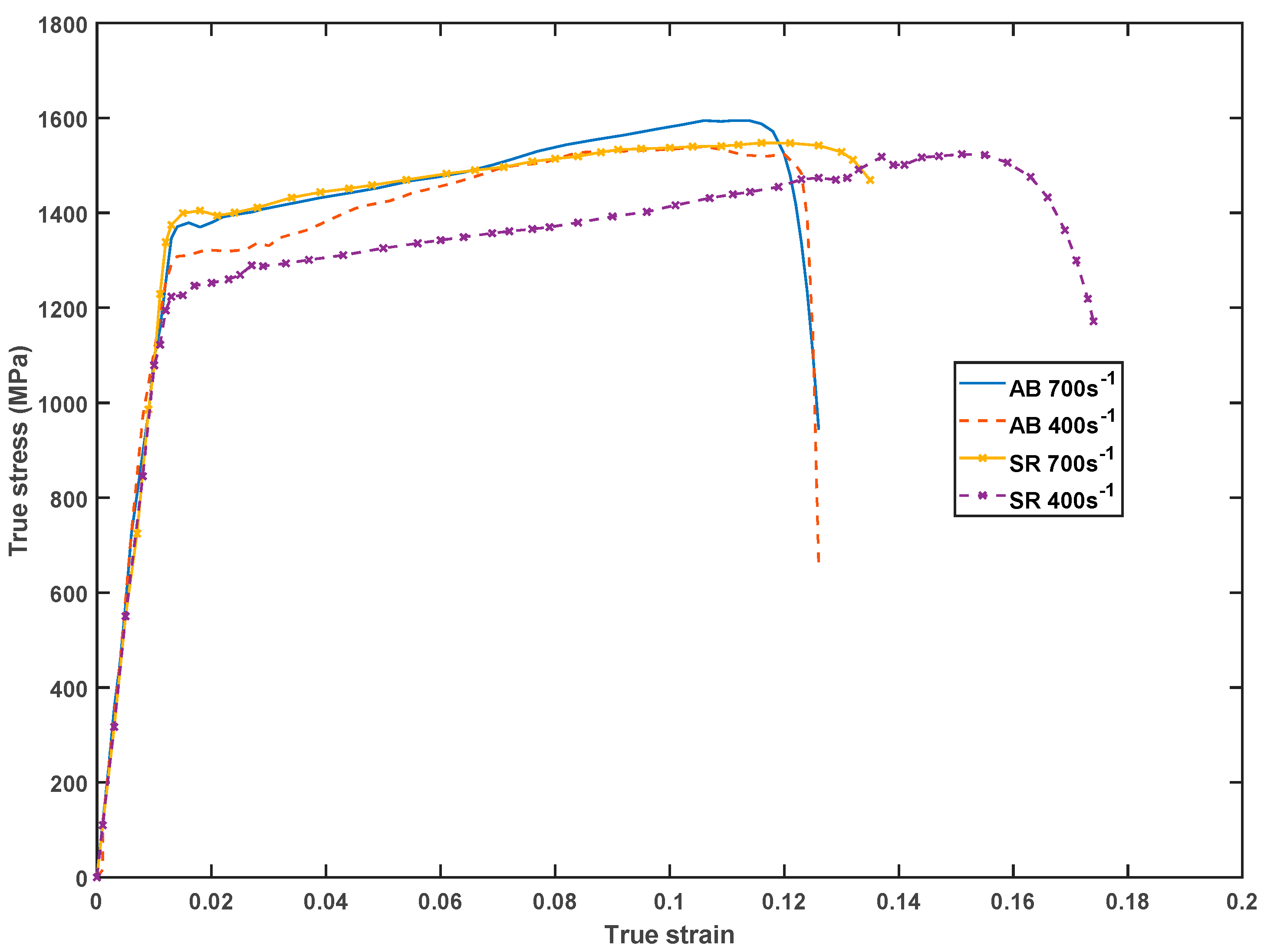

3.2. Flow Stress and Strain Rate Dependency

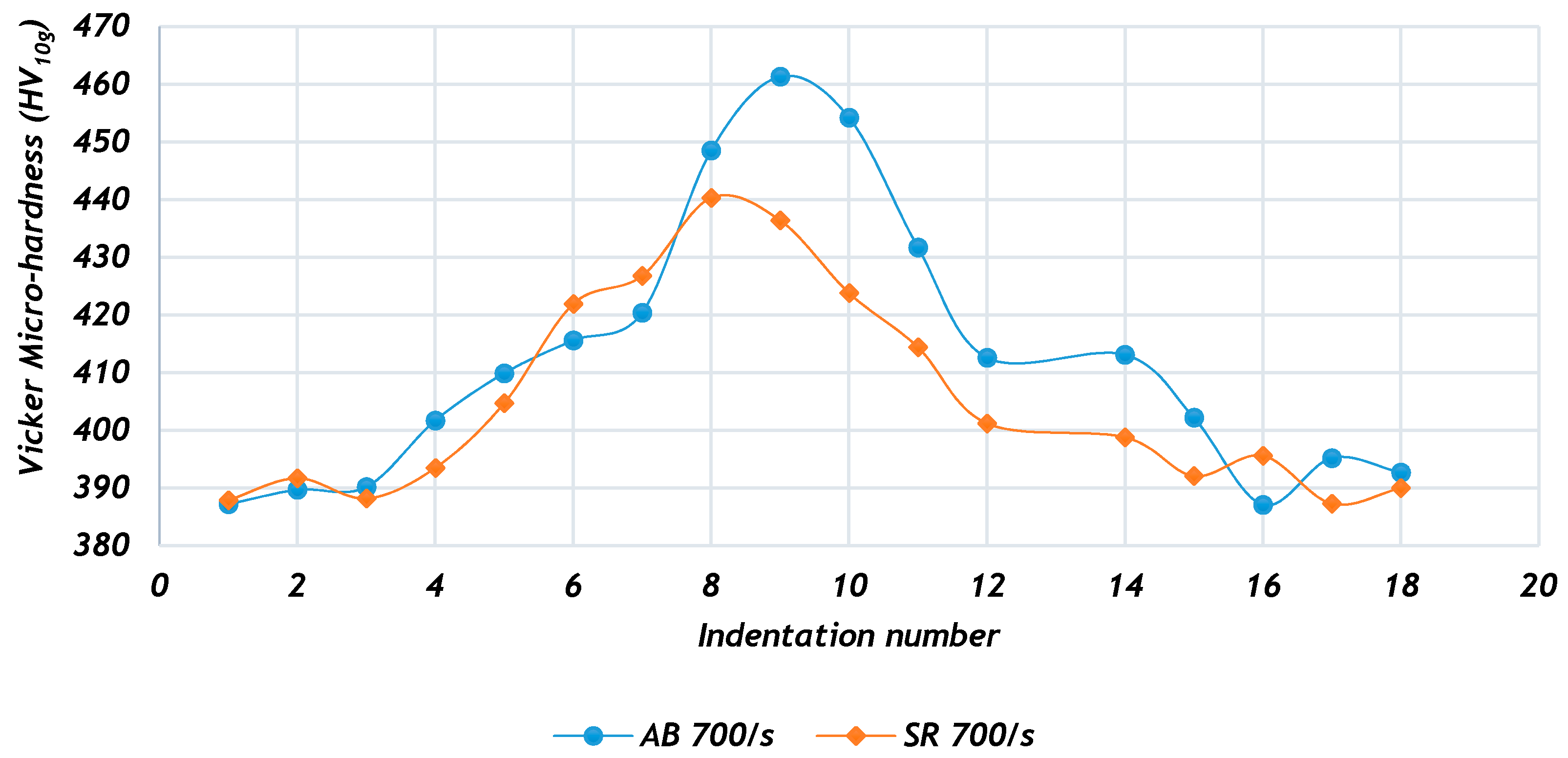

3.3. Hardness Test Result

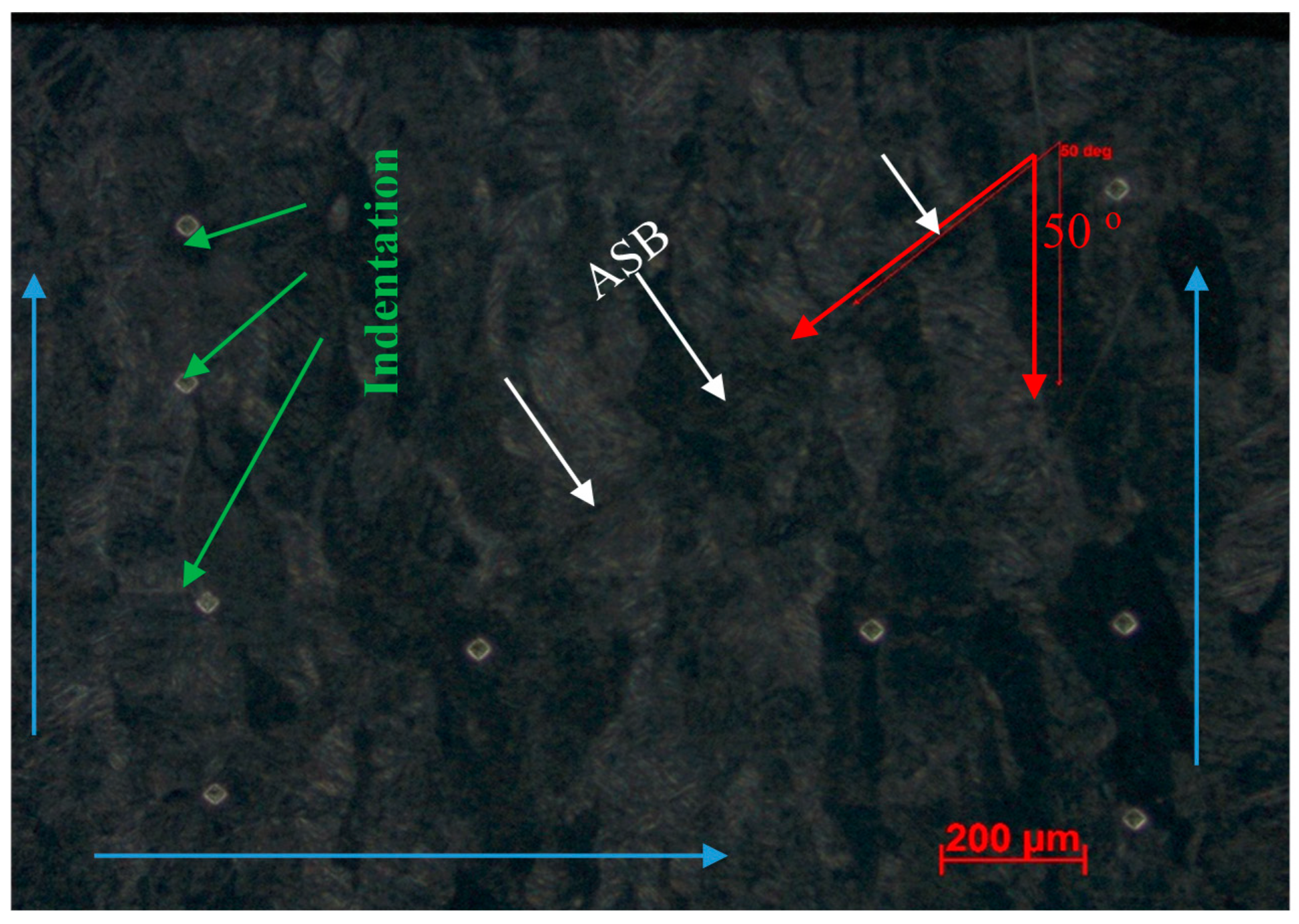

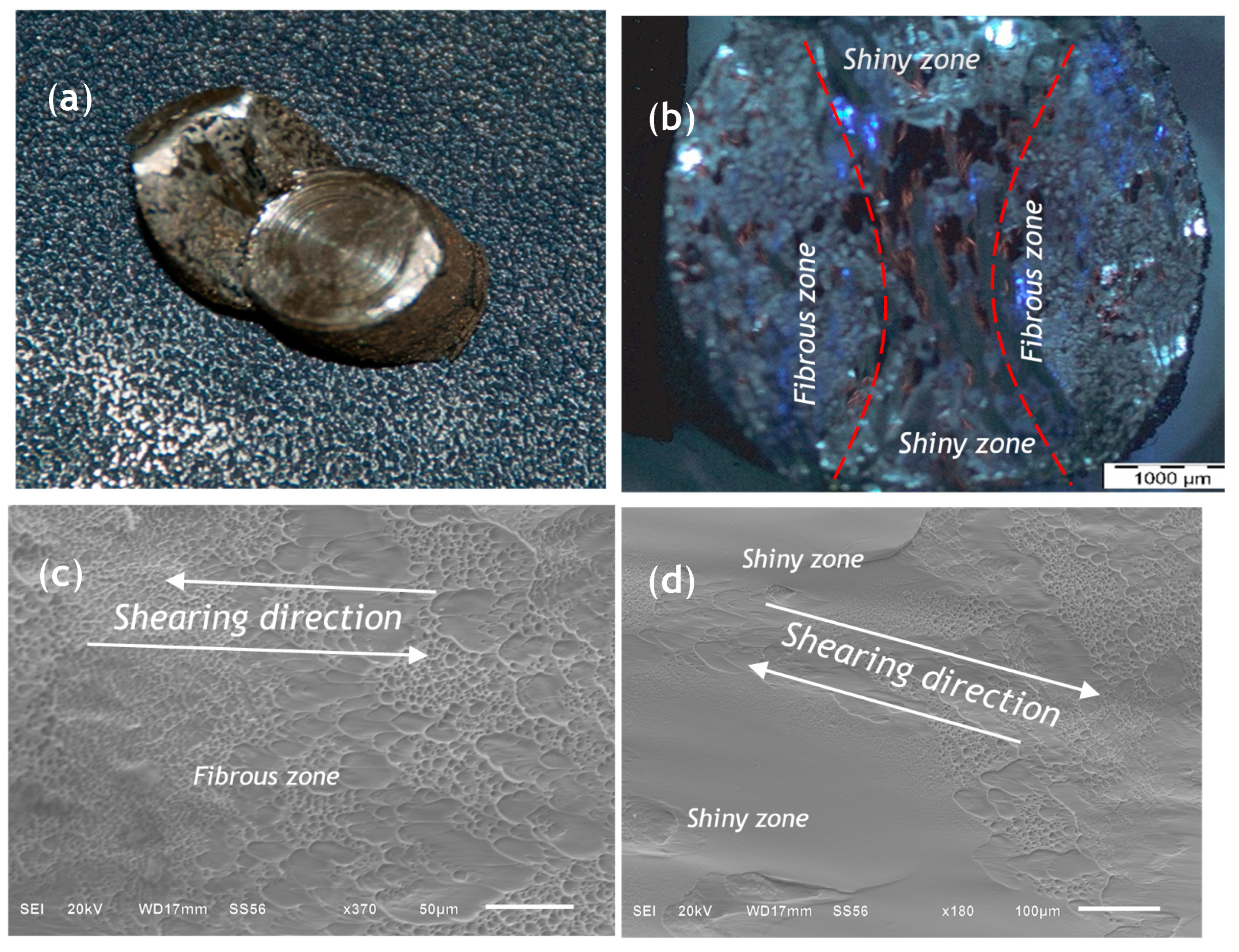

3.4. Observation and Analysis of Sectioned and Fractured Surfaces

4. Conclusions

- (a)

- The compressive fracture strength of the AB DMLS Ti6Al4V (ELI) decreased as a result of stress-relieving heat treatment, while ductility increased for both forms of the alloy.

- (b)

- The flow stress under the compressive loading increased, while the fracture strain decreased with a higher strain rate for both forms of the alloy.

- (c)

- The strain rate sensitivity of the SR specimens was higher in comparison to that of AB specimens at the same true strain, implying that SR DMLS Ti6Al4V (ELI) specimens are strengthened much faster under dynamic loading conditions than AB specimens under the same loading.

- (d)

- Stress-relieving heat treatment resulted in the reduction of the microhardness of the specimens. This is thought to be due to the reduction in tensile residual stresses created in the DMLS process.

- (e)

- The values of microhardness for both the AB and SR specimens were higher for the higher compressive strain rates. However, microhardness was greater near the ASBs, and declined gradually towards the regions far from the ASBs.

- (f)

- SEM image analysis indicated that the compressive fracturing of both forms of the alloy was a result of the development of ASBs for the two test strain rates.

- (g)

- At the same strain rate, the transformed ASBs for AB samples were narrower than those for the SR specimens.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ivanova, O.; Williams, C.; Campbell, T. Additive manufacturing (AM) and nanotechnology: Promises and challenges. Rapid Prototyp. J. 2013, 19, 353–364. [Google Scholar] [CrossRef]

- Ralf, C.; Claus, A.; Coube, O.; Keith, M. Introduction to Additive Manufacturing Technology: A Guide for Designer and Engineers, 2nd ed.; European Powder Metallurgy Association: Shrewsbury, UK, 2015. [Google Scholar]

- DebRoy, T.; Wei, L.; Zuback, S.; Mukherjee, T.; Elmer, W.; Milewski, O.; Zhang, W. Additive manufacturing of metallic components–process, structure and properties. Prog. Mater. Sci. 2018, 2, 112–224. [Google Scholar] [CrossRef]

- Ikuhiro, I.; Tsutomu, T.; Yoshihisa, S.; Nozomu, A. Application and Features of Titanium for Aerospace Industry; Technical Review—Nippon Steel Technical Report No 106; Nippon Steel Corporation: Osaka, Japan, 2014. [Google Scholar]

- Properties: Titanium Alloys—Ti6Al4V Grade 5—AzoM.com. Available online: https://www.azom.com/properties.aspx?ArticleID=1547 (accessed on 28 April 2020).

- Reducing the Buy-to-Fly Ratio with Metal 3D Printing. Available online: http://www.materialise.com/en/manufacturing/whitepaper-buy-to-fly-ratio-cutting-costs-metal-3d-printing (accessed on 19 April 2018).

- Uriondo, A.; Esperson-Miguez, M.; Perinpanyangam, S. The present and future of additive manufacturing in aerospace sector: A review of important aspects. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2015, 229, 1–16. [Google Scholar] [CrossRef]

- Patterson, E.; Sherri, L.; Messimer, L.; Farrington, P. Overhanging features and the SLM/DMLS residual stresses problem. Review and future research need. Addit. Manuf. Tech. 2017, 5, 15. [Google Scholar] [CrossRef]

- Rafi, H.K.; Karthik, N.V.; Gong, H.L.; Starr, S.E. Microstructures and mechanical properties of Ti6Al4V parts fabricated by selective laser melting and electron beam melting. Mater. Eng. Perf. 2013, 22, 3372–3383. [Google Scholar] [CrossRef]

- Todd, M.M.; Long, M.J. Mechanical behaviour of additive manufactured, powder-bed laser-fused materials. Mater. Sci. Eng. A 2015, 651, 198–213. [Google Scholar] [CrossRef]

- Moletsane, G.; Krakhmalev, P.; Du Plessis, A.; Yadroitsava, I.; Yadroitsev, I.; Kazantseva, I. Tensile properties and microstructure of direct metal laser-sintered Ti-6Al-4V (ELI) alloy. SAJIE 2016, 27, 110–121. [Google Scholar] [CrossRef]

- Du Plessis, A.; Ina Yadroistava, I.; Roux, S.; Yadroitsev, I.; Fieres, J.; Reinhart, C.; Rossouw, P. Prediction of mechanical performance of Ti6Al4V cast alloy based on microCT-based load simulation. J. Alloys Compd. 2017, 724, 267–274. [Google Scholar] [CrossRef]

- Yatnalkar, R. Experimental Investigation of Plastic Deformation of Ti-6Al-4V under Various Loading Conditions. Master’s Thesis, The Ohio State University, Columbus, OH, USA, 2010. [Google Scholar]

- Wulf, G.L. High strain rate compression of titanium and some titanium alloys. IJMSCI 1976, 21, 713–718. [Google Scholar] [CrossRef]

- Lee, W.-S.; Lin, M.-T. The effects of strain rate and temperature on the compressive deformation behaviour of Ti6Al4V alloy. J. Mater. Process. Technol. 1997, 71, 235–246. [Google Scholar] [CrossRef]

- Li, P.H.; Guo, W.G.; Huang, W.D.; Su, Y.; Lin, X.; Yuan, K.B. Thermomechanical response of 3D laser-deposited Ti–6Al–4V alloy over a wide range of strain rates and temperatures. Mater. Sci. Eng. 2015, 647, 34–42. [Google Scholar] [CrossRef]

- Mohammadhosseini, A.; Masood, S.; Fraser, D.; Jahedi, M. Dynamic compressive behaviour of Ti-6Al-4V alloy processed by electron beam melting under high strain rate loading. Adv. Manuf. 2015, 3, 232–243. [Google Scholar] [CrossRef]

- Bradley, D.; Yilong, B. Introduction to Adiabatic Shear Localization, Revised ed.; Imperial College Press: London, UK, 2015; pp. 29–32. [Google Scholar]

- Lee, W.-S.; Lin, C.-F. Plastic deformation and fracture behaviour of Ti–6Al–4V alloy loaded with high strain rate under various temperatures. Mater. Sci. Eng. 1998, 241, 48–56. [Google Scholar] [CrossRef]

- Lanyon, L.E.; Hampson, W.G.; Goodship, A.E.; Shah, J.S. Bone deformation recorded in vivo from strain gauges attached to the human tibial shaft. Acta Orthop. Scand. 1975, 46, 256–268. [Google Scholar] [CrossRef] [PubMed]

- Burr, D.B.; Milgrom, C.; Fyhrie, D.; Forwood, M.; Nyska, M.; Finestone, A.; Hoshaw, S. In vivo measurement of human tibial strains during vigorous activity. Bone 1996, 18, 405–410. [Google Scholar] [CrossRef]

- Hansen, U.; Zioupos, P.; Simpson, R.; Currey, D.; Hynd, D. The effect of strain rate on the mechanical properties of human cortical bone. J. Biomed. Eng. 2008, 130, 11–18. [Google Scholar] [CrossRef]

- Wood, P.K.; Schley, C.A. Strain Rate Testing of Metallic Materials and Their Modelling for Use in CAE Based Automotive Crash Simulation Tools (Recommendations and Procedures); Ismithers: Shrewsbury, UK, 2009. [Google Scholar]

- Wiesner, C.; McGillivray, H. Loading Rate Effects on Tensile Properties and Fracture Toughness of Steel; TAGSI Seminar; Imperial College: London, UK, 1999; Available online: https://www.twi-global.com/technical-knowledge/published-papers/loading-rate-effects-on-tensile-properties-and-fracture-toughness-of-steel (accessed on 3 April 2018).

- Wang, X.; Feng, Z.; Wang, F.; Yue, Z. Dynamic response analysis of bird strike on aircraft windshield based on damage-modified nonlinear viscoelastic constitutive relation. Chin. J. Aeronaut. 2007, 20, 511–517. [Google Scholar]

- Mango Planes Engine Damaged in Bird Strike at OR Tambo. Available online: http://www.traveller24.com/News/Flights/watch-mango-planes-engine-damaged-in-bird-strike-after-or-tambo-take-off-20171119 (accessed on 19 May 2018).

- Noori, S.A. Dimension effect on dynamic stress equilibrium in SHPB tests. IJMP 2014, 5, 15–26. [Google Scholar]

- Gray, G.T., III. Classic split-Hopkinson pressure bar testing. In ASM Handbook: Mechanical Testing and Evaluation; ASM International: Materials Park, OH, USA, 2008; Volume 8, pp. 462–476. [Google Scholar]

- Kariem, M.A.; Santiago, R.C.; Govender, R.; Shu, D.W.; Ruan, D.; Nurick, G.; Alves, M.; Lu, G.; Langdon, G.S. Round-Robin test of split Hopkinson pressure bar. Int. J. Impact Eng. 2019, 126, 62–75. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Krakhmalev, P.; Yadroitsava, I.; Du Plessis, A. Qualification of Ti6Al4V ELI alloy produced by laser powder bed fusion for biomedical applications. JOM 2007, 70, 372–377. [Google Scholar] [CrossRef]

- Xue, Q.; Meyers, M.; Nesterenko, V. Self–organization of shear bands in Titanium and Ti6Al4V alloy. Acta Mater. 2002, 50, 575–596. [Google Scholar] [CrossRef]

- William, F.H. Mechanical Behaviour of Materials, 2nd ed.; Cambridge University Press: New York, NY, USA, 2010; p. 92. [Google Scholar]

- Sudhanshu, S.; Anuradha, N.M.; Chavan, V.M. Deformation response of Titanium alloy under static and dynamic loading. Procedia Eng. 2007, 173, 1894–1900. [Google Scholar]

- Kim, J.Y.; Shim, I.O.; Kim, H.K.; Hong, S.S.; Hong, S.H. Dynamic deformation and high velocity impact behaviors of TI-6Al-4V Alloys. Mater. Sci. Forum. 2007, 539, 2269–2274. [Google Scholar] [CrossRef]

- Wang, X.B. Effects of temperature and strain rate on the evolution of thickness of transformed adiabatic shear band. Solid State Phenom. 2008, 138, 385–392. [Google Scholar] [CrossRef]

| Strain Rates (s−1) | Conditions | Strained Parts | Ref. |

|---|---|---|---|

| 0.004 | Walking | Tibia and cortical bones | [20] |

| 0.05 | Sprinting and downhill running | Human bones | [21] |

| 1–50 | Traumatic fracture events (accidents) | Human bones | [22] |

| 1–500 | Automotive crash | Automobile body parts | [23] |

| 10–1000 | Aircraft undercarriage | Landing gears | [24] |

| Materials | Al | V | Fe | C | O | N | H | Ti |

|---|---|---|---|---|---|---|---|---|

| Wt. % | 6.34 | 3.944 | 0.25 | 0.006 | 0.082 | 0.006 | 0.001 | Bal. |

| Specimens | As-built (AB) | Stress Relieved (SR) | ||

|---|---|---|---|---|

| Plastic strain rates (s−1) | 400 | 700 | 400 | 700 |

| No. of fractured specimens | 1 | 3 | 2 | 5 |

| No. of unfractured specimens | 6 | 4 | 5 | 2 |

| Total | 7 | 7 | 7 | 7 |

| Strain | 0.02 | 0.04 | 0.08 | 0.12 |

| Form of samples | Strain rate sensitivity (m) | |||

| AB | 0.074 | 0.064 | 0.001 | −0.04 |

| SR | 0.183 | 0.182 | 0.15 | 0.09 |

| Ti6Al4V | Microstructure | Strain Rate (s−1) | YS (MPa) | UCS (MPa) | Ref. | |

|---|---|---|---|---|---|---|

| DMLS-SR | Martensitic | 400 | 1225 | 1525 | 0.174 | Present study |

| DMLS-SR | Martensitic | 700 | 1402 | 1550 | 0.135 | Present study |

| Wrought | Α + β lamellar | 1100 | 1130 | 1180 | 0.180 | [33] |

| Wrought | α + β lamellar | 4100 | 1376 | 1400 | 0.300 | [33] |

| Wrought | α + β Equaxied | 2630 | 1210 | 1346 | 0.320 | [34] |

| Wrought | Α + β Equaxied | 6400 | 1385 | 1410 | 0.270 | [34] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muiruri, A.; Maringa, M.; du Preez, W.; Masu, L. Effect of Stress-Relieving Heat Treatment on the High Strain Rate Dynamic Compressive Properties of Additively Manufactured Ti6Al4V (ELI). Metals 2020, 10, 653. https://doi.org/10.3390/met10050653

Muiruri A, Maringa M, du Preez W, Masu L. Effect of Stress-Relieving Heat Treatment on the High Strain Rate Dynamic Compressive Properties of Additively Manufactured Ti6Al4V (ELI). Metals. 2020; 10(5):653. https://doi.org/10.3390/met10050653

Chicago/Turabian StyleMuiruri, Amos, Maina Maringa, Willie du Preez, and Leonard Masu. 2020. "Effect of Stress-Relieving Heat Treatment on the High Strain Rate Dynamic Compressive Properties of Additively Manufactured Ti6Al4V (ELI)" Metals 10, no. 5: 653. https://doi.org/10.3390/met10050653

APA StyleMuiruri, A., Maringa, M., du Preez, W., & Masu, L. (2020). Effect of Stress-Relieving Heat Treatment on the High Strain Rate Dynamic Compressive Properties of Additively Manufactured Ti6Al4V (ELI). Metals, 10(5), 653. https://doi.org/10.3390/met10050653