Dislocation Emission and Crack Dislocation Interactions

Abstract

1. Introduction

- (i)

- To establish that dislocation emission from cracks plays a major role in the fatigue process.

- (ii)

- To point out the methodologies and recent progresses in analytical formulation of the dislocation interactions, and the role they play in fatigue and fatigue processes.

- (iii)

- To present some very recent results pertaining to the changes in grain morphology, orientations and residual stresses as the materials undergo fatigue.

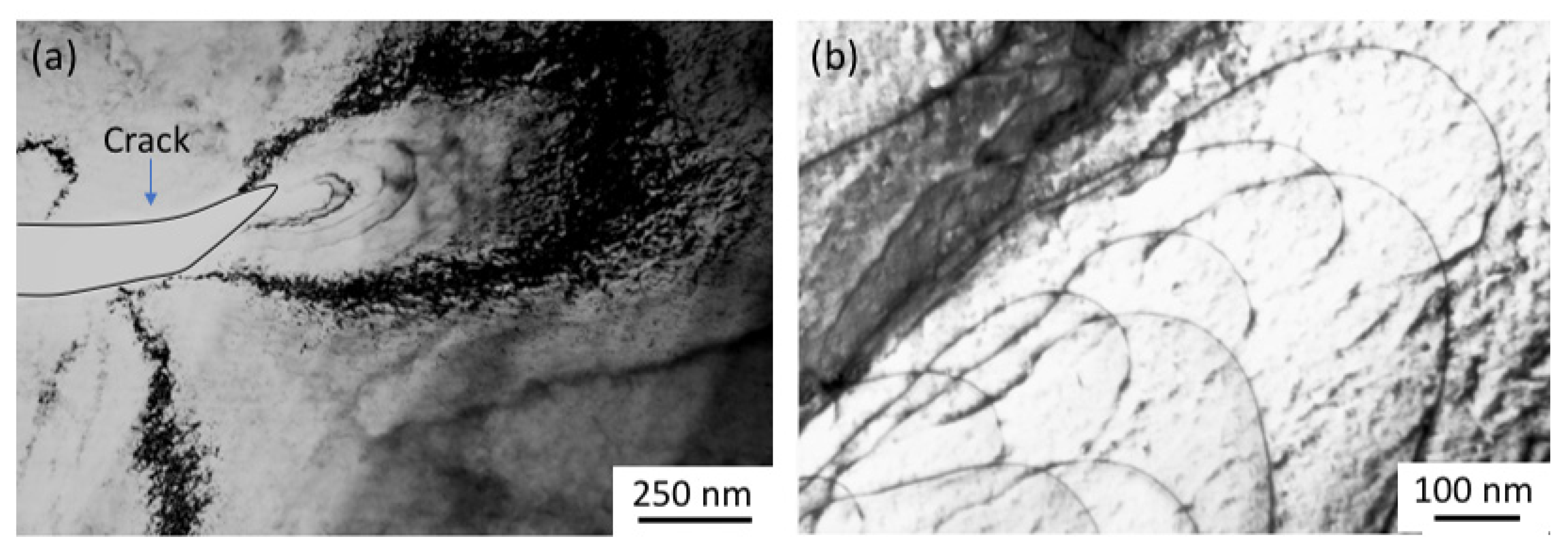

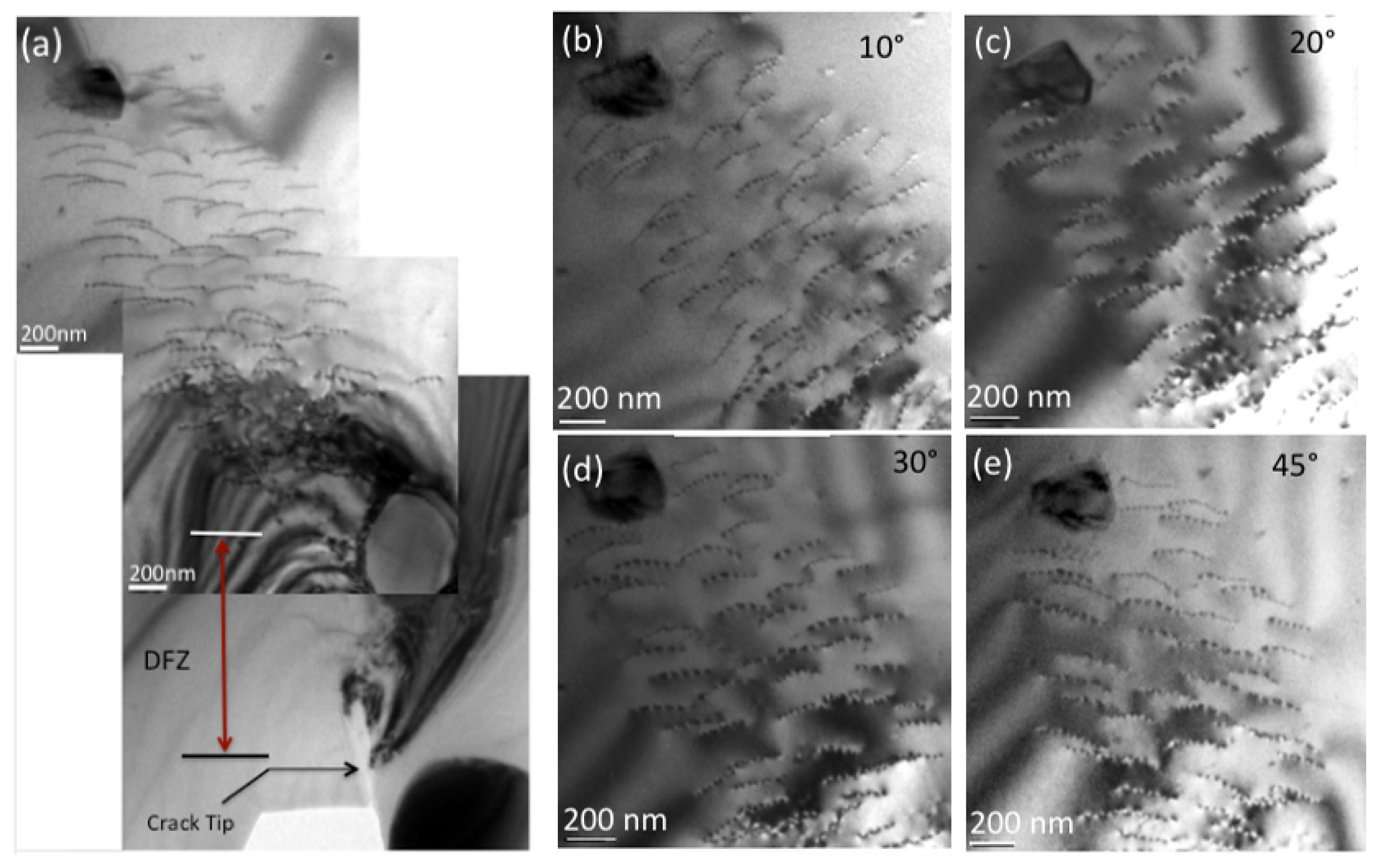

2. Dislocations Emission From Cracks

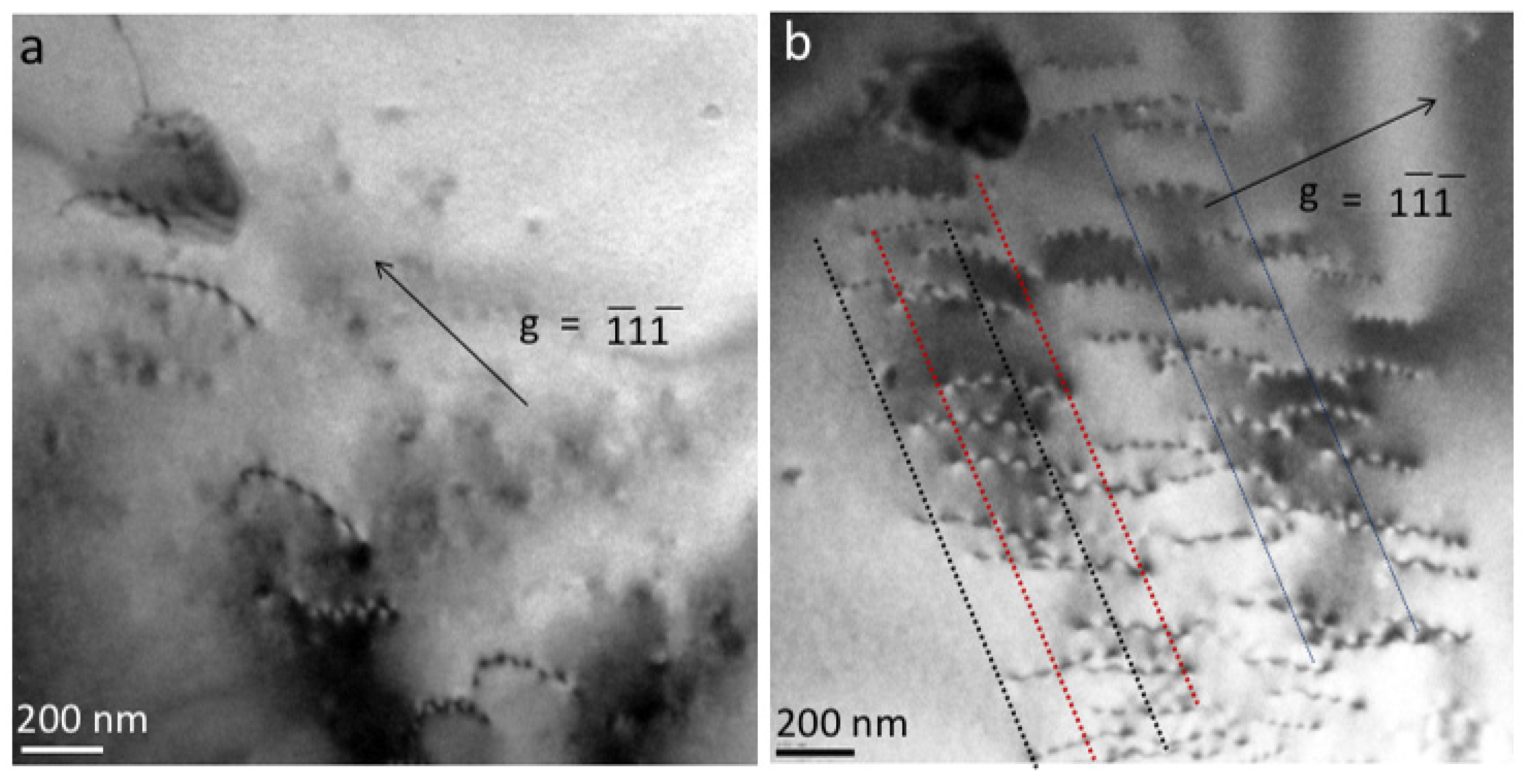

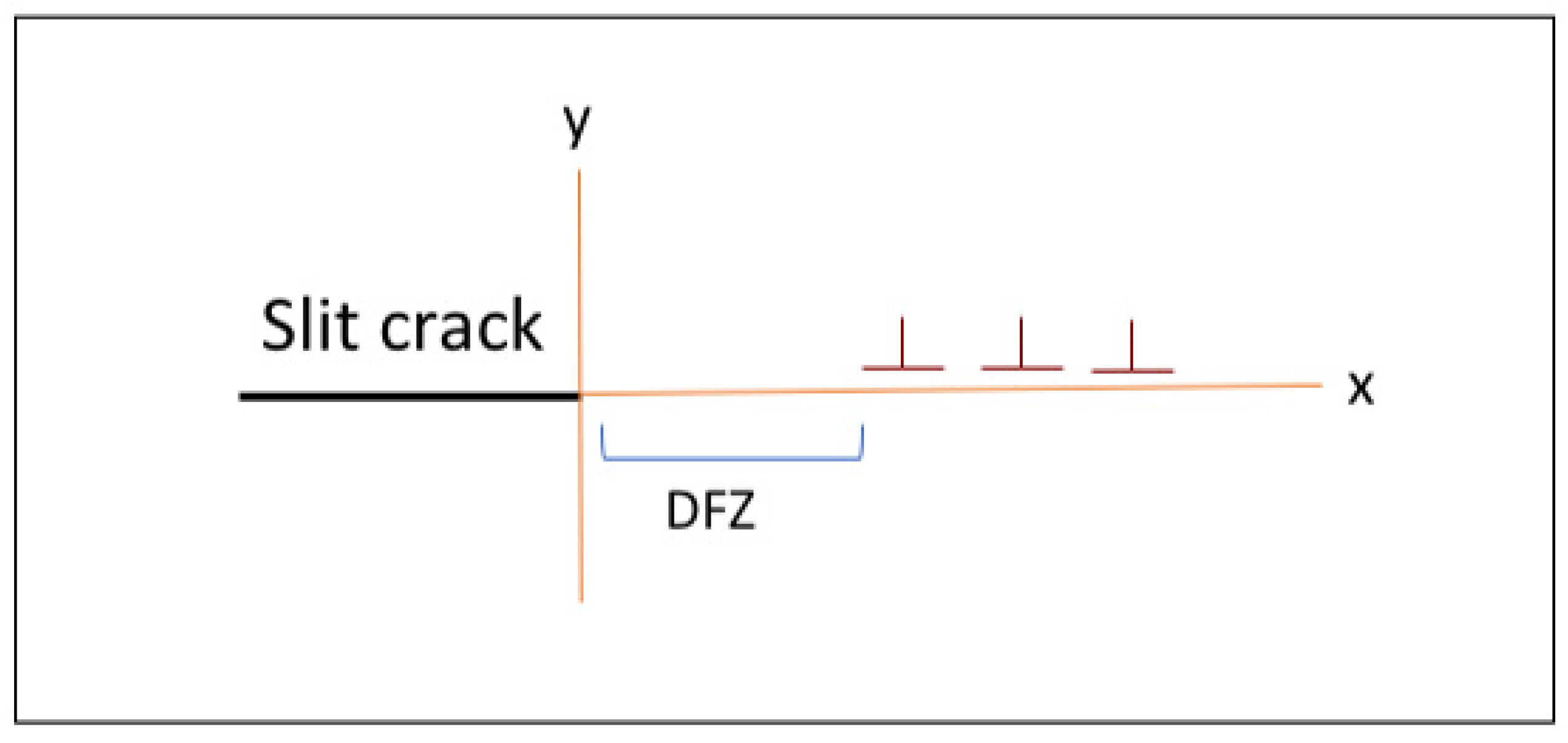

3. Crack-Dislocation Interaction(s)

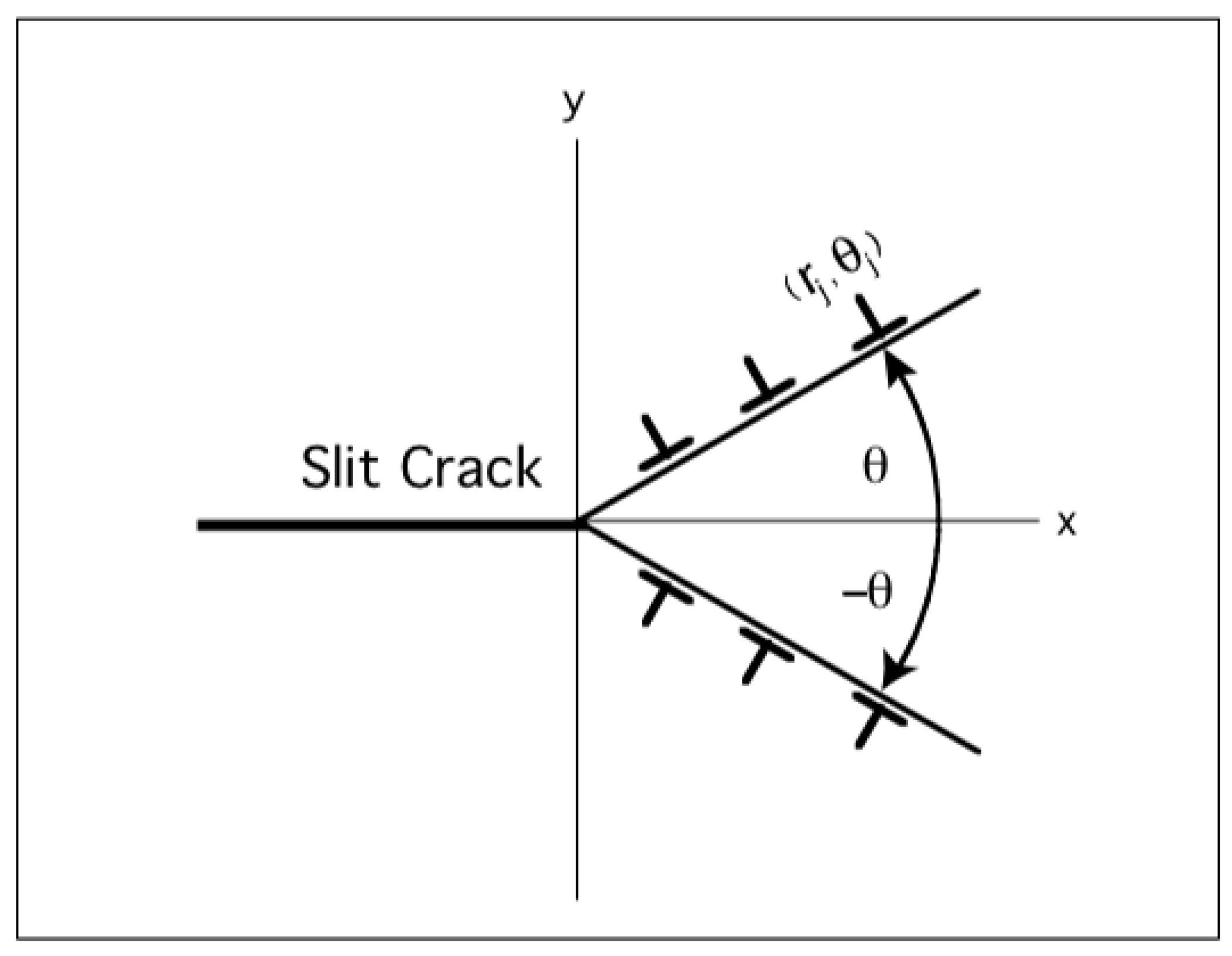

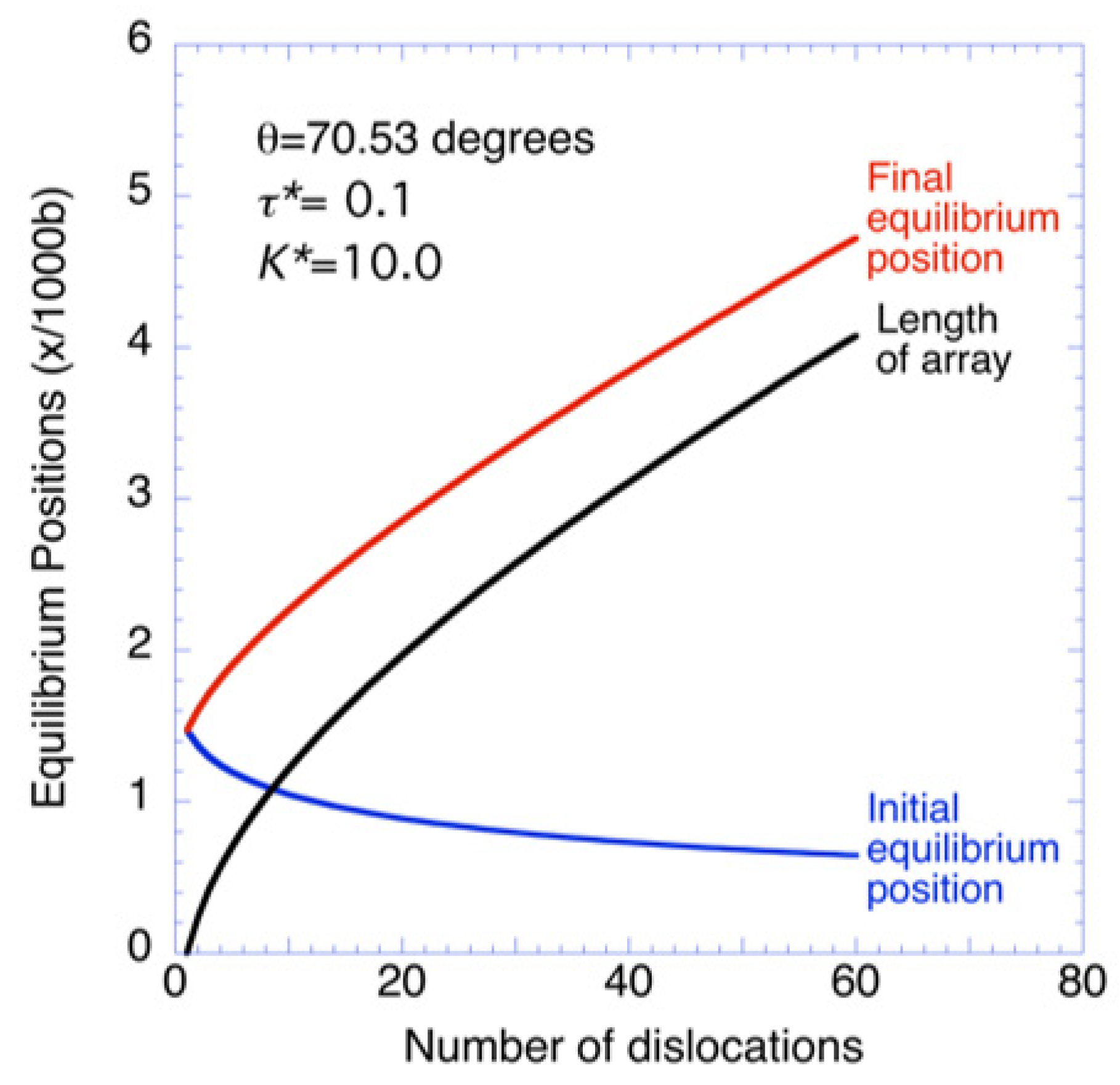

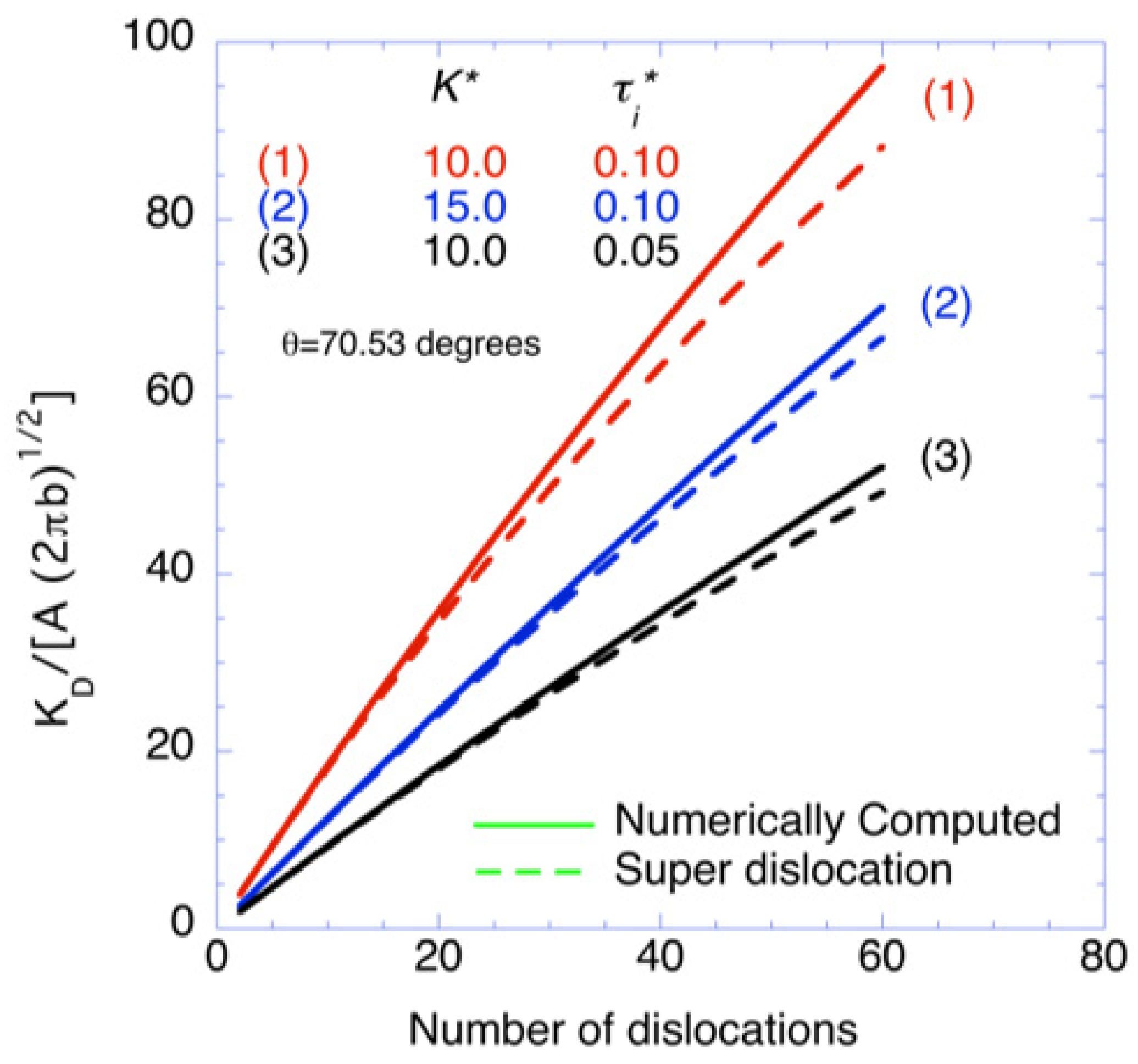

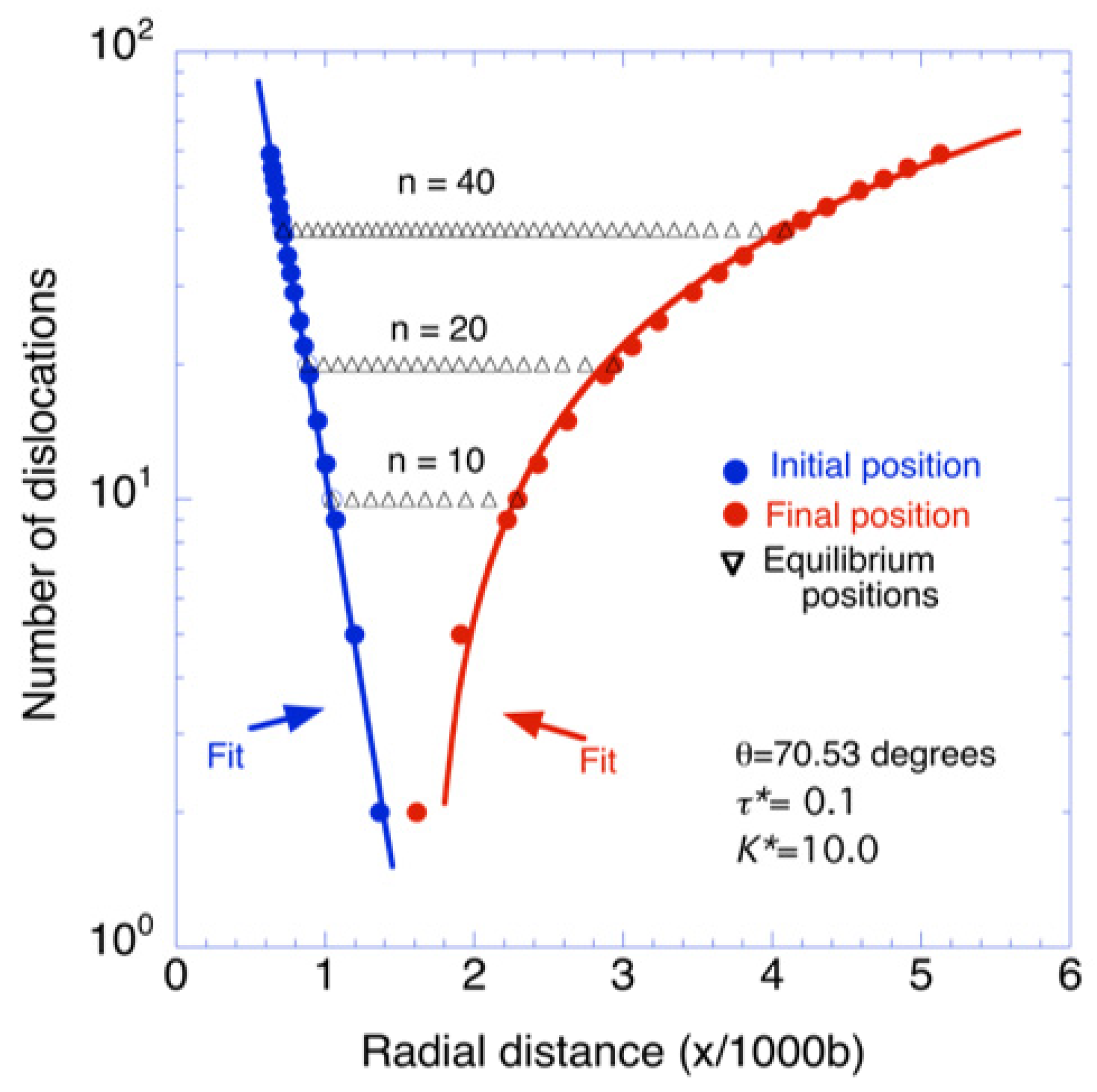

Pande, Masamura and Chou Model

4. Experimental Verification

5. Effect of Dislocation Emissions

6. Concluding Remarks

Funding

Acknowledgments

Conflicts of Interest

References

- Findlay, S.J.; Harrison, N.D. Why aircraft fail. Mater. Today 2002, 55, 18–25. [Google Scholar] [CrossRef]

- Basinski, Z.S.; Basinski, S.J. Low amplitude fatigue of copper single crystals-III PSB sections. Acta Metall. 1985, 33, 1319–1327. [Google Scholar] [CrossRef]

- Mott, N.F. A theory of the origin of fatigue cracks. Acta Metall. 1958, 6, 195–197. [Google Scholar] [CrossRef]

- Antonopoulos, J.G.; Brown, L.M.; Winter, A.T. Vacancy dipoles in fatigued copper. Philos. Mag. 1976, 34, 549–563. [Google Scholar] [CrossRef]

- Differt, K.U.; Essmann, U.; Mughrabi, H. A model of extrusions and intrusions in fatigued metals-II surface roughening by random irreversible slip. Philos. Mag. A 1986, 54, 237–258. [Google Scholar] [CrossRef]

- Neumann, P. Coarse slip model of fatigue. Acta Metall. 1969, 17, 1219–1225. [Google Scholar] [CrossRef]

- Kobayashi, S.; Ohr, S.M. Proceedings of the 37th Annual Meeting Electron Microscopy Society of America; Bailey, G.W., Ed.; Claitors Publishing: Baton Rouge, LA, USA, 1979; pp. 424–425. [Google Scholar]

- Kobayashi, S.; Ohr, S.M. In-situ Fracture Experiments in BCC Metals. Philos. Mag. 1980, A42, 763–772. [Google Scholar] [CrossRef]

- Kobayashi, S.; Ohr, S.M. In-situ Observations of the Formation of Plastic Zone Ahead of a Crack Tip in Copper. Scr. Metall. 1981, 15, 343–348. [Google Scholar] [CrossRef]

- Park, C.G.; Lee, S.; Chang, Y.W. Mechanical behavior of materials. In Proceedings of the 6th International Conference, Kyoto, Japan, 29 July–2 August 1991; Volume 4, pp. 3–9. [Google Scholar]

- Goswami, R.; Pande, C.S. Investigations of Crack-Dislocation Interactions Ahead of Mode-III Crack. Mater. Sci. Eng. A 2015, 627, 217–222. [Google Scholar] [CrossRef]

- Du, K.L.; Lu, J.B.; Li, R.W. A continuous dislocation model of mode-I crack. In Proceedings of the 15th ASCE Engineering Mechanics Conference, New York, NY, USA, 2–5 June 2002; Columbia University: New York, NY, USA, 2002; pp. 1–8. [Google Scholar]

- Chang, S.J.; Ohr, S.M. Dislocation free zone model of fracture. J. Appl. Phys. 1981, 52, 7174–7181. [Google Scholar] [CrossRef]

- Suresh, S. Fatigue of Materials, 2nd ed.; Cambridge University Press: Cambridge, UK, 1998. [Google Scholar]

- Pippan, R. Dislocation emission and fatigue crack growth threshold. Acta Metall. Mater. 1991, 39, 255–262. [Google Scholar] [CrossRef]

- Pippan, R. The condition for the cyclic plastic deformation of the crack tip: The influence of dislocation obstacles. Int. J. Fract. 1992, 58, 305–318. [Google Scholar] [CrossRef]

- Riemelmoser, F.O.; Pippan, R.; Stuwe, H.P. A comparison of a discrete dislocation model and a continuous description of cyclic crack tip plasticity. Int. J. Fract. 1997, 85, 157–168. [Google Scholar] [CrossRef]

- Riemelmoser, F.O.; Pippan, R.; Stuwe, H.P. An argument for a cycle-by-cycle propagation of fatigue cracks at small stress intensity ranges. Acta Mater. 1998, 46, 1793–1799. [Google Scholar] [CrossRef]

- Deshpande, V.S.; Needleman, A.; Giessen, E. A discrete dislocation analysis of near-threshold fatigue crack growth. Acta Mater. 2001, 49, 3189–3203. [Google Scholar] [CrossRef]

- Mastorakos, I.N.; Zbib, H.M. Dislocation-cracks interaction during fatigue: A discrete dislocation dynamics simulation. J. Met. 2008, 60, 59–63. [Google Scholar] [CrossRef]

- Curtin, W.A.; Deshpande, V.S.; Needleman, A.; Giessen, E.; Wallin, M. Hybrid discrete dislocation models for fatigue crack growth. Int. J. Fatigue 2010, 32, 1511–1520. [Google Scholar] [CrossRef][Green Version]

- Wilkinson, A.J.; Roberts, S.G. A dislocation model for the two critical stress intensities required for threshold fatigue crack propagation. Scr. Mater. 1996, 35, 1365–1371. [Google Scholar] [CrossRef]

- Wilkinson, A.J.; Roberts, S.G.; Hirsch, P.B. Modelling the threshold conditions for propagation of stage-I fatigue cracks. Acta Mater. 1998, 46, 379–390. [Google Scholar] [CrossRef]

- Doquet, V. Crack initiation mechanisms in torsional fatigue. Fract. Eng. Mater. Struct. 1998, 21, 661–672. [Google Scholar] [CrossRef]

- Giessen, E.; Deshpande, V.S.; Cleveringa, R.P.; Needleman, A. Discrete dislocation plasticity and crack tip fields in single crystals. J. Mech. Phys. Solids 2001, 49, 2133–2153. [Google Scholar] [CrossRef]

- Pippan, R.; Riemelmoser, F.O.; Weinhandl, H.; Kreuzer, H. Plasticity-induced crack closure under plane-strain conditions in the near-threshold regime. Philos. Mag. 2002, 82, 3299–3309. [Google Scholar] [CrossRef]

- Pippan, R.; Riemelmoser, F.O. Dislocation shielding of fatigue cracks. Metallkunde 1995, 86, 823–826. [Google Scholar]

- Riemelmoser, F.O.; Gumbsch, P.; Pippan, R. Dislocation modelling of fatigue cracks: An overview. Mater. Trans. A 2001, 42, 2–13. [Google Scholar] [CrossRef]

- Hansson, P.; Melin, S. Simulation of simplified zigzag crack paths emerging during fatigue crack growth. Eng. Fract. Mech. 2008, 75, 1400–1411. [Google Scholar] [CrossRef]

- Bjerkn, C.; Melin, S. A tool to model short crack fatigue growth using a discrete dislocation formulation. Int. J. Fatigue 2003, 25, 559–566. [Google Scholar] [CrossRef]

- Bjerkn, C.; Melin, S. A study of the influence of grain boundaries on short crack growth during varying load using a dislocation technique. Eng. Fract. Mech. 2004, 71, 2215–2227. [Google Scholar] [CrossRef]

- Hansson, P.; Melin, S. Dislocation-based modelling of the growth of a microstructurally short crack by single shear due to fatigue loading. Int. J. Fatigue 2005, 27, 347–356. [Google Scholar] [CrossRef]

- Groh, S.; Olarnrithinum, S.; Curtin, W.A.; Needleman, A.; Deshpande, V.S.; Giessen, E. Fatigue crack growth from a cracked elastic particle into a ductile matrix. Philos. Mag. 2008, 88, 3565–3583. [Google Scholar] [CrossRef]

- Kunkler, B.; Duber, O.; Koster, P.; Krupp, U.; Fritzen, C.P.; Christ, H.J. Modeling of short crack propagation - Transition from stage I to stage II. Eng. Fract. Mech. 2008, 75, 715–725. [Google Scholar] [CrossRef]

- Ohr, S.M.; Narayan, J. Electron Microscope Observation of Shear Cracks in Stainless Steel Single Crystals. Philos. Mag. 1980, 41, 81–89. [Google Scholar] [CrossRef]

- Horton, J.A.; Ohr, S.M. Determination of emission condition from the experiments and theory. Scr. Metall. 1982, 16, 621–626. [Google Scholar] [CrossRef]

- Horton, J.A.; Ohr, S.M. TEM observations of dislocation emission at crack tip in aluminum. J. Mater. Sci. 1982, 17, 3140–3148. [Google Scholar] [CrossRef]

- Ohr, S.M. An electron microscope study of crack tip deformation and its impact on the dislocation theory of fracture. Mater. Sci. Eng. 1985, 72, 1–35. [Google Scholar] [CrossRef]

- Majumdar, B.; Burns, S.A. Crack tip shielding-anelastic theory of dislocation and dislo- cation arrays near a sharp crack. Acta Metall. 1981, 29, 579–588. [Google Scholar] [CrossRef]

- Majumdar, B.; Burns, S.A. A Griffith crack shielded by a dislocation pile-up. Int. J. Fract. Mech. 1983, 21, 229–240. [Google Scholar] [CrossRef]

- Dai, S.H.; Li, J.C.M. Dislocation free zone at the crack tip. Scr. Metall. 1982, 16, 183–188. [Google Scholar] [CrossRef]

- Thomson, R. Physics of fracture. J. Phys. Chem. Solids 1987, 48, 965–983. [Google Scholar] [CrossRef]

- Sadananda, K.; Glinka, G. Dislocation processes that affect kinetics of fatigue crack growth. Philos. Mag. 2005, 85, 189–203. [Google Scholar] [CrossRef]

- Bilby, B.; Cottrell, A.; Swinden, K. The spread of plastic yield from a notch. Proc. Roy. Soc. A 1963, 272, 304–314. [Google Scholar]

- Lin, I.H.; Thomson, R. Cleavage, dislocation emission, and shielding for cracks under general loading. Acta Metall. 1986, 34, 187–206. [Google Scholar] [CrossRef]

- Weertman, J. Fracture mechanics-unified view for Griffith-Irwin-Orowan cracks. Acta Metall. 1978, 26, 1731–1738. [Google Scholar] [CrossRef]

- Weertman, J. Fracture stress obtained from the elastic crack tip enclave model. J. Mater. Sci. 1980, 15, 1306–1310. [Google Scholar] [CrossRef]

- Weertman, J.; Lin, I.H.; Thomson, R. Double slip plane crack model. Acta Metall. 1983, 31, 473–482. [Google Scholar] [CrossRef]

- Weertman, J. Dislocation emission into a mode III plastic zone. Scr. Metall. 1986, 20, 1483–1488. [Google Scholar] [CrossRef]

- Masumura, R.A.; Pande, C.S.; Chou, Y.T. Model for interaction of dislocation arrays with a crack. Int. J. Fatigue 2005, 27, 1170–1174. [Google Scholar] [CrossRef]

- Pande, C.S.; Masumura, R.A.; Chou, Y.T. Shielding of crack tips by inclined pile-ups of dislocations. Acta Metall. 1988, 36, 49–54. [Google Scholar] [CrossRef]

- Muskhelishvili, N. Singular Integral Equations; P. Noordhoof Ltd.: Groningen, The Netherlands, 1953. [Google Scholar]

- Zhang, T.Y.; Tong, P.; Ouyang, H.; Lee, S. Interaction of an edge dislocation with a wedge crack. J. Appl. Phys. 1995, 78, 4873–4880. [Google Scholar] [CrossRef]

- Pande, C.S.; Masumura, R.A.; Chou, Y.T. Shielding of crack tips by critical parameters for fatigue damage. Int. J. Fatigue 2001, 23, 1170–1174. [Google Scholar]

- Vasudevan, A.K.; Sadananda, K.; Glinka, G. Critical parameters for fatigue damage. Int. J. Fatigue 2001, 23, S39–S53. [Google Scholar] [CrossRef]

- Rice, J.R.; Thomson, R. Ductile versus brittle behavior of crystals. Philos. Mag. 1974, 29, 73–97. [Google Scholar] [CrossRef]

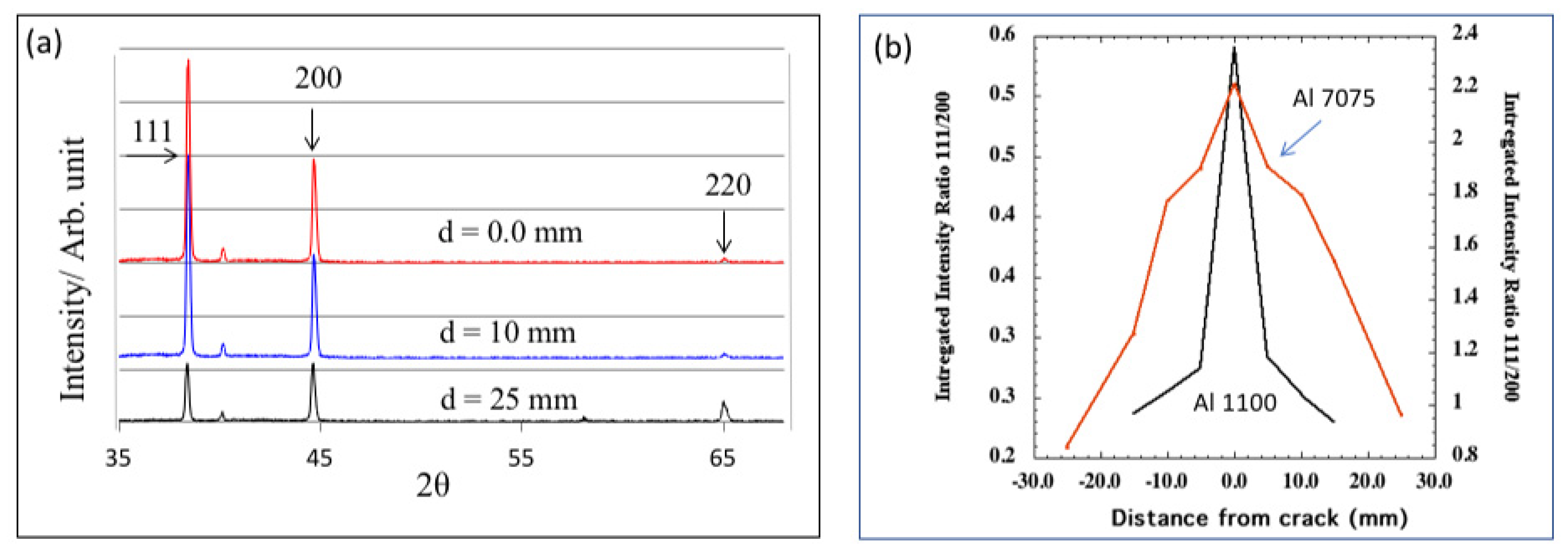

- Goswami, R.; Qadri, S.B.; Pande, C.S. Fatigue mediated lattice rotation in Al Alloys. Acta Mater. 2017, 129, 33–40. [Google Scholar] [CrossRef]

- Goswami, R.; Feng, C.R.; Qadri, S.B.; Pande, C.S. Fatigue-assisted grain growth in Al alloys. Sci. Rep. 2017, 7, 10179–10186. [Google Scholar] [CrossRef] [PubMed]

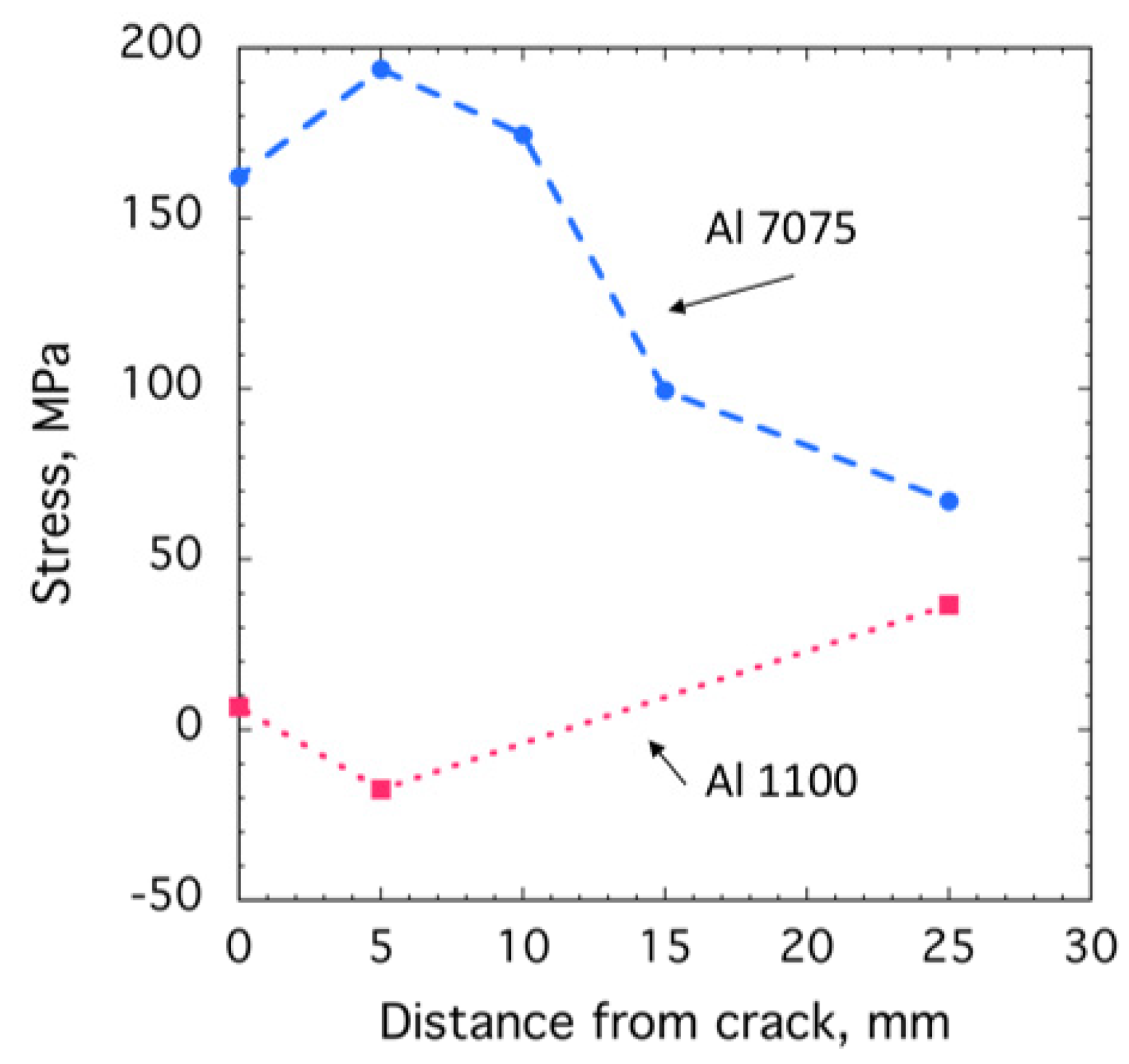

- Goswami, R.; Qadri, S.B.; Pande, C.S. Residual Stresses and Localized Lattice Rotation Under Fatigue Loading. Mater. Sci. Eng. A 2019, 763, 113–138. [Google Scholar] [CrossRef]

- Lam, Y.C.; Lian, K.S. Effect of residual stress and its redistribution on fatigue crack growth. Theor. Appl. Fract. Mech. 1989, 12, 59–66. [Google Scholar] [CrossRef]

- LaRue, J.E.; Daniewicz, S.R. The effect of residual stress on fatigue crack growth rate in AISI 304LN stainless steel. Int. J. Fatigue 2007, 29, 508–515. [Google Scholar] [CrossRef]

- Reid, C.N. A Method of mapping residual stress in a compact tension specimen. Scr. Metall. 1988, 22, 451–456. [Google Scholar] [CrossRef]

- Schindler, H.J. Determination of Residual Stress Distributions from Measured Stress Intensity Factors. Int. J. Fract. 1995, 74, R23–R30. [Google Scholar] [CrossRef]

- Schindler, H.J.; Cheng, W.; Finnie, I. Experimental determination of stress intensity factors due to residual stresses. Exp. Mech. 1997, 37, 272–277. [Google Scholar] [CrossRef]

- Mughrabi, H. Revisiting Steady-State Monotonic and Cyclic Deformation: Emphasizing the Quasi-Stationary State of Deformation. Metall. Mater. Trans. A 2020, 51A, 1441–1456. [Google Scholar] [CrossRef]

- Pippan, R.; Riemelmoser, F.O. Modeling of Fatigue Crack Growth: Dislocation Models. Compr. Struct. Integr. 2003, 191–207. [Google Scholar] [CrossRef]

- Bhat, S.; Patibandla, R. Metal Fatigue and Basic Theoretical Models: A Review, Alloy Steel-Properties and Use; Morales, E.V., Ed.; InTech: Lagos, Nigeria, 2011. [Google Scholar]

- Olarnrithinun, S. A Short Review of 2D-Discrete Dislocation Modeling for Fracture/Fatigue. AIJSTPME 2013, 6, 45–57. [Google Scholar]

- Horstemeyer, M.F.; Farkas, D.; Kim, S.; Tang, T.; Potirniche, G. Nanostructurally small cracks (NSC): A review on atomistic modeling of fatigue. Int. J. Fatigue 2010, 32, 1473–1502. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pande, C.S.; Goswami, R. Dislocation Emission and Crack Dislocation Interactions. Metals 2020, 10, 473. https://doi.org/10.3390/met10040473

Pande CS, Goswami R. Dislocation Emission and Crack Dislocation Interactions. Metals. 2020; 10(4):473. https://doi.org/10.3390/met10040473

Chicago/Turabian StylePande, Chandra S., and Ramasis Goswami. 2020. "Dislocation Emission and Crack Dislocation Interactions" Metals 10, no. 4: 473. https://doi.org/10.3390/met10040473

APA StylePande, C. S., & Goswami, R. (2020). Dislocation Emission and Crack Dislocation Interactions. Metals, 10(4), 473. https://doi.org/10.3390/met10040473