Application of the Progressive Forming Method in Simulation and Experimental Study of Rectangular Fins in a Heat Exchanger

Abstract

1. Introduction

2. Method of Experiment and Simulation

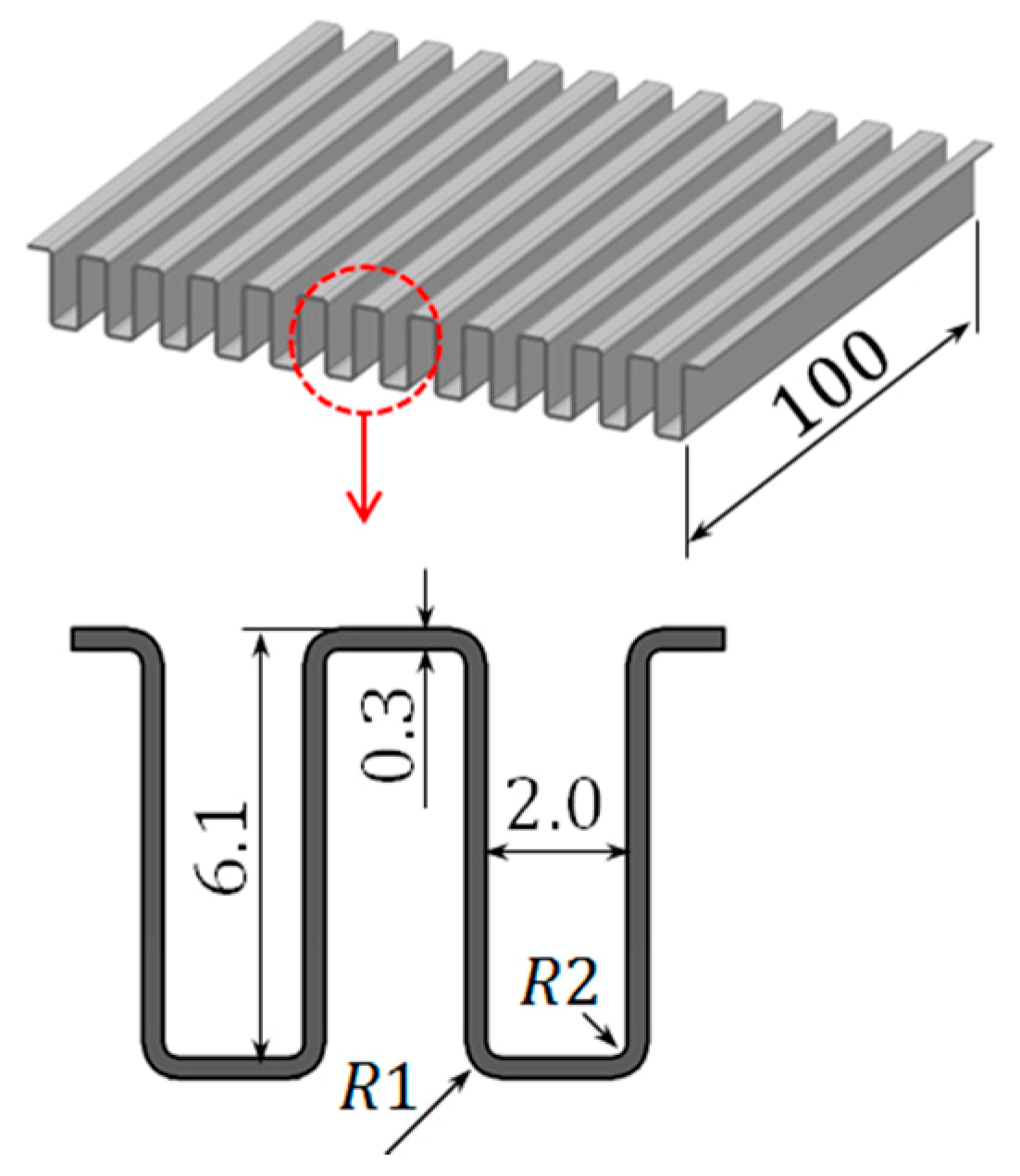

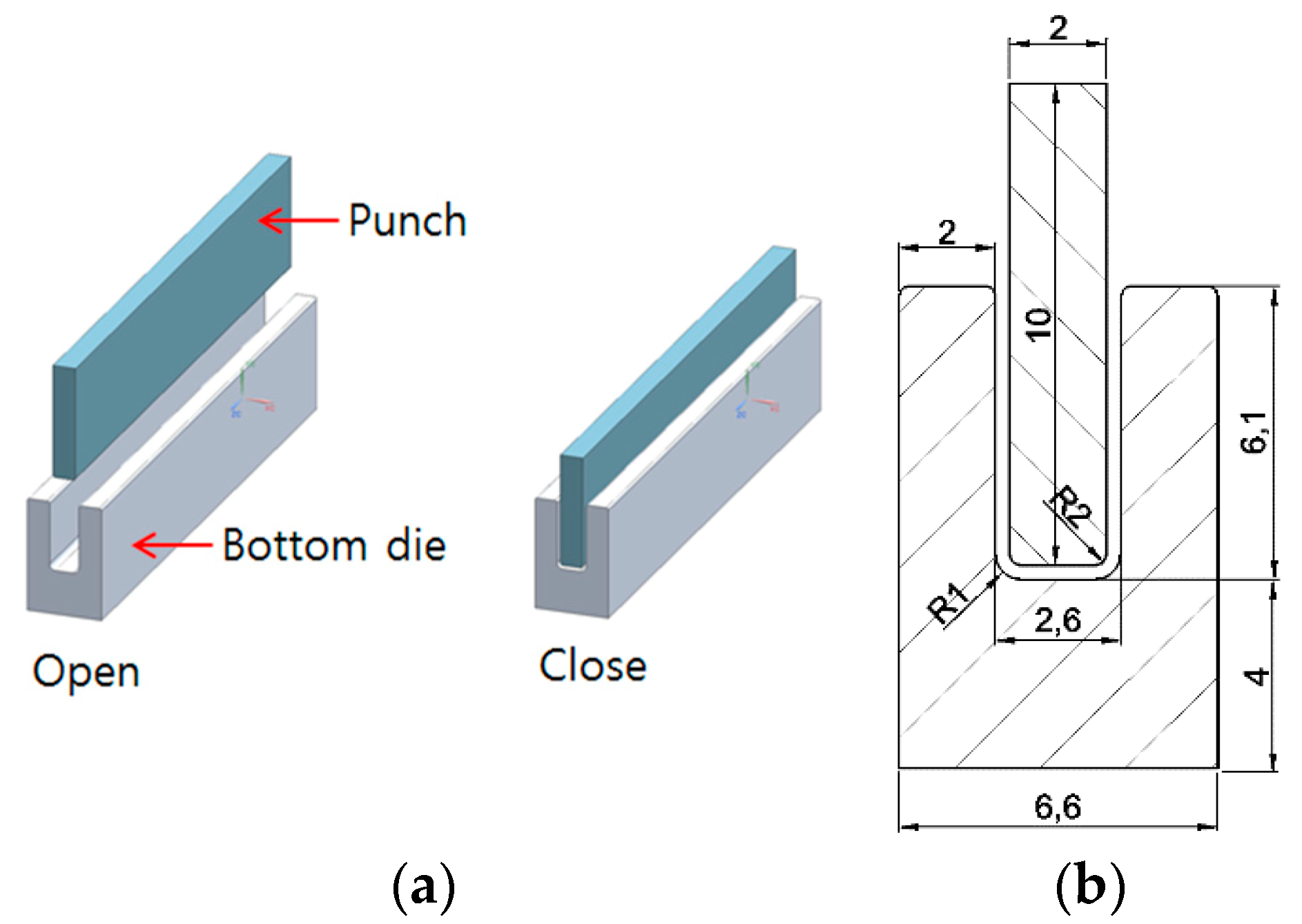

2.1. Design of Inner Fins

2.2. Material of Inner Fins

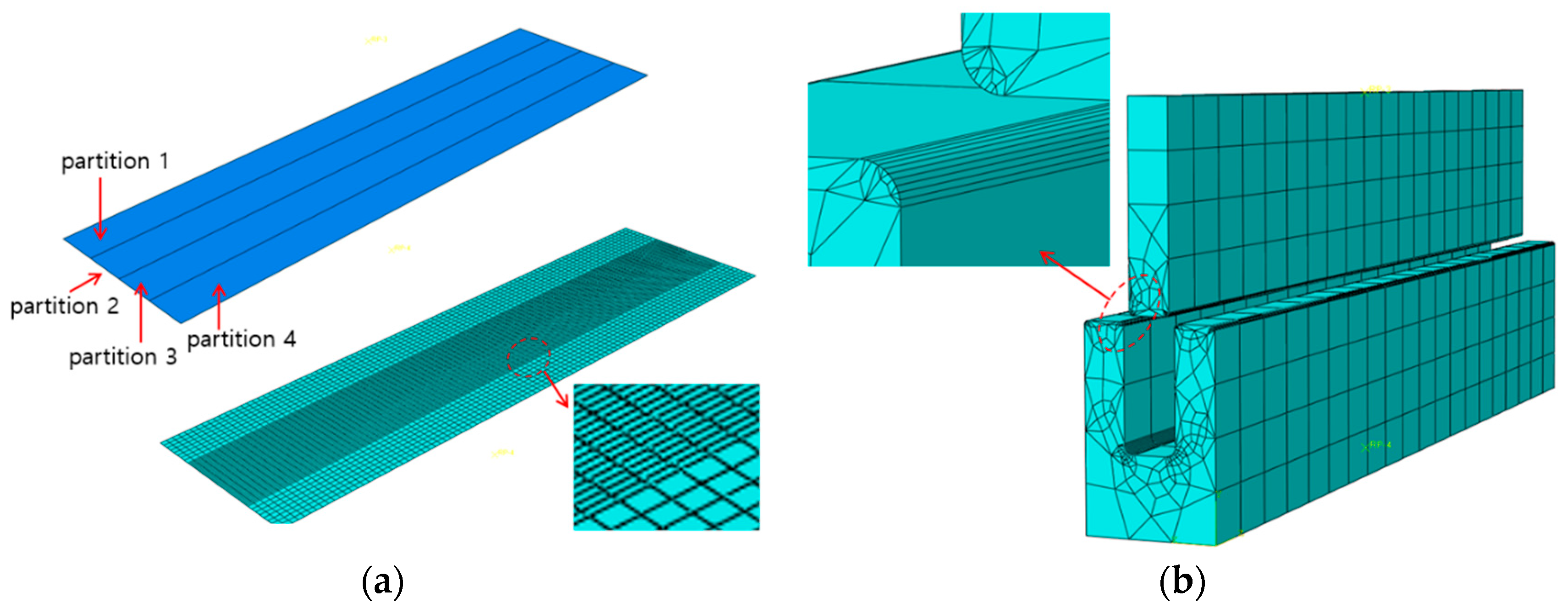

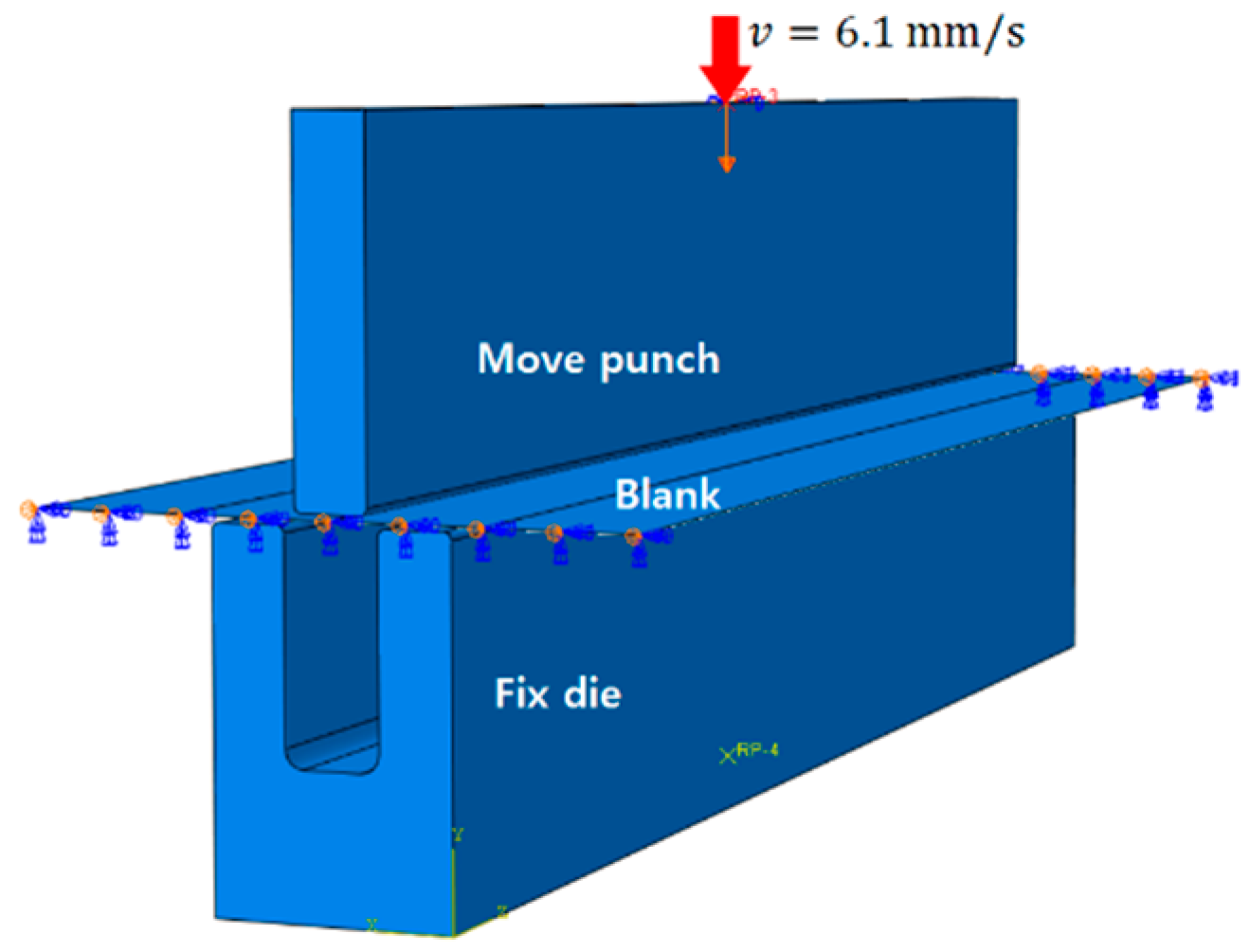

2.3. Simulation Method

2.4. Experimental Method

3. Results of Experiment and Simulation

3.1. Simulation

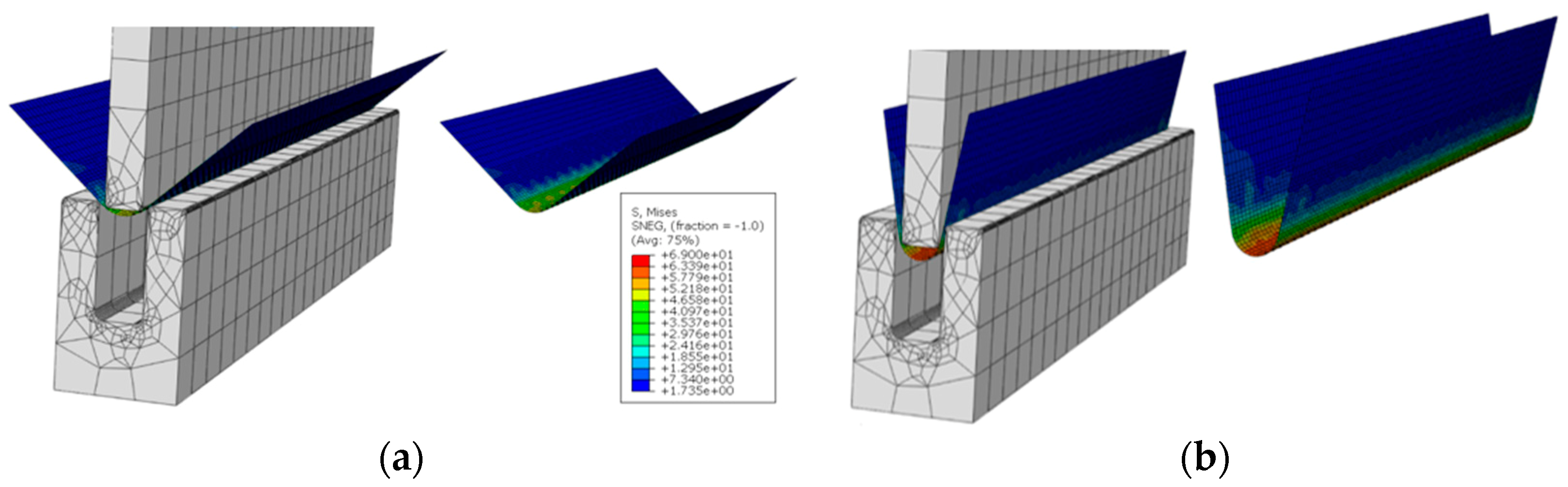

3.1.1. First Forming

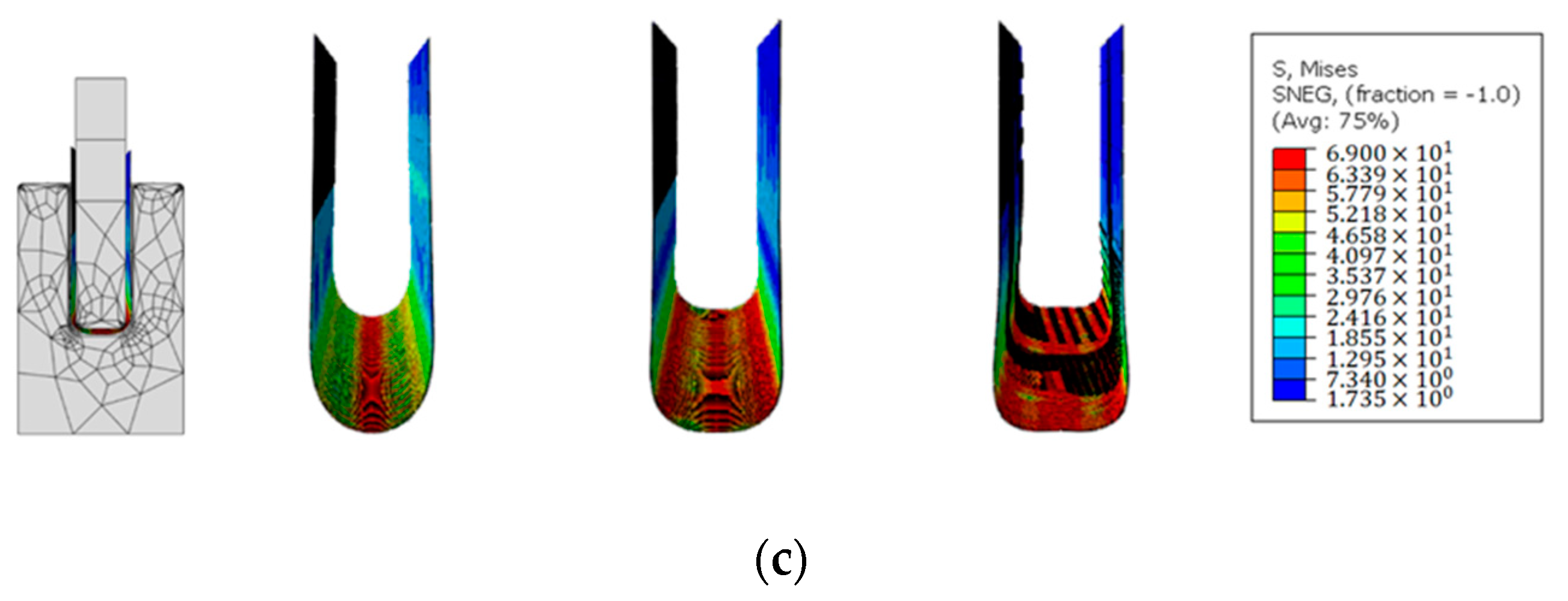

3.1.2. Second Forming

3.2. Experiment

4. Conclusions

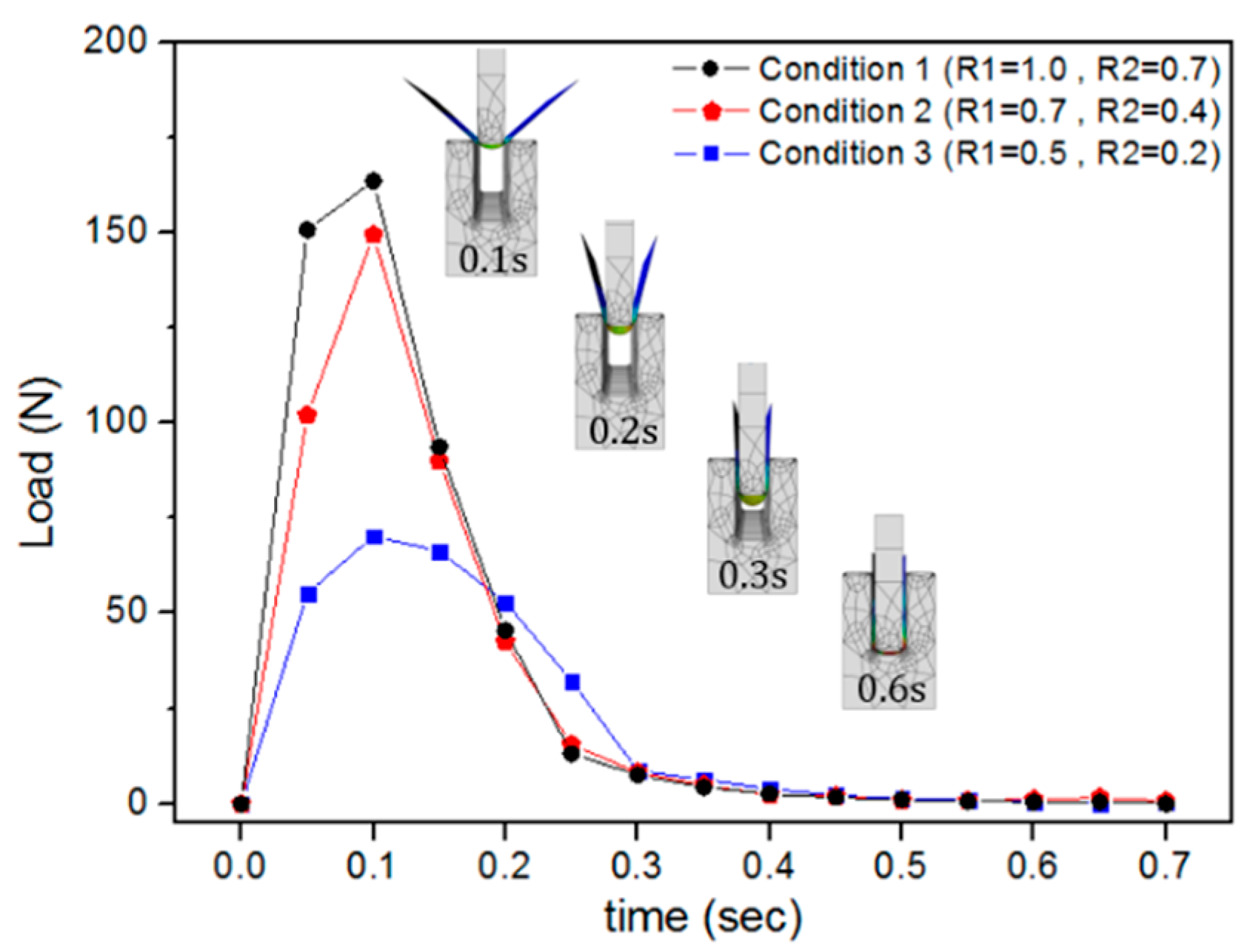

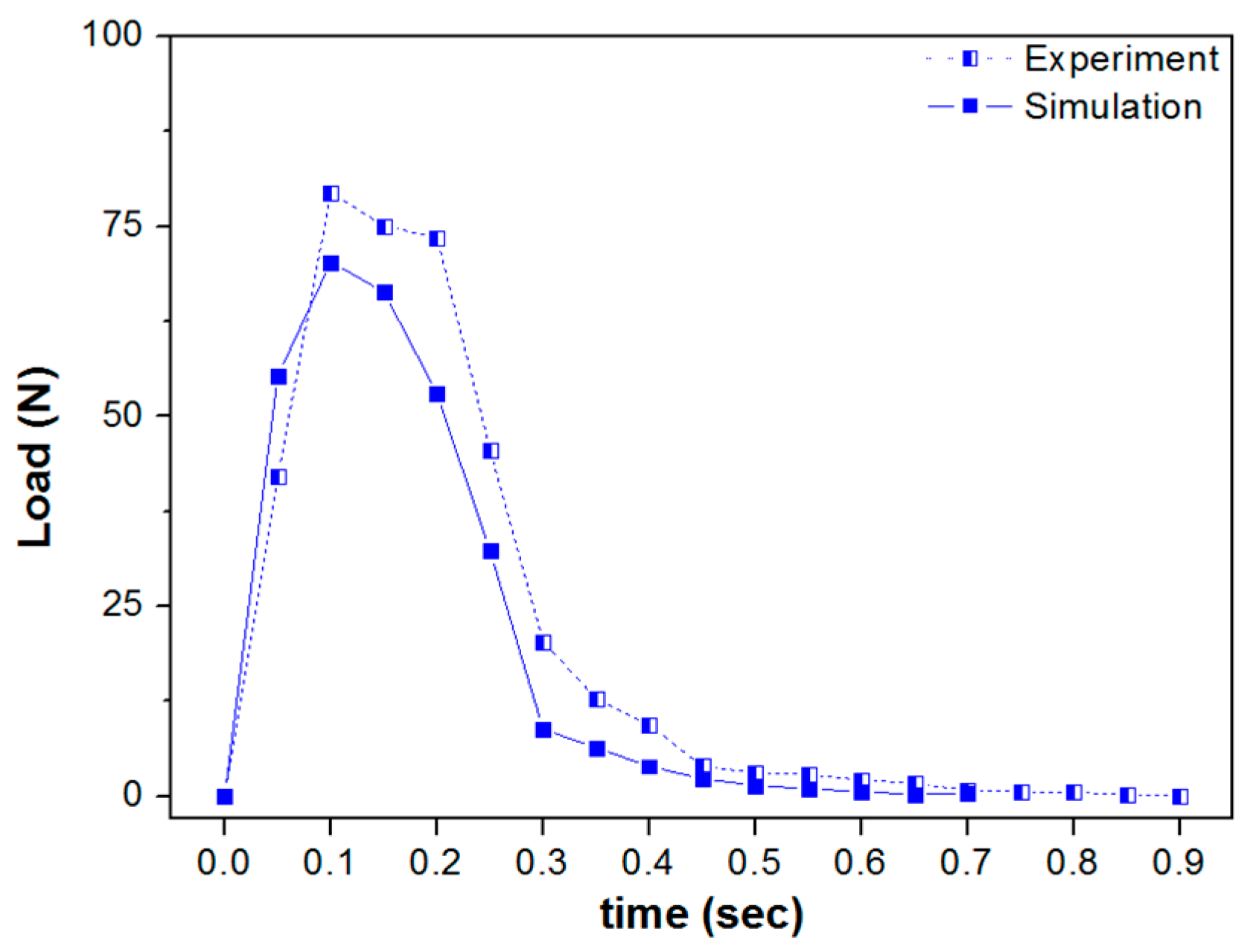

- The blank was deformed while it was pushed into the entrance of the die cavity by the punch, and the largest load (79 N) was consumed during this stage. The V shaped fin became U shaped when the blank entered the die cavity by a gradual descend of the punch. When the punch contacted the bottom of the die cavity, the fin was formed to a final shape.

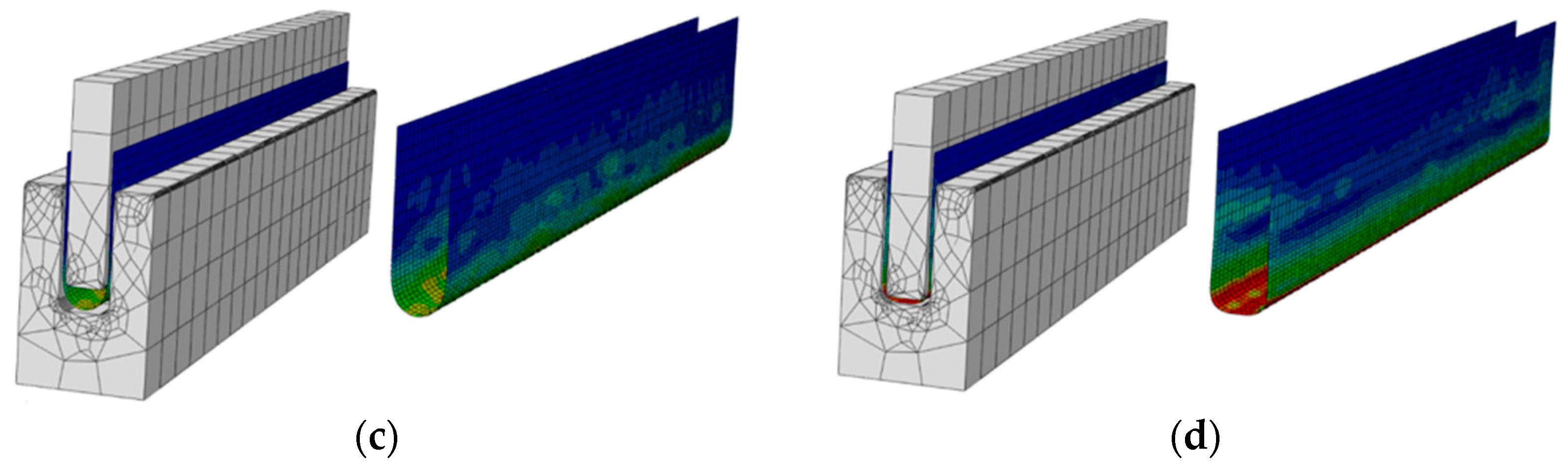

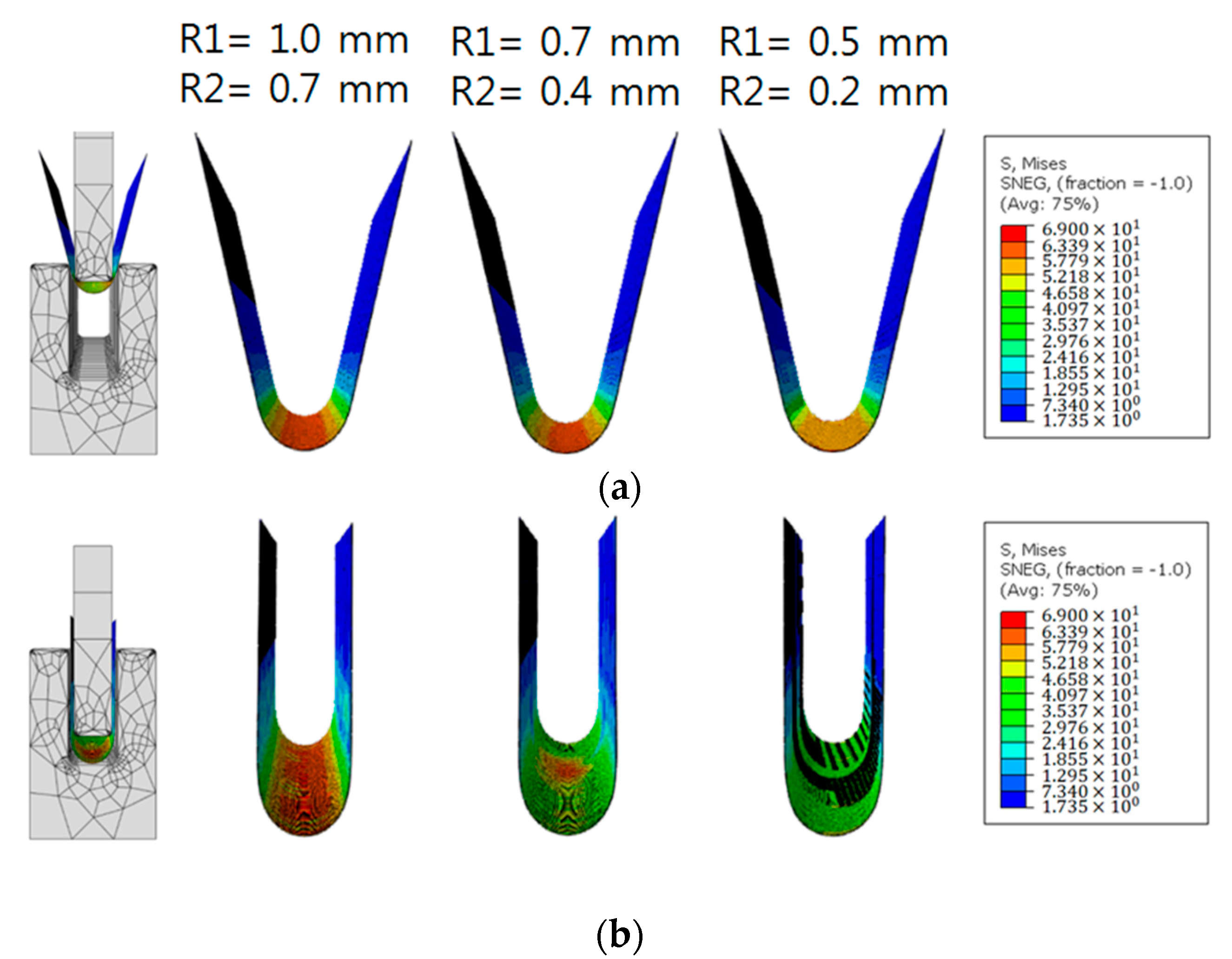

- As the edge radii of the die R1 and those of the punch R2 became smaller, the effective stresses generated during blank deformation became smaller. Moreover, the forming load as the fin deformed to a V shape, likewise became smaller. The optimal edge radius of the die R1 was found to be 0.5 mm and the edge radius of the punch R2 was found to be 0.2 mm in order to manufacture a rectangular fin with a depth of 6.1 mm, width of 2.0 mm, and thickness of 0.3 mm.

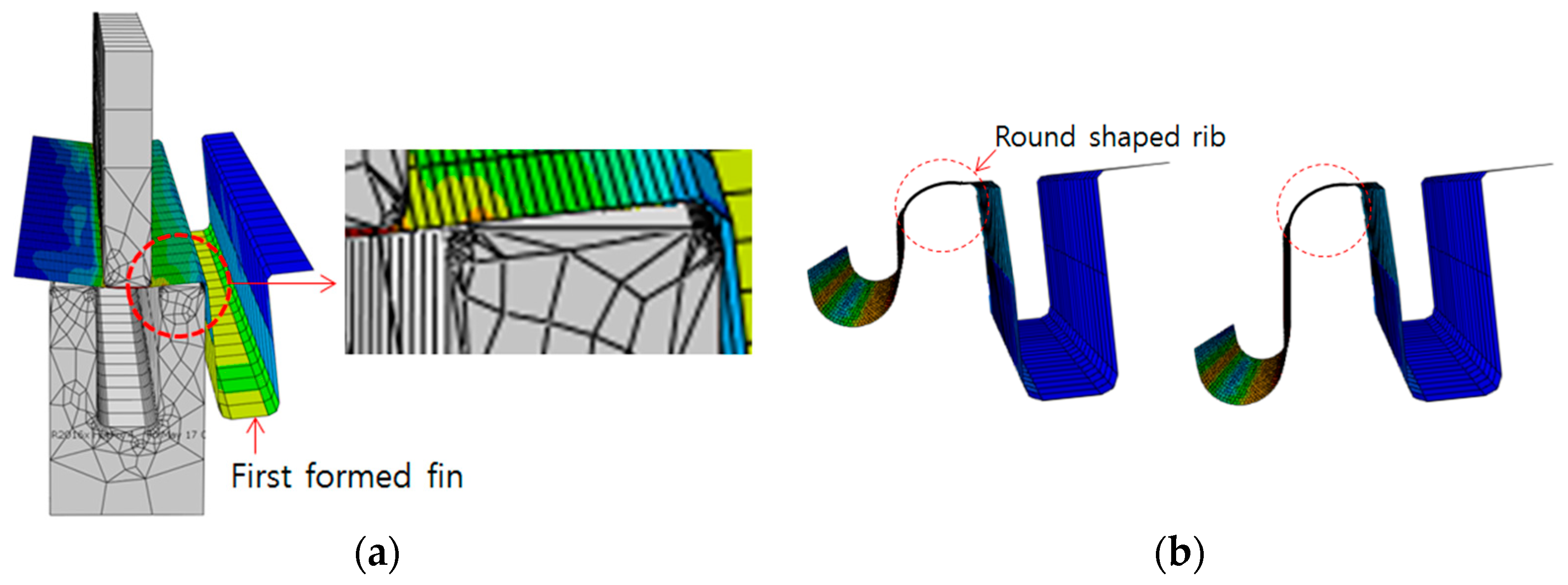

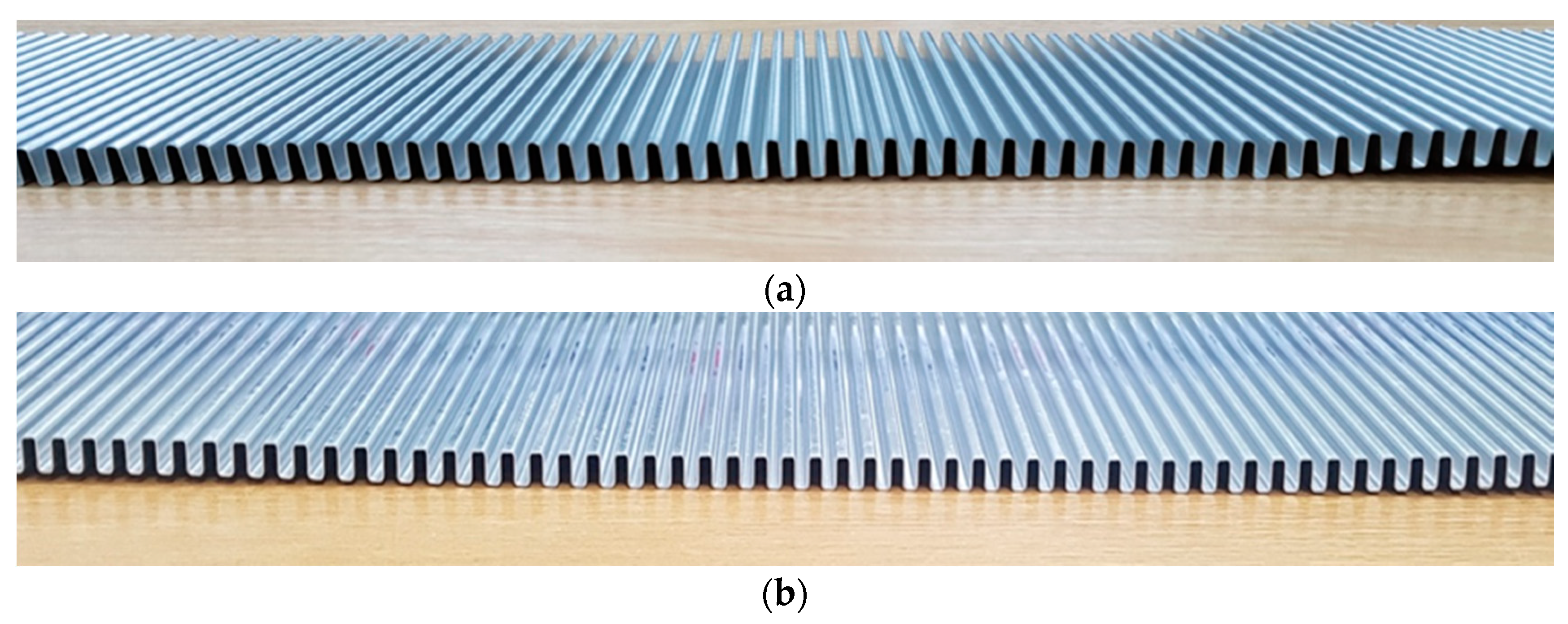

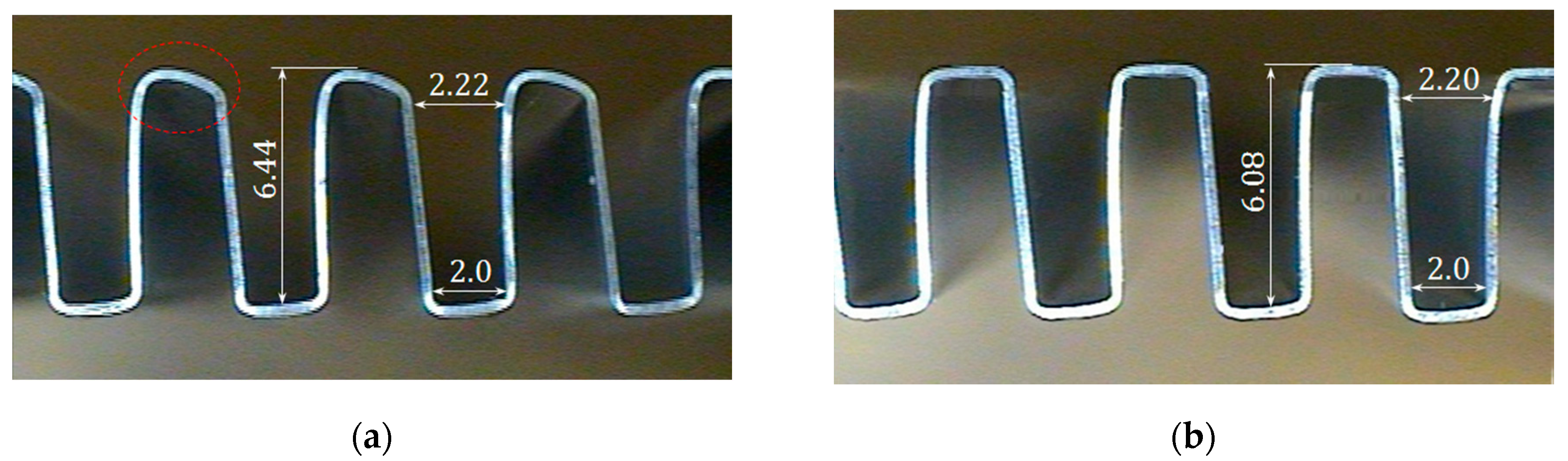

- From the simulation, it was concluded that when the second fin and the third fin were formed, overforming occurred at the ribs. The overforming was also observed in the samples prepared in the laboratory with the results being the same as the simulation. The punch was modified so that the punch could compress the rib at the same time the fin was formed by the punch. The modified punch could produce the inner fins having right-angled ribs, however, the spring-back occurred during forming, resulting in the bottom of the fin width being 2.0 mm, while the top of the fin measured 2.20 mm and the depth of the fin measured 6.08 mm.

Acknowledgments

Conflicts of Interest

References

- Shah, R.K.; Sekulic, D.P. Classification of Heat Exchanger. In Fundamentals of Heat Exchanger Design; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2003; pp. 1–74. [Google Scholar]

- Thulukkanam, K. Classification of Heat Exchanger. In Heat Exchanger Design Handbook, 2nd ed.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2013; pp. 1–27. [Google Scholar]

- Rajvir, S.D.; Pradeep, K.K.; Govind, M. Exergy based optimization and experimental evaluation of plate fin heat exchanger. Appl. Therm. Eng. 2016, 102, 80–90. [Google Scholar]

- Yorikata, M.; Toshihide, I.; Fumiko, K.; Noriyuki, S.; Masanori, T.; Tetsuo, Y.; Tetsuyuki, H. Development of structural design procedure of plate-fin heat exchanger for HTGR. Nucl. Eng. Des. 2013, 255, 248–262. [Google Scholar]

- Sai, K.M.; Sun, X.; Richard, N.C.; Raymond, R.U.; Richard, E.G.; Mike, W.P. Fabrication and design aspects of high-temperature compact diffusion bonded heat exchangers. Nucl. Eng. Des. 2012, 249, 49–56. [Google Scholar]

- Sommers, A.; Wang, Q.; Han, X.; T’Joen, C.; Park, Y.; Jacobi, A. Ceramics and ceramic matrix composites for heat exchangers in advanced thermal systems—A review. Appl. Therm. Eng. 2010, 30, 1277–1291. [Google Scholar] [CrossRef]

- David, C.D.; Michael, J.B.; Joshua, M.P.; John, Z. Expanded microchannel heat exchanger: Design, fabrication, and preliminary experimental test. P I Mech. Eng. A-J. Pow. 2012, 226, 532–544. [Google Scholar]

- Arun, M.; Carl, K.; Bengt, S.; Ramesh, K.S. Foam heat exchangers: A technology assessment. Heat Transf. Eng. 2012, 33, 42–51. [Google Scholar]

- Christophe, M.; Kevin, W.K. Fabrication and Performance of a Pin Fin Micro Heat Exchanger. J. Heat Transf. 2004, 126, 434–444. [Google Scholar]

- Chen, C.H.; Chen, C.T.; Wang, P.F.; Wang, Y.T.; Hsu, P.H.; Lin, C.L. A novel anatomical thin titanium mesh plate with patient-matched bending technique for orbital floor reconstruction. J. Cranio Maxill. Surg. 2018, 46, 126–1532. [Google Scholar] [CrossRef] [PubMed]

- Jin, B.J.; Lee, J.P.; Park, M.H.; Yun, T.J.; Song, Y.H.; Kim, I.S. A study on forming for plate-type heat exchangers of the Ti material. Procedia Eng. 2017, 174, 171–178. [Google Scholar] [CrossRef]

- Choi, S.W.; Park, S.H.; Jeong, H.S.; Cho, J.R.; Park, S.; Ha, M.Y. Improvement of formability for fabricating thin continuously corrugated structures in sheet metal forming process. J. Mech. Sci. Technol. 2012, 26, 2397–2403. [Google Scholar] [CrossRef]

- Kim, M.J.; Jin, C.K.; Kang, C.G. Comparison of formabilities of stainless steel 316L bipolar plates using static and dynamic load stamping. Int. J. Adv. Manuf. Tech. 2014, 75, 651–657. [Google Scholar] [CrossRef]

- Qinghui, H.; Dongming, Z.; Hao, F.; KaiKai, H. Investigation of stamping process of metallic bipolar plates in PEM fuel cell—Numerical simulation and experiments. Int. J. Hydrogen Energy 2014, 39, 13770–13776. [Google Scholar]

- Dou, S.; Xia, J. Analysis of sheet metal forming (stamping process): A study of the variable friction coefficient on 5052 aluminum alloy. Metals 2019, 9, 853. [Google Scholar] [CrossRef]

- Diogo, M.N.; Marta, C.O.; José, L.A.; Luís, F.M. Numerical study on the formability of metallic bipolar plates for proton exchan.e membrane (PEM) fuel cells. Metals 2019, 9, 810. [Google Scholar]

- Marciniak, Z.; Duncan, J.L.; Hu, S.J. Sheet deformation processes. In Mechanics of Sheet Metal Forming, 2nd ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2002; pp. 14–29. [Google Scholar]

- Abaqus/Explicit. Available online: https://www.3ds.com/products-services/simulia/products/abaqus/ (accessed on 7 March 2020).

| Direction of Specimen | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Work Hardening Exponent |

|---|---|---|---|---|

| 0° | 24.5 | 96.5 | 25.0 | 0.215 |

| 45° | 21.2 | 95.3 | 22.5 | 0.210 |

| 90° | 29.2 | 98.3 | 24.0 | 0.212 |

| Edge Radius | Condition 1 | Condition 2 | Condition 3 |

|---|---|---|---|

| R1 | 1.0 mm | 0.7 mm | 0.5 mm |

| R2 | 0.7 mm | 0.4 mm | 0.2 mm |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, C.K. Application of the Progressive Forming Method in Simulation and Experimental Study of Rectangular Fins in a Heat Exchanger. Metals 2020, 10, 395. https://doi.org/10.3390/met10030395

Jin CK. Application of the Progressive Forming Method in Simulation and Experimental Study of Rectangular Fins in a Heat Exchanger. Metals. 2020; 10(3):395. https://doi.org/10.3390/met10030395

Chicago/Turabian StyleJin, Chul Kyu. 2020. "Application of the Progressive Forming Method in Simulation and Experimental Study of Rectangular Fins in a Heat Exchanger" Metals 10, no. 3: 395. https://doi.org/10.3390/met10030395

APA StyleJin, C. K. (2020). Application of the Progressive Forming Method in Simulation and Experimental Study of Rectangular Fins in a Heat Exchanger. Metals, 10(3), 395. https://doi.org/10.3390/met10030395