Effects of Processing Parameters on the Corrosion Performance of Plasma Electrolytic Oxidation Grown Oxide on Commercially Pure Aluminum

Abstract

1. Introduction

2. Experimental Procedures

2.1. Preparation of the Samples

2.2. Sample Characterization

3. Results and Discussion

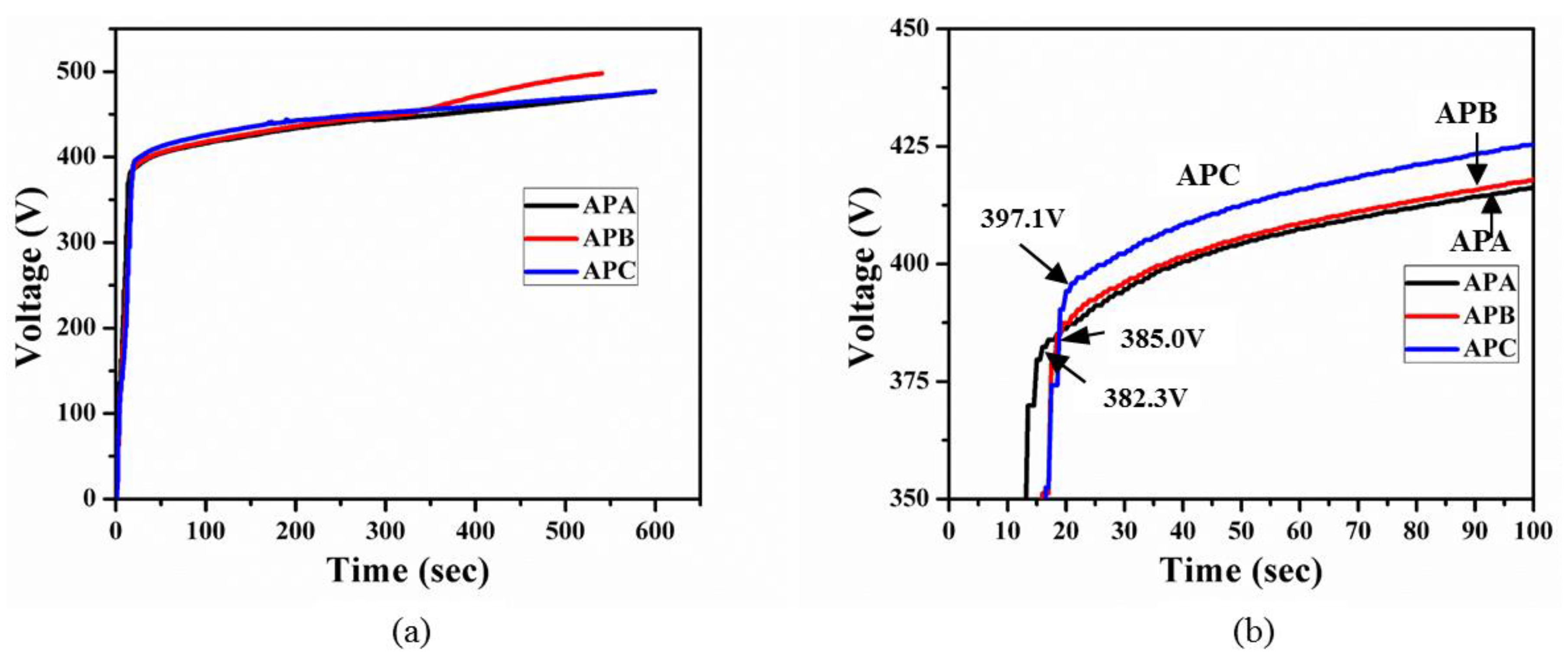

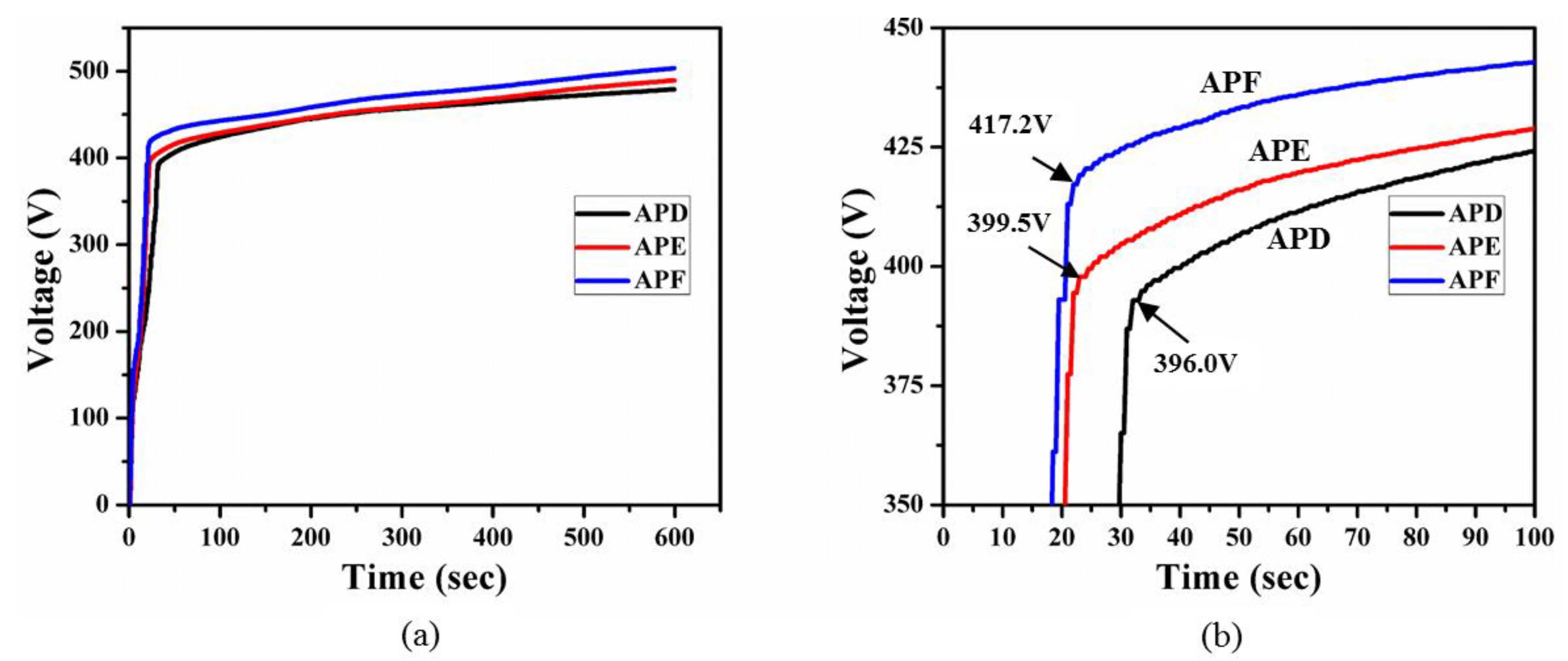

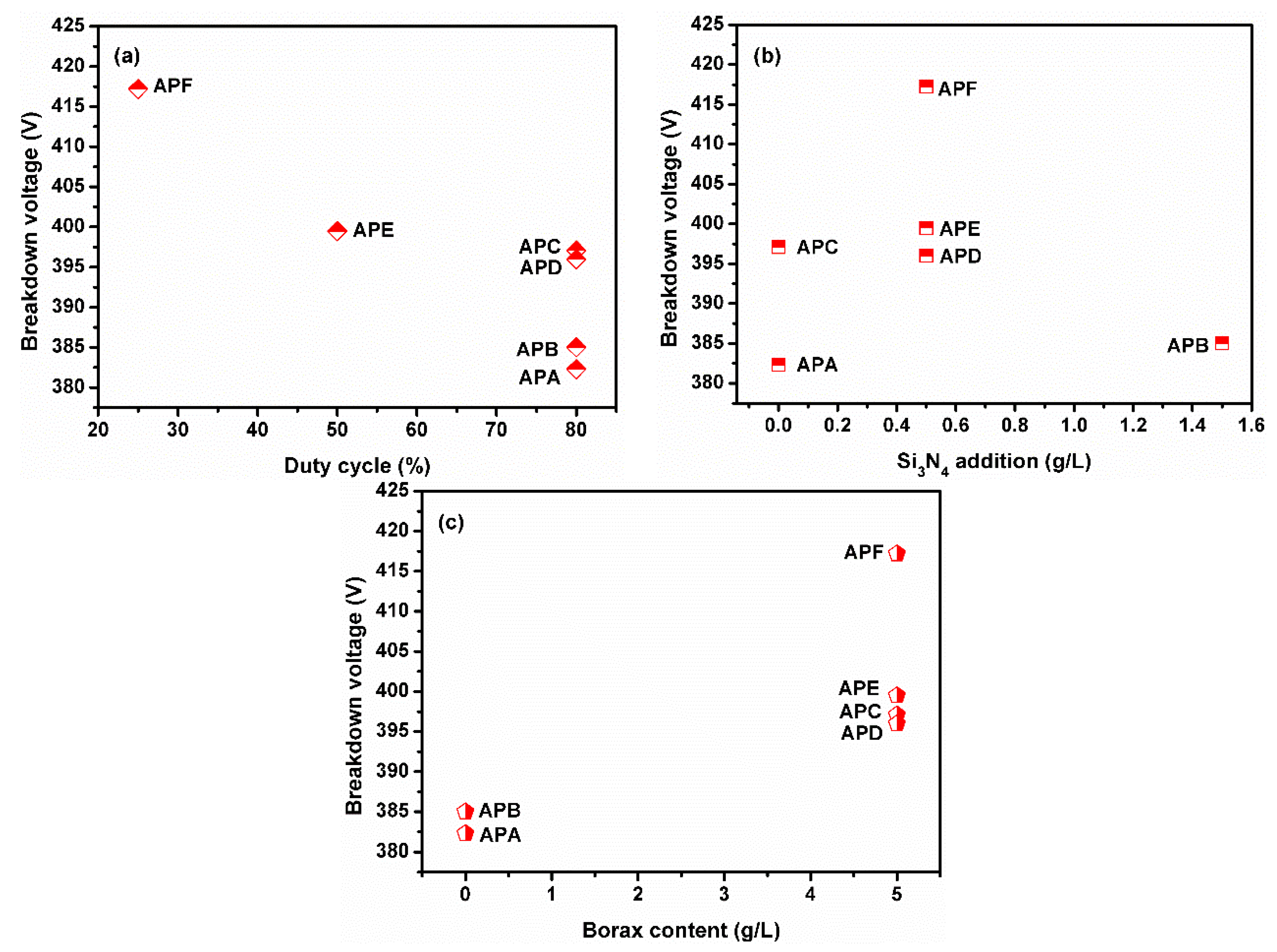

3.1. Voltage-Time Response of PEO Coatings

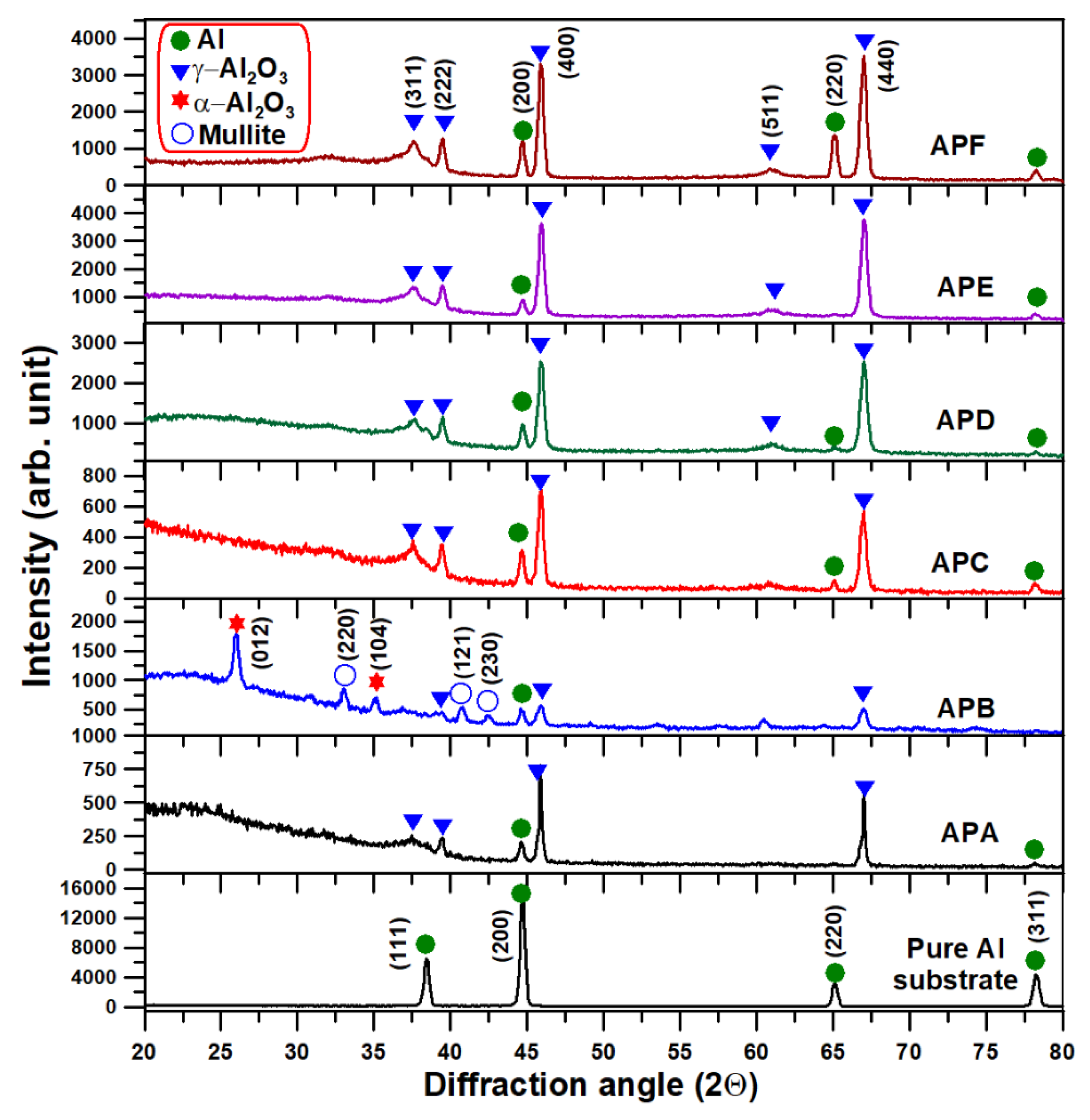

3.2. Phase and Composition Analysis

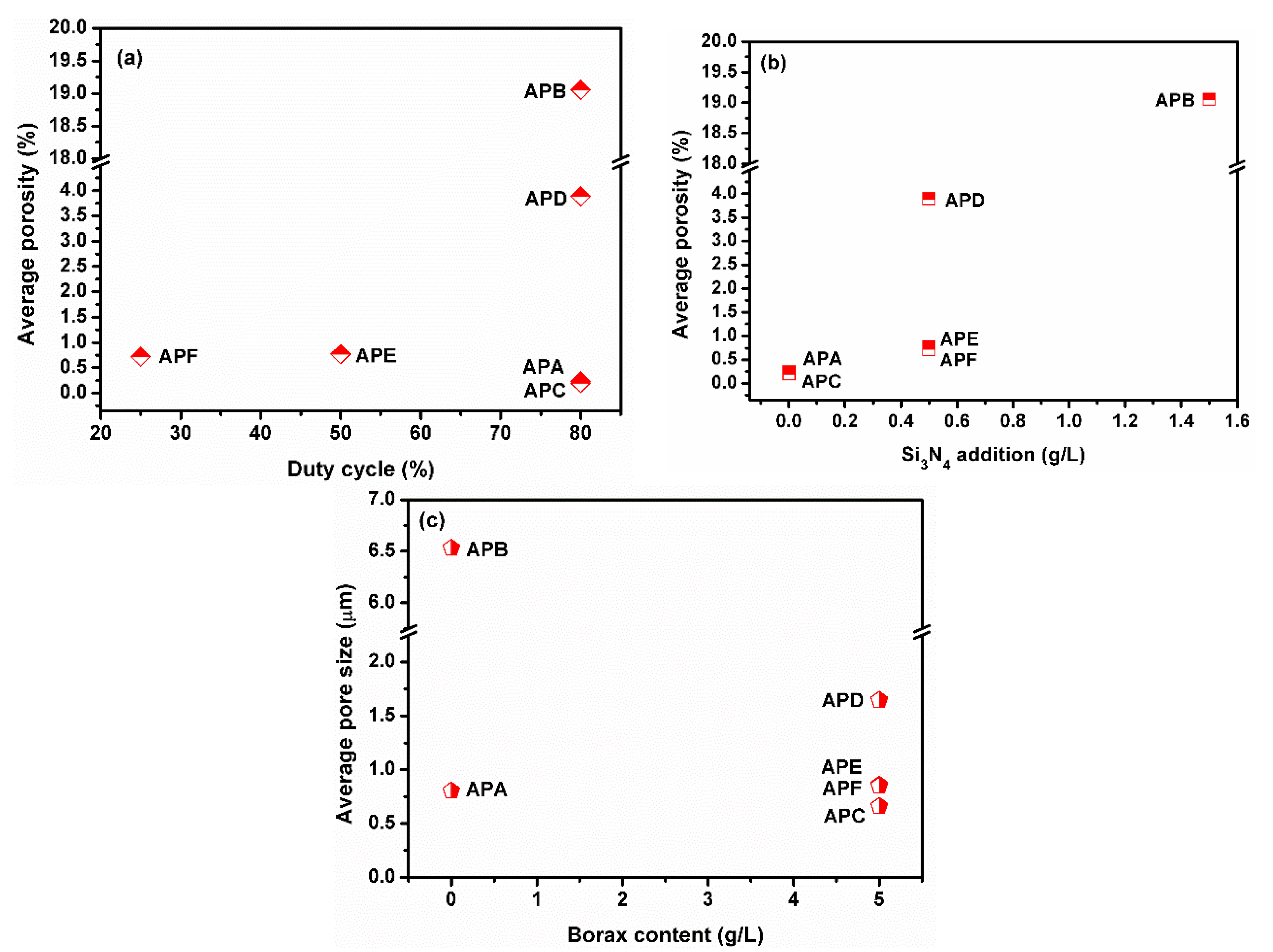

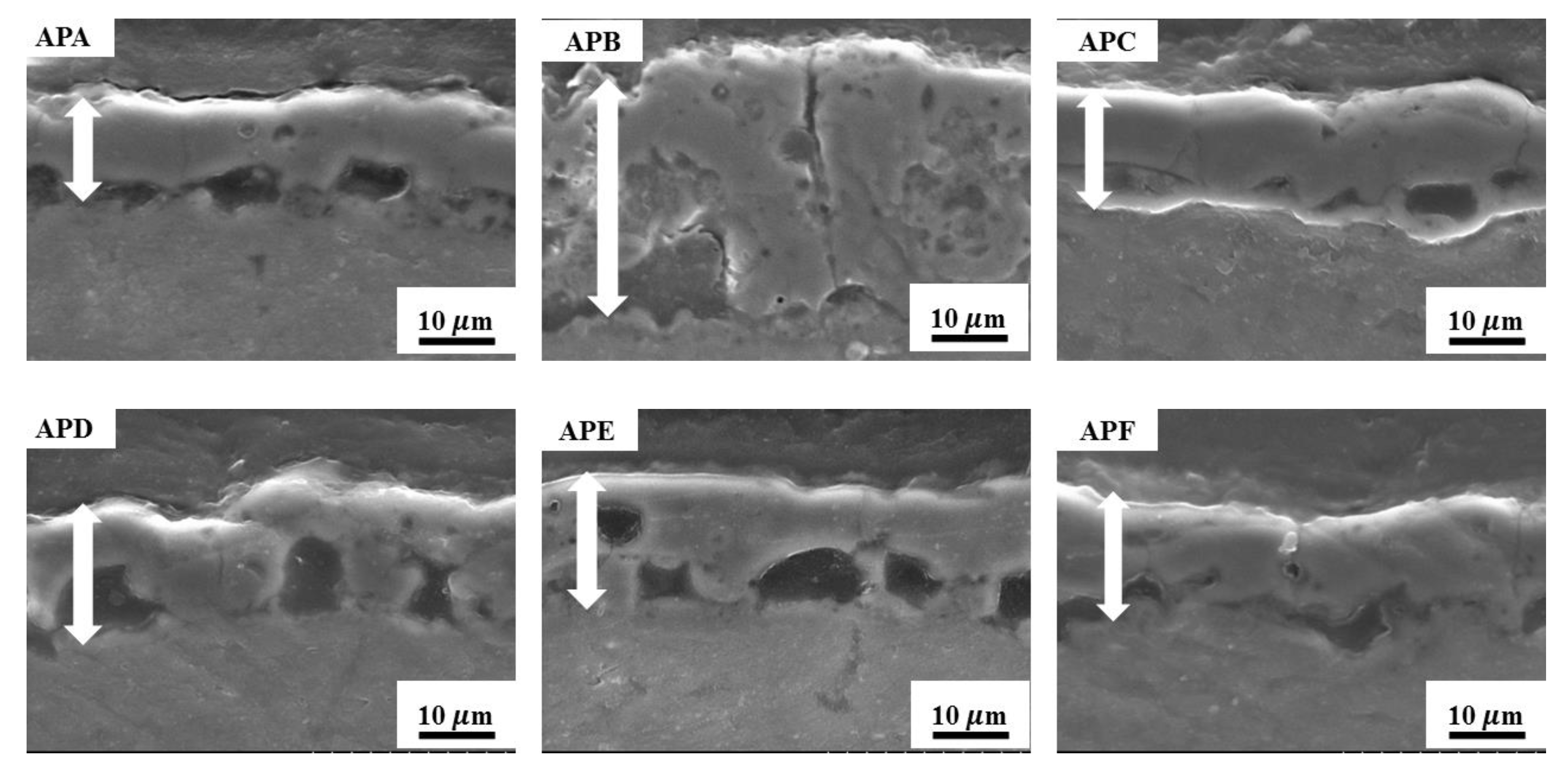

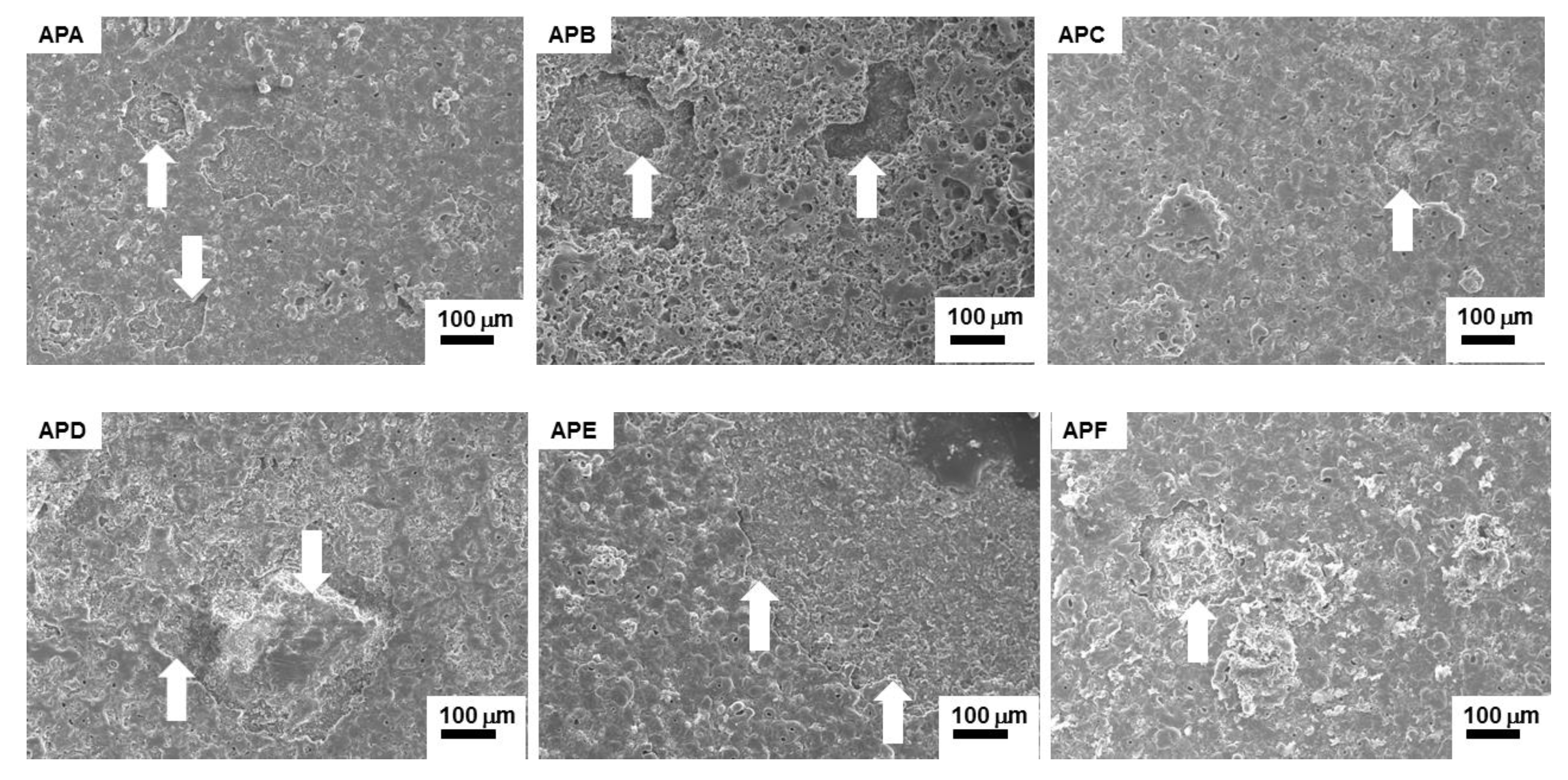

3.3. Microstructure Analysis of PEO Coatings

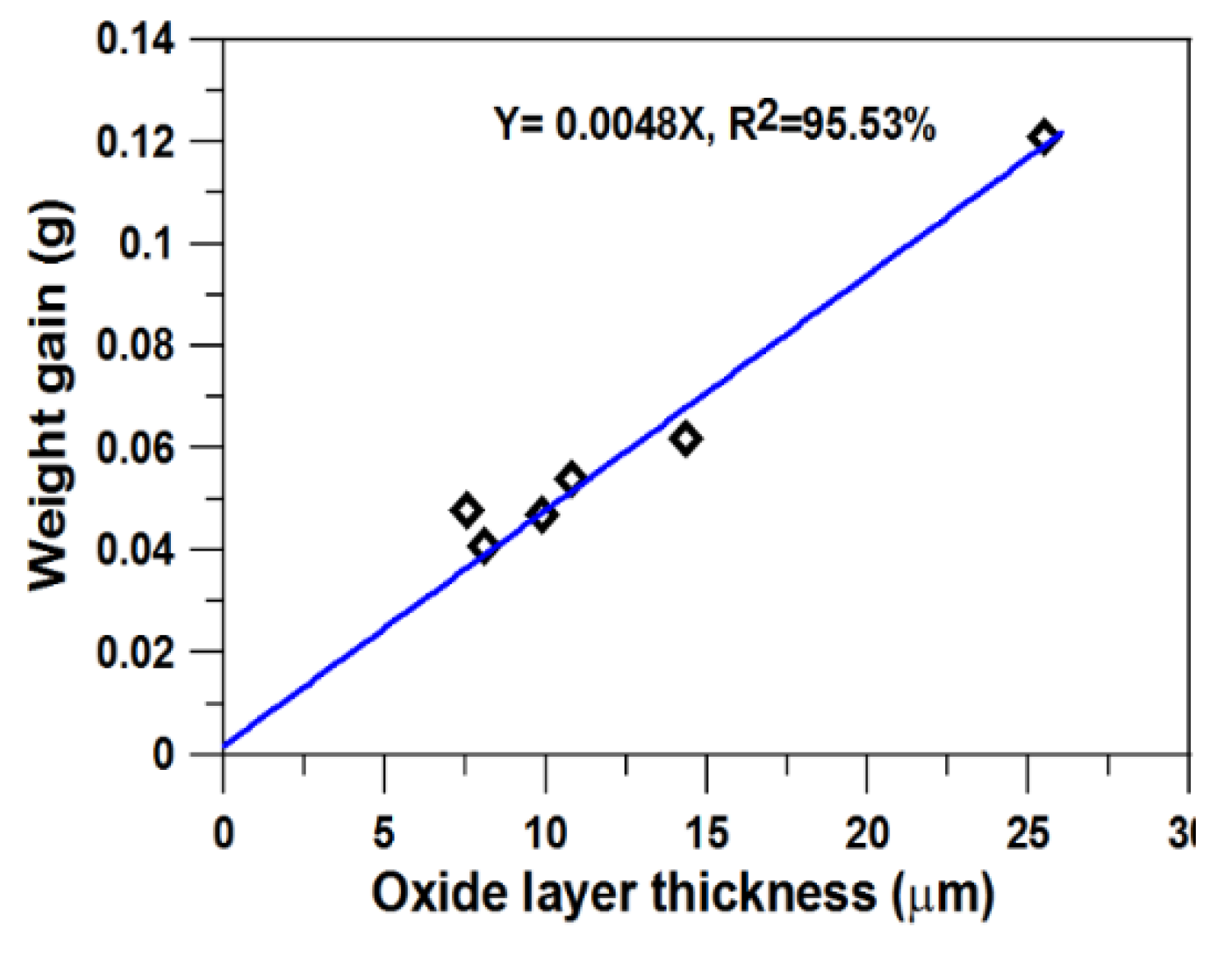

3.4. PEO Layer Thickness and Weight Gain

3.5. The Anti-Corrosion Performance Evaluation of PEO Coatings

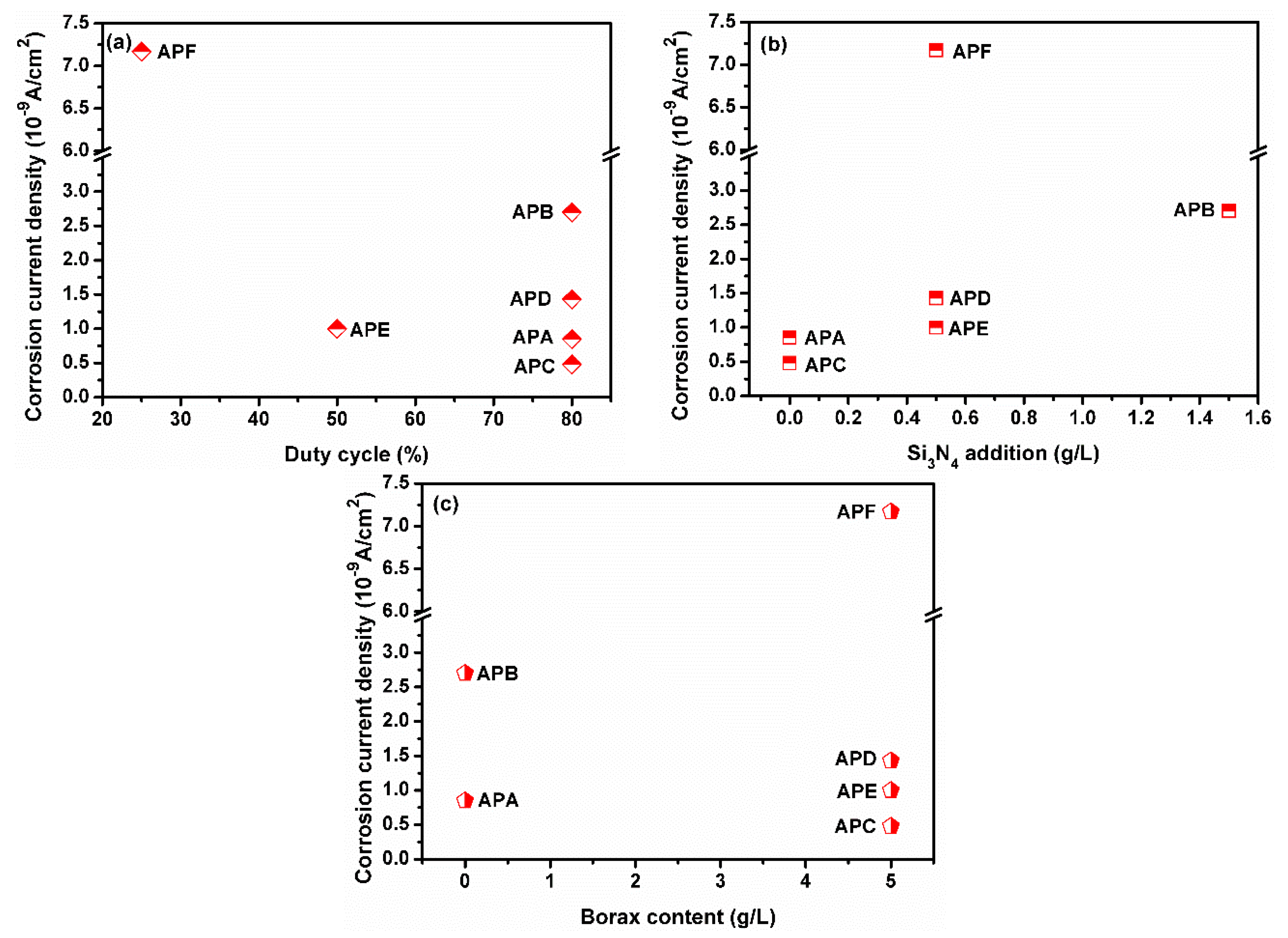

3.5.1. Potentiodynamic Polarization Tests

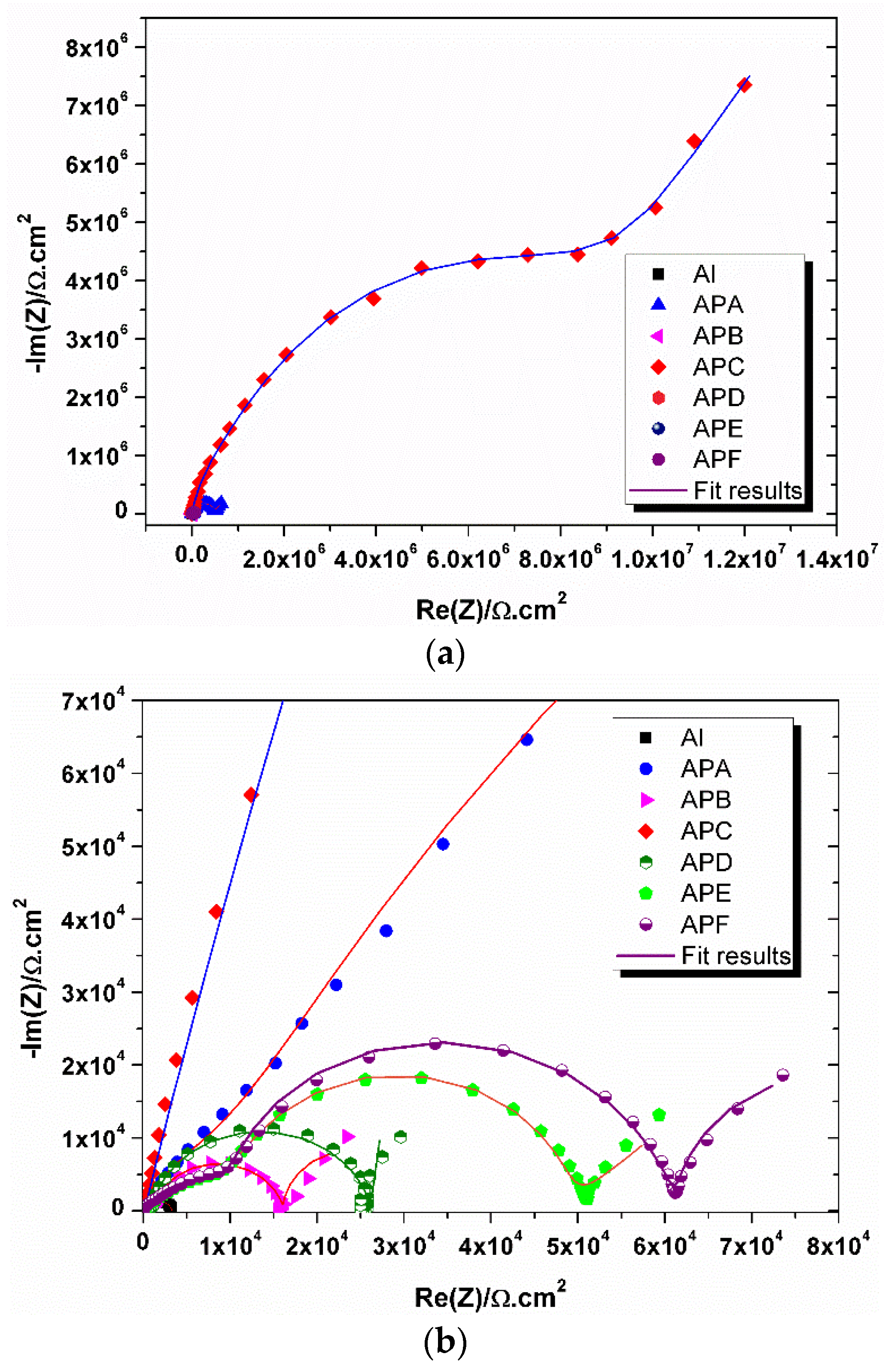

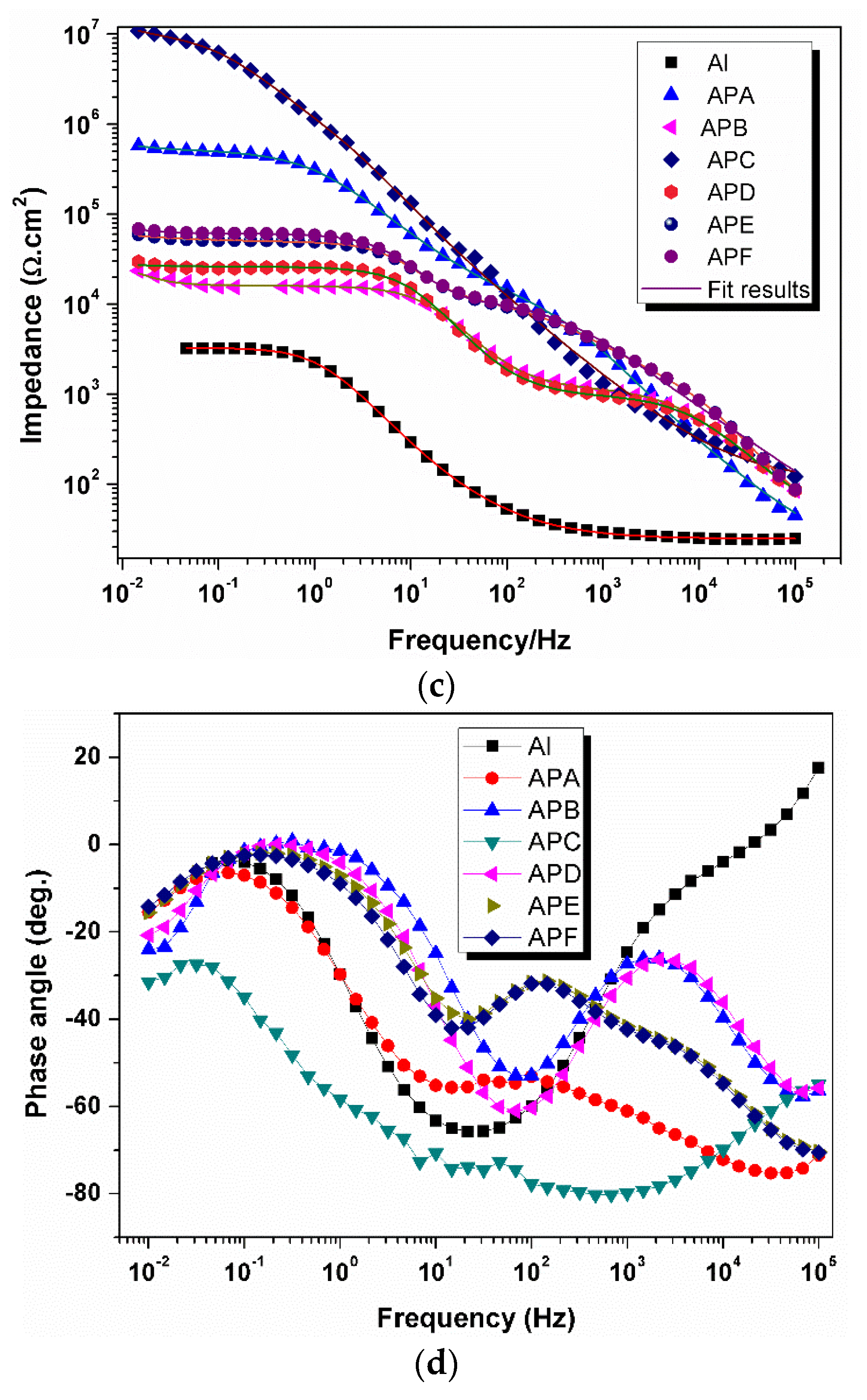

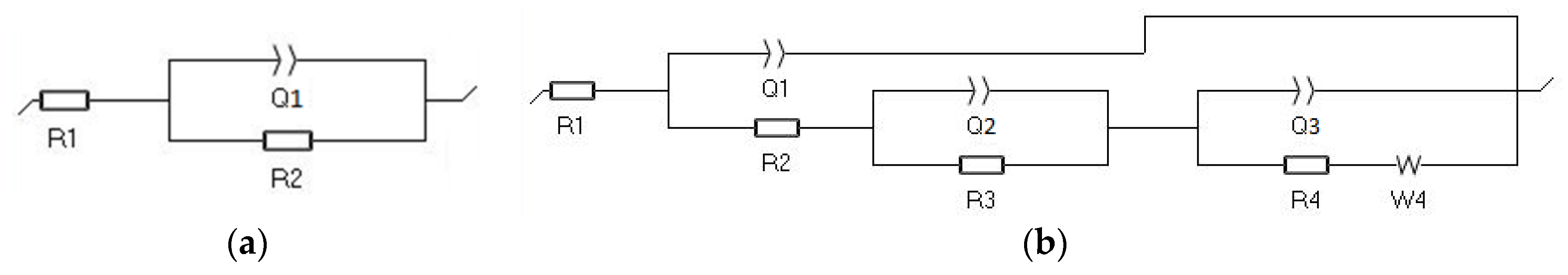

3.5.2. Electrochemical Impedance Spectroscopy (EIS) Test

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Allachi, H.; Chaouket, F.; Draoui, K. Corrosion inhibition of AA6060 aluminium alloy by lanthanide salts in chloride solution. J. Alloys compd. 2009, 475, 300–303. [Google Scholar] [CrossRef]

- Chakraborty, S.; Banerjee, S.; Sharma, I.G.; Paul, B.; Suri, A.K. Studies on the synthesis and characterization of a molybdenum-based alloy. J. Alloys Compd. 2009, 477, 256–261. [Google Scholar] [CrossRef]

- Yerokhin, A.L.; Nie, X.; Leyland, A.; Matthews, A.; Dowey, S.J. Plasma electrolysis for surface engineering. Surf. Coat. Technol. 1999, 0, 73–93. [Google Scholar] [CrossRef]

- Xue, W.; Wu, X.; Li, X.; Tian, H. Anti-corrosion film on 2024/SiC aluminum matrix composite fabricated by microarc oxidation in silicate electrolyte. J. Alloys Compd. 2006, 425, 302–306. [Google Scholar] [CrossRef]

- Dean, J.; Gu, T.; Clyne, T.W. Evaluation of residual stress levels in plasma electrolytic oxidation coatings using a curvature method. Surf. Coat. Technol. 2015, 269, 47–53. [Google Scholar] [CrossRef]

- Yerokhin, A.L.; Lyubimov, V.V.; Ashitkov, R.V. Phase formation in ceramics coatings during plasma electrolytic oxidation of aluminum alloys. Ceram. Int. 1998, 24, 1–6. [Google Scholar] [CrossRef]

- Byeon, S.S.; Wang, K.; Seo, Y.J.; Jung, Y.G.; Koo, B.H. Structural properties of the oxide coatings prepared by electrolyte plasma process on the Al 2021 alloy in various nitrogen solutions. Ceram. Int. 2012, 38S, S665–S668. [Google Scholar] [CrossRef]

- Gnedenkov, S.V.; Khrisanfova, O.A.; Zavidnaya, A.G.; Sinebrukhov, S.L.; Gordienko, P.S.; Iwatsubo, S.; Matsui, A. Composition and adhesion of protective coatings on aluminum. Surf. Coat. Technol. 2001, 145, 146–151. [Google Scholar] [CrossRef]

- Yang, X.; Chen, L.; Jin, X.; Du, J.; Xue, W. Influence of temperature on tribological properties of microarc oxidation coating on 7075 aluminium alloy at 25 °C–300 °C. Ceram. Int. 2019, 45, 12312–12318. [Google Scholar] [CrossRef]

- Wang, K.; Byeon, S.S.; Jung, Y.G.; Koo, B.H. Effect of the nitrogen inducing agents on the corrosion behavior of the oxide coatings prepared by electrolytic plasma processing on the Al 2021 alloy. Ceram. Int. 2012, 38S, S669–S672. [Google Scholar] [CrossRef]

- Malayoglu, U.; Tekin, K.C.; Malayoglu, U.; Shrestha, S. An investigation into the mechanical and tribological properties of plasmaelectrolytic oxidation and hard-anodized coatings on 6082 aluminum alloy. Mater. Sci. Eng. A 2011, 528, 7451–7456. [Google Scholar] [CrossRef]

- Sharifi, H.; Aliofkhazraei, M.; Darband, G.B.; Shrestha, S. A review on adhesion strength of PEO coatings by scratch test method. Surf. Rev. Lett. 2017, 25, 1830004. [Google Scholar] [CrossRef]

- Kuhn, A. Plasma anodizing of magnesium alloys. Met. Finish. 2003, 101, 44–50. [Google Scholar] [CrossRef]

- Hussein, R.O.; Northwood, D.O.; Nie, X. The effect of processing parameters and substrate composition on the corrosion resistance of plasma electrolytic oxidation (PEO) coated magnesium alloys. Surf. Coat. Technol. 2013, 237, 357–368. [Google Scholar] [CrossRef]

- Nie, X.; Meletis, E.; Jiang, J.C.; Leyland, A.; Yerokhin, A.; Matthews, A. Abrasive Wear/Corrosion Properties and TEM Analysis of Al2O3 Coatings Fabricated Using Plasma Electrolysis. Surf. Coat. Technol. 2002, 149, 245–251. [Google Scholar] [CrossRef]

- Sreekanth, D.; Rameshbabu, N.; Venkateswarlu, K. Effect of various additives on morphology and corrosion behavior of ceramic coatings developed on AZ31 magnesium alloy by plasma electrolytic oxidation. Ceram. Int. 2012, 38, 4607–4615. [Google Scholar] [CrossRef]

- Shokouhfar, M.; Dehghanian, C.; Baradaran, A. Preparation of ceramic coating on Ti substrate by Plasma electrolytic oxidation in different electrolytes and evaluation of its corrosion resistance. Appl. Surf. Sci. 2011, 257, 2617–2624. [Google Scholar] [CrossRef]

- Cheng, Y.; Matykina, E.; Arrabal, R.; Skeldon, P.; Thompson, G.E. Plasma electrolytic oxidation and corrosion protection of Zircaloy-4. Surf. Coat. Technol. 2012, 206, 3230–3239. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, X.R.; Wu, Y.K.; Wu, G.R.; Wang, D.D.; Liu, X.T.; Han, H.P.; Su, Y.; Shen, D.J. The correlation between the Na2SiO3·9H2O concentrations and the characteristics of plasma electrolytic oxidation ceramic coatings. Ceram. Int. 2019, 45, 19388–19394. [Google Scholar] [CrossRef]

- Ghasemi, A.; Scharnagl, N.; Blawert, C.; Dietzel, W.; Kainer, K.U. Influence of electrolyte constituents on corrosion behaviour of PEO coatings on magnesium alloys. Surf. Eng. 2010, 26, 321–327. [Google Scholar] [CrossRef]

- Yao, Z.P.; Wang, D.L.; Xia, Q.X.; Zhang, Y.J.; Jiang, Z.H.; Wang, F.P. Effect of PEO power modes on structure and corrosion resistance of ceramic coatings on AZ91D Mg alloy. Surf. Eng. 2012, 28, 96–101. [Google Scholar] [CrossRef]

- Sreekanth, D.; Rameshbabu, N.; Venkateswarlu, K.; Challapalli, S.; Krishna, L.; Kalvala, P. Effect of K2TiF6 and Na2B4O7 as electrolyte additives on pore morphology and corrosion properties of plasma electrolytic oxidation coatings on ZM21 magnesium alloy. Surf. Coat. Technol. 2013, 222, 31–37. [Google Scholar] [CrossRef]

- Bespalova, Z.I.; Panenko, I.N. Impact of Electrolyte Composition and Modes of Operation on the Structure, Morphology, and Properties of Oxide Ceramic Coatings Fabricated by Microarc Oxidation. Surf. Eng. Appl. Electrochem. 2019, 55, 38–45. [Google Scholar] [CrossRef]

- Sankara Narayanan, T.S.N.; Park, I.S.; Lee, M.H. Strategies to improve the corrosion resistance of microarc oxidation (MAO) coated magnesium alloys for degradable implants: Prospects and challenges. Prog. Mater. Sci. 2014, 60, 1–71. [Google Scholar] [CrossRef]

- Li, X.; Luan, B. Discovery of Al2O3 particles incorporation mechanism in plasma electrolytic oxidation of AM60B magnesium alloy. Mater. Lett. 2012, 86, 88–91. [Google Scholar] [CrossRef]

- Wang, Y.; Wei, D.; Yu, J.; Di, S. Effects of Al2O3 Nano-additive on Performance of Micro-arc Oxidation Coatings Formed on AZ91D Mg Alloy. J. Mater. Sci. Technol. 2014, 30, 984–990. [Google Scholar] [CrossRef]

- Toorani Farani, M.; Aliofkhazraei, M.; Sabour Rouh Aghdam, A. Microstructural, protective, inhibitory and semiconducting properties of PEO coatings containing CeO2 nanoparticles formed on AZ31 Mg alloy. Surf. Coat.Technol. 2018, 352, 561–580. [Google Scholar] [CrossRef]

- Cai, J.; Cao, F.; Chang, L.; Zheng, J.; Zhang, J.; Cao, C. The preparation and corrosion behaviors of MAO coating on AZ91D with rare earth conversion precursor film. Appl. Surf. Sci. 2011, 257, 3804–3811. [Google Scholar] [CrossRef]

- Daroonparvar, M.; Yajid, M.A.M.; Yusof, N.M.; Bakhsheshi-Rad, H.R. Preparation and corrosion resistance of a nanocomposite plasma electrolytic oxidation coating on Mg-1%Ca alloy formed in aluminate electrolyte containing titania nano-additives. J. Alloys Compd. 2016, 688, 841–857. [Google Scholar] [CrossRef]

- Liang, J.; Hu, L.; Hao, J. Preparation and Characterization of Oxide Films Containing Crystalline TiO2 on Magnesium Alloy by Plasma Electrolytic Oxidation. Electrochim. Acta. 2007, 52, 4836–4840. [Google Scholar] [CrossRef]

- Lu, X.; Blawert, C.; Huang, Y.; Ovri, H.; Zheludkevich, M.L.; Kainer, K. Plasma electrolytic oxidation coatings on Mg alloy with addition of SiO2 particles. Electrochim. Acta. 2015, 187, 20–33. [Google Scholar] [CrossRef]

- Arrabal, R.; Matykina, E.; Viejo, F.; Skeldon, P.; Thompson, G.; Merino, M. AC Plasma Electrolytic Oxidation of Magnesium with Zirconia Nanoparticles. Appl. Surf. Sci. 2008, 254, 6937–6942. [Google Scholar] [CrossRef]

- Liang, J.; Bala Srinivasan, P.; Blawert, C.; Dietzel, W. Comparison of electrochemical corrosion behaviour of MgO and ZrO2 coatings on AM50 magnesium alloy formed by plasma electrolytic oxidation. Corros. Sci. 2009, 51, 2483–2492. [Google Scholar] [CrossRef]

- Han, B. Plasma-Electrolytic-Oxidation Coating containing Y2O3 Nanoparticles on AZ91 Magnesium Alloy. Int. J. Electrochem. Sci. 2018, 13, 5681–5697. [Google Scholar] [CrossRef]

- Krstic, Z.; Krstic, V.D. Silicon nitride: The engineering material of the future. J. Mater. Sci. 2012, 47, 535–552. [Google Scholar] [CrossRef]

- Lou, B.S.; Lin, Y.Y.; Tseng, C.M.; Lu, Y.C.; Duh, J.G.; Lee, J.W. Plasma electrolytic oxidation coatings on AZ31 magnesium alloys with Si3N4 nanoparticle additives. Surf. Coat. Technol. 2017, 332, 358–367. [Google Scholar] [CrossRef]

- Lu, X.; Blawert, C.; Scharnagl, N.; Kainer, K.U. Influence of incorporating Si3N4 particles into the oxide layer produced by plasma electrolytic oxidation on AM50 Mg alloy on coating morphology and corrosion properties. J. Magnes. Alloys 2013, 1, 267–274. [Google Scholar] [CrossRef]

- Qin, D.; Xu, G.; Yang, Y.; Chen, S. Multiphase Ceramic Coatings with High Hardness and Wear Resistance on 5052 Aluminum Alloy by a Microarc Oxidation Method. ACS Sustain. Chem. Eng. 2018, 6, 2431–2437. [Google Scholar] [CrossRef]

- Dehnavi, V.; Luan, B.L.; Liu, X.Y.; Shoesmith, D.W.; Rohani, S. Correlation between plasma electrolytic oxidation treatment stages and coating microstructure on aluminum under unipolar pulsed DC mode. Surf. Coat. Technol. 2015, 269, 91–99. [Google Scholar] [CrossRef]

- Dehnavi, V.; Liu, X.Y.; Luan, B.L.; Shoesmith, D.W.; Rohani, S. Phase transformation in plasma electrolytic oxidation coatings on 6061 aluminum alloy. Surf. Coat. Technol. 2014, 251, 106–114. [Google Scholar] [CrossRef]

- Macêdo, M.I.F.; Bertran, C.A.; Osawa, C.C. Kinetics of the γ → α-alumina phase transformation by quantitative X-ray diffraction. J. Mater. Sci. 2007, 42, 2830–2836. [Google Scholar] [CrossRef]

- Loong, C.K.; Richardson, J.W.; Ozawa, M. Structural phase transformations of rare-earth modified transition alumina to corundum. J. Alloys Compd. 1997, 250, 356–359. [Google Scholar] [CrossRef]

- Yurekturk, Y.; Muhaffel, F.; Baydogan, M. Characterization of micro arc oxidized 6082 aluminum alloy in an electrolyte containing carbon nanotubes. Surf. Coat. Technol. 2015, 269, 83–90. [Google Scholar] [CrossRef]

- Khan, R.H.U.; Yerokhin, A.; Li, X.; Dong, H.; Matthews, A. Surface characterisation of DC plasma electrolytic oxidation treated 6082 aluminium alloy: Effect of current density and electrolyte concentration. Surf. Coat. Technol. 2010, 205, 1679–1688. [Google Scholar] [CrossRef]

- Doolabi, D.S.; Ehteshamzadeh, M.; Mirhosseini, S.M.M. Effect of NaOH on the Structure and Corrosion Performance of Alumina and Silica PEO Coatings on Aluminum. J. Mater. Eng. Perform. 2012, 21, 2195–2202. [Google Scholar] [CrossRef]

- Venugopal, A.; Srinath, J.; Rama Krishna, L.; Ramesh Narayanan, P.; Sharma, S.C.; Venkitakrishnan, P.V. Corrosion and nanomechanical behaviors of plasma electrolytic oxidation coated AA7020-T6 aluminum alloy. Mater. Sci. Eng. A 2016, 660, 39–46. [Google Scholar] [CrossRef]

- Dehnavi, V.; Luan, B.; Shoesmith, D.; Liu, X.Y.; Rohani, S. Effect of duty cycle and applied current frequency on plasma electrolytic oxidation (PEO) coating growth behavior. Surf. Coat. Technol. 2013, 226, 100–107. [Google Scholar] [CrossRef]

- Cheng, Y.L.; Qin, T.W.; Li, L.L.; Wang, H.M.; Zhang, Z. Comparison of corrosion resistance of microarc oxidation coatings prepared with different electrolyte concentrations on AM60 magnesium alloy. Corros. Eng. 2011, 46, 17–23. [Google Scholar] [CrossRef]

- Malayoglu, U.; Tekin, K.; Shrestha, S. Influence of post-treatment on the corrosion resistance of PEO coated AM50B and AM60B Mg alloys. Surf. Coat. Technol. 2010, 205, 1793–1798. [Google Scholar] [CrossRef]

- Demirba, Ç.A.; Ayday, A. The influence of Nano-TiO2 and Nano-Al2O3 Particles in Silicate Based Electrolytes on Microstructure and Mechanical Properties of Micro Arc Coated Ti6Al4V Alloy. Mater. Res. 2018, 21, 1–5. [Google Scholar] [CrossRef]

- Wu, X.Q.; Xie, F.Q.; Hu, Z.C.; Wang, L. Effects of additives on corrosion and wear resistance of micro-arc oxidation coatings on TiAl alloy. Trans. Nonferrous Met. Soc. China 2010, 20, 1032–1036. [Google Scholar] [CrossRef]

- Li, B.; Zhang, W. Microstructural, surface and electrochemical properties of pulse electrodeposited Ni–W/Si3N4 nanocomposite coating. Ceram. Int. 2018, 44, 19907–19918. [Google Scholar] [CrossRef]

- Xue, W.; Jin, Q.; Zhu, Q.; Hua, M.; Ma, Y. Anti-corrosion microarc oxidation coatings on SiC P/AZ31 magnesium matrix composite. J. Alloys Compd. 2009, 482, 208–212. [Google Scholar] [CrossRef]

- Dehnavi, V.; Shoesmith, D.W.; Luan, B.L.; Yari, M.; Liu, X.Y.; Rohani, S. Corrosion properties of plasma electrolytic oxidation coatings on an aluminium alloy–The effect of the PEO process stage. Mater. Chem. Phys. 2015, 161, 49–58. [Google Scholar] [CrossRef]

- Gu, C.; Wang, L.; Hu, X.; Dong, W.; DaCosta, H. Borate’s effects on coatings by PEO on AZ91D alloy. Surf. Eng. 2017, 33, 773–778. [Google Scholar]

- Butyagin, P.I.; Khokhryakov, Y.V.; Mamaev, A.I. Microplasma systems for creating coatings on aluminium alloys. Mater. Lett. 2003, 57, 1748–1751. [Google Scholar] [CrossRef]

- Liang, J.; Guo, B.; Tian, J.; Liu, H.; Zhou, J.; Xu, T. Effect of potassium fluoride in electrolytic solution on the structure and properties of microarc oxidation coatings on magnesium alloy. Appl. Surf. Sci. 2005, 252, 345–351. [Google Scholar] [CrossRef]

- Venkateswarlu, K.; Rameshbabu, N.; Sreekanth, D.; Bose, A.C.; Muthupandi, V.; Subramanian, S. Fabrication and characterization of micro-arc oxidized fluoride containing titania films on Cp Ti. Ceram. Int. 2013, 39, 801–812. [Google Scholar] [CrossRef]

- Shi, L.; Xu, Y.; Li, K.; Yao, Z.; Wu, S. Effect of Additives on Structure and Corrosion Resistance of ceramic Coatings on Mg-Li Alloy by Micro-Arc Oxidation. Curr. Appl. Phys. 2010, 10, 719–723. [Google Scholar] [CrossRef]

- Yagi, S.; Kuwabara, K.; Fukuta, Y.; Kubota, K.; Matsubara, E. Formation of self-repairing anodized film on ACM522 magnesium alloy by plasma electrolytic oxidation. Corros. Sci. 2013, 73, 188–195. [Google Scholar] [CrossRef]

- Shen, M.J.; Wang, X.; Zhang, M.F. High-compactness coating grown by plasma electrolytic oxidation on AZ31 magnesium alloy in the solution of silicate–borax. Appl. Surf. Sci. 2012, 259, 362–366. [Google Scholar] [CrossRef]

- Zhang, R.F.; Zhang, S.F.; Shen, Y.L.; Zhang, L.H.; Liu, T.Z.; Zhang, Y.Q.; Guo, S.B. Influence of sodium borate concentration on properties of anodic coatings obtained by micro arc oxidation on magnesium alloys. Appl. Surf. Sci. 2012, 258, 6602–6610. [Google Scholar] [CrossRef]

- Kaseem, M.; Yang, H.W.; Ko, Y.G. Toward a nearly defect-free coating via high-energy plasma sparks. Sci. Rep. 2017, 7, 2378. [Google Scholar] [CrossRef] [PubMed]

- Lv, G.H.; Gu, W.C.; Chen, H.; Li, L.; Niu, E.W.; Yang, S.Z. Microstructure and Corrosion Performance of Oxide Coatings on Aluminium by Plasma Electrolytic Oxidation in Silicate and Phosphate Electrolytes. Chin. Phys. Lett. 2006, 23, 3331–3333. [Google Scholar]

- Shao, L.; Li, H.; Jiang, B.; Liu, C.; Gu, X.; Chen, D. A Comparative Study of Corrosion Behavior of Hard Anodized and Micro-Arc Oxidation Coatings on 7050 Aluminum Alloy. Metals 2018, 8, 165. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, L.; Cai, W.; Shan, A.; Jiang, Z. Effects of fluoride on the structure and properties of microarc oxidation coating on aluminium alloy. J. Alloys Compd. 2010, 505, 188–193. [Google Scholar] [CrossRef]

- Bisquert, J.; Compte, A. Theory of the electrochemical impedance of anomalous diffusion. J. Electroanal. Chem. 2001, 499, 112–120. [Google Scholar] [CrossRef]

- Suay, J.J.; Gimenez, E.; Rodriguez, T.; Habbib, K.; Saura, J.J. Characterization of anodized and sealed aluminium by EIS. Corro. Sci. 2003, 45, 611–624. [Google Scholar] [CrossRef]

- Yao, Z.; Jiang, Z.; Xin, S.; Xuetong, S.; Wu, X. Electrochemical Impedance Spectroscopy of Ceramic Coatings on Ti–6Al–4V by Micro-Plasma Oxidation. Electrochim. Acta. 2005, 50, 3273–3279. [Google Scholar] [CrossRef]

- Liu, C.; Bi, Q.; Leyland, A.; Matthews, A. An electrochemical impedance spectroscopy study of the corrosion behaviour of PVD coated steels in 0.5 N NaCl aqueous solution: Part I. Establishment of equivalent circuits for EIS data modelling. Corro. SCi. 2003, 45, 1243–1256. [Google Scholar] [CrossRef]

| Specimen Designation | APA | APB | APC | APD | APE | APF | |

|---|---|---|---|---|---|---|---|

| Size (cm) | 5 × 5 × 0.1 | ||||||

| Si3N4 concentration in electrolyte (g L−1) | 0 | 1.5 | 0 | 0.5 | 0.5 | 0.5 | |

| Electrolyte concentration | Na2SiO3·5H2O (g L−1) | 7 | |||||

| KOH (g L−1) | 2.5 | ||||||

| Na3PO4·12H2O (g L−1) | 5 | ||||||

| Na2B4O7·10H2O (g L−1) | 0 | 0 | 5 | 5 | 5 | 5 | |

| Duty cycle (%) | 80 | 50 | 25 | ||||

| Frequency (Hz) | 1000 | ||||||

| Voltage (V) | 600 | ||||||

| Current density (mA·cm−2) | 100 | ||||||

| Time (sec) | 600 | ||||||

| Breakdown voltage (V) | 382.3 | 385.0 | 397.1 | 396.0 | 399.5 | 417.2 | |

| The time to reach breakdown voltage (s) | 16.5 | 18.5 | 22.0 | 34.5 | 24.5 | 22.0 | |

| Sample | APA | APB | APC | APD | APE | APF | |

|---|---|---|---|---|---|---|---|

| Composition | |||||||

| O | 62.37 | 60.97 | 61.13 | 59.56 | 60.88 | 58.98 | |

| Na | 0.14 | 0.20 | 0.08 | 0.06 | 0.11 | 0.12 | |

| Al | 36.29 | 30.77 | 36.15 | 34.36 | 35.30 | 35.33 | |

| Si | 1.15 | 5.85 | 1.37 | 4.03 | 1.63 | 3.29 | |

| P | 0.02 | 1.33 | 0.08 | 0.19 | 0.09 | 0.34 | |

| K | 0.03 | 0.13 | 0.06 | 0.03 | 0.24 | 0.13 | |

| N | 0.00 | 0.75 | 0.00 | 0.25 | 0.33 | 0.19 | |

| B | 0.00 | 0.00 | 1.13 | 1.52 | 1.42 | 1.62 | |

| Sample No. | APA | APB | APC | APD | APE | APF |

|---|---|---|---|---|---|---|

| Weight gain (g) | 0.048 | 0.121 | 0.041 | 0.062 | 0.054 | 0.047 |

| Layer thickness (µm) | 7.55 ± 0.58 | 25.5 ± 52.02 | 8.10 ± 0.62 | 14.35 ± 1.13 | 10.8 ± 1.05 | 9.88 ± 1.01 |

| Surface roughness (µm) | 1.01 ± 0.11 | 4.88 ± 0.2 | 1.44 ± 0.13 | 2.2 ± 0.17 | 1.83 ± 0.12 | 1.54 ± 0.09 |

| Average pore size (µm) | 0.804 | 6.532 | 0.662 | 1.647 | 0.859 | 0.850 |

| Average porosity (%) | 0.229 | 19.057 | 0.201 | 3.888 | 0.769 | 0.717 |

| Sample No. | Al | APA | APB | APC | APD | APE | APF |

|---|---|---|---|---|---|---|---|

| Icorr (A⋅cm−2) | 4.97 × 10−7 | 8.49 × 10−10 | 2.70 × 10−9 | 4.83 × 10−10 | 1.43 × 10−9 | 1.01 × 10−9 | 7.17 × 10−9 |

| Ecorr (V) | −0.773 | −0.639 | −0.775 | −0.599 | −0.762 | −0.727 | −0.706 |

| Rp (Ω·cm2) | 8.15 × 103 | 3.07 × 107 | 9.66 × 106 | 5.40 × 107 | 1.83 × 107 | 2.60 × 107 | 3.64 × 107 |

| Substrate | Electrolyte | NaCl Solution | Icorr (A·cm−2) | Ecorr (V) | Ref. |

|---|---|---|---|---|---|

| Al-Mg-Si alloy | alkaline-phosphate-based electrolytes and Na3AlF6 | 3.5 wt % | 9.40 × 109 | −0.659 | [63] |

| pure aluminum | NaOH, Na2SiO3 and (NaPO3)6 | 4.32 × 10−9 | −1.390 | [64] | |

| 7050 Al | Sodium hexametaphosphate, Sodium silicate, Sodium tungstate and Sulfuric acid | 2.10 × 10−10 | −0.665 | [65] | |

| LY12 aluminum alloy | NaAlO2 and with and without NaF | 0.88 × 10−7 | −0.602 | [66] |

| Parameter | Al | APA | APB | APC | APD | APE | APF |

|---|---|---|---|---|---|---|---|

| R1 (Ω⋅cm2) | 25.36 | 20.96 | 28.87 | 29.3 | 28.83 | 30.92 | 29.66 |

| Q1 (S⋅sn1)) | 5.13 × 10−5 | 8.31 × 10−8 | 1.3 × 10−7 | 6.45 × 10−8 | 1.22 × 10−7 | 1.77 × 10−8 | 0.22 × 10−6 |

| n1 | 0.839 | 0.85 | 0.81 | 0.87 | 0.82 | 0.80 | 0.72 |

| R2 (Ω⋅cm2) | 3.40 × 103 | 2.02 × 104 | 1.42 × 103 | 3.26 × 106 | 1.54 × 103 | 2.18 × 103 | 1.01 × 104 |

| Q2 (S⋅sn2) | -- | 6.51 × 10−6 | 8.76 × 10−4 | 8.98 × 10−9 | 7.01 × 10−7 | 5.03 × 10−8 | 0.76 × 10−6 |

| n2 | -- | 0.90 | 1.00 | 0.77 | 0.92 | 0.80 | 0.82 |

| R3 (Ω⋅cm2) | -- | 4.38 × 105 | 1.72 × 104 | 7.49 × 106 | 2.51 × 104 | 2.97 × 104 | 4.25 × 104 |

| Q3 (S⋅sn3) | -- | 0.32 × 10−6 | 7.93 × 10−7 | 1.56 × 10−6 | 9.49 × 10−4 | 5.83 × 10−7 | 0.49 × 10−3 |

| n3 | -- | 0.74 | 0.91 | 0.89 | 0.93 | 0.80 | 0.80 |

| R4 (Ω⋅cm2) | -- | 5.05 × 105 | 1.49 × 104 | 2.85 × 107 | 2.70 × 104 | 3.66 × 104 | 1.42 × 105 |

| W (Ω⋅s-1/2) | -- | 1.09 | 1.05 × 10−8 | 2.23 × 105 | 9.39 × 10−7 | 0.26 × 10−4 | 6.78 × 10−6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mengesha, G.A.; Chu, J.P.; Lou, B.-S.; Lee, J.-W. Effects of Processing Parameters on the Corrosion Performance of Plasma Electrolytic Oxidation Grown Oxide on Commercially Pure Aluminum. Metals 2020, 10, 394. https://doi.org/10.3390/met10030394

Mengesha GA, Chu JP, Lou B-S, Lee J-W. Effects of Processing Parameters on the Corrosion Performance of Plasma Electrolytic Oxidation Grown Oxide on Commercially Pure Aluminum. Metals. 2020; 10(3):394. https://doi.org/10.3390/met10030394

Chicago/Turabian StyleMengesha, Getinet Asrat, Jinn P. Chu, Bih-Show Lou, and Jyh-Wei Lee. 2020. "Effects of Processing Parameters on the Corrosion Performance of Plasma Electrolytic Oxidation Grown Oxide on Commercially Pure Aluminum" Metals 10, no. 3: 394. https://doi.org/10.3390/met10030394

APA StyleMengesha, G. A., Chu, J. P., Lou, B.-S., & Lee, J.-W. (2020). Effects of Processing Parameters on the Corrosion Performance of Plasma Electrolytic Oxidation Grown Oxide on Commercially Pure Aluminum. Metals, 10(3), 394. https://doi.org/10.3390/met10030394