Comprehensive Analysis on the Performance and Material of Automobile Brake Discs

Abstract

1. Automotive Brake Analysis

1.1. Analysis of External Conditions of Automobile Braking

1.2. Working Analysis of Brake Discs

2. Brake Disc Performance Analysis

2.1. Thermal and Thermal Analysis

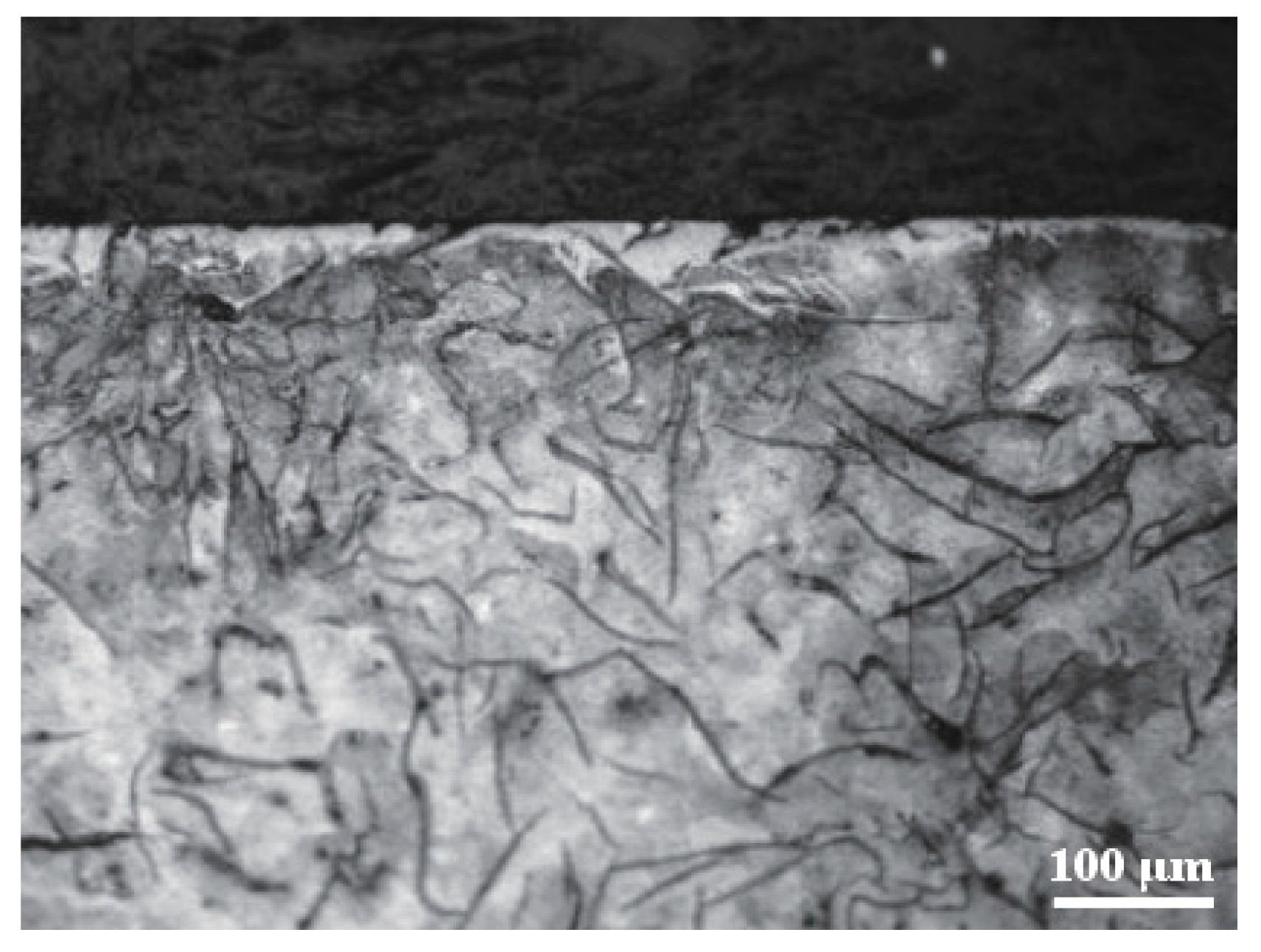

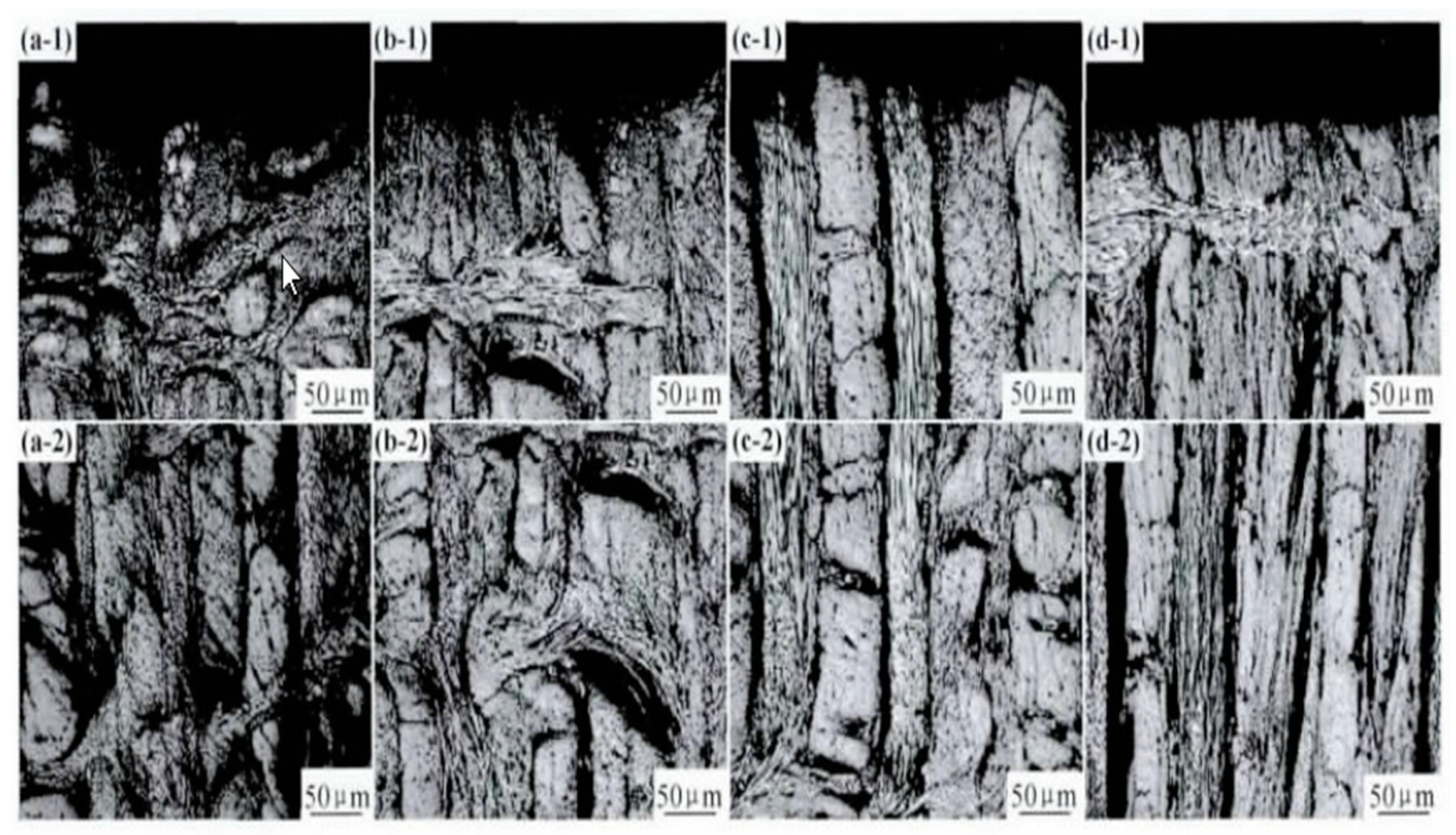

2.2. Thermal Fatigue Analysis

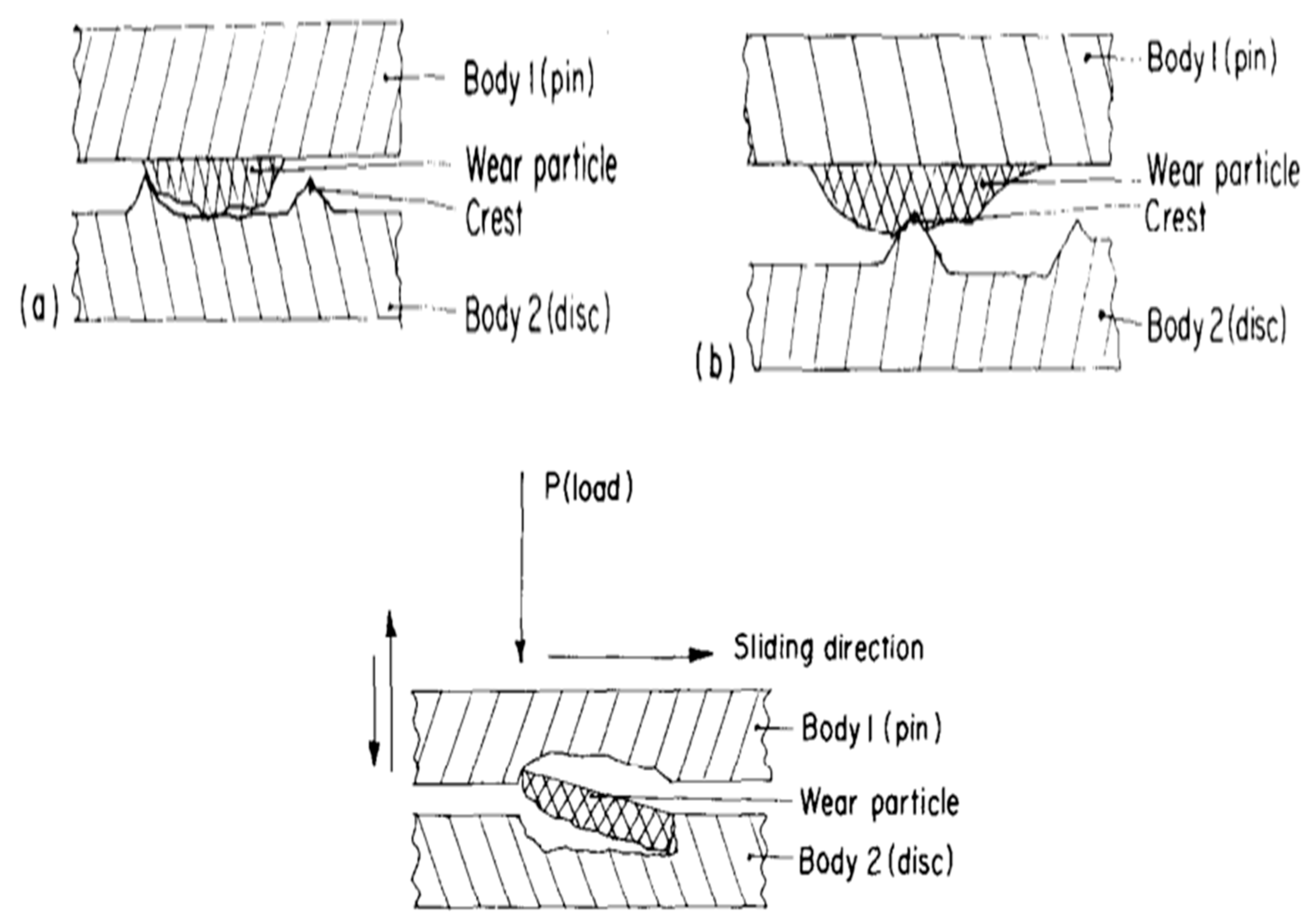

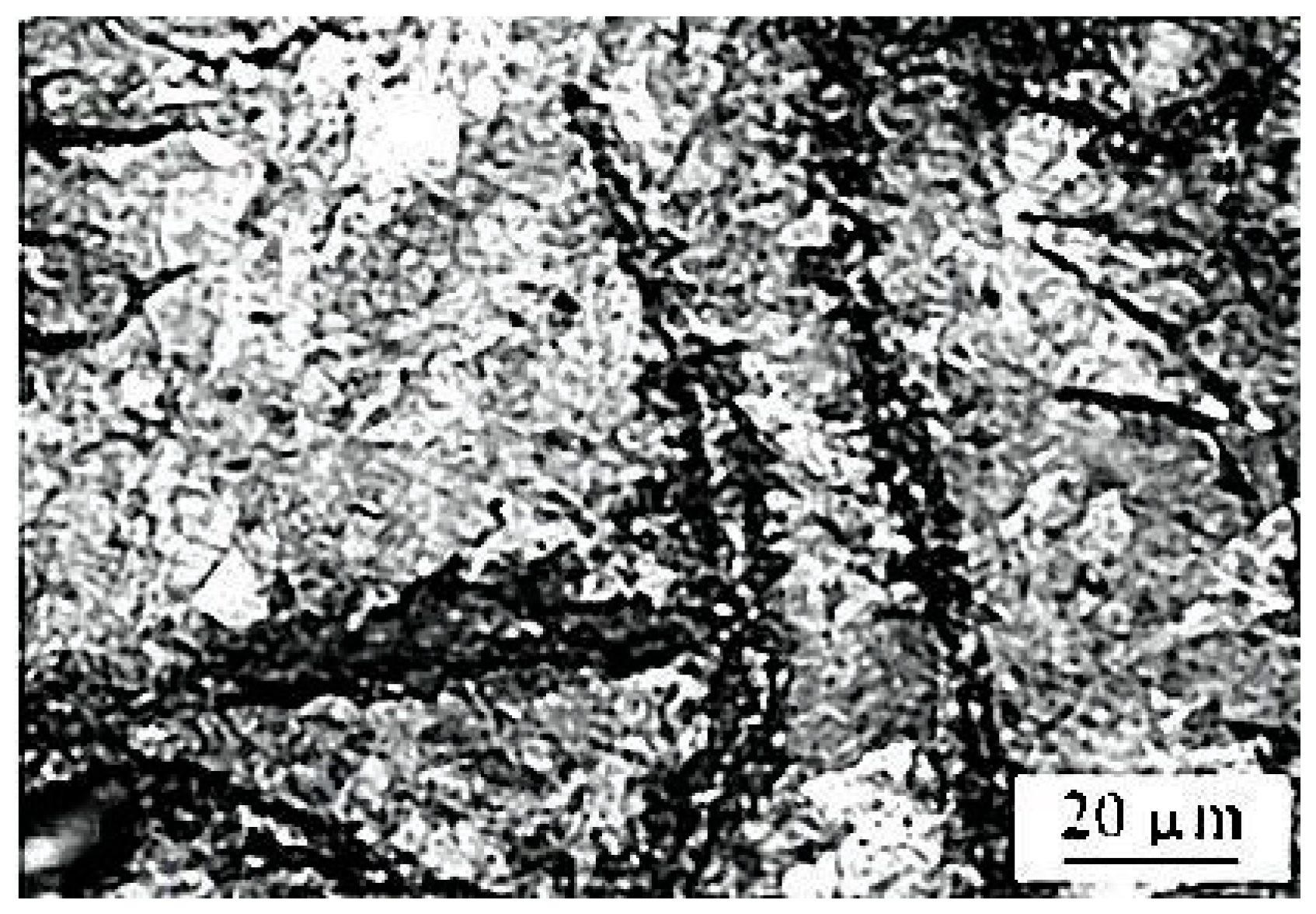

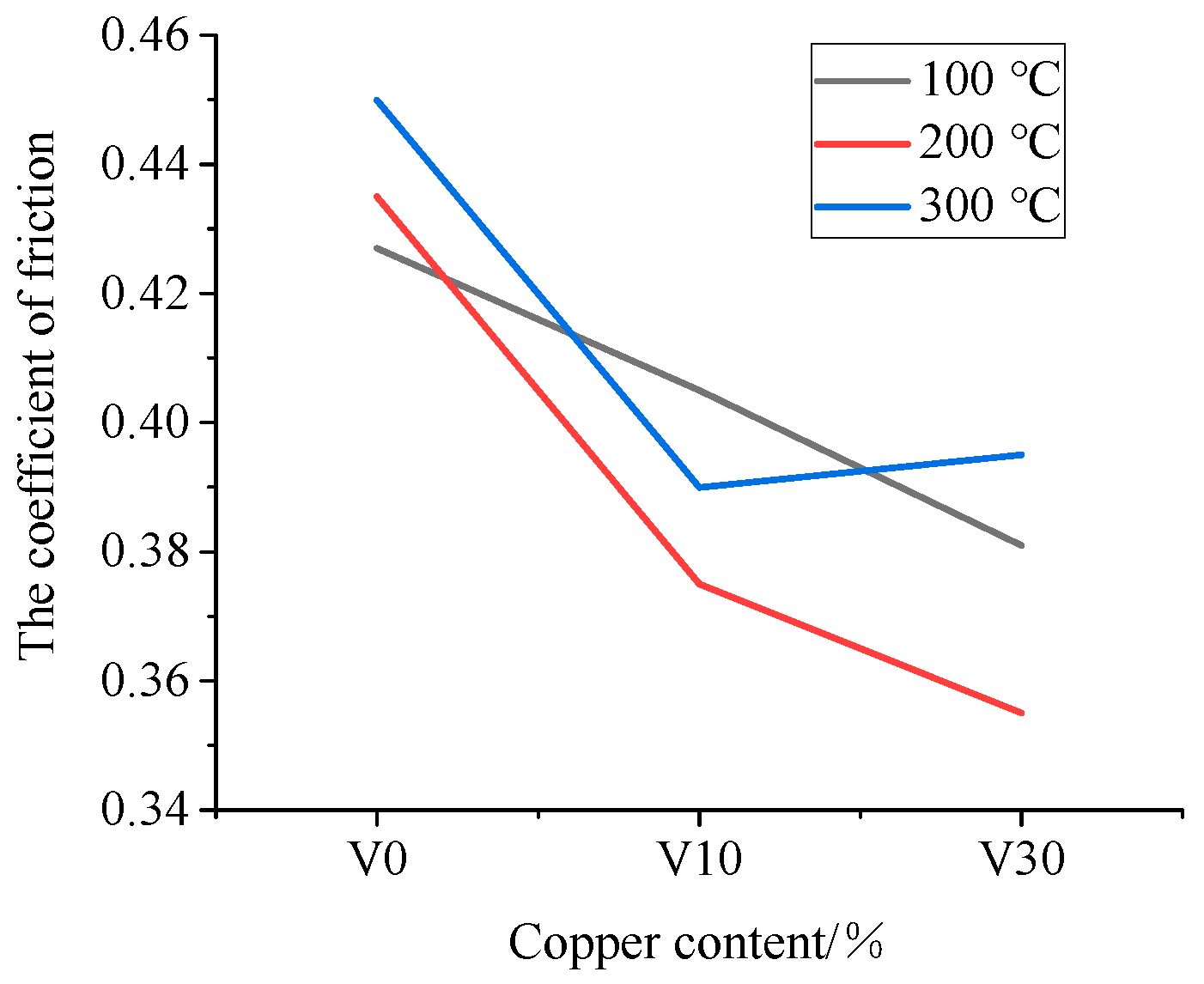

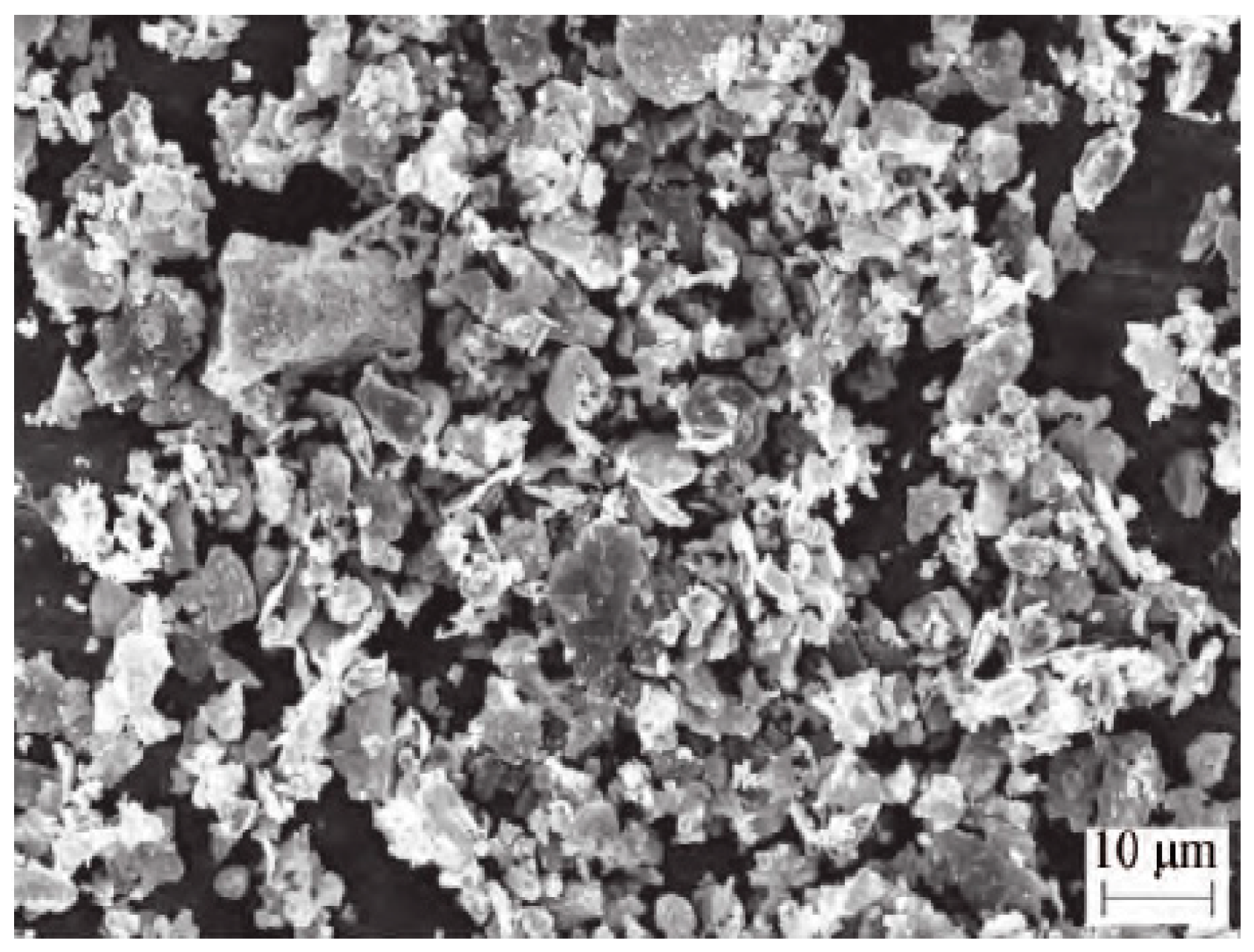

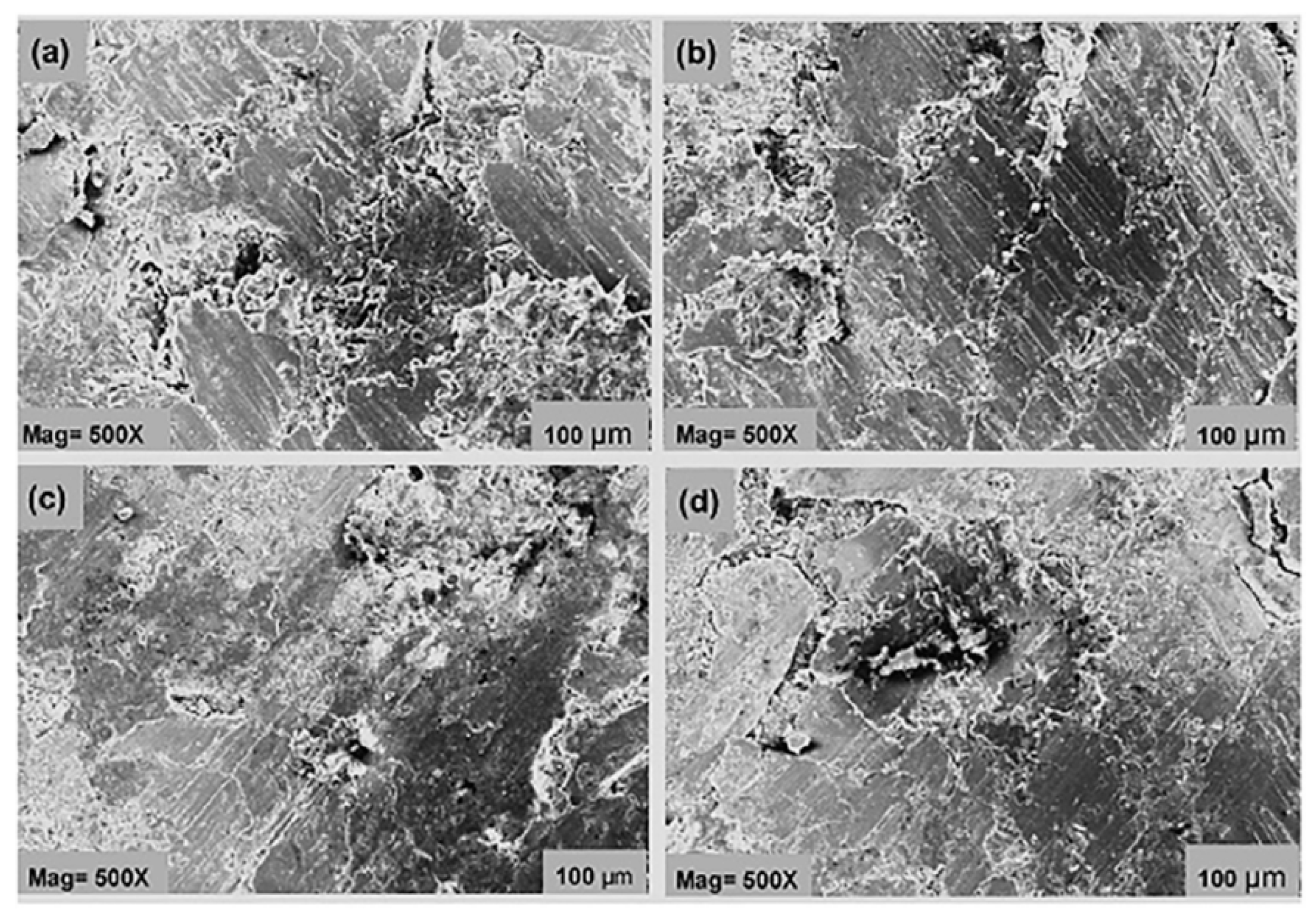

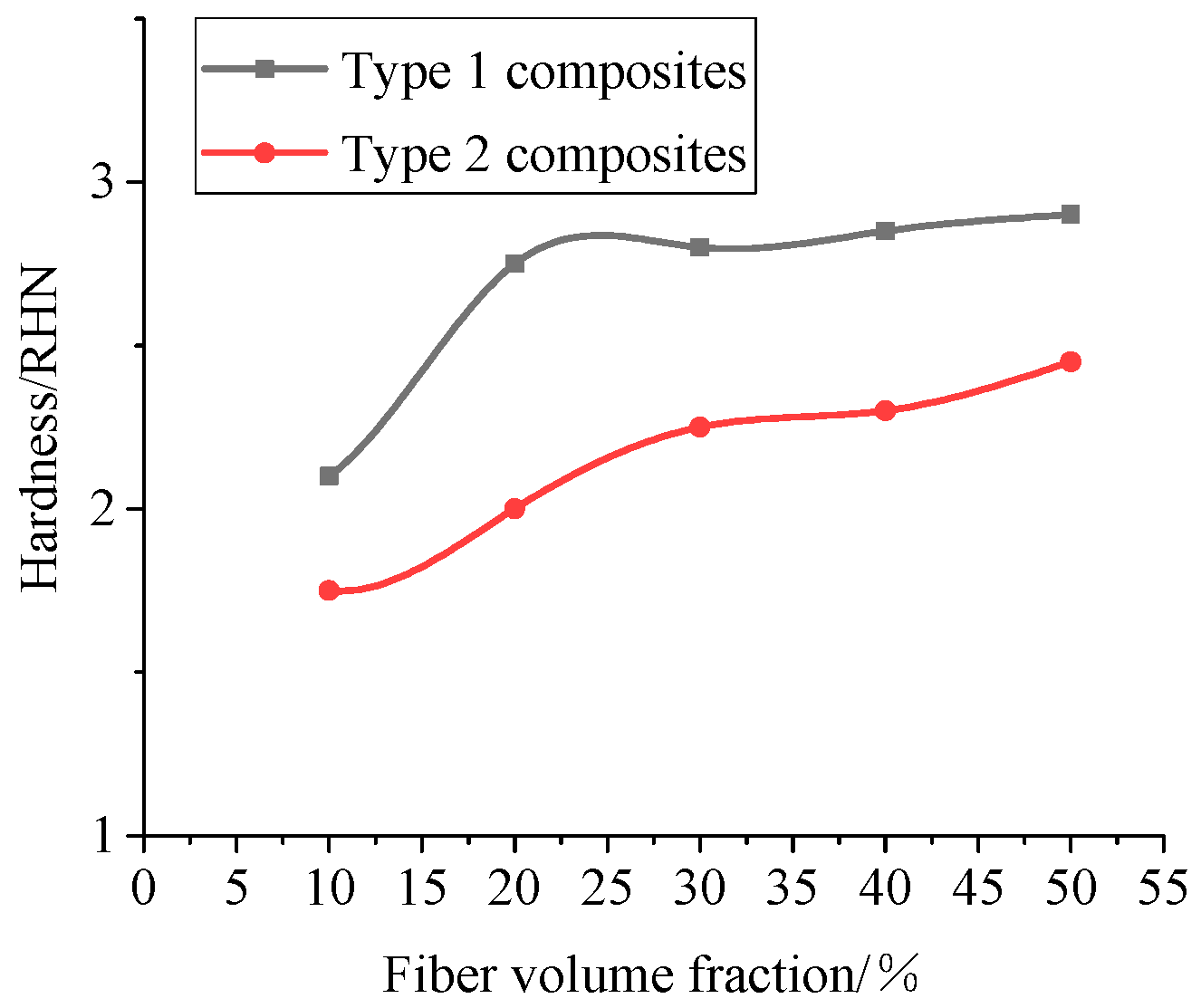

2.3. Wear Resistance Analysis

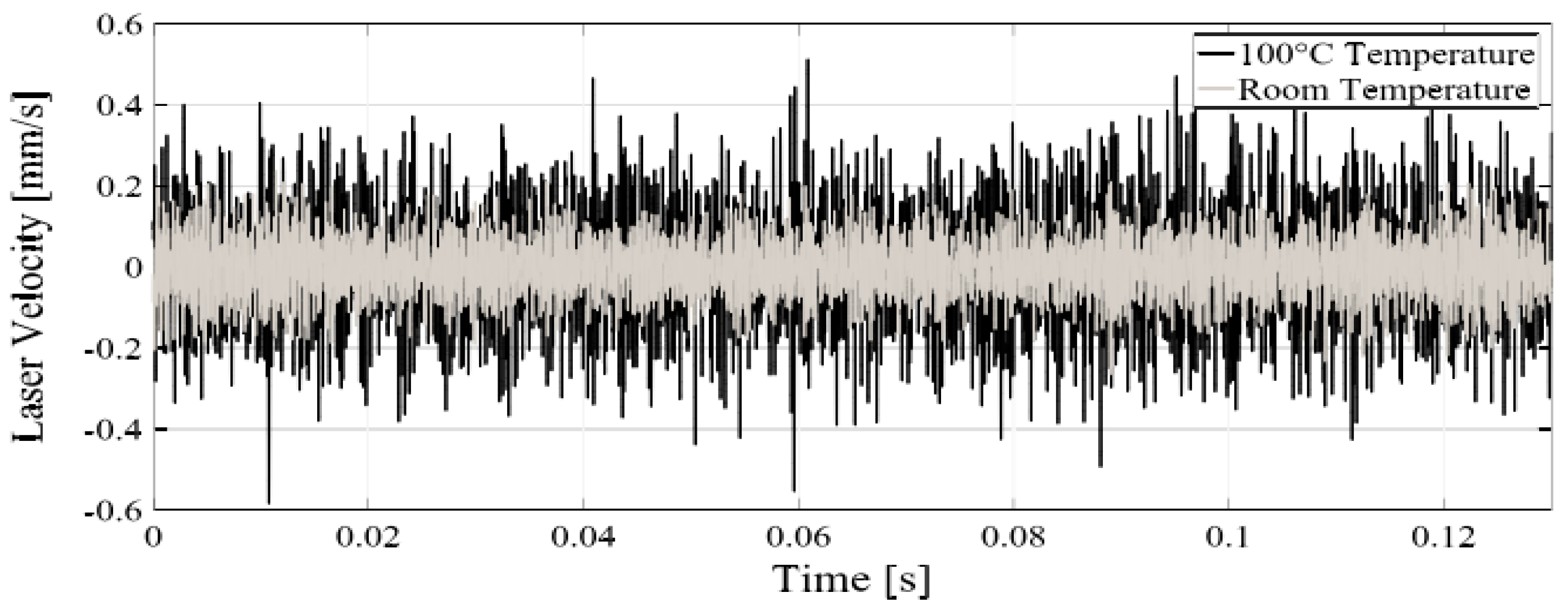

2.4. Noise Analysis

3. Brake Disc Manufacturing Analysis

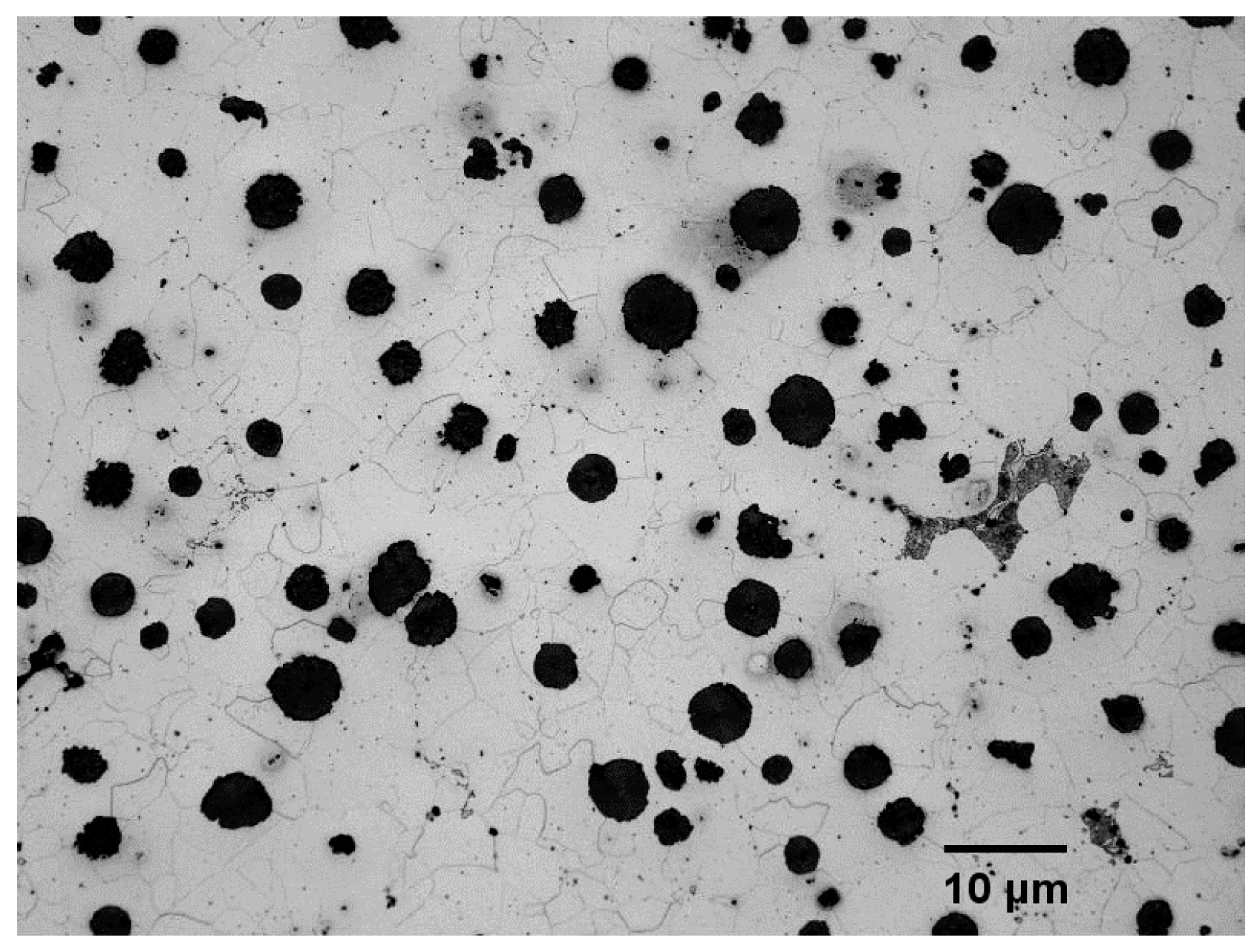

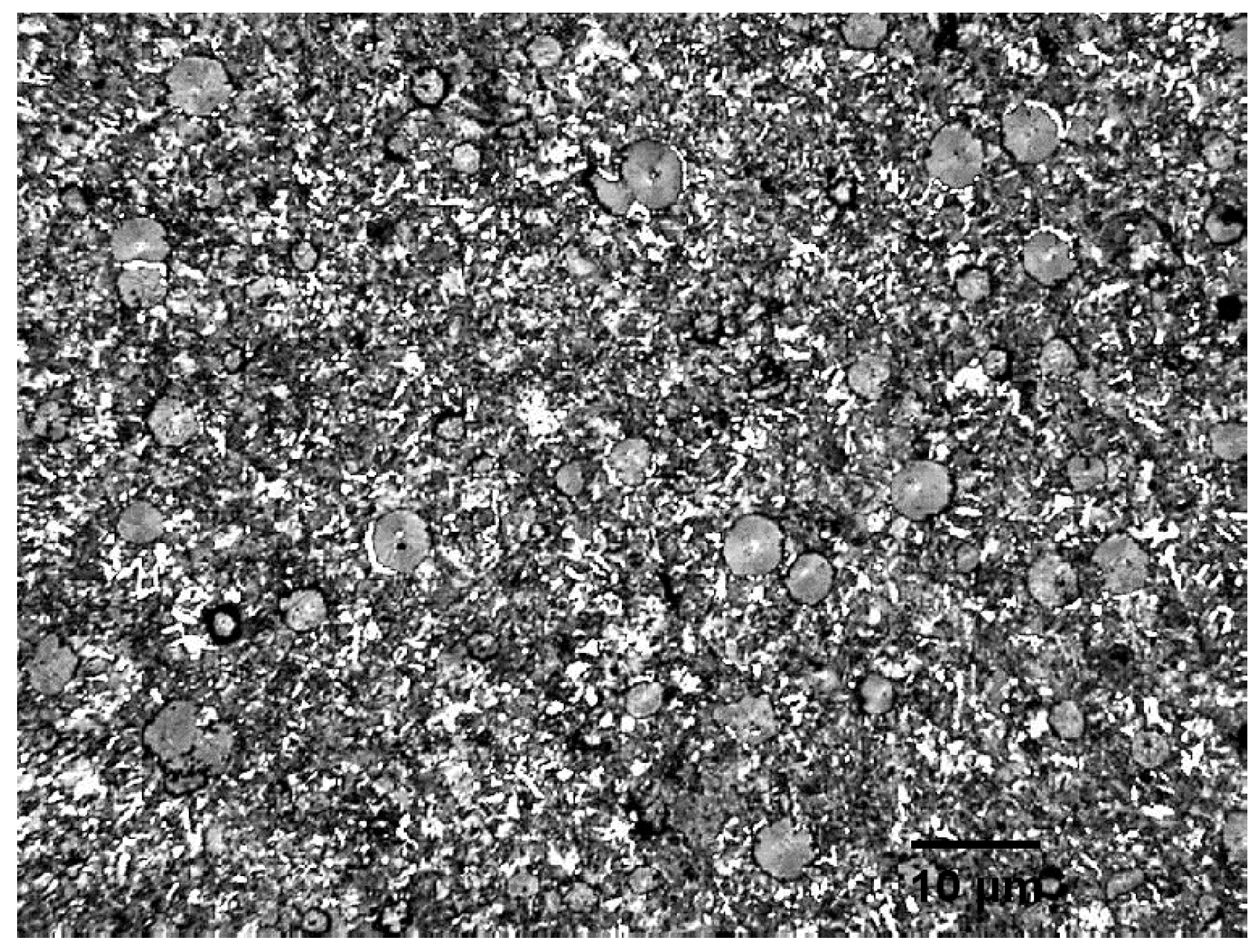

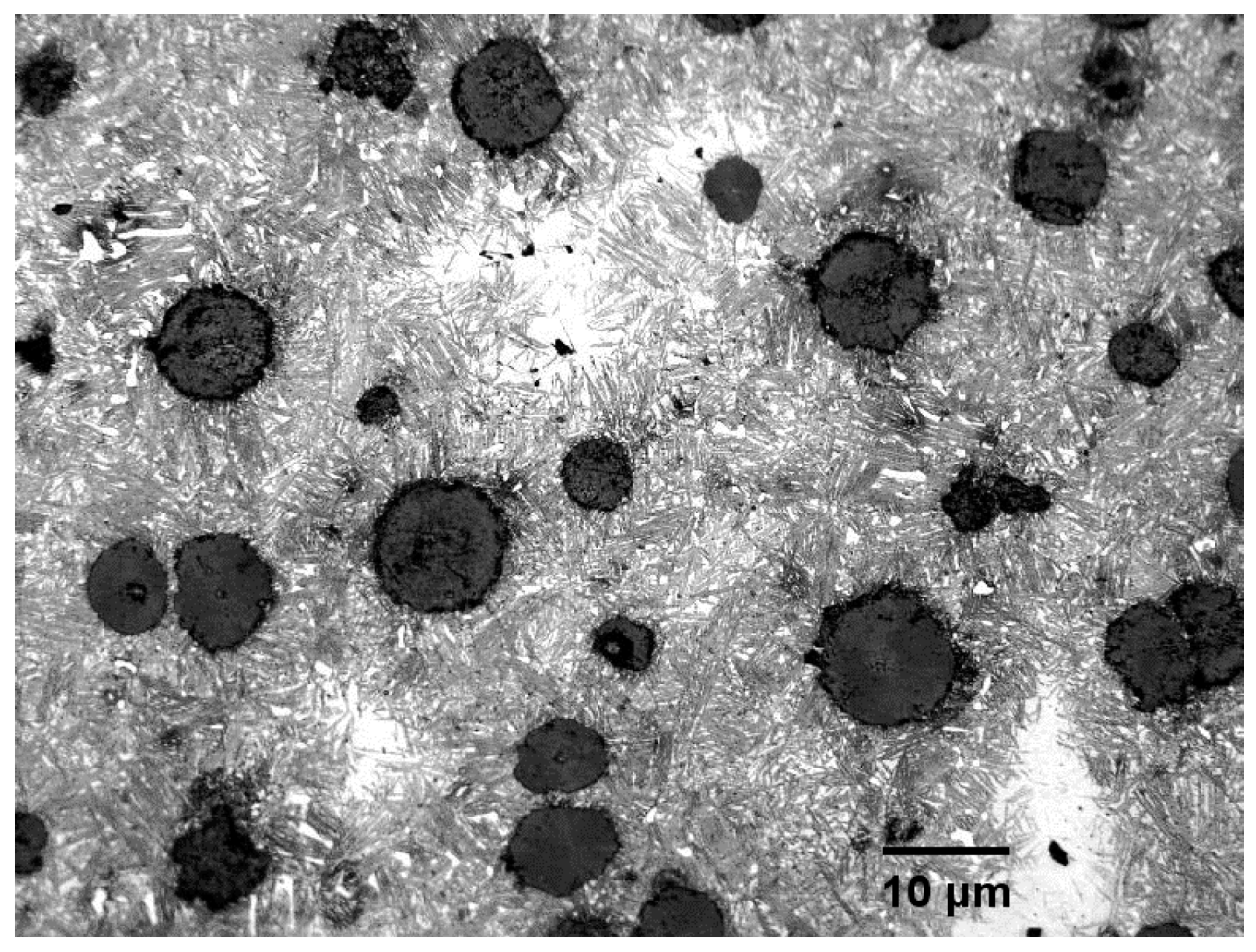

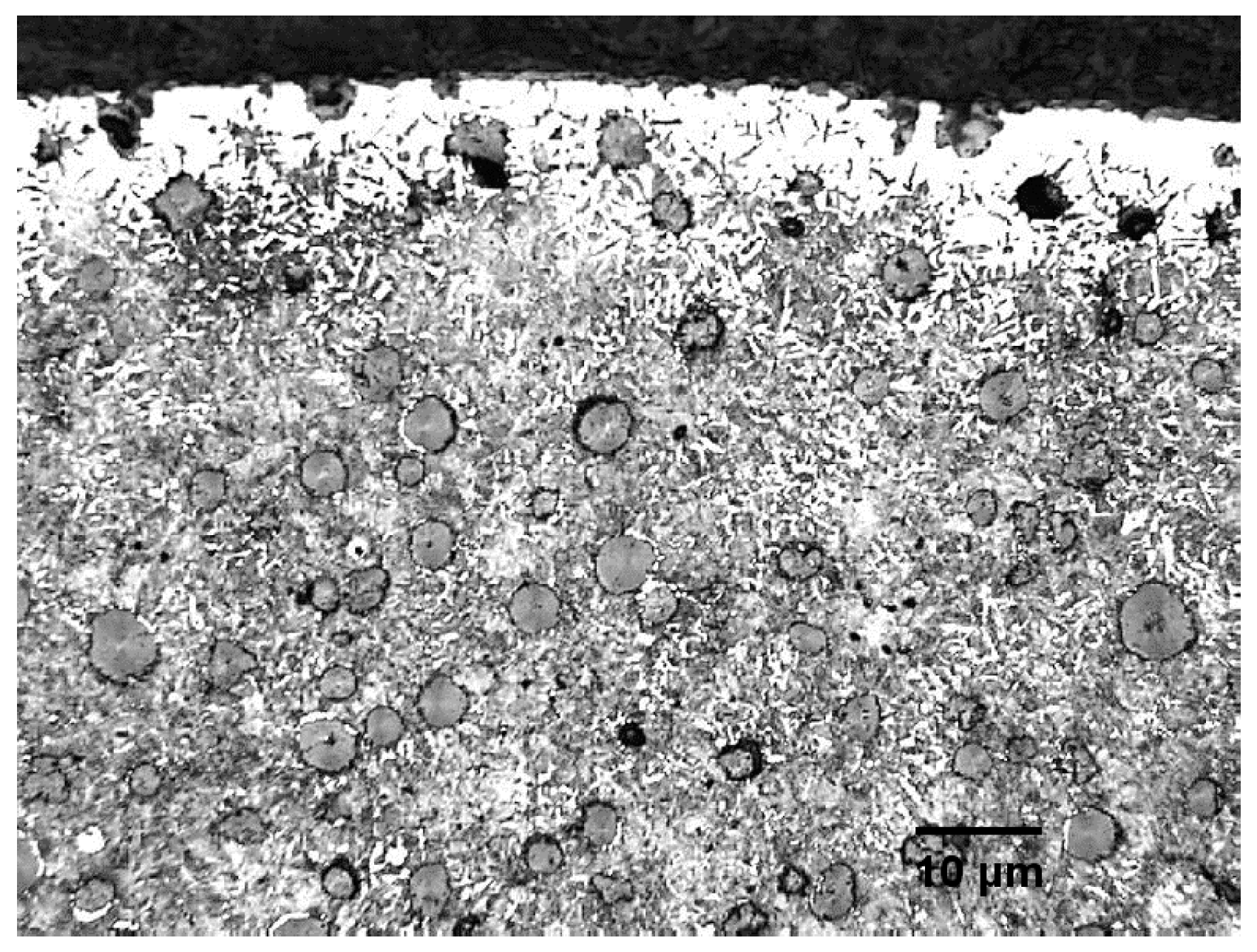

3.1. Alloy Process

3.2. Heat Treatment Process

3.3. Composite Material Technology

3.4. New Structure and New Materials

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Long, W.; Choy, Y.S.; Cheung, C.S. A study of brake contact pairs under different friction conditions with respect to characteristics of brake pad surfaces. Tribol. Int. 2019, 138, 99–110. [Google Scholar]

- Lu, W. Cast Iron and Smelting; Mechanical Industry Publisher: Beijing, China, 1981. [Google Scholar]

- Riahi, A.R.; Alpas, A.T. Wear map for grey cast iron. Wear 2003, 255, 401–409. [Google Scholar] [CrossRef]

- Sugishita, J.; Fujiyoshi, S. The effect of cast iron graphites on friction and wear performance I: Graphite film formation on grey cast iron surfaces. Wear 1981, 66, 209–221. [Google Scholar] [CrossRef]

- Eyre, T.S.; Iles, R.F.; Gasson, D.W. Wear characteristics of flake and nodular graphite cast iron. Wear 1969, 13, 229–245. [Google Scholar] [CrossRef]

- Montgomery, R.S. Run-in and glaze formation on gray cast iron surfaces. Wear 1969, 14, 99–105. [Google Scholar] [CrossRef]

- Terheci, M.; Manory, R.R.; Hensler, J.H. The Friction and Wear of Automotive Grey Cast Iron under Dry Sliding Conditions Part 2. Friction and Wear-Particle Generation Mechanisms and Their Progress with Time. Wear 1995, 185, 119–124. [Google Scholar] [CrossRef]

- Majcherczak, D.; Dufrenoy, P. Third body influence on Thermal friction contact problems: Application to braking. J. Tribol. 2005, 127, 89–95. [Google Scholar] [CrossRef]

- Aleksandrov, M.P.; Nosko, A.L. Design for heat in braking system with small angle of mutual overlapping. Sumitomo Met. 1991, 45, 2–32. [Google Scholar]

- Benseddiq, N.; Weichet, D.; Seidermann, J.; Minet, M. Optimization of design of railway disc brake pads. J. Rail. Rapid. Trandsit. 1996, 210, 51–61. [Google Scholar] [CrossRef]

- Holmgren, D.; Dioszegi, A.; Svensson, I.L. Effects of Carbon Content and Solidification Rate on the Thermal Conductivity of Grey Cast Iron. Tsinghua Sci. Technol. 2008, 2, 170–176. [Google Scholar] [CrossRef]

- Fritz, G.; Sinou, J.J.; Duffal, J.M.; Jezequel, L. Effects of damping on brake squeal coalescence patterns-application on a finite element model. Mech. Res. Commun. 2006, 34, 181–190. [Google Scholar] [CrossRef]

- Hecht, R.L.; Dinwiddie, R.B.; Wang, H. The effect of graphite brake morphology on the thermal diffusivity of gray cast irons used for automotive brake discs. J. Mater. Sci. 1999, 34, 4775–4781. [Google Scholar] [CrossRef]

- Lazzari, A.; Tonazzi, D.; Massi, F. Squeal propensity characterization of brake lining materials through friction noise measurements. Mech. Syst. Signal Process. 2019, 128, 216–288. [Google Scholar] [CrossRef]

- Blaschke, P.; Tan, M.; Wang, A. On the Analysis of Brake Squeal Propensity Using Finite Element Method; SAE Technical Paper: Warrendale, PA, USA, 2000. [Google Scholar] [CrossRef]

- Liu, P.; Zheng, H.; Cai, C. Analysis of disc brake squeal using the complex eigenvalue method. Appl. Acoust. 2007, 68, 603–615. [Google Scholar] [CrossRef]

- Massi, F.; Baillet, L.; Giannini, O.; Sestieri, A. Brake squeal: Linear and nonlinear numerical approaches. Mech. Syst. Signal Process. 2006, 21, 2374–2393. [Google Scholar] [CrossRef]

- Abdelounis, H.B.; Bot, A.L.; Liaudet, J.P.; Zahouani, H. An Experimental Study on Roughness Noise of Dry Rough Flat Surfaces. Wear 2010, 268, 335–345. [Google Scholar] [CrossRef]

- Hammersrom, L.; Jacobson, S. Surface Modification of Brake Discs to Reduce Squeal Problems. Wear 2006, 261, 53–57. [Google Scholar] [CrossRef]

- Chen, F.; Tong, H.; Chen, S.E. On Automotive Disc Brake Squeal Part IV: Reduction and Prevention; SAE Technical Paper: Warrendale, PA, USA, 2003. [Google Scholar] [CrossRef]

- Zhang, H.; Mullen, R.L.; Muhanna, R.L. Interval Monte Carlo methods for structural reliability. Struct. Saf. 2010, 32, 183–190. [Google Scholar] [CrossRef]

- Liaquat, H.; Shi, X.L.; Yang, K.; Huang, Y.; Liu, X.; Wang, Z. Tribological behavior of TiAl metal matrix composite brake disk with tic-reinforcement under dry sliding conditions. J. Mater. Eng. Perform. 2017, 26, 3457–3464. [Google Scholar] [CrossRef]

- Bosnjak, B.; Radulovic, B.; Tonev, K.P. Influence of micro-alloying and heat treatment on the kinetics of bainitic reaction in austempered ductile iron. J. Mater. Eng. Perform. 2001, 10, 203–211. [Google Scholar] [CrossRef]

- Refaey, A.; Fatahalla, N. Effect of microstructure on properties of ADI and low alloyed ductile iron. J. Mater. Sci. 2003, 38, 351–362. [Google Scholar] [CrossRef]

- Luan, J.F. Microstructure and wear resistance of ductile cast iron laser clad with Ni-Ti-Co-C. J. Mater. Sci. Technol. 1999, 15, 222–224. [Google Scholar]

- Tomlinson, W.J.; Cash, M. Dry sliding wear of grey iron laser surface cladded with 14%–40% chromium. Wear 1991, 142, 383–386. [Google Scholar] [CrossRef]

- Barros, L.Y.; Poletto, J.C.; Neis, P.D.; Ferreira, N.F.; Pereira, C.H. Influence of copper on automotive brake performance. Wear 2019, 426, 741–749. [Google Scholar] [CrossRef]

- Jeganmohan, S.R.; Christy, T.V.; Solomon, D.G.; Sugozu, B. Influence of calcium sulfate whiskers on the tribological characteristics of automotive brake friction materials. Eng. Sci. Technol. 2019. [Google Scholar] [CrossRef]

- Cueva, G.; Sinatora, A.; Guesser, W.L.; Tschiptschin, A.P. Wear resistance of cast irons used in brake disc rotors. Wear 2003, 255, 1256–1260. [Google Scholar] [CrossRef]

- Sun, J.Q.; Yan, Z.F.; Cui, H.Z.; Li, J.; Wang, J.S.; Chen, Y.B. Surface catalysis gaseous nitriding of alloy cast iron at lower temperature. Catal. Today 2010, 158, 205–208. [Google Scholar] [CrossRef]

- Li, C.X.; Sun, Y.; Bell, T. Factors influencing fretting fatigue properties of plasma-nitrided low alloy steel. Mater. Sci. Eng. A 2000, 292, 18–25. [Google Scholar] [CrossRef]

- Cao, Y.J. Effect of the microstructure and residual stress on tribological behavior of induction hardened GCr15 steel. Tribol. Int. 2017, 115, 108–115. [Google Scholar] [CrossRef]

- Corengia, P.; Walther, F.; Ybarra, G.; Sommadossi, S.; Corbari, R.; Broitman, E. Friction and rolling-sliding wear of DC-pulsed plasma nitrided AISI 410 martensitic stainless steel. Wear 2006, 260, 479–485. [Google Scholar] [CrossRef]

- Yen, B.K.; Ishihara, T. On temperature dependent tribological regimes and oxidation of carbon-carbon composites up to 18000 °C. Wear 1996, 196, 254–262. [Google Scholar] [CrossRef]

- Yen, B.K.; Ishihara, T. An investigation of friction and wear mechanisms of carbon-carbon composites in nitrogen and air atelevated temperatures. Carbon 1996, 34, 489–498. [Google Scholar] [CrossRef]

- Chen, J.D.; Chern, L.J.H.; Ju, C.P. Effect of load on tribological behavior of carbon-carbon composites. J. Mater. Sci. 1996, 193, 38–47. [Google Scholar]

- Murdie, N.; Ju, C.P.; Don, J.; Fortunato, F.A. Microstructure of worn pitch-resin-CVI C-C composites. Carbon 1991, 29, 335–342. [Google Scholar] [CrossRef]

- Awasthi, S.; Wood, J.L. C/C composites materials for aircraft brakes. Adv. Ceram. Mater. 2008, 3, 553–559. [Google Scholar] [CrossRef]

- Houdayer, M.; Spitz, J.; Tran, V.D. Process for the Densification of a Porous Structure. US Patent US4472454, 18 September 1984. [Google Scholar]

- Scaringgella, D.T.; Connors, D.E.; Thurston, G.S. Method for Densifying and Refurbishing Brakes. US Patent US5547717, 20 August 1996. [Google Scholar]

- Kuo, H.H.; Lin, J.H.C.; Ju, C.P. Tribological behavior of fast-carbonized PAN/phenolic-based carbon/carbon composite and method for improving same. Wear 2005, 258, 1555–1561. [Google Scholar] [CrossRef]

- Cai, P.; Wang, Y.; Wang, T.; Wang, Q. Effect of resins on thermal, mechanical and tribological properties of friction materials. Tribol. Int. 2015, 87, 1–10. [Google Scholar] [CrossRef]

- Neis, P.D.; Ferreira, N.F.; Silva, F.P.D. Comparison between methods for measuring wear in brake friction materials. Wear 2014, 319, 191–199. [Google Scholar] [CrossRef]

- Chan, D.; Stachowiak, G. Review of automotive brake friction materials. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2004, 218, 953–966. [Google Scholar] [CrossRef]

- Cho, M.H.; Ju, J.; Kim, S.J.; Jang, H. Tribological properties of solid lubricants (graphite, Sb2S3, MoS2) for automotive brake friction materials. Wear 2006, 260, 855–860. [Google Scholar] [CrossRef]

- Singh, T.; Patnaik, A.; Gangil, B.; Chauhan, R. Optimization of tribo-performance of brake friction materials: Effect of nano filler. Wear 2015, 324, 10–16. [Google Scholar] [CrossRef]

- Cho, K.H.; Jang, H.; Hong, Y.S.; Kim, S.J.; Basch, R.H.; Fash, J.W. The size effect of zircon particles on the friction characteristics of brake lining materials. Wear 2008, 264, 291–297. [Google Scholar] [CrossRef]

- Bijwe, J.; Aranganathan, N.; Sharma, S.; Dureja, N.; Kumar, R. Nano-abrasives in friction materials-influence on tribological properties. Wear 2012, 296, 693–701. [Google Scholar] [CrossRef]

- Hong, U.S.; Jung, S.L.; Cho, K.H.; Cho, M.H.; Kim, S.J.; Jang, H. Wear mechanism of multiphase friction materials with different phenolic resin matrices. Wear 2009, 266, 739–744. [Google Scholar] [CrossRef]

- Betancourt, S.; Cruz, J.; Toro, A. Friction and wear in sliding contact of cast iron against phenolic resin composites reinforced with carbonaceous fibres from plantain fibre bundles. Lubr. Sci. 2013, 25, 163–172. [Google Scholar] [CrossRef]

- Fei, J.; Li, H.L.; Fu, Y.W.; Qi, L.H.; Zhang, Y.L. Effect of phenolic resin content on performance of carbon fiber reinforced paper-based friction material. Wear 2010, 269, 534–540. [Google Scholar] [CrossRef]

- Fu, H.; Liao, B.; Qi, F.J.; Sun, B.C.; Liu, A.P.; Ren, D.L. The application of PEEK in stainless steel fiber and carbon fiber reinforced composites. Compos. Part B Eng. 2008, 39, 585–591. [Google Scholar] [CrossRef]

- Fei, J.; Luo, W.; Huang, J.F.; Ouyang, H.; Xu, Z.; Yao, C. Effect of carbon fiber content on the friction and wear performance of paper-based friction materials. Tribol. Int. 2015, 87, 91–97. [Google Scholar] [CrossRef]

- Pujari, S.; Srikiran, S. Experimental investigations on wear properties of Palm kernel reinforced composites for brake pad applications. Def. Technol. 2019, 15, 295–299. [Google Scholar] [CrossRef]

- Venkatesh, S.; Murugapoopathiraja, K. Scoping review of brake friction material for automotive. Mater. Today Proc. 2019, 16, 927–933. [Google Scholar] [CrossRef]

| Speed /(km·h−1) | 150 | 120 | 90 | |

|---|---|---|---|---|

| Adhesion Coefficient | ||||

| 1.0 | 151.08 | 106.69 | 69.39 | |

| 0.7 | 189.02 | 130.99 | 83.06 | |

| Growth rate (%) | 25 | 23 | 20 | |

| The Road | Speed/(km∙h–1) | 10 | 20 | 30 | 40 | 50 | 60 | 70 | |

|---|---|---|---|---|---|---|---|---|---|

| Adhesion Coefficient | |||||||||

| Icy roads, clay wasteland | 0.2–0.3 | 2 | 7.9 | 17.7 | 31.5 | 49.2 | 70.8 | 96.4 | |

| Wet asphalt and concrete | 0.3–0.4 | 1 | 3.9 | 8.8 | 15.7 | 24.6 | 35.4 | 48.2 | |

| Dry gravel road | 0.6–0.7 | 0.7 | 2.6 | 5.9 | 10.5 | 16.4 | 23.6 | 32.1 | |

| Dry asphalt or concrete | 0.7–0.8 | 0.6 | 2.2 | 5 | 9 | 14 | 20.2 | 27.5 | |

| Phase Composition | Morphology | 0–100 °C Thermal Conductivity/ (W∙(m∙K)−1) | Phase Composition | 0–100 °C Thermal Conductivity/ (W∙(m∙K)–1) |

|---|---|---|---|---|

| Graphite | Spheroidal graphite | 83.7 | Ferrite | 71.2–79.6 |

| Pearlite | 50.2 | |||

| Flake graphite | 433.1–418.7 | Cementite | 7.1 |

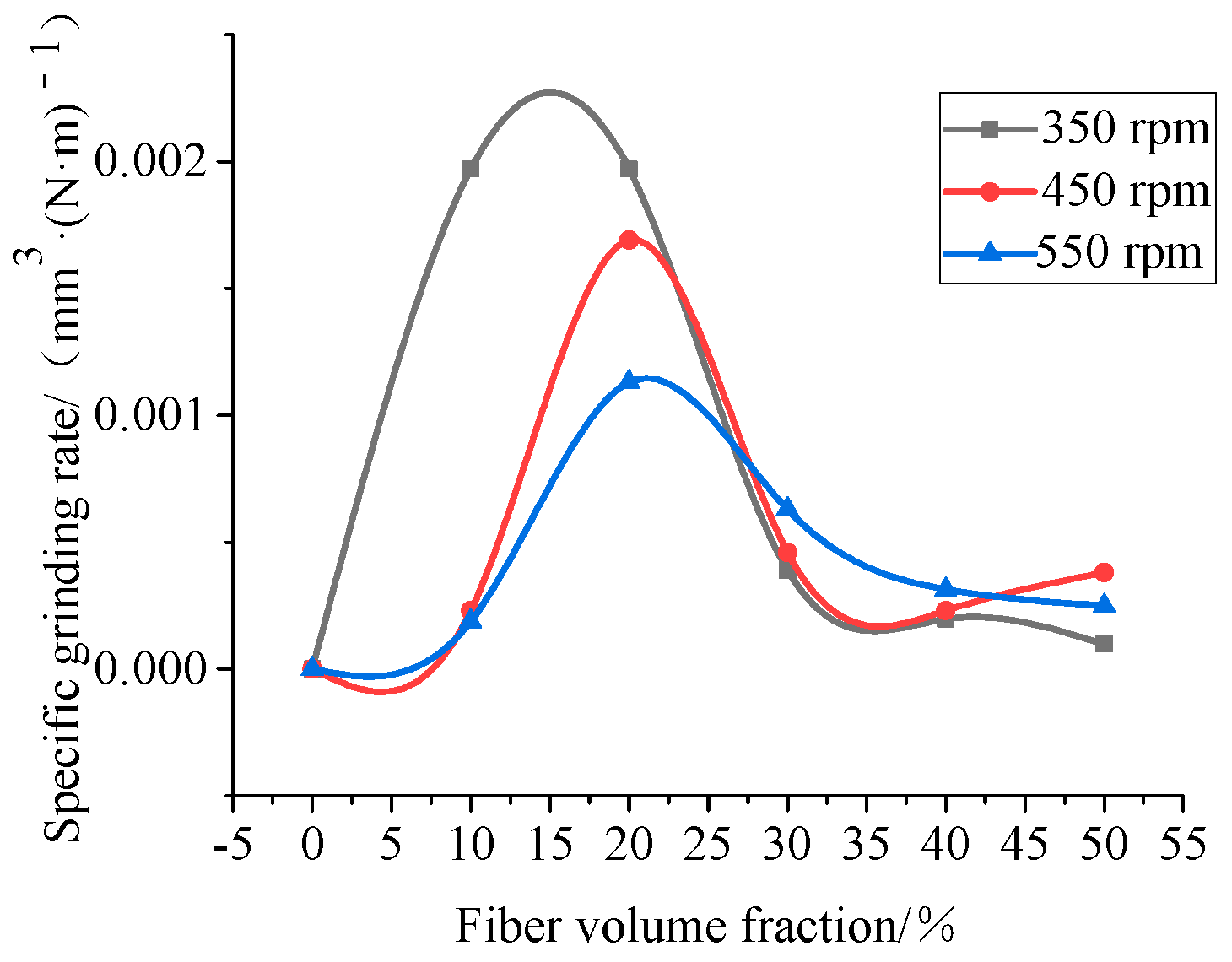

| Sample Number | Specific Grinding Rate/(mm3∙(N∙m)–1) | ||

|---|---|---|---|

| At 350 rpm | At 450 rpm | At 550 rpm | |

| S1 | 0.000197 | 0.000230 | 0.000188 |

| S2 | 0.001970 | 0.001690 | 0.001130 |

| S3 | 0.000390 | 0.000460 | 0.000629 |

| S4 | 0.000197 | 0.000230 | 0.000314 |

| S5 | 0.000098 | 0.000380 | 0.000250 |

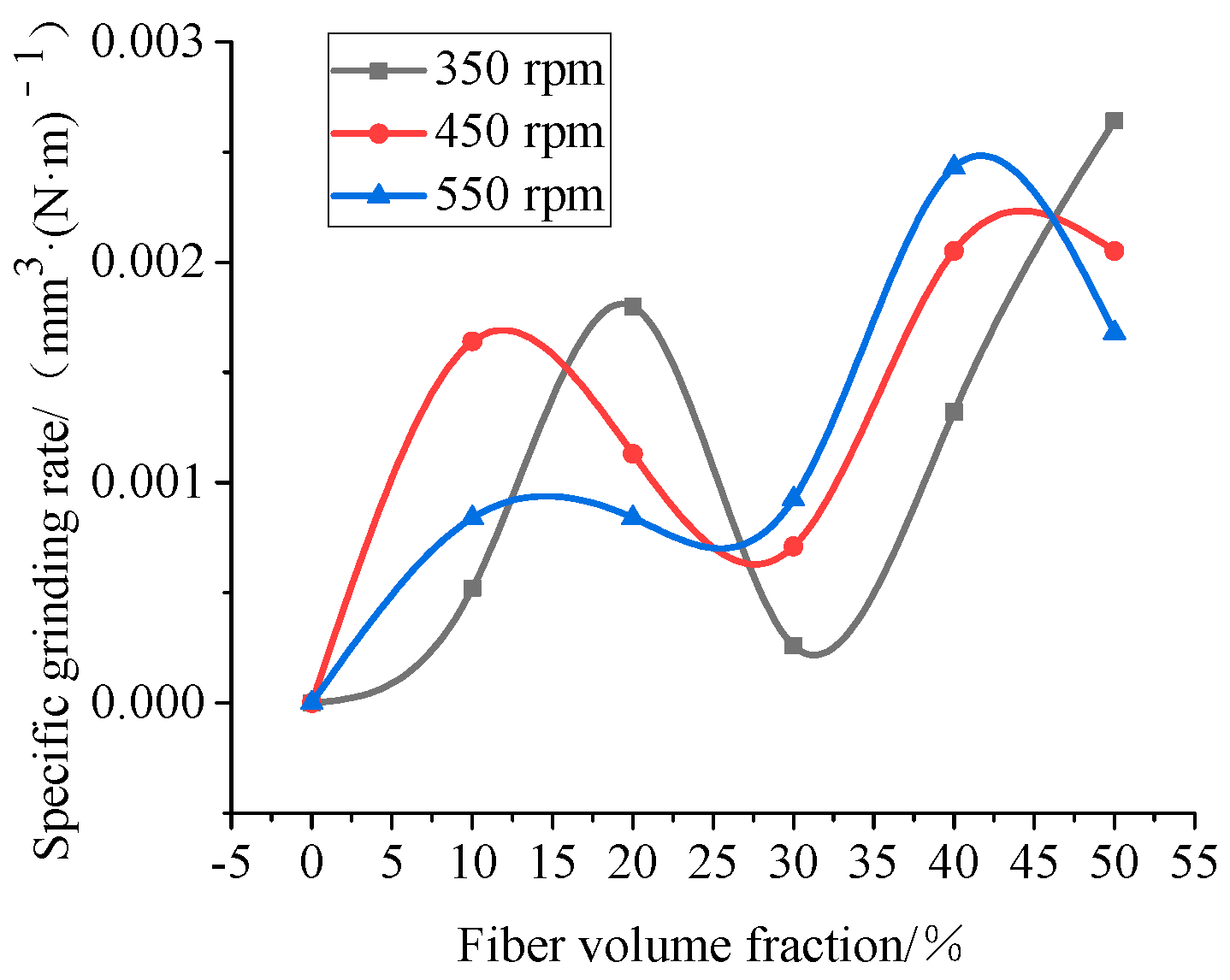

| Sample Number | Specific Grinding Rate/(mm3∙(N∙m)–1) | ||

|---|---|---|---|

| At 350 rpm | At 450 rpm | At 550 rpm | |

| S1 | 0.000520 | 0.001640 | 0.000840 |

| S2 | 0.001180 | 0.001130 | 0.000840 |

| S3 | 0.000260 | 0.000710 | 0.000925 |

| S4 | 0.001320 | 0.002050 | 0.002430 |

| S5 | 0.002640 | 0.002050 | 0.001680 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Yang, X.; Wang, S.; Xiao, J.; Hou, Q. Comprehensive Analysis on the Performance and Material of Automobile Brake Discs. Metals 2020, 10, 377. https://doi.org/10.3390/met10030377

Li W, Yang X, Wang S, Xiao J, Hou Q. Comprehensive Analysis on the Performance and Material of Automobile Brake Discs. Metals. 2020; 10(3):377. https://doi.org/10.3390/met10030377

Chicago/Turabian StyleLi, Wanyang, Xuefeng Yang, Shouren Wang, Jupeng Xiao, and Qimin Hou. 2020. "Comprehensive Analysis on the Performance and Material of Automobile Brake Discs" Metals 10, no. 3: 377. https://doi.org/10.3390/met10030377

APA StyleLi, W., Yang, X., Wang, S., Xiao, J., & Hou, Q. (2020). Comprehensive Analysis on the Performance and Material of Automobile Brake Discs. Metals, 10(3), 377. https://doi.org/10.3390/met10030377