1. Introduction

Micro process devices often consist of multiple microstructured thin sheets of metal. The variation of the thickness of cold-rolled sheet material is in the range of 20–50 µm regardless of the actual thickness due to the cold rolling process. So, relative variation is quite high for thin sheets and cannot be neglected, especially for larger lateral dimensions [

1]. Thickness tolerances affect deformation during diffusion bonding too. For multilayered devices, tolerances may add up or balance out without being measurable with reasonable effort. In addition, multiple surface roughness must be leveled to make atomic contact. Both effects contribute to the percentage of deformation. It leads to poor reproducibility of vacuum tightness and the deformation on diffusion bonding in serial production, despite identical bonding parameters. At the beginning of the bonding process, a much higher contact pressure may apply locally. A localized deformation may result in the blocking of internal microstructures.

Considerable production-oriented design effort is required to ensure force transmission between different layers. [

2].

In consequence, for microprocess engineering and single or small series production, it is difficult to predict suitable bonding parameters, e.g., bonding temperature, dwell time and contact pressure to obtain the desired deformation and to ensure high vacuum-tight components. Furthermore, for multilayered designs, it is not possible to specify a fixed percentage of deformation to reach these goals.

For the reasons described above, it is essential to control the deformation during the diffusion bonding of microprocessor devices. Surprisingly, there is not too much literature facing deformation on the microscopic and macroscopic scale during diffusion bonding [

3,

4,

5].

Moravec et al. give a set of parameters including the deformation using a thermomechanical simulator

Gleeble 3500-device (Poestenkill, NY, USA) [

6]. The experiments were performed on specimens by applying a temperature profile along the axis in which the force was acting. Hence, the comparability to multilayer stacks at constant temperature is low. Most papers are focused on the characterization of the bonding surface, formation of precipitates or brittle intermetallic phases and residual pores according to bonding parameters [

7,

8,

9].

In [

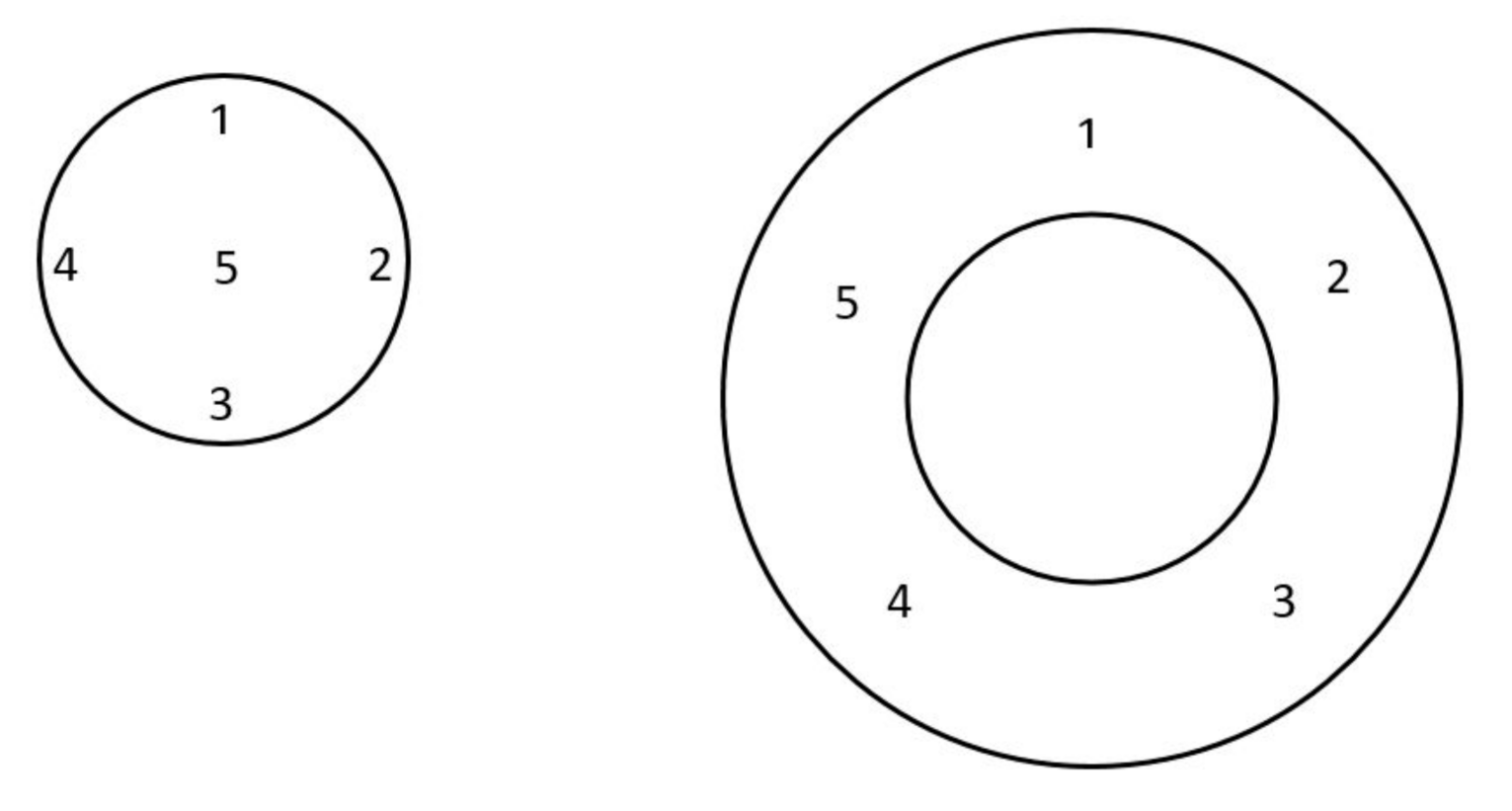

10], the authors examined the influence of the number of layers per construction height in comparison to components made of two only pieces, as well as the impact of overall cross-section and aspect ratio (in

Appendix A) on deformation. However, the roughness values of the surfaces were not characterized. In [

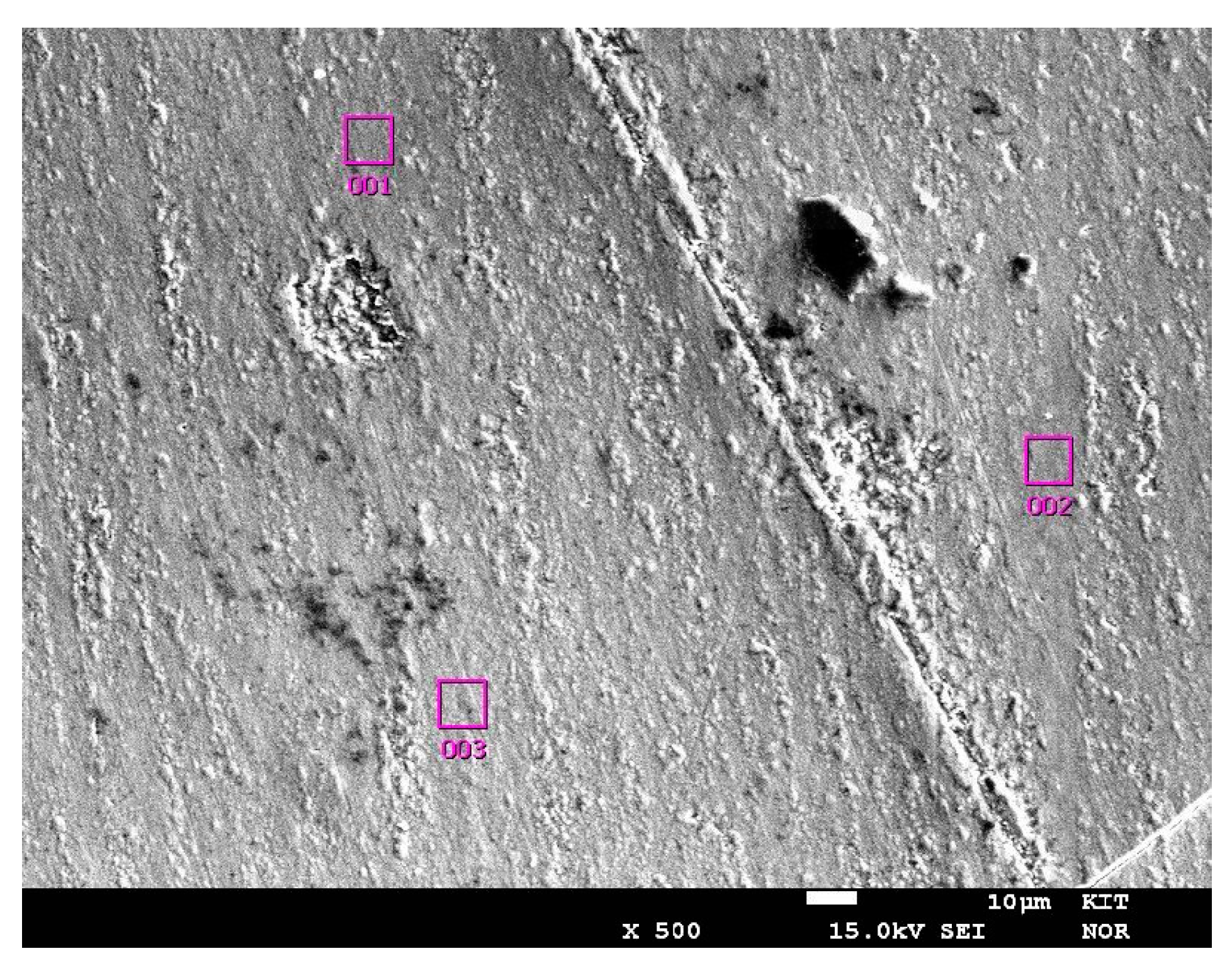

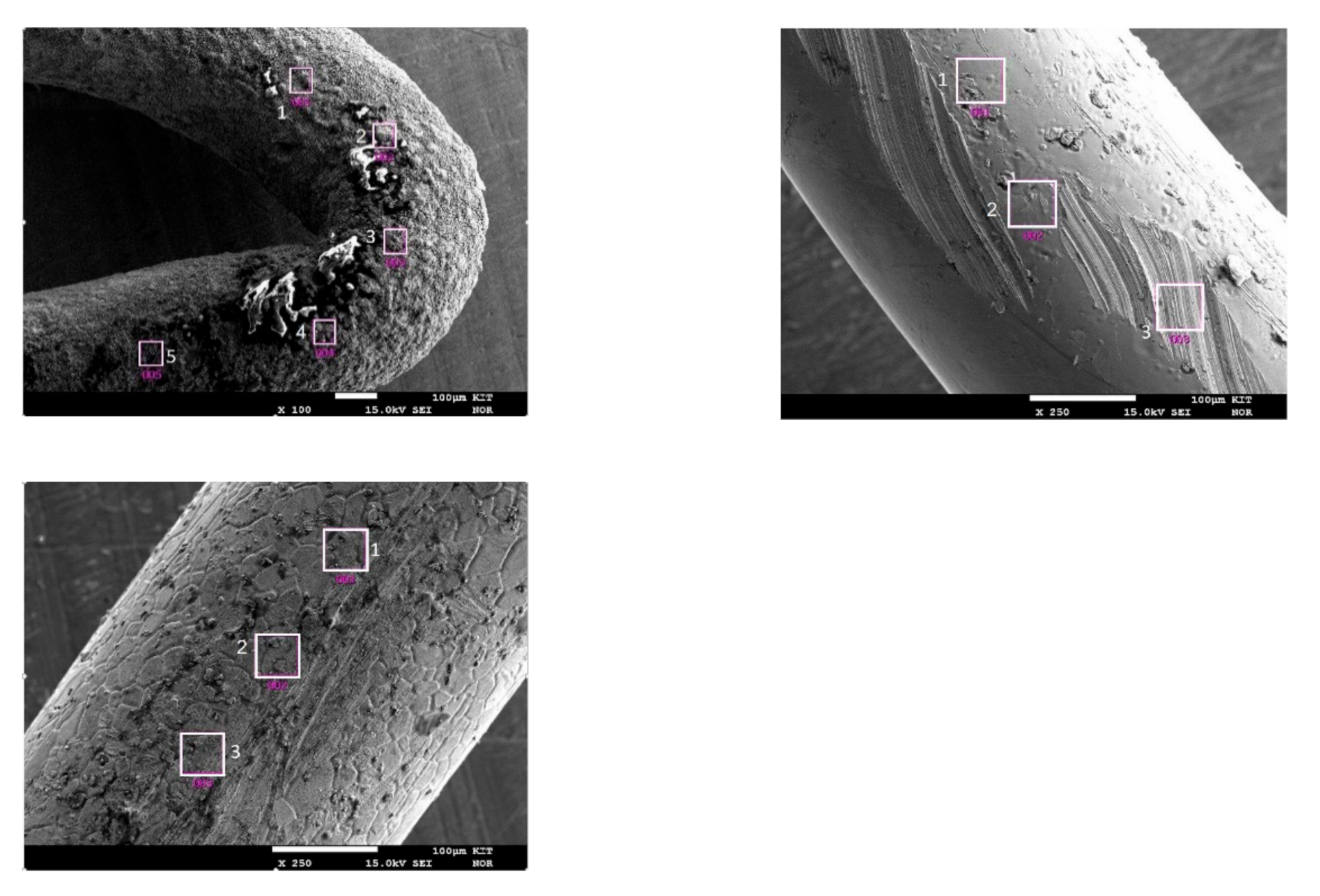

11], Zhang et al. investigated the deformation behavior of asperities during diffusion bonding of milled surfaces possessing a surface roughness R

a = 1.6 µm at T = 1080 °C, t = 20 min and varying contact pressures of 5, 10, 15 and 20 MPa, respectively, in terms of remaining pores. However, different roughness values were not investigated and compared. In [

12], the authors investigated the depth of singular scratches on vacuum tightness and compared the impact of constant contact pressure to a contact pressure superimposed by short peak loads. However, the impact of the absolute width of joining cross-sections on the deformation behavior was not yet investigated systematically.

In addition to the issues mentioned above, the composition, origin and prehistory of the material have an impact on diffusion and formation of passivation layers affecting deformation, grain growth across the bonding planes and diffusion bonding result [

13,

14]. Therefore, a certain bonding temperature, bonding time and contact pressure do not lead to a reproducible deformation for different parts and/or materials. In consequence, for each alloy and even each design, the bonding parameters must be optimized separately.

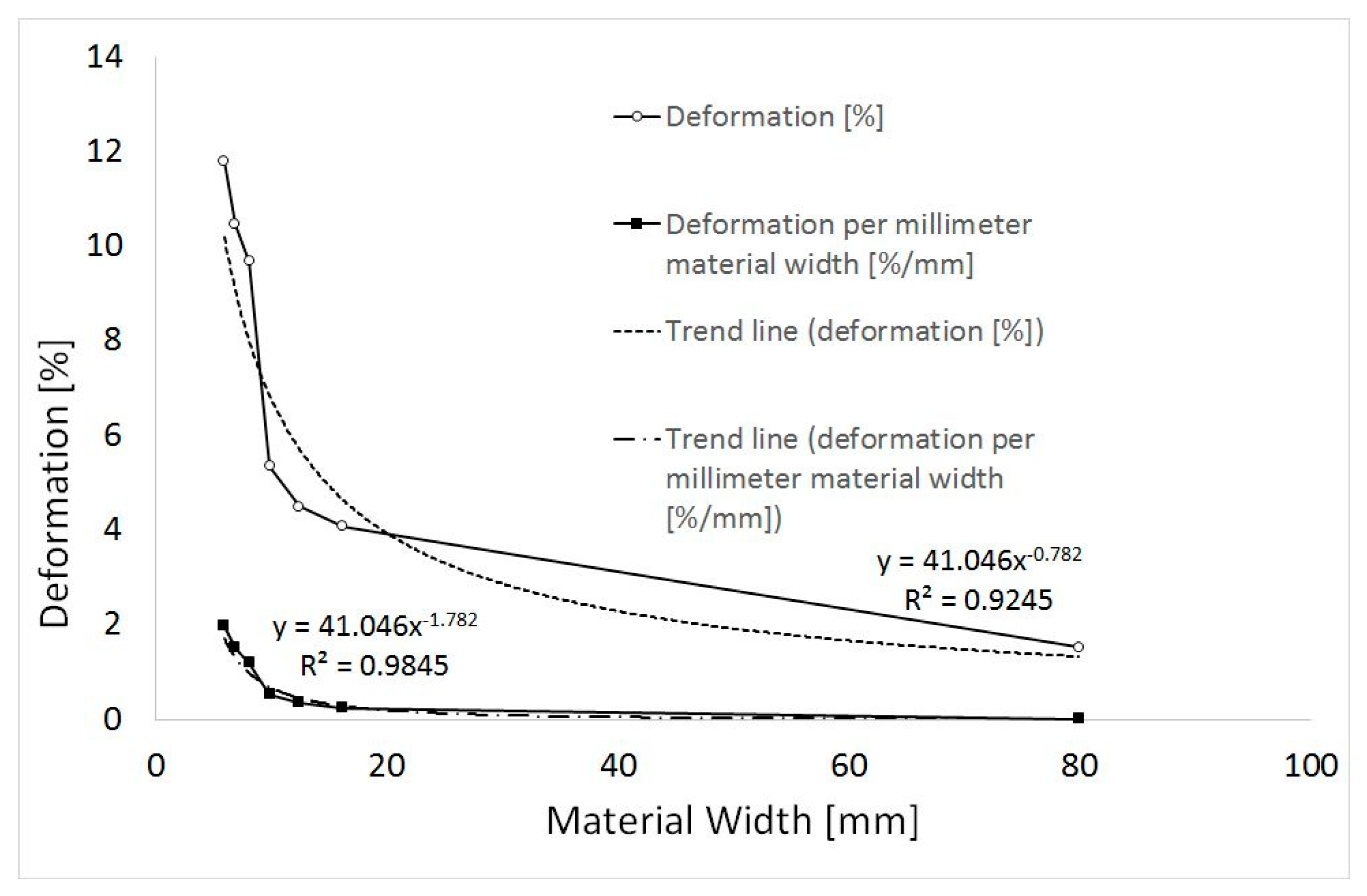

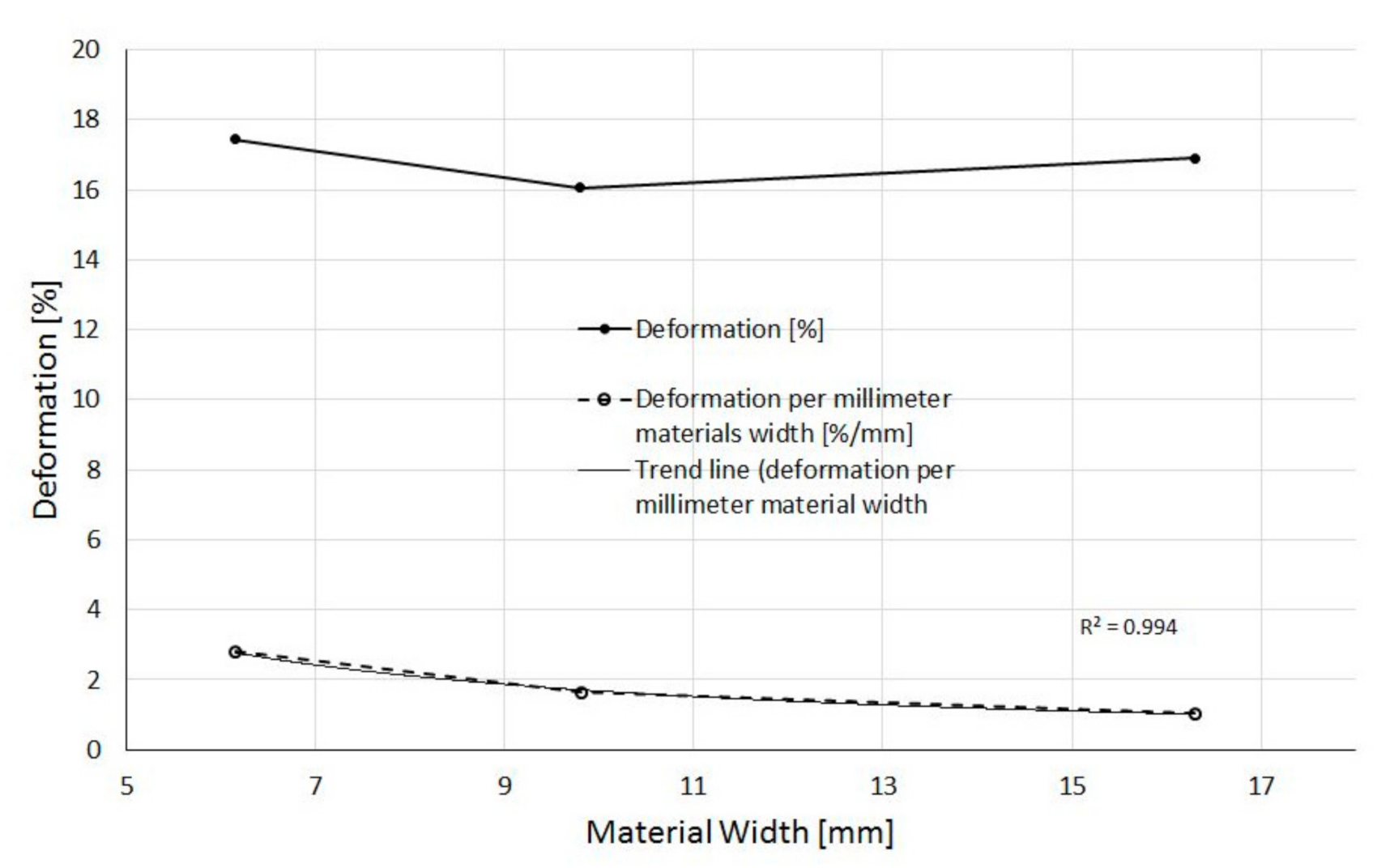

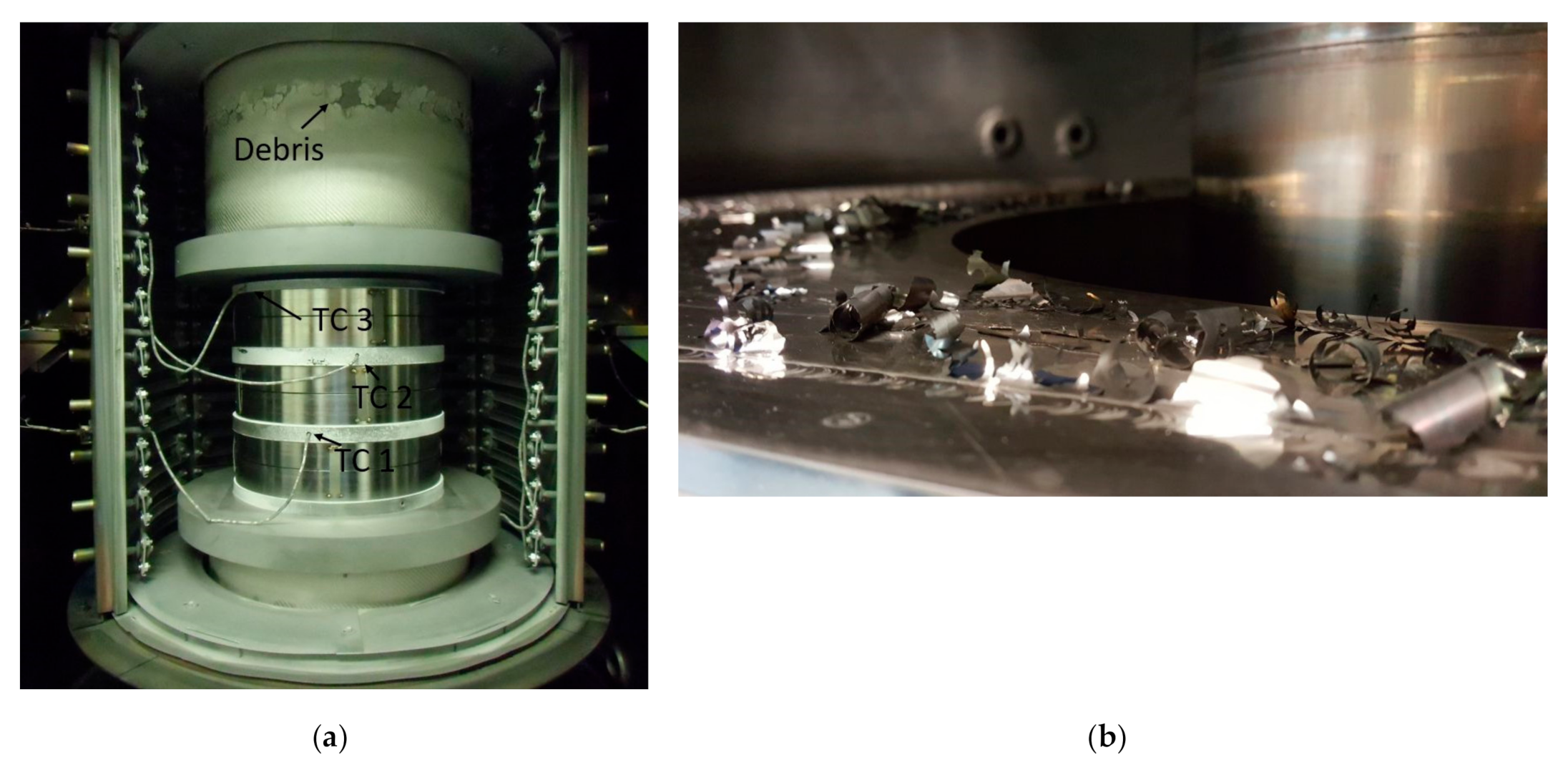

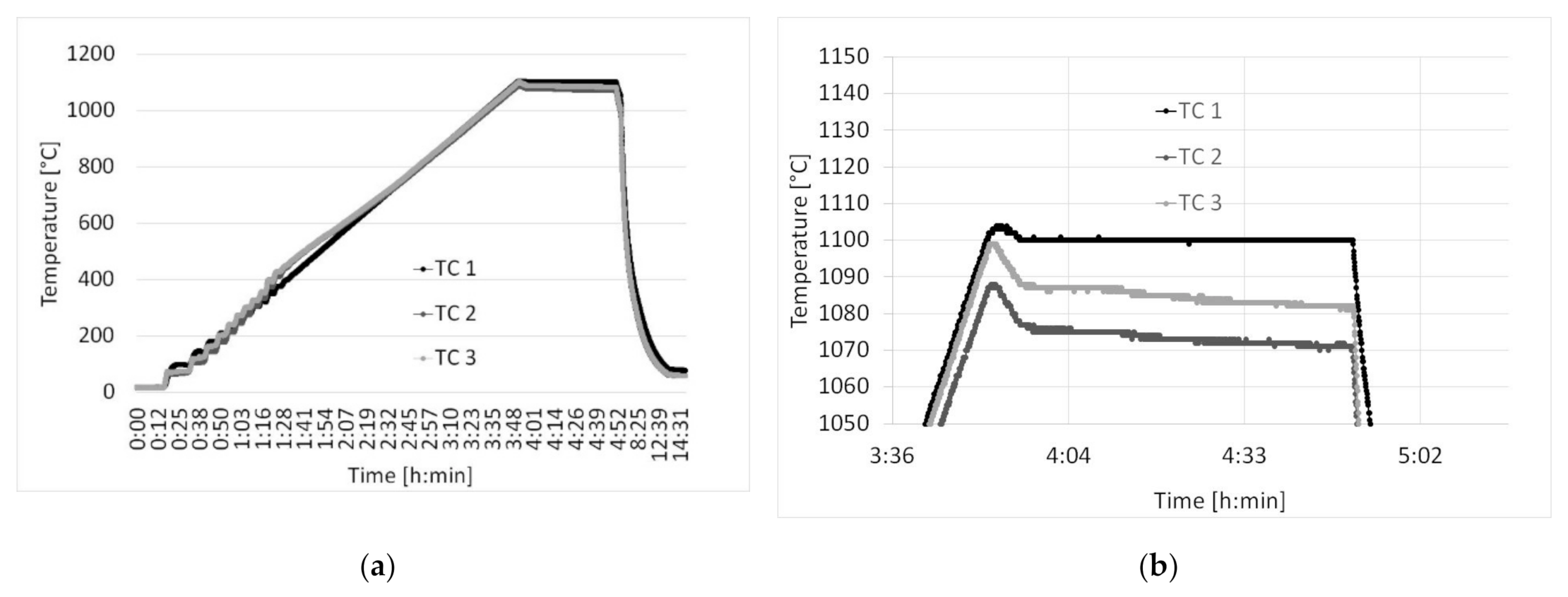

In this paper, the impact of the material width on deformation and the aspect ratio was investigated. For comparison reasons, samples with an aspect ratio of about three were bonded. However, the deformation obtained did not follow the expected trend. It was found that the aging of thermocouples was the reason. This emphasizes the importance of accurate temperature measurement during diffusion bonding and monitoring of thermocouples, which is being neglected at the most macroscopic applications of diffusion bonding.

4. Summary

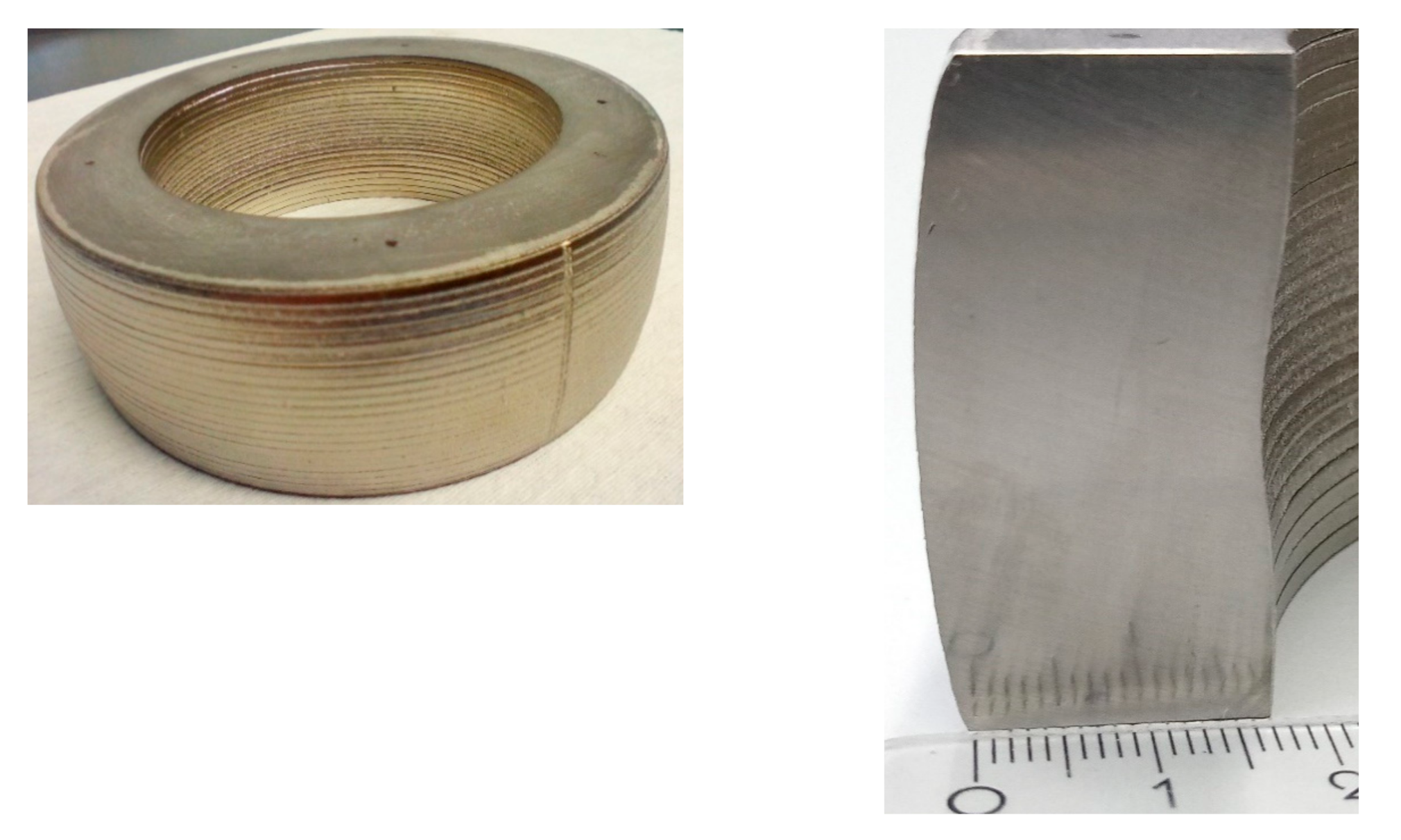

In this paper, for the first time, a comprehensive and systematic study of the deformation of layered materials and depending on material width was performed. It was shown that constant bonding temperature, contact pressure and dwell time might result in a completely different percentage of deformations depending on material width and aspect ratio. The reason for this is that for large material cross-sections through the surrounding material exert a greater restriction on deformation than thinner ones. Furthermore, larger cross-sections are more hindered in deformation by friction on the compression dies than smaller ones. The deformation behavior of multilayer structures is subject to large fluctuations due to manufacturing tolerances in sheet metal thickness from production and the leveling of many surface roughnesses.

Hence, it is difficult to estimate the expected deformation in advance for parts of arbitrary geometry.

The two batches of experiments underlined the importance of exact temperature measurement and showed the aging effects of thermocouples for consecutively diffusion bonding processes.

This allows the following conclusions to be drawn:

First, the thermocouples are subject to aging. Some thermoelectric voltage is generated along the wires. Cutting off and reshaping the sensing tip before each bonding run does not ensure exact temperature measurement.

Second: From the heating power consumption at a steady temperature level, a change in temperature can be concluded. This is, however, only valid for identical parts. Especially in research with permanently changing components, it is difficult to detect such effects.

Thirdly, since it is economically not feasible to replace the complete thermocouples after each run, temperature measurement is subject to uncertainty. Calibration runs should be performed after a certain number of runs for being able to correct actual temperature. Hence, it is hard to predict reliably the deformation of new designs, based on the deformation obtained from previously diffusion-bonded components.

Fourthly, the deformation, as investigated in this paper and as described above, depends strongly on the component geometry.

Fifthly, despite it is desirable, we believe that there is much work to do for being able to facilitate all impacts on deformation into the simulation. It is very difficult to perform simulations in such a way that they anticipate the practical deformation that will occur in advance. Reasons are that the modulus of elasticity of the materials at such high temperatures is unknown, the deformation behavior depends strongly on the grain size, and the contribution of thickness tolerances from sheet metal production with the size of the cross-section to be bonded as well as the contribution of the surface roughness to the deformation in detail is unclear. The coexistence of different material cross-sections in one component makes this task even more difficult.

Generally, an applicable and reliable design of the diffusion bonding process is desirable. To guarantee a reproducibly and successful diffusion bonding with limited deformation independent of the geometric constraints and layout, there are two ways:

First, the constant contact pressure should be temporarily increased to a level where the flow rate of the material is high. This is necessary to level thickness tolerances and surface roughnesses of multilayered parts and enlarge the contact area at the atomic level. Due to short dwell time, the overall deformation of the components is limited. Afterwards, the contact pressure should decrease to a level where the materials flow rate is very low. By maintaining the low contact pressure for a longer period, remaining pores are closed by grain boundary and volume diffusion.

Unfortunately, the materials flow rate depends on the geometric condition of the parts to be bonded and grain size. It is also subjected to changes due to the kind and content of alloying elements, changing the diffusion coefficient for different materials. In consequence, it is hard to estimate both levels of contact pressure.

Thereby, it seems advantageous to select the constant contact pressure in a range where only a moderate strain rate of the material applies. The deformation of roughness peaks and the expansion of the contact area on the atomic scale, on the other hand, occurs predominantly during the short-term peak load. This increased contact pressure should be chosen two to three times as high. During the predominant duration of the overall dwell time at lower contact pressure, atomic diffusion takes place, closing pores at a considerably lower volume diffusion coefficient. This is also the difference to the procedure proposed in [

23,

24,

25]. The sole multiple application of peak loads does not necessarily lead to the filling of remaining pore spaces. Instead, longer dwell times are required between peak loads.

Secondly, this can be addressed by appropriate process control by setting a maximum permissible deformation in millimeters per program step. If a certain deformation is achieved, the next program step proceeds, regardless of whether the programmed dwell time has expired or not. By specifying two independent criteria (dwell time and deformation), excessive deformation can be avoided. At the same time, no specific deformation is forced to the part, but the deformation is effectively limited. A prerequisite for this is that the component to be diffusion bonded has a minimum height in relation to the resolution of the distance measuring accuracy during the bonding process.

In prospective research, we will systematically investigate the impact of temperature variations in steps of 20 K around 1075 °C and its impact on deformation as well as mechanical strength, e.g., yield strength, tensile strength and elongation to rupture as well. Furthermore, the dependence of the mechanical properties at a much lower bonding temperature and variation of contact pressure and contact pressure regimes will be evaluated.