Influence of Ultrasound on Pore and Crack Formation in Laser Beam Welding of Nickel-Base Alloy Round Bars

Abstract

:1. Introduction

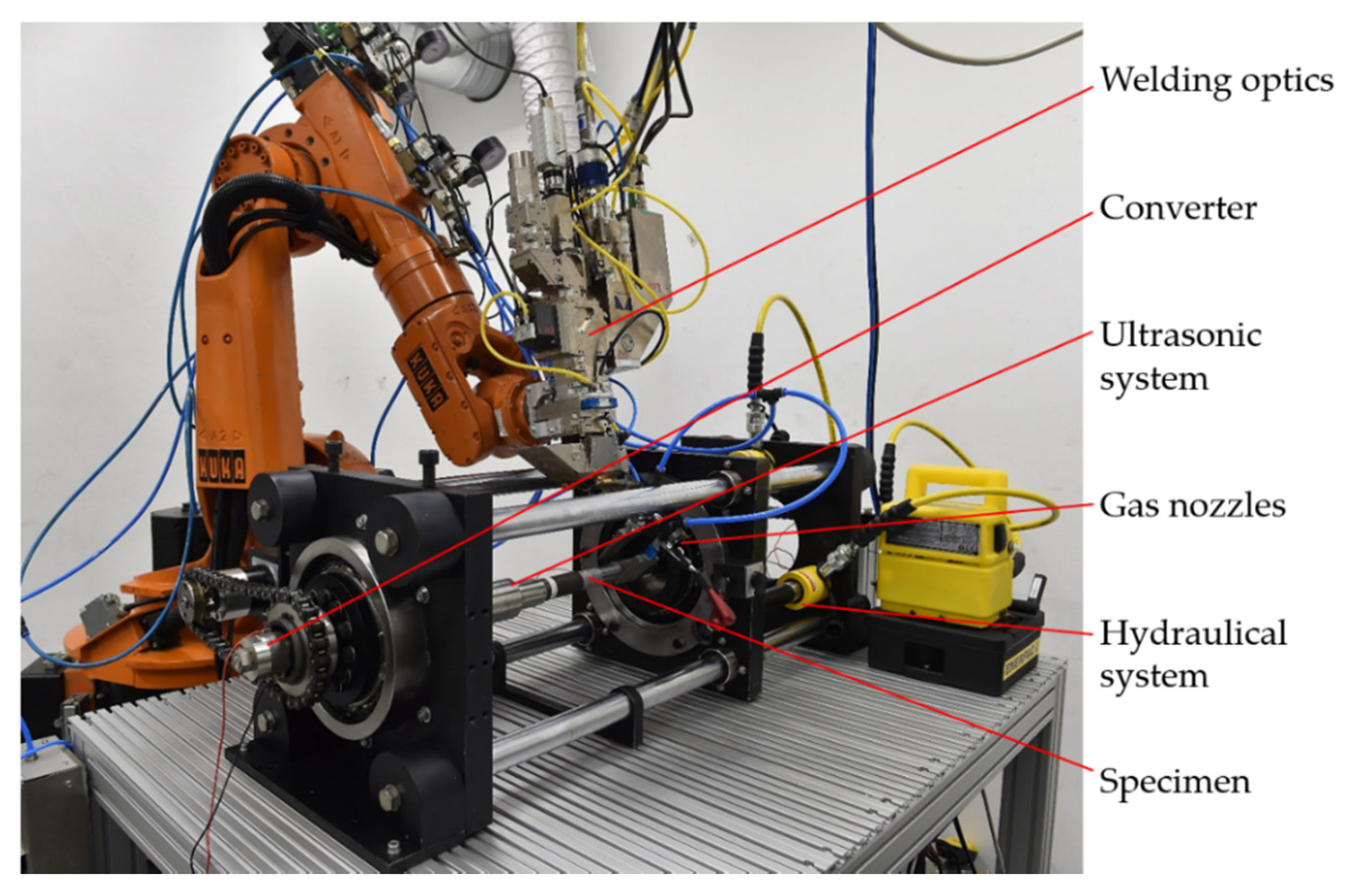

2. Experimental Setup

2.1. Laser Beam Welding Setup

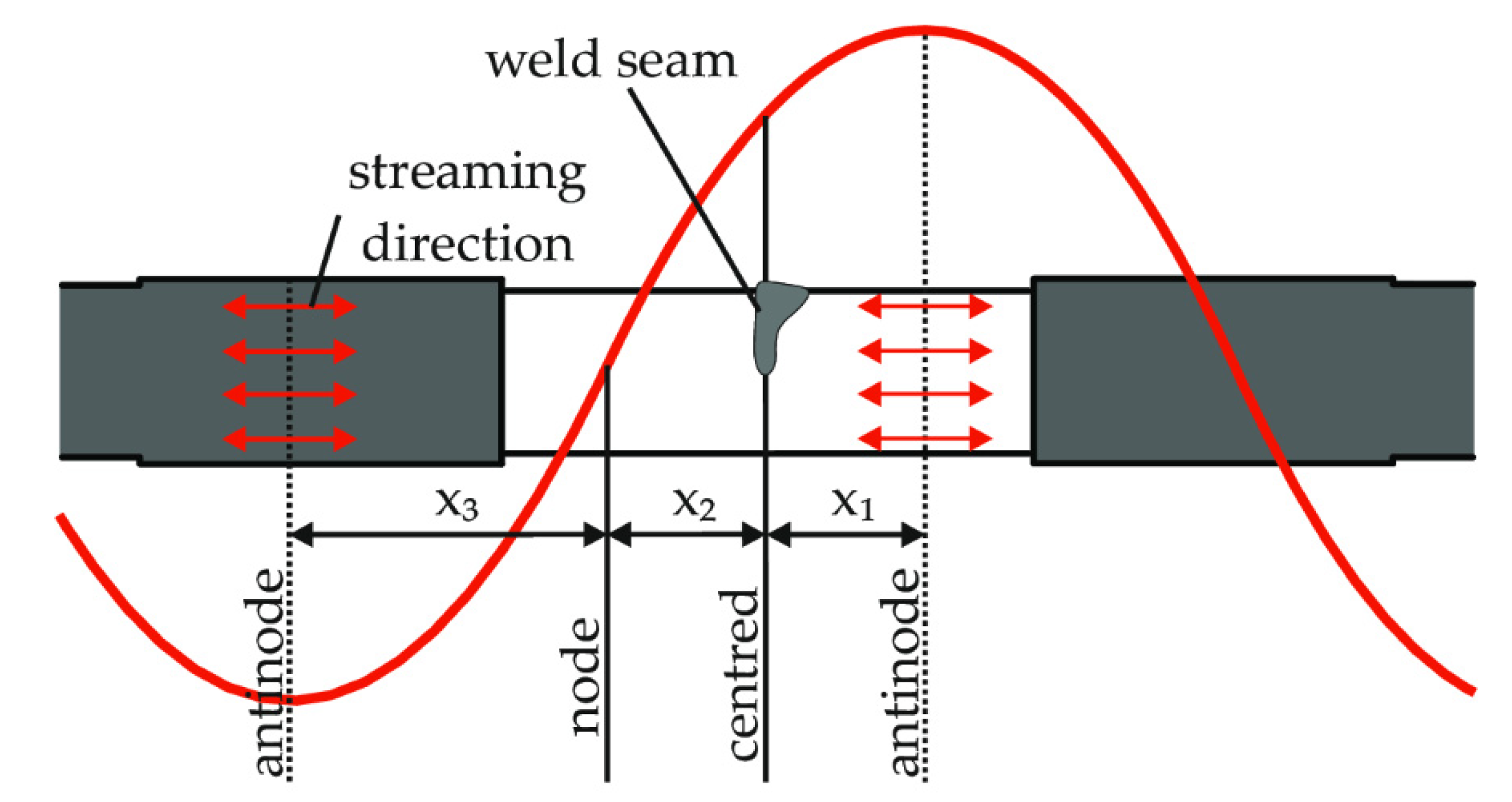

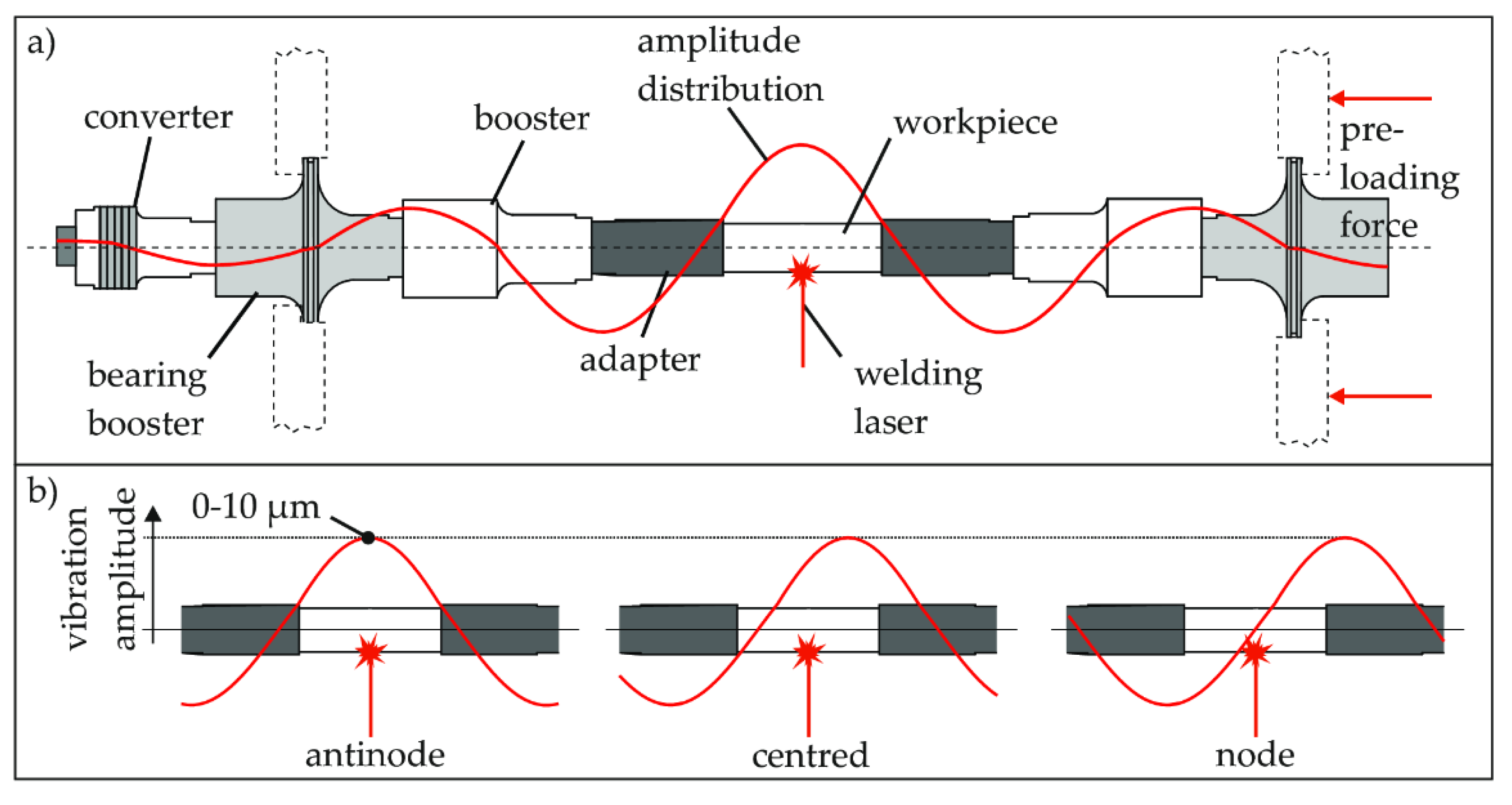

2.2. Ultrasonic System

3. Experimental Procedure

4. Experimental Results

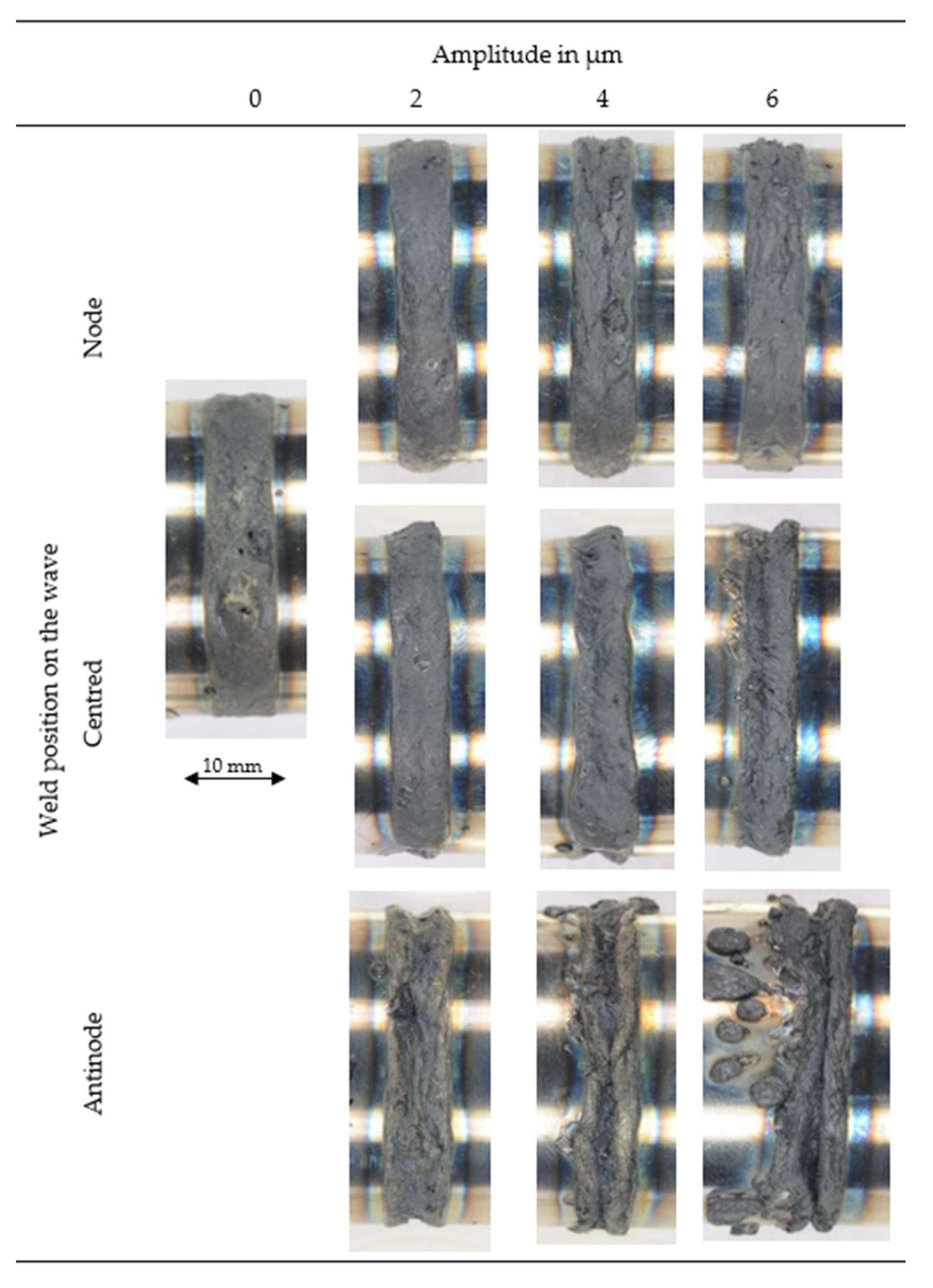

4.1. Weld Appearance

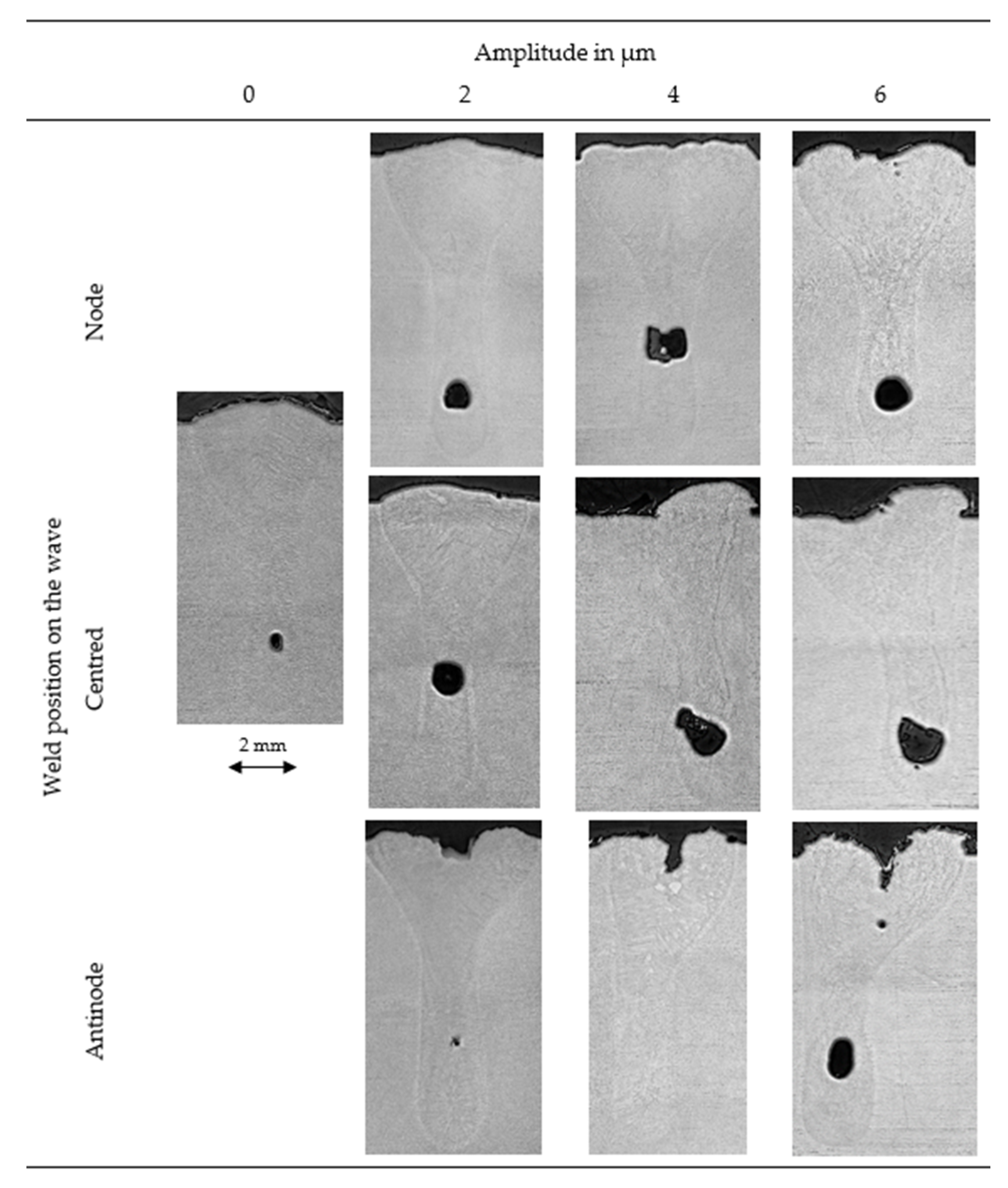

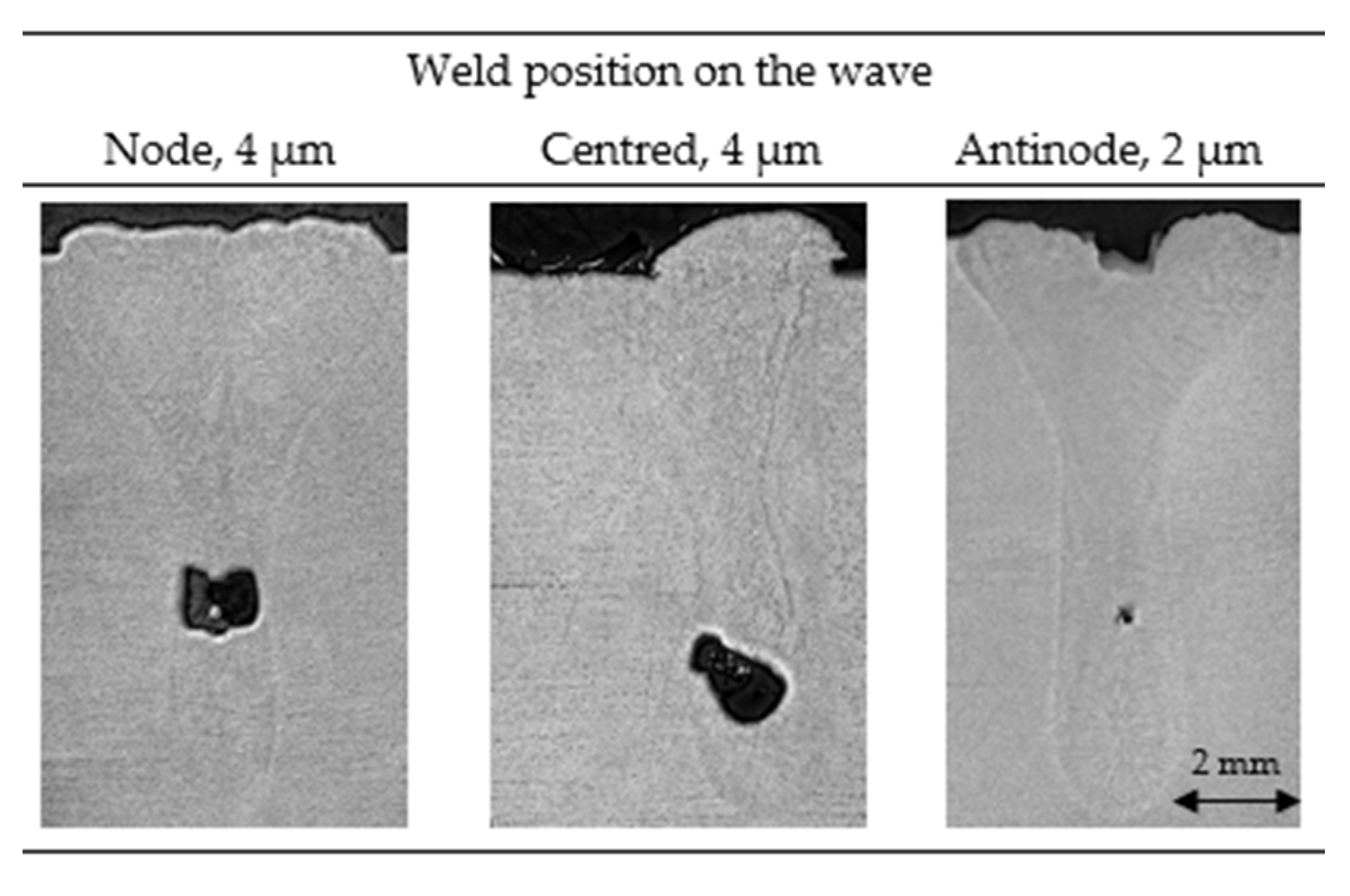

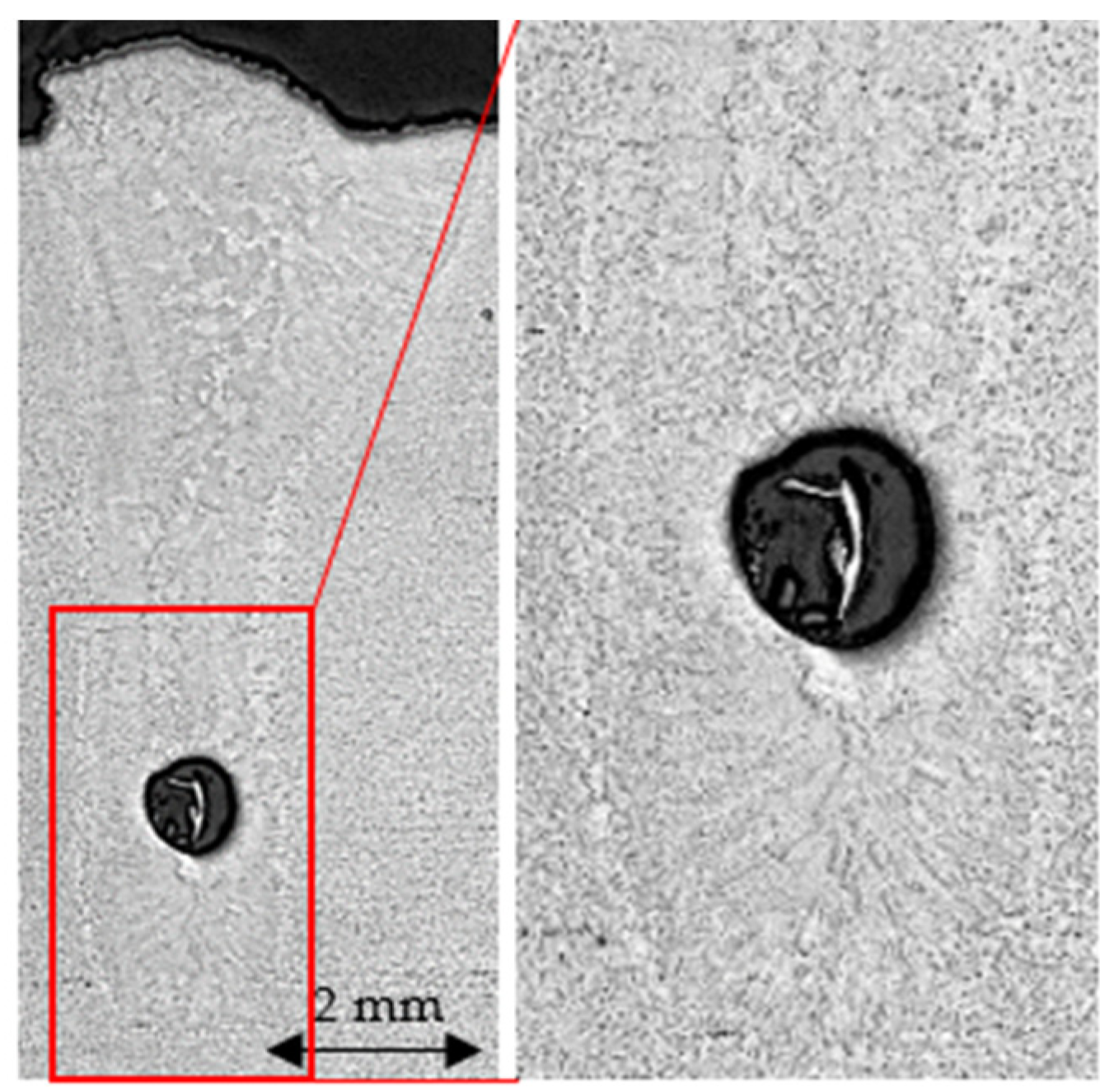

4.2. Pore Formation

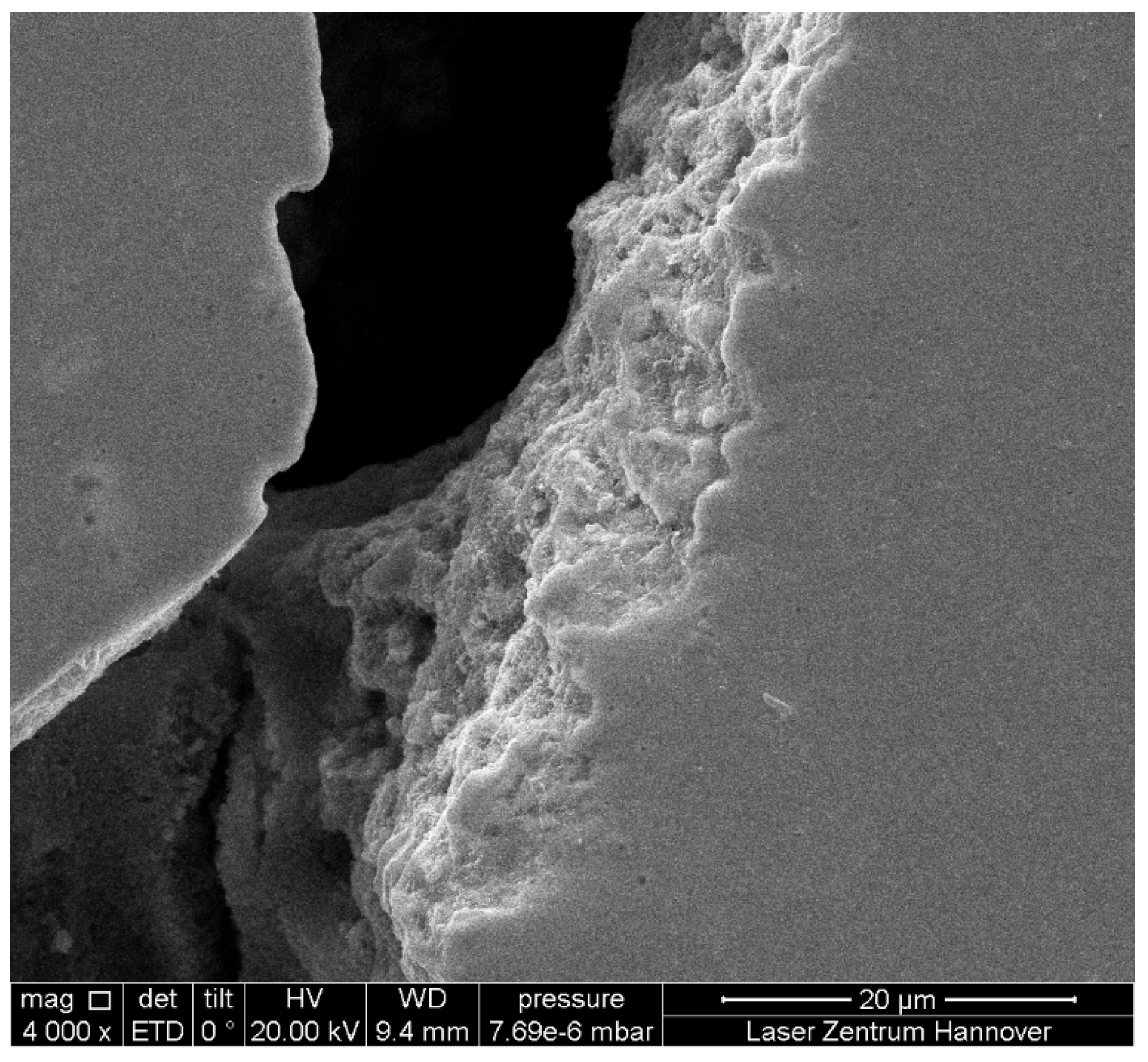

4.3. Crack Formation

5. Conclusions

6. Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhou, S.; Ma, G.; Dongjiang, W.; Chai, D.; Lei, M. Ultrasonic vibration assisted laser welding of nickel-based alloy and Austenite stainless steel. J. Manuf. Process. 2018, 31, 759–767. [Google Scholar] [CrossRef]

- Lee, H.T.; Wu, J.L. Intergranular corrosion resistance of nickel-based alloy 690 weldments. Corros. Sci. 2010, 52, 1545–1550. [Google Scholar] [CrossRef]

- Dommaschk, C.D.; Hübler, J.H. Auswirkungen einer Vibrationsbehandlung auf das Erstarrungs- und Speisungsverhalten von Gusswerkstoffen. Gießerei-Prax. 2003, 12, 505–512. [Google Scholar]

- Nothdurft, S.; Ohrdes, H.; Twiefel, J.; Wallaschek, J.; Mildebrath, M.; Maier, H.J.; Hassel, T.; Overmeyer, L.; Kaierle, S. Influence of ultrasonic amplitude and position in the vibration distribution on the microstructure of a laser beam welded aluminum alloy. J. Laser Appl. 2019, 31, 022402. [Google Scholar] [CrossRef]

- Krajewski, A.; Włosiński, W.; Chmielewski, T.; Kołodziejczak, P. Ultrasonic-vibration assisted arc-welding of aluminium alloys. Bull. Pol. Acad. Sci. Tech. Sci. 2012, 60, 841–852. [Google Scholar]

- Kim, J.S.; Watanabe, T.; Yoshida, Y. Ultrasonic vibration aided laser welding of Al alloys: Improvement of laser welding-quality. J. Laser Appl. 1995, 7, 38–46. [Google Scholar] [CrossRef]

- Deutsche Gesellschaft für Akustik, e.V. DEGA-Empfehlung 101: Akustische Wellen und Felder. Available online: https://www.dega-akustik.de/fileadmin/dega-akustik.de/publikationen/DEGA_Empfehlung_101.pdf (accessed on 14 August 2020).

- Wu, J. Acoustic Streaming and Its Applications. Fluids 2018, 3, 108. [Google Scholar] [CrossRef] [Green Version]

- Wang, G.; Croaker, P.; Dargusch, M.; McGuckin, D.; StJohn, D. Simulation of convective flow and thermal conditions during ultrasonic treatment of an Al-2Cu alloy. Comput. Mater. Sci. 2017, 134, 116–125. [Google Scholar] [CrossRef]

- Foundry Lexicon: Gas Blister. Available online: www.giessereilexikon.com/en (accessed on 17 August 2020).

- Ohrdes, H.; Nothdurft, S.; Nowroth, C.; Grajczak, J.; Twiefel, J.; Hermsdorf, J.; Kaierle, S.; Wallaschek, J. Influence of ultrasonic vibration amplitude on the weld shape of EN AW-6082 utilizing a new excitation system for laser beam welding. Prod. Eng. Special Issue under review.

- Nothdurft, S.; Ohrdes, H.; Twiefel, J.; Wallaschek, J.; Hermsdorf, J.; Overmeyer, L.; Kaierle, S. Investigations on the effect of different ultrasonic amplitudes and positions in the vibration distribution on the microstructure of laser beam welded stainless steel. In High-Power Laser Materials Processing: Applications, Diagnostics, and Systems 2020, IX; International Society for Optics and Photonics: Bellingham, WA, USA, 2020; p. 112730J. [Google Scholar]

- VDM Metals. Datenblatt Nr. 4118: VDM Alloy 625. Available online: https://www.vdm-metals.com/fileadmin/userupload/Downloads/DataSheets/DatenblattVDMAlloy625.pdf (accessed on 11 August 2020).

- Ille, I.; Twiefel, J. Model-based Feedback Control of an Ultrasonic Transducer for Ultrasonic Assisted Turning Using a Novel Digital Controller. Phys. Procedia 2015, 70, 63–67. [Google Scholar] [CrossRef] [Green Version]

| Element in wt.% | Ni | Cr | Fe | C | Mn | Si | Co | Al | Ti | P | S | Mo | Nb + Ta |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Minimum | 58 | 21 | - | - | - | - | - | - | - | - | - | 8.00 | 3.20 |

| Maximum | 71 | 23 | 5.00 | 0.03 | 0.50 | 0.40 | 1.00 | 0.40 | 0.40 | 0.01 | 0.01 | 10.00 | 3.80 |

| Model | Trumpf TruDisk 16002 |

|---|---|

| Wavelength in nm | 1030 |

| Optical fiber diameter in µm | 200 |

| Collimation length in mm | 200 |

| Focal length in mm | 400 |

| Focal spot diameter in µm | 400 |

| Number of Specimens | Amplitude in µm | ||||

|---|---|---|---|---|---|

| 0 | 2 | 4 | 6 | ||

| Wave position of weld | Node | 3 | 3 | 3 | 1 |

| Centred | 3 | 3 | 1 | ||

| Antinode | 3 | 3 | 1 | ||

| Position | Results | |||

|---|---|---|---|---|

| Weld Reinforcement | Cracks | Pores | Equiaxial Structure Amount | |

| Without excitation | standard | no | yes | medium |

| Node | wavy | yes | yes | high |

| Centred | unidirectional | yes | yes | high |

| Antinode | V-shaped | no | no | low |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grajczak, J.; Nowroth, C.; Nothdurft, S.; Hermsdorf, J.; Twiefel, J.; Wallaschek, J.; Kaierle, S. Influence of Ultrasound on Pore and Crack Formation in Laser Beam Welding of Nickel-Base Alloy Round Bars. Metals 2020, 10, 1299. https://doi.org/10.3390/met10101299

Grajczak J, Nowroth C, Nothdurft S, Hermsdorf J, Twiefel J, Wallaschek J, Kaierle S. Influence of Ultrasound on Pore and Crack Formation in Laser Beam Welding of Nickel-Base Alloy Round Bars. Metals. 2020; 10(10):1299. https://doi.org/10.3390/met10101299

Chicago/Turabian StyleGrajczak, Jan, Christian Nowroth, Sarah Nothdurft, Jörg Hermsdorf, Jens Twiefel, Jörg Wallaschek, and Stefan Kaierle. 2020. "Influence of Ultrasound on Pore and Crack Formation in Laser Beam Welding of Nickel-Base Alloy Round Bars" Metals 10, no. 10: 1299. https://doi.org/10.3390/met10101299

APA StyleGrajczak, J., Nowroth, C., Nothdurft, S., Hermsdorf, J., Twiefel, J., Wallaschek, J., & Kaierle, S. (2020). Influence of Ultrasound on Pore and Crack Formation in Laser Beam Welding of Nickel-Base Alloy Round Bars. Metals, 10(10), 1299. https://doi.org/10.3390/met10101299