Effect of Four Manufacturing Techniques (Casting, Laser Directed Energy Deposition, Milling and Selective Laser Melting) on Microstructural, Mechanical and Electrochemical Properties of Co-Cr Dental Alloys, Before and After PFM Firing Process

Abstract

:1. Introduction

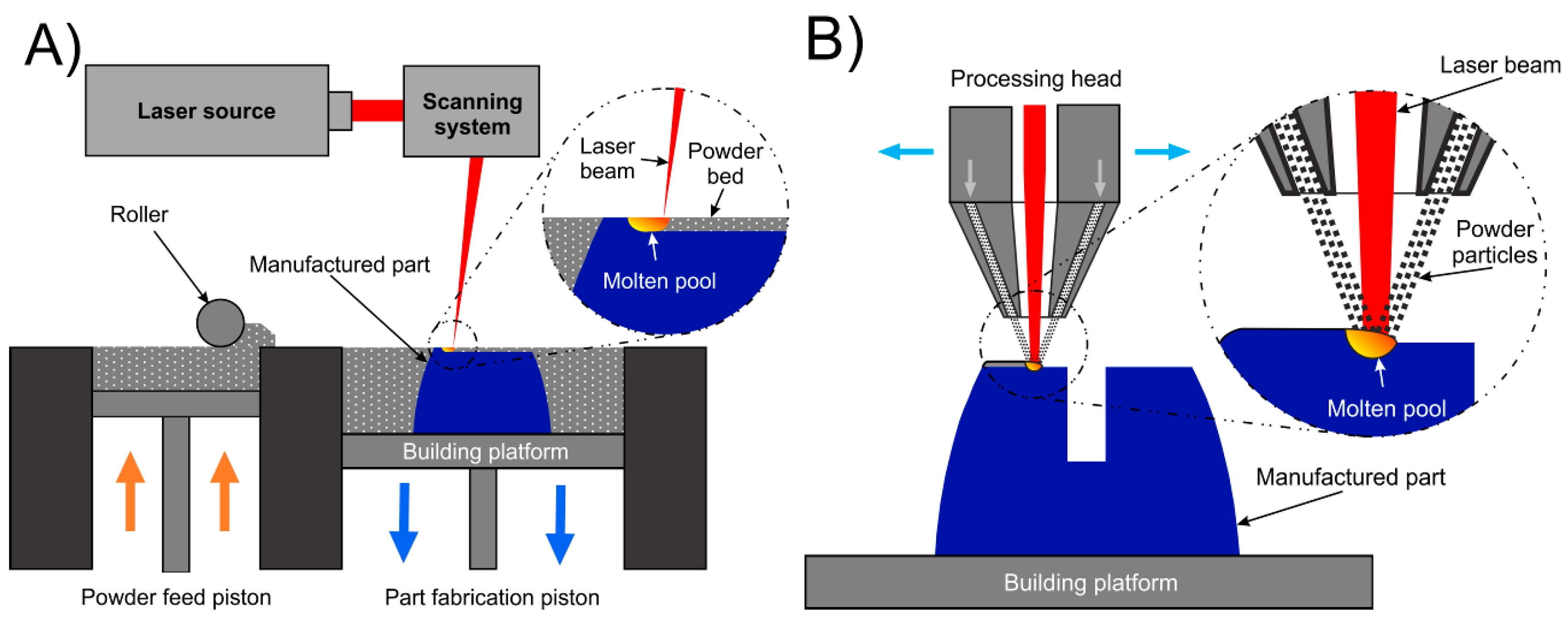

2. Materials and Methods

2.1. Specimen Generation

2.2. PFM Simulation

2.3. Microstructural Characterization

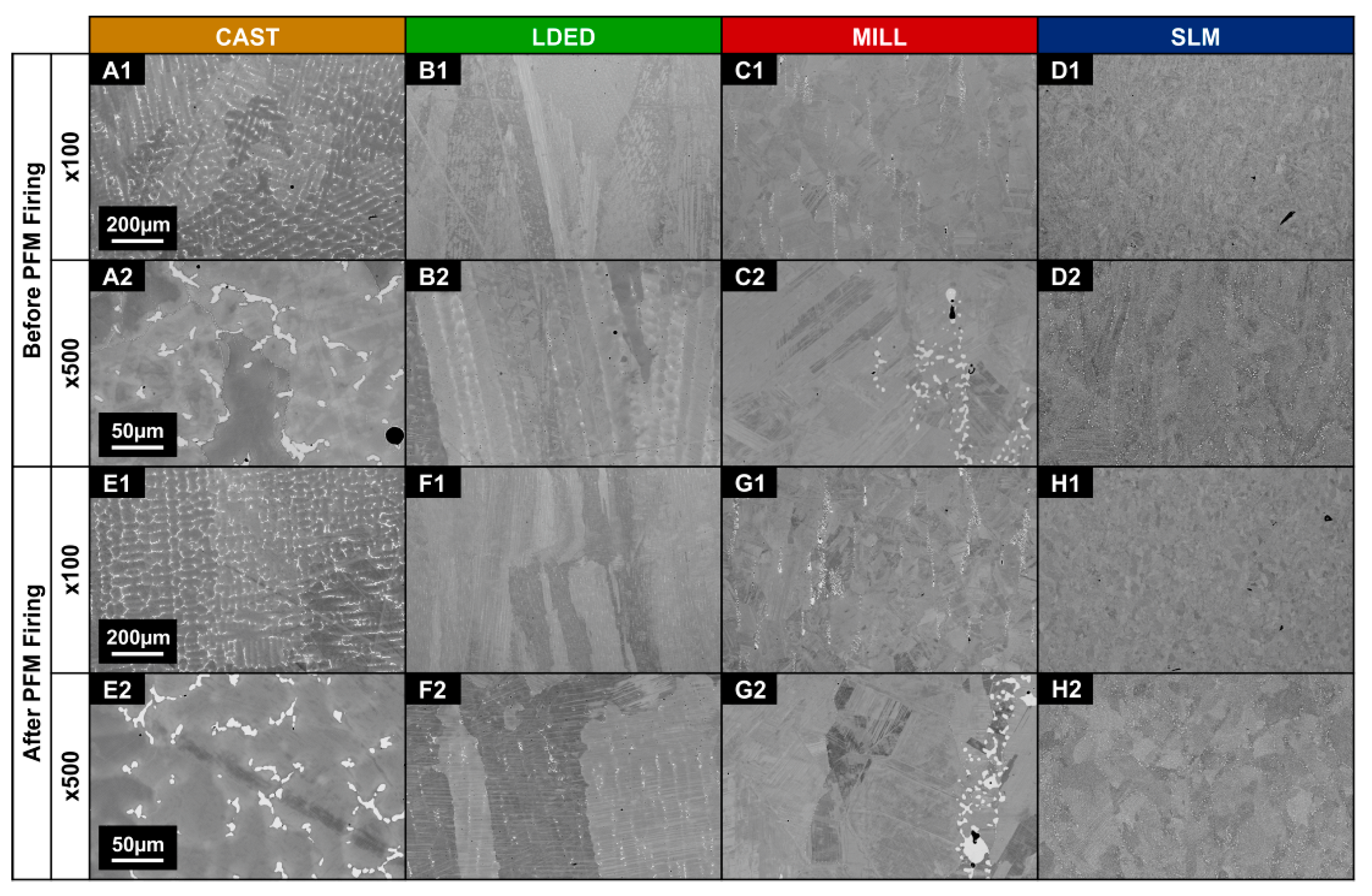

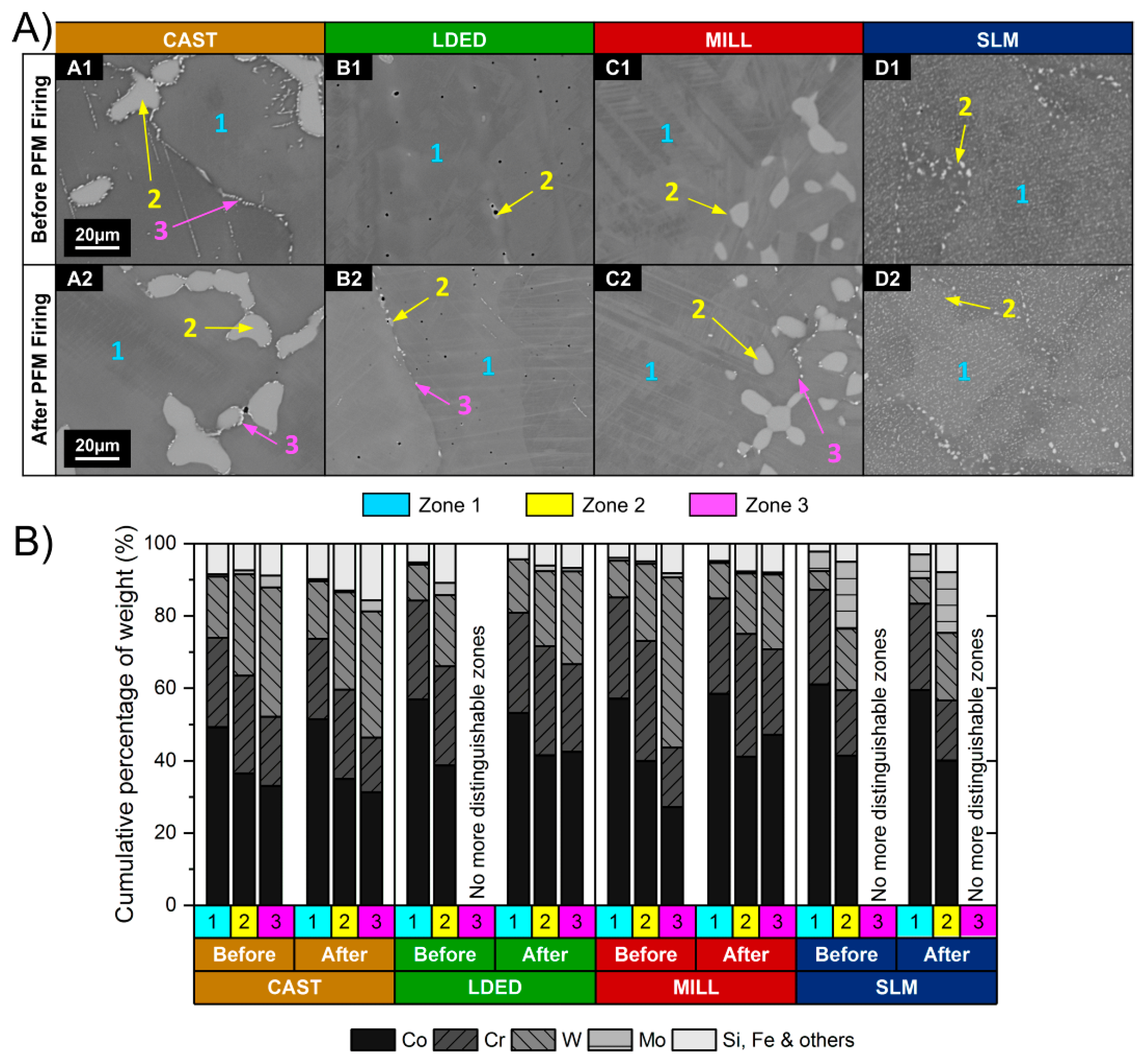

2.3.1. SEM-EDS-EBSD Analysis

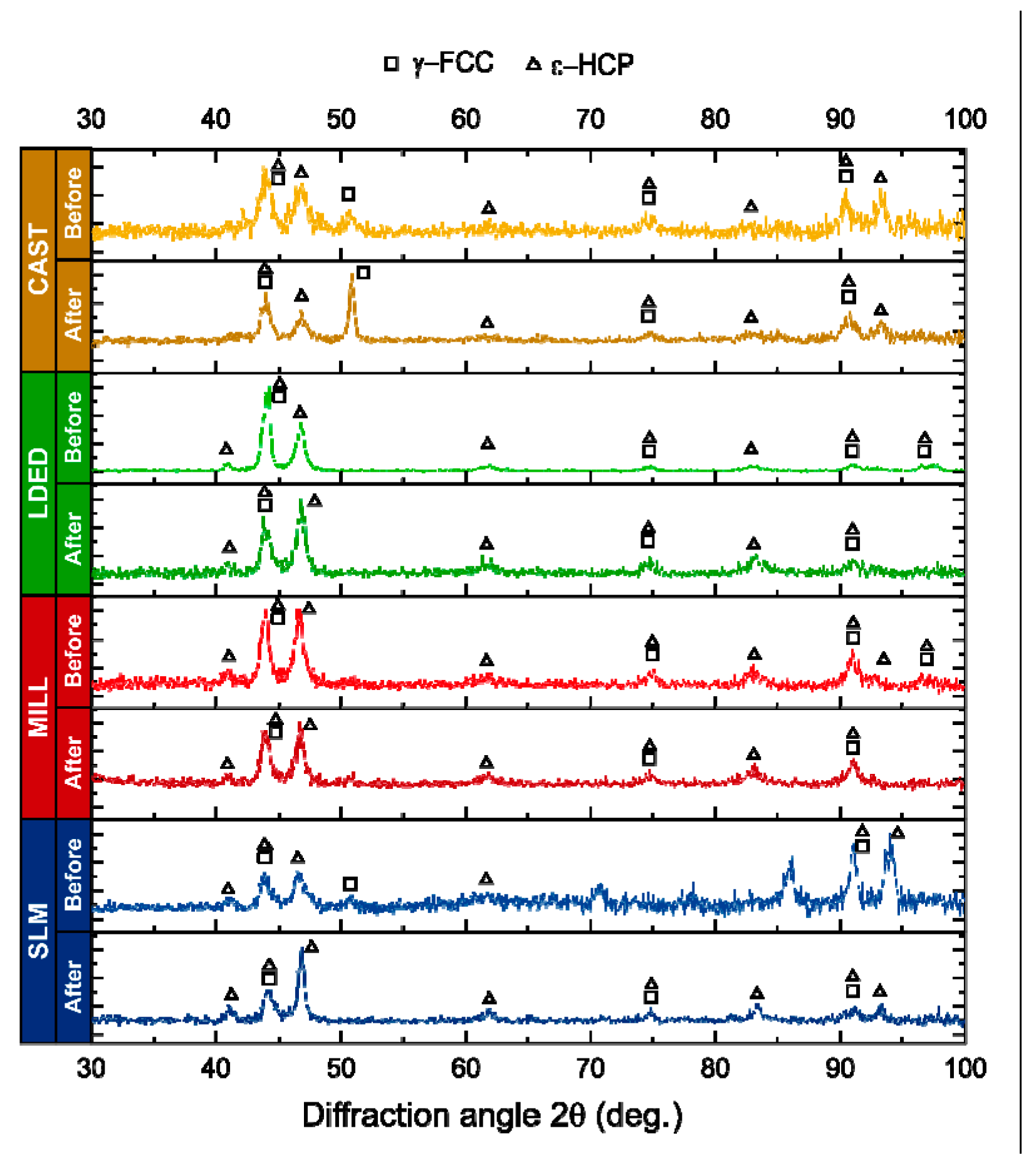

2.3.2. XRD Analysis

2.4. Mechanical Characterization

2.5. Electrochemical Characterization

2.6. Statistical Analysis

3. Results

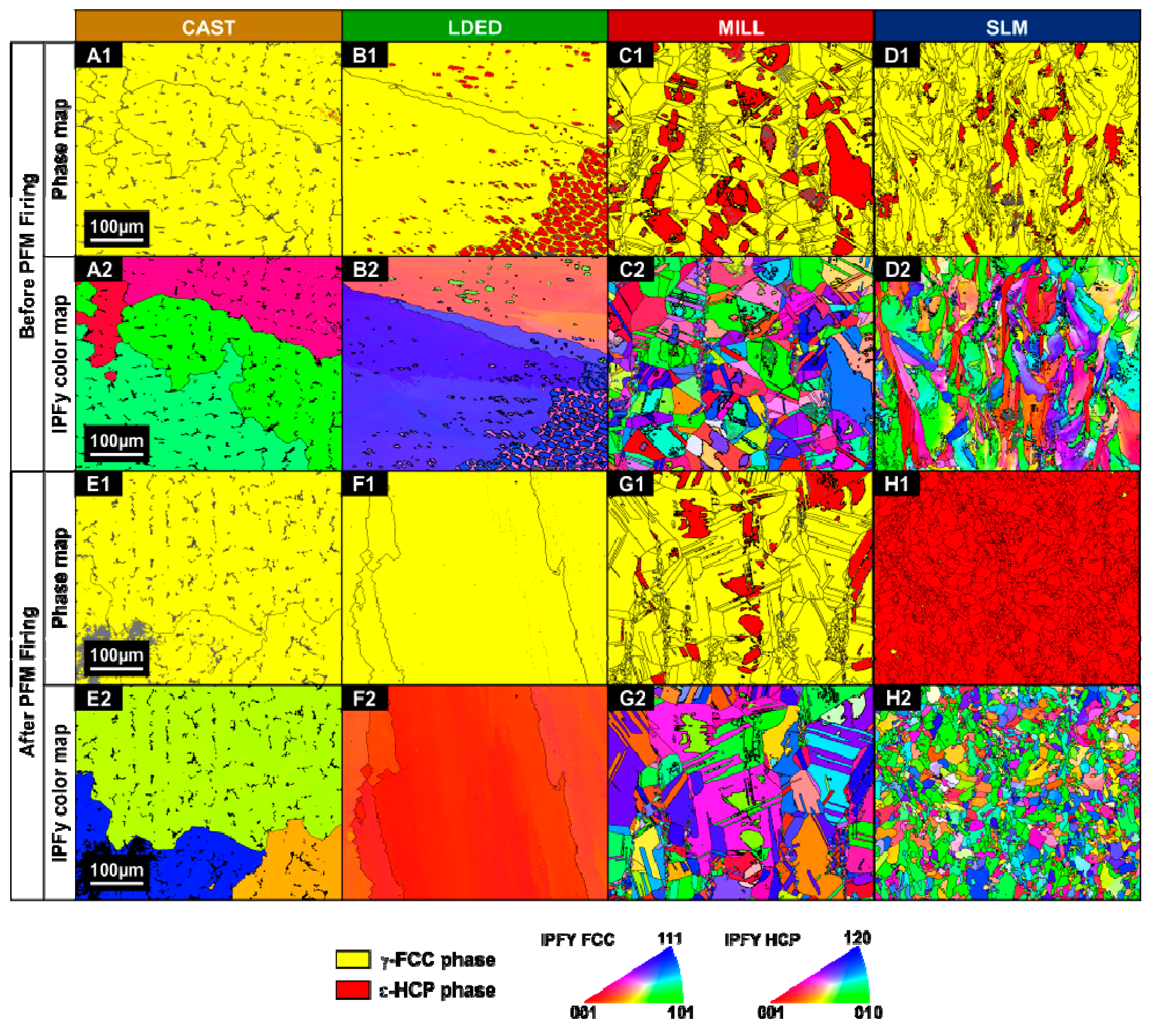

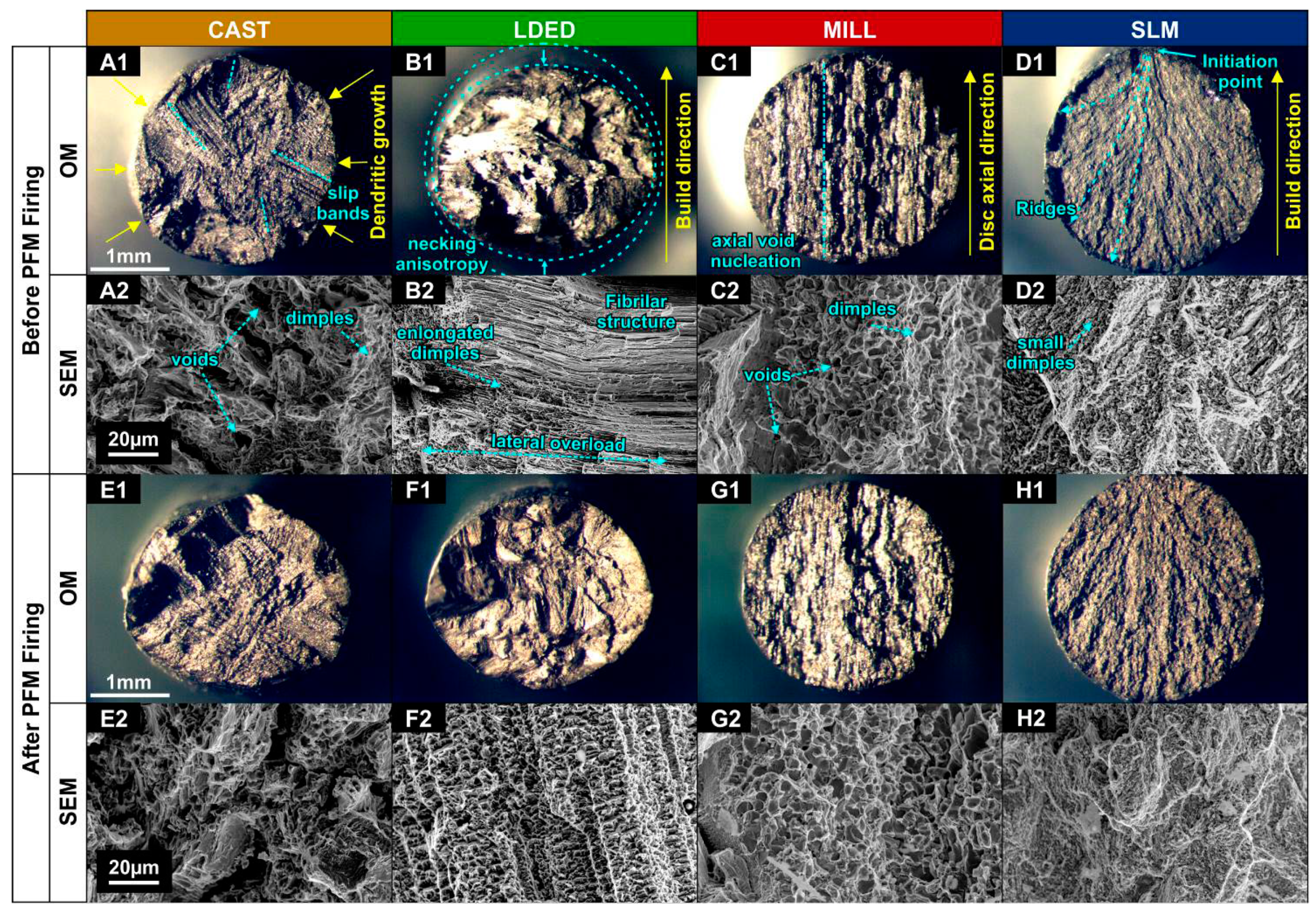

3.1. Microstructural Analysis

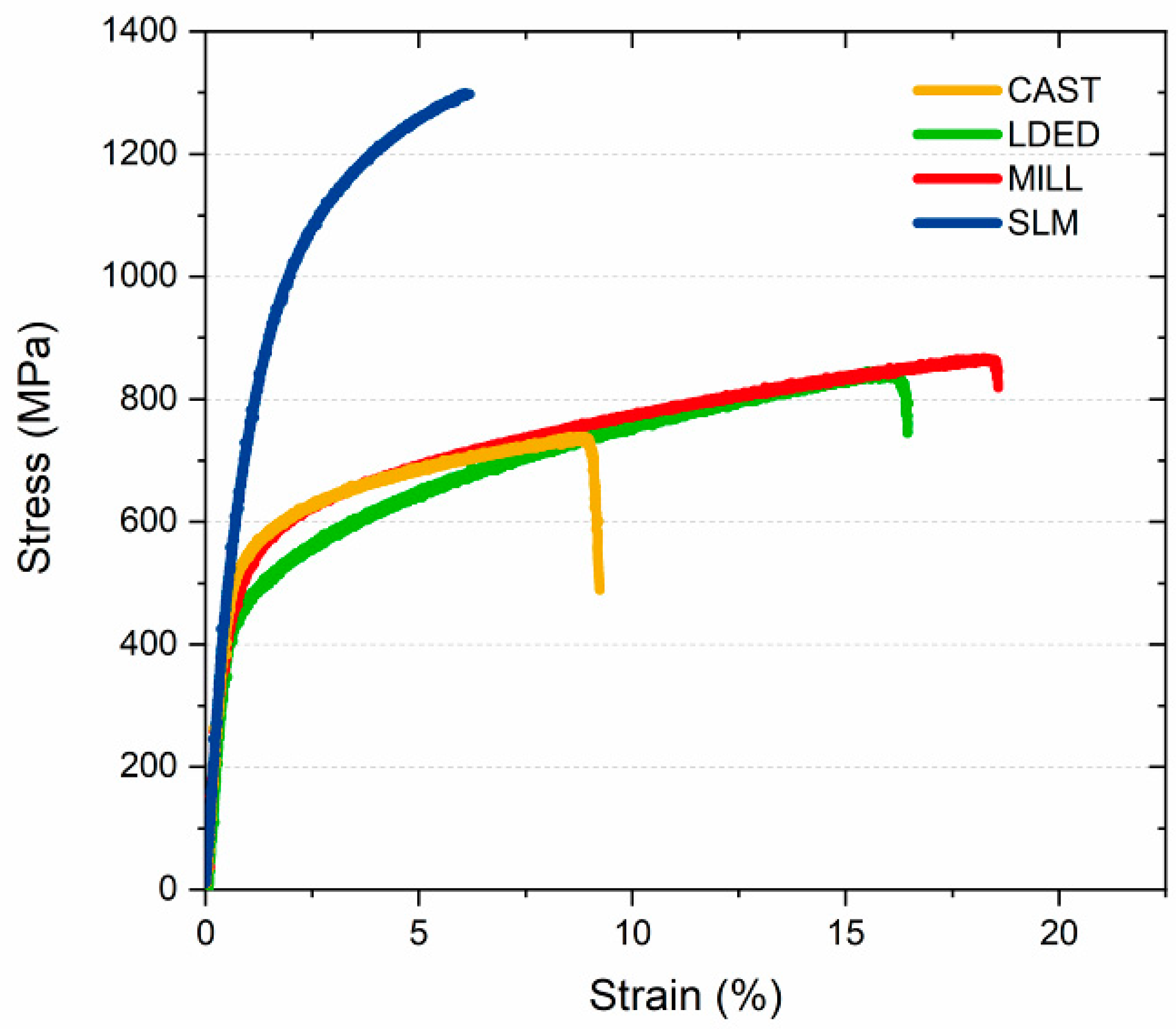

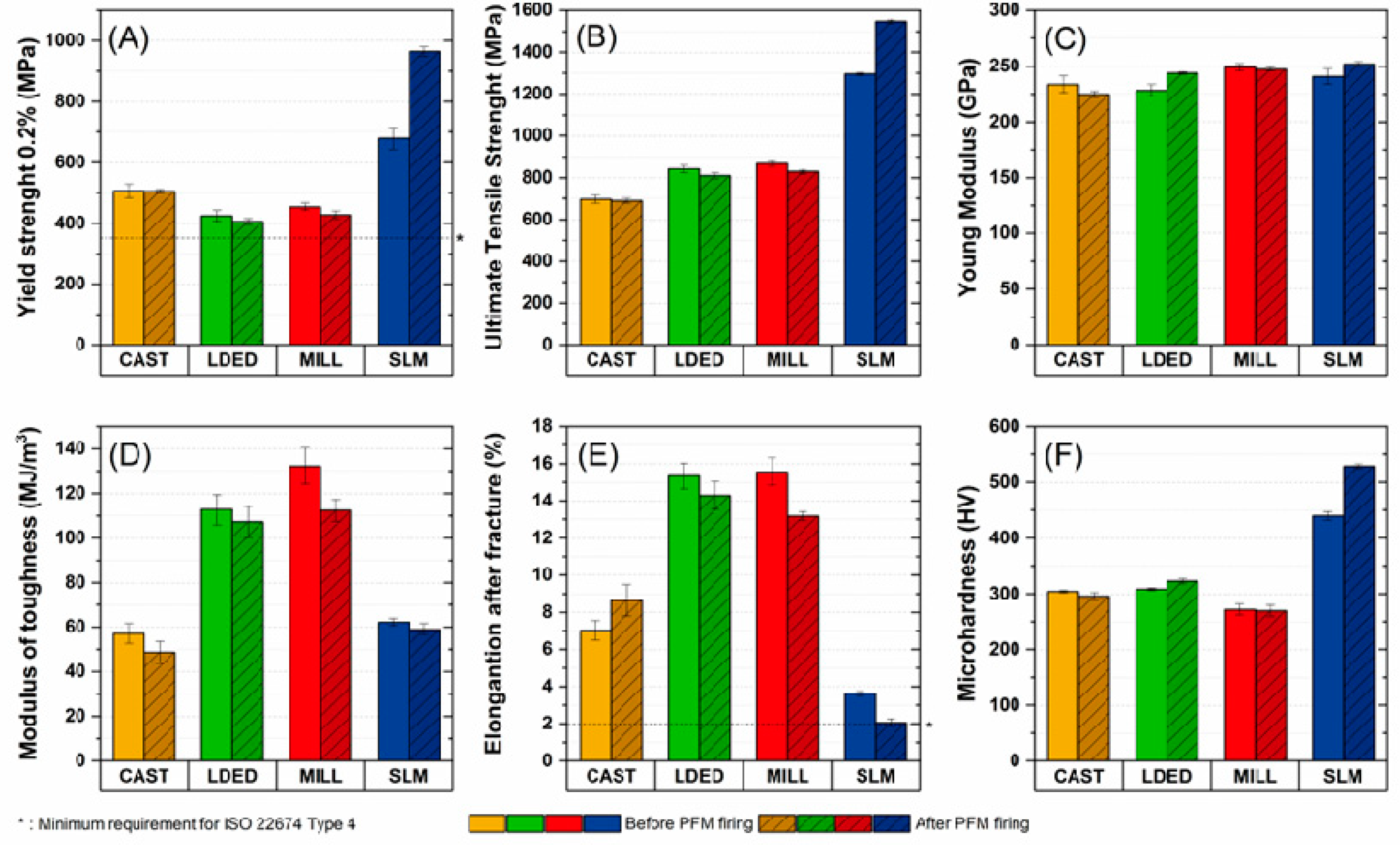

3.2. Mechanical Properties

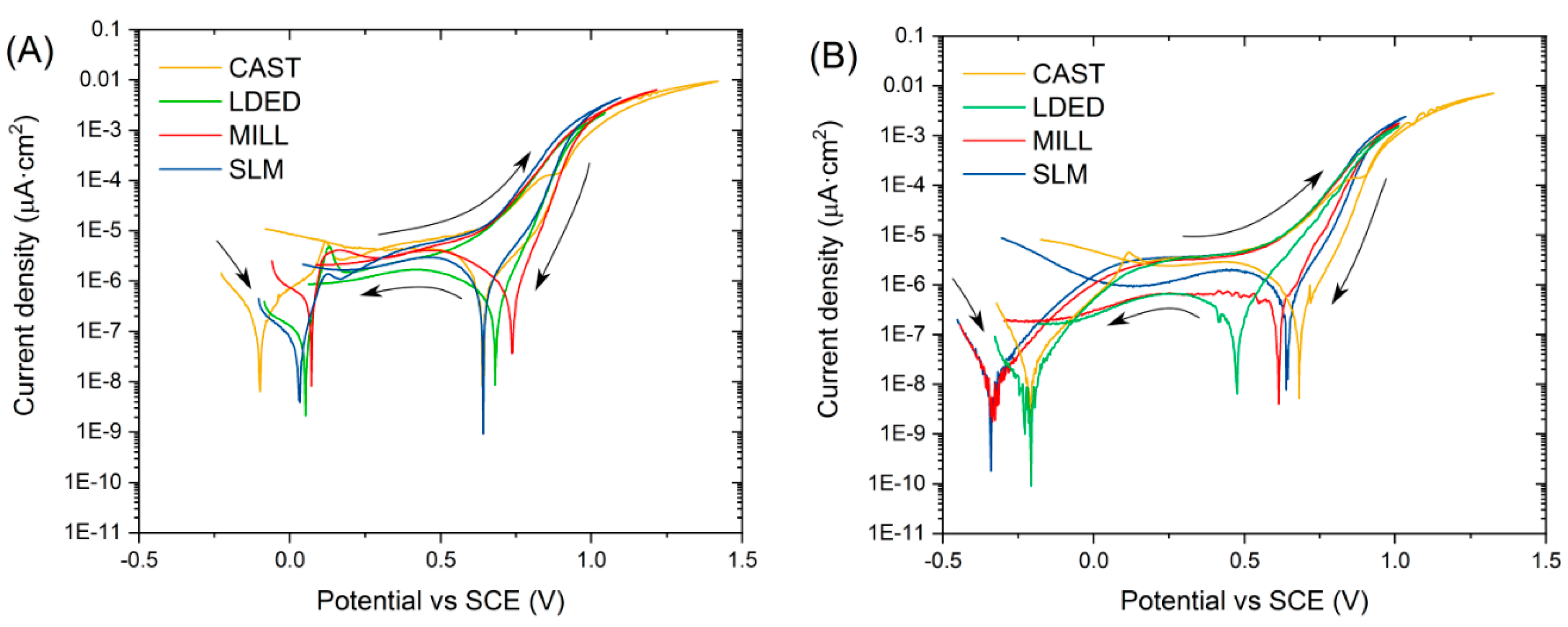

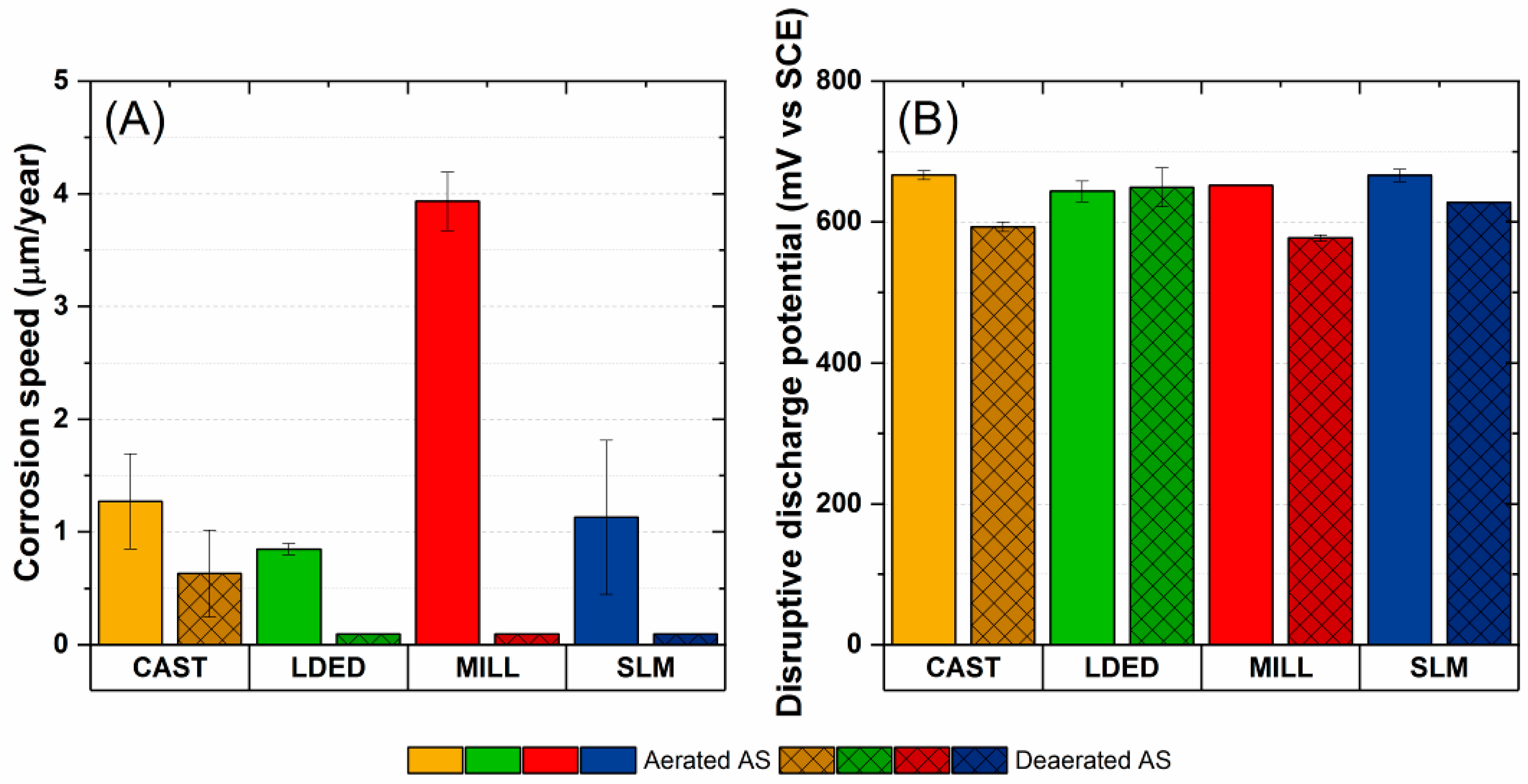

3.3. Electrochemical Properties

4. Discussion

4.1. Microstructure

4.2. Mechanical Properties

4.3. Electrochemical Properties

5. Conclusions

- Co-Cr dental alloys manufactured via casting, LDED, milling, and SLM techniques present evident differences in their mechanical properties.

- The electrochemical performance of all Co-Cr alloys was similar, with high resistance to corrosion in artificial saliva in both aerated and deaerated media.

- Microstructure has an important impact in mechanical behavior of dental Co-Cr alloys. The size and spatial disposition of segregations have a remarkable influence on mechanical properties affecting fracture mechanisms.

- Standards have an important role in assessing the quality of the materials employed in the industry, but care has to be taken because of their limitations, and some important properties may not be evaluated.

- The modulus of toughness is an important property in order to evaluate the overall performance of the materials. LDED and milling were the best techniques in this study, with better results in this characteristic.

- LDED is an additive manufacturing technique that can be implemented in the restorative dental industry with high overall performance. This manufacturing process can compete directly with the best quality techniques, and taking the best part of each of them, mechanical properties from milling disk, and freeform generation from SLM processes.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Materials Compared | Mechanical Properties Evaluated | ||||||

|---|---|---|---|---|---|---|---|

| Material 1 | Material 2 | Yield Strength 0.2% (MPa) | Ultimate Tensile Strength (MPa) | Young Modulus (GPa) | Modulus of Toughness (MJ/m3) | Enlongation After Fracture (%) | Microhardness (HV) |

| CAST before | CAST after | - | - | - | - | - | - |

| CAST before | LDED before | - | Yes | - | Yes | Yes | Yes |

| CAST before | LDED after | - | Yes | - | Yes | Yes | Yes |

| CAST before | MILL before | - | Yes | - | Yes | Yes | - |

| CAST before | MILL after | - | Yes | - | Yes | Yes | - |

| CAST before | SLM before | Yes | Yes | - | - | Yes | Yes |

| CAST before | SLM after | Yes | Yes | - | - | Yes | Yes |

| CAST after | LDED before | - | Yes | - | Yes | Yes | - |

| CAST after | LDED after | - | Yes | - | Yes | Yes | - |

| CAST after | MILL before | - | Yes | - | Yes | Yes | - |

| CAST after | MILL after | - | Yes | - | Yes | Yes | - |

| CAST after | SLM before | Yes | Yes | - | - | Yes | Yes |

| CAST after | SLM after | Yes | Yes | - | - | Yes | Yes |

| LDED before | LDED after | - | - | - | - | - | - |

| LDED before | MILL before | - | - | - | - | - | Yes |

| LDED before | MILL after | - | - | - | - | - | Yes |

| LDED before | SLM before | Yes | Yes | - | Yes | Yes | Yes |

| LDED before | SLM after | Yes | Yes | - | Yes | Yes | Yes |

| LDED after | MILL before | - | - | - | Yes | - | Yes |

| LDED after | MILL after | - | - | - | - | - | Yes |

| LDED after | SLM before | Yes | Yes | - | Yes | Yes | Yes |

| LDED after | SLM after | Yes | Yes | - | Yes | Yes | Yes |

| MILL before | MILL after | - | - | - | - | - | - |

| MILL before | SLM before | Yes | Yes | - | Yes | Yes | Yes |

| MILL before | SLM after | Yes | Yes | - | Yes | Yes | Yes |

| MILL after | SLM before | Yes | Yes | - | Yes | Yes | Yes |

| MILL after | SLM after | Yes | Yes | - | Yes | Yes | Yes |

| SLM before | SLM after | Yes | Yes | - | - | - | Yes |

References

- Knosp, H.; Holliday, R.J.; Corti, C.W. Gold in dentistry: Alloys, uses and performance. Gold Bull. 2003, 36, 93–102. [Google Scholar] [CrossRef] [Green Version]

- Denkhaus, E.; Salnikow, K. Nickel essentiality, toxicity, and carcinogenicity. Crit. Rev. Oncol. 2002, 42, 35–56. [Google Scholar] [CrossRef]

- Steinemann, S.; Perren, S. Titanium alloys as metallic biomaterials. Titan. Sci. Technol. 1984, 2, 1327–1334. [Google Scholar]

- Helsen, J.A.; Breme, J. Metals As Biomaterials; Wiley-VCH: Chichester, UK, 1998; ISBN 978-0-471-96935-8. [Google Scholar]

- Davis, J.R. ASM Specialty Handbook: Nickel, Cobalt, and Their Alloys; ASM International: Materials Park, OH, USA, 2001; Volume 38, ISBN 978-0-87170-685-0. [Google Scholar]

- Mani, A.; Salinas-Rodriguez, A.; Lopez, H. Deformation induced FCC to HCP transformation in a Co-27Cr-5Mo-0.05C alloy. Mater. Sci. Eng. A 2011, 528, 3037–3043. [Google Scholar] [CrossRef]

- Tian, L.-Y.; Lizárraga, R.; Larsson, H.; Holmström, E.; Vitos, L. A first principles study of the stacking fault energies for fcc Co-based binary alloys. Acta Mater. 2017, 136, 215–223. [Google Scholar] [CrossRef]

- Li, K.C.; Prior, D.J.; Waddell, J.N.; Swain, M. Comparison of the microstructure and phase stability of as-cast, CAD/CAM and powder metallurgy manufactured Co-Cr dental alloys. Dent. Mater. 2015, 31, e306–e315. [Google Scholar] [CrossRef]

- Al Jabbari, Y.S.; Koutsoukis, T.; Barmpagadaki, X.; Zinelis, S. Metallurgical and interfacial characterization of PFM Co-Cr dental alloys fabricated via casting, milling or selective laser melting. Dent. Mater. 2014, 30, e79–e88. [Google Scholar] [CrossRef]

- Espevik, S. Corrosion of base metal alloys in vitro. Acta Odontol. Scand. 1978, 36, 113–116. [Google Scholar] [CrossRef]

- Karaali, A.; Mirouh, K.; Hamamda, S.; Guiraldenq, P. Microstructural study of tungsten influence on Co–Cr alloys. Mater. Sci. Eng. A 2005, 390, 255–259. [Google Scholar] [CrossRef]

- Yamanaka, K.; Mori, M.; Chiba, A. Assessment of precipitation behavior in dental castings of a Co-Cr-Mo alloy. J. Mech. Behav. Biomed. Mater. 2015, 50, 268–276. [Google Scholar] [CrossRef] [Green Version]

- Yamanaka, K.; Mori, M.; Kuramoto, K.; Chiba, A. Development of new Co-Cr-W-based biomedical alloys: Effects of microalloying and thermomechanical processing on microstructures and mechanical properties. Mater. Des. 2014, 55, 987–998. [Google Scholar] [CrossRef]

- Ramírez, L.; Castro, M.; Mendez, M.; Lacaze, J.; Herrera, M.; Lesoult, G. Precipitation path of secondary phases during solidification of the Co- 25.5%Cr- 5.5%Mo– 0.26% C alloy. Scr. Mater. 2002, 47, 811–816. [Google Scholar] [CrossRef]

- Yamanaka, K.; Mori, M.; Chiba, A. Developing high strength and ductility in biomedical Co–Cr cast alloys by simultaneous doping with nitrogen and carbon. Acta Biomater. 2016, 31, 435–447. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Padrós, R.; Punset, M.; Molmeneu, M.; Velasco, A.B.; Herrero-Climent, M.; Rupérez, E.; Gil, F.J. Mechanical properties of CoCr dental-prosthesis restorations made by three manufacturing processes. influence of the microstructure and topography. Metals 2020, 10, 788. [Google Scholar] [CrossRef]

- Xin, X.-Z.; Chen, J.; Xiang, N.; Gong, Y.; Wei, B. Surface characteristics and corrosion properties of selective laser melted Co-Cr dental alloy after porcelain firing. Dent. Mater. 2014, 30, 263–270. [Google Scholar] [CrossRef]

- Padrós, R.; Tarrida, L.G.; Herrero-Climent, M.; Punset, M.; Gil, F.J. Corrosion resistance and ion release of dental prosthesis of CoCr obtained by CAD-CAM milling, casting and laser sintering. Metals 2020, 10, 827. [Google Scholar] [CrossRef]

- Karpuschewski, B.; Pieper, H.J.; Krause, M.; Döring, J. CoCr is Not the Same: CoCr-Blanks for Dental Machining. In Future Trends in Production Engineering; Springer Science and Business Media LLC: Berlin, Germany, 2012; pp. 261–274. [Google Scholar]

- Li, J.; Chen, C.; Liao, J.; Liu, L.; Ye, X.; Lin, S.; Ye, J.-T. Bond strengths of porcelain to cobalt-chromium alloys made by casting, milling, and selective laser melting. J. Prosthet. Dent. 2016, 118, 69–75. [Google Scholar] [CrossRef] [PubMed]

- Zangeneh, S.; Lashgari, H.R.; Alsaadi, S.; Mohamad-Moradi, S.; Saghafi, M. The effect of cyclic solution heat treatment on the martensitic phase transformation and grain refinement of Co-Cr-Mo dental alloy. Metals 2020, 10, 861. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Koutsoukis, T.; Zinelis, S.; Eliades, G.; Al-Wazzan, K.; Al Rifaiy, M.; Al Jabbari, Y.S. Selective laser melting technique of Co-Cr dental alloys: A Review of structure and properties and comparative analysis with other available techniques. J. Prosthodont. 2015, 24, 303–312. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Kolla, S.; Eckert, J. Additive manufacturing processes: Selective laser melting, electron beam melting and binder jetting-selection guidelines. Materials 2017, 10, 672. [Google Scholar] [CrossRef] [Green Version]

- Fortunato, A.; Lulaj, A.; Melkote, S.; Liverani, E.; Ascari, A.; Umbrello, D. Milling of maraging steel components produced by selective laser melting. Int. J. Adv. Manuf. Technol. 2017, 94, 1895–1902. [Google Scholar] [CrossRef]

- Sameni, M.K.; Toyserkani, E.; Khajepour, A. Fuzzy Model and Compact Fuzzy Model Identification of Laser Cladding Process; Laser Institute of America: Orlando, FL, USA, 2004; Volume 2004, p. 604. [Google Scholar]

- Zhong, C.; Gasser, A.; Schopphoven, T.; Poprawe, R. Experimental study of porosity reduction in high deposition-rate laser material deposition. Opt. Laser Technol. 2015, 75, 87–92. [Google Scholar] [CrossRef]

- Arias-González, F.; Del Val, J.; Comesaña, R.; Penide, J.; Lusquiños, F.; Quintero, F.; Riveiro, A.; Boutinguiza, M.; Pou, J.; Penide, J. Fiber laser cladding of nickel-based alloy on cast iron. Appl. Surf. Sci. 2016, 374, 197–205. [Google Scholar] [CrossRef]

- Amado, J.; Rodríguez, A.; Montero, J.; Tobar, M.; Yáñez, A. A comparison of laser deposition of commercially pure titanium using gas atomized or Ti sponge powders. Surf. Coatings Technol. 2019, 374, 253–263. [Google Scholar] [CrossRef]

- Ram, G.D.J.; Esplin, C.K.; Stucker, B.E. Microstructure and wear properties of LENS® deposited medical grade CoCrMo. J. Mater. Sci. Mater. Electron. 2007, 19, 2105–2111. [Google Scholar] [CrossRef]

- Del Val, J.; Comesaña, R.; Riveiro, A.; Lusquiños, F.; Quintero, F.; Boutinguiza, M.; Pou, J. Laser direct writing of Co-superalloy lines for micro-fabrication applications. Surf. Coatings Technol. 2018, 345, 76–88. [Google Scholar] [CrossRef]

- Schmidt, M.; Merklein, M.; Bourell, D.; Dimitrov, D.; Hausotte, T.; Wegener, K.; Overmeyer, L.; Vollertsen, F.; Levy, G.N. Laser based additive manufacturing in industry and academia. CIRP Ann. 2017, 66, 561–583. [Google Scholar] [CrossRef]

- Comesaña, R.; Lusquiños, F.; Del Val, J.; Quintero, F.; Riveiro, A.; Boutinguiza, M.; Jones, J.R.; Hill, R.G.; Pou, J. Toward smart implant synthesis: Bonding bioceramics of different resorbability to match bone growth rates. Sci. Rep. 2015, 5, 10677. [Google Scholar] [CrossRef] [Green Version]

- Shamsaei, N.; Yadollahi, A.; Bian, L.; Thompson, S.M. An overview of direct laser deposition for additive manufacturing; Part II: Mechanical behavior, process parameter optimization and control. Addit. Manuf. 2015, 8, 12–35. [Google Scholar] [CrossRef]

- Huang, Y.; Ansari, M.; Asgari, H.; Farshidianfar, M.H.; Sarker, D.; Khamesee, M.B.; Toyserkani, E. Rapid prediction of real-time thermal characteristics, solidification parameters and microstructure in laser directed energy deposition (powder-fed additive manufacturing). J. Mater. Process. Technol. 2019, 274, 116286. [Google Scholar] [CrossRef]

- Bai, Y.; Chaudhari, A.; Wang, H. Investigation on the microstructure and machinability of ASTM A131 steel manufactured by directed energy deposition. J. Mater. Process. Technol. 2020, 276, 116410. [Google Scholar] [CrossRef]

- Mantrala, K.M.; Das, M.; Balla, V.K.; Rao, C.S.; Rao, V.K. Laser-deposited CoCrMo alloy: Microstructure, wear, and electrochemical properties. J. Mater. Res. 2014, 29, 2021–2027. [Google Scholar] [CrossRef]

- España, F.A.; Balla, V.K.; Bose, S.; Bandyopadhyay, A. design and fabrication of CoCrMo alloy based novel structures for load bearing implants using laser engineered net shaping. Mater. Sci. Eng. C 2010, 30, 50–57. [Google Scholar] [CrossRef]

- Smith, E. The nucleation and growth of cleavage microcracks in mild steel. Phys. Basis Yield Fract. Conf. Proc. 1966, 1966, 36–46. [Google Scholar]

- Akram, J.; Chalavadi, P.; Pal, D.; Stucker, B. Understanding grain evolution in additive manufacturing through modeling. Addit. Manuf. 2018, 21, 255–268. [Google Scholar] [CrossRef]

- Arias-González, F.; Del Val, J.; Comesaña, R.; Penide, J.; Lusquiños, F.; Quintero, F.; Riveiro, A.; Boutinguiza, M.; Gil, F.J.; Pou, J. Microstructure and crystallographic texture of pure titanium parts generated by laser additive manufacturing. Met. Mater. Int. 2018, 24, 231–239. [Google Scholar] [CrossRef]

- Shishkovsky, I.V.; Missemer, F.; Smurov, I. Metal matrix composites with ternary intermetallic inclusions fabricated by laser direct energy deposition. Compos. Struct. 2018, 183, 663–670. [Google Scholar] [CrossRef]

- Reclaru, L.; Ardelean, L.C. Alternative Processing Techniques for CoCr Dental Alloys; Elsevier BV: Amsterdam, The Netherlands, 2019; pp. 1–15. [Google Scholar]

- Xiang, D.; Wang, P.; Tan, X.; Chandra, S.; Wang, C.; Nai, M.; Tor, S.; Liu, W.; Liu, E. Anisotropic microstructure and mechanical properties of additively manufactured Co-Cr-Mo alloy using selective electron beam melting for orthopedic implants. Mater. Sci. Eng. A 2019, 765, 138270. [Google Scholar] [CrossRef]

- Zhao, Y.; Koizumi, Y.; Aoyagi, K.; Wei, D.; Yamanaka, K.; Chiba, A. Comprehensive study on mechanisms for grain morphology evolution and texture development in powder bed fusion with electron beam of Co-Cr-Mo alloy. Materials 2019, 6, 100346. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, N.; Yan, J.; Zeng, Q. Comparative analysis of the microstructures and mechanical properties of Co-Cr dental alloys fabricated by different methods. J. Prosthet. Dent. 2018, 120, 617–623. [Google Scholar] [CrossRef]

- Al Jabbari, Y.S.; Barmpagadaki, X.; Psarris, I.; Zinelis, S. Microstructural, mechanical, ionic release and tarnish resistance characterization of porcelain fused to metal Co-Cr alloys manufactured via casting and three different CAD/CAM techniques. J. Prosthodont. Res. 2019, 63, 150–156. [Google Scholar] [CrossRef] [PubMed]

- Knott, J. Micro-Mechanisms of Fracture and The Fracture Toughness of Engineering Alloys. In Advances in Research on the Strength and Fracture of Materials; Elsevier BV: Amsterdam, The Netherlands, 1978; pp. 61–92. [Google Scholar]

- ASM Handbook Committee Fractography; ASM International: Materials Park, OH, USA, 1987; ISBN 978-1-62708-181-8.

- Brandon, D.; Kaplan, W.D. Microstructural Characterization of Materials; Wiley: Chichester, UK, 2008. [Google Scholar]

- Sun, S.-H.; Koizumi, Y.; Kurosu, S.; Li, Y.; Matsumoto, H.; Chiba, A. Build direction dependence of microstructure and high-temperature tensile property of Co-Cr-Mo alloy fabricated by electron beam melting. Acta Mater. 2014, 64, 154–168. [Google Scholar] [CrossRef]

- Takaichi, A.; Suyalatu; Nakamoto, T.; Joko, N.; Nomura, N.; Tsutsumi, Y.; Migita, S.; Doi, H.; Kurosu, S.; Chiba, A.; et al. Microstructures and mechanical properties of Co- 29Cr- 6Mo alloy fabricated by selective laser melting process for dental applications. J. Mech. Behav. Biomed. Mater. 2013, 21, 67–76. [Google Scholar] [CrossRef]

- Dikova, T. Properties of Co-Cr Dental Alloys Fabricated Using Additive Technologies. In Biomaterials in Regenerative Medicine; IntechOpen: London, UK, 2018; Volume I, p. 13. [Google Scholar]

- Ayyıldız, S.; Soylu, E.H.; Ide, S.; Kılıç, S.; Sipahi, C.; Pişkin, B.; Gokce, H.S. Annealing of Co-Cr dental alloy: Effects on nanostructure and Rockwell hardness. J. Adv. Prosthodont. 2013, 5, 471–478. [Google Scholar] [CrossRef]

- Qian, B.; Saeidi, K.; Kvetková, L.; Lofaj, F.; Xiao, C.; Shen, Z. Defects-tolerant Co-Cr-Mo dental alloys prepared by selective laser melting. Dent. Mater. 2015, 31, 1435–1444. [Google Scholar] [CrossRef]

- Lee, H.W.; Jung, K.-H.; Hwang, S.-K.; Kang, S.-H.; Kim, D.-K. Microstructure and mechanical anisotropy of CoCrW alloy processed by selective laser melting. Mater. Sci. Eng. A 2019, 749, 65–73. [Google Scholar] [CrossRef]

- Kalpakjian, S.; Schmid, S.R. Manufacturing Engineering, 6th ed.; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2009; ISBN 978-9810681449. [Google Scholar]

- Tobolski, E.L.; Fee, A. ASM Handbook: Mechanical Testing and Evaluation; ASM International: Materials Park, OH, USA, 2000; Volume 8, ISBN 0-87170-389-0. [Google Scholar]

- Wang, Q.; Eltit, F.; Wang, R. Corrosion of Orthopedic Implants. In Encyclopedia of Biomedical Engineering; Elsevier BV: Amsterdam, The Netherlands, 2019; pp. 65–85. [Google Scholar]

- Norman, P.; Iyengar, S.; Svensson, I.; Flivik, G. Fatigue fracture in dual modular revision total hip arthroplasty stems. J. Arthroplast. 2014, 29, 850–855. [Google Scholar] [CrossRef]

- Wang, Q.; Parry, M.; Masri, A.B.; Duncan, C.; Wang, R. Failure mechanisms in CoCrMo modular femoral stems for revision total hip arthroplasty. J. Biomed. Mater. Res. Part B Appl. Biomater. 2016, 105, 1525–1535. [Google Scholar] [CrossRef]

- Esmailzadeh, S.; Aliofkhazraei, M.; Sarlak, H. Interpretation of cyclic potentiodynamic polarization test results for study of corrosion behavior of metals: A review. Prot. Met. Phys. Chem. Surfaces 2018, 54, 976–989. [Google Scholar] [CrossRef]

- Diaz, I.; Martinez-Lerma, J.; Montoya, R.; Llorente, I.; Escudero, M.; Garcia-Alonso, M.C. Study of overall and local electrochemical responses of oxide films grown on CoCr alloy under biological environments. Bioelectrochemistry 2017, 115, 1–10. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schweitzer, P.A. Fundamentals of Corrosion-Mechanisms, Causes, and Preventative Methods; CRC Press: Boca Raton, FL, USA, 2013; Volume 53, ISBN 9788578110796. [Google Scholar]

| Brand Name | Manufacturer | Co | Cr | W | Mo | Si | Mn | Fe | ISO 22674 Type | Used in Technique |

|---|---|---|---|---|---|---|---|---|---|---|

| Heraenium Pw | Kulzer GmbH, Germany | 55.2 | 24 | 15 | 4 | 1 | 0.8 | 4 | 4 | CAST |

| Starbond Easy Powder 30+ | S and S Scheftner GmbH, Germany | 61 | 27.5 | 8.5 | - | 1.6 | <1 | <1 | 4 | LDED |

| Kera®-Disc | Eisenbacher Dentalwaren ED GmbH, Germany | 61.65 | 27.75 | 8.45 | - | - | 0.25 | 0.2 | 4 | MILL |

| EOS CobaltChrome SP2 | EOS GmbH, Germany | 63.8 | 24.7 | 5.4 | 5.1 | 1 | 0.1 | 0.5 | 4 | SLM |

| Firing Process | Preheating Temperature (°C) | Drying Time (min) | Raise of Temperature (°C/min) | Vacuum | Final Temperature (°C) | Holding Time (min) | Total Approx. Time (min) |

|---|---|---|---|---|---|---|---|

| Bonding | 650 | 6 | 55 | Yes | 980 | 1 | 15 |

| Opaquer 1 | 550 | 6 | 80 | Yes | 940 | 1 | 15 |

| Opaquer 2 | 550 | 6 | 80 | Yes | 940 | 1 | 15 |

| Dentin 1 | 580 | 6 | 55 | Yes | 900 | 1 | 18 |

| Dentin 2 | 580 | 6 | 55 | Yes | 900 | 1 | 18 |

| Glaze | 600 | 2 | 55 | Yes | 860 | 1 | 17 |

| Technique | PFM Firing | Zone | Co | Cr | W | Mo | Si, Fe and Others |

|---|---|---|---|---|---|---|---|

| CAST | Before | 1 | 49.27 | 24.67 | 16.94 | 0.62 | 8.50 |

| CAST | Before | 2 | 36.54 | 26.98 | 28.05 | 1.04 | 7.39 |

| CAST | Before | 3 | 33.06 | 19.12 | 35.74 | 3.24 | 8.84 |

| CAST | After | 1 | 51.44 | 22.22 | 15.93 | 0.56 | 9.84 |

| CAST | After | 2 | 34.95 | 24.69 | 26.87 | 0.54 | 12.95 |

| CAST | After | 3 | 31.27 | 15.11 | 34.92 | 3.01 | 15.69 |

| LDED | Before | 1 | 57.01 | 27.27 | 9.95 | 0.59 | 5.18 |

| LDED | Before | 2 | 38.7 | 27.36 | 19.77 | 3.36 | 10.81 |

| LDED | Before | 3 | - | - | - | - | - |

| LDED | After | 1 | 53.21 | 27.66 | 14.8 | 0 | 4.33 |

| LDED | After | 2 | 41.52 | 30.16 | 20.71 | 1.55 | 6.06 |

| LDED | After | 3 | 42.45 | 24.21 | 25.62 | 1.04 | 6.68 |

| MILL | Before | 1 | 57.14 | 27.98 | 10.21 | 0.73 | 3.94 |

| MILL | Before | 2 | 39.99 | 33.12 | 21.33 | 0.63 | 4.93 |

| MILL | Before | 3 | 27.18 | 16.47 | 47.01 | 1.22 | 8.12 |

| MILL | After | 1 | 58.54 | 26.26 | 9.79 | 0.58 | 4.83 |

| MILL | After | 2 | 41.09 | 33.97 | 16.65 | 0.57 | 7.72 |

| MILL | After | 3 | 47.19 | 23.6 | 20.69 | 0.57 | 7.95 |

| SLM | Before | 1 | 61.09 | 26.17 | 5.15 | 5.40 | 2.19 |

| SLM | Before | 2 | 41.4 | 18.04 | 17.02 | 18.5 | 5.04 |

| SLM | Before | 3 | - | - | - | - | - |

| SLM | After | 1 | 59.57 | 23.8 | 7.13 | 6.50 | 3.01 |

| SLM | After | 2 | 40.09 | 16.59 | 18.65 | 16.84 | 7.83 |

| SLM | After | 3 | - | - | - | - | - |

| Technique | PFM Firing | Phase | Area-Weighted Average Grain Size (µm) | Phase Area Fraction (%) |

|---|---|---|---|---|

| CAST | Before | γ-FCC | 371.76 (107.84) | 99.95% |

| CAST | Before | ε-HCP | 1.10 (0.21) | 0.05% |

| CAST | After | γ-FCC | 337.47 (104.98) | 100.00% |

| CAST | After | ε-HCP | - | 0.00% |

| LDED | Before | γ-FCC | 289.13 (79.84) | 89.10% |

| LDED | Before | ε-HCP | 16.35 (14.25) | 10.90% |

| LDED | After | γ-FCC | 317.54 (108.15) | 100.00% |

| LDED | After | ε-HCP | - | 0.00% |

| MILL | Before | γ-FCC | 17.40 (9.93) | 77.73% |

| MILL | Before | ε-HCP | 27.12 (23.97) | 22.27% |

| MILL | After | γ-FCC | 29.13 (19.00) | 87.91% |

| MILL | After | ε-HCP | 20.78 (12.89) | 12.09% |

| SLM | Before | γ-FCC | 23.84 (16.77) | 93.05% |

| SLM | Before | ε-HCP | 11.15 (6.06) | 6.95% |

| SLM | After | γ-FCC | 3.62 (1.71) | 0.20% |

| SLM | After | ε-HCP | 9.90 (5.74) | 99.80% |

| Technique | PFM Firing | Yield Strength 0.2% (MPa) | Ultimate Tensile Strength (MPa) | Young Modulus (GPa) | Modulus of Toughness (MJ/m3) | Enlongati-on After Fracture (%) | Microhardness (HV) |

|---|---|---|---|---|---|---|---|

| CAST | Before | 506 (57) | 697 (52) | 229 (17) | 57 (10.9) | 7.0 (1.31) | 304 (5) |

| CAST | After | 505 (15) | 690 (30) | 220 (7) | 49 (11.8) | 8.6 (1.47) | 296 (16) |

| LDED | Before | 425 (43) | 842 (41) | 223 (13) | 113 (16.6) | 15.3 (1.7) | 308 (5) |

| LDED | After | 406 (22) | 810 (34) | 239 (3) | 107 (17.5) | 14.3 (1.81) | 322 (10) |

| MILL | Before | 454 (23) | 868 (28) | 244 (7) | 132 (19.9) | 15.6 (1.81) | 272 (21) |

| MILL | After | 428 (34) | 829 (24) | 242 (4) | 112 (12.3) | 13.2 (0.59) | 269 (23) |

| SLM | Before | 679 (88) | 1296 (17) | 236 (16) | 62 (4.0) | 3.6 (0.28) | 440 (17) |

| SLM | After | 965 (37) | 1548 (24) | 247 (5) | 59 (6.3) | 2.1 (0.52) | 529 (10) |

| Electrolytic Medium | Manufacturing Technique | Ecorr (mV vs SCE) | icorr (nA/cm2) | Corrosion Rate (μm/year) | Eb (mV vs SCE) |

|---|---|---|---|---|---|

| Aerated | CAST | −88 | 122 | 1.3 | 667 |

| LDED | 30 | 76 | 0.8 | 644 | |

| MILL | 82 | 365 | 4.0 | 652 | |

| SLM | 36 | 107 | 1.2 | 666 | |

| Deaerated | CAST | −208 | 58 | 0.6 | 593 |

| LDED | −328 | 11 | 0.1 | 650 | |

| MILL | −341 | 8 | 0.1 | 578 | |

| SLM | −298 | 9 | 0.1 | 628 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barro, Ó.; Arias-González, F.; Lusquiños, F.; Comesaña, R.; del Val, J.; Riveiro, A.; Badaoui, A.; Gómez-Baño, F.; Pou, J. Effect of Four Manufacturing Techniques (Casting, Laser Directed Energy Deposition, Milling and Selective Laser Melting) on Microstructural, Mechanical and Electrochemical Properties of Co-Cr Dental Alloys, Before and After PFM Firing Process. Metals 2020, 10, 1291. https://doi.org/10.3390/met10101291

Barro Ó, Arias-González F, Lusquiños F, Comesaña R, del Val J, Riveiro A, Badaoui A, Gómez-Baño F, Pou J. Effect of Four Manufacturing Techniques (Casting, Laser Directed Energy Deposition, Milling and Selective Laser Melting) on Microstructural, Mechanical and Electrochemical Properties of Co-Cr Dental Alloys, Before and After PFM Firing Process. Metals. 2020; 10(10):1291. https://doi.org/10.3390/met10101291

Chicago/Turabian StyleBarro, Óscar, Felipe Arias-González, Fernando Lusquiños, Rafael Comesaña, Jesús del Val, Antonio Riveiro, Aida Badaoui, Félix Gómez-Baño, and Juan Pou. 2020. "Effect of Four Manufacturing Techniques (Casting, Laser Directed Energy Deposition, Milling and Selective Laser Melting) on Microstructural, Mechanical and Electrochemical Properties of Co-Cr Dental Alloys, Before and After PFM Firing Process" Metals 10, no. 10: 1291. https://doi.org/10.3390/met10101291

APA StyleBarro, Ó., Arias-González, F., Lusquiños, F., Comesaña, R., del Val, J., Riveiro, A., Badaoui, A., Gómez-Baño, F., & Pou, J. (2020). Effect of Four Manufacturing Techniques (Casting, Laser Directed Energy Deposition, Milling and Selective Laser Melting) on Microstructural, Mechanical and Electrochemical Properties of Co-Cr Dental Alloys, Before and After PFM Firing Process. Metals, 10(10), 1291. https://doi.org/10.3390/met10101291