Design of Wear-Resistant Diecast AlSi9Cu3(Fe) Alloys for High-Temperature Components

Abstract

1. Introduction

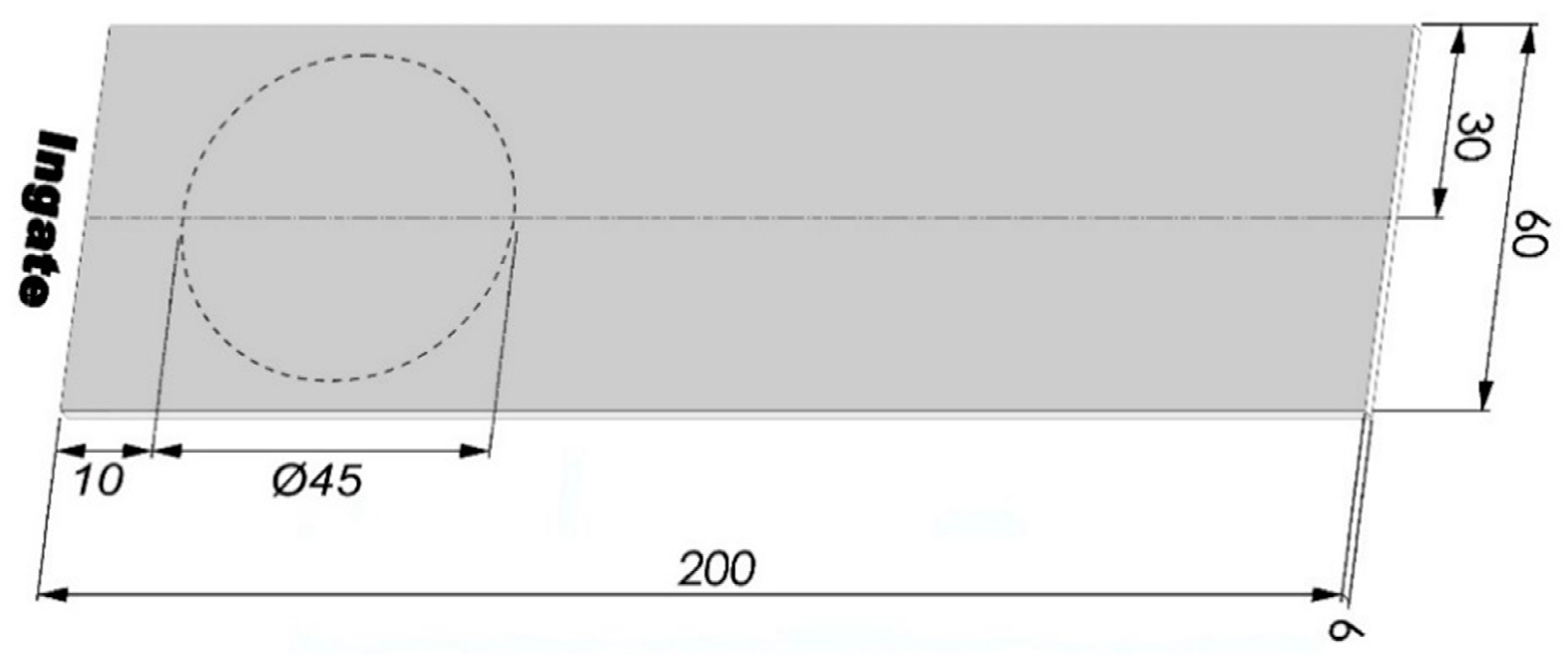

2. Materials and Methods

2.1. Experimental Alloys and Casting Parameters

2.2. Wear Testing

2.3. Hardness and Nanoindentation Measurements

2.4. Microstructural Investigations

3. Results and Discussion

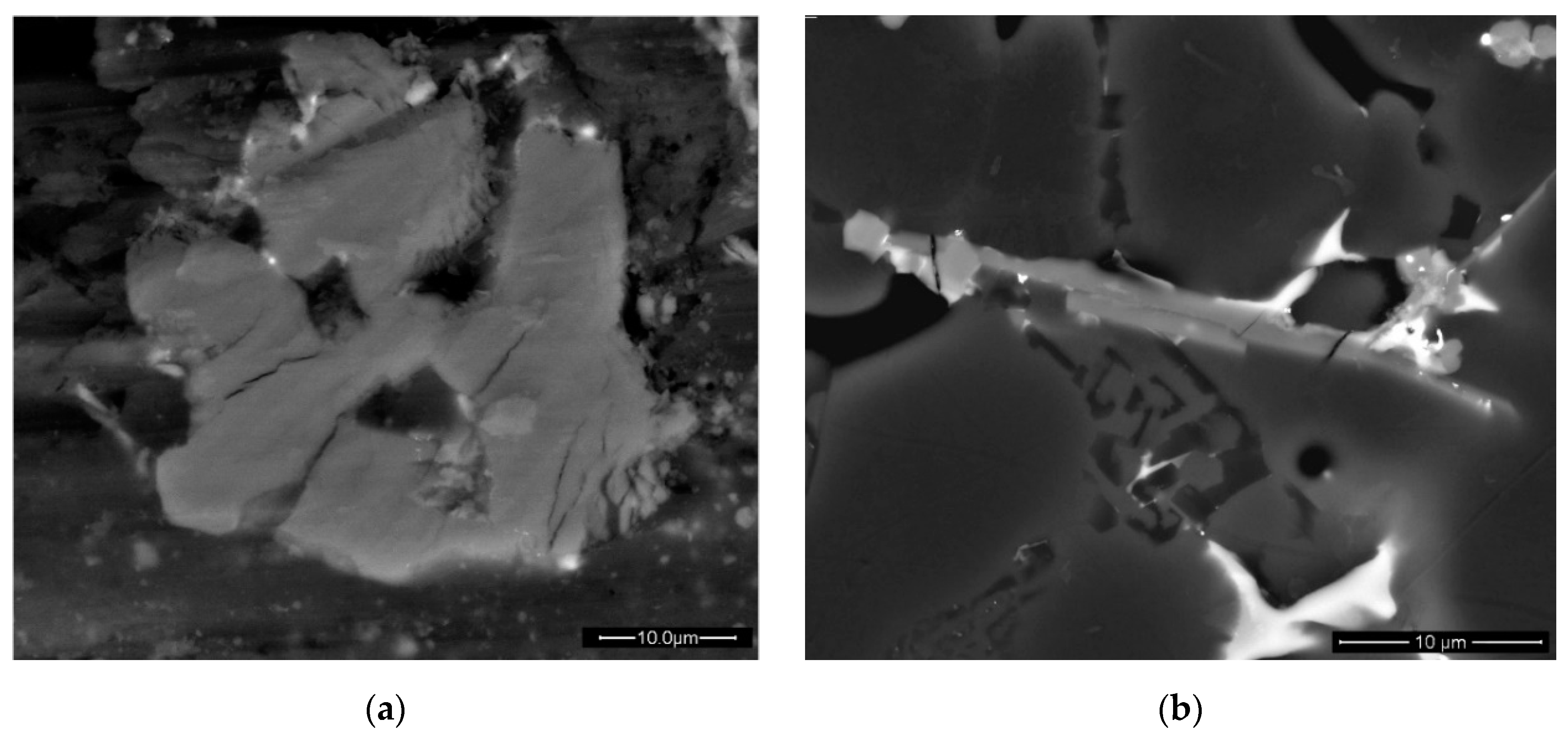

3.1. Microstructural Analysis

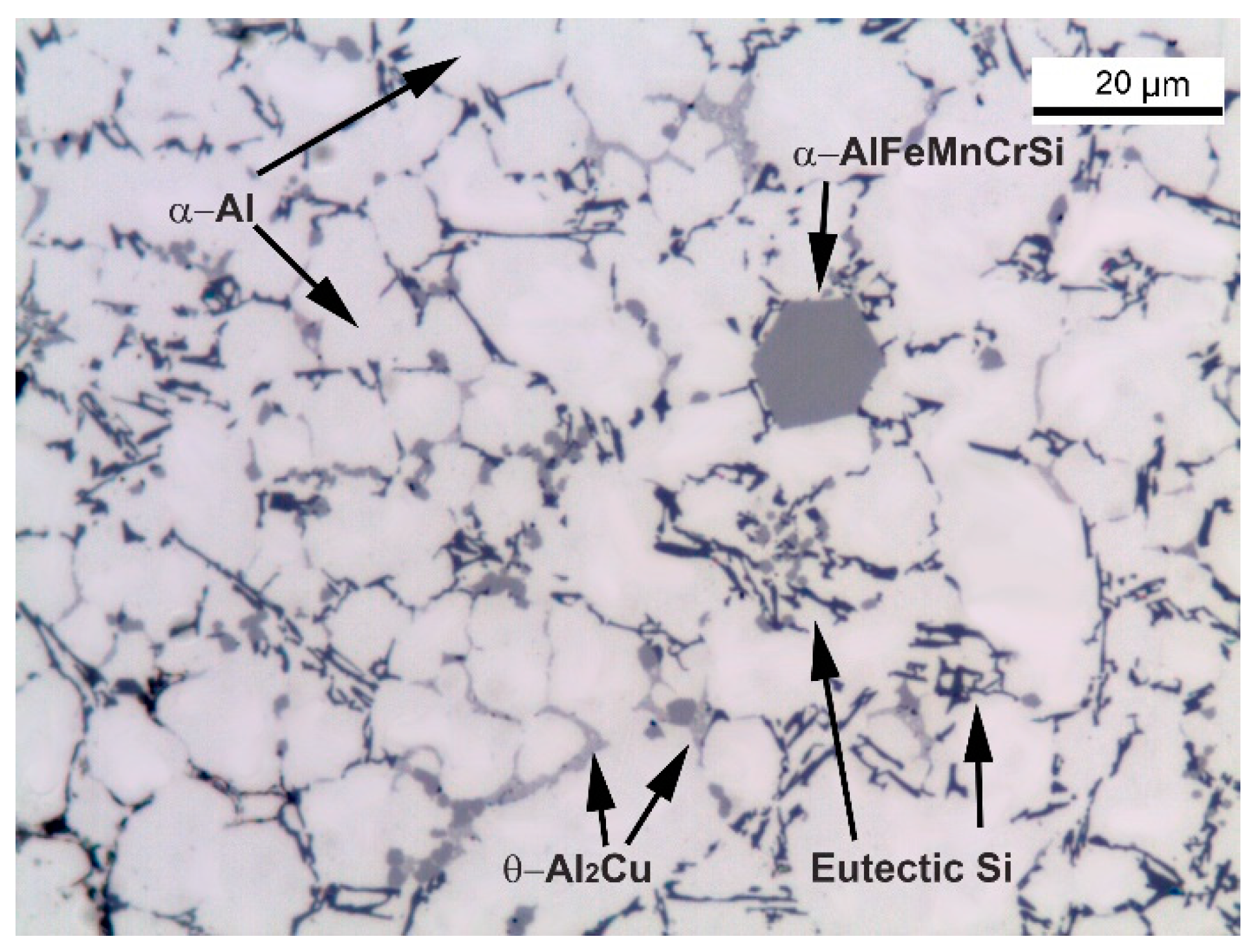

3.1.1. Diecast AlSi9Cu3(Fe) Alloy

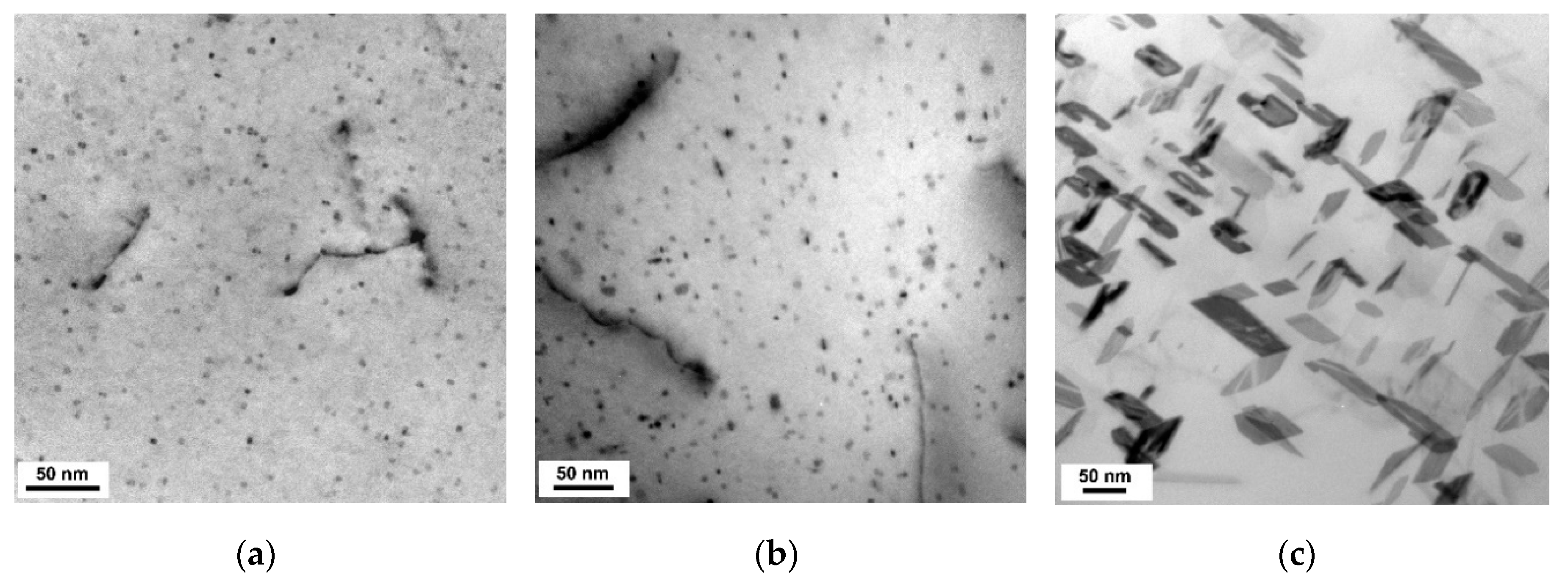

3.1.2. Influence of High Temperature on the Microstructure

3.1.3. Influence of Iron, Manganese, and Chromium on the Microstructure

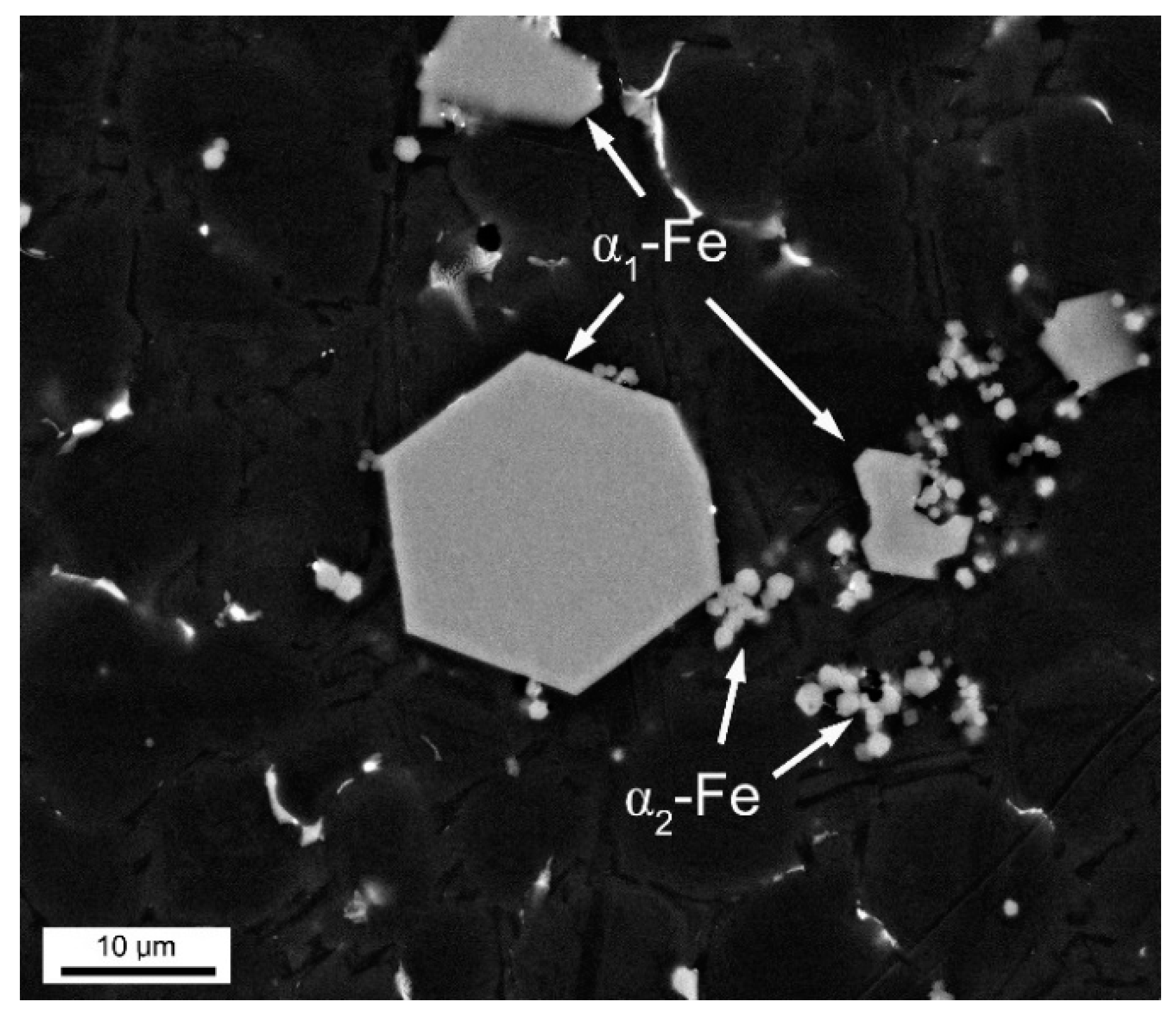

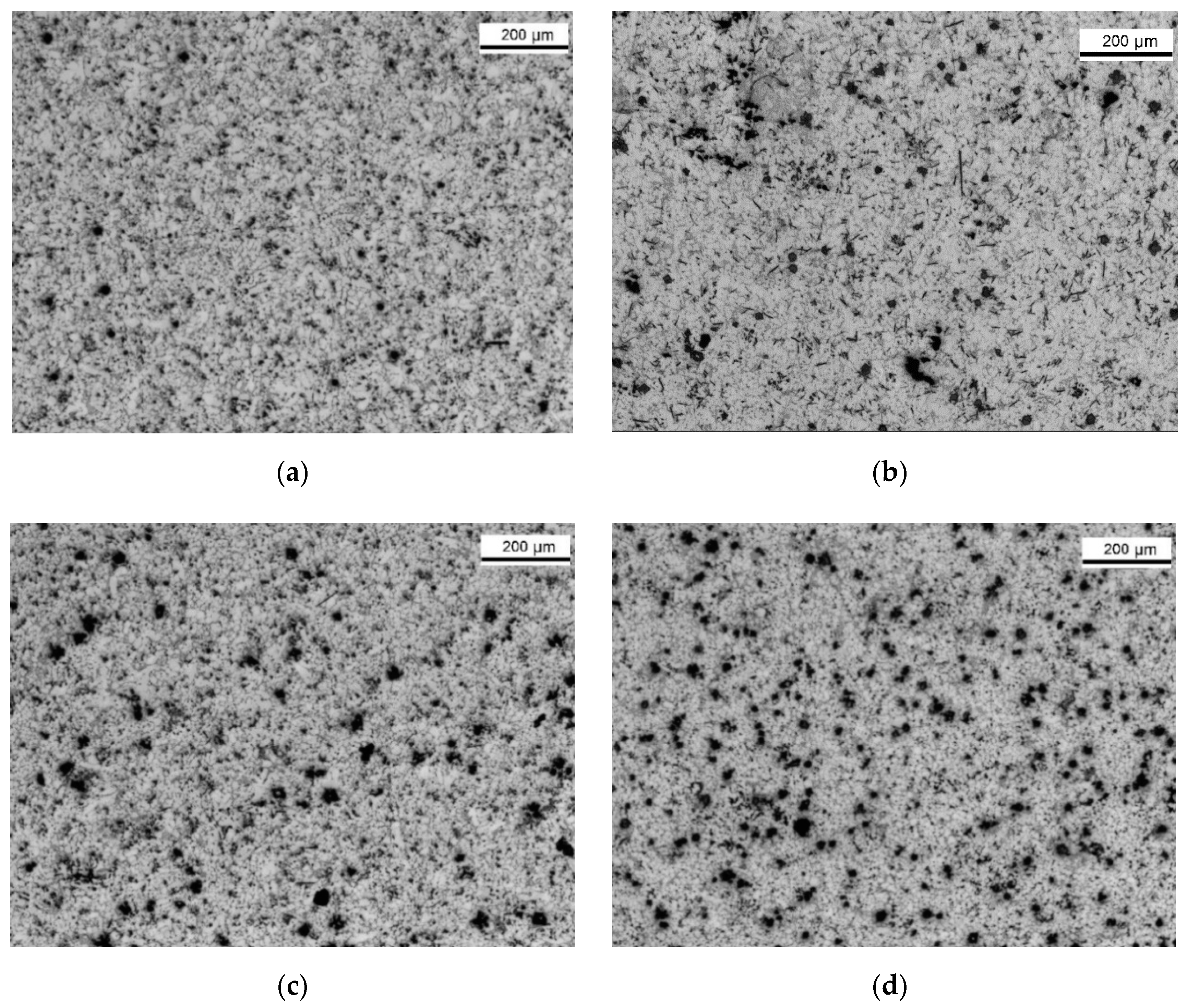

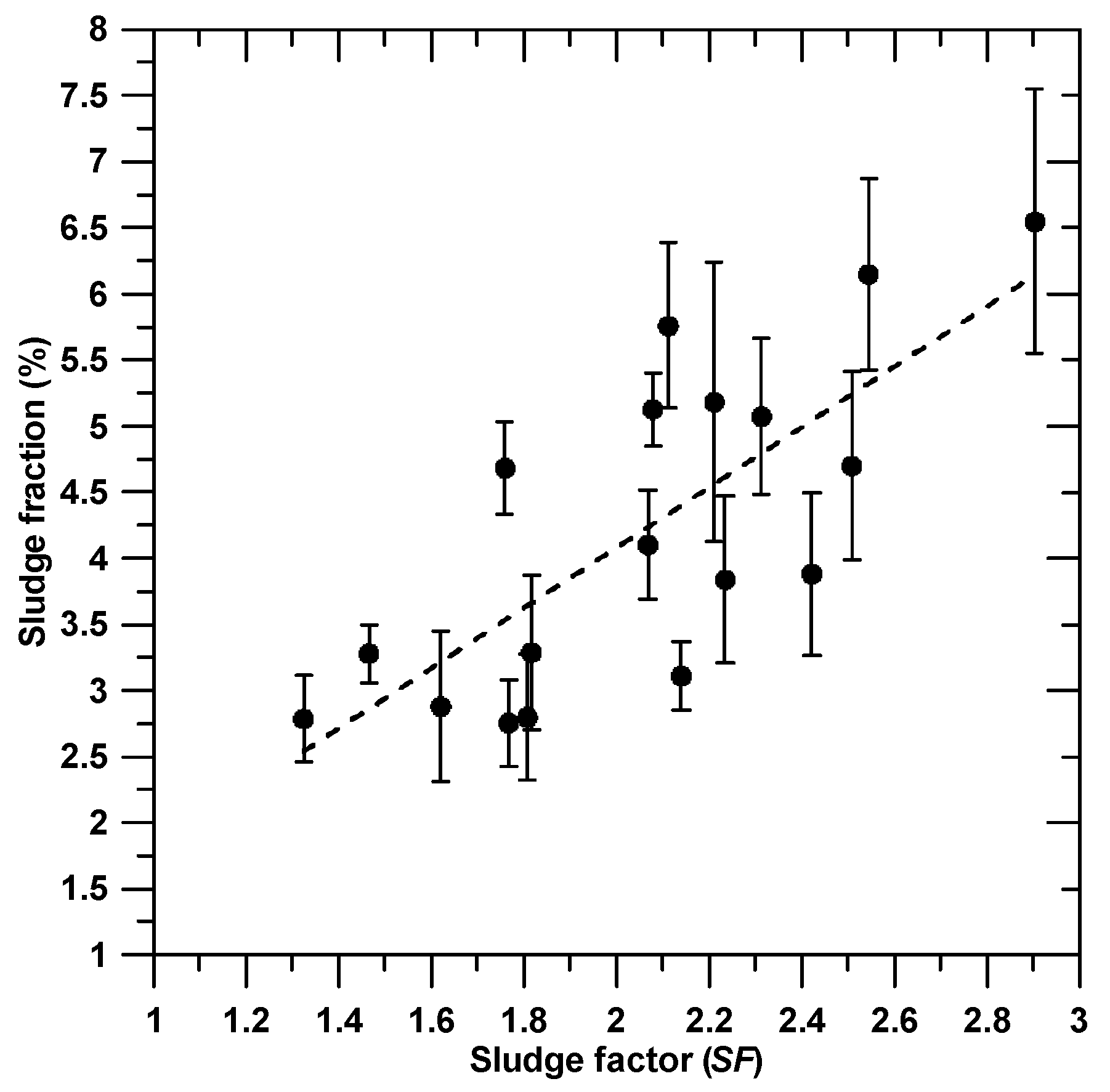

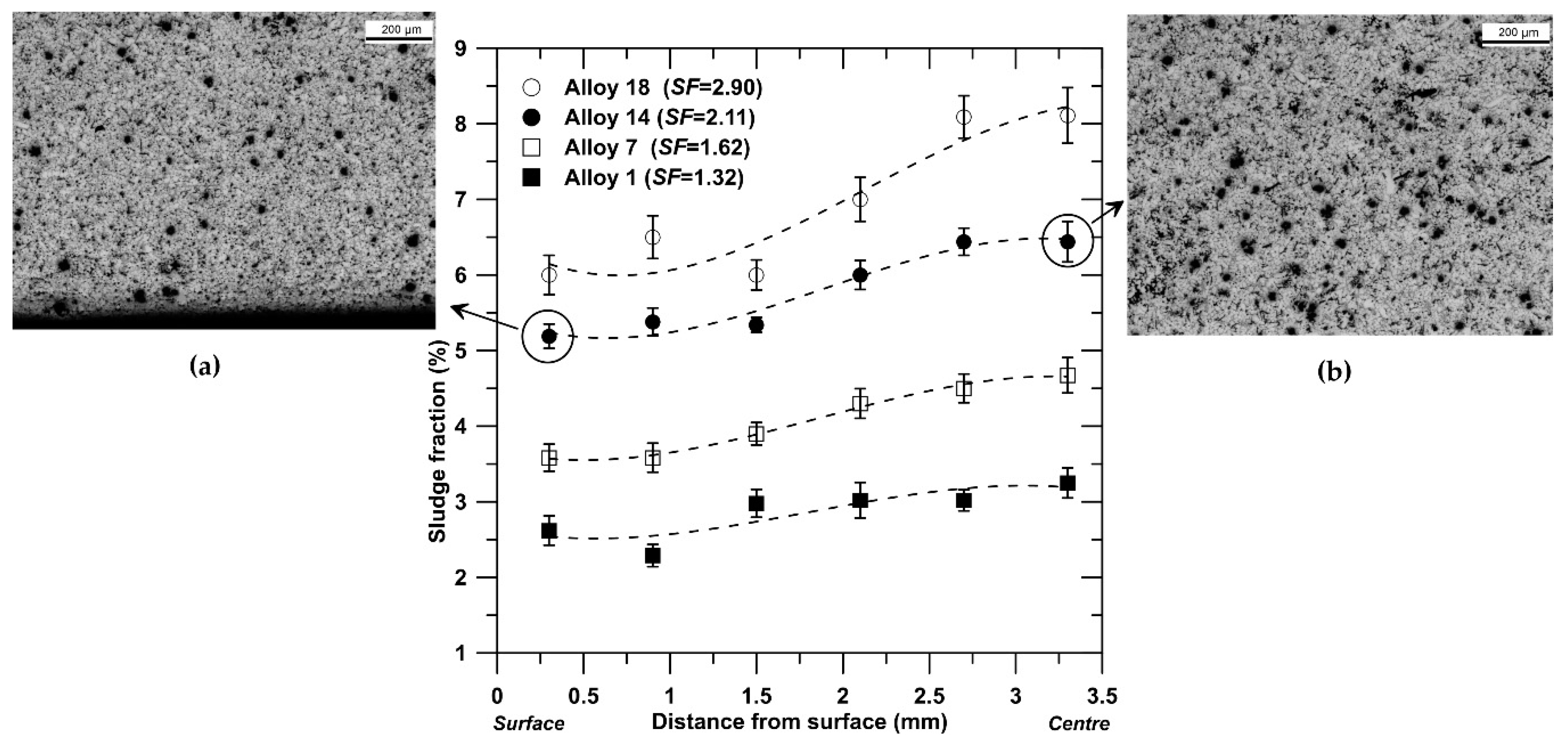

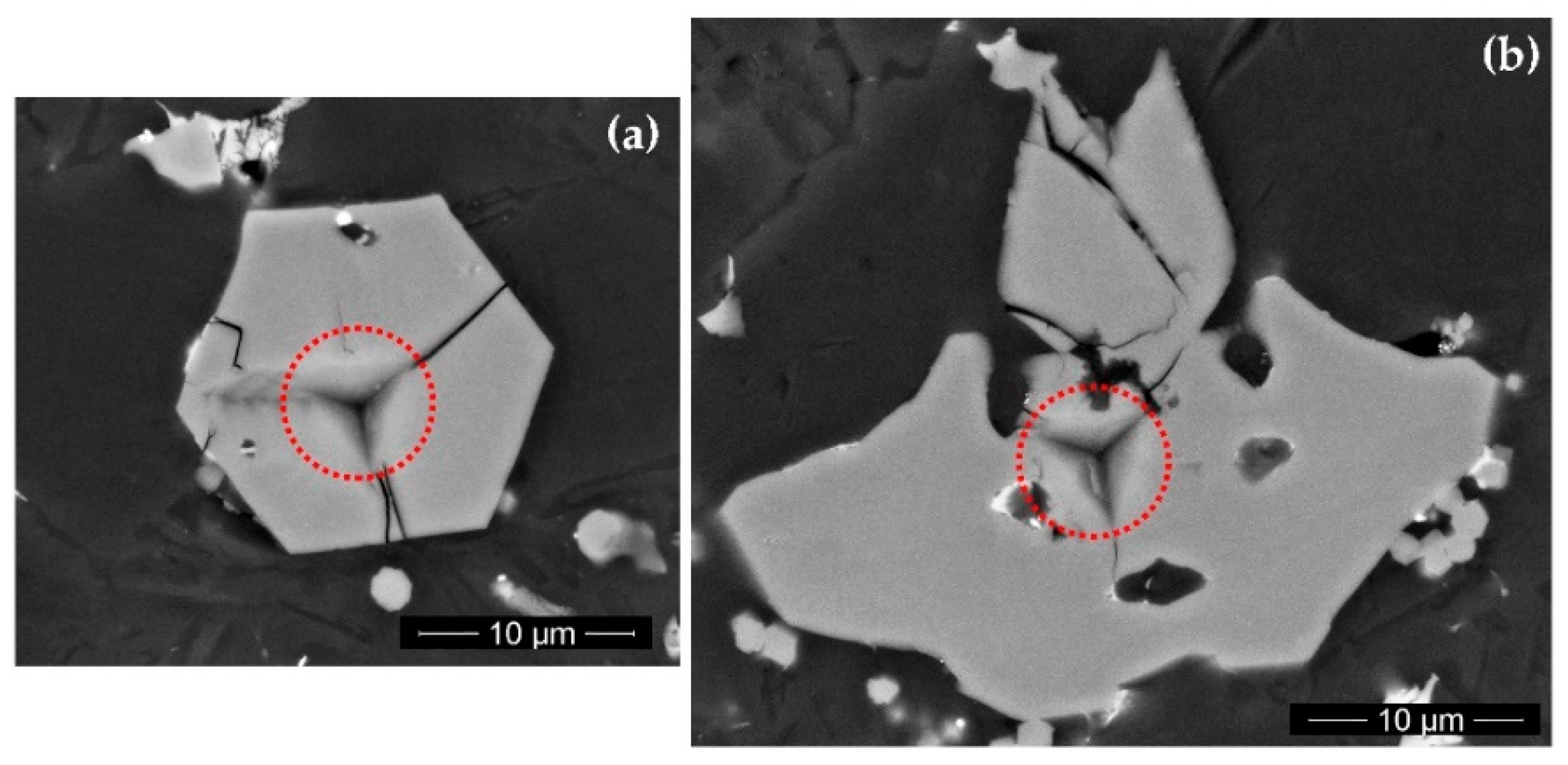

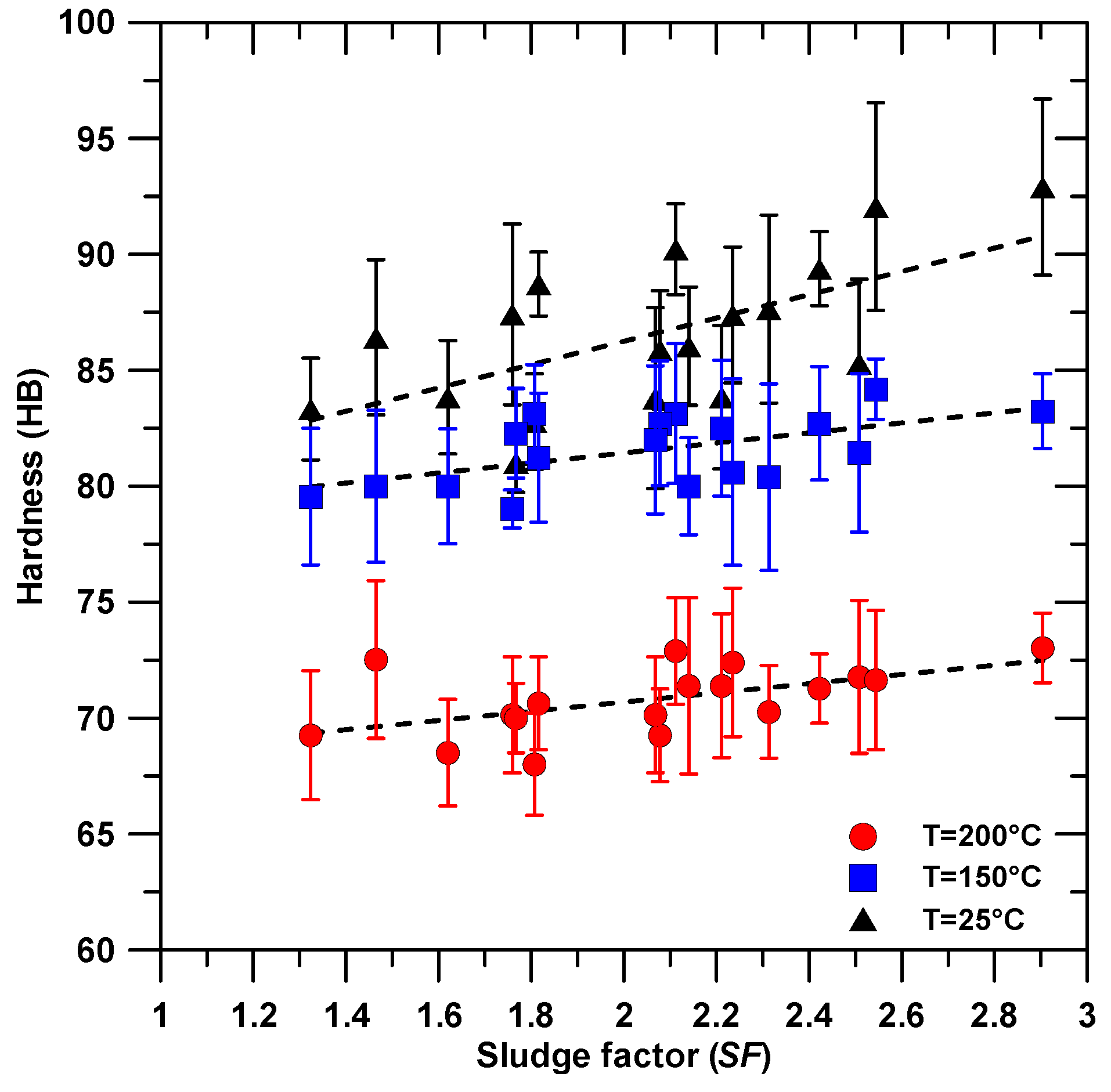

3.2. Hardness and Nanoindentation

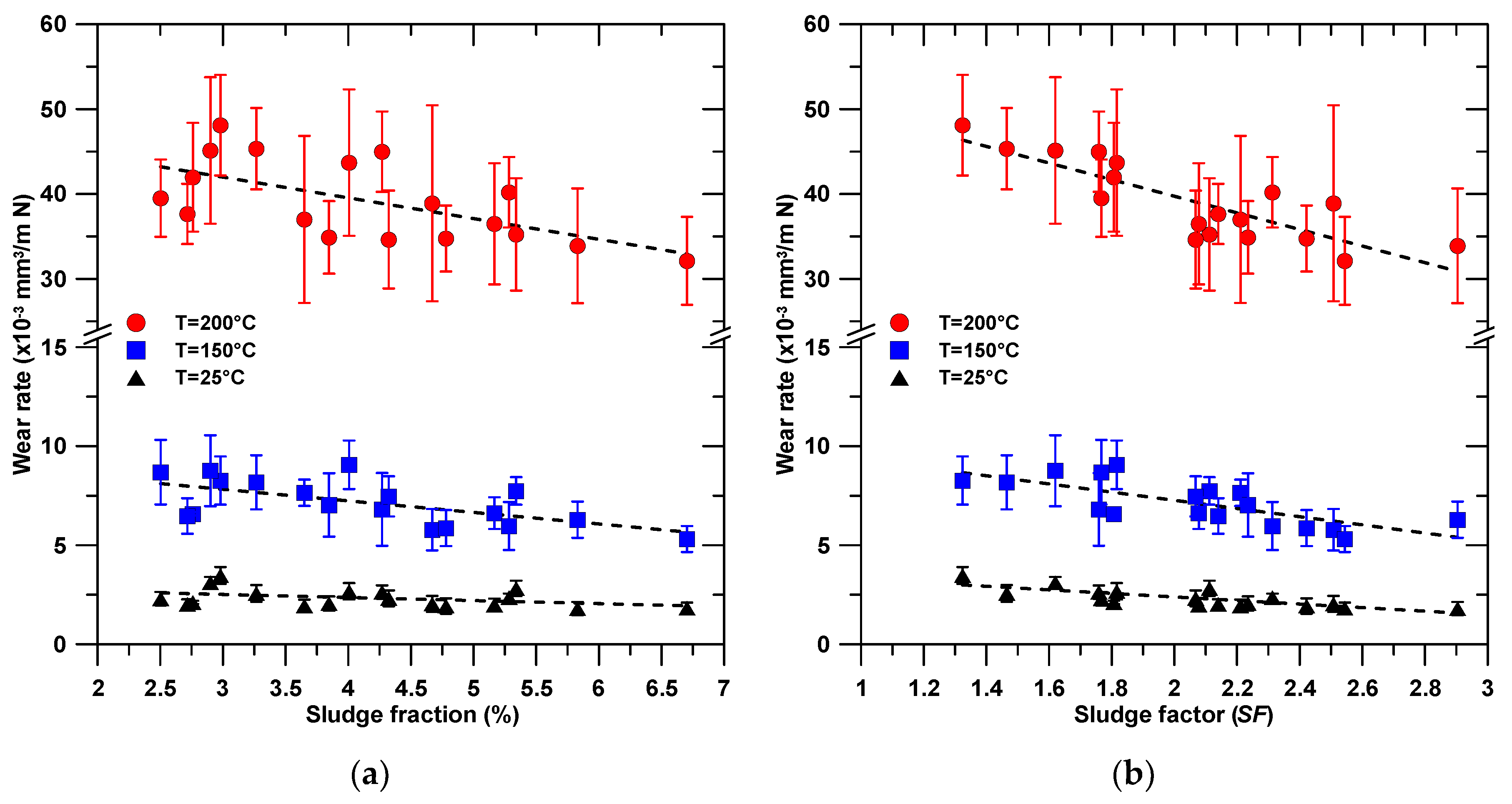

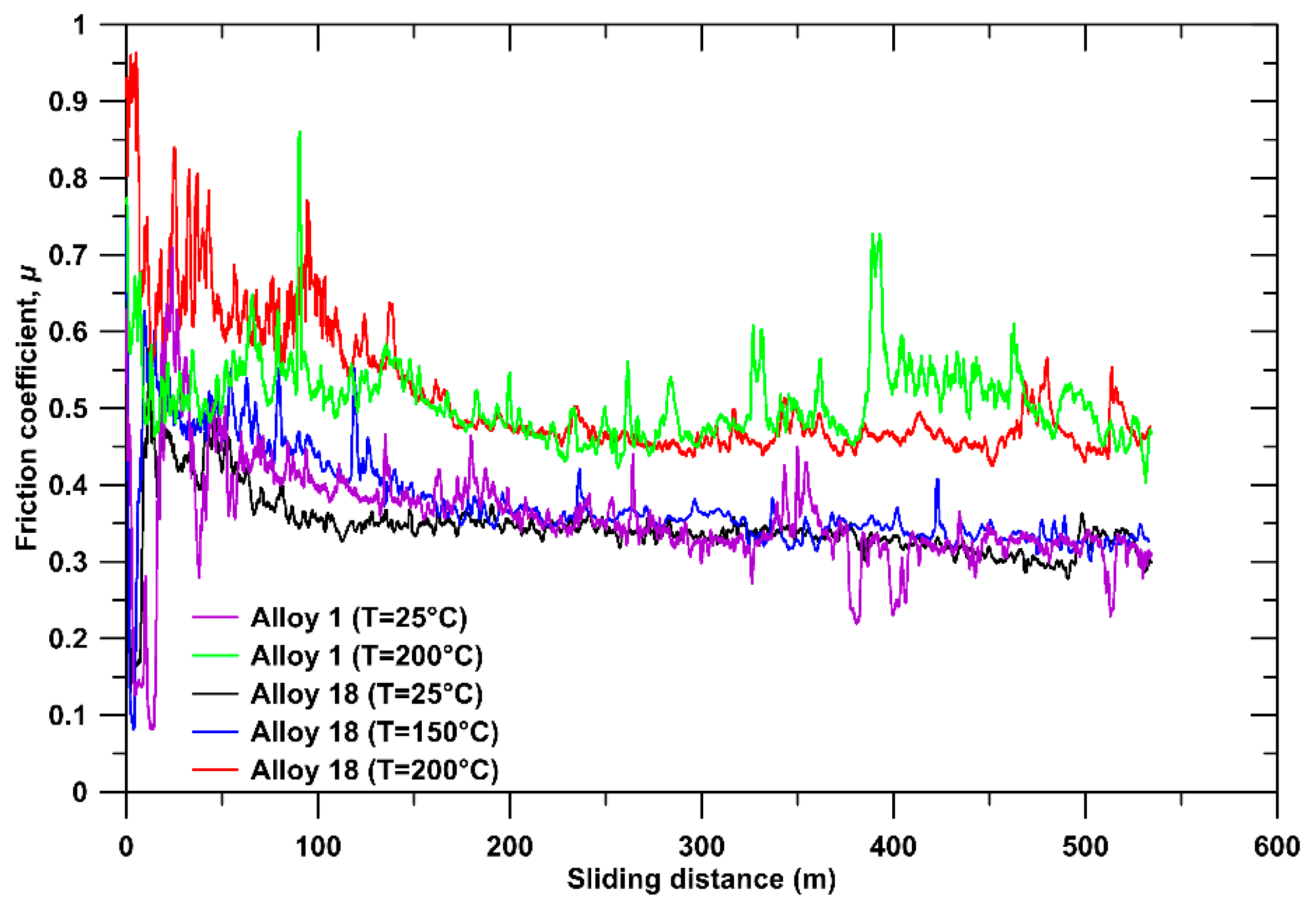

3.3. Wear Behaviour

4. Conclusions

- The microstructure reveals primary α-Fe particles with star-like and polyhedral morphologies. At higher Fe:Mn ratio, needle-like β-Fe phase appears too.

- The contents of primary Fe-rich compounds (sludge), as well as secondary Fe-rich particles, increase by increasing the Fe, Mn, and Cr contents in the alloy.

- Sludge particles show high hardness and reduced modulus, which are not affected by the initial contents of Fe, Mn, and Cr in the alloy; in addition, the different sludge morphology does not cause any variation in the hardness behavior.

- At high temperatures, the experimental AlSi9Cu3(Fe) alloys show lower average hardness, especially at 200 °C; however, greater sludge fraction leads to higher hardness values.

- The wear rate decreases progressively with the amount of sludge particles, and this behavior is even more pronounced by increasing the temperature during testing. This feature is correlated to the hardening effect of the α-Fe phase that helps the Al-matrix to support the load.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rajaram, G.; Kumaran, S.; Srinivasa Rao, T. High temperature tensile and wear behaviour of aluminum silicon alloy. Mater. Sci. Eng. A 2010, 528, 247–253. [Google Scholar] [CrossRef]

- Slattery, B.E.; Perry, T.; Edrisya, A. Microstructural evolution of a eutectic Al-Si engine subjected to severe running conditions. Mater. Sci. Eng. A 2009, 512, 76–81. [Google Scholar] [CrossRef]

- Slattery, B.E.; Edrisya, A.; Perry, T. Investigation of wear induced surface and subsurface deformation in a linerless Al-Si engine. Wear 2010, 269, 298–309. [Google Scholar] [CrossRef]

- Abouei, V.; Saghafian, H.; Shabestari, S.G.; Zarghami, M. Effect of Fe-rich intermetallics on the wear behavior of eutectic Al-Si piston alloy (LM13). Mater. Design 2010, 31, 3518–3524. [Google Scholar] [CrossRef]

- Zhang, J.; Alpas, A.T. Transition between mild and severe wear in aluminium alloys. Acta Mater. 1997, 45, 513–528. [Google Scholar] [CrossRef]

- Pauschitz, A.; Roy, M.; Franek, F. Mechanisms of sliding wear of metals and alloys at elevated temperatures. Tribol. Int. 2008, 41, 584–602. [Google Scholar] [CrossRef]

- Culliton, D.; Betts, A.J.; Kennedy, D. Impact of intermetallic precipitates on the tribological and/or corrosion performance of cast aluminium alloys: a short review. Int. J. Cast Metal. Res. 2013, 26, 65–71. [Google Scholar] [CrossRef]

- Lee, K.Y.; Lee, S.L.; Wu, C.T.; Chen, W.C.; Lin, J.C. Effects of T6 heat treatment on thermal stability and wear behaviour of Al-12.5Si-4.5Cu-1.0Mg alloy. Mater. Sci. Technol. 2012, 28, 639–643. [Google Scholar] [CrossRef]

- Tomida, S.; Nakata, K.; Shibata, S.; Zenkouji, I.; Saji, S. Improvement in wear resistance of hyper-eutectic Al-Si cast alloy by laser surface remelting. Surf. Coat. Tech. 2003, 169–170, 468–471. [Google Scholar] [CrossRef]

- Taghiabadi, R.; Ghasemi, H.M.; Shabestari, S.G. Effect of iron-rich intermetallics on the sliding wear behaviour of Al-Si alloys. Mater. Sci. Eng. A 2008, 490, 162–170. [Google Scholar] [CrossRef]

- Makhlouf, M.M.; Apelian, D.; Wang, L. Microstructure and Properties of Aluminium Die Casting Alloys, 1st ed.; North American Die Casting Association: Rosemont, IL, USA, 1998. [Google Scholar]

- Dhiman, M.; Dwivedi, D.K.; Sehgal, R.; Bhat, I.K. Effect of iron (wt.%) on adhesive wear response of Al-12Si-1Cu-0.1Mg alloy in dry sliding conditions. Trans. Indian Inst. Met. 2008, 61, 451–456. [Google Scholar] [CrossRef]

- Cao, X.; Campbell, J. Morphology of β-Al5FeSi Phase in Al-Si Cast Alloys. Mater. Trans. 2006, 47, 1303–1312. [Google Scholar] [CrossRef]

- Mahta, M.; Emamy, M.; Cao, X.; Campbell, J. Overview of β-Al5FeSi Phase in Al-Si Alloys; Nova Science Publisher: New York, NY, USA, 2008; pp. 251–271. [Google Scholar]

- Timelli, G.; Fiorese, E. Methods to neutralize the effects of iron in Al-Si foundry alloys. Metall. Ital. 2011, 103, 9–23. [Google Scholar]

- Timelli, G.; Bonollo, F. The influence of Cr content on the microstructure and mechanical properties of AlSi9Cu3(Fe) die-casting alloys. Mater. Sci. Eng. A 2010, 528, 273–282. [Google Scholar] [CrossRef]

- Zahedi, H.; Emamy, M.; Razaghian, A.; Mahta, M.; Campbell, J.; Tiryakioğlu, M. The effect of Fe-rich intermetallics on the weibull distribution of tensile properties in a cast Al-5 Pct Si-3 Pct Cu-1 Pct Fe-0.3 Pct Mg alloy. Metall. Mater. Trans. A 2007, 38, 659–670. [Google Scholar] [CrossRef]

- Timelli, G.; Capuzzi, S.; Fabrizi, A. Precipitation of primary Fe-rich compounds in secondary AlSi9Cu3(Fe) alloys. J. Therm. Anal. Calorim. 2016, 123, 249–262. [Google Scholar] [CrossRef]

- Bidmeshki, C.; Aboudei, V.; Saghafian, H.; Shabestari, S.G.; Noghani, M.T. Effect of Mn addition on Fe-rich intermetallics morphology and dry sliding wear investigation of hypereutectic Al-17.5%Si alloy. J. Mater. Res. Technol. 2016, 5, 250–258. [Google Scholar] [CrossRef]

- Cao, X.; Campbell, J. Effect of precipitation of primary intermetallic compounds on mechanical properties of cast Al-11.5Si-0.4Mg alloy. AFS Trans. 2000, 108, 391–400. [Google Scholar]

- Cao, X.; Campbell, J. The nucleation of Fe-rich phases on oxide films in Al-11.5Si-0.4Mg cast alloys. Metall. Mater. Trans. A 2003, 34, 1409–1420. [Google Scholar] [CrossRef]

- Gobrecht, J. Settling-out of Fe, Mn and Cr in Al-Si casting alloys. Giesserei 1975, 62, 263–266. [Google Scholar]

- Jorstad, J.L. Understanding sludge. Die Cast. Eng. 1986, 30, 30–36. [Google Scholar]

- Irish Standard, EN 1706:2010. Aluminium and Aluminium Alloys—Castings-Chemical Composition and Mechanical Properties; CEN–Comité Européen de Normalisation: Brussel, Belgium, 2007. [Google Scholar]

- Timelli, G.; Ferraro, S.; Grosselle, F.; Bonollo, F.; Voltazza, F.; Capra, L. Mechanical and microstructural characterization of diecast aluminium alloys. Metall. Ital. 2011, 103, 5–17. [Google Scholar]

- Timelli, G.; Grosselle, F.; Voltazza, F.; Della Corte, E. A new reference die for mechanical properties evaluation in diecasting, Part 1—Design and process optimization. In Proceedings of the 4th International Conference High Tech Die Casting (HTDC2008), Montichiari (BS), Italy, 9–10 April 2008; Italian Association of Metallurgy (AIM): Milan, Italy, 2008. [Google Scholar]

- ASTM E10-15a. Standard Test Method for Brinell Hardness of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Ferraro, S.; Fabrizi, A.; Timelli, G. Evolution of sludge particles in secondary die-cast aluminum alloys as function of Fe, Mn and Cr contents. Mater. Chem. Phys. 2015, 153, 168–179. [Google Scholar] [CrossRef]

- Flemings, M.C. Behavior of metal alloys in the semisolid state. Metall. Trans. A 1991, 22A, 957–981. [Google Scholar] [CrossRef]

- Bäckerud, L.; Chai, G.; Tamminen, J. Solidification Characteristics of Aluminum Alloys, 1st ed.; American Foundrymen’s Society Inc.: Des Plaines, IL, USA, 1990; Volume 2, pp. 201–204. [Google Scholar]

- Helenius, R.; Lohne, O.; Arnberg, L.; Laukli, H.I. The heat transfer during filling of a high-pressure die-casting shot sleeve. Mater. Sci. Eng. A 2005, 413-414, 52–55. [Google Scholar] [CrossRef]

- Guo, Z.-P.; Xiong, S.-M.; Liu, B.-C.; Li, M.; Allison, J. Effect of process parameters, casting thickness, and alloys on the interfacial heat-transfer coefficient in the high-pressure die-casting process. Metall. Mater. Trans. A 2008, 39A, 2896–2905. [Google Scholar] [CrossRef]

- Shabestari, S.G. The effect of iron and manganese on the formation of intermetallic compounds in aluminum-silicon alloys. Mater. Sci. Eng. A 2004, 383, 289–298. [Google Scholar] [CrossRef]

- Mondolfo, L.F. Aluminium Alloys: Structure and Properties; Butterworth-Heinemann: Oxford, UK, 1976. [Google Scholar]

- Fabrizi, A.; Ferraro, S.; Timelli, G. The influence of Fe, Mn and Cr additions on the formation of iron-rich intermetallic phases in an Al-Si die-casting alloy. In Shape Casting: 5th International Symposium 2014; Tiryakioğlu, M., Campbell, J., Byczynski, G., Eds.; Minerals, Metals and Materials Society: Warrendale, PA, USA, 2014; pp. 277–284. ISBN 9781118888186. [Google Scholar]

- Timelli, G.; Fabrizi, A.; Capuzzi, S.; Bonollo, F.; Ferraro, S. The role of Cr additions and Fe-rich compounds on microstructural features and impact toughness of AlSi9Cu3(Fe) diecasting alloys. Mater. Sci. Eng. A 2014, 603, 58–68. [Google Scholar] [CrossRef]

- Lombardi, A.; D’Elia, F.; Ravindran, C.; Murty, B.S.; MacKay, R. Analysis of the secondary phases in the microstructure of 319 type Al alloy engine blocks using electron microscopy and nanoindentation. Trans. Indian Inst. Met. 2011, 64, 7–11. [Google Scholar] [CrossRef]

- Chen, C.L.; Richter, A.; Thomson, R.C. Mechanical properties of intermetallic phases in multi-component Al-Si alloys using nanoindentation. Intermetallics 2010, 17, 634–641. [Google Scholar] [CrossRef]

- Fischer-Cripps, A.C. Nanoindentation, 3rd ed.; Springer: New York, NY, USA, 2011. [Google Scholar]

- Ferraro, S.; Timelli, G. Influence of sludge particles on the tensile properties of die-cast secondary aluminum alloys. Metall. Mater. Trans. B 2015, 46, 1022–1034. [Google Scholar] [CrossRef]

- Scott, G.D.; Shabel, B.S.; Morales, A. Aluminum alloy suitable for pistons. U.S. Patent 5162065 10 November 1992. [Google Scholar]

- Cho, Y.-H.; Joo, D.-H.; Kim, C.-H.; Lee, H.-C. The effect of alloy addition on the high temperature properties of over-aged Al-Si(CuNiMg) cast alloys. Mater. Sci. Forum 2006, 519–521, 461–466. [Google Scholar] [CrossRef]

- Qian, Z.; Liu, X.; Zhao, D.; Zhang, G. Effects of trace Mn addition on the elevated temperature tensile strength and microstructure of a low-iron Al–Si piston alloy. Mater. Lett. 2008, 62, 2146–2149. [Google Scholar] [CrossRef]

- Mayer, H.; Papakyriacou, M.; Zettl, B.; Vacic, S. Endurance limit and threshold stress intensity of die cast magnesium and aluminium alloys at elevated temperatures. Int. J. Fatigue 2005, 27, 1076–1088. [Google Scholar] [CrossRef]

- Rohatgi, P.K.; Riu, Y.; Ray, S. Friction, Lubrication and Wear Technology; American Society for Metals: Metals Park, OH, USA, 1992; p. 85. [Google Scholar]

- Mrówka-Nowotnik, G. The effect of intermetallics on the fracture mechanism in AlSi1MgMn alloy. J. Achiev. Mater. Manuf. Eng. 2008, 30, 35–42. [Google Scholar]

- Campbell, J. An overview of the effects of bifilms on the structure and properties of cast alloys. Metall. Mater. Trans. B 2006, 37B, 857–863. [Google Scholar] [CrossRef]

- Gariboldi, E.; Lemke, J.N.; Ozhoga-Maslovskaja, O.; Timelli, G.; Bonollo, F. High temperature behaviour of 46000, 46100, 47100 Al die cast parts. Metall. Ital. 2016, 108, 49–52. [Google Scholar]

- Wang, L.; He, Y.; Zhou, J.; Duszczyk, J. Effect of temperature on the frictional behaviour of an aluminium alloy sliding against steel during ball-on-disc tests. Tribol. Int. 2010, 43, 299–306. [Google Scholar] [CrossRef]

- Kamminga, J.D.; Janssen, G.C.A.M. Experimental discrimination of plowing friction and shear friction. Tribol. Lett. 2007, 25, 149–152. [Google Scholar] [CrossRef]

- Farhat, Z.N. Contribution of crystallographic texturing to the sliding friction behaviour of fcc and hcp metals. Wear 2001, 250, 401–408. [Google Scholar] [CrossRef]

| Si | Fe | Cu | Mg | Mn | Cr | Ni | Zn | Pb | Bi | Sn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8.40 | 0.72 | 2.43 | 0.19 | 0.22 | 0.056 | 0.05 | 1.05 | 0.092 | 0.034 | 0.033 | 0.037 | bal. |

| Alloy No. | Fe | Mn | Cr | SF |

|---|---|---|---|---|

| 1 * | 0.72 | 0.22 | 0.056 | 1.32 |

| 2 | 0.72 | 0.22 | 0.102 | 1.47 |

| 3 | 0.73 | 0.43 | 0.061 | 1.77 |

| 4 | 0.71 | 0.39 | 0.105 | 1.81 |

| 5 | 0.72 | 0.59 | 0.058 | 2.07 |

| 6 | 0.72 | 0.56 | 0.104 | 2.14 |

| 7 | 1.01 | 0.22 | 0.057 | 1.62 |

| 8 | 1.03 | 0.22 | 0.099 | 1.76 |

| 9 | 1.04 | 0.43 | 0.059 | 2.08 |

| 10 | 1.05 | 0.43 | 0.108 | 2.24 |

| 11 | 1.01 | 0.57 | 0.056 | 2.31 |

| 12 | 1.01 | 0.57 | 0.094 | 2.42 |

| 13 | 1.22 | 0.21 | 0.055 | 1.82 |

| 14 | 1.38 | 0.22 | 0.099 | 2.11 |

| 15 | 1.25 | 0.40 | 0.054 | 2.21 |

| 16 | 1.39 | 0.43 | 0.100 | 2.54 |

| 17 | 1.27 | 0.53 | 0.056 | 2.51 |

| 18 | 1.42 | 0.59 | 0.103 | 2.90 |

| Alloy | Hardness (GPa) | Reduced modulus (GPa) |

|---|---|---|

| Alloy 1 | 10.1 ± 1.4 | 154 ± 15 |

| Alloy 13 | 10.3 ± 1.3 | 157 ± 14 |

| Alloy 18 | 10.7 ± 1.5 | 156 ± 15 |

| α-Al matrix | 1.1 ± 0.6 | 79 ± 30 |

| Sludge Morphology | Hardness (GPa) |

|---|---|

| Polyhedral shape | 10.6 ± 1.5 |

| Star-like shape | 10.8 ± 1.0 |

| Coefficient | SF | ||

|---|---|---|---|

| Room Temperature | 150 °C | 200 °C | |

| a | −0.90 | −2.07 | −9.78 |

| b | 4.18 | 11.40 | 59.30 |

| R2 | 0.61 | 0.55 | 0.70 |

| p-value | 0.0001 | 0.0001 | 0.006 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Timelli, G.; Fabrizi, A.; Vezzù, S.; De Mori, A. Design of Wear-Resistant Diecast AlSi9Cu3(Fe) Alloys for High-Temperature Components. Metals 2020, 10, 55. https://doi.org/10.3390/met10010055

Timelli G, Fabrizi A, Vezzù S, De Mori A. Design of Wear-Resistant Diecast AlSi9Cu3(Fe) Alloys for High-Temperature Components. Metals. 2020; 10(1):55. https://doi.org/10.3390/met10010055

Chicago/Turabian StyleTimelli, Giulio, Alberto Fabrizi, Simone Vezzù, and Alessandro De Mori. 2020. "Design of Wear-Resistant Diecast AlSi9Cu3(Fe) Alloys for High-Temperature Components" Metals 10, no. 1: 55. https://doi.org/10.3390/met10010055

APA StyleTimelli, G., Fabrizi, A., Vezzù, S., & De Mori, A. (2020). Design of Wear-Resistant Diecast AlSi9Cu3(Fe) Alloys for High-Temperature Components. Metals, 10(1), 55. https://doi.org/10.3390/met10010055