Energy Consumption and CO2 Emissions in Ironmaking and Development of a Novel Flash Technology

Abstract

1. Introduction

1.1. The Blast Furnace (BF)

1.2. Direct Reduction (DR)

1.3. Smelting Reduction (SR)

2. Critical Issues in Ironmaking

2.1. Technical Issues

2.2. Energy Requirements

2.3. Carbon Dioxide Emissions

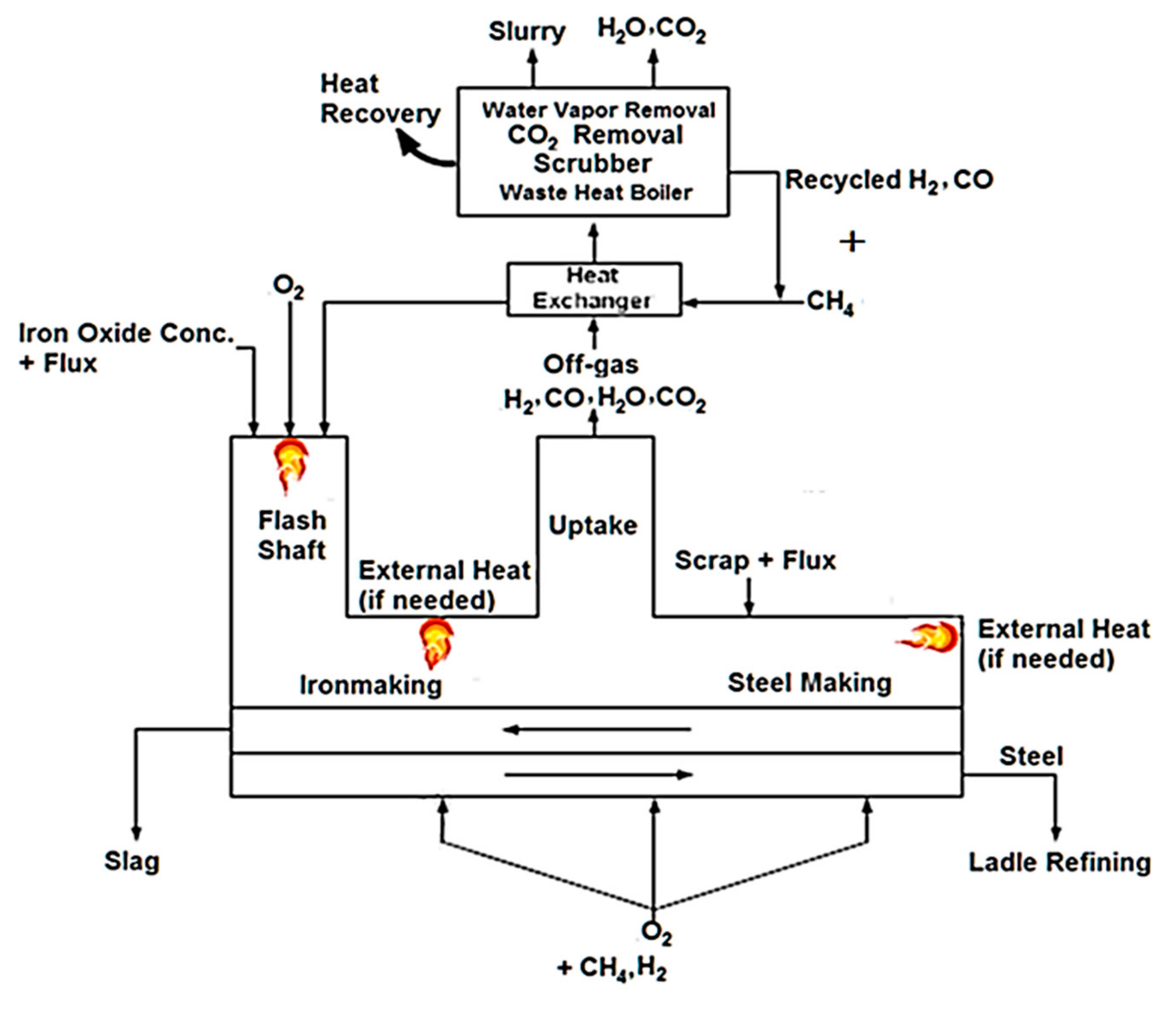

3. Development of Novel Flash Ironmaking Technology (FIT)

3.1. Background

3.2. Energy Requirements

3.3. Carbon Dioxide Emissions

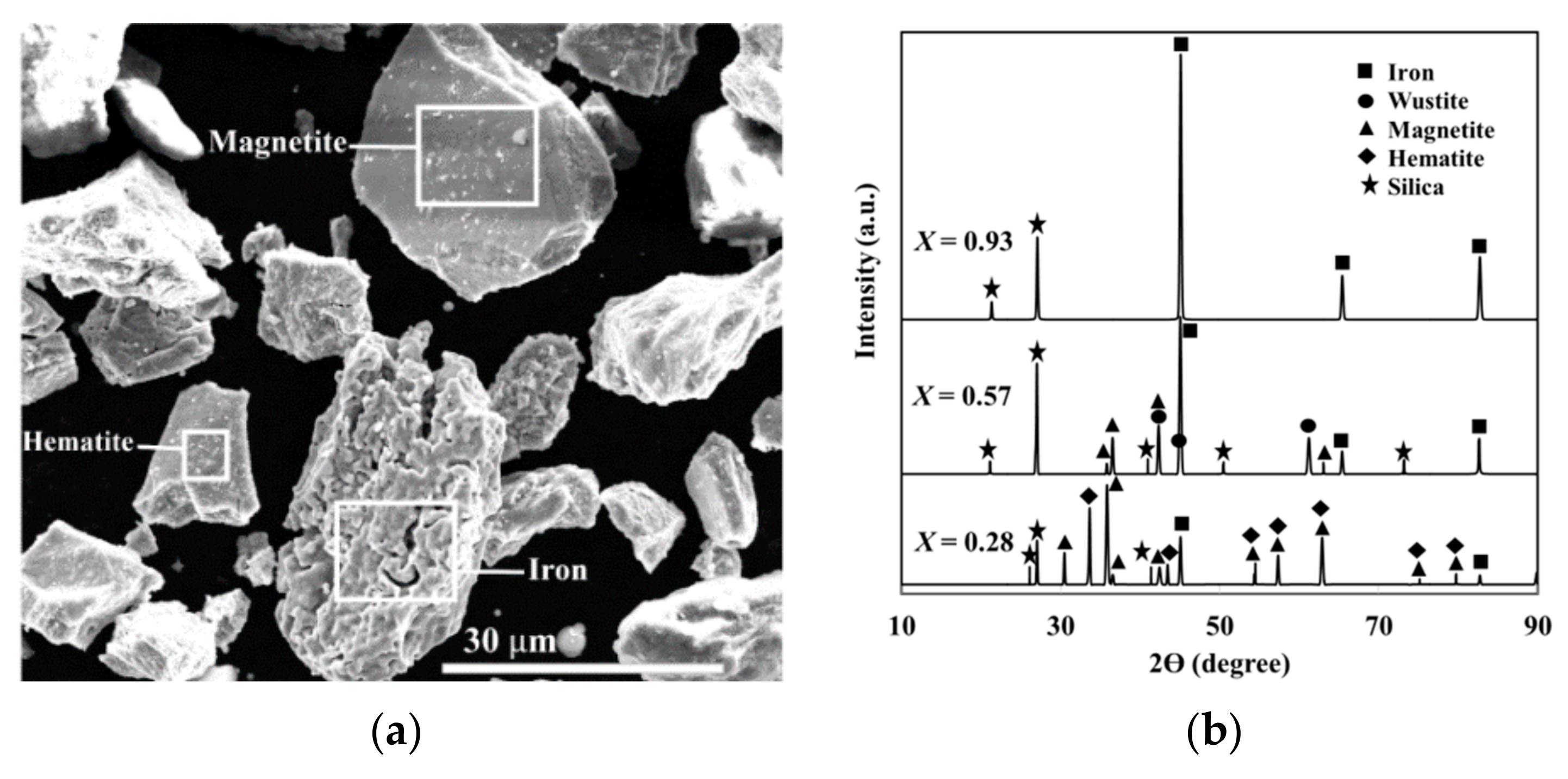

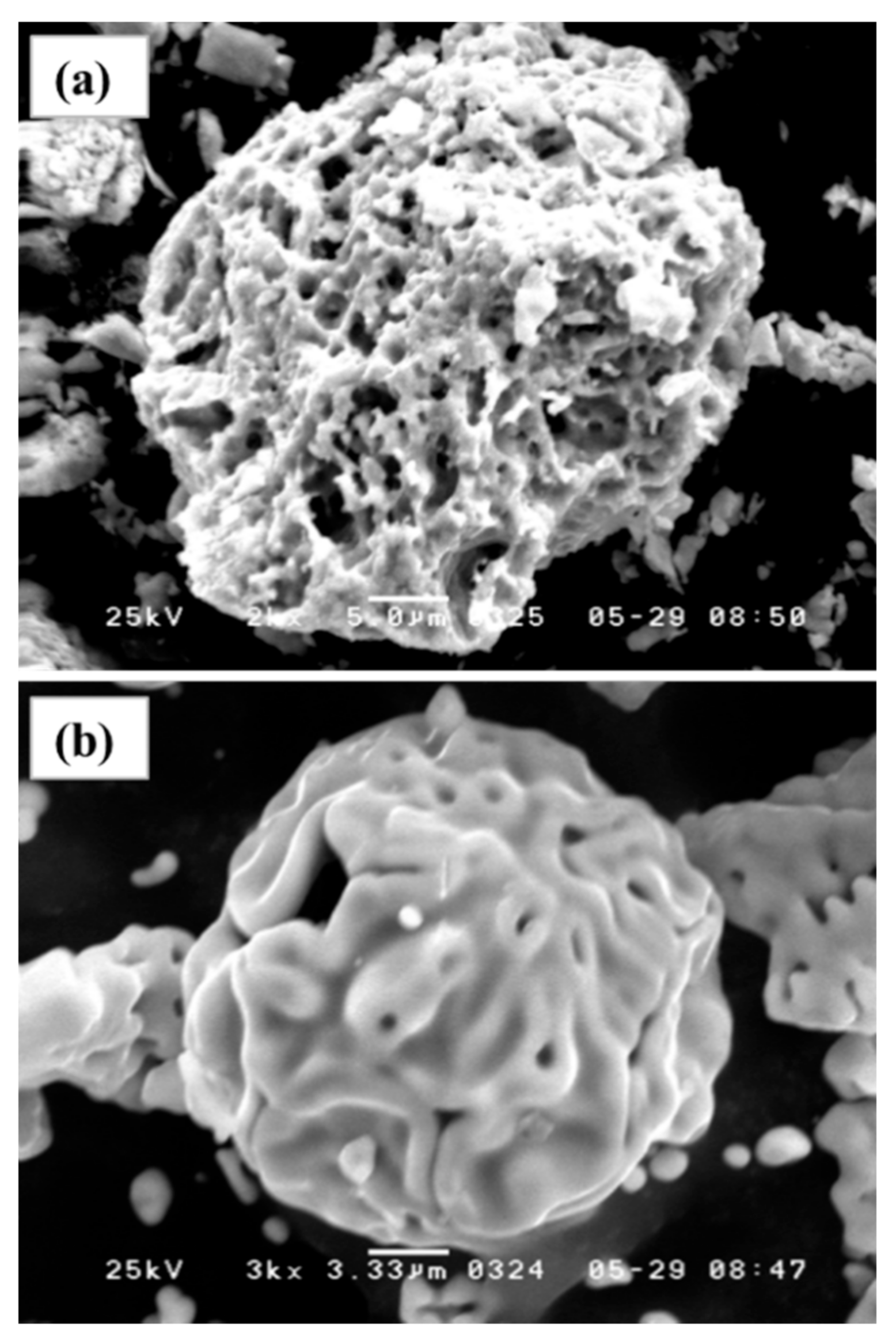

3.4. Reduction Kinetics of Concentrate Particles

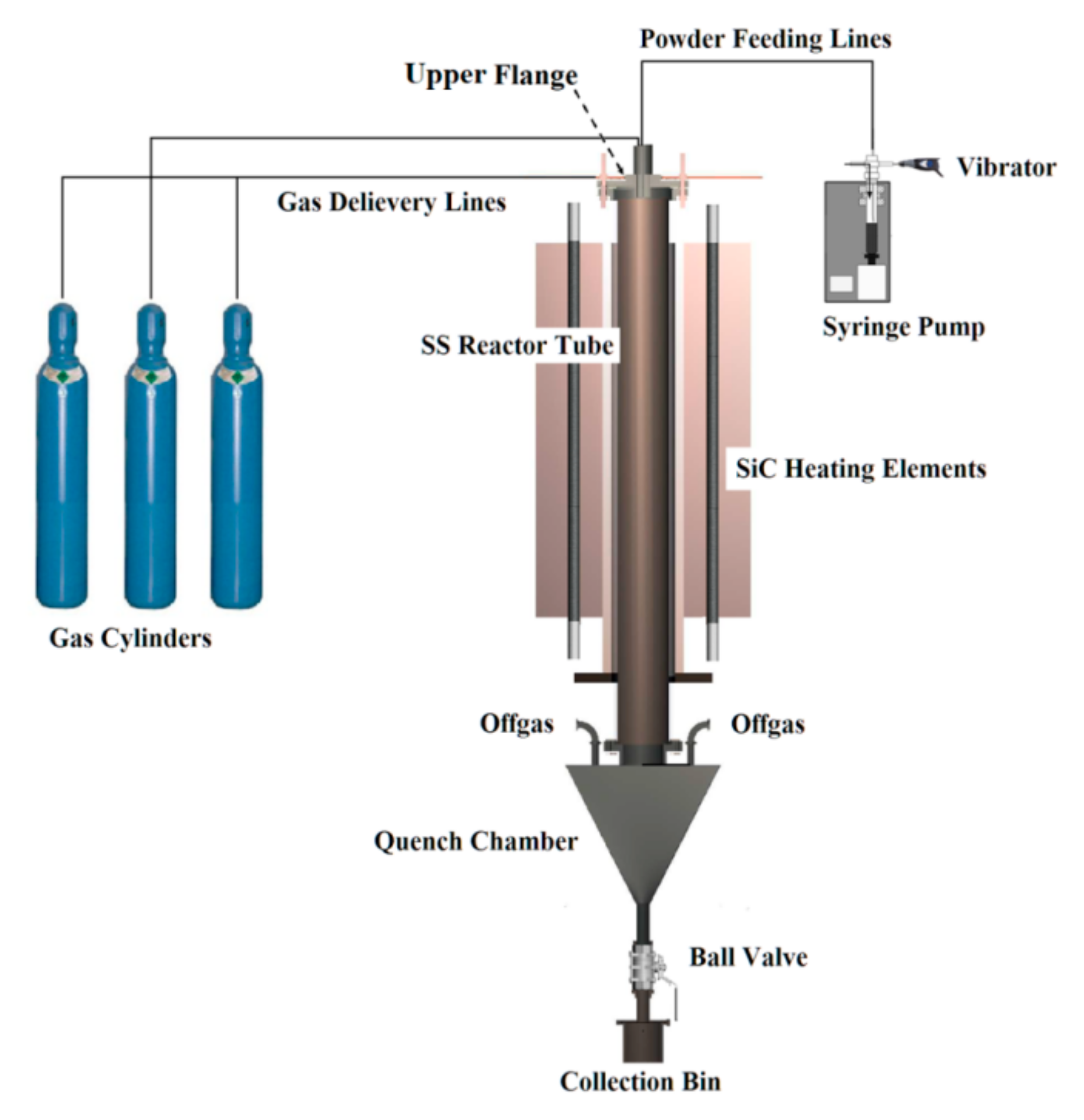

3.5. Laboratory Flash Reactor

3.5.1. Experiments with Hydrogen

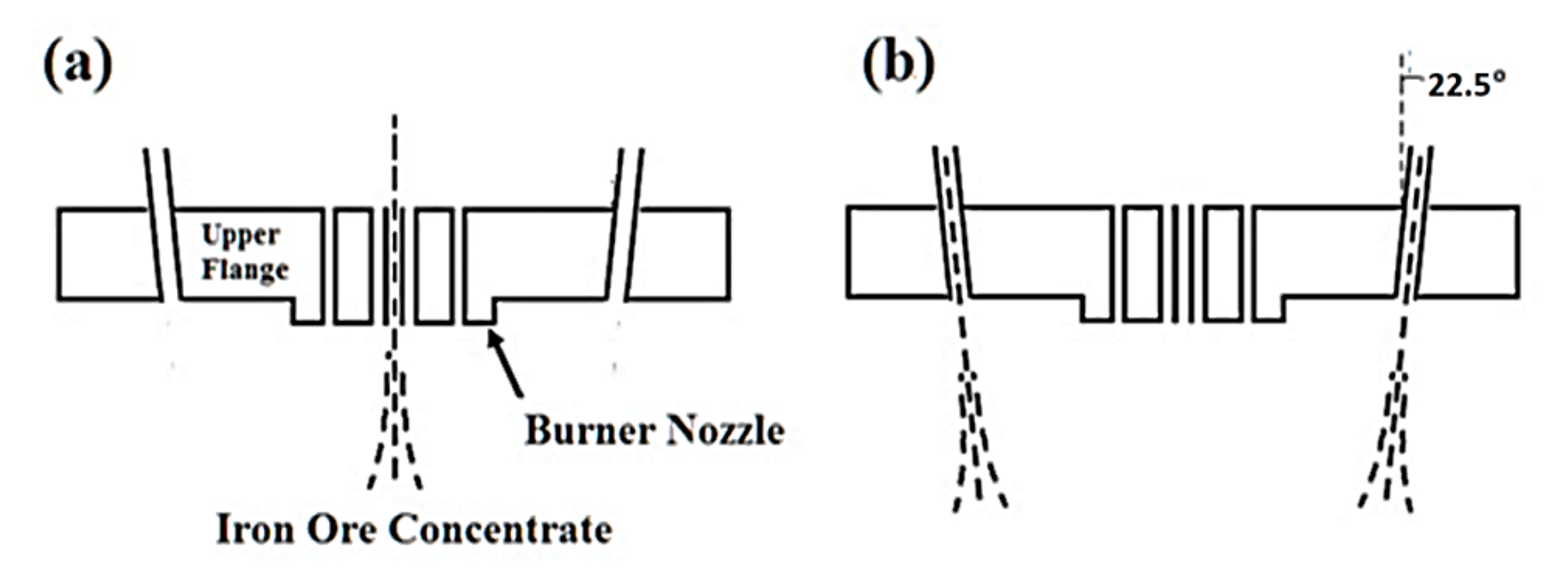

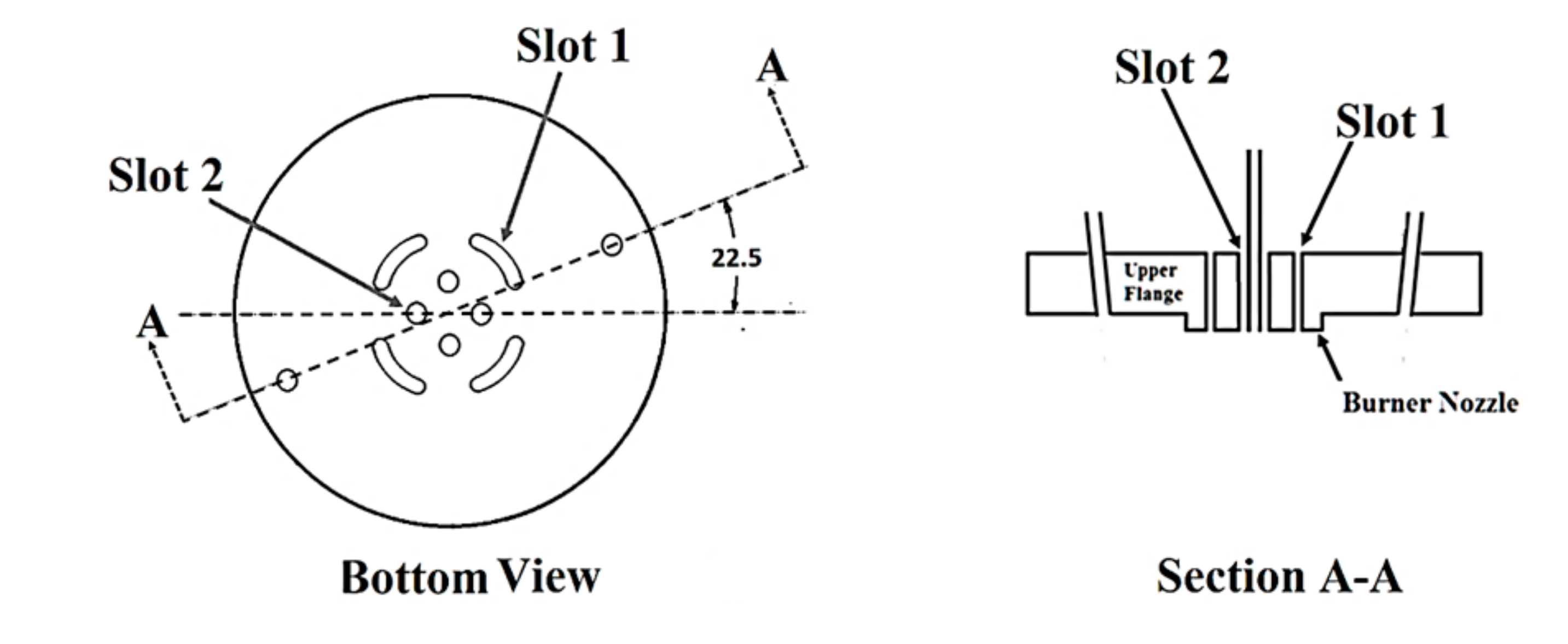

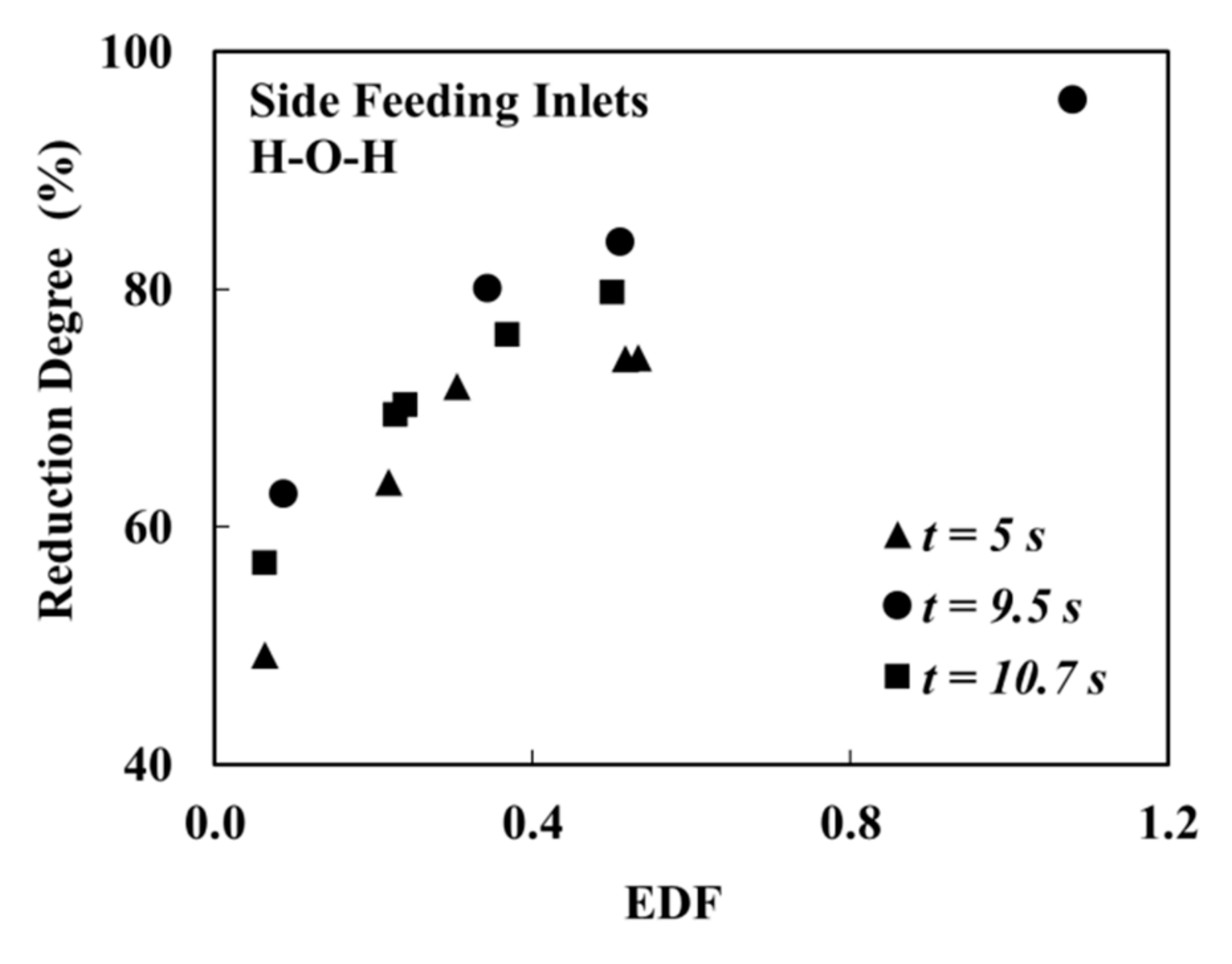

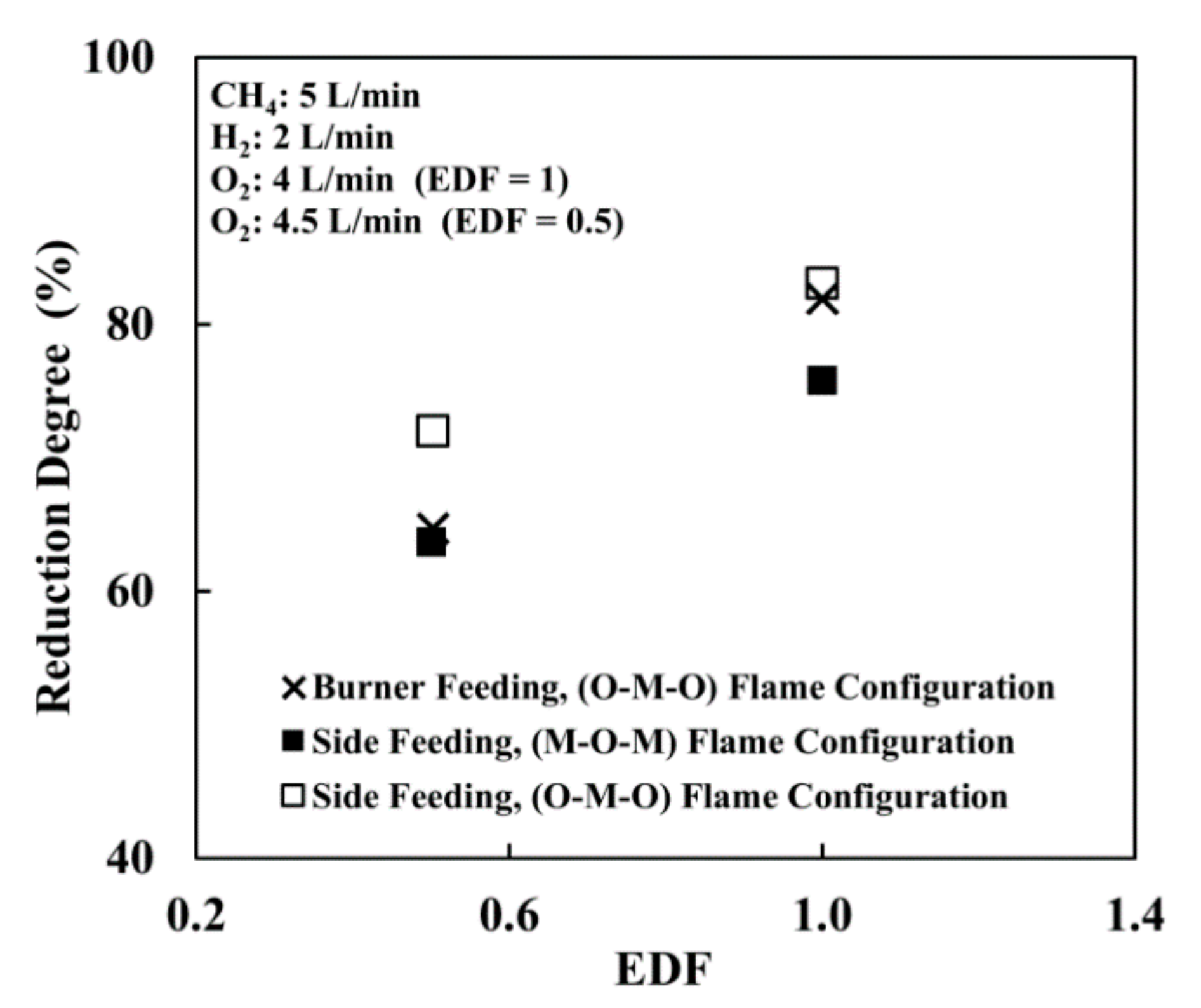

3.5.2. Experiments with Methane

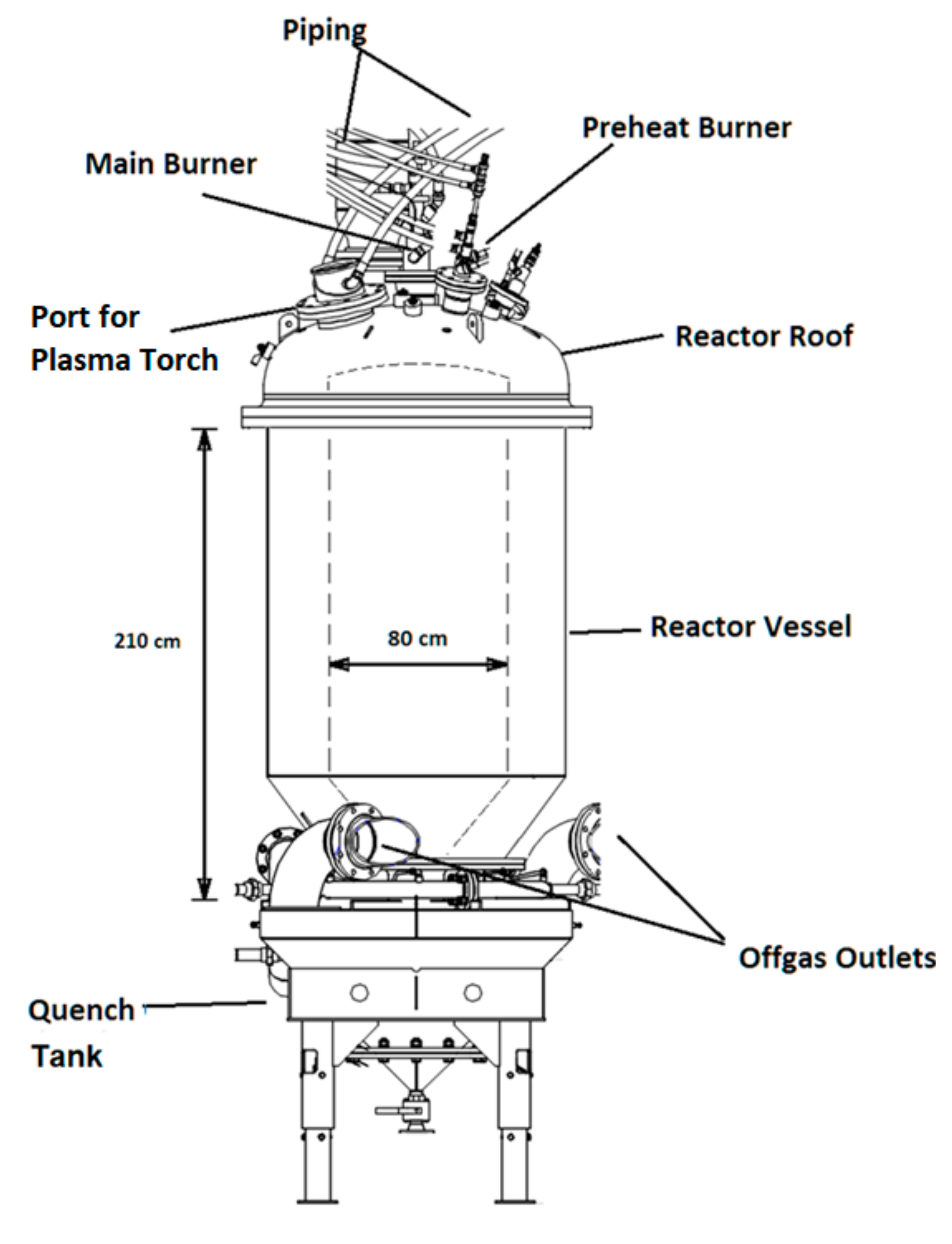

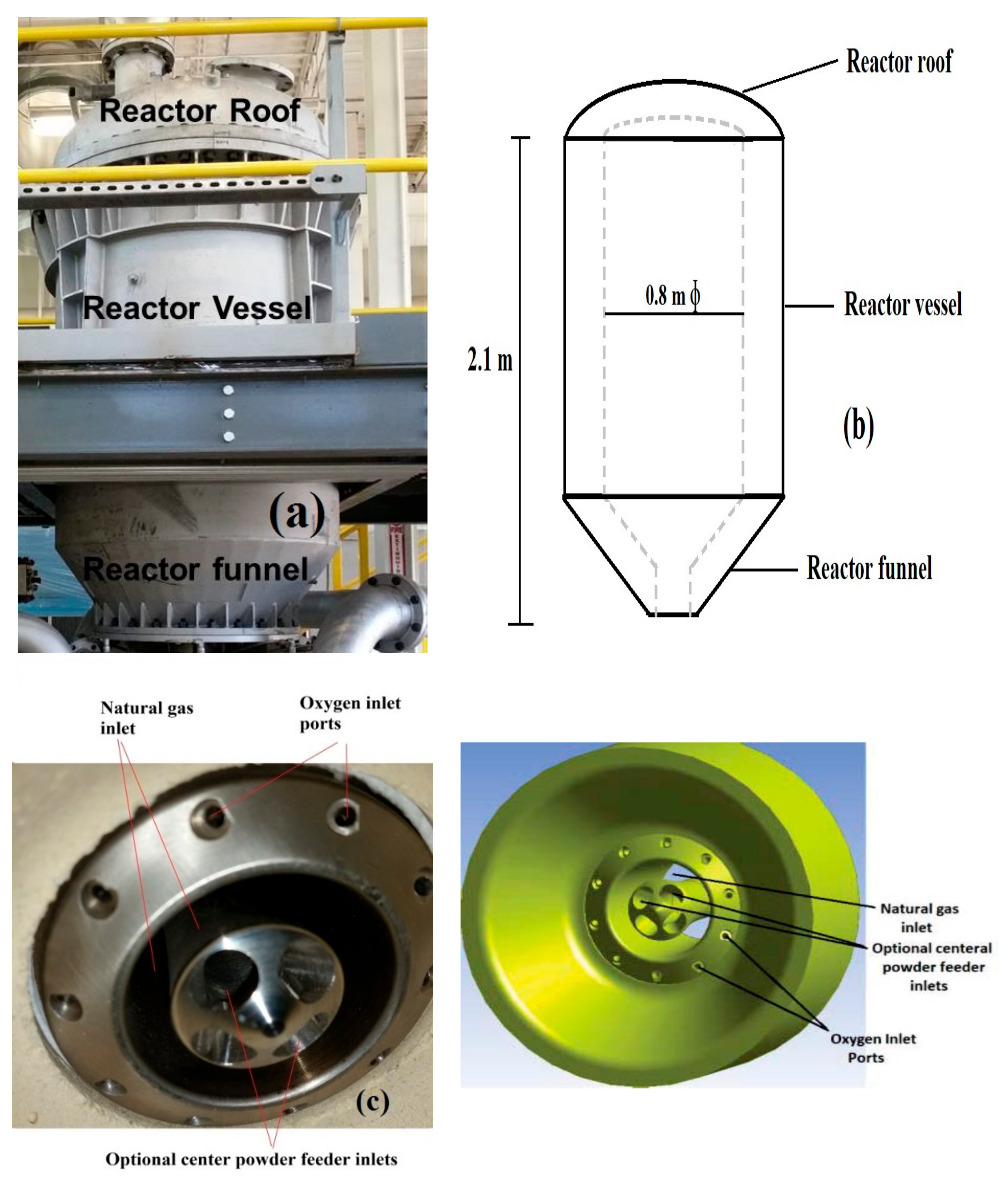

3.6. Mini-Pilot Reactor Testing

3.7. Computational Fluid Dynamics Simulation

3.8. Economic Analysis

4. Concluding Remarks

Funding

Acknowledgments

Conflicts of Interest

Disclaimer

References

- World Steel Association. World Steel in Figures. 2018. Available online: https://www.worldsteel.org/en/dam/jcr:f9359dff-9546-4d6b-bed0-996201185b12/World+Steel+in+Figures+2018 (accessed on 16 December 2019).

- Sun, W.; Cai, J.; Ye, Z. Advances in energy conservation of China steel industry. Sci. World J. 2013, 2013, 247035. [Google Scholar] [CrossRef] [PubMed]

- Matejak, E.-M.; POSCO S. Ignites the Largest Blast Furnace in the World. Available online: http://e-metallicus.com/en/news/world/posco-ignites-the-largest-blast-furnace-in-the-world.html (accessed on 30 March 2018).

- Institute for Industrial Productivity. Available online: http://www.ietd.iipnetwork.org/content/direct-reduced-iron (accessed on 30 May 2019).

- Midrex, World Direct Reduction Statistics. 2016. Available online: https://www.midrex.com/assets/user/news/MidrexStatsBook2016.pdf (accessed on 30 March 2018).

- Duarte, P.E.; Becerra, J.; Lizcano, C.; Martinis, A. ENERGIRON direct reduction technology-economical, flexible, environmentally friendly. Acero Latino Americano 2008, 6, 52–58. [Google Scholar]

- Hassan, A.; Whipp, R.H. Finmet Process for Direct Reduction of Fine Ore. Available online: https://www.researchgate.net/publication/292554156_Finmet_process_for_direct_reduction_of_fine_ore 1996/06/01 (accessed on 30 March 2018).

- Husain, R.; Sneyd, S.; Weber, P. Circored and Circofer—Two New Fine Ore Reduction Processes. In Proceedings of the International Conference on Alternative Routes of Iron and Steelmaking (ICARISM ′99), Perth, Australia, 15–17 September 1999; pp. 123–129. [Google Scholar]

- Macauley, D. Options increase for non-BF ironmaking. Steel Times Int. 1997, 21, 20. [Google Scholar]

- IspatGuru. 2017. Available online: https://www.ispatguru.com/coal-based-direct-reduction-rotary-kiln-process/ (accessed on 24 May 2019).

- Primetals Technologies, Brochure Nr.: T01-0-N001-L4-P-V4-EN, 2015, Primetals Technologies Ltd. and Posco Ltd. Available online: https://www.primetals.com/fileadmin/user_upload/content/01_portfolio/1_ironmaking/finex/The_Finex_process.pdf (accessed on 24 May 2019).

- World Steel Association. Steel’s Contribution to a Low Carbon Future and Climate Resilient Societies. Available online: https://www.worldsteel.org/en/dam/jcr:66fed386-fd0b-485e-aa23-b8a5e7533435/Position_paper_climate_2018.pdf (accessed on 30 May 2019).

- Orth, A.; Anastasijevic, N.; Eichberger, H. Low CO2 emission technologies for iron and steelmaking as well as titania slag production. Miner. Eng. 2007, 20, 854–861. [Google Scholar] [CrossRef]

- Sohn, H.Y. Suspension Ironmaking Technology with Greatly Reduced Energy Requirement and CO2 Emissions. Steel Times Int. 2007, 31, 68–72. [Google Scholar]

- Worrell, E.; Price, L.; Neelis, M.; Galitsky, C.; Nan, Z. World Best Practice Energy Intensity Values for Selected Industrial Sectors; LBNL-62806; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2008. Available online: http://eaei.lbl.gov/sites/all/files/industrial_best_practice_en.pdf (accessed on 16 December 2019).

- Sohn, H.Y.; Olivas-Martinez, M. Methods for Calculating Energy Requirements for Processes in Which a Reactant Is Also a Fuel: Need for Standardization. JOM 2014, 66, 1557–1564. [Google Scholar] [CrossRef]

- Remus, R.; Aguado Monsonet, M.A.; Roudier, S.; Delgado Sancho, L. Best Available Techniques (BAT) in Reference Document for Iron and Steel Production. Industrial Emissions Directive 2010/75/EU (Integrated Pollution Prevention and Control); Joint Research Centre (JRC) of the European Union: Seville, Spain, 2013; pp. 304–305. [Google Scholar]

- Fruehan, R.J.; Fortini, O.; Paxton, H.W.; Brindle, R. Theoretical Minimum Energies to Product Steel for Selected Conditions; Department of Energy: Washington, DC, USA, 2000. Available online: http://www1.eere.energy.gov/industry/steel/pdfs/theoretical_minimum_energies.pdf (accessed on 27 July 2013).

- Stubbles, J. Energy Use in the U.S. In Steel Industry: An Historical Perspective and Future Opportunities; Department of Energy: Washington, DC, USA, 2000. Available online: http://www1.eere.energy.gov/manufacturing/resources/steel/pdfs/steel_energy_use.pdf (accessed on 27 July 2013).

- Pinegar, H.K.; Moats, M.S.; Sohn, H.Y. Process Simulation and Economic Feasibility Analysis for a Hydrogen-Based Novel Suspension Ironmaking Technology. Steel Res. Int. 2011, 82, 951–963. [Google Scholar] [CrossRef]

- Pinegar, H.K.; Moats, M.S.; Sohn, H.Y. Flowsheet development, process simulation and economic feasibility analysis for novel suspension ironmaking technology based on natural gas: Part 1—Flowsheet and simulation for ironmaking with reformerless natural gas. Ironmak. Steelmak. 2012, 39, 398–408. [Google Scholar] [CrossRef]

- Pinegar, H.K.; Moats, M.S.; Sohn, H.Y. Flowsheet development, process simulation and economic feasibility analysis for novel suspension ironmaking technology based on natural gas: Part 2—Flowsheet and simulation for ironmaking combined with steam methane reforming. Ironmak. Steelmak. 2013, 40, 32–43. [Google Scholar] [CrossRef]

- Burgo, J.A. The Manufacture of Pig Iron in the Blast Furnace. In The Making, Shaping and Treating of Steel, 11th ed.; Wakelin, D.H., Ed.; The AISE Steel Foundation: Pittsburgh, PA, USA, 1999; pp. 712–713. [Google Scholar]

- Metius, G.E.; McClelland, J.M.; Hornby-Anderson, S. Comparing CO2 emissions and energy demands for alternative ironmaking routes. Steel Times Int. 2006, 30, 32–36. [Google Scholar]

- Hasanbeigi, A.; Arens, M.; Price, L. Alternative emerging ironmaking technologies for energy-efficiency and carbon dioxide emissions reduction: A technical review. Renew. Sustain. Energy Rev. 2014, 33, 645–658. [Google Scholar] [CrossRef]

- Sohn, H.Y. From Sulfide Flash Smelting to a Novel Flash Ironmaking Technology. In Proceedings of the 143rd TMS Annual Meeting on Celebrating the Megascale, EPD Symposium on Pyrometallurgy, San Diego, CA, USA, 10–20 February 2014; Mackey, P.J., Grimsey, E., Jones, R., Brooks, G., Eds.; TMS/Wiley: Hoboken, NJ, USA, 2014; pp. 69–76. [Google Scholar]

- Sohn, H.Y. From Nonferrous Flash Smelting to Flash Ironmaking: Development of an ironmaking technology with greatly reduced CO2 emissions and energy consumption. In Treatise on Process Metallurgy, Volume 3 Industrial Processes Part B, Section 4.5.2.2; Elsevier: Oxford, UK; Waltham, MA, USA, 2014; pp. 1596–1691. [Google Scholar]

- Sohn, H.Y.; Mohassab, Y. Development of a Novel Flash Ironmaking Technology with Greatly Reduced Energy Consumption and CO2 Emissions. J. Sustain. Metall. 2016, 2, 216–227. [Google Scholar] [CrossRef]

- Sohn, H.Y.; Choi, M.E.; Zhang, Y.; Ramos, J.E. Suspension Reduction Technology for Ironmaking with Low CO2 Emission and Energy Requirement. Iron Steel Technol. 2009, 6, 158–165. [Google Scholar]

- Sohn, H.Y.; Mohassab, Y.; Elzohiery, M.; Fan, D.-Q.; Abdelghany, A. Status of the Development of Flash Ironmaking Technology. In Applications of Process Engineering Principles in Materials Processing, Energy and Environmental Technologies; Wang, S., Free, M.L., Alam, S., Zhang, M., Taylor, P.R., Eds.; The Minerals, Metals & Materials Series; Springer: Berlin/Heidelberg, Germany, 2017; pp. 15–23. [Google Scholar] [CrossRef]

- Sohn, H.Y.; Elzohiery, M.; Fan, D.-Q. Chapter 2 Development of Flash Ironmaking Technology. In Advances in Engineering Research; Petrova, V.M., Ed.; Nova Science Publishers: New York, NY, USA, 2019; Volume 26, ISBN 987-1-715-5. [Google Scholar]

- Sohn, H.Y.; Choi, M.E. Steel Industry and Carbon Dioxide Emissions—A Novel Ironmaking Process with Greatly Reduced Carbon Footprint. In Carbon Dioxide Emissions: New Research; Carpenter, M., Shelton, E.J., Eds.; Nova Science Publishers: Hauppauge, NY, USA, 2012. [Google Scholar]

- U.S. Geological Survey. Iron Ore Statistics and Information. 2018. Available online: https://minerals.usgs.gov/minerals/pubs/commodity/iron_ore/mcs-2018-feore.pdf (accessed on 30 March 2018).

- U.S. Environmental Protection Agency. Office of Air Quality Planning and Standards, Emission Factor Documentation for AP-42, Section 11.23, Taconite Ore Processing. February 1997. Available online: https://www3.epa.gov/ttnchie1/ap42/ch11/final/c11s23.pdf (accessed on 30 March 2018).

- Themelis, N.J.; Zhao, B. Flash Reduction of Metal Oxides. In Flash Reaction Processes; Davies, T.W., Ed.; Kluwer Academic Publishers: Dordrecht, The Netherlands, 1995; pp. 273–293. [Google Scholar]

- Fan, D.-Q.; Sohn, H.Y.; Elzohiery, M. Analysis of the Reduction Rate of Hematite Concentrate Particles by H2 or CO in a Drop-Tube Reactor through CFD Modeling. Metall. Mater. Trans. B 2017, 48, 2677–2684. [Google Scholar] [CrossRef]

- Fan, D.-Q.; Elzohiery, M.; Mohassab, Y.; Sohn, H.Y. A CFD Based Algorithm for Kinetics Analysis of the Reduction of Hematite Concentrate by H2+CO Mixtures in a Drop Tube Reactor. In 8th International Symposium on High-Temperature Metallurgical Processing; Hwang, J.-Y., Jiang, T., Kennedy, M.W., Yücel, O., Pistorius, P.C., Seshadri, V., Zhao, B., Gregurek, D., Keskinkilic, E., Eds.; The Minerals, Metals & Materials Series; Springer: Berlin/Heidelberg, Germany, 2017; pp. 61–70. [Google Scholar] [CrossRef]

- Fan, D.; Mohassab, Y.; Elzohiery, M.; Sohn, H.Y. Analysis of the Hydrogen Reduction Rate of Magnetite Concentrate Particles in a Drop Tube Reactor through CFD Modeling. Metall. Mater. Trans. B 2016, 47, 1669–1680. [Google Scholar] [CrossRef]

- Elzohiery, M.; Sohn, H.Y.; Mohassab, Y. Kinetics of Hydrogen Reduction of Magnetite Concentrate Particles in Solid State Relevant to Flash Ironmaking. Steel Res. Int. 2017, 88, 1600133. [Google Scholar] [CrossRef]

- Chen, F.; Mohassab, Y.; Jiang, T.; Sohn, H.Y. Hydrogen Reduction Kinetics of Hematite Concentrate Particles Relevant to a Novel Flash Ironmaking Process. Metall. Mater. Trans. B 2015, 46, 1133–1145. [Google Scholar] [CrossRef]

- Chen, F.; Mohassab, Y.; Zhang, S.; Sohn, H.Y. Kinetics of the Reduction of Hematite Concentrate Particles by Carbon Monoxide Relevant to a Novel Flash Ironmaking Process. Metall. Mater. Trans. B 2015, 46, 1716–1728. [Google Scholar] [CrossRef]

- Choi, M.E.; Sohn, H.Y. Development of Green Suspension Ironmaking Technology based on Hydrogen Reduction of Iron Oxide Concentrate: Rate Measurements. Ironmak. Steelmak. 2010, 37, 81–88. [Google Scholar] [CrossRef]

- Elzohiery, M.; Fan, D.-Q.; Mohassab, Y.; Sohn, H.Y. Kinetics of Hydrogen Reduction of Magnetite Concentrate Particles at 1623–1873 K Relevant to Flash Ironmaking; University of Utah: Salt Lake City, UT, USA, 2020; Unpublished work. [Google Scholar]

- Fan, D.-Q.; Elzohiery, M.; Mohassab, Y.; Sohn, H.Y. The Kinetics of Carbon Monoxide Reduction of Magnetite Concentrate Particles through CFD Modeling; University of Utah: Salt Lake City, UT, USA, 2020; Unpublished work. [Google Scholar]

- Fan, D.-Q.; Elzohiery, M.; Mohassab, Y.; Sohn, H.Y. Rate-Amplification Effect of CO in Magnetite Concentrate Particle Reduction by H2+CO Mixtures; University of Utah: Salt Lake City, UT, USA, 2020; Unpublished work. [Google Scholar]

- Yuan, Z.; Sohn, H.Y. Re-Oxidation Kinetics of Flash Reduced Iron Particles in O2–N2 Gas Mixtures Relevant to a Novel Flash Ironmaking Process. ISIJ Int. 2014, 54, 1235–1243. [Google Scholar] [CrossRef]

- Yuan, Z.; Sohn, H.Y.; Olivas-Martinez, M. Re-oxidation Kinetics of Flash-Reduced Iron Particles in H2-H2O(g) Atmosphere Relevant to a Novel Flash Ironmaking Process. Metall. Mater. Trans. B 2013, 44, 1520–1530. [Google Scholar] [CrossRef]

- Fan, D.Q.; Sohn, H.Y.; Mohassab, Y.; Elzohiery, M. Computational Fluid Dynamics Simulation of the Hydrogen Reduction of Magnetite Concentrate in a Laboratory Flash Reactor. Metall. Mater. Trans. B 2016, 47, 1–12. [Google Scholar] [CrossRef]

- Mohassab, Y.; Elzohiery, M.; Sohn, H.Y. Flash Reduction of Magnetite Concentrate Based on Partial Oxidation of Natural Gas Relevant to a Novel Ironmaking Process. In AISTech 2016 Proceedings; AIST: Warrendale, PA, USA, 2016; pp. 713–722. [Google Scholar]

- Abdelghany, A.; Fan, D.Q.; Elzohiery, M.; Sohn, H.Y. Flash Ironmaking from Magnetite Concentrate using a Large-Scale Bench Reactor: Experimental and CFD Work. In AISTech 2018 Proceedings; AIST: Warrendale, PA, USA, 2018. [Google Scholar]

- Pinegar, H.K.; Moats, M.S.; Sohn, H.Y. Flowsheet development, process simulation and economic feasibility analysis for novel suspension ironmaking technology based on natural gas: Part 3—Economic feasibility analysis. Ironmak. Steelmak. 2013, 40, 44–49. [Google Scholar] [CrossRef]

| Production Step | Process | BF-BOF | DR-EAF | SR-BOF * | EAF-Scrap |

|---|---|---|---|---|---|

| Feed preparation | Sintering | 2.2 | 2.2 | ||

| Pelletizing | 0.8 | 0.8 | |||

| Coking | 1.1 | ||||

| Ironmaking | 12.4 | 9.2 | 17.9 | ||

| Steelmaking | Main Step | −0.3 | 5.9 | −0.3 | 5.5 |

| Refining | 0.4 | 0.4 | |||

| Total (GJ/t) | 15.8 | 18.1 | 18.8 | 5.5 | |

| BF-BOF a | Midrex Process b | HYL III-Energiron a | SL/RN Process a | SR a,c | Circored a,d |

|---|---|---|---|---|---|

| ~1.9 | ~1.1 | 0.77–0.92 | ~3.2 | 1.3–1.8 | ~1.2 |

| Process | Reformerless Natural Gas | Hydrogen d | Blast Furnace a,e | |

|---|---|---|---|---|

| ITEMIZED INPUT (GJ/ton Fe) | Fuel combustion b | 19.22 | 14.05 | 13.60 |

| Heat recovery (sum of next 2) | −4.77 | −2.80 | −1.32 | |

| (Waste heat boiler) | (−3.39) | |||

| (Steam not used) | (−1.38) | |||

| Sub-total | 14.45 | 11.25 | 12.28 | |

| Ore/Coke preparation c | 5.68 | |||

| CaCO3 and MgCO3 calcination (external) | 0.26 | 0.26 | ||

| Total | 14.7 | 11.5 | 18.0 | |

| Process | Reformerless Natural Gas | Hydrogen | Blast Furnace a | |

|---|---|---|---|---|

| ITEMIZED OUTPUT (GJ/ton Fe) | Reduction b | 6.68 | 6.68 | 7.37 |

| Sensible heat of iron | 1.27 (1773 K) | 1.35 (1873 K) | ||

| Sensible heat of slag | 0.24 (1773 K) | 0.47 (1873 K) | ||

| Slurry (H2O (l)) | 2.25 (323 K) | 1.93 | ||

| Hot water not used | 1.57 (493 K) | |||

| Flue gas | 0.79 (573 K) | 0.26 (363 K) | ||

| Removed water vapor | 0.01 | |||

| CaCO3 decomposition | 0.33 | |||

| Slagmaking | −0.17 | |||

| Heat loss in the reactor | 0.78 | 0.78 | 2.60 | |

| Heat loss in the heat exchangers (sum of next 3) | 0.73 | 0.34 | 0.07 | |

| (Reactor feed gas heater) | (0.40) | |||

| (Natural gas heater) | (0.21) | |||

| (WGS reactor feed gas heater) | (0.12) | |||

| Steam not used (363 K) | 0.14 | |||

| Sub-total | 14.45 | 11.25 | 12.28 | |

| Pelletizing c | 3.01 | |||

| Sintering c | 0.65 | |||

| Cokemaking c | 2.02 | |||

| CaCO3 and MgCO3 calcination (external) | 0.26 | 0.26 | ||

| Total | 14.7 | 11.5 | 18.0 | |

| Parameters | Run 1 | Run 2 | Run 3 | Run 4 | Run 5 | Run 6 |

|---|---|---|---|---|---|---|

| Concentrate feeding rate, kg h−1 | 2.5 | 4.3 | 5.0 | 5.0 | 4.6 | 4.0 |

| Particle size range, µm | 32–90 | less than 90 | less than 90 | 32–90 | less than 90 | less than 90 |

| Mass average particle size, µ m(used for simulation) | 45 | 32 | 32 | 45 | 32 | 32 |

| Natural Gas flow rate, (a) m3 h−1 | 25.16 | 30.56 | 20.36 | 24.80 | 17.36 | 15.86 |

| Natural Gas input temperature, K | 300 | |||||

| O2 flow rate, (a) m3 h−1 | 19.85 | 19.67 | 14.27 | 21.53 | 16.35 | 14.81 |

| O2 input temperature, K | 300 | |||||

| Total inlet gas flow rate, (a) m3 h−1 | 45.01 | 50.23 | 34.63 | 46.33 | 33.71 | 30.67 |

| O2 to Natural Gas mole ratio | 0.79 | 0.64 | 0.70 | 0.87 | 0.94 | 0.93 |

| Inner wall temperature, (b) K | 1483–1563 | 1503–1603 | 1573–1673 | 1403–1473 | 1563–1623 | 1573–1623 |

| Inner wall temperature, K (used for simulation) | 1526 | 1548 | 1626 | 1440 | 1594 | 1599 |

| Run | Experimental (pct) | Simulation (pct) |

|---|---|---|

| 1 | 94.0 | 99.8 |

| 2 | 80.0 | 84.5 |

| 3 | 94.5 | 99.6 |

| 4 | 74.0 | 99.8 |

| 5 | 72.5 | 99.5 |

| 6 | 50.0 | 85.0 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sohn, H.Y. Energy Consumption and CO2 Emissions in Ironmaking and Development of a Novel Flash Technology. Metals 2020, 10, 54. https://doi.org/10.3390/met10010054

Sohn HY. Energy Consumption and CO2 Emissions in Ironmaking and Development of a Novel Flash Technology. Metals. 2020; 10(1):54. https://doi.org/10.3390/met10010054

Chicago/Turabian StyleSohn, Hong Yong. 2020. "Energy Consumption and CO2 Emissions in Ironmaking and Development of a Novel Flash Technology" Metals 10, no. 1: 54. https://doi.org/10.3390/met10010054

APA StyleSohn, H. Y. (2020). Energy Consumption and CO2 Emissions in Ironmaking and Development of a Novel Flash Technology. Metals, 10(1), 54. https://doi.org/10.3390/met10010054